Abstract

With the deepening electrification of transportation, hydrogen fuel cell electric vehicles (FCEVs) are emerging as a vital component of clean and electrified transportation systems. Nonetheless, renewable-based hydrogen production–refueling stations (HPRSs) for FCEVs still need solid models for accurate simulations and a practical capacity optimization method for cost reduction. To address this gap, this study leverages real operation data from China’s largest HPRS to establish and validate a comprehensive model integrating hydrogen production, storage, renewables, FCEVs, and the power grid. Building on this validated model, a novel capacity optimization framework is proposed, incorporating an improved Jellyfish Search Algorithm (JSA) to minimize the initial investment cost, operating cost, and levelized cost of hydrogen (LCOH). The results demonstrate the framework’s significant innovations and effectiveness: It achieves the maximum reductions of 29.31% in the initial investment, 100% in the annual operational cost, and 44.19% in LCOH while meeting FCEV demand. Simultaneously, it reduces peak grid load by up to 43.80% and enables renewable energy to cover up to 89.30% of transportation hydrogen demand. This study contributes to enhancing economic performance and optimizing the design and planning of HPRS for FCEVs, as well as promoting sustainable transportation electrification.

1. Introduction

Due to climate change and environmental pollution, the decarbonization of electricity generation, transportation, and buildings is becoming imperative. In 2022, the carbon emission of the transportation sector increased by 3% [1], exceeding the average growth rate over the past two decades. This acceleration underscores the critical role of transportation electrification in carbon emission mitigation. Compared to battery electric vehicles (BEVs), hydrogen fuel cell electric vehicles (FCEVs) demonstrate advantages, including zero emissions, long cruise range, and rapid refueling capability, which positions them as a critical driver of transportation electrification [2]. Notably, FCEVs exhibit lower carbon emissions (51 gCO2eq/km) than BEVs (68.7 gCO2eq/km) in summer urban driving cycles [3], offering further carbon reduction potential. By 2024, China’s FCEV fleet quantity reached 26,900, with continued market expansion [4]. The widespread adoption of FCEVs is contingent upon the sustainable production of renewable energy. Specifically, renewable energy sources, such as wind, solar, and wave power, are widely recognized as effective alternatives to fossil fuels, but their intermittency poses challenges to grid stability and imposes limitations on their direct use. Although the availability of hydrogen is very limited in nature, the utilization of renewable electricity in the electrolysis of water for green hydrogen production is one of the ways to obtain sustainable hydrogen resources, which also contributes to addressing the intermittency and variability of renewable energy sources [5]. Meanwhile, hydrogen refueling stations for FCEVs are also under fast development, and some of them are powered by onsite renewable energy to form renewable-based hydrogen production–refueling stations (HPRSs), which produce green hydrogen and help further reduce carbon emissions [6].

HPRSs adopt hydrogen as an energy medium connecting the power grid and transportation (grid-to-hydrogen-to-vehicle), and its system configuration affects intricate energy flows and efficiency performance [7,8], necessitating optimal system design and energy management to maximize the economic and low-carbon benefits, among others [9]. Cardona et al. [10] proposed a generic modeling method for HPRSs, which designs a day-ahead operational strategy for grid-based hydrogen production capable of servicing up to 310 FCEVs, resulting in a total hydrogen sale of 7200 kg in one month. Demir [11] designed three distinct hybrid renewable energy systems to reliably, economically, and cleanly meet campus electricity demands and supply hydrogen for campus hydrogen fuel-cell-powered buses, which used the HOMER software (v3.16.2) to identify the optimal system configuration. Tezer [12] optimized a renewable-based hydrogen production system using a genetic algorithm and then conducted a comprehensive analysis of the impacts of different locations, cost variations, and energy storage types/capacities on system performance. Wang et al. [13] compared the performance of energy infrastructure for BEVs and FCEVs. They found that the BEV charging station exhibited lower costs (90.3% of the cost of the FCEV refueling station), while the FCEV refueling station had lower carbon emissions (only 37.3% of that of the BEV charging station). Li et al. [14] used the Monte Carlo method to simulate FCEV refueling demand and optimize system configuration under different scenarios. It was found that the system’s economic performance could be further improved when proper demand response strategies were incorporated. Kopacak et al. [15] demonstrated that for multi-energy systems that supply both electricity and hydrogen for vehicles, appropriately managing the charging (for EVs) and refueling (for FCEVs) behaviors could not only meet transportation energy demand but also enhance grid reliability. Song et al. [16] designed a novel energy storage model that reduced the total annual cost of storage facilities by 47.34% and increased the annual revenue of a hydrogen refueling station by 49.37%.

Despite the above-stated benefits, the research gaps in the existing studies on the configuration and optimization of HPRSs still exist in the current academia as follows:

(1) Existing studies on HPRS system configuration and capacity optimization predominantly rely on theoretical assumptions for vehicle refueling behaviors and hydrogen production processes [10,11,12,14]. In other words, the HPRS models developed in existing studies are rarely validated using real HPRS data, and the models’ robustness is somewhat questionable, which may lead to significant deviations in performance analysis and optimization.

(2) Current research frequently overlooks the operational constraints of energy components of real HPRSs. For instance, in practice, electrolyzers can only operate at constant or discrete power levels for safety, rather than rapidly track fluctuations in renewable power generation. The idealized assumption of the highly flexible electrolyzer power may result in an overestimation of actual hydrogen production quantity by 8–20% [17]. For FCEVs serving industrial facilities, their refueling schedules are usually fixed to prioritize meeting the industry process and may be difficult to adjust, as assumed by researchers, to create demand-responsive refueling behaviors. These limitations are usually ignored in previous studies due to the lack of real project information, which may cause significant deviations when analyzing and optimizing HPRSs.

(3) Existing optimization frameworks commonly assume that HPRSs generate revenue through hydrogen sales to FCEVs. For practical HPRSs owned by industrial park owners, they usually offer free hydrogen to FCEVs serving the industrial parks. This issue should be considered in the capacity optimization framework of HPRSs, along with other factors, including the cost (initial investment cost, annual operational cost, and levelized cost of hydrogen (LCOH)) and the availability of renewable energy for hydrogen production (namely, HPRSs with or without integrating renewable energy systems).

To address these critical gaps, first, this study establishes a comprehensive HPRS model integrating hydrogen production/storage, renewable energy systems, FCEVs, and grid interaction. Then, this study crucially validates this model using actual operational data from the largest HPRS for FCEVs in China (Sany Hydrogen Energy Technology Co., Ltd., Beijing, China). Afterwards, this study incorporates the real operational constraints, specifically the fixed FCEV refueling schedule and the electrolyzer’s discrete operating power levels, to develop a capacity optimization framework based on the improved Jellyfish Search Algorithm (JSA) aimed at minimizing key economic metrics (initial investment cost, annual operational cost, or LCOH). Further, taking the largest HPRS for FCEVs in China as the example case, the framework was used to optimize the system capacity parameters, achieving different economic benefits under different scenarios with or without renewable systems. Meanwhile, the renewable penetration in hydrogen production and the grid interaction of the optimized HPRS were also analyzed. This study not only represents the setup of the largest HPRS for FCEVs in China but also provides valuable references for the design and planning of HPRSs for FCEVs, as well as for advancing sustainable transportation electrification.

2. Methods

2.1. System Construction

The largest HPRS for FCEVs in China is located in Changsha, southern China. The station can produce up to 2000 kg of hydrogen per day, with a total investment of about USD 5.18 million. The HPRS is owned by a nearby industrial park, and its hydrogen demand is primarily attributed to heavy-duty trucks that are owned by and serve the industrial park. For now, on average, 40 fuel-cell-powered electric trucks are refueled at the HPRS per day (except weekends). Currently, the HPRS mainly consumes the electricity imported from the local power grid to produce hydrogen, while the renewable system is under construction and will generate green electricity for hydrogen production in the future. Detailed information about the HPRS can be found at https://www.sanygroup.com/activity/12793.html (accessed on 28 June 2025).

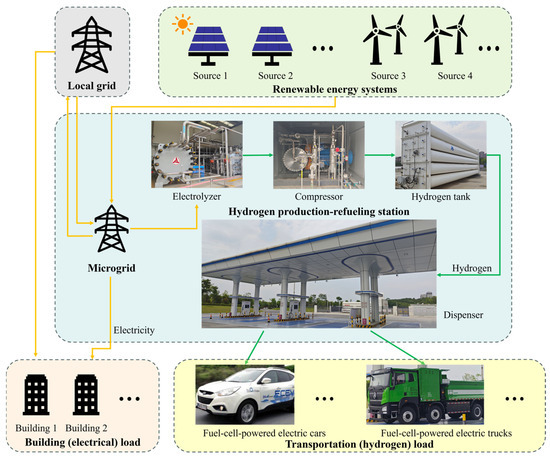

Based on the configuration of the above-stated real HPRS, the boundaries of this study were clearly defined (shown in Figure 1), and the model has several components, as follows:

Figure 1.

The system configuration based on the largest hydrogen production-refueling station in China.

- (1)

- Renewables: Existing photovoltaic (PV) systems near the station and wind power systems to be installed in the future.

- (2)

- Buildings: primarily industrial buildings near the HPRS.

- (3)

- Hydrogen production and storage system: electrolyzers, compressors, and hydrogen tanks.

