Impact of Digitalization on Carbon Emissions in Guangdong’s Manufacturing Sector: An Input–Output Perspective

Abstract

1. Introduction

2. Literature Review

2.1. Industrial Digitalization and Industrial Transformation

2.2. Influence Mechanism of Digital Technology on Carbon Emissions in Manufacturing Industry

2.3. Comparison of Digitalization Research Methods

- It delves into the correlation between digitalization investments and carbon emissions among listed manufacturing firms in Guangdong Province, thereby furnishing empirical evidence to underpin regional-level carbon emissions research.

- It explores the heterogeneity of the carbon reduction effects across different industries during the digital transformation process, providing valuable insights to refine policy development and enhance resource allocation strategies.

3. Model Building

3.1. Digitalization Degree Calculation

3.2. Carbon Emission Accounting

3.3. Data Sources

3.4. SDA Model

3.5. Scenario Simulation

3.6. Result

4. Conclusion and Policies

4.1. Research Conclusions and Policy Recommendations

4.2. Research Limitations and Future Outlook

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GHG | Greenhouse Gas |

| IEA | International Energy Agency |

| CEADs | China Emission Accounts and Datasets |

| SDA | Structural Decomposition Analysis |

| EEIO | Environmentally-Extended Input–Output |

Appendix A

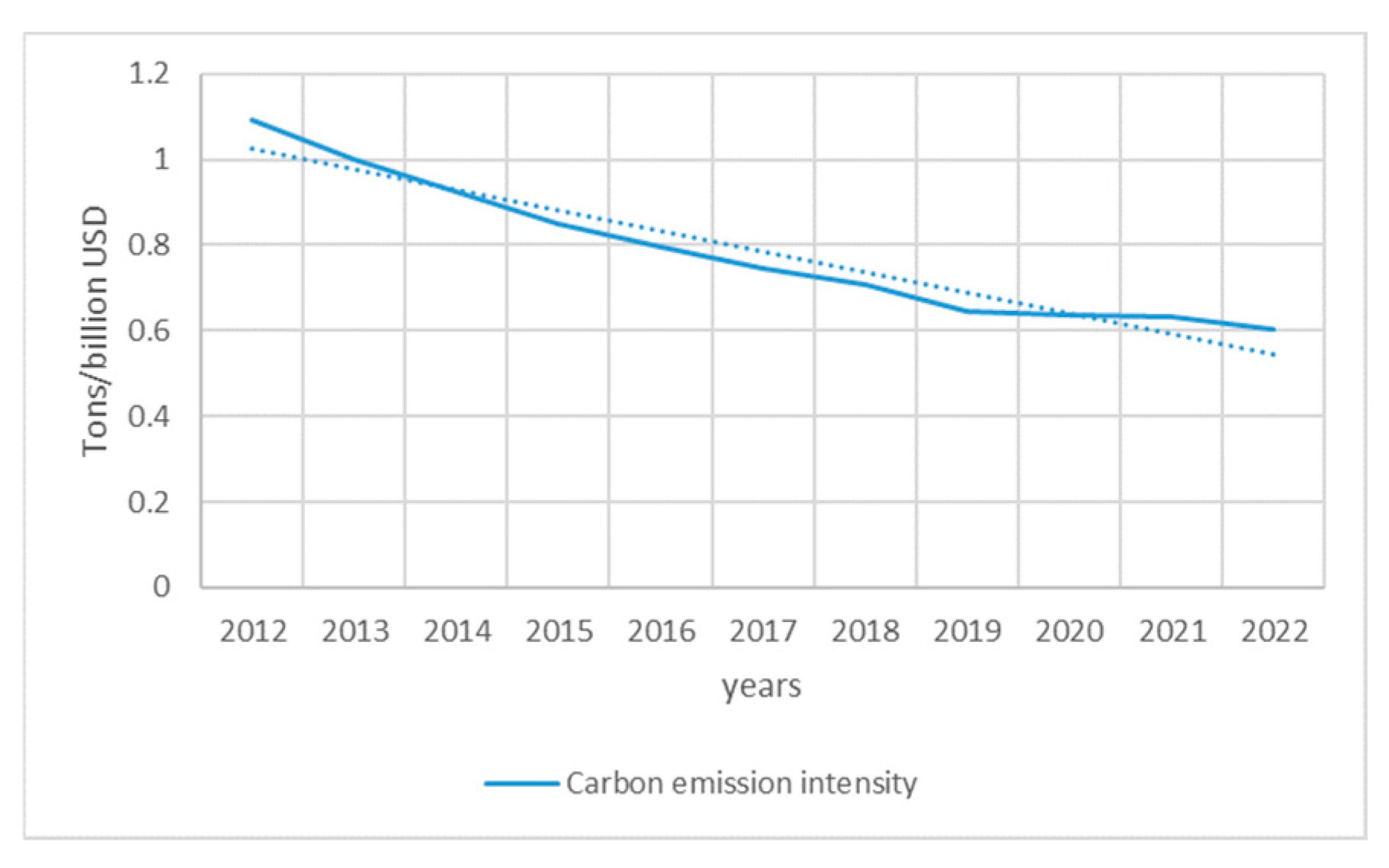

| Year | Carbon Emissions (million Tons CO2) | GDP (Billion CNY) | Carbon Emission Intensity (Tons/ Billion CNY) |

|---|---|---|---|

| 2012 | 62,253.41 | 57,007.7 | 1.092018 |

| 2013 | 62,637.52 | 62,503.4 | 1.002146 |

| 2014 | 63,078.54 | 68,173 | 0.925272 |

