Enhancing the Compressibility of Seasonally Frozen Subgrade Clay Subjected to Freeze-Thaw Cycles Using Lignin Fibers

Abstract

1. Introduction

2. Compression Tests and Results Analysis

2.1. Materials and Experimental Procedures

2.1.1. Materials

2.1.2. Specimen Preparation

2.1.3. Application of Freeze-Thaw Cycles

2.1.4. One-Dimensional Compression Tests

2.2. Results and Discussion

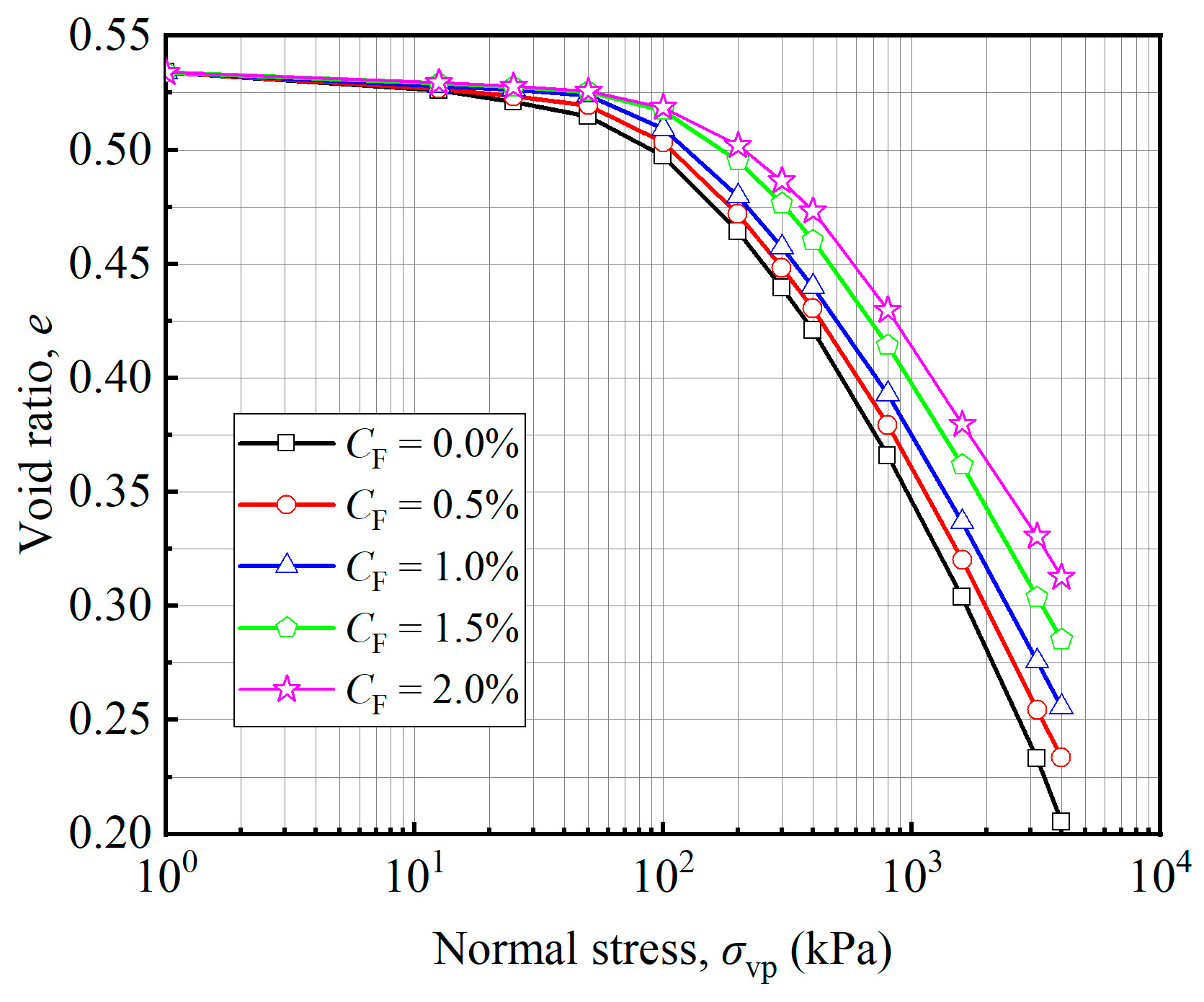

2.2.1. Effect of Lignin Fiber Content

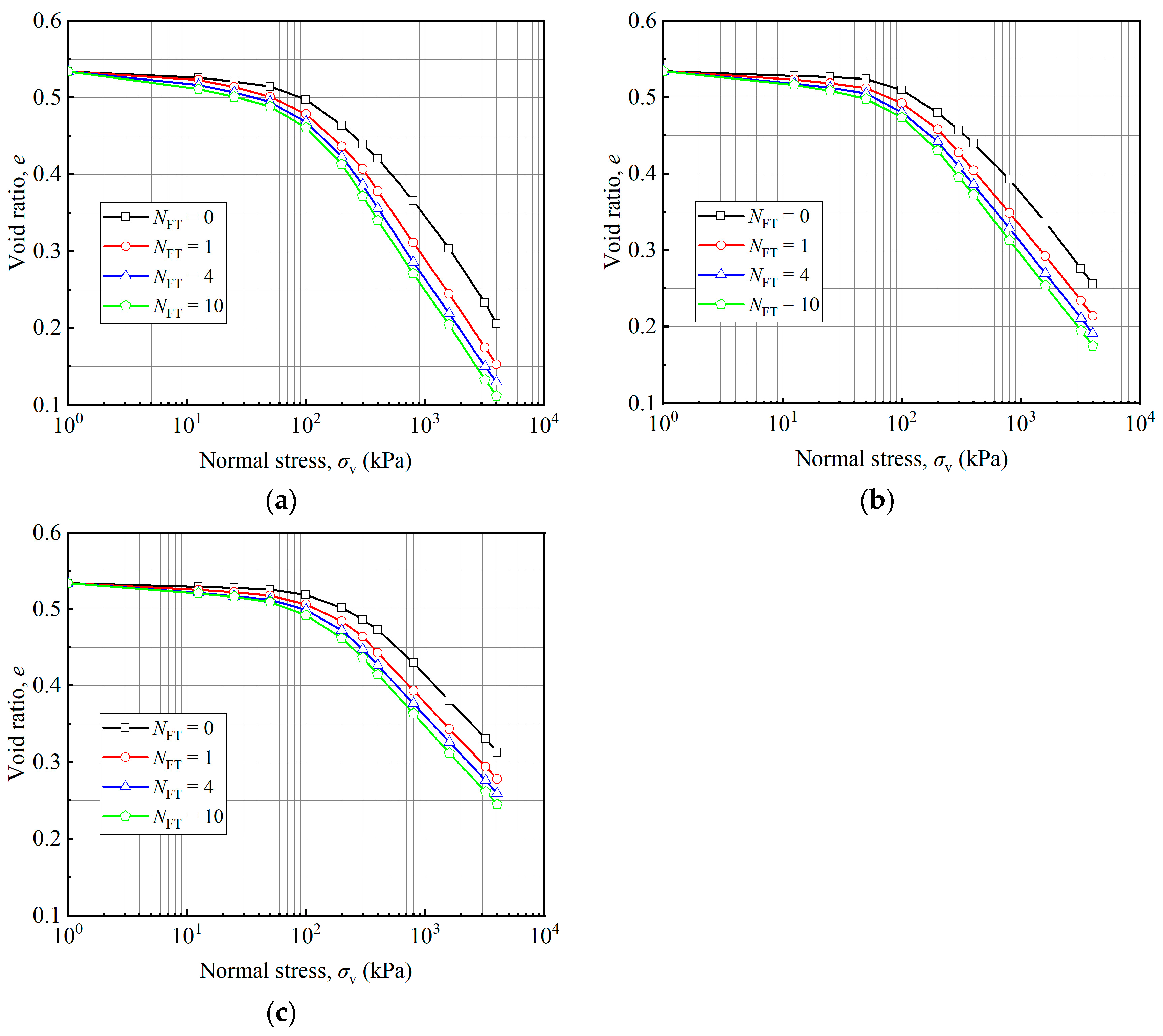

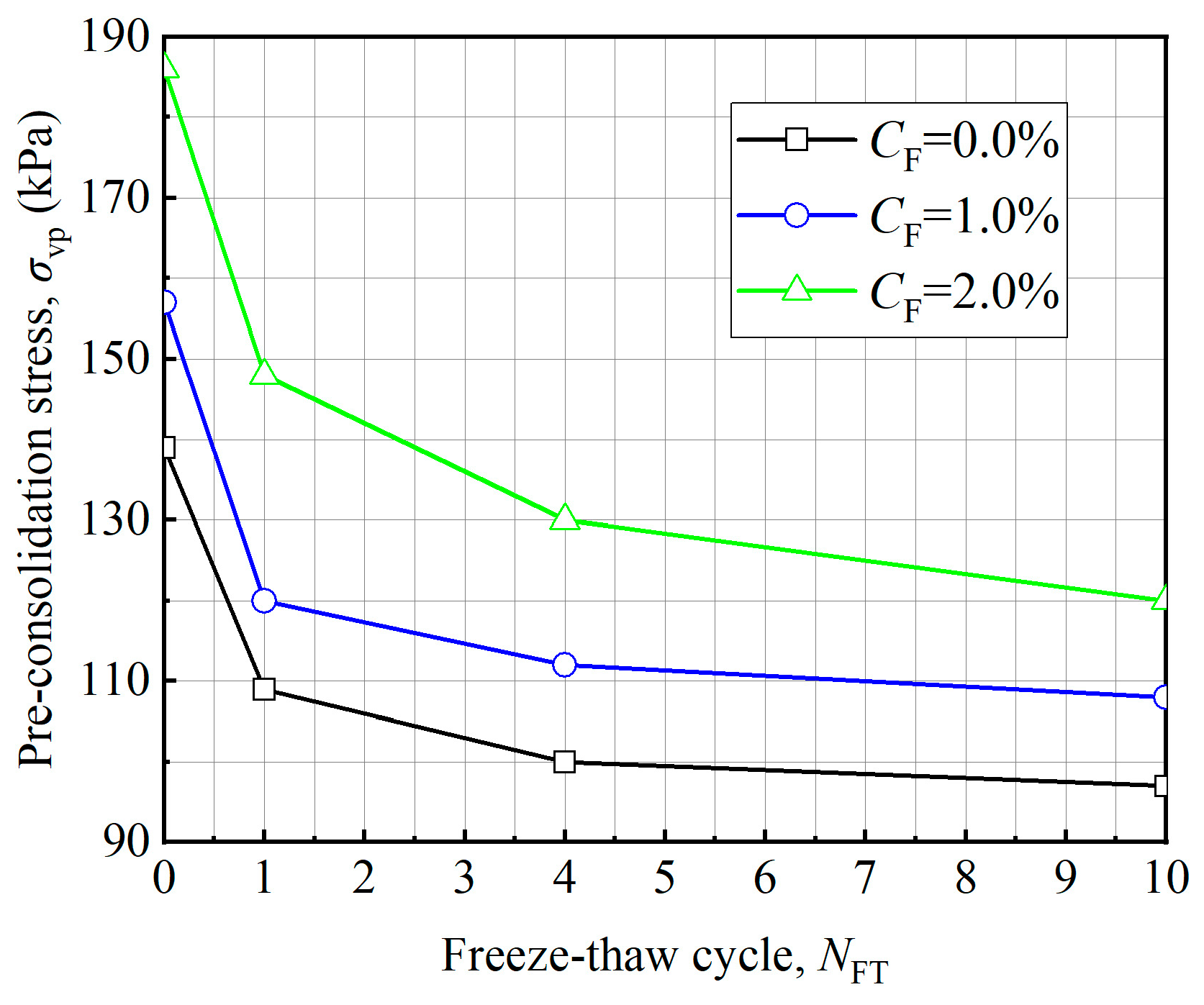

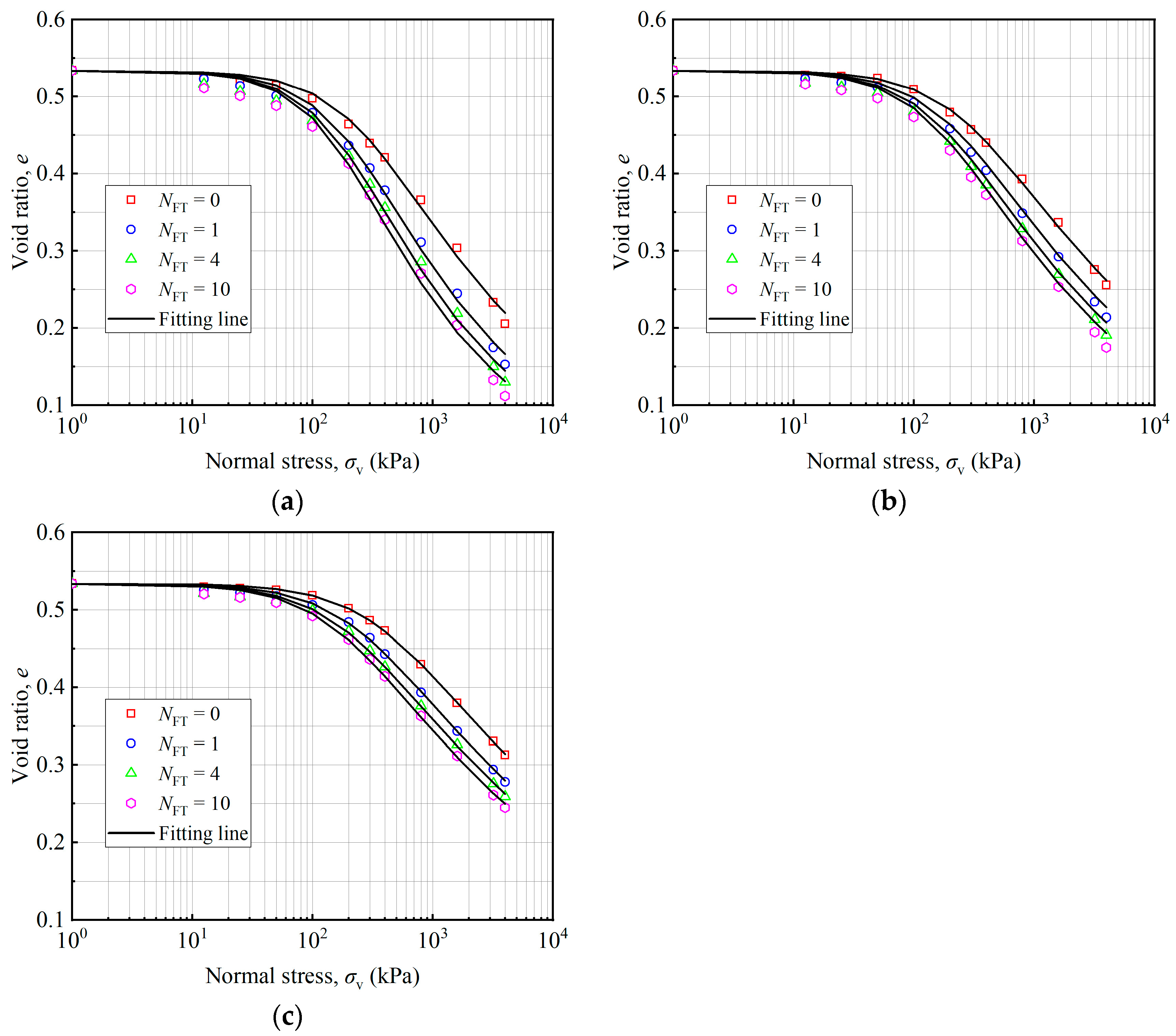

2.2.2. Effect of Freeze-Thaw Cycles

3. Microstructural Tests and Results Analysis

3.1. Microstructural Test Procedures

- Small cubic samples approximately 10 mm in size were cut from compacted specimens after freeze-thaw treatment. These samples were rapidly frozen using liquid nitrogen, followed by freeze-drying to preserve the original microstructure by removing pore water.

- After freeze-drying, samples were carefully trimmed to approximately 5 mm cubes using diamond tools, ensuring flat and even surfaces.

- The specimens were then gold-coated to enhance surface conductivity and reduce charging effects under electron beam irradiation. SEM imaging was conducted using a JEM-2100 scanning electron microscope (Tokyo, Japan) at a magnification of 200×.

- The MIP procedure was as follows:

- Small clay samples weighing 1–2 g were taken from similarly treated specimens, rapidly frozen in liquid nitrogen, and subsequently freeze-dried to retain the original pore structure.

- After drying, samples were gently ground to particles smaller than 2 mm, avoiding pore structure damage. The prepared samples were placed into a PoreMaster 33GT mercury porosimeter (Quantachrome Instruments, Boynton Beach, FL, USA), where pressure was gradually increased from vacuum to a maximum of 400 MPa.

- The pore size distribution was determined by measuring mercury intrusion volume as a function of applied pressure, converted into pore diameter via the Washburn equation.