- (4)

- FCEVs: may include light-duty vehicles (e.g., cars) and heavy-duty vehicles (e.g., trucks), but only the latter ones are involved in this study, according to the real HPRS project. It should be noted here that this study is for the design phase of HPRSs, and the hydrogen demand of FCEVs is adopted as the input for optimization, while the detailed model of FCEVs (such as the thermal management of FCEVs), which is more suitable for operation optimization, is not involved.

- (5)

- Grid: the microgrid for connecting the above-stated facilities (buildings, renewables, and HPRS) and the local grid for energy balance.

The following simplifying assumptions were made in the design of the HPRS model:

- (1)

- The simulation time step in this study is 1 h, and all input variables within one time step are considered constant values.

- (2)

- Renewable energy losses due to inverters and grid connection are 5% [18].

- (3)

- The energy consumption of electrolyzer auxiliary equipment is estimated according to the electrolyzer power (Section 2.3.3), which is consistent with real operation data of the real HPRS.

- (4)

- In this real project, the start-up time of the electrolyzer is less than 5 min, which is negligible in the simulation.

- (5)

- No hydrogen loss occurs during the hydrogen production process.

- (6)

- At each time step, the HPRS’s largest quantity of charging FCEVs is 12.

Since the electrolyzer and hydrogen tank work as the energy storage of renewable electricity, which can achieve high renewable penetration into hydrogen production (see Section 3.4), neither the real project nor the model include electric batteries, which are also expensive and may largely increase the total cost.

2.2. Optimization Framework Configuration

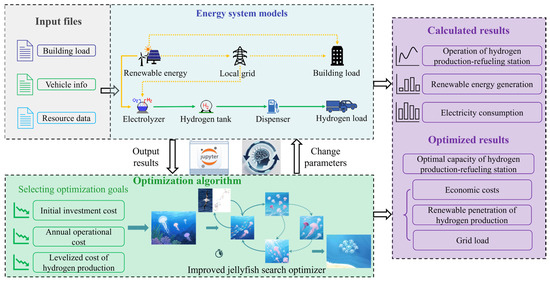

A framework for optimizing the HPRS capacity was developed using Python 3.13. This framework consists of input files, energy system models, and an optimization algorithm (shown in Figure 2).

Figure 2.

The configuration of the proposed optimization framework for hydrogen production-refueling stations.

- Input files are primarily imported through CSV files, mainly including:

- Building load: hourly building electricity demand.

- Vehicle info: FCEV parameters, including the quantities of FCEVs of different groups (each group has the same parameter), daily hydrogen charging schedules, and daily hydrogen load.

- Resource data: weather data for renewable systems, parameters of the hydrogen production and storage system (like electrolyzers and hydrogen tank), the prices of different devices and grid electricity, investment information (like the upper limit of different device capacities), and more.

- The system models primarily include the components described in Section 2.1, whose mathematical models are represented in Section 2.3. Besides, rule-based energy control strategies are formulated to regulate the flow and conversion of electricity and hydrogen within the system (see Section 2.4). Finally, these components and control strategies are integrated for simulation with each time step at one hour.

- The optimization algorithm primarily employs the improved JSA (see Section 2.5), which can conduct repeated simulations to determine the optimal system capacity. In this study, the optimization goals include the initial investment cost, annual operational cost, and LCOH, since HPRSs usually have high costs that determine the feasibility in practical projects. The above-stated three goals are further clarified in Section 2.5.2.

2.3. Energy Component Models

2.3.1. Renewable Energy

The renewable energy (Pre(t)) calculation can be conducted using the corresponding models with EPW weather parameters (including hourly temperature, wind speed, solar radiation intensity, and more) as inputs, as stated in the subsequent sections.

where PW(t) is the wind power generation, unit in kW; and PPV(t) is the PV power generation, unit in kW.

- Wind power

Wind power generation is mainly affected by wind speed v, and it is calculated as follows [19]:

where vi, vr, and vf are the cut-in wind speed, rated wind speed, and cut-out wind speed of the wind turbine, respectively, with units in m/s set at 3.0, 9.3, and 22.0 m/s in this study. A is the area of the wind turbine blade, unit in m2, determined based on the equipment parameters in the resource data inputted by user; this study adopts the wind turbine products of the real project, specifically models such as the HF47.0-500 (Qingdao Hengfeng Wind Power Generator Co., Ltd., Qingdao, Shandong, China) and SE15532 (https://www.sanygroup.com/product/575.html, accessed on 28 June 2025, Sany Hydrogen Energy Technology Co., Ltd., Beijing, China), and the model has a rotor diameter range of 50–160 m. Cp is the wind energy utilization factor, set at 0.48 [20]; Pw(t) and Ew are the power generation and the rated capacity of wind power equipment, respectively, unit in kW.

- 2.

- PV

PV power generation is mainly affected by the intensity of solar radiation and is calculated as follows [19]:

where GC and GN are the actual and rated solar irradiance, respectively, units in W/m2, and GN is set at 1000 W/m2 in this study; δ is the temperature coefficient of power for the PV module, unit in K−1, set at −0.004 K−1 in this study; Ta, TSC, and TSN are the ambient temperature, PV cell surface temperature, and rated temperature, respectively, units in K, and TSN is set at 298.15 K in this study; 1 − η is the temperature correction factor, set at 0.885 in this study; TCNOCT, TANOCT, and GTNOCT are the nominal operating cell temperature (unit in K), nominal ambient temperature (unit in K), and nominal solar irradiance (unit in W/m2), respectively, and TCNOCT is set at 323.15 K, TANOCT is set at 323.15 K, and GTNOCT is set at 800 W/m2 [19]; and PPV(t) and EPV are the power generation and the rated capacity of PV equipment, respectively, units in kW.

2.3.2. Building Load

Hourly building electricity demand is obtained by importing hourly load profiles for a full year (8760 h) provided by the user. Users can set up load profiles of multiple building groups and specify the quantity of each group to generate multiple building components. The total electrical demand power of all buildings at time t is calculated as follows:

where Pbu is the total electrical demand power of all buildings, unit in kW; Loadi is the electrical demand power of a single building of group i, unit in kW; Numi is the quantity of the i-th building group; and n is the quantity of all building groups.

It should be noted here that, in this study, renewable energy is mainly for hydrogen production, rather than covering building energy demand. Thus, this study only includes buildings such as offices and control rooms of the HPRS to simplify the optimization.

2.3.3. Electrolyzer

The quantity of hydrogen produced by the electrolyzer is calculated as follows:

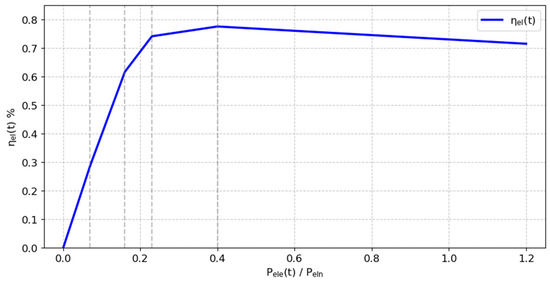

where Mele(t) is the hydrogen production mass of the electrolyzer at time t, unit in kg; t is the simulation time step, set at 1 h in this study; Pele(t) is the power of the electrolyzer at time t, unit in kW; ρ is the electrical-to-hydrogen conversion coefficient, set at 0.02 kg/kWh in this study according to the real HPRS project; and ηel(t) is the operational efficiency of the electrolyzer at time t (%), and its rated value is 0.73 according to the efficiency curves provided by the real HPRS manager and reference [21,22], as shown in Figure 3.

Figure 3.

Electrolyzer efficiency curve.

Electrolyzers are the main hydrogen production equipment. An electrolyzer can operate within a power regulation range of 10% to 120% of its rated power. Consequently, the operational power constraint for the electrolyzer at time t can be calculated as follows:

where Peln is the rated power of the electrolyzer, unit in kW; 1.2Peln is the maximum power of the electrolyzer, unit in kW; Pele(t) is determined by the state of charge of the HPRS hydrogen tank SOCtan(t), Pre(t), and the electricity price level (see Section 2.4), units in kW.

In addition, the power consumption of auxiliary equipment (Pau(t), unit in kW) for hydrogen production (e.g., compressors and purification systems) is estimated as 10% of the electrolyzer’s operating power, according to reference [23] and the real HPRS.

2.3.4. Hydrogen Storage System

The hydrogen mass stored in the tank is decided by the residual hydrogen mass at the previous timestep, hydrogen inflow from the production, and hydrogen outflow for refueling FCEVs. Thus, the hydrogen storage level is calculated as follows:

where Mtan(t) is the hydrogen mass in the storage tank at time t, unit in kg; Mtan(t−1) is the hydrogen mass in the storage tank at the previous timestep, unit in kg; Min(t) and Mout(t) are the hydrogen inflow rate and outflow masses at time t, respectively, units in kg; Moutmax is the maximum allowable outflow mass during one time step (equal to the maximum refueling capacity of the station), unit in kg, set at 480 kg/h in this study; and Mele(t) and Hload(t) are the available hydrogen production and the hydrogen load demand (see Section 2.3.5) at time t, respectively, units in kg.

SOCtan(t), the state of charge (SOC) of the HPRS hydrogen tank, is a critical control variable for electrolyzer operation. In this study, the upper and lower limits of SOCtan(t) (SOCupper, limit and SOClower, limit) are set at 0.2 and 0.8 to enable the safe operation of the HPRS hydrogen tank. SOCtan(t) can be calculated as follows:

where MHT is the rated capacity of the hydrogen tank, unit in kg.