| 2015 | 63,485.74 | 74,732.4 | 0.849508 |

| 2016 | 65,295.89 | 82,163.2 | 0.79471 |

| 2017 | 68,253.42 | 91,648.7 | 0.744729 |

| 2018 | 70,549.51 | 99,945.2 | 0.705882 |

| 2019 | 69,855.48 | 107,987 | 0.646888 |

| 2020 | 70,717.62 | 111,152 | 0.636224 |

| Sector | Emission Reduction (Tons) | Contribution Rate |

|---|---|---|

| Petroleum, Coking Products, and Processed Nuclear Fuel | 88,905.63 | 1.19% |

| Nonmetal Mineral Products | 1,098,474 | 14.71% |

| Smelting and Pressing of Metals | 2,963,725 | 39.69% |

| Sector | Emission Reduction (Tons) | Contribution Rate |

|---|---|---|

| Woodwork and Furniture | 1674.365 | 0.02% |

| Transportation Equipment | 1468.8 | 0.02% |

| Textile Industry | 27,285.52 | 0.37% |

| Textile Clothing Shoes and Hats Leather Down and Its Products | 1366.427 | 0.02% |

| Telecommunications Equipment, Computers and Other Electronic Equipment | 11,220.35 | 0.15% |

| Paper, Printing, and Stationery | 33,806.21 | 0.45% |

| Other Manufacturing Products and Scrap Waste | 13,886.3 | 0.19% |

| Ordinary Machinery | 10,053.25 | 0.13% |

| Metal Products | 7523.814 | 0.10% |

| Instrumentation Machinery | 1485.774 | 0.02% |

| Food and Tobacco Processing | 6770.343 | 0.09% |

| Equipment for Special Purposes | 939.3312 | 0.01% |

| Electric Equipment and Machinery | 3646.407 | 0.05% |

| Chemical Products | 41,799.83 | 0.56% |

References

- Murphy, R. What is undermining climate change mitigation? How fossil-fuelled practices challenge low-carbon transitions. Energy Res. Soc. Sci. 2024, 108, 103390. [Google Scholar] [CrossRef]

- IEA. CO2 Emissions in 2023, IEA, Paris. 2024. Available online: https://www.iea.org/reports/co2-emissions-in-2023 (accessed on 28 March 2025).

