1. Introduction

Carbon dioxide (CO

2) emissions are widely recognized as a significant driver of global warming [

1], with China’s CO

2 emissions constituting a substantial portion of global emissions [

2]. Thus, reducing China’s CO

2 emissions is crucial for enhancing the global environment [

3]. The manufacturing sector plays a pivotal role in this effort, accounting for roughly 70% of China’s CO

2 emissions from industrial and energy production [

4]. In response, the Chinese government has embraced a new era of green development. This commitment is exemplified by the introduction of the “Industrial Green Development Plan during the 14th Five-Year Plan Period”, “China’s Green Development in the New Era”, and the report of the 20th CPC National Congress. These documents collectively underscore the necessity of green transformation as a critical pathway for industrial upgrading, promoting profound adjustments to the manufacturing structure within the stringent constraints of resource and environmental limitations.

The industrial system of China’s manufacturing industry is expansive and sizable, comprehensive in system and strong in competitiveness, and forms a vital component of China’s economy [

3,

5]. Currently, a part of the Chinese manufacturing sector still adheres to a pattern of development that is resource-intensive, polluting, and labor-dependent, while offering minimal added value [

4]. As a result, green development is a prominent feature of the Chinese-style modernization, which faces the dual constraints of current resource endowment and environmental regulation. Moreover, the green transition in the manufacturing industry is crucial for achieving a balance between economic prosperity and ecological health, shifting from a mode of production with high levels of emissions, pollution, and energy use to a more sustainable and low-impact alternative.

Green technological innovation, whether it is substantive innovation or policy innovation, has become a vital route for the green manufacturing transition and a significant driving force for the high-quality sustainable development of China’s economy [

6]. A green transition of the manufacturing industry not only requires a transformation of the production mode, but also of the industrial chain innovation. Such a transition will lead to improved outcomes from environmental pollution, resource consumption, economic benefits, and an industrial structure perspective [

7].

The launch of the “Made in China” policy in 2015 by the Chinese government signaled an important attempt which specifically addressed the green transformation and development of the manufacturing industry. However, although this policy has been implemented for a number of years, the empirical evidence to ascertain its impact has been underexplored [

6]. Thus, what is needed is a measurement approach which can provide a comprehensive account of China’s green manufacturing transition.

Given this, the aim of this paper is to construct a comprehensive evaluation index system comprising four dimensions: environment, resources, economy, and industrial structure for China’s green manufacturing transition. The index would allow for a more informed interpretation of the impact of green manufacturing transition. To achieve the main aim of this paper, the following research questions are addressed:

RQ1: What are the key factors influencing the convergence of China’s green manufacturing transition?

RQ2: Are there regional disparities in the degree of China’s green manufacturing transition?

RQ3: What is the trend of the inter-regional differences in the level of China’s green manufacturing transition?

By investigating these questions, and applying a new evaluation index, this paper contributes to the developing body of research on China’s green manufacturing transition by responding to the need for more analysis within green manufacturing research. The scientific novelty of this research mainly lies in three aspects. First, it constructs a comprehensive evaluation index system for the green transformation of the manufacturing industry from four dimensions: environment, resources, economy, and industrial structure. This multi-dimensional comprehensive measurement method is rarely seen in previous studies and can more comprehensively reflect the actual situation of the green transformation of the manufacturing industry. Second, it measures the level of green transformation of the manufacturing industry using the entropy method and analyzes its convergence characteristics. This combined approach not only objectively assesses the level of green transformation but also deeply analyzes the dynamic changes in trends among regions, providing a scientific basis for regional coordinated development. Third, the research not only focuses on the national level of the green transformation of the manufacturing industry but also deeply analyzes the differences and convergence characteristics among the eastern, central, and western regions, revealing the “catch-up effect” among regions and providing theoretical support for regional differentiated policies.

From a practical perspective, the results help inform policy formulation as it provides a scientific basis for the government to formulate regional differentiated green development strategies and help the government better balance economic development and environmental protection in policy-making. Some examples include (i) the provision of financial subsidies and tax incentives to support regions with lower levels of green transformation; (ii) improved regional coordinated development, by revealing the “catch-up effect” among regions (this would provide a reference for regional coordinated development strategies, promoting the flow of factors and knowledge spillover between developed and underdeveloped regions, and promoting the green transformation of the manufacturing industry within the country); and (iii) enhanced enterprise decision support that focuses on the green transformation of enterprises, helping them better adapt to the policy environment, optimize resource allocation, and enhance green competitiveness. Furthermore, the multi-dimensional measurement method and convergence analysis framework of this study can provide references for research in other related fields, promoting in-depth academic research on green transformation.

The remainder of this paper is structured as follows.

Section 2 provides an overview of the green transformation of the manufacturing industry.

Section 3 reviews the methodology employed by this study.

Section 4 discusses the convergence analysis results while

Section 5 provides the main conclusions and recommendations along with the limitations and future lines of research.

2. Green Manufacturing Transition

Guided by the concept of green development, the green manufacturing transition promotes a fundamental shift towards sustainable economic and environment practices, policies, and outcomes [

8]. This holistic view focuses on the efficient integration of economic performance with environmental benefits to arrive at substantial value addition for the manufacturing industry.

