Research on Innovative Design of Two-in-One Portable Electric Scooter Based on Integrated Industrial Design Method

Abstract

1. Introduction

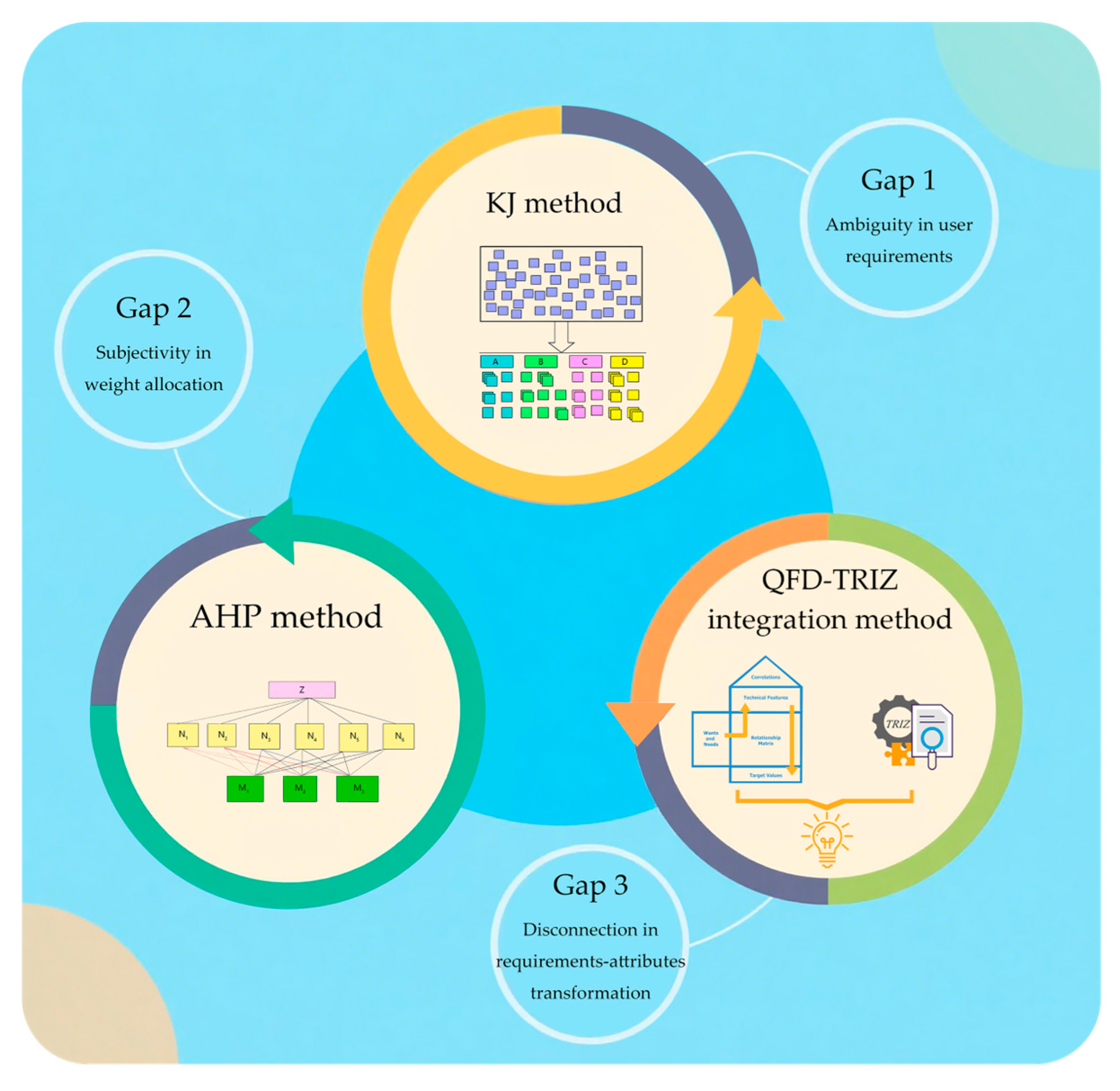

2. Research Methods

2.1. Theoretical Model