In addition, to meet the daily hydrogen refueling demand, the hydrogen production by the electrolyzer should enable the hydrogen tank SOC in one day to exceed a level that satisfies the next day’s hydrogen load (SOCload(d+1), unit in kg), which is incorporated in the control logic in Section 2.4.2. SOCload(d+1) is calculated as follows:

where Hload(d+1) is the next day’s hydrogen refueling demand, unit in kg; Hload(td+1) is the hourly hydrogen load on the next day, unit in kg; and td+1 is the timestep (at one hour) on the next day.

2.3.5. FCEVs

The hydrogen load for refueling FCEVs is calculated via refueling schedules, vehicle quantity, daily hydrogen consumption, and more. The hydrogen load of the refueling station at time t (Hload(t), unit in kg) is calculated as follows [8]:

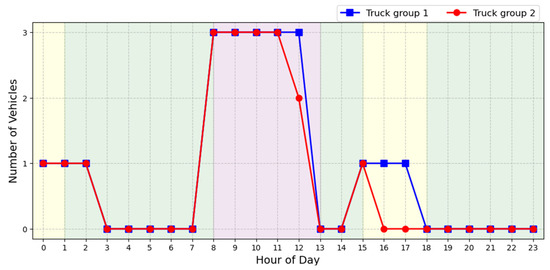

where NV is the quantity of different FCEV groups refueled by the station; Nj,t is the quantity of j-th FCEV group arriving at the station at time t; tankVolVj is the maximum hydrogen storage capacity, unit in kg, set at 38 kg in this study; μj and σj are the mean value and standard deviation of the hydrogen refueling quantity of one FCEV in the j-th group, respectively, units in kg; Dj is the total quantity of FCEVs in the j-th group within a scheduled refueling period; and Ts is the total available refueling period duration for the j-th group. The truck group parameters for hydrogen load calculations are shown in Table 1.

Table 1.

Truck group parameters for hydrogen load calculations.

Figure 4 shows the hourly FCEV refueling schedule on a typical weekday, according to the actual operational records of the real HPRS. Furthermore, part of the model validation was performed by comparing the simulated hydrogen load and the actual hydrogen load (see Section 3.1).

Figure 4.

FCEV refueling profile of a typical week at the realistic HPRS.

2.4. Energy Control Strategy

In this study, a rule-based strategy is adopted for energy control based on the real HPRS setup. The control inputs (control states) include renewable energy generation (Pre(t)), hydrogen load (H(t)), electrolyzer rated power (Peln), hydrogen tank SOC of HPRS (SOCtan(t)), the upper and lower SOC limits of the hydrogen tank (SOCupper, limit and SOClower, limit), the hydrogen tank SOC limit for meeting the next-day load (SOCload(d+1)), and the electricity price level. The control outputs include electrolyzer power (Pele(t)) and system grid power (Pgrid(t), depending on the energy balance represented in Section 2.5.3. All the power-related control variables are in kW. The overall energy flows are illustrated in Figure 4, and the detailed control information is clarified in Section 2.4.1 and Section 2.4.2.

2.4.1. Operation Without Renewable Energy Systems

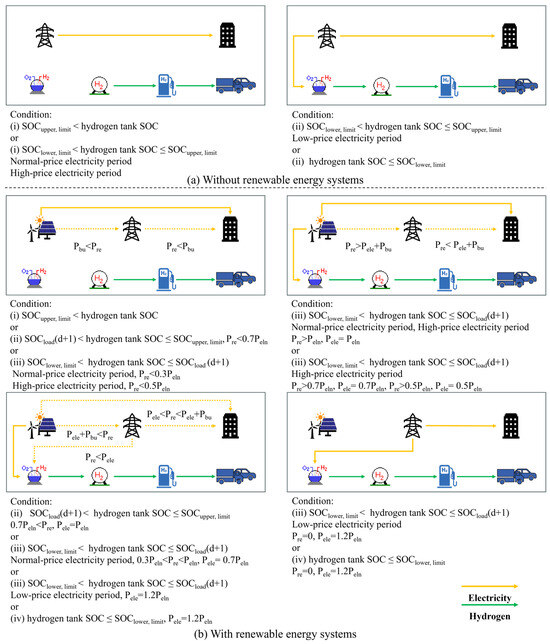

The energy flow of the HPRS without renewable energy systems is based on SOCtan(t) and the electricity price level, as shown in Figure 5a. The control operates as follows:

Figure 5.

Energy flows of the hydrogen production–refueling station: (a) without renewable energy systems, and (b) with renewable energy systems.

- (i)

- The electrolyzer is kept off either when SOCtan(t) is above SOCupper, limit or during the normal- or high-price electricity period (see Section 2.7).

- (ii)

- The electrolyzer operates at Peln when SOCtan(t) is below SOCupper, limit during the low-price electricity period (see Section 2.7), or when SOCtan(t) is below SOClower, limit (whatever the period is), until SOCtan(t) reaches SOCupper, limit.

2.4.2. Operation with Renewable Energy Systems

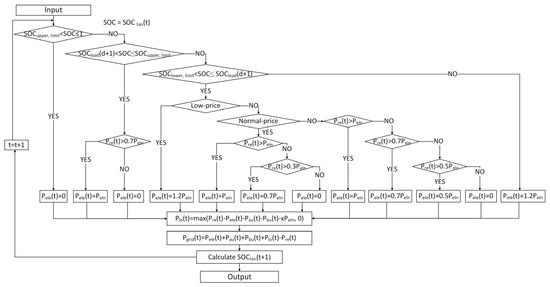

The energy flow of the HPRS with renewable energy systems is based on SOCtan(t), Pre(t), and the electricity price level, as shown in Figure 5b. The control logic is illustrated in Figure 5 and Figure 6. Before executing control, SOCload(d+1) is calculated (see Section 2.3.4), then the control operates as follows:

Figure 6.

The rule-based control logic of the hydrogen production–refueling station with renewable energy systems.

(i) The electrolyzer is kept off when SOCtan(t) is above SOCupper, limit (whatever the period is).

(ii) When SOCtan(t) is below SOCupper, limit but above SOCload(d+1), the electrolyzer operates at Peln if Pre(t) exceeds 0.7Peln, until SOCtan(t) reaches SOCupper, limit; otherwise, the electrolyzer is kept off (whatever the period is).

(iii) When SOCtan(t) is below SOCload(d+1) but remains above SOClower, limit, the electrolyzer operates at the maximum power (1.2Peln) during the low-price electricity period and operates at discrete power levels during the normal- or high-price electricity period according to Pre(t), until SOCtan(t) reaches SOCload(d+1). The above-stated discrete power levels during the normal- or high-price electricity period were developed based on Refs. [24,25] as follows: during the normal-price period, the electrolyzer operates at Peln if Pre(t) is higher than Peln, at 0.7Peln if Pre(t) is higher than 0.3Peln but lower than Peln, and stays off if Pre(t) is lower than 0.3Peln; during the high-price period, the electrolyzer operates at Peln if Pre(t) is higher than Peln, at 0.7Peln if Pre(t) is higher than 0.7Peln but lower than Peln, at 0.5Peln if Pre(t) is higher than 0.5Peln but lower than 0.7Peln, and stays off if Pre(t) is lower than 0.5Peln.

(iv) When SOCtan(t) is below SOClower, limit, the electrolyzer operates at the maximum power (1.2Peln), until SOCtan(t) reaches SOClower, limit (whatever the period is).

2.5. Optimization Algorithm Configuration

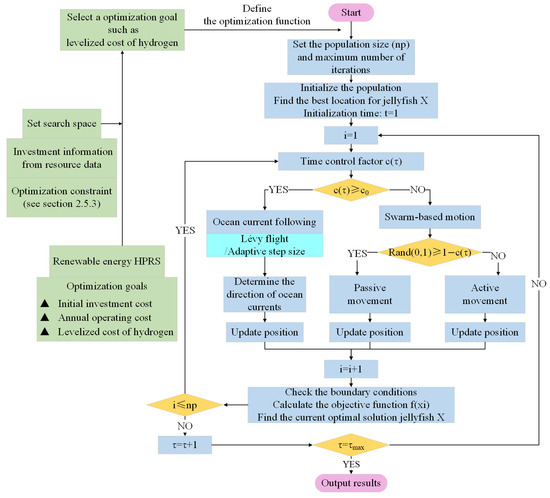

2.5.1. Optimization Algorithm

Capacity optimization for an HPRS involves many decisive factors (like the maximum available device capacity and the device price) and thus constitutes a multi-constraint problem. The JSA [26] is adopted for solution determination (see Figure 7). Through mimicking jellyfish swarm behavior, the JSA has been demonstrated to have strong search capability and rapid convergence, and is able to preserve decision-variable diversity and reduce computational complexity.

Figure 7.

The configuration of the improved JSA.

As shown in Figure 7, after setting the optimization goal (see Section 2.5.2) and constraints (see Section 2.5.3) for defining the optimization function and search space, Latin Hypercube Sampling [27] is adopted and initializes the population to enhance diversity. This strategy significantly enhances diversity by ensuring uniform coverage of the search space: each of the dim dimensions is partitioned into population-size equiprobable intervals, and a single sample is drawn randomly from each interval.