Prior studies on the green manufacturing transition frequently emphasize the facets of (i) evaluation measurement; (ii) green total factor productivity; (iii) influencing factors; and (iv) development path. With respect to evaluation measurement, Xiong and Fan [

9] constructed a comprehensive evaluation index system to measure the level of green manufacturing transition from four dimensions: green development contribution, green innovation drive, green environmental regulation, and regional green security. They found varying degrees of regional discrepancies partly due to differences in Chinese financial technology and spontaneous collaboration. Amrina [

10] constructed an evaluation index system by selecting 19 indicators through the three dimensions of economy, environment, and society, and used hierarchical analysis to assign weights to each indicator to comprehensively evaluate the level of green and sustainable development of the cement manufacturing industry in Indonesia [

7]. Amrina’s evaluation index system showed the benefit of employing a comprehensive scoring system via a set of key performance indicators (KPIs) to identify areas that can improve the sustainability of an industry.

For green total factor productivity, Li and Bai [

11] measured this for the manufacturing industry based on input–output indicators to assess the green competitiveness of the manufacturing industry. They found that when local authorities formulate policies that balance economic and environmental concerns, it can increase the green competitiveness of the manufacturing sector. With respect to measurement approaches for total factor productivity, although a number exist, there are typically three main approaches: (i) a directional distance function (DDF) [

12,

13]; (ii) a non-radial directional distance function (SBM) [

14,

15,

16]; and (iii) an EBM model that comprehensively handles both radial and non-radial feature case for measurement [

11,

17,

18].

Regarding influencing factors, Lei et al. [

19] showed that one such factor was environmental regulations, particularly command-and-control regulations which had a notably positive impact on green manufacturing transition, whereas market-incentive regulations were not significant. Thus, the repercussions of distinct environmental policies were heterogeneous. A study by [

20] showed that a significant positive factor that promotes the green manufacturing transition is local financial expenditure. Xiao et al. [

21] conducted a study with the Yangtze River Economic Belt region and found that the improvement of regional digitalization levels can significantly promote green technological innovation in the manufacturing production process, thereby optimizing manufacturing production.

Finally, in terms of development direction and path, Onsay [

22] selected green growth indicators from the four dimensions, two of which center environmental productivity and environmental quality of life, while the other two focus on the economic and socio-economic spheres. The four dimensions are then employed to comprehensively measure the green growth direction of Southeast Asian countries. The study showed that good governance and corporate social responsibility can inform policies that promote a greener society. Cheba et al. [

23] identified key indicators of green growth across four critical areas: environmental and resource efficiency, the foundation of natural assets, the environmental aspect of life quality, and economic prospects along with policy strategies. They applied the TOPSIS approach to derive a composite score for each set of indicators, aiming to ascertain the trajectory of green transformation across EU countries. Their results showed that a more informed understanding of the green transformation process can occur via a comparative analysis. Zhang and Chen [

24] suggest that the government, enterprises, and consumers need to fulfill their respective functions and roles: the government should formulate and implement scientific and reasonable environmental policies and establish corresponding environmental systems and tools. Meanwhile, enterprises should accelerate the establishment of effective green manufacturing management systems, and they should strive to awaken consumers’ awareness of green consumption and stimulate their demand for green products, thereby promoting China’s green manufacturing transition. Wan et al. [

25] believe that the sewage port and the production process should be technologically reformed as part of a green manufacturing transition that is more in line with reality. Wang and Xiong [

26], who analyzed their study from the perspective of the corporate life cycle, proposed that the digital empowerment enhanced dual innovation capabilities, internal control capabilities, and operational capabilities, which in turn promoted green manufacturing transition. This was seen as a key pathway to achieving the green manufacturing transition. In addition, Liu and Chen [

27] undertook a convergence analysis and found that there was no significant convergence and no catch-up effect between low- and high-productivity provinces with respect to greening the agricultural industry.

The above review shows that, in the face of increasingly complex economic, social and ecological environments, there is a lack of consensus regarding both the measurement and selection of indicators of the green manufacturing transition in the existing literature. Hence, it is necessary to construct a comprehensive indicator system that reflects the green manufacturing transition from the aspects of a nation’s economy, environment, resources, and their industrial structure.

Furthermore, there is lack of research on the convergence of China’s green manufacturing transition as a whole and in subregions [

28], which can hinder policy prescriptions. Of the limited studies in this area, Zhao et al.’s [

29] Chinese study on regional differences and convergence of green innovation efficiency in China showed that while regional differences between western and central regions were constricting, the eastern regions still lag somewhat behind. With respect to the Chinese manufacturing sector, Yan et al. [

28] analyzed differences in convergence characteristics of 29 manufacturing industries and identified that most green innovation efficiency comprised high-end technology. In terms of research purpose, this paper aims to objectively and accurately measure the level of green transformation in the manufacturing industry and analyze its convergence characteristics. The objectivity and scientificity of the entropy method can better meet this research purpose and ensure the reliability and credibility of the results.

To realize China’s goal to achieve high-quality economic growth, the manufacturing sector, which is the largest contributor towards growth, needs to meet its goal of green transition. Thus, it is of practical significance to also identify regional differences as it can provide differentiated policy strategies to arrive at an optimal outcome.

