Enhancing Structural, Mechanical, and Radiation-Shielding Properties of Al-B4C Hybrid Composites

Abstract

1. Introduction

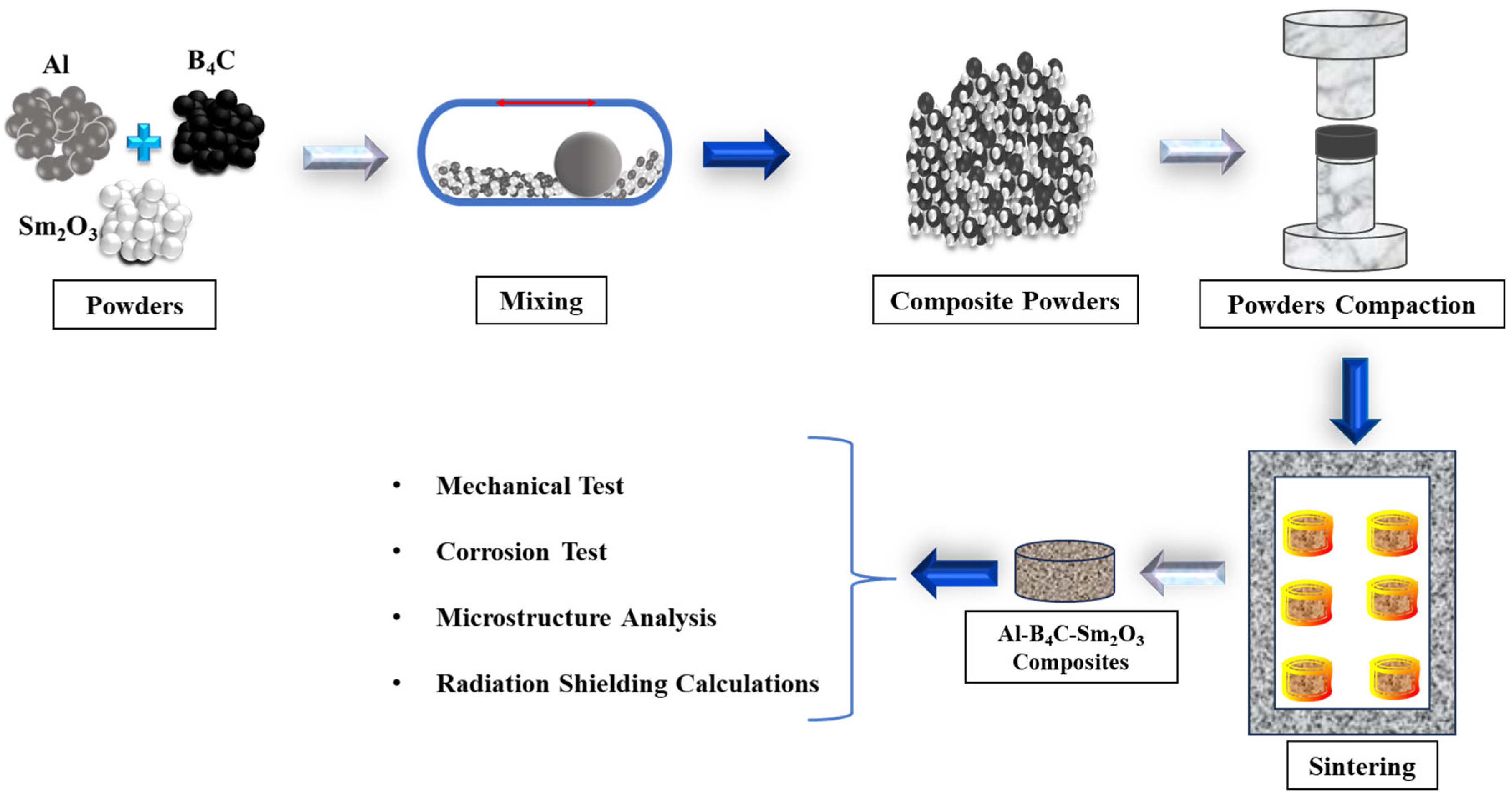

2. Experimental Procedures

2.1. Preparation of the Al-B4C-Sm2O3 Hybrid Composites

2.2. Compaction and Sintering

2.3. Density Measurements

2.4. Structural and Microstructural Characterization

2.5. Microhardness and Wear Testing

- V is the wear volume (mm3),

- S is the sliding distance (m),

- A represents the cross-sectional area of the wear track (mm2),

- L is the length of the wear path (mm),

- WR denotes the wear rate (mm3/m).