The JSA mimics the foraging behavior of jellyfish in the ocean to determine optimal solutions. Its core algorithm emulates two movement modes, namely, ocean current following and swarm-based motion. Through these two movements, it finds places in the ocean (search space) with a higher available quantity of food (the optimal solution). To regulate the two movements of jellyfish, the time control mechanism includes a time control factor c(τ) and a constant c0 (set at 0.5 in this study). The deterministic control mechanism c(τ) is calculated as follows:

where τ is the time specified as the iteration number, and τmax is the maximum number of iterations, which is defined before optimization. Compared with random control, it can achieve a smoother and more stable transition from global exploration to local development, avoiding the abruptness of phase switching and the risk of falling into local optima.

For each jellyfish i, its movement is determined as follows: When c(τ) is higher than c0, the jellyfish migrates toward the global best position (ocean current following). Conversely, if c(τ) is lower than c0, the jellyfish moves within the swarm, depending on a random number between 0 and 1 (Rand(0, 1)): If Rand(0, 1) is higher than 1 − c(τ), the jellyfish has passive motion (local exploitation), whereas it triggers active motion (accelerated local convergence) when Rand(0, 1) is lower than 1 − c(τ). After the above-stated motion, the current optimal solution, jellyfish (X), is identified. This solution guides the ocean current direction of the next iteration, and the above-stated solution search continues until the global optimal solution or the maximum allowable iteration quantity is reached.

To strengthen the global search, the Lévy flight [28] is incorporated during ocean current following, which generates occasional large-step random jumps, effectively escaping local optimization. The Lévy flight basic step size is calculated using a standard formula with the characteristic exponent at 1.5. Concurrently, an adaptive step-size mechanism is employed, dynamically adjusting the movement magnitude throughout iterations. The advantages of the above-stated approach include the following: (1) Larger initial steps accelerate exploration of the search space during early stages, and (2) progressively smaller steps enhance local exploitation and precision near convergence, significantly reducing the risk of overshooting or skipping the optimal solution [29]. The adaptive step-size mechanism is as follows:

where ls is the step-size control coefficient, and after multiple simulations and comparisons, it is set at 0.2.

2.5.2. Optimization Goal

Different from BEV charging stations, HPRSs usually need a very high investment due to expensive devices like electrolyzers and hydrogen tanks. Thus, the economic cost is the main optimization goal in this study. Other benefits, like renewable energy penetration and grid load, are evaluated after the cost is optimized (see Section 2.6). The economic goals include initial investment cost, annual operational cost, and LCOH, which are incorporated as goal functions for HPRS capacity optimization. Users may select one of the above-stated economic goals before performing optimization according to the actual demand. Specifically, minimizing the initial investment cost may be proper for projects that have limited funding for building HPRSs. Minimizing the annual operational cost may be proper for projects that have sufficient funding for building HPRSs and will earn economic benefits through refueling FCEVs. Minimizing the LCOH may be proper for HPRSs that are built to serve the FCEVs owned by the same owner (like the real HPRS mentioned in Section 2.1).

The initial investment cost (Cini) is calculated as follows:

where kWT, kPV, kEL, and kHT are the unit prices of wind power (unit in USD/kW), PV (unit in USD/kW), electrolyzers (unit in USD/kW), and hydrogen tanks (unit in USD/kg), see Section 2.7; EWT, EPV, EEL, and EHT are the rated capacities of wind power (unit in kW), PV (unit in kW), electrolyzers (unit in kW), and hydrogen tanks (unit in kg); and γ is the equipment investment coefficient, which represents the amortized value of the purchase and installation of equipment (including the auxiliary equipment) and is set at 1.25 [30].

The annual operational cost (COP,a) is calculated as follows [31]:

where CG,a is the annual system electricity cost, unit in USD; COM,a is the annual operation and maintenance costs, unit in USD; CP,a is the annual system penalty cost for wind and PV curtailment, unit in USD; oWT, oPV, oEL, and oHT are the unit prices of operation and maintenance costs of wind power (unit in USD/kW·a), PV (unit in USD/kW·a), electrolyzers (unit in USD/kW·a), and hydrogen tanks (unit in USD/kg·a), see Section 2.7; plo is the wind/solar curtailment penalty, unit in USD/kWh, see Section 2.7; and Plo(t) is the wind/solar curtailment penalty, unit in kW, see Section 2.5.3.

The LCOH, which incorporates the initial investment and operational cost over the system lifetime, is calculated below [32,33]:

where CR,a is the annual system replacement cost of equipment, unit in USD. In this study, only the electrolyzer needs to be replaced one time during the project lifetime, and the replacement cost is the same as the investment cost of the electrolyzer. Ht is the annual production of hydrogen, unit in kg; D is the annual degradation rate of the hydrogen production system (1%); i is the discount rate (8%); and T is the project lifetime (20 years).

2.5.3. Constraints

For renewable systems, the constraints on the capacity are as follows:

where EWT, max and EPV, max are the capacity upper limits for wind power and PV, respectively, units in kW. In this study, according to the real HPRS project, the renewable capacity upper limit is set at 20 MW, while the PV capacity upper limit is 15 MW.

Wind and solar power curtailment Plo(t) may occur due to the limited grid capacity, which can be calculated as follows:

where x is the grid absorption factor, which is set at 1.5 according to Ref. [34] and the real HPRS setup.

To enhance renewable energy utilization, the annual renewable energy curtailment rate should not exceed a specified threshold, calculated as follows:

where Rlo is the maximum allowable renewable energy curtailment rate, set at 10% in this study.

Moreover, the whole system should have an energy balance constraint as follows:

2.6. Other Evaluation Indicators

Besides the economic cost, this study also employs grid power metrics and the renewable energy hydrogen production penetration rate to evaluate the renewable energy utilization and grid interaction performance of the HPRS.

The grid load is evaluated using the mean hourly grid power (Ph), which is the average grid power at a certain time point (like 8:00 a.m.) over one year.

Moreover, to analyze renewable energy utilization efficiency, the renewable penetration rate of hydrogen production (Rre) is evaluated, which quantifies the proportion of hydrogen produced using renewable electricity to the total hydrogen production. It can be calculated as follows:

where Pre, ele(t) is the renewable electric power input into the electrolyzer for hydrogen production, unit in kW.

2.7. Research Cases

To validate the HPRS model, this study collected the operational data of the real HPRS from 12 May to 17 May 2025 (one typical week, except the weekend), including hydrogen refueling quantity, hydrogen tank SOC, and electrolyzer power, which are compared with the simulated results by the established HPRS model (see Section 3.1).

Then, the reference case is defined, and the key parameters are represented in Table 2, where the data originate from the real HPRS mentioned in Section 2.1 and Refs. [30,35]. The reference case represents the current condition of the real HPRS, where renewable systems are not fully constructed and the hydrogen production relies on consuming the electricity imported from the local power grid. Moreover, three cases are configured for performing capacity optimization using the proposed framework (Table 3). To be specific, like the reference case, Case 1 has no renewable systems and only relies on the power grid for hydrogen production. Case 2 has PV systems as the renewable source, while Case 3 has both PV and wind power systems as the renewable sources. It should be noted that Case 2 represents the near-future development of the real HPRS mentioned in Section 2.1, which may be supported by its nearby PV systems. Case 3 represents the far-future plan of the HPRS, where wind power is considered to be added.

Table 2.

Key parameters of the reference case.

Table 3.

Investigated cases for HPRS capacity optimization in this study.

3. Results

3.1. Model Validation

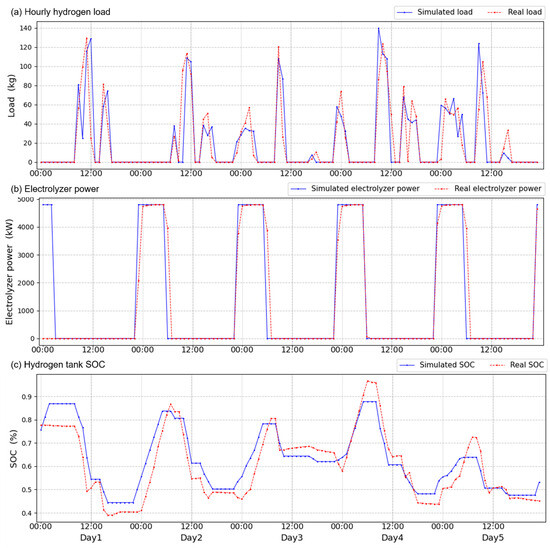

3.1.1. Real Project Validation

A comparison of actual operational data versus simulation data of an HPRS during a typical week (excluding the weekend) in the reference case is shown in Figure 8. Figure 8a depicts the temporal variation in the hydrogen load. The simulated and the actual hydrogen loads are very close, with a total error of 1.21%, which indicates that the model effectively predicts the actual fluctuations in hydrogen refueling demand. Figure 8b illustrates the operational power profile of the electrolyzer. The simulated power aligns with actual measurements, and minor discrepancies occur during startup/shutdown periods. Figure 8c shows the SOC variation in the hydrogen tank of the HPRS. During the initial hours of Day 1, the real electrolyzer remains off due to the unplanned manual shutdown operation, which results in a higher simulated SOC value compared to the actual values during this period, while the average SOC error during a typical week is 4.03%, indicating the high accuracy of the established model.

Figure 8.

The comparison between the actual and simulated results during a typical week: (a) hourly hydrogen load, (b) electrolyzer power, and (c) hydrogen tank SOC.