3. Measurement of Green Manufacturing Transition

3.1. Entropy Value Method

In view of the differences between the subjective and objective assignment methods for determining the weights in the comprehensive evaluation method, this paper adopts the latter method to ensure the objectivity and accuracy of the results. This approach determines the weights by analyzing the characteristics of the data itself [

30]. Specifically, the entropy method is employed due to the following reasons: First, as an objective weighting method, the determination of weights is completely dependent on the degree of variation in the indicators, rather than subjective judgment. This method can avoid the influence of human factors on the weight distribution and ensure the objectivity and scientificity of the results. Second, the entropy method is based on the concept of information entropy and can effectively measure the degree of dispersion of the indicators. For instance, the smaller the information entropy, the greater the degree of variation in the indicator and the greater its contribution to the comprehensive evaluation. Third, in terms of adaptability, the entropy method is suitable for multi-indicator comprehensive evaluation problems, especially when there are many indicators and significant differences among them. Therefore, since this research involves multiple dimensions and indicators, and comprises units and dimensions of each indicator which are different, the entropy method eliminates the dimensional differences through the standardization processing which can better adapt to such complex data characteristics.

Although other objective weighting methods were considered they were not employed due to their various limitations. For example, although the Analytic Hierarchy Process can comprehensively consider expert opinions, its weight distribution depends on subjective judgment and is easily influenced by the personal preferences and experience of experts, resulting in insufficient objectivity of the results. Another consideration was the Principal Component Analysis which can also extract main information. However, since its results depend on the distribution characteristics of the data, it may lose some important information when processing indicators. In addition, the PCA has certain requirements for the normality of the data, while the entropy method has lower requirements for data distribution. Finally, the CRITIC method was not considered since its calculation process is relatively complex and has higher requirements for the standardization processing of data. In contrast, the entropy method has a simpler calculation process and is easier to understand and operate. Given the above considerations, the objectivity and scientificity of the entropy method is best suited to ensure the reliability and credibility of the results.

The entropy method is employed on the panel data with the introduction of the time variable to measure the comprehensive level of green manufacturing transition. This is to achieve the comparability of the level of green manufacturing transition in different years. The detailed steps are outlined below:

Step one: select indicators. Suppose there are k years, i provinces, and j indicators, which represent the data corresponding to the j-th indicator of the i-th province in the k-th year.

Step two: standardize the indicators to eliminate the differences in dimensions and units between various indicators, ensuring the comparability of each indicator.

Of these, the and denote, respectively, the first indicator corresponding to the minimum and maximum values in all provinces for all years. Indicators are normalized to take values in the range (0, 1).

Step three: determine the weight e of the

j-th indicator for province

i in year

k. By calculating the information entropy of each indicator, the information utility value of each indicator is further calculated, and the weights are determined accordingly.

Step four: calculate the information entropy value s of the

j-th indicator. The dispersion degree and information volume of each index are quantified through information entropy, thereby providing a scientific basis for the subsequent allocation of weights. The smaller the information entropy is, the greater the degree of variation in this index, and the greater its contribution to the comprehensive evaluation is. The greater the information entropy is, the smaller the degree of variation in this index, and the smaller its contribution to the comprehensive evaluation is.

Among them, and .

Step five: calculate the information utility value

of the

j-th indicator. The value depends on the difference between the information entropy value s of the indicator and 1. The magnitude of an indicator’s informational utility significantly influences its weight assignment within the evaluation framework. The smaller the information entropy, the larger the information utility value, indicating that the degree of variation in the indicator is greater and its contribution to the comprehensive evaluation is also greater. Generally, indicators with higher utility values are deemed more critical in the overall assessment, consequently carrying a greater weight.

Step six: assign weights to the indicators

. This step standardizes the information utility value of each indicator to make it a weight that can be used for comprehensive evaluation.

Finally, figure out an integrated score h for each specimen. This step combines the weights of each indicator with the standardized indicator values, thereby obtaining a quantitative indicator that comprehensively reflects the overall level of the sample.

3.2. Indicator Selection and Data Sources

To more accurately assess the dynamic changes in the level of China’s green manufacturing transition from 2011 to 2021, specific evaluation indicators are selected according to the principles of comprehensiveness, systematicity, operability, scientificity, and effectiveness [

31,

32]. The selection of the four first-level indicators is based on a comprehensive consideration of multiple factors. The first factor, the existing literature, provides a theoretical basis for the selection of the four dimensions of environment, resources, economy, and industrial structure. For instance, research on the green transformation of the manufacturing industry, environmental, and resource indicators are widely regarded as hard indicators for measuring the success of green transformation (such as pollution emissions and resource consumption) [

8,

10,

20]. Moreover, many studies have verified the validity and importance of these indicators. The green transformation of the manufacturing industry needs to balance economic performance and environmental performance [

8]. Green innovation and efficient integration of resources are of great significance [

25]. The next factor for selection is related to policy relevance, where indicators are selected to better align with policy requirements and reflect the effects of policy implementation. For instance, policy documents such as the “14th Five-Year Plan for Industrial Green Development” and “Green Development in China in the New Era” explicitly state that the green transformation of the manufacturing industry is an important direction for industrial upgrading, emphasizing the importance of resource and environmental constraints and industrial structure adjustment. To ensure the effectiveness of the construction of indicators, the opinions of experts in the field were referred to. Experts recognized environmental and resource indicators as the basic indicators for measuring green transformation, while economic and industrial structure indicators reflected the sustainability and development direction of the transformation [

8,

19,

21].

Thus, a hierarchical model was constructed for the evaluation of the level of green manufacturing transition, which contains a total of four first-level indicators: (i) environmental; (ii) resource; (iii) economic; and (iv) industrial structure; along with 10 s-level indicators. These indicators are displayed in

Table 1.