2.6. Electrochemical Testing

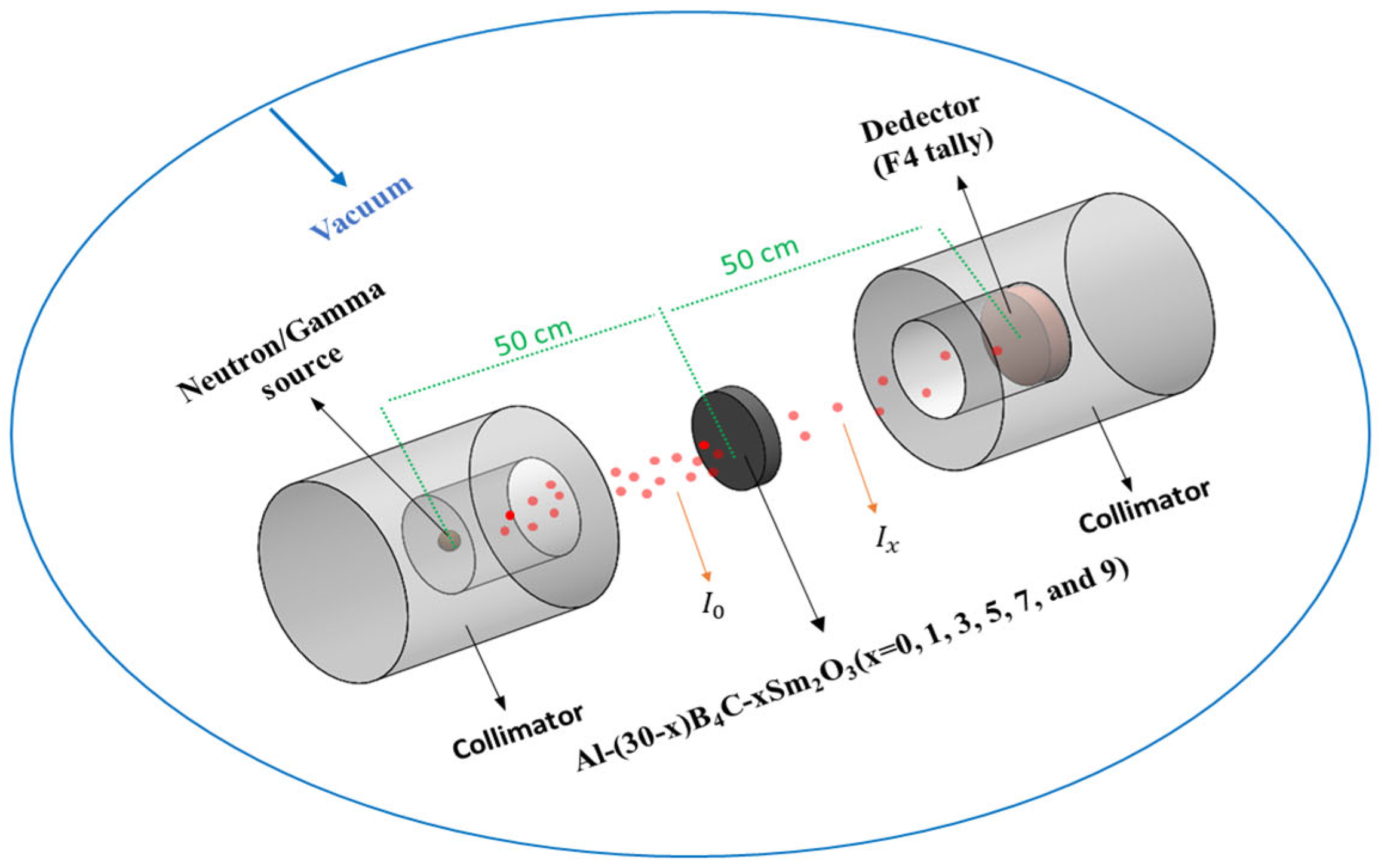

2.7. Monte Carlo Simulations

3. Results and Discussion

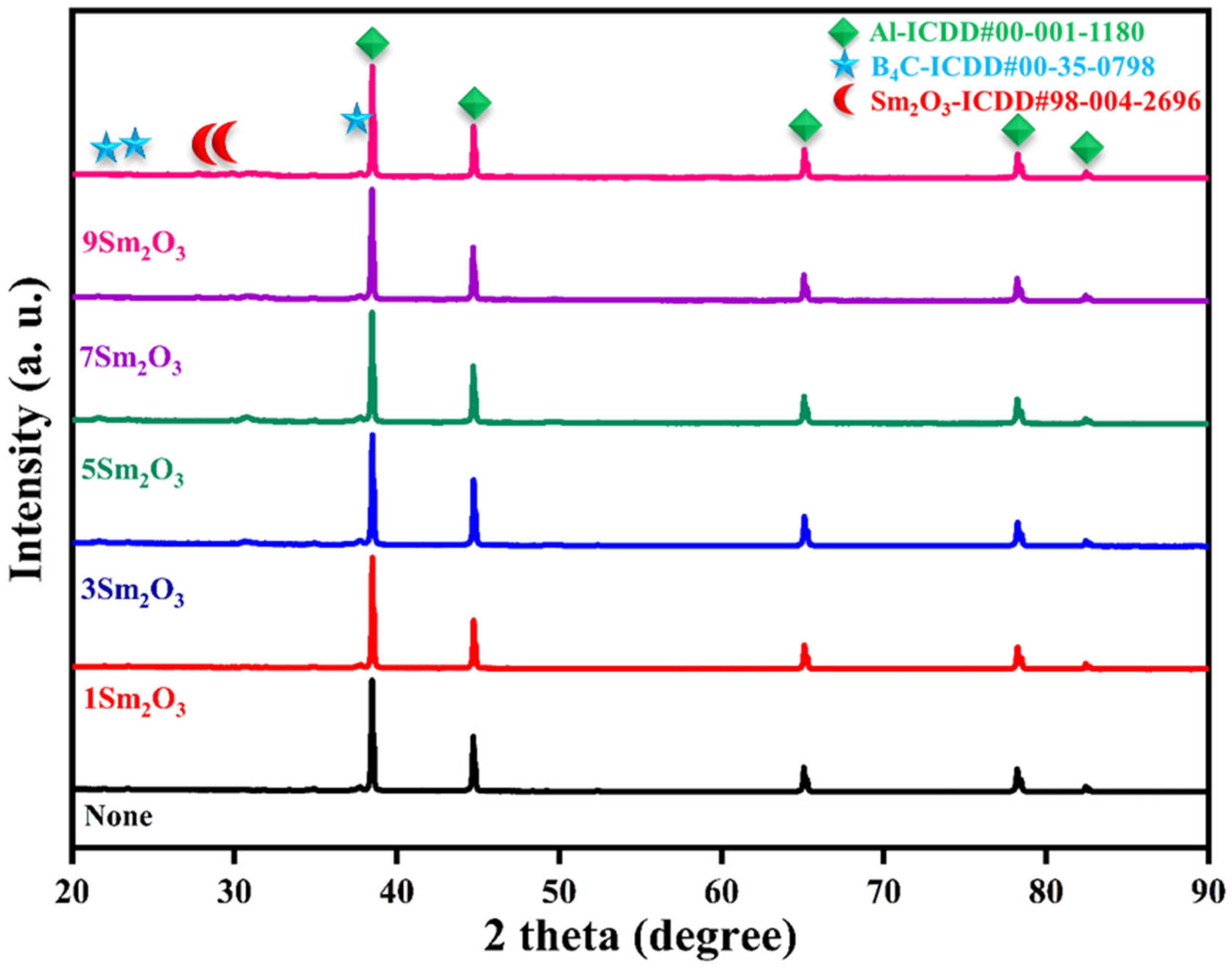

3.1. XRD Analysis

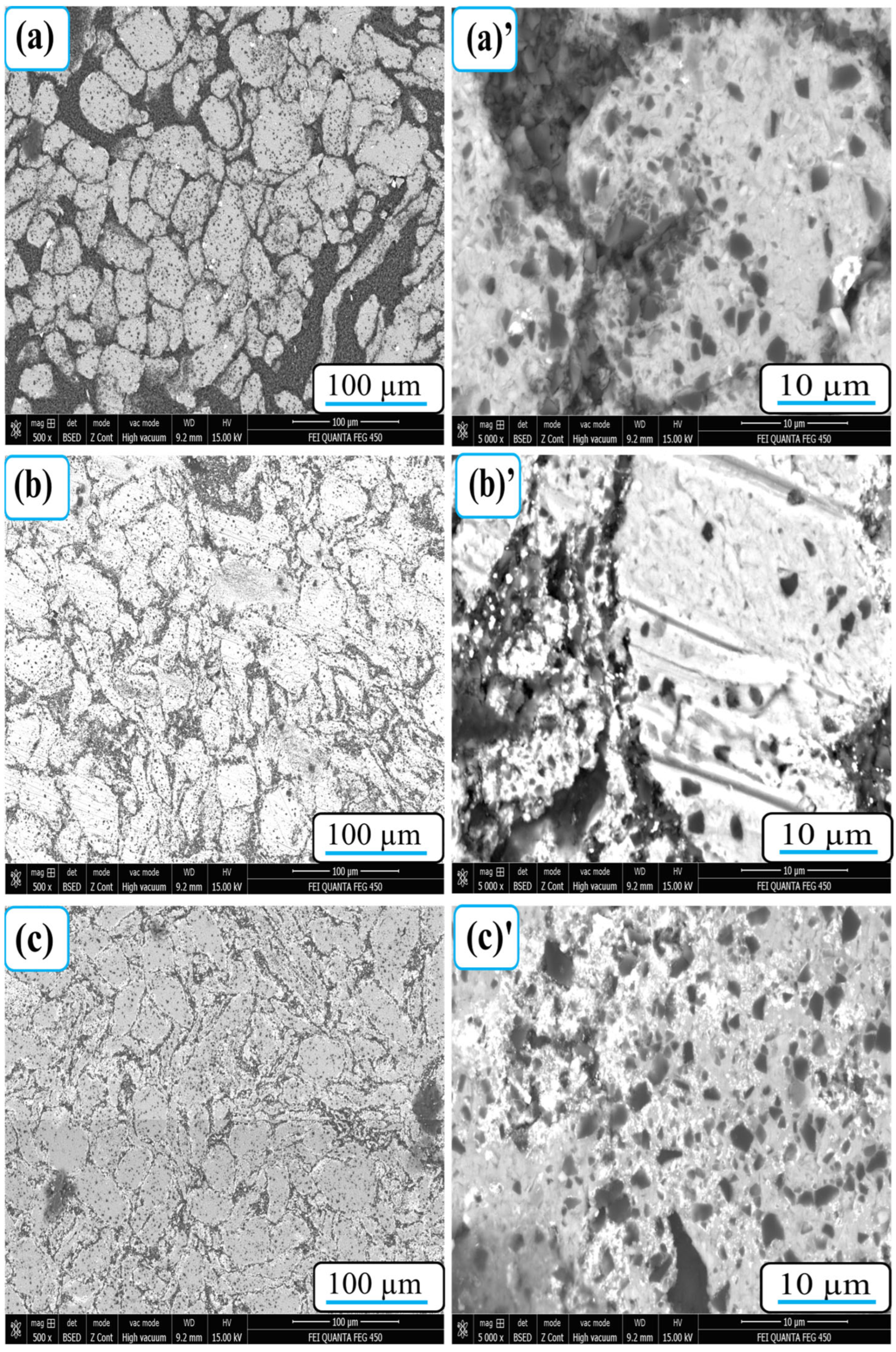

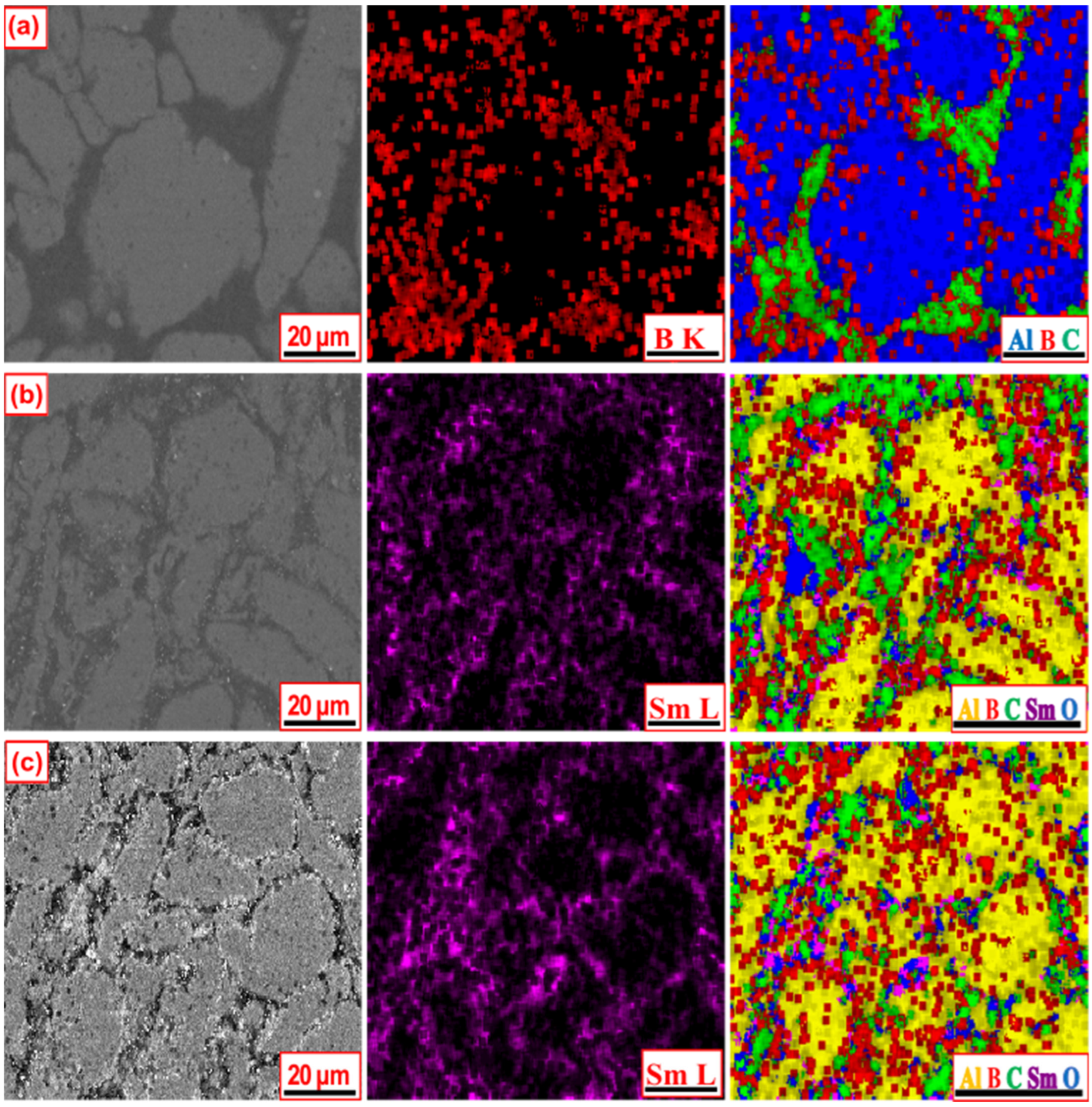

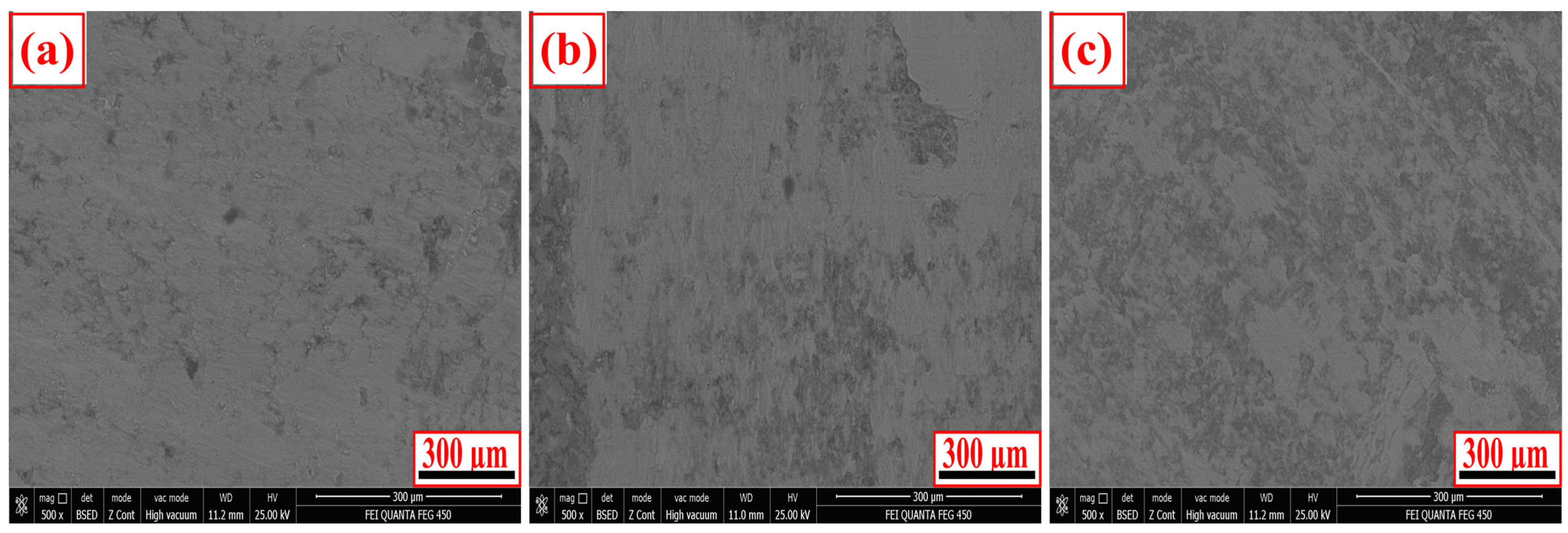

3.2. SEM-EDX Analysis

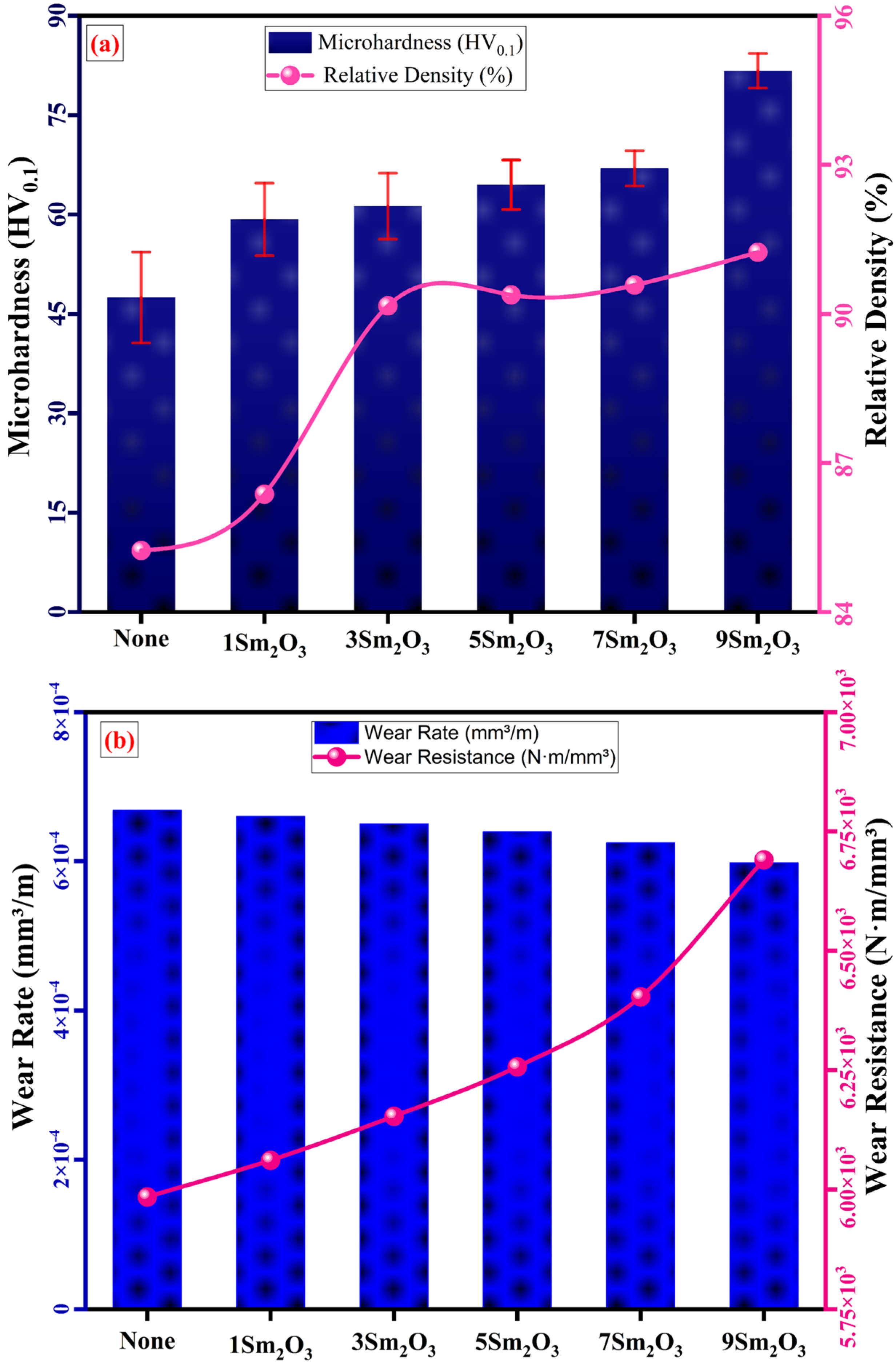