3.1.2. Optimization Algorithm Comparison

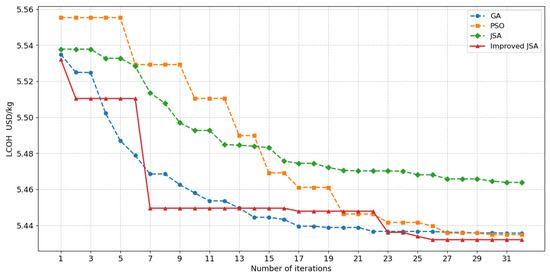

Figure 9 shows the optimization performance of the improved JSA in the optimal solution (LCOH) and convergence speed, compared with other optimization algorithms, including the original JSA, genetic algorithm (GA), and particle swarm optimization (PSO). The results demonstrate that the improved JSA achieves the lowest LCOH among all the optimization methods, and it has a similar high convergence speed to GA. Especially, it achieves a 12.90% increase in the convergence speed compared to the original JSA.

Figure 9.

Comparison of different optimization algorithms.

3.2. Optimization Results

3.2.1. Case 1 Without Renewable Systems

In Case 1, without any renewable energy system, HPRS can only utilize the low-price grid electricity for hydrogen production. The optimization results in Case 1 for different goals are represented in Table 4. The proposed optimization framework reduces the defined economic costs of the HPRS. To be specific, when the goal is to minimize the initial investment cost, the proposed optimization framework achieves a 29.31% reduction. However, this goal incurs a 28.17% increase in the annual operational cost compared to the reference case. When the goal is to minimize the annual operational cost, the optimization framework achieves a 6.66% reduction in the annual operational cost and a 2.30% reduction in the LCOH. When the goal is to minimize the LCOH, the optimization framework achieves a 2.83% reduction in LCOH, with the operational cost increasing by only 0.09% compared to the condition when the goal is to minimize the annual operational cost.

Table 4.

Optimization results in Case 1.

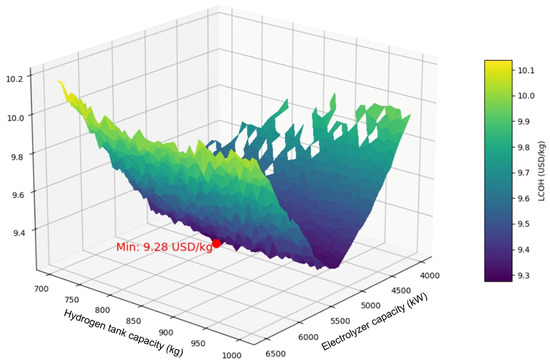

Figure 10 illustrates the variation of LCOH with the changes in electrolyzer and hydrogen tank capacities in Case 1. The LCOH exhibits weak sensitivity to the change in hydrogen tank capacity. The relationship between LCOH and electrolyzer capacity demonstrates a distinct U-shaped curve. Specifically, when the electrolyzer capacity increases from 4000 to 5305 kW, the system’s annual electricity consumption almost stays unchanged (<1%), but the electrolyzer consumes more low-price electricity during off-peak hours for hydrogen production, leading to a significantly reduced operational cost, which drives the LCOH down from USD 10.00 to 9.28/kg. When the electrolyzer capacity exceeds 5305 kW, LCOH increases due to the rising initial investment costs.

Figure 10.

Variation in LCOH with the changes in electrolyzer and hydrogen tank capacities.

3.2.2. Case 2 with Only PV Systems

Case 2 has PV systems to provide renewable electricity for hydrogen production. The optimization results in Case 2 for different goals are represented in Table 5. It can be seen that, with PV systems, the proposed optimization framework significantly reduces the economic cost of HPRS. To be specific, compared to the reference case without renewable energy systems, in Case 2, when the goal is to minimize the initial investment, the optimization framework achieves a 21.83% reduction in the initial investment, while the operational cost is only reduced by 7.48%. When the goal is to minimize the annual operational cost, the optimization framework reduces the operational cost by 100% (compared to the reference case, there is no operational cost but some income due to selling renewable electricity to the local power grid. Thus, the reduction in operational cost is regarded as 100%). As a result, the LCOH is cut down by 40.10% even though the initial investment increases a lot. When the goal is to minimize the LCOH, the optimization framework achieves a 43.14% reduction in LCOH, and meanwhile, the annual operational cost is reduced by 82.81% compared to the reference case without renewable systems.

Table 5.

Optimization results in Case 2.

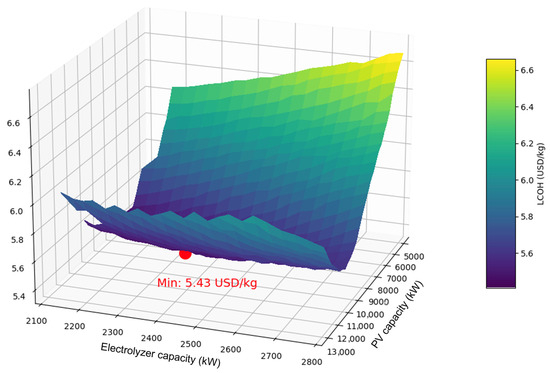

Figure 11 illustrates the variation in LCOH with PV and electrolyzer capacity in Case 2 at a fixed hydrogen tank capacity of 800 kg (considering that the hydrogen tank capacity has a limited effect on the LCOH in Case 1, it is kept constant here). It can be seen that increasing PV capacity from 5000 to 8705 kW continuously drives LCOH down, due to the increased free renewable electricity for hydrogen production. Nonetheless, when PV capacity exceeds 8705 kW, continuing to increase it leads to elevated curtailed PV power and penalty costs and elevated initial investment, which is far more than the compensation of hydrogen production (using renewable energy instead of grid electricity) and the income from selling renewable electricity to the grid; thus, the LCOH increases after the PV capacity exceeds 8705 kW. In addition, unlike Case 1, increasing the electrolyzer capacity in Case 2 generally causes an increased LCOH. This is because the availability of renewable energy provides long periods with free electricity for the electrolyzer’s hydrogen production. Thus, the electrolyzer with relatively small capacity is sufficient to cover the hydrogen load, and increasing electrolyzer capacity has a low effect on meeting hydrogen demand but causes an obvious increase in the initial investment and LCOH.

Figure 11.

Variation in LCOH with the changes in PV and electrolyzer capacities.

3.2.3. Case 3 with PV and Wind Power Systems

Case 3 has PV and wind power systems to provide renewable electricity for hydrogen production. The optimization results in Case 3 for different goals are represented in Table 6. Similar to the results in Case 2, with renewable energy systems, the proposed optimization framework significantly reduces the system’s economic cost. To be specific, compared to the reference case without renewable energy systems, when the goal is to minimize the initial investment, the optimization framework achieves an 11.71% reduction in the initial investment. When the goal is to minimize the annual operational cost, the optimization framework reduces the operational cost by 100%. As a result, the LCOH is cut down by 39.68%, even though the initial investment increases. When the goal is to minimize the LCOH, the optimization framework achieves a 44.19% reduction in LCOH, and meanwhile, the annual operational cost is reduced by 86.19% compared to the reference case without renewable energy systems.

Table 6.

Optimization results in Case 3.

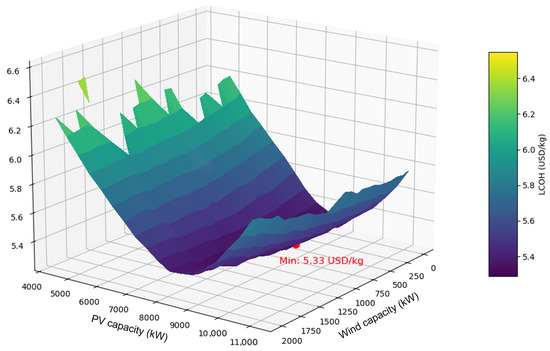

Figure 12 illustrates the variation in LCOH with PV and wind power capacity in Case 3 at a fixed electrolyzer capacity of 2220 kW and a fixed hydrogen tank capacity of 695 kg. It can be seen that the relationship between LCOH and PV capacity demonstrates a distinct U-shaped curve, consistent with the results observed in Case 2. Specifically, when the PV capacity increases from 5000 to 8705 kW, it continuously drives LCOH down. Then, the LCOH starts to increase after the PV capacity exceeds 8705 kW. In addition, due to relatively low wind resources in Changsha, the LCOH starts to increase after the wind power capacity exceeds 635 kW, and the optimal LCOH is achieved by using PV systems as the main renewable energy source, which indicates the low economic feasibility of using wind power for hydrogen production in this case.

Figure 12.

Variation in LCOH with the changes in wind power and PV capacities.

3.3. Grid Load

LCOH represents the overall economic performance of HPRSs, which may be the priority goal in practice. Thus, this section analyzes the grid load during a typical week under the case with the goal of minimizing the LCOH. The annual grid loads under scenarios with different economic goals are represented afterwards. Moreover, it should be noted here that the peak grid load refers to the maximum absolute power value of the local grid (whether grid-imported or grid-exported power).