Firstly, environmental and resource indicators are the rigid benchmarks for guiding the green manufacturing transition and for assessing whether the transformation is successful [

23]. They mainly encompass two aspects: pollution emissions and resource consumption. Pollution discharges are assessed based on three secondary indicators: the volume of wastewater discharged relative to the value of manufacturing output, the volume of waste gas emitted per unit of manufacturing output, and the volume of solid waste generated per unit of manufacturing output. The higher the values of these indicators, the greater the degree of environmental pollution, which in turn indicates a lower level of green manufacturing transition. Resource usage is appraised using three metrics: energy consumption ratio to manufacturing output value, water consumption ratio to manufacturing output value, and electricity consumption ratio to manufacturing output value. Higher values of these metrics correspond to a higher resource intensity in manufacturing, indicating a lower degree of green transformation.

Secondly, economic indicators are crucial for representing whether resources in green manufacturing transition are efficiently allocated and whether they can sustainably generate benefits. They reflect the outcomes of the manufacturing industry output and operational activities during the green transformation process. Two indicators are employed for assessment: the overall production value of the manufacturing sector and the increase in value added by the manufacturing sector. The larger the values of these indicators, the stronger the ability to create economic performance, and the higher the level of green manufacturing transition. Lastly, industrial structure upgrading is crucial to encourage green manufacturing transition. The evaluation of the industrial structure is conducted through two indicators: the proportion of clean industry output value and the proportion of high-tech industry output value in the manufacturing industry. The higher the values of these indicators, the more the structure of the manufacturing sector reflects an enhancement in the level of green transition.

The data for this paper comes from the Statistical Yearbook of 30 provinces (excluding Tibet, Hong Kong, Macao, and Taiwan due to missing data from these provinces), specifically, the China Statistical Yearbook on Environment, China Energy Statistical Yearbook, High-Tech Statistical Yearbook, and China Statistical Yearbook for the period of 2011 to 2021. The individual missing data are processed by the linear interpolation method, and the data of the corresponding price indicators are also deflated to obtain more accurate conclusions. To achieve this, the subtraction treatment was employed on the indicators to adjust them to the same price level, thereby reflecting the actual economic changes more accurately. This enables a better comparison across time, ensuring the accuracy and reliability of the research results. Specifically, we used the price level of 2011 as the base period and adjusted the data from 2012 to 2021 to this base period level. To ensure the reliability and robustness of the fixed effect estimates, the study conducted Hausman, Robustness, serial-correlation and heteroskedasticity, model-diagnostic, multicollinearity, endogeneity, and sensitivity tests.

3.3. Estimation Results of Green Manufacturing Transition

After processing the data during the sample period using the entropy method, the comprehensive scores and rankings of China’s green manufacturing transition from 2011 to 2021 were obtained (refer to

Table 2), where the higher the score, the higher the level of green manufacturing transition. The average comprehensive score of China’s green manufacturing transition from 2011 to 2021 increased markedly, rising from 0.279 to 0.368. This represented an overall average increase of about 32%, indicating that the overall level of China’s green manufacturing transition has drastically improved. It is worth noting that the average comprehensive score of the green manufacturing transition reached a peak in 2016, possibly due to the combined effects of green manufacturing transition orientation and policy effects. Among them, the “Made in China 2025” action plan which emphasized “green manufacturing” as an important focus for building a strong manufacturing country, continuously promoting the improvement of China’s green manufacturing transition level.

From the point of view of regional differences, the comprehensive scores among the manufacturing industry in the eastern region are higher than the national average, while the comprehensive scores in the central and western regions are lower than the national average. In fact, the average score of green transition for the eastern manufacturing industry (0.445) was two times greater than the western region (0.226) and over 40% more than the central region (0.317). All three regions showed a distinct gap between them regarding the green transition level of their manufacturing industries. This disparity not only reflects the differences among various regions in terms of resource endowment, economic development level and policy support, but also highlights the significance of regional coordinated development and enhancing the degree of openness to the outside world. These insights provide an important reference basis for formulating differentiated green development strategies and promoting coordinated development among regions.

With respect to provinces, not surprisingly, seven of the top ten highest scoring provinces came from the eastern region. Conversely, seven of the poorest scoring provinces regarding green manufacturing transition were located in the western region. The highest scoring province was the Guangdong province located in the eastern region with an average score value of 0.725, while the lowest scoring province was the Qinghai province located in the western region with an average score of 0.115. Thus, Guangdong has an average score that is more than six times higher and further embodies the differences between the two regions.

The results show that both the inter-regional and inter-provincial level of green manufacturing transition has significant differences. From this, the following insights are obtained. First, the impact of resource endowment on the level of economic development. As a key development target of the country, the eastern region has attracted a large amount of capital, high-tech talents, and innovative industries, occupying a geographical advantage and obtaining sufficient production factors. Therefore, it has performed outstandingly in the green transformation of manufacturing. Although the central region lags behind the eastern region in terms of economic development and resource endowment, it is also actively promoting green transformation and has made certain progress. However, the overall level is still lower than that of the eastern region. The western region is restricted by its economic level, science and technology, and production resources. The degree of green transformation in the manufacturing industry is relatively low, and the overall level lags.

Second, the role of policy and market factors. The eastern region has advantages in policy support and resource allocation and can promote the green transformation more effectively. For instance, in 2015, China put forward the aforementioned action plan of “Made in China 2025”, emphasizing “green manufacturing” as an important focus for building manufacturing power. The eastern region has been more proactive in policy implementation and resource input. The eastern region has a developed economy, and market demand has a higher preference for green products and services. Enterprises have a stronger motivation to carry out green transformation to meet market demand and enhance competitiveness.