- Danish; Khan, N.; Baloch, M.A.; Saud, S.; Fatima, T. The effect of ICT on CO2 emissions in emerging economies: Does the level of income matters? Environ. Sci. Pollut. Res. 2018, 25, 22850–22860. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Zhao, Q.; Ren, Y. Nexus among government digital development, resource dependence, and carbon emissions in China. Resour. Policy 2024, 95, 105186. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, R.; Yang, Y.; Chen, J.; Yang, S. Has enterprise digital transformation facilitated the carbon performance in Industry 4.0 era? Evidence from Chinese industrial enterprises. Comput. Ind. Eng. 2023, 184, 109576. [Google Scholar] [CrossRef]

- Xu, G.; Dong, H.; Xu, Z.; Bhattarai, N. China can reach carbon neutrality before 2050 by improving economic development quality. Energy 2022, 243, 123087. [Google Scholar] [CrossRef]

- The State Council of China. Action Plan for Carbon Dioxide Peaking Before 2030. 24 October 2021. Available online: https://en.ndrc.gov.cn/policies/202110/t20211027_1301020.html (accessed on 28 March 2025).

- Cui, H.; Chen, L. “Intelligent Manufacturing” in the “Made in China 2025” Strategy. Sci. Technol. Econ. Mark. 2022, 4, 7–9. (In Chinese) [Google Scholar]

- Guangdong Provincial Bureau of Statistics & Office of the Leading Group for the Fifth National Economic Census of Guangdong Province. Bulletin of the Fifth National Economic Census of Guangdong Province (No. 1). Southern Daily, 13 March 2025, p. A07. Available online: https://epaper.nfnews.com/nfdaily/html/202503/13/content_10129508.html (accessed on 28 March 2025). (In Chinese)

- Ding, Y.; Song, X.; Zhu, Y.; Xi, R.; Shi, Z. Digital technology and Chinese-style industrial modernization: Dynamic threshold effect based on R&D Human resources. Heliyon 2024, 10, e38484. [Google Scholar] [CrossRef]

- Nie, C.; Xie, L.; Feng, Y. The digital path to carbon neutrality: Examining the carbon abatement effect of digital place-based policy in China. Energy Econ. 2025, 147, 108537. [Google Scholar] [CrossRef]

- China Academy of Information and Communications Technology. China Digital Economy Development White Paper 13 July 2017. Available online: https://www.cac.gov.cn/files/pdf/baipishu/shuzijingjifazhan.pdf (accessed on 28 March 2025).

- Tianren, L.; Sufeng, H. Does digital-industrial technology integration reduce corporate carbon emissions? Environ. Res. 2024, 257, 119313. [Google Scholar] [CrossRef] [PubMed]

- Naseem, S. Linkages between digitalization and carbon emissions generated from natural resource-based energy sources: Empirical evidence from Asia. Miner. Econ. 2025, 1–17. [Google Scholar] [CrossRef]

- Wang, X.; Su, X. Does digitalization facilitate pollution and carbon emissions reduction synergies?: Evidence based on Chinese A-share manufacturing companies. Environ. Dev. Sustain. 2025, 1–37. [Google Scholar] [CrossRef]

- Guo, Z.; Li, T.; Shi, B.; Zhang, H. Economic impacts and carbon emissions of electric vehicles roll-out towards 2025 goal of China: An integrated input-output and computable general equilibrium study. Sustain. Prod. Consum. 2022, 31, 165–174. [Google Scholar] [CrossRef]

- Wu, F.; Hu, H.; Lin, H.; Ren, X. Enterprise Digital Transformation and Capital Market Performance: Empirical Evidence from Stock Liquidity. Manag. World 2021, 37, 130–144. (In Chinese) [Google Scholar] [CrossRef]

- Li, Y.; Jiao, W.; Yang, Z. Enterprise Digital Transformation and Auditor Risk Decision-Making. Account. Mon. 2023, 44, 111–119. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, J.; He, W.; Liu, J. Strategies for Building a Modern Industrial System in Guangdong Province. Sichuan Prov. Res. 2025, 01, 56–58. (In Chinese) [Google Scholar]