3.3.1. Grid Load in Case 1

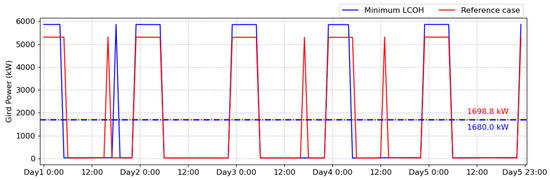

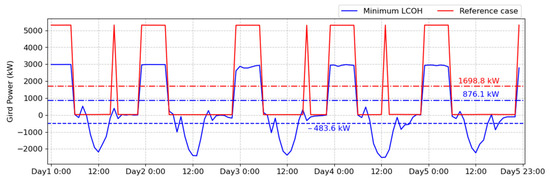

Figure 13 shows the grid power during a typical week in Case 1, with the goal of minimizing LCOH. Compared to the reference case, the peak grid load increases by 10.36%, from 5316.0 to 5866.5 kW. The reason is that the optimization framework makes the best use of the low-price electricity at night, which leads to elevated grid-imported power at night.

Figure 13.

The variation in typical weekday grid power in Case 1.

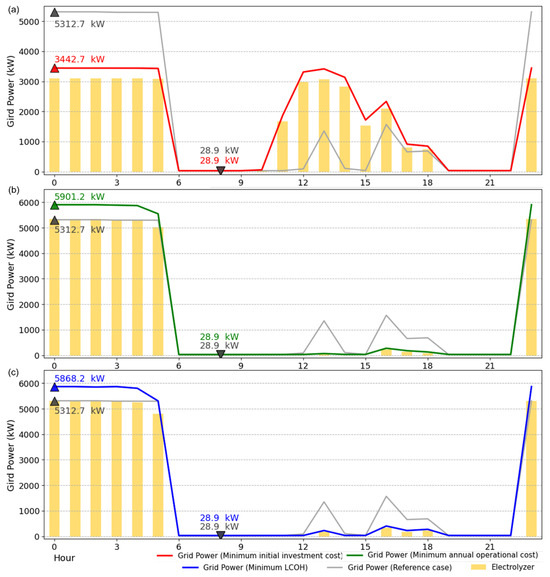

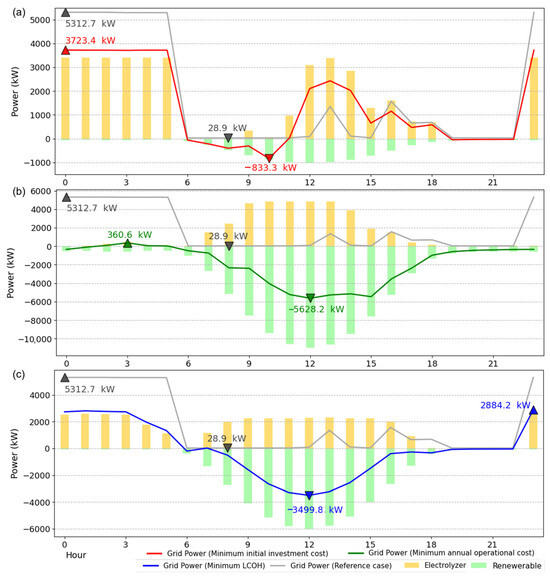

Figure 14 shows the mean hourly grid power in Case 1. When the goal is to minimize the initial investment, the peak grid load is reduced by 35.12%, from 5312.7 to 3442.7 kW. When the goals are to minimize the annual operational cost and LCOH, the peak grid loads increase by 11.08% and 10.46%, from 5312.7 to 5901.2 and 5868.2 kW, respectively. Similar to the above-stated results during a typical week, the focused electricity consumption during the low-price period causes the increased grid load.

Figure 14.

Mean hourly grid power in Case 1: (a) minimum initial investment cost, (b) minimum annual operational cost, and (c) minimum LCOH.

3.3.2. Grid Load in Case 2

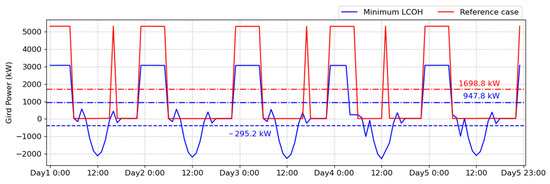

Figure 15 shows the grid power during a typical week in Case 2, with the goal of minimizing LCOH. It can be seen that the grid load is significantly lowered after the system capacity is optimized. Specifically, compared to the reference case without renewable energy systems, the peak grid load is reduced by 42.18%, from 5316.0 to 3073.6 kW.

Figure 15.

The variation in typical weekday grid power in Case 2.

Figure 16 shows the mean hourly grid power in Case 2. When the goals are to minimize the initial investment and LCOH, the peak grid load is reduced by 26.21% and 37.40%, from 5312.7 to 3920.1 and 3326.0 kW, respectively. Nonetheless, when the goals are to minimize the annual operational cost, the peak grid load slightly increases by 1.21%, from 5312.7 to 5376.8 kW, due to the enlarged capacity of the renewable system, which injects a significant amount of electricity into the local grid.

Figure 16.

Mean hourly grid power in Case 2: (a) minimum initial investment cost, (b) minimum annual operational cost, and (c) minimum LCOH.

3.3.3. Grid Load in Case 3

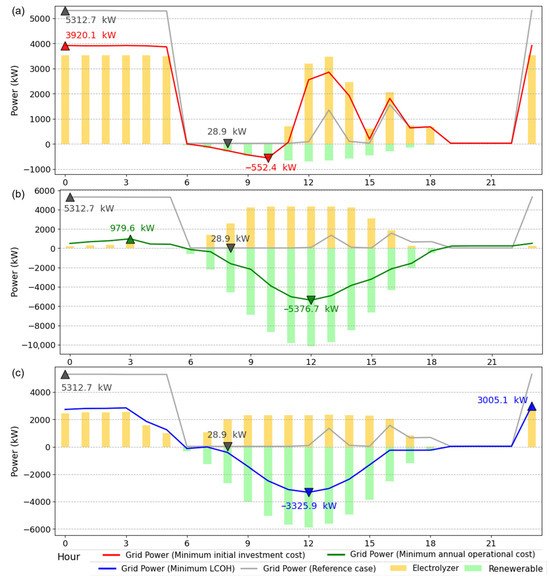

Figure 17 shows the grid power during a typical week in Case 3, with the goal of minimizing LCOH. After optimization, the grid load is significantly lowered, similar to in Case 2. Specifically, compared to the reference case, the peak grid load is reduced by 43.80%, from 5316.0 to 2987.5 kW.

Figure 17.

The variation in typical weekday grid power in Case 3.

Figure 18 shows the mean hourly grid power in Case 3. When the goals are to minimize the initial investment and LCOH, the peak grid loads are reduced by 29.92% and 34.12%, from 5312.7 to 3723.4 and 3499.8 kW, respectively. Nonetheless, when the goal is to minimize the annual operational cost, the peak grid load slightly increases by 5.94%, from 5312.7 to 5628.2 kW, due to the enlarged capacity of the renewable system, which injects a significant amount of electricity into the local grid.

Figure 18.

Mean hourly grid power in Case 3: (a) minimum initial investment cost, (b) minimum annual operational cost, and (c) minimum LCOH.

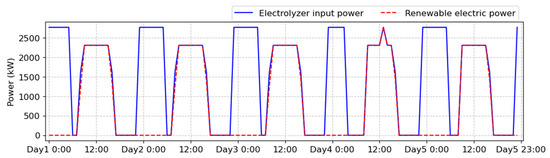

3.4. Renewable Energy Penetration into Hydrogen Production

Figure 19 illustrates the renewable electric power and the electrolyzer input power during a typical week in Case 2, with the goal of minimizing LCOH. The renewable penetration rate during a typical week reaches 48.01%. When the goals are to minimize the initial investment, annual operational cost, and LCOH, the annual renewable penetration rates are 4.10%, 88.21%, and 56.94%; meanwhile, the annual renewable energy self-consumption rates are 43.06%, 46.96%, and 51.00%, respectively.

Figure 19.

Renewable electric power and electrolyzer input power during a typical week in Case 2, with the goal of minimizing LCOH.

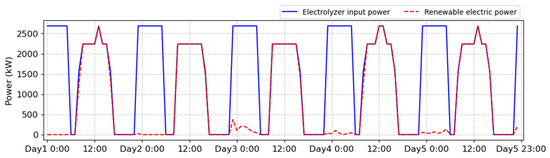

Figure 20 illustrates the renewable electric power and the electrolyzer input power during a typical week in Case 3, with the goal of minimizing LCOH. The renewable penetration rate during the typical week reaches 47.52%. When the goals are to minimize the initial investment, annual operational cost, and LCOH, the annual renewable penetration rates are 9.30%, 89.30%, and 57.39%; meanwhile, the annual renewable energy self-consumption rates are 49.45%, 40.29%, and 50.10%, respectively.

Figure 20.

Renewable electric power and electrolyzer input power during a typical week in Case 3, with the goal of minimizing LCOH.

3.5. Sensitivity Analysis

To evaluate the robustness of the proposed optimization framework, a sensitivity analysis was performed on key parameters influencing the economic and operational performance of the HPRS. Given that the impact of the optimization variables was analyzed in Section 3.2, this analysis focuses primarily on the impact of grid feed-in tariffs and hydrogen load variations on optimization results, which was conducted under the condition of Case 3; the results are represented in Table 7. The percentages of grid feed-in tariffs and hydrogen load are the ratios compared to the original level in Case 3. As the grid feed-in tariffs decrease, the optimal capacities of PV and wind power decline, as does the electrolyzer, while the LCOH slightly increases. Conversely, increasing the hydrogen load elevates the optimal capacities of the wind power, PV, electrolyzers, and hydrogen tank, while the optimization algorithm achieves a 7.3% LCOH reduction when the hydrogen load increases by 60% due to the use of renewable electricity for hydrogen production.