Third, the necessity of regional coordinated development. The significant gap in the level of green transformation among regions indicates that there is an obvious regional imbalance in the green transformation of China’s manufacturing industry. This imbalance may further exacerbate the gap in regional economic development and affect the overall green transformation process of the country. The paper suggests implementing a differentiated green development strategy, with developed regions driving developing regions. Through the flow of factors and knowledge spillover, it promotes coordinated development among regions. For instance, the eastern region can export green technologies and management experience to the central and western regions, helping them enhance their level of green transformation.

Finally, the paper points out that enhancing the degree of openness to the outside world is a key factor that promotes the convergence of the green transformation of China’s manufacturing industry. Due to its high degree of openness, the eastern region can better attract foreign investment, introduce green technologies and talents, thereby promoting green transformation. However, due to the relatively low degree of openness in the central and western regions, it is necessary to further enhance the level of openness to the outside world to promote green transformation.

4. Convergence Analysis of Green Manufacturing Transition

4.1. Research Methodology

Convergence represents the law that the differences gradually decrease with the passage of time, and the commonly used convergence analysis methods are generally

σ-convergence, absolute

β-convergence, and conditional

β-convergence [

21]. The combination of the absolute

β convergence model and the conditional β convergence model can analyze the convergence of the green transformation of the manufacturing industry from different perspectives. The absolute β convergence model provides a basic judgment of convergence, while the conditional β convergence model further reveals the real convergence situation under the influence of external factors. The combination of the two can more comprehensively reflect the regional differences and dynamic changes in the green transformation of China’s manufacturing industry.

Under this approach,

σ convergence represents the trend of gradual reduction in the gap between the green manufacturing transitions in each region. In this paper, the σ coefficient reflects the dynamic evolution trend of the gap between China’s green manufacturing transition, and the

σ convergence model is as follows.

Among that, denotes the σ coefficient of province i in year t denotes the composite green transition score of the manufacturing sector in year t for province i; is the number of provinces in the sample; and denotes taking the natural logarithm of the composite score of green manufacturing transition.

The

β-convergence of green manufacturing transition means that the speed of manufacturing green transition in different provinces is negatively correlated with the level of manufacturing green transition. Based on whether to consider the conditions of convergence, the

β-convergence of manufacturing green transition in China can be classified into absolute

β-convergence and conditional

β-convergence. Absolute

β-convergence indicates that the green transition of manufacturing industry in all provinces of China will converge at the same steady-state equilibrium point, while conditional

β-convergence indicates that there are many factors affecting the rate of change in China’s green manufacturing transition. However, the differences among them are still gradually shrinking. Referring to the existing research [

22,

23], the absolute

β-convergence model of manufacturing green transition is constructed as follows.

Based on the absolute

β-convergence model, the control variables related to green manufacturing transition are introduced, i.e., the conditional

β-convergence model is shown below.

In Equations (9) and (10), is the average growth rate of during the period t to in province i, while is the constant term, and is the error term. denotes the level of manufacturing green transition in province i in year t. is the corresponding convergence coefficient. If β < 0, the development of manufacturing green transition tends to converge, i.e., the speed of manufacturing green transition shows a faster downward trend in the provinces with higher initial manufacturing green transition level. If β > 0, the development of manufacturing green transition tends to diverge, and the gap of manufacturing green transition gradually expands in each region. and denote the individual effect and time effect, respectively. In Equation (10), denotes the relevant control variables, and denotes the regression coefficient of each control variable.