- Li, Y.; Li, N.; Li, Z. Evolution of carbon emissions in China’s digital economy: An empirical analysis from an entire industry chain perspective. J. Clean. Prod. 2023, 414, 137419. [Google Scholar] [CrossRef]

- Hong, J.; Huang, H.; Wang, X.; Dockerill, B.; Ye, J.; Zhang, S. Structural effects of provincial digital economy on carbon emissions within China: A multi-region input-output based structural decomposition analysis. Sci. Total Environ. 2024, 934, 173140. [Google Scholar] [CrossRef] [PubMed]

- Dou, B.; Guo, S.; Chang, X.; Wang, Y. Corporate digital transformation and labor structure upgrading. Int. Rev. Financial Anal. 2023, 90, 102904. [Google Scholar] [CrossRef]

| Tech Effect (Tons) | Struct Effect (Tons) | Scale Effect (Tons) | |

|---|---|---|---|

| Food and Tobacco Processing | −1,523,954.663 | −40,273.39793 | 1,554,247.136 |

| Textile Industry | −6,334,503.097 | 2,743,807.047 | 4,009,767.908 |

| Textile Clothing Shoes and Hats Leather Down and Its Products | −1,265,568.841 | −211,542.9817 | 940,001.822 |

| Woodwork and Furniture | −474,611.8052 | 189,779.7323 | 290,159.3434 |

| Paper, Printing, and Stationery | −3,456,984.744 | 2,259,874.772 | 2,784,573.23 |

| Petroleum, Coking Products, and Processed Nuclear Fuel | 4,350,120.727 | −3,572,788.784 | 1,543,157.142 |

| Chemical Products | −414,517.3999 | 733,783.2996 | 2,764,731.79 |

| Nonmetal Mineral Products | −38,760,022.87 | 87,124,698.11 | 70,779,646.35 |

| Smelting and Pressing of Metals | 7,675,511.848 | 76,891,809.72 | 126,129,635.2 |

| Metal Products | −1,622,959.736 | 335,345.0404 | 1,148,140.695 |

| Ordinary Machinery | −120,892.5008 | 140,086.1948 | 1,218,281.694 |

| Equipment for Special Purposes | −622,493.426 | −232,772.5191 | 593,749.7327 |

| Transportation Equipment | −768,201.821 | −166,827.9607 | 595,702.0655 |

| Electric Equipment and Machinery | −1,302,721.86 | −234,572.8099 | 809,394.5448 |

| Telecommunications Equipment, Computers, and Other Electronic Equipment | −3,414,791.295 | −1,749,447.061 | 2,310,817.422 |

| Instrumentation Machinery | −415,960.8536 | 129,899.6814 | 210,468.0162 |

| Other Manufacturing Products and Scrap Waste | −58,676,734.6 | 47,202,190.78 | 8,200,623.011 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jingren, J.; Yabar, H.; Mizunoya, T. Impact of Digitalization on Carbon Emissions in Guangdong’s Manufacturing Sector: An Input–Output Perspective. Sustainability 2025, 17, 7234. https://doi.org/10.3390/su17167234

Jingren J, Yabar H, Mizunoya T. Impact of Digitalization on Carbon Emissions in Guangdong’s Manufacturing Sector: An Input–Output Perspective. Sustainability. 2025; 17(16):7234. https://doi.org/10.3390/su17167234

Chicago/Turabian StyleJingren, Jiao, Helmut Yabar, and Takeshi Mizunoya. 2025. "Impact of Digitalization on Carbon Emissions in Guangdong’s Manufacturing Sector: An Input–Output Perspective" Sustainability 17, no. 16: 7234. https://doi.org/10.3390/su17167234

APA StyleJingren, J., Yabar, H., & Mizunoya, T. (2025). Impact of Digitalization on Carbon Emissions in Guangdong’s Manufacturing Sector: An Input–Output Perspective. Sustainability, 17(16), 7234. https://doi.org/10.3390/su17167234