3.2. Analysis and Discussion

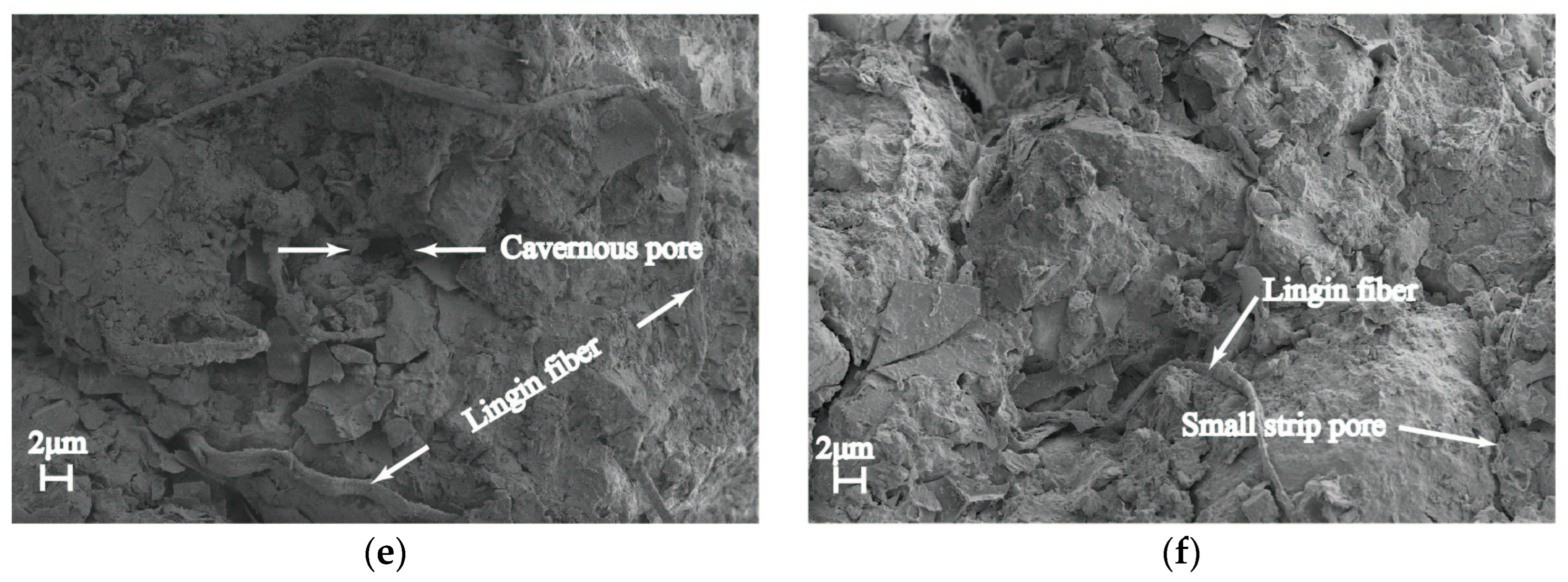

3.2.1. SEM Analysis

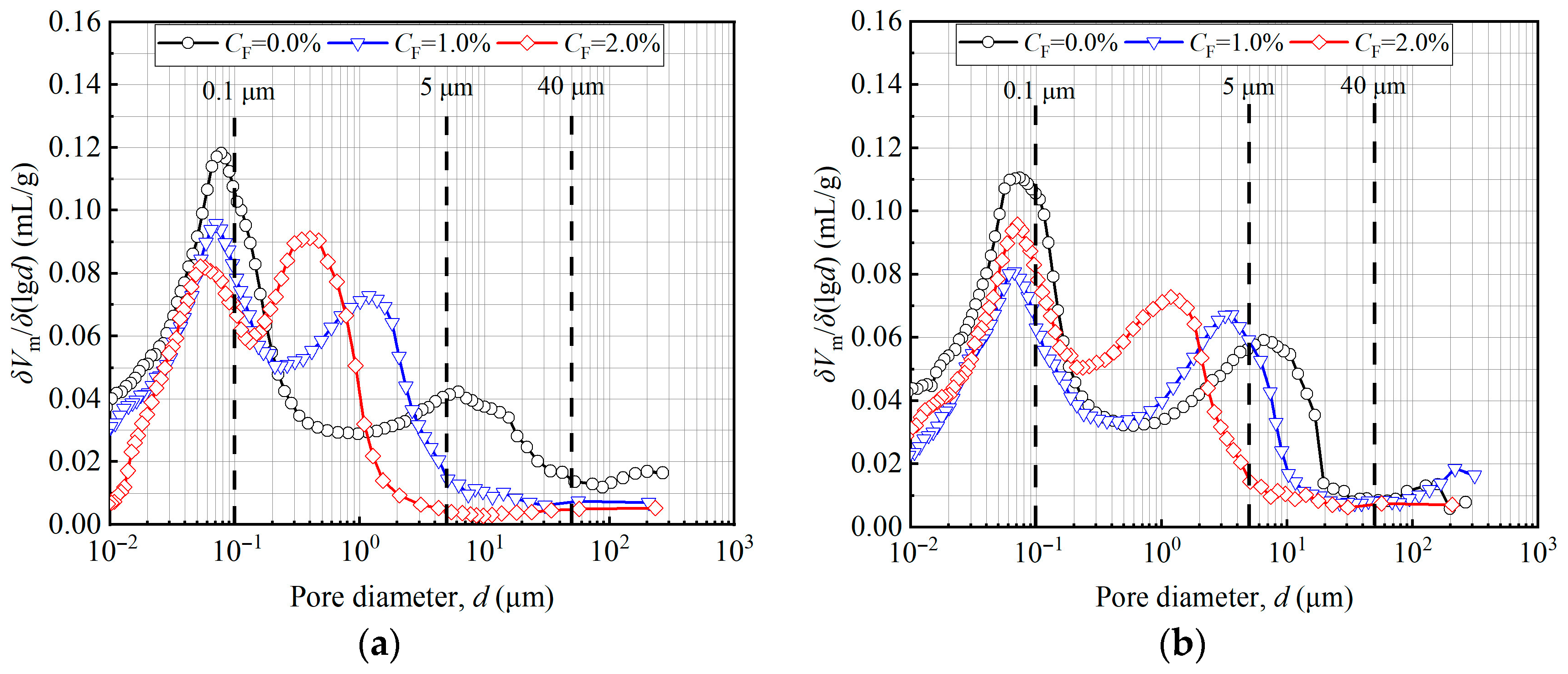

3.2.2. MIP Analysis

4. Compression Model

4.1. Modified Van Genuchten Model for Clay Compression

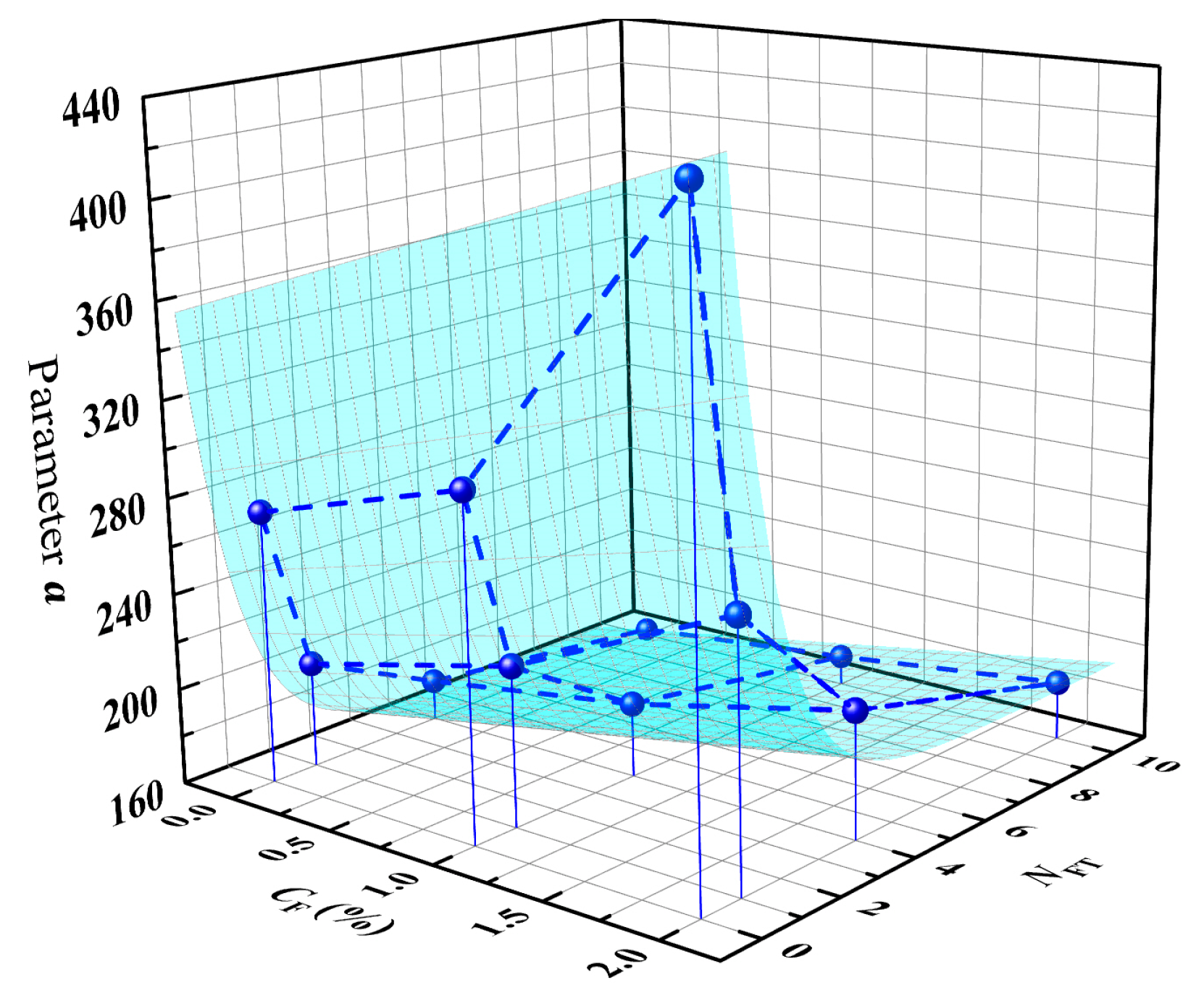

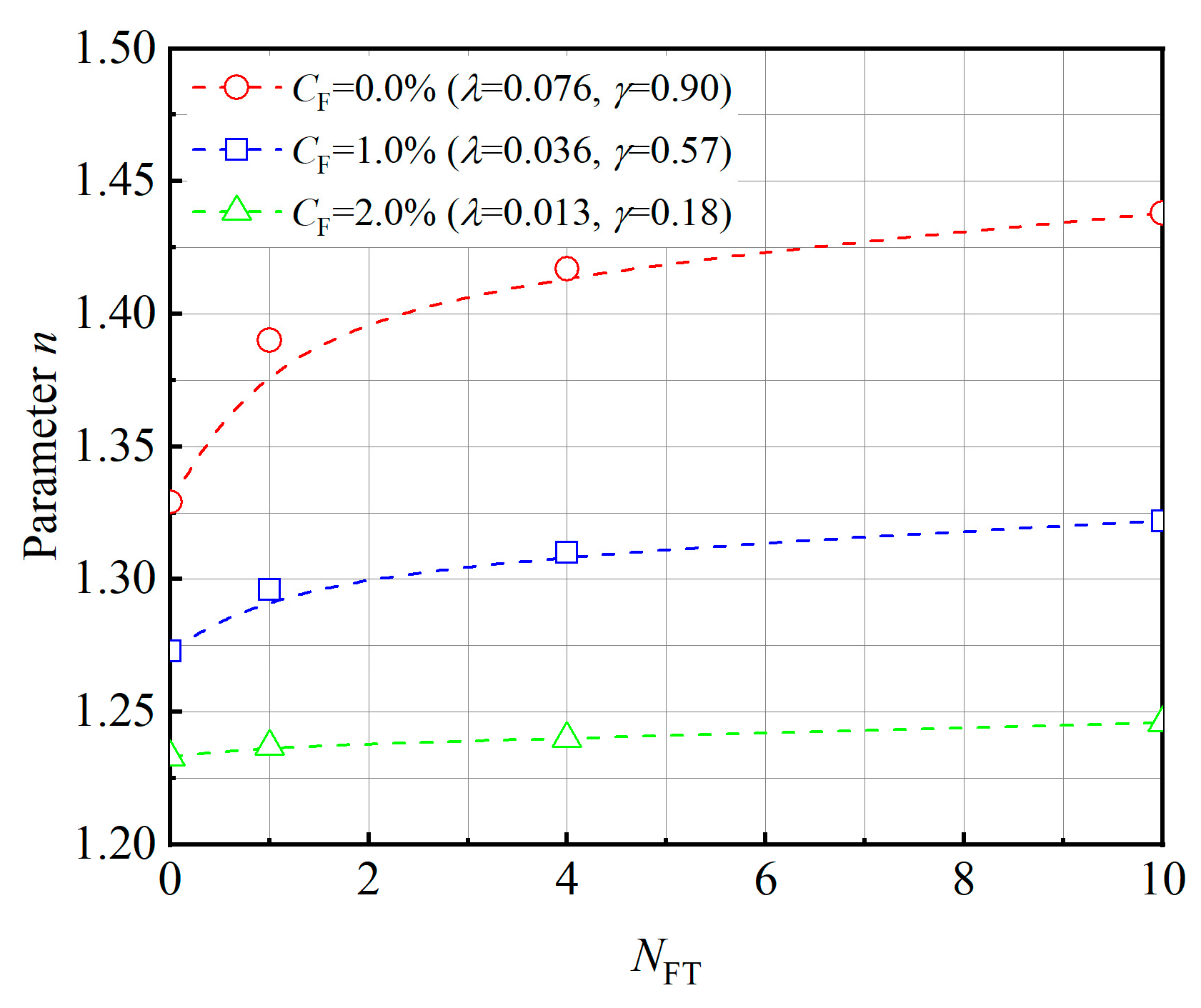

4.2. Coupling Effect of Fiber Content and Freeze-Thaw Cycles on the Parameters in the Model

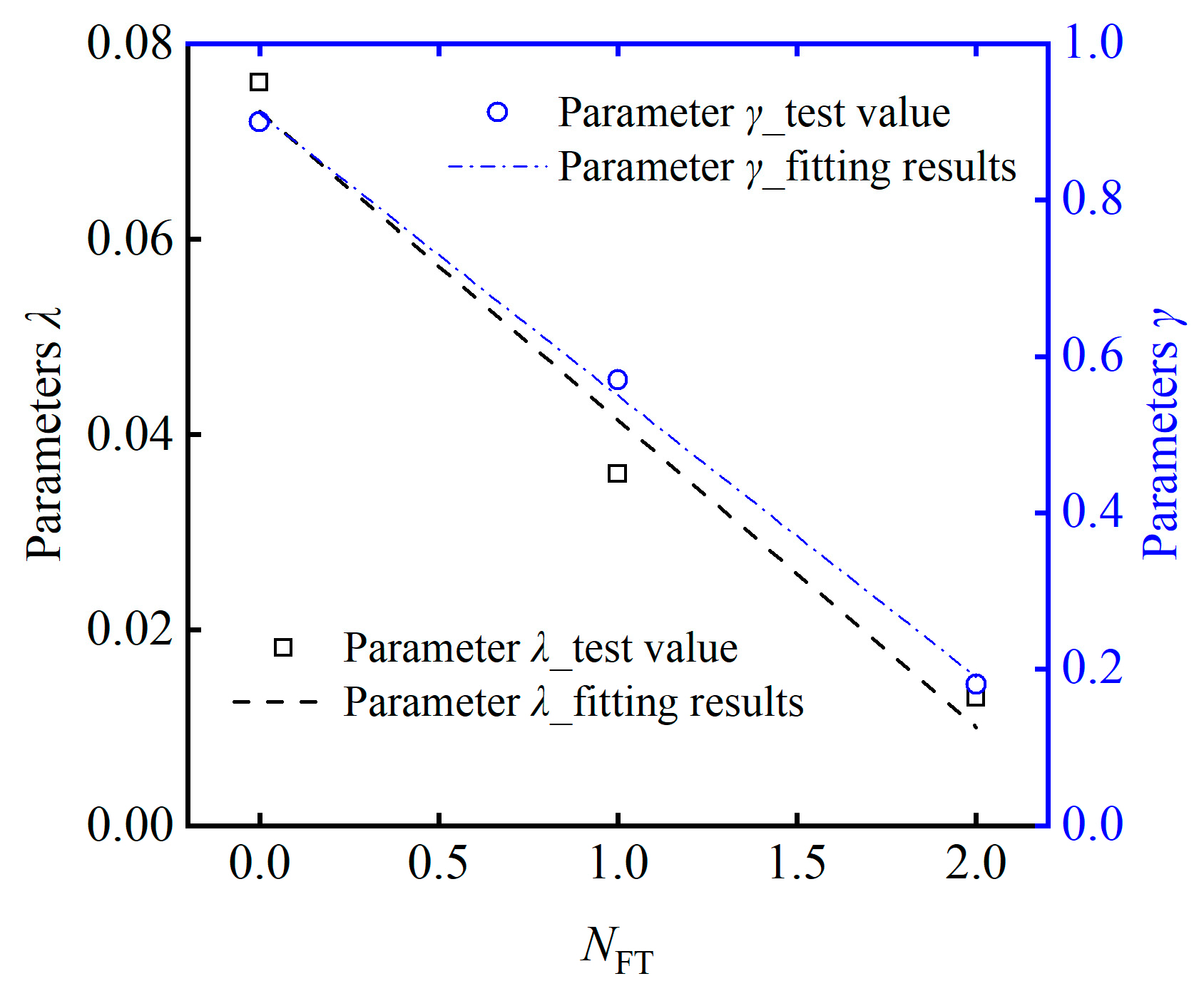

4.3. Integrated Compression Model Development

5. Discussion

- Optimization of lignin fiber content and economic considerations: The experimental results indicate that fiber contents ranging from 0.5% to 2.0% are effective, with the range of 1.0 to 1.5% identified as offering optimal performance-to-cost ratios. Below 1.0%, the reinforcement effect deteriorates rapidly with increasing numbers of freeze-thaw cycles, while above 1.5%, further improvements are marginal despite increased cost. The selection of fiber content in engineering practice should therefore be based on the anticipated severity of freeze-thaw conditions and settlement control requirements.