3.3. Density and Microhardness Measurements

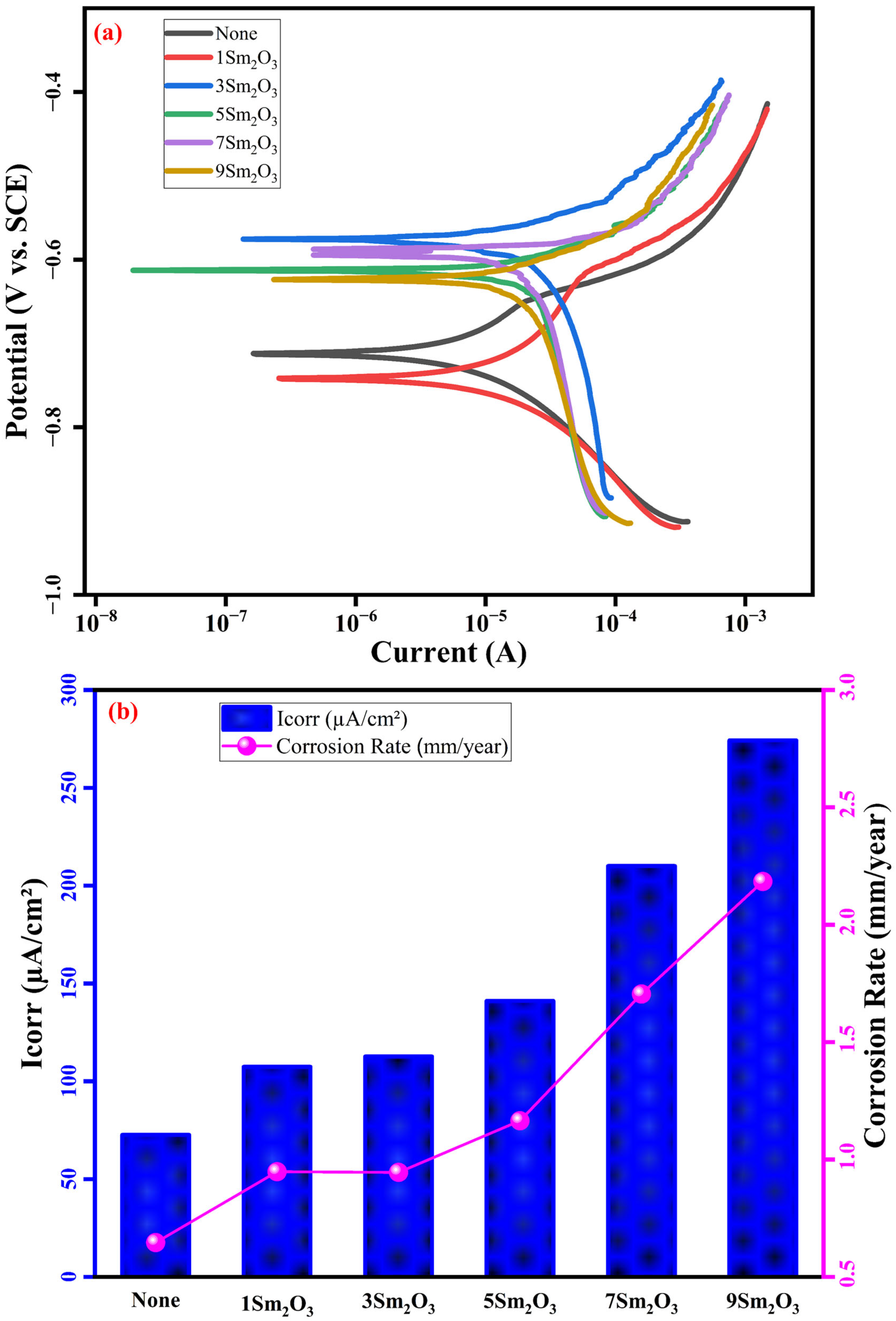

3.4. Electrochemical Corrosion Test

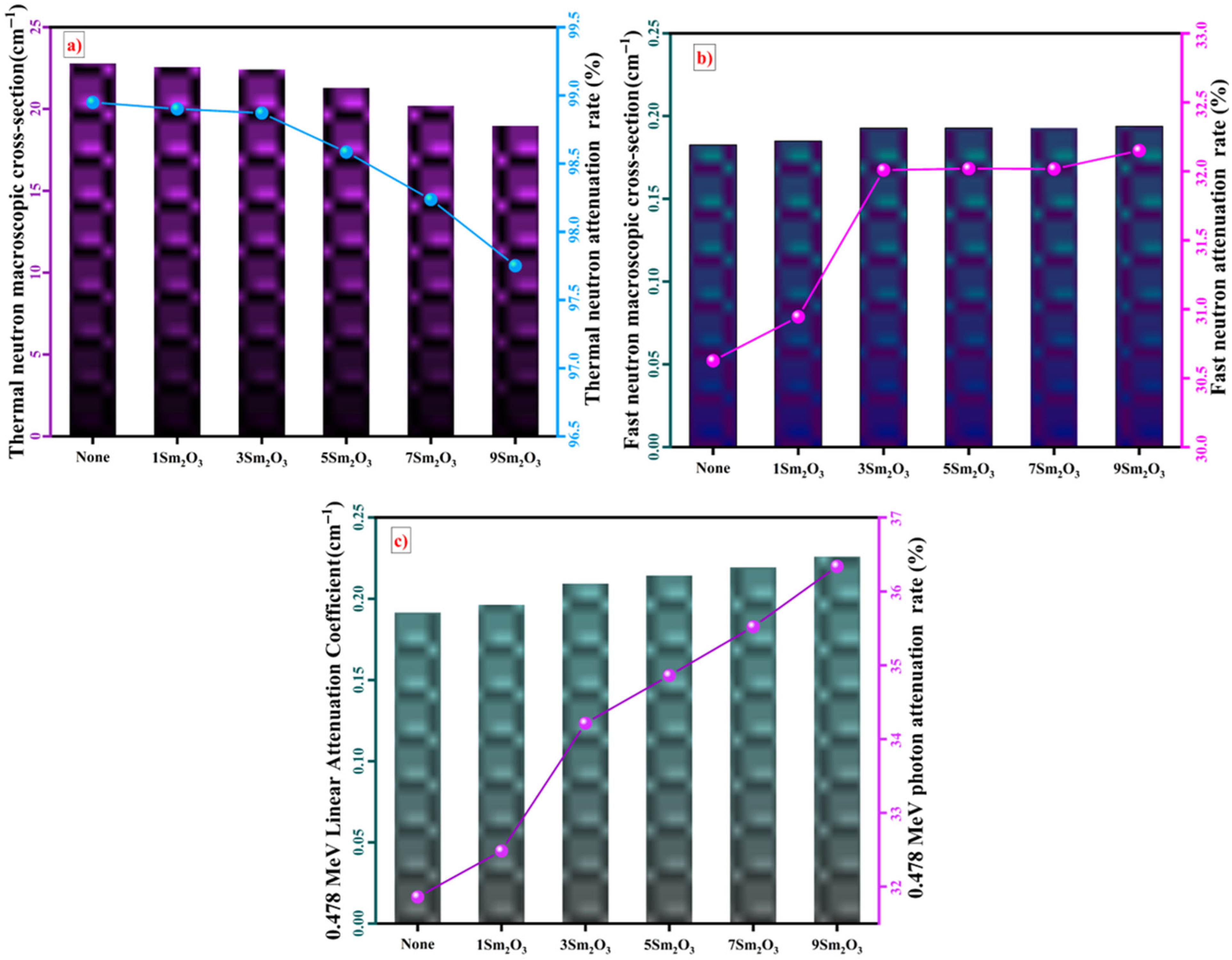

3.5. Neutron and Gamma-Radiation-Shielding Properties

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lalkovičová, M. Neuroprotective Agents Effective against Radiation Damage of Central Nervous System. Neural Regen. Res. 2022, 17, 1885. [Google Scholar] [CrossRef]

- Thomas, G.A.; Symonds, P. Radiation Exposure and Health Effects—Is It Time to Reassess the Real Consequences? Clin. Oncol. 2016, 28, 231–236. [Google Scholar] [CrossRef] [PubMed]

- Echeweozo, E.O.; Alomairy, S.; Alsaiari, N.S.; Al-Buriahi, M.S. Effect of Lead Oxide Addition on Gamma Radiation Shielding Properties of Newly Developed Geopolymers: Theoretical and Simulation Studies. Sci. Rep. 2024, 14, 29968. [Google Scholar] [CrossRef] [PubMed]

- Chang, Q.; Guo, S.; Zhang, X. Radiation Shielding Polymer Composites: Ray-Interaction Mechanism, Structural Design, Manufacture and Biomedical Applications. Mater. Des. 2023, 233, 112253. [Google Scholar] [CrossRef]