2.2. Rationale for Methodological Selection

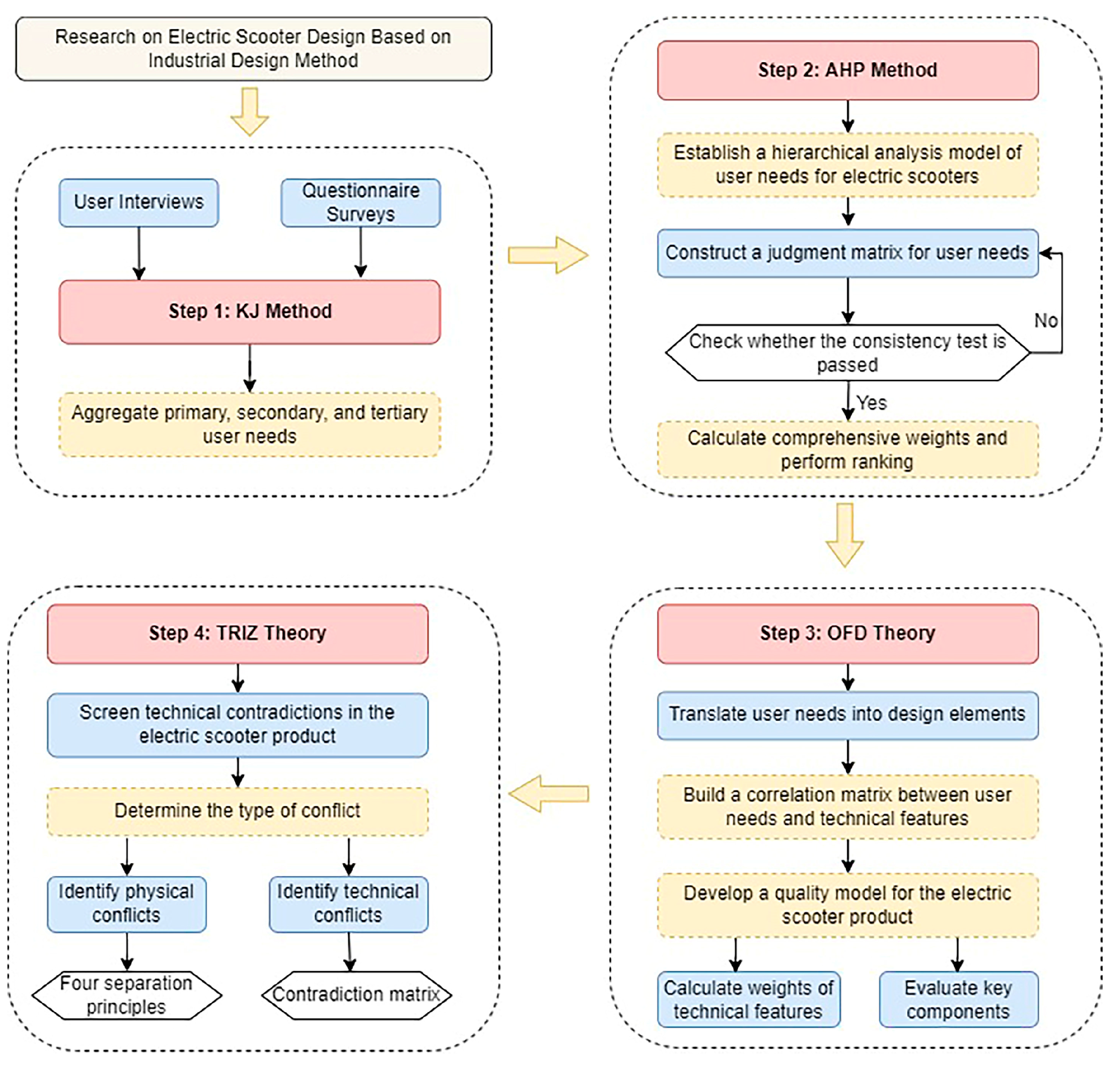

2.3. Research Framework

3. Results

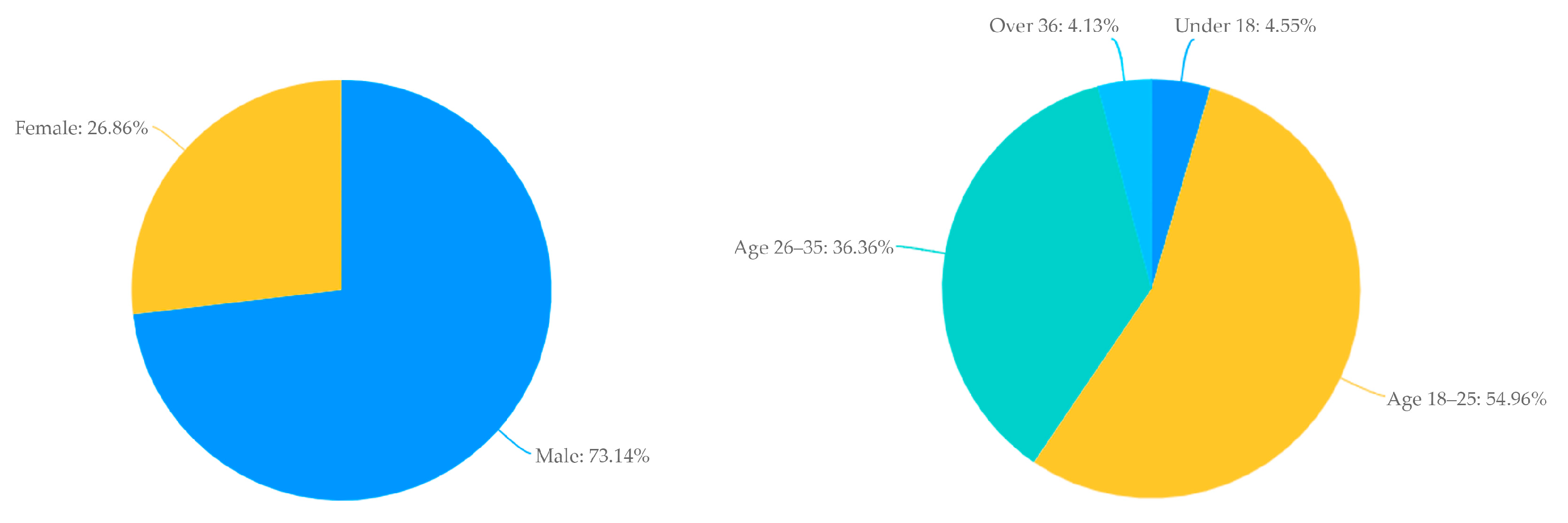

3.1. User Requirements Analysis of Electric Scooters Based on the KJ Method