- Key construction procedures: To ensure optimal fiber performance, uniform dispersion must be prioritized, as shown in Figure 11. It is recommended that procedures similar to those adopted in this study be implemented: pre-sieving of fibers, dry mixing in layers with soil followed by the gradual addition of water, and sufficient resting time to ensure moisture equilibrium. Bulk mixing of fibers or direct incorporation into wet soil should be avoided to prevent fiber clumping.

- Compression model applicability: The proposed compression model can be directly embedded into numerical simulations or simplified design analyses for foundation settlement in seasonally frozen regions. By inputting the expected equivalent number of freeze-thaw cycles over the service life and the selected fiber content, the compressibility characteristics (e-lgσv relationship) of the modified soil can be predicted, thereby providing more reliable design parameters and overcoming the limitations of conventional methods that cannot account for long-term environmental effects.

- Long-term performance and durability: While this study focused on the effects of up to 10 freeze-thaw cycles, during which mechanical degradation tended to stabilize, actual engineering applications may involve dozens or even hundreds of cycles, as well as additional environmental stressors such as wetting–drying alternation and microbial activity. Although the lignin fiber-reinforced clay specimens exhibited stable mechanical and microstructural performance under the tested conditions, long-term durability under more extreme environmental exposures remains to be evaluated. While the aromatic structure of lignin provides some inherent resistance to biodegradation, its sustained performance in complex soil environments warrants further experimental verification to support its use in infrastructure projects with extended service lifespans.