Table 7.

The results of sensitivity analysis.

4. Discussion

4.1. Research Advantages

(1) Real-project-based HPRS model: Current studies rarely validate their energy models using actual data. The HPRS model established in this study was validated using the actual operational data of the largest HPRS in China, with the hydrogen load prediction error at merely 1.21% and the hydrogen tank SOC prediction error at merely 4.03%, which demonstrates the strong validation of the established model. Moreover, the established model not only integrates real FCEV refueling demand behaviors and renewable energy planning but also the real constraints of an HPRS (such as the electrolyzer power limit and the FCEVs’ refueling schedule), which is consistent with the real HPRS and makes the model and the optimization practical.

(2) User-friendly optimization framework: The proposed optimization framework is proper for the design phase of HPRSs and only requires users to provide easy-to-obtain input data (e.g., vehicle information and climate data). It does not require the users to develop complicated system models and configure optimal algorithms [36]. Meanwhile, the optimization framework allows users to select different economic goals (initial investment cost, operational cost, or LCOH) according to the actual needs in practice. The above-stated characteristics of the optimization framework make it easy to be deployed in the HPRS design.

(3) High-performance optimization algorithm: The improved JSA, which incorporates the Lévy flight strategy, significantly enhances optimization performance. To be specific, the algorithm achieves significant reductions in the economic costs of HPRSs (see Section 3.2). Meanwhile, the optimization speed is also satisfying and practical. For instance, in Case 3, with LCOH minimization as the objective, the optimization was completed in 108 min using a normal laptop (12th Gen Intel(R) Core(TM) i7-12650H), with more than 1000 parameter combination conditions being simulated and compared to obtain the final optimal solution.

4.2. Research Limitations

(1) The model validation was conducted exclusively on the operational data of one HPRS station, which provides free hydrogen to FCEVs in limited quantities. If there are more FCEVs and the refueled hydrogen is not free, the optimization results may be different.

(2) This study was conducted with the climate data of Changsha (southern China). In other regions with different climates, due to the different renewable generation characteristics [37,38], the optimization framework still works but may give a different optimal capacity design of the HPRS.

(3) The performance degradation of the devices of HPRSs is not fully considered. For example, the degradation of PV systems over time is not incorporated into the energy model. The electrolyzer efficiency model relies solely on parameters provided by the manufacturer and does not quantify startup and shutdown losses, lifetime degradation effects, or dynamic response times. Additionally, this study does not incorporate a long-term reliability assessment of fuel cells. The detailed simulations of fuel cells can enhance the accuracy of operation performance evaluation on HPRSs, while it is more appropriate for the operation phase when the specific type, structure, and use behaviors of FCEVs are determined. Examples include water management mechanisms, fuel cell life prediction considering the recovery phenomenon of reversible voltage loss, and the degradation prediction of fuel cell performance based on a transformer model [39]. This omission may lead to inaccuracies in hydrogen refueling demand calculations, primarily affecting the accuracy of scheduling during long-term operational phases.

4.3. Recommendations for Hydrogen Infrastructure

The proposed capacity optimization framework demonstrates significant economic advantages for HPRSs, which also provides references for hydrogen energy infrastructure planning as follows:

- (1)

- Case 1 reduced LCOH by merely 2.83%, while Cases 2 and 3 achieved an LCOH reduction of over 40%, clearly demonstrating the necessity of implementing renewable energy in HPRSs, rather than fully depending on the local power grid.

- (2)

- For the studied region, wind power offers limited economic benefits. Thus, in capital-constrained projects and low-wind-resource regions, PV systems should be prioritized for HPRSs.

- (3)

- The investigated HPRS achieves peak shaving and valley filling in the power grid by integrating renewable energy and utilizing electricity during the low-price electricity period. In practice, the design and planning of HPRSs should be incorporated into grid peak regulation systems to mitigate grid pressure.

5. Conclusions

This study proposes a novel capacity optimization framework for HPRSs, which integrates a validated HPRS model (with reference to the largest HPRS in China) and the improved JSA. The framework significantly improves the economic efficiency, grid flexibility, and renewable energy utilization rate of the HPRS. Key findings demonstrate that:

(1) The HPRS model exerts high reliability, with prediction errors at merely 1.21% for hydrogen refueling loads and 4.03% for hydrogen tank SOC, compared to the actual operational data of the largest HPRS in China.

(2) The optimization framework substantially reduces the economic costs of the HPRS. Specifically, compared to the reference case (the current status of the real HPRS), in the case without a renewable energy system (Case 1), the initial investment, annual operational cost, and LCOH are reduced by 29.31%, 6.66%, and 2.83%, respectively. In the case with a PV system (Case 2), the initial investment, annual operational cost, and LCOH are reduced by 21.83%, 100.0%, and 43.14%, respectively. In the case with PV and wind power systems (Case 3), the initial investment, annual operational cost, and LCOH are reduced by 11.71%, 100.00%, and 44.19%, respectively.

(3) The optimization framework helps decrease the grid load caused by the HPRS. Specifically, compared to the reference case (the current status of the real HPRS), in the case without a renewable energy system (Case 1), with a PV system (Case 2), and with PV and wind power systems (Case 3), the peak grid powers are reduced by 35.12%, 37.40%, and 34.12%, respectively.

(4) The optimization framework also promotes the renewable energy use in HPRSs for green hydrogen production. Specifically, in the case with a PV system (Case 2) and in the case with PV and wind power systems (Case 3), the renewable penetration rates of hydrogen production reach up to 88.21% and 89.30%, respectively.

Author Contributions

Conceptualization, Y.Z., W.Z., Y.H., H.Z., W.C., C.Y. and H.D.; Methodology, Y.Z., W.Z., Y.H., H.Z., W.C., C.Y. and H.D.; Validation, Y.Z. and Y.H.; Formal analysis, Y.Z., W.C., C.Y. and H.D.; Investigation, Y.Z., Y.H. and H.Z.; Resources, Y.H. and H.Z.; Data curation, Y.Z., Y.H. and H.Z.; Writing—original draft, Y.Z. and H.Z.; Writing—review & editing, W.Z. and Y.H.; Project administration, Y.H.; Funding acquisition, Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the National Natural Science Foundation of China (project No. 52308092) and the Fundamental Research Funds for the Central Universities of China (number 531118010826).

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| FCEV | Hydrogen Fuel Cell Electric Vehicle |

| HPRS | Hydrogen Production–Refueling Stations |

| JSA | Jellyfish Search Algorithm |

| LCOH | Levelized Cost of Hydrogen |

| EV | Battery Electric Vehicle |

| PV | Photovoltaic |

References

- Liu, F.; Shafique, M.; Luo, X. Quantifying Delayed Climate Mitigation Benefits in Electric and Hydrogen Fuel Cell Vehicle Deployment for Sustainable Mobility. Sustain. Prod. Consum. 2024, 49, 398–414. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.; Huang, X.; Liu, F.; Zhou, F.; Lim, M.K. Uncovering Determinants and Barriers to Hydrogen Fuel Cell Vehicle Adoption: Evidence from Chongqing, China. Int. J. Hydrog. Energy 2025, 106, 875–887. [Google Scholar] [CrossRef]

- Lu, Q.; Zhang, B.; Yang, S.; Peng, Z. Life Cycle Assessment on Energy Efficiency of Hydrogen Fuel Cell Vehicle in China. Energy 2022, 257, 124731. [Google Scholar] [CrossRef]

- Du, Y.; Jia, D.; Li, X. A Robust Dynamic Hydrogenation Network Layout Model Considering Station Capacity Expansion and Flexible Transportation Modes. Int. J. Hydrogen Energy 2024, 58, 223–238. [Google Scholar] [CrossRef]

- Li, X.; Ye, T.; Meng, X.; He, D.; Li, L.; Song, K.; Jiang, J.; Sun, C. Advances in the Application of Sulfonated Poly(Ether Ether Ketone) (SPEEK) and Its Organic Composite Membranes for Proton Exchange Membrane Fuel Cells (PEMFCs). Polymers 2024, 16, 2840. [Google Scholar] [CrossRef]

- Roslan, M.F.; Ramachandaramurthy, V.K.; Mansor, M.; Mokhzani, A.S.; Jern, K.P.; Begum, R.A.; Hannan, M.A. Techno-Economic Impact Analysis for Renewable Energy-Based Hydrogen Storage Integrated Grid Electric Vehicle Charging Stations in Different Potential Locations of Malaysia. Energy Strategy Rev. 2024, 54, 101478. [Google Scholar] [CrossRef]

- Marchenko, O.V.; Solomin, S.V. Modeling of Hydrogen and Electrical Energy Storages in Wind/PV Energy System on the Lake Baikal Coast. Int. J. Hydrog. Energy 2017, 42, 9361–9370. [Google Scholar] [CrossRef]

- Wang, Z.; He, Y. AlphaHydrogen: A Virtual Platform for Simulating and Evaluating Station-Based Regional Hydrogen-Electricity Networks with Distributed Renewables, Buildings, and Fuel-Cell Vehicles. Energy Convers. Manag. 2023, 280, 116802. [Google Scholar] [CrossRef]