4.2. σ-Convergence of Green Manufacturing Transition

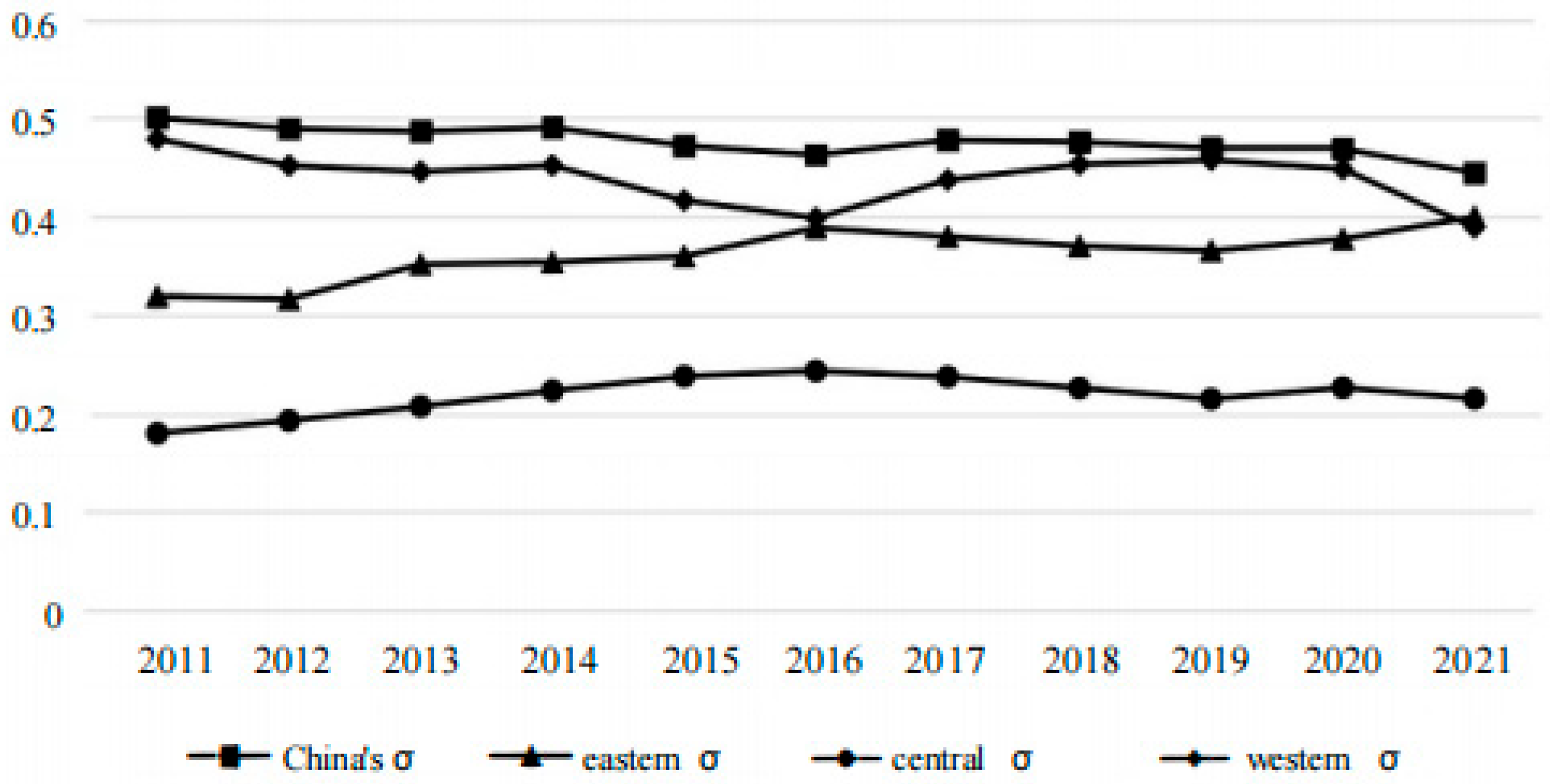

Based on the comprehensive score of China’s green manufacturing transition, the σ coefficients of China’s whole country, the eastern region, the central region, and the western region, were calculated, respectively, using Equation (8), and the trend of their changes was plotted as a line graph (e.g.,

Figure 1).

From the national point of view, from 2011 to 2021, China’s green manufacturing transition σ coefficient over time shows a significant downward trend. Thus, there is a significant σ convergence, indicating that the sample period of China’s green manufacturing transition results shows a continuous reduction in the absolute gap between the various provinces. However, this trend of narrowing the gap does not necessarily mean that the development level of green manufacturing transition in all regions of China is absolutely narrowed. Rather, the narrowing of the gap may be based on two reasons: one is that the higher degree of green manufacturing transition is converging to the lower regions, and the other is that the lower degree of green manufacturing transition is converging to the higher regions.

Regionally, the convergence trend in the eastern and central regions is relatively similar, with the σ coefficient showing an increasing trend from 2011 to 2016. This indicates that the gap between the green manufacturing transition in the eastern and central regions of China tends to be dispersed at this stage, i.e., there is no σ convergence. The degree of dispersion of the green manufacturing transition in the central and eastern regions shows a decreasing trend post-2016, reflecting the σ-convergence characteristic of the green manufacturing transition in these two regions at this stage. The σ coefficient of green manufacturing transition in the western region experienced a fluctuating process of change, with a decline, then rise, and then another decline. The overall performance of the σ convergence characteristics shows that the overall green manufacturing transition gap is significantly narrowed, but the gap is different at different stages. In fact, the gap of the green manufacturing transition in the western region was significantly narrowed from 2011 to 2016, where the significant σ convergence characteristics post-2016 suggest that the green manufacturing transition gap tends to diverge as there are no σ convergence characteristics.

Nationwide, the σ convergence of China’s green manufacturing transition is noteworthy, with the variance continuously decreasing over time. To clarify the deep-seated reasons for the narrowing gaps, further analysis of absolute σ-convergence and conditional σ-convergence is conducted to clarify whether there is a “catch-up effect” in different regions.

4.3. β Convergence for Green Manufacturing Transition

4.3.1. Absolute β-Convergence Analysis

For the absolute

β-convergence results for 2011 to 2021 in

Table 3, the Hausman test was performed and showed that a fixed effects (FE) model was considered more adaptable. Moreover, the results demonstrated that, from the national level, there is an absolute

β-convergence feature in the level of green manufacturing transition in each province. This suggests that there is a tendency for provinces with low levels of green manufacturing transition to catch up with provinces with high levels of green manufacturing transition. From the regional level, the

β coefficients in the eastern, central, and western regions are all less than 0 at the significance level, indicating that there is an absolute

β-convergence feature in the level of green manufacturing transition in each region, and that the green manufacturing transition among the provinces in the region is converging at the same steady-state equilibrium point, with the difference between provinces to be continuously reduced. From a convergence speed perspective, the quickest convergence was experienced by the central region, with the slowest being the eastern region who failed to reach the average level of the national convergence speed.