- Greenberg, M.R.; Mayer, H.J.; Harkema, M.; Krahn, S. Can Collaboration Succeed in Siting a Spent Nuclear Fuel Facility in the United States?—A Challenge in Political Sustainability. Sustainability 2025, 17, 4906. [Google Scholar] [CrossRef]

- Ge, Z.; Geng, Y.; Wei, W.; Zhong, C. Assessing Samarium Resource Efficiency in China: A Dynamic Material Flow Analysis. Resour. Policy 2022, 76, 102638. [Google Scholar] [CrossRef]

- Alzahrani, F.M.A.; Albarkaty, K.S.; Çalişkan, F.; Olarinoye, I.O.; Al-Buriahi, M.S. Physical, Microstructural, and Radiation Energy Absorption Properties of Recycled CRT-Screen Glass Doped with Bi2O3. J. Radiat. Res. Appl. Sci. 2023, 16, 100727. [Google Scholar] [CrossRef]

- Katubi, K.M.; Basha, B.; Alsufyani, S.J.; Alrowaili, Z.A.; Sriwunkum, C.; Alnairi, M.M.; Al-Buriahi, M.S. Radiation Attenuation and Optical Properties of P2O5-Based Glass System. J. Radiat. Res. Appl. Sci. 2023, 16, 100688. [Google Scholar] [CrossRef]

- Kursun, C.; Gao, M.; Guclu, S.; Gaylan, Y.; Parrey, K.A.; Yalcin, A.O. Measurement on the Neutron and Gamma Radiation Shielding Performance of Boron-Doped Titanium Alloy Ti50Cu30Zr15B5 via Arc Melting Technique. Heliyon 2023, 9, e21696. [Google Scholar] [CrossRef]

- Gaylan, Y.; Avar, B. Al–B4C-(Gd, Gd2O3) Composite Materials: Synthesis and Characterization for Neutron Shielding Applications. Nucl. Eng. Technol. 2024, 56, 5201–5211. [Google Scholar] [CrossRef]

- Li, Y.Z.; Wang, Q.Z.; Xiao, B.L.; Ma, Z.Y. Effect of Welding Parameters and B4C Contents on the Microstructure and Mechanical Properties of Friction Stir Welded B4C/6061Al Joints. J. Mater. Process Technol. 2018, 251, 305–316. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Y.; Wang, W.; Gao, Z.; Wang, B. The Design, Fabrication and Properties of B4C/Al Neutron Absorbers. J. Nucl. Mater. 2013, 437, 350–358. [Google Scholar] [CrossRef]

- Lee, D.; Kim, J.; Lee, S.K.; Kim, Y.; Lee, S.B.; Cho, S. Experimental and Thermodynamic Study on Interfacial Reaction of B4C–Al6061 Composites Fabricated by Stir Casting Process. J. Alloys Compd. 2021, 859, 157813. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, Z.; Zhang, Y.; Cui, Y.; Sun, L.; Chen, D. Improving the Mechanical Properties of B4C/Al Composites by Solid-State Interfacial Reaction. J. Alloys Compd. 2020, 829, 154521. [Google Scholar] [CrossRef]

- Topcu, I.; Gulsoy, H.O.; Kadioglu, N.; Gulluoglu, A.N. Processing and Mechanical Properties of B4C Reinforced Al Matrix Composites. J. Alloys Compd. 2009, 482, 516–521. [Google Scholar] [CrossRef]

- Çağlar, S. Impact of B4C Reinforcement on the Microstructure, Wear, Hardness, Corrosion Behavior, and Radiation Shielding Properties of Al-40Sm2O3 Hybrid Composites. Nucl. Eng. Technol. 2025, 57, 103566. [Google Scholar] [CrossRef]

- Chen, H.S.; Wang, W.X.; Li, Y.L.; Zhang, P.; Nie, H.H.; Wu, Q.C.; Carlo, M. The Design, Microstructure and Tensile Properties of B4C Particulate Reinforced 6061Al Neutron Absorber Composites. J. Alloys Compd. 2015, 632, 23–29. [Google Scholar] [CrossRef]

- Deng, K.; Shi, J.; Wang, C.; Wang, X.; Wu, Y.; Nie, K.; Wu, K. Composites: Part A Microstructure and Strengthening Mechanism of Bimodal Size Particle Reinforced Magnesium Matrix Composite. Composites Part. A 2012, 43, 1280–1284. [Google Scholar] [CrossRef]

- Luo, G.; Wu, J.; Xiong, S.; Shen, Q.; Wu, C. Microstructure and Mechanical Behavior of AA2024/B4C Composites with a Network Reinforcement Architecture. J. Alloys Compd. 2017, 701, 554–561. [Google Scholar] [CrossRef]

- He, Y.; Xu, H.; Liu, Y.; Chen, Y.; Ji, Z. Strengthening Mechanism of B4C@APC/Al Matrix Composites Reinforced with Bimodal-Sized Particles Prepared by Hydrothermal Carbonized Deposition on Chips. J. Mater. Sci. Technol. 2022, 123, 60–69. [Google Scholar] [CrossRef]

- Abrefah, R.G.; Sogbadji, R.B.M.; Ampomah-Amoako, E.; Birikorang, S.A.; Odoi, H.C.; Nyarko, B.J.B. Comparison of the Effects of Cadmium-Shielded and Boron Carbide-Shielded Irradiation Channel of the Ghana Research Reactor-1. Nucl. Eng. Des. 2011, 241, 3017–3020. [Google Scholar] [CrossRef]

- Wan, S.; Wang, W.; Chen, H.; Zhou, J.; Zhang, Y.; Liu, R.; Feng, R. 155/157Gd Areal Density: A Model for Design and Fabrication of Gd2O3/316L Novel Neutron Shielding Composites. Vacuum 2020, 176, 109304. [Google Scholar] [CrossRef]

- Florez, R.; Colorado, H.A.; Giraldo, C.H.C.; Alajo, A. Preparation and Characterization of Portland Cement Pastes with Sm2O3 Microparticle Additions for Neutron Shielding Applications. Constr. Build. Mater. 2018, 191, 498–506. [Google Scholar] [CrossRef]

- Kursun, C.; Gaylan, Y.; Yalcin, A.O.; Parrey, K.A.; Gao, M. Advanced Neutron and γ-Ray Shielding Characteristics of Nanostructured (90-x)Al-XGd2O3 Composites Reinforced by Tungsten. J. Alloys Compd. 2025, 1010, 177372. [Google Scholar] [CrossRef]

- Fernandez, V. Rare-Earth Elements Market: A Historical and Financial Perspective. Resour. Policy 2017, 53, 26–45. [Google Scholar] [CrossRef]

- Bagheri Khatibani, A.; Khoshhal, A.R.; Basiri Tochaee, E.; Rasouli Jamnani, S.; Milani Moghaddam, H. Physical and Gamma Radiation Shielding Features of Sm2O3/Graphene Nanoparticles: A Comparison between Experimental and Simulated Gamma Shielding Capability. Inorg. Chem. Commun. 2024, 167, 112772. [Google Scholar] [CrossRef]

- May, E.; Thoennessen, M. Discovery of Samarium, Europium, Gadolinium, and Terbium Isotopes. At. Data Nucl. Data Tables 2013, 99, 1–21. [Google Scholar] [CrossRef][Green Version]