- Zhao, H.; Yao, Y.; Peng, D.; Zhao, P. A Preference Adjustable Capacity Configuration Optimization Method for Hydrogen-Containing Integrated Energy System Considering Dynamic Energy Efficiency Improvement and Load Fast Tracking. Renew. Energy 2024, 235, 121314. [Google Scholar] [CrossRef]

- Cardona, P.; Costa-Castelló, R.; Roda, V.; Carroquino, J.; Valiño, L.; Ocampo-Martinez, C.; Serra, M. Modelling and Operation Strategy Approaches for On-Site Hydrogen Refuelling Stations. Int. J. Hydrogen Energy 2024, 52, 49–64. [Google Scholar] [CrossRef]

- Demir, H. Design and Optimization of Hybrid Renewable Energy Systems for Hydrogen Production at Aksaray University Campus. Process Saf. Environ. Prot. 2024, 192, 543–556. [Google Scholar] [CrossRef]

- Tezer, T. Multi-Objective Optimization of Hybrid Renewable Energy Systems with Green Hydrogen Integration and Hybrid Storage Strategies. Int. J. Hydrogen Energy 2025, 142, 1249–1271. [Google Scholar] [CrossRef]

- Wang, S.; Peng, Z.; Wang, P.; Chen, A.; Zhuge, C. A Data-Driven Multi-Objective Optimization Framework for Determining the Suitability of Hydrogen Fuel Cell Vehicles in Freight Transport. Appl. Energy 2023, 347, 121452. [Google Scholar] [CrossRef]

- Li, Y.; Liu, F.; Chen, K.; Liu, Y. Technical and Economic Analysis of a Hybrid PV/Wind Energy System for Hydrogen Refueling Stations. Energy 2024, 303, 131899. [Google Scholar] [CrossRef]

- Kopacak, N.; Guldorum, H.C.; Erdinc, O. Implementation of a Decision-Making Approach for a Hydrogen-Based Multi-Energy System Considering EVs and FCEVs Availability. IEEE Access 2024, 12, 114705–114721. [Google Scholar] [CrossRef]

- Song, X.; Qu, Z.; Wang, Y.; Chong, Z. Optimization of Multi-Energy Cloud Energy Storage for Multi-Microgrid System with Hydrogen Refueling Station. Renew. Energy 2025, 241, 122382. [Google Scholar]

- Liu, X.; Hong, H.; Liu, Y.; Wang, R.; Li, J.; Li, Z.; Sun, Q. Research on Multi-Time Scale Optimization Strategy for PV-Electrolyzers Hydrogen Production System Based on MPC. Int. J. Hydrogen Energy 2025, 157, 150301. [Google Scholar] [CrossRef]

- Park, C.-Y.; Hong, S.-H.; Lim, S.-C.; Song, B.-S.; Park, S.-W.; Huh, J.-H.; Kim, J.-C. Inverter Efficiency Analysis Model Based on Solar Power Estimation Using Solar Radiation. Processes 2020, 8, 1225. [Google Scholar] [CrossRef]

- Maghfuri, A.M.; Kuku, M. Optimized Hydrogen Production through Machine Learning: Comparative Analysis of Electrolyzer Technologies Using Hybrid Renewable Energy. Appl. Therm. Eng. 2025, 276, 126923. [Google Scholar] [CrossRef]

- Esmaeilion, F.; Soltani, M.; Nathwani, J.; Al-Haq, A. Design, Analysis, and Optimization of a Novel Poly-Generation System Powered by Solar and Wind Energy. Desalination 2022, 543, 116119. [Google Scholar] [CrossRef]

- Ulleberg, Ø. Modeling of Advanced Alkaline Electrolyzers: A System Simulation Approach. Int. J. Hydrogen Energy 2003, 28, 21–33. [Google Scholar] [CrossRef]

- Koponen, J. Review of Water Electrolysis Technologies and Design of Renewable Hydrogen Production Systems. Veden Elektrolyysiteknologiat ja Uusiutuvan Vedyn Tuotantojärjestelmien Suunnittelu 2015. Available online: https://lutpub.lut.fi/handle/10024/104326 (accessed on 28 June 2025).

- Zhang, Y.; Zhang, F.; Song, X.; Chen, R.; Chen, Z.; Duan, X.; Xia, Y. Optimization of Multiple Alkaline Water Electrolyzers Coupled with Solar Photovoltaic Power for Green Hydrogen Production on a Large Scale. Int. J. Hydrogen Energy 2025, 136, 511–532. [Google Scholar] [CrossRef]

- Liang, T.; Chen, M.; Tan, J.; Jing, Y.; Lv, L.; Yang, W. Large-Scale off-Grid Wind Power Hydrogen Production Multi-Tank Combination Operation Law and Scheduling Strategy Taking into Account Alkaline Electrolyzer Characteristics. Renew. Energy 2024, 232, 121122. [Google Scholar] [CrossRef]

- Huan, Z.; Sun, C.; Ge, M. Progress in Profitable Fe-Based Flow Batteries for Broad-Scale Energy Storage. Wiley Interdiscip. Rev. Energy Environ. 2024, 13, e541. [Google Scholar] [CrossRef]

- Chou, J.-S.; Truong, D.-N. A Novel Metaheuristic Optimizer Inspired by Behavior of Jellyfish in Ocean. Appl. Math. Comput. 2021, 389, 125535. [Google Scholar] [CrossRef]

- Fathy, A.; Bouaouda, A.; Hashim, F.A. Optimal Arrangement of Shaded Photovoltaic Array Using New Modified Black-Winged Kite Algorithm. Expert Syst. Appl. 2025, 289, 128375. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, X.; Qin, B.; Guo, L. Improved Multi-Objective Grasshopper Optimization Algorithm and Application in Capacity Configuration of Urban Rail Hybrid Energy Storage Systems. J. Energy Storage 2023, 72, 108363. [Google Scholar] [CrossRef]

- Bhetalam, A.; Naik, K.A. Adaptive Maximum Power Point Tracking Method for Photovoltaic Systems Using Step-Size Reduction and Adapted Salp Swarm Optimization for Dynamic Conditions. Electr. Power Syst. Res. 2025, 246, 111655. [Google Scholar] [CrossRef]

- Chen, Y.; Hill, D.; Billings, B.; Hedengren, J.; Powell, K. Hydrogen Underground Storage for Grid Electricity Storage: An Optimization Study on Techno-Economic Analysis. Energy Convers. Manag. 2024, 322, 119115. [Google Scholar] [CrossRef]

- Wenjie, G.; Litao, Y.; Aoyang, H.; Zhengjie, L. Optimal Dispatch Model of Active Distribution Network Based on Particle Swarm Optimization Algorithm with Random Weight. In Proceedings of the 2021 IEEE 2nd International Conference on Big Data, Artificial Intelligence and Internet of Things Engineering (ICBAIE), Nanchang, China, 26–28 March 2021; pp. 482–485. [Google Scholar]

- Roy, T.K.; Saha, S.; Oo, A.M.T. Optimizing Hybrid Energy Systems for Remote Australian Communities: The Role of Tilt Angle in Cost-Effective Green Hydrogen Production. Appl. Energy 2025, 391, 125921. [Google Scholar] [CrossRef]

- Chowdhury, P.; Das, P.; Yeassin, R.; Bonah Agyekum, E.; Irshied Al-Maaitah, M.; Odoi-Yorke, F. Exploring the Potential of Solar and Wind-Powered Green Hydrogen: Production, Costs and Environmental Impacts in South Asia. Int. J. Hydrogen Energy 2025, 137, 288–302. [Google Scholar] [CrossRef]

- Klyve, Ø.S.; Grab, R.; Olkkonen, V.; Marstein, E.S. Influence of High-Resolution Data on Accurate Curtailment Loss Estimation and Optimal Design of Hybrid PV–Wind Power Plants. Appl. Energy 2024, 372, 123784. [Google Scholar] [CrossRef]

- Zhang, R.; Lee, M. Optimization of Feed-in Tariff Mechanism for Residential and Industrial Photovoltaic Adoption in Hong Kong. J. Clean. Prod. 2023, 406, 137043. [Google Scholar] [CrossRef]

- Liu, X.; Gou, Z. Hybrid Forecasting and Optimization Framework for Residential Photovoltaic-Battery Systems: Integrating Data-Driven Prediction with Multi-Strategy Scenario Analysis. Build. Simul. 2025, 1–23. [Google Scholar] [CrossRef]

- Ren, Z.; Chen, Y.; Song, C.; Liu, M.; Xu, A.; Zhang, Q. Economic Analysis of Rooftop Photovoltaics System under Different Shadowing Conditions for 20 Cities in China. Build. Simul. 2024, 17, 235–252. [Google Scholar] [CrossRef]

- Dong, H.; Xu, C.; Chen, W. Modeling and Configuration Optimization of the Rooftop Photovoltaic with Electric-Hydrogen-Thermal Hybrid Storage System for Zero-Energy Buildings: Consider a Cumulative Seasonal Effect. Build. Simul. 2023, 16, 1799–1819. [Google Scholar] [CrossRef]

- Tang, X.; Shi, L.; Li, M.; Xu, S.; Sun, C. Health State Estimation and Long-Term Durability Prediction for Vehicular PEM Fuel Cell Stacks Under Dynamic Operational Conditions. IEEE Trans. Power Electron. 2025, 40, 4498–4509. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).