4.3.2. Conditional β-Convergence Analysis

In order to further analyze the conditional

β-convergence of the level of green manufacturing transition, this paper draws on the methodology of Li et al. [

24] to include the degree of openness to the outside world

, environmental regulation intensity

, foreign direct investment level

, and the level of human capital

. These four control variables are introduced into the FE model.

When choosing the control variables in the conditional β convergence model, we mainly base our selection on the theoretical analysis of the influencing factors of the green transformation of the manufacturing industry and the summary of existing research. The selection of these control variables has clear economic and policy grounds as evidenced by the following:

A higher degree of openness means that a region can more easily obtain advanced international green technologies and management experiences, thereby promoting the green transformation of the manufacturing industry. The existing research indicates that the degree of openness to the outside world can significantly promote the green transformation of the manufacturing industry (e.g., [

21]). Therefore, taking the degree of openness to the outside world as a control variable can better analyze its promoting effect on the green transformation of the manufacturing industry.

- 2.

Intensity of Environmental Regulation

Environmental regulation is an important tool for the government to constrain and standardize the environmental behavior of manufacturing production activities through policy means. For example, the revision and implementation of the “Environmental Protection Law” have put forward higher requirements for the environmental behavior of manufacturing enterprises. This is supported by empirical research as per Lei Yu et al. [

19] who found that environmental regulation can significantly affect the green transformation of the manufacturing industry.

- 3.

Level of Foreign Direct Investment (FDI)

The inflow of FDI can promote technology diffusion and industrial upgrading, thereby driving the green transformation of the manufacturing industry. The existing research indicates that FDI can significantly promote the green transformation of the manufacturing industry (e.g., [

21]). Therefore, taking the level of FDI as a control variable can better analyze its promoting effect on the green transformation of the manufacturing industry.

- 4.

Level of Human Capital

Human capital is a key factor in promoting technological innovation and industrial upgrading where great importance is attached to education and talent cultivation. This improves the quality of the labor force and provides talent support for the green transformation of the manufacturing industry. As Li Xiao [

20] found, the improvement of human capital can significantly promote the green transformation of the manufacturing industry. Therefore, taking the level of human capital as a control variable can more accurately analyze its impact on the green transformation of the manufacturing industry.

To reduce the degree of sample heteroskedasticity, each control variable is logarithmically treated. As shown in

Table 4 of the test results, the national as well as the eastern, central and western regions’

coefficients are all significantly negative. This implies that under the condition of controlling individual variables, the level of green manufacturing transition in each region has significant conditional

-convergence characteristics. Furthermore, it also suggests that each region’s green transition development converges towards its own steady-state level. From the convergence speed, the result was similar to the national average convergence speed insofar as the quickest convergence was from the central region, with the western region next, and the slowest being the eastern region.

In addition, the level of human capital has a significant negative impact on the level of green manufacturing transition in the national as well as the eastern and western regions. This may be attributed to the fact that the increase in the level of human capital at the early stages of the green manufacturing transition greatly increases the cost of enterprises and thus has a “crowding out” effect on the green inputs to the manufacturing industry. This, in effect, inhibits the enhancement of the level of green manufacturing transition. Conversely, a positive impact on the green transition was evident with the degree of openness to the outside world. Here, the more open a region, the better the green manufacturing transition. A potential reason for this is that higher levels of openness to the outside world can improve the overall level of economic development of the region which further promotes the level of green manufacturing transition.

5. Main Conclusions and Recommendations

5.1. Conclusions

An evaluation index system of green manufacturing transition which included 10 indicators was constructed from the consideration of four dimensions: environment, resources, economy, and industrial structure. The level of green transformation of China’s green manufacturing transition from 2011 to 2020 was measured by the entropy method, and the convergence characteristics of green manufacturing transition was also examined by using the σ-convergence and β-convergence models.

The results demonstrated a significant increase in the level of China’s green manufacturing transition between 2011 and 2021, especially in 2016, when the level of China’s green manufacturing transition reached the highest level, which indicates that the effectiveness of China’s recent green development strategies is evident. Given the differences in resource conditions and economic development in various regions, the level of green manufacturing transition shows significant differences, with the eastern region being significantly higher than the central and western regions.

From a convergence characteristics perspective, there are different σ convergence and β convergence characteristics. Specifically, there is a significant σ convergence in the development of green manufacturing transition in the whole country and the western region, while the trend of σ convergence in the east and middle regions is not obvious. For β convergence, there is a significant absolute β convergence in the development of green manufacturing transition in the whole country and for all three regions. For conditional β convergence, there is a significant catch-up effect between the regions, in which the central region had the quickest convergence rate, followed by the western region, and then the eastern region. The reason for the significant differences in the regional convergence speed of China’s manufacturing industry’s green transformation lies in the fact that the central region can quickly absorb the technological diffusion and knowledge spillover from the eastern region. Moreover, the industrial structure in the central region is relatively simple, and the difficulty of transformation is relatively small. At the same time, by taking advantage of the country’s policy support and resource allocation, the level of human capital has rapidly improved, giving full play to the late-mover advantage.

Although the speed of convergence of the regions is inconsistent, they all tend towards their own steady-state level of convergence. Compared with other related studies, such as those that define the green transformation of manufacturing as a reduction in pollution emissions, structural upgrading, and an increase in green total factor productivity, it is evident that the overall trends are largely consistent. However, discrepancies in specific values remain observable. These differences can primarily be attributed to variations in data sources, indicator selection, and methodological approaches [

33]. Furthermore, considering the real-world context of China’s manufacturing sector, this study identifies and analyzes the unique challenges encountered during its green transformation process, including regional development imbalances, an irrational industrial structure, and insufficient technological innovation capabilities. Based on these findings, targeted solutions and policy recommendations are proposed.