- Çağlar, S. Influence of Gd2O3 Reinforcement on the Mechanical, Physical and Radiation Shielding Properties of Al-30Sm2O3 Composites. J. New Results Sci. 2024, 13, 232–248. [Google Scholar] [CrossRef]

- Gaylan, Y.; Dag, I.E.; Caglar, S.; Avar, B. Investigation of Mechanical and Radiation Shielding Properties of Sm–Sm2O3 Reinforced Al–B4C Composite. Radiat. Phys. Chem. 2025, 226, 112325. [Google Scholar] [CrossRef]

- Zhang, D.-Y.; Shen, X.-Y.; Ruan, Q.; Xu, X.-L.; Yang, S.-P.; Lu, Y.; Xu, H.-Y.; Hao, F.-L. Effects of Subchronic Samarium Exposure on the Histopathological Structure and Apoptosis Regulation in Mouse Testis. Environ. Toxicol. Pharmacol. 2014, 37, 505–512. [Google Scholar] [CrossRef] [PubMed]

- Castley, D.; Goodwin, C.; Liu, J. Computational and Experimental Comparison of Boron Carbide, Gadolinium Oxide, Samarium Oxide, and Graphene Platelets as Additives for a Neutron Shield. Radiat. Phys. Chem. 2019, 165, 108435. [Google Scholar] [CrossRef]

- Gaylan, Y.; Caglar, S. Effect of Sm2O3 on Radiation Shielding and Mechanical Properties of Al-Sm2O3 Composites. Ceram. Int. 2024, 51, 10133–10142. [Google Scholar] [CrossRef]

- Fatih Kilicaslan, M.; Uzun, O.; Yilmaz, F.; Çağlar, S. Effect of Different Production Methods on the Mechanical and Microstructural Properties of Hypereutectic Al-Si Alloys. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2014, 45, 1865–1873. [Google Scholar] [CrossRef]

- Manjunatha, B.; Niranjan, H.B.; Satyanarayana, K.G. Effect of Mechanical and Thermal Loading on Boron Carbide Particles Reinforced Al-6061 Alloy. Mater. Sci. Eng. A 2015, 632, 147–155. [Google Scholar] [CrossRef]

- Sun, Y.; Bai, X.-Y.; Guo, R.-F.; Shen, P. Ultrafast Pressure Sintering of B4C-Based Composites via Direct Joule Heating. J. Mater. Sci. Technol. 2025, 210, 188–194. [Google Scholar] [CrossRef]

- Qiu, X.; Qi, L.; Tang, J.R.; Wang, J.Q.; Xiong, T.Y. A Viable Approach to Repair Neutron Shielding B4C/6061 Al Composite Sheets through Cold Spray and Hot Rolling Co-Treatment. J. Mater. Sci. Technol. 2022, 106, 173–182. [Google Scholar] [CrossRef]

- Zhang, P.; Li, J.; Wang, W.; Tan, X.; Xie, L.; Guo, F. The Design, Microstructure and Mechanical Properties of a Novel Gd2O3/6061Al Neutron Shielding Composite. Vacuum 2019, 162, 92–100. [Google Scholar] [CrossRef]

- Lin, Q.; Shen, P.; Qiu, F.; Zhang, D.; Jiang, Q. Wetting of Polycrystalline B4C by Molten Al at 1173–1473K. Scr. Mater. 2009, 60, 960–963. [Google Scholar] [CrossRef]

- Guo, R.-F.; Chen, S.-M.; Shen, P. Influence of Si, Ti, and Cu as Alloying Elements on the Wettability and Reactivity of an Al/B4C System. J. Mater. Res. Technol. 2023, 27, 6104–6116. [Google Scholar] [CrossRef]

- Ibrahim, M.F.; Ammar, H.R.; Samuel, A.M.; Soliman, M.S.; Songmene, V.; Samuel, F.H. Why Al-B4C Metal Matrix Composites? A Review. In Advances in High-Entropy Alloys—Materials Research, Exotic Properties and Applications; IntechOpen: London, UK, 2021. [Google Scholar]

- Ghayebloo, M.; Mostaedi, M.T.; Rad, H.F. A Review of Recent Studies of Fabrication of Al–B4C Composite Sheets Used in Nuclear Metal Casks. Trans. Indian. Inst. Met. 2022, 75, 2477–2490. [Google Scholar] [CrossRef]

- Ranjitha, P.; Bavan, D.S.; Ajaykumar, B.S.; Raju, T.H.; Udayashankar, S. Investigation of Mechanical Properties of Al6061–SiC–B4C Composites Produced by Using Stir Casting Method. J. Inst. Eng. (India) Ser. D 2024, 106, 339–351. [Google Scholar] [CrossRef]

- ASTM D792-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020.

- Aktaş, B.; Toprak, M.; Çalık, A.; Tekgüler, A. Effect of Pack-Boriding on the Tribological Behavior of Hardox 450 and HiTuf Steels. Rev. Adv. Mater. Sci. 2020, 59, 314–321. [Google Scholar] [CrossRef]

- Carboga, C.; Aktas, B.; Kurt, B. Dry Sliding Wear Behavior of Boron-Doped 205 Manganese Steels. J. Mater. Eng. Perform. 2020, 29, 3120–3126. [Google Scholar] [CrossRef]

- Werner, C.J. MCNP Users Manual-Code Version 6.2; Los Alamos National Laboratory: Los Alamos, NM, USA, 2017; Volume 746.

- Akkas, A.; Beril Tugrul, A.; Tazegul, O. Shielding Performance of Al–B4C–W Composite Materials against Gamma-Ray, Beta and Neutron Radiations. Radiat. Phys. Chem. 2025, 232, 112662. [Google Scholar] [CrossRef]

- Niksarlıoğlu, S.; Akman, F.; Pekdemir, M.E.; Yalçın Kuzu, S.; Kaçal, M.R.; Yılmaz, M. An Extensive Investigation on Gamma Shielding Properties of PLA/Gd2O3 Nanocomposites. Radiat. Phys. Chem. 2023, 208, 110936. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, B.; Gu, Y.; Wang, S.; Li, M. Gamma Radiation Shielding Property of Continuous Fiber Reinforced Epoxy Matrix Composite Containing Functional Filler Using Monte Carlo Simulation. Nucl. Mater. Energy 2022, 33, 101246. [Google Scholar] [CrossRef]

- Pan, J.; Wang, C.; Wang, Z.; Zhang, C.; Fang, L.; Li, J.; Mei, Q.; Gao, J.; Wang, M.; Li, H.; et al. Microstructure Characteristics and Properties of a Novel Ni-Based Alloy for Thermal Neutron and Gamma Ray Co-Shielding. Mater. Charact. 2024, 210, 113840. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Chen, Y. Extended Development of the Monte Carlo Code MCNP for Effective Delayed Neutron Fraction Calculation in Molten Salt Reactors. Progress. Nucl. Energy 2024, 176, 105392. [Google Scholar] [CrossRef]

- Gaylan, Y.; Bozkurt, A.; Avar, B. Investigating Thermal and Fast Neutron Shielding Properties of B4C, B2O3, Sm2O3, and Gd2O3 Doped Polymer Matrix Composites Using Monte Carlo Simulations. Süleyman Demirel Üniversitesi Fen. Edeb. Fakültesi Fen. Derg. 2021, 16, 490–499. [Google Scholar] [CrossRef]