- Engineering applicability and sustainable deployment scenarios: The use of lignin fiber-reinforced clay is not only technically effective, but is also well-aligned with current sustainability goals in geotechnical engineering. Its application is particularly advantageous in scenarios requiring minimal environmental impact, such as temporary embankments, ecological slope protection, low-volume roads, and other infrastructure within natural reserves or water conservation zones. In such contexts, lignin fiber can serve as a viable substitute for traditional chemical stabilizers, reducing both carbon emissions and the risk of secondary pollution while maintaining adequate soil performance. This highlights its potential as an eco-friendly and practical solution for sustainable infrastructure development, especially under conditions where environmental constraints limit the use of conventional treatment methods.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Samuel, R.; Puppala, A.J.; Radovic, M. Sustainability benefits assessment of metakaolin-based geopolymer treatment of high plasticity clay. Sustainability 2020, 12, 10495. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Shibuya, S.; Fuenkajorn, K.; Katkan, W. Assessment of engineering properties of Bangkok clay. Can. Geotech. J. 2007, 44, 173–187. [Google Scholar] [CrossRef]

- Zheng, G.; Wang, J.; Zhou, H.; Xia, B.; Bui, P.D. Settlement characteristics and evaluation approach of embankment widening over soft clay. Can. Geotech. J. 2025, 62, 1–10. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, J.; Zhu, T.; Li, J. Experimental and MPM modelling of widened levee failure under the combined effect of heavy rainfall and high riverine water levels. Comput. Geotech. 2025, 184, 107259. [Google Scholar] [CrossRef]

- Staubach, P.; Machaček, J.; Tafili, M.; Wichtmann, T. A high-cycle accumulation model for clay and its application to monopile foundations. Acta Geotech. 2022, 17, 677–698. [Google Scholar] [CrossRef]

- Fan, K.; Zou, W.; Zhang, P.; Wang, X.; Shen, Y. Laboratory investigation and theoretical analysis of lateral pressure exerted by expansive soils on retaining walls with expanded polystyrene geofoam block upon water infiltration. Geotext. Geomembr. 2024, 52, 332–341. [Google Scholar] [CrossRef]

- Liu, S.; Gao, C.; Fan, K.; Zhang, C.; Wang, Z.; Shen, C.; Han, Z. Repairing expansive soil channel slope with soilbags. Geosynth. Int. 2022, 30, 450–459. [Google Scholar] [CrossRef]

- Han, Z.; Zhang, P.; Zou, W.; Fan, K.; Vanapalli, S.K.; Wan, L. At-rest lateral earth pressure of compacted expansive soils: Experimental investigations and prediction approach. J. Rock Mech. Geotech. Eng. 2024, 16, 1425–1435. [Google Scholar] [CrossRef]

- Pei, Q.Y.; Zou, W.L.; Han, Z.; Wang, X.Q.; Xia, X.L. Compression behaviors of a freeze-thaw impacted clay under saturated and unsaturated conditions. Acta Geotech. 2024, 19, 4485–4502. [Google Scholar] [CrossRef]

- Kværnø, S.H.; Øygarden, L. The influence of freeze-thaw cycles and soil moisture on aggregate stability of three soils in Norway. Catena 2006, 67, 175–182. [Google Scholar] [CrossRef]

- Zwissler, B.; Oommen, T.; Vitton, S. Method to quantify freeze-thaw effects on temperate climate soils: Calvert Cliffs. J. Cold Reg. Eng. 2016, 30, 06016002. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, C.; Liu, X.; Pan, X.; Pan, Y.; Jia, P. Effects of freeze-thaw cycles on permeability behavior and desiccation cracking of Dalian red clay in China considering saline intrusion. Sustainability 2023, 15, 3858. [Google Scholar] [CrossRef]

- Di Remigio, G.; Rocchi, I.; Zania, V. Scanning Electron Microscopy and clay geomaterials: From sample preparation to fabric orientation quantification. Appl. Clay Sci. 2021, 214, 106249. [Google Scholar] [CrossRef]

- Zhang, P.; Vanapalli, S.K.; Han, Z. Modeling compression behaviors of freeze-thaw-impacted soils extending the disturbed state concept. J. Rock Mech. Geotech. Eng. 2025. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, Y.; Wang, S.; Wu, M.; Wang, W. Effects of freeze-thaw cycles on volume change behavior and mechanical properties of expansive clay with different degrees of compaction. Int. J. Geomech. 2022, 22, 04022050. [Google Scholar] [CrossRef]

- Han, Z.; Zhao, G.; Lin, J.; Fan, K.; Zou, W. Influences of temperature and moisture histories on the hydrostructural characteristics of a clay during desiccation. Eng. Geol. 2022, 297, 106533. [Google Scholar] [CrossRef]

- Tao, Z.; Zhang, Y.; Chen, X.; Gu, X. Effects of freeze-thaw cycles on the mechanical properties of cement-fiber composite treated silty clay. Constr. Build. Mater. 2022, 316, 125867. [Google Scholar] [CrossRef]

- Shirmohammadi, S.; Ghaffarpour Jahromi, S.; Payan, M.; Senetakis, K. Effect of lime stabilization and partial clinoptilolite zeolite replacement on the behavior of a silt-sized low-plasticity soil subjected to freezing-thawing cycles. Coatings 2021, 11, 994. [Google Scholar] [CrossRef]

- Sengul, T.; Akray, N.; Vitosoglu, Y. Investigating the effects of stabilization carried out using fly ash and polypropylene fiber on the properties of highway clay soils. Constr. Build. Mater. 2023, 400, 132590. [Google Scholar] [CrossRef]

- Abdrabbo, F.M.; Gaaver, K.E.; Elwakil, A.Z.; Khalifa, S.A. Towards construction of embankment on soft soil: A comparative study of lightweight materials and deep replacement techniques. Sci. Rep. 2024, 14, 29628. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Chen, R.; Cai, Y.; Wang, J.; Wang, P.; Su, D.; Chen, X. Experimental and consolidation modeling of flowing mud during vacuum preloading considering transient clogging and vacuum pressure attenuation. Geotext. Geomembr. 2025, 53, 767–779. [Google Scholar] [CrossRef]

- Ghorbani, J.; Nazem, M.; Carter, J.P. Dynamic compaction of clays: Numerical study based on the mechanics of unsaturated soils. Int. J. Geomech. 2020, 20, 04020195. [Google Scholar] [CrossRef]