5.2. Recommendations

First, a comprehensive investigation into the underlying causes of regional disparities in the green transformation of the manufacturing industry is warranted. For instance, from the perspective of regional resource heterogeneity, it is essential to analyze how differences in natural resources, human capital, and technological resources across regions influence the trajectory and pace of the green transformation of the manufacturing industry. Additionally, from the standpoint of regional economic complexity and industrial interdependence, this paper examines the structural differences in industries across regions and investigates how inter-industry correlation effects either hinder or facilitate the process of green transformation. Such analyses can provide a robust theoretical foundation for formulating more targeted and differentiated regional green development strategies.

Second, there is a need to enhance scientific inquiry into green technology innovation and diffusion. The core of the green transformation of the manufacturing industry lies in the advancement and dissemination of green technologies. The “catch-up” effect highlighted in this study, along with regional disparities in convergence rates, indicates significant variations in the diffusion and absorption of green technologies across regions. Future studies could further investigate the mechanisms of green technology innovation and deeply explore ways to accelerate the research, development, and innovation of green technologies through policy incentives and collaboration among industry, academia, and research institutions. Simultaneously, the diffusion patterns of green technologies across regions should be studied, with a focus on key influencing factors such as economic linkages, information flow, and talent mobility between regions, thereby providing a scientific basis for promoting the efficient nationwide diffusion of green technologies.

Third, expanding the multi-disciplinary research perspective on the green transformation of the manufacturing industry is crucial. Although this study constructed an evaluation index system from four dimensions: environment, resources, economy, and industrial structure, there remains potential for further expansion. Subsequent research could draw upon methodologies and theories from various disciplines to examine the green transformation of the manufacturing industry from a broader macro, micro, and integrated perspective. For example, from an environmental science perspective, in-depth research could be conducted on the long-term impact of the green transformation on the ecological environment and its feedback mechanisms. From a sociological perspective, the influence of the green transformation on employment structures and social equity, as well as strategies for promoting sustainable social development through synergistic policies, could be explored. From a management perspective, the mechanisms by which enterprise-level green management practices and strategic decisions affect the green transformation of the manufacturing industry could be investigated. Through interdisciplinary research, a more comprehensive understanding of the inherent laws governing the green transformation of the manufacturing industry can be achieved, offering stronger theoretical support for the formulation of comprehensive green transformation policies.

Finally, attention must be paid to dynamic balance and sustainability during the green transformation process. Research findings indicate that while the overall level of green transformation in China’s manufacturing industry is improving, regional disparities persist. It is recommended that future studies, while emphasizing the speed and effectiveness of green transformation, also prioritize dynamic balance and sustainability throughout the process. For example, strategies could be developed to elevate the green transformation of the manufacturing industry in the eastern region to a higher level without exerting excessive resources or technological pressure on the central and western regions, thereby achieving regional coordinated development. Furthermore, the stability of ecosystems and biodiversity should be maintained during the pursuit of economic and environmental win-win outcomes, avoiding ecological imbalances caused by overemphasis on green transformation. Additionally, the dynamic relationship between the green transformation of the manufacturing industry and societal sustainable development could be explored, such as ensuring the continuous improvement in residents’ quality of life during the green transformation process and achieving balanced development among the economy, environment, and society, thus providing empirical support for constructing a scientific theoretical framework for sustainable development.

5.3. Limitations and Future Lines of Research

When interpreting the research results, readers should be aware of several potential limitations and uncertainties related to the data and models used. These limitations may affect the robustness and general applicability of the research results. For instance, missing data were interpolated to fill in the blanks which might cause errors or deviations in the analysis. Also, since the data are derived from multiple statistical yearbooks and professional reports (such as environmental, energy, and high-tech statistical reports), differences in data collection methods, definitions, and reporting standards may lead to data inconsistency.

Although the paper has constructed an indicator system from four dimensions, environment, resources, economy, and industrial structure, some key factors may not have been fully considered. For instance, indicators such as green financial support may have a significant impact on the green transformation of the manufacturing industry, but they are not included in the existing indicator system. Future research will introduce more indicators reflecting key factors such as green technological innovation and green financial support on the basis of the existing indicator system.

At present, the evaluation index system for the green transformation of the manufacturing industry has not been completely unified, and there may be significant differences among different studies. Establishing a standardized and highly operational indicator system can provide a unified assessment standard for the green transformation of different regions and industries. With the advancement of green transformation and the development of technology, the indicator system needs to be constantly updated and optimized to reflect the latest dynamics and trends of green transformation.

This study employed a fixed effect model to control for unobserved heterogeneity among provinces. Although this method is applicable to panel data, it assumes that the unobserved influencing factors are constant over time and do not interact with the explanatory variables. If there are unobserved factors that vary over time affecting the green transition, then the fixed effect model may not be able to fully capture these influences.

Suggestions for further research include conducting a long-term analysis with dynamic tracking research to assess the trends and changing factors of green manufacturing transition, as well as the consideration of more influencing factors such as social culture, consumption behavior, and international trade to build a more comprehensive research model. Furthermore, studies should focus on strengthening regional difference studies by exploring the characteristics and pathways of the manufacturing industry’s green transition in different regions.