- Andrew, T. Boothroyd Principles of Neutron Scattering from Condensed Matter; Oxford University Press: Oxford, UK, 2020. [Google Scholar]

- Akman, F.; Kaçal, M.R.; Sayyed, M.I.; Karataş, H.A. Study of Gamma Radiation Attenuation Properties of Some Selected Ternary Alloys. J. Alloys Compd. 2019, 782, 315–322. [Google Scholar] [CrossRef]

- Chen, H.S.; Wang, W.X.; Li, Y.L.; Zhou, J.; Nie, H.H.; Wu, Q.C. The Design, Microstructure and Mechanical Properties of B4C/6061Al Neutron Absorber Composites Fabricated by SPS. Mater. Des. 2016, 94, 360–367. [Google Scholar] [CrossRef]

- Chand, S.; Chandrasekhar, P.; Roy, S.; Singh, S. Influence of Dispersoid Content on Compressibility, Sinterability and Mechanical Behaviour of B4C/BN Reinforced Al6061 Metal Matrix Hybrid Composites Fabricated via Mechanical Alloying. Met. Mater. Int. 2021, 27, 4841–4853. [Google Scholar] [CrossRef]

- Ipek, R. Adhesive Wear Behaviour of B4C and SiC Reinforced 4147 Al Matrix Composites (Al/B4C–Al/SiC). J. Mater. Process Technol. 2005, 162–163, 71–75. [Google Scholar] [CrossRef]

- Gaylan, Y.; Avar, B.; Panigrahi, M.; Aygün, B.; Karabulut, A. Effect of the B4C Content on Microstructure, Microhardness, Corrosion, and Neutron Shielding Properties of Al–B4C Composites. Ceram. Int. 2023, 49, 5479–5488. [Google Scholar] [CrossRef]

- Caglar, S.; Kilicaslan, M.F.; Atasoy, A.; Tiryaki, H.; Erkovan, M.; Hong, S. jik Effect of Heat Treatment on Magnetic Properties of Nanocomposite Nd-Lean Nd7Fe73B20 Ribbons. J. Mater. Sci. Mater. Electron. 2021, 32, 2338–2345. [Google Scholar] [CrossRef]

- McCafferty, E. Validation of Corrosion Rates Measured by the Tafel Extrapolation Method. Corros. Sci. 2005, 47, 3202–3215. [Google Scholar] [CrossRef]

- Aydın, F. A Review of Recent Developments in the Corrosion Performance of Aluminium Matrix Composites. J. Alloys Compd. 2023, 949, 169508. [Google Scholar] [CrossRef]

- Ozturk, K.; Gecu, R.; Karaaslan, A. Microstructure, Wear and Corrosion Characteristics of Multiple-Reinforced (SiC–B4C–Al2O3) Al Matrix Composites Produced by Liquid Metal Infiltration. Ceram. Int. 2021, 47, 18274–18285. [Google Scholar] [CrossRef]

- Çanakçı, A.; Karabacak, A.H.; Çelebi, M.; Özkaya, S.; Arpacı, K.A. A Study on the Optimization of Nano-B4C Content for the Best Wear and Corrosion Properties of the Al-Based Hybrid Nanocomposites. Arab. J. Sci. Eng. 2024, 49, 14625–14641. [Google Scholar] [CrossRef]

- Tian, J.J.; Wang, K.; Xu, K.W.; Luo, X.T.; Shao, G.S.; Li, C.J. Effect of Coating Composition on the Micro-Galvanic Dissolution Behavior and Antifouling Performance of Plasma-Sprayed Laminated-Structured Cu[Sbnd]Ti Composite Coating. Surf. Coat. Technol. 2021, 410, 126963. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Y.; Liu, J.; Xu, J.; Guo, D.; Li, C.; Zhou, X.; Yang, P.; Zhang, S. Impact of Rare Earth Elements on Micro-Galvanic Corrosion in Magnesium Alloys: A Comparative Study of Mg-Nd and Mg-Y Binary Alloys. Int. J. Electrochem. Sci. 2023, 18, 100160. [Google Scholar] [CrossRef]

- Jiang, L.T.; Xu, Z.G.; Fei, Y.K.; Zhang, Q.; Qiao, J.; Wu, G.H. The Design of Novel Neutron Shielding (Gd+B4C)/6061Al Composites and Its Properties after Hot Rolling. Compos. B Eng. 2019, 168, 183–194. [Google Scholar] [CrossRef]

| Materials | Chemical Composition (wt.%) | ||

|---|---|---|---|

| Al6061 | B4C | Sm2O3 | |

| Al-30B4C | 70 | 30 | 0 |

| Al-29B4C-1Sm2O3 | 70 | 29 | 1 |

| Al-27B4C-3Sm2O3 | 70 | 27 | 3 |

| Al-25B4C-5Sm2O3 | 70 | 25 | 5 |

| Al-23B4C-7Sm2O3 | 70 | 23 | 7 |

| Al-21B4C-9Sm2O3 | 70 | 21 | 9 |

| Materials Code | Theoretical Density (g/cm3) | Experimental Density (g/cm3) | Relative Density (%) |

|---|---|---|---|

| None | 2.64 | 2.25 | 85.24 |

| 1Sm2O3 | 2.66 | 2.30 | 86.37 |

| 3Sm2O3 | 2.70 | 2.43 | 90.16 |

| 5Sm2O3 | 2.74 | 2.48 | 90.38 |

| 7Sm2O3 | 2.78 | 2.52 | 90.58 |

| 9Sm2O3 | 2.83 | 2.58 | 91.24 |

| Materials Code | MAC (cm2/g) | MFP (cm) | HVL (cm) |

|---|---|---|---|

| None | 0.085 | 5.131 | 3.556 |

| 1Sm2O3 | 0.085 | 5.093 | 3.529 |

| 3Sm2O3 | 0.085 | 4.776 | 3.310 |

| 5Sm2O3 | 0.086 | 4.666 | 3.233 |

| 7Sm2O3 | 0.086 | 4.557 | 3.158 |

| 9Sm2O3 | 0.087 | 4.427 | 3.068 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Çağlar, S. Enhancing Structural, Mechanical, and Radiation-Shielding Properties of Al-B4C Hybrid Composites. Sustainability 2025, 17, 7249. https://doi.org/10.3390/su17167249

Çağlar S. Enhancing Structural, Mechanical, and Radiation-Shielding Properties of Al-B4C Hybrid Composites. Sustainability. 2025; 17(16):7249. https://doi.org/10.3390/su17167249

Chicago/Turabian StyleÇağlar, Seyit. 2025. "Enhancing Structural, Mechanical, and Radiation-Shielding Properties of Al-B4C Hybrid Composites" Sustainability 17, no. 16: 7249. https://doi.org/10.3390/su17167249

APA StyleÇağlar, S. (2025). Enhancing Structural, Mechanical, and Radiation-Shielding Properties of Al-B4C Hybrid Composites. Sustainability, 17(16), 7249. https://doi.org/10.3390/su17167249