- Liu, S.; Fan, K.; Xu, S. Field study of a retaining wall constructed with clay-filled soilbags. Geotext. Geomembr. 2019, 47, 87–94. [Google Scholar] [CrossRef]

- Zheng, G.; Zhao, J.; Yu, X.; Zhou, H. Calibration of partial factors for tensile strain design in geosynthetic-reinforced and pile-supported embankment. Transp. Geotech. 2025, 52, 101495. [Google Scholar] [CrossRef]

- Koohestani, B.; Darban, A.K.; Mokhtari, P.; Yilmaz, E.; Darezereshki, E. Comparison of different natural fiber treatments: A literature review. Int. J. Environ. Sci. Tech. 2019, 16, 629–642. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural fiber reinforced composites: Sustainable materials for emerging applications. Results Eng. 2021, 11, 100263. [Google Scholar] [CrossRef]

- Prasad, V.; Alliyankal Vijayakumar, A.; Jose, T.; George, S.C. A comprehensive review of sustainability in natural-fiber-reinforced polymers. Sustainability 2024, 16, 1223. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Y. Mechanical and microstructural changes in expansive soils treated with lime and lignin fiber from paper industry. Appl. Sci. 2024, 14, 3393. [Google Scholar] [CrossRef]

- Zwawi, M. A review on natural fiber bio-composites, surface modifications and applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef]

- Xie, B.L.; Liu, Y.C.; Zhang, W.Y. Reinforcement mechanisms of lignin fiber-stabilized loess: A multi-scale analysis. Constr. Build. Mater. 2025, 491, 142624. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, G.; Xiao, G.; Jiang, G.; Yin, L. Study on Strength and Deformation Characteristics of Lignin Fiber-Amended Expansive Soils. Waste Biomass Valor. 2025, 16, 3155–3166. [Google Scholar] [CrossRef]

- Fan, K.; Pei, Q.; Liu, L.; Han, Z.; Zou, W. Strength and microstructure of a lignin fiber-reinforced expansive soil in cold regions. Geosynth. Int. 2022, 29, 622–629. [Google Scholar] [CrossRef]

- de Azevedo, A.R.; Cruz, A.S.; Marvila, M.T.; de Oliveira, L.B.; Monteiro, S.N.; Vieira, C.M.F.; Fediuk, R.; Timokhin, R.; Vatin, N.; Daironas, M. Natural fibers as an alternative to synthetic fibers in reinforcement of geopolymer matrices: A comparative review. Polymers 2021, 13, 2493. [Google Scholar] [CrossRef]

- Badakhshan, E.; Noorzad, A.; Vaunat, J. Stabilization of soft clays exposed to freeze-thaw cycles using chitosan. J. Cold Reg. Eng. 2023, 37, 04023004. [Google Scholar] [CrossRef]

- Changizi, F.; Ghasemzadeh, H.; Ahmadi, S. Evaluation of strength properties of clay treated by nano-SiO2 subjected to freeze-thaw cycles. Road Mater. Pavement 2022, 23, 1221–1238. [Google Scholar] [CrossRef]

- Jia, J.; Wei, H.; Yang, D.; Wu, Y. The impact of freeze-thaw cycles on the shear and microstructural characteristics of compacted silty clay. Buildings 2023, 13, 2308. [Google Scholar] [CrossRef]

- Casagrande, A. The determination of the preconsolidation load and its practical significance. In Proceedings of the International Conference on Soil Mechanics and Foundation Engineering, Harvard University, Cambridge, MA, USA, 22–26 June 1936; Volume 3, p. 60. [Google Scholar]

- Zheng, Y.; Baudet, B.A.; Delage, P.; Pereira, J.M.; Sammonds, P. Pore changes in an illitic clay during one-dimensional compression. Géotechnique 2023, 73, 917–932. [Google Scholar] [CrossRef]

- Han, Z.; Vanapalli, S.K.; Zou, W.L.; Wang, X.Q.; Zhang, J.F. Modelling virgin compression line of compacted unsaturated soils. Acta Geotech. 2019, 14, 1991–2006. [Google Scholar] [CrossRef]

- Liu, M.D.; Zhuang, Z.; Horpibulsuk, S. Estimation of the compression behaviour of reconstituted clays. Eng. Geol. 2013, 167, 84–94. [Google Scholar] [CrossRef]

- Zou, W.L.; Han, Z.; Vanapalli, S.K.; Zhang, J.F.; Zhao, G.T. Predicting volumetric behavior of compacted clays during compression. Appl. Clay Sci. 2018, 156, 116–125. [Google Scholar] [CrossRef]

- Liu, C.; Lv, Y.; Yu, X.; Wu, X. Effects of freeze-thaw cycles on the unconfined compressive strength of straw fiber-reinforced soil. Geotext. Geomembr. 2020, 48, 581–590. [Google Scholar] [CrossRef]

| Properties | Values |

|---|---|

| Specific gravity, Gs | 2.68 |

| Liquid limit, wL/% | 54.0 |

| Plastic limit, wP/% | 24.4 |

| Maximum dry density, dmax/(g/cm3) | 1.75 |

| Optimum water content, wopt/% | 22.7 |

| Sand, % | 11 |

| Silt, % | 48 |

| Clay, % | 41 |

| Classification | CL |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, Y.; Li, Z.; Xu, S. Enhancing the Compressibility of Seasonally Frozen Subgrade Clay Subjected to Freeze-Thaw Cycles Using Lignin Fibers. Sustainability 2025, 17, 7303. https://doi.org/10.3390/su17167303

Tao Y, Li Z, Xu S. Enhancing the Compressibility of Seasonally Frozen Subgrade Clay Subjected to Freeze-Thaw Cycles Using Lignin Fibers. Sustainability. 2025; 17(16):7303. https://doi.org/10.3390/su17167303

Chicago/Turabian StyleTao, Yi, Zhibin Li, and Siyuan Xu. 2025. "Enhancing the Compressibility of Seasonally Frozen Subgrade Clay Subjected to Freeze-Thaw Cycles Using Lignin Fibers" Sustainability 17, no. 16: 7303. https://doi.org/10.3390/su17167303

APA StyleTao, Y., Li, Z., & Xu, S. (2025). Enhancing the Compressibility of Seasonally Frozen Subgrade Clay Subjected to Freeze-Thaw Cycles Using Lignin Fibers. Sustainability, 17(16), 7303. https://doi.org/10.3390/su17167303