3.1.1. User Requirements Collection

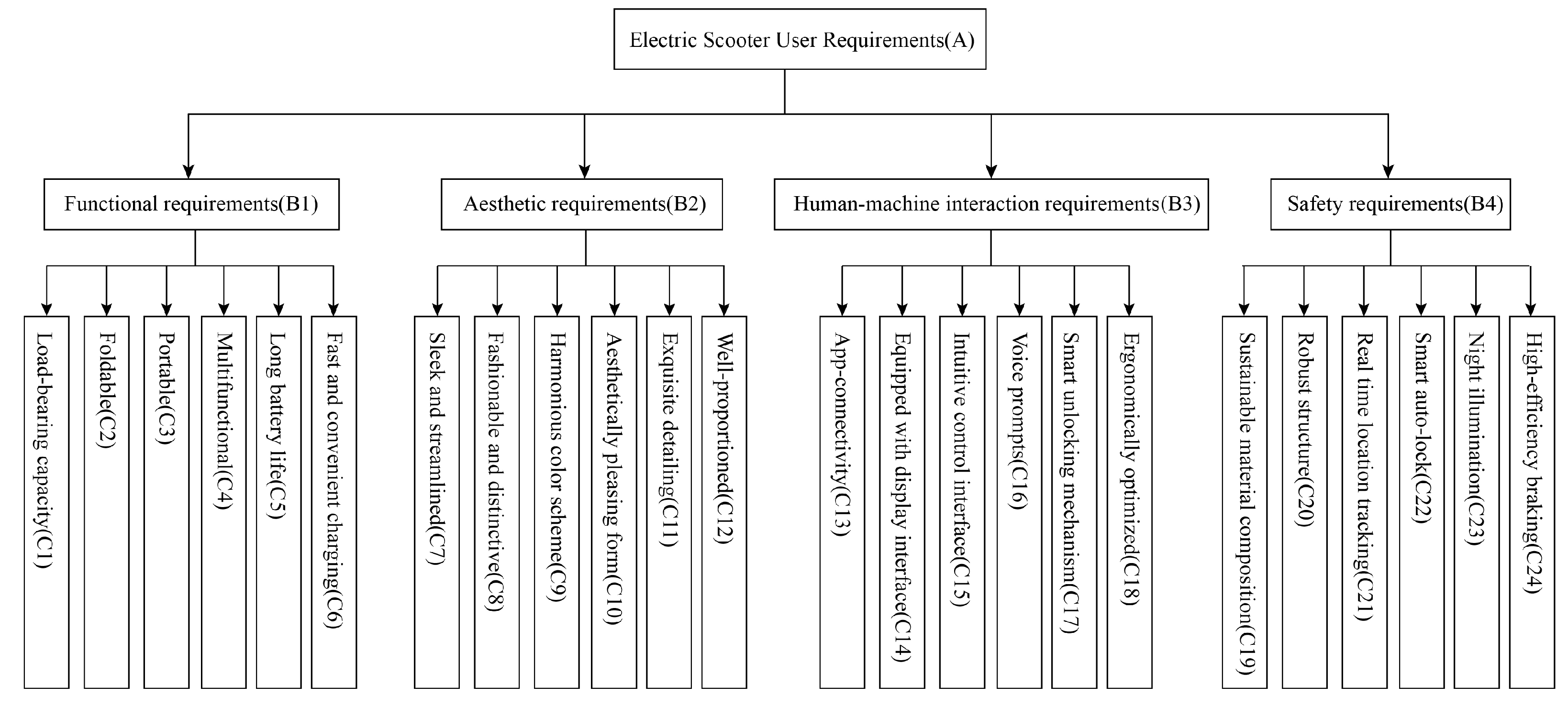

3.1.2. KJ Analysis and Demand Categorization

3.2. AHP Model Construction and Weighting

3.2.1. AHP Model Construction

3.2.2. Judgment Matrix Formation and Weight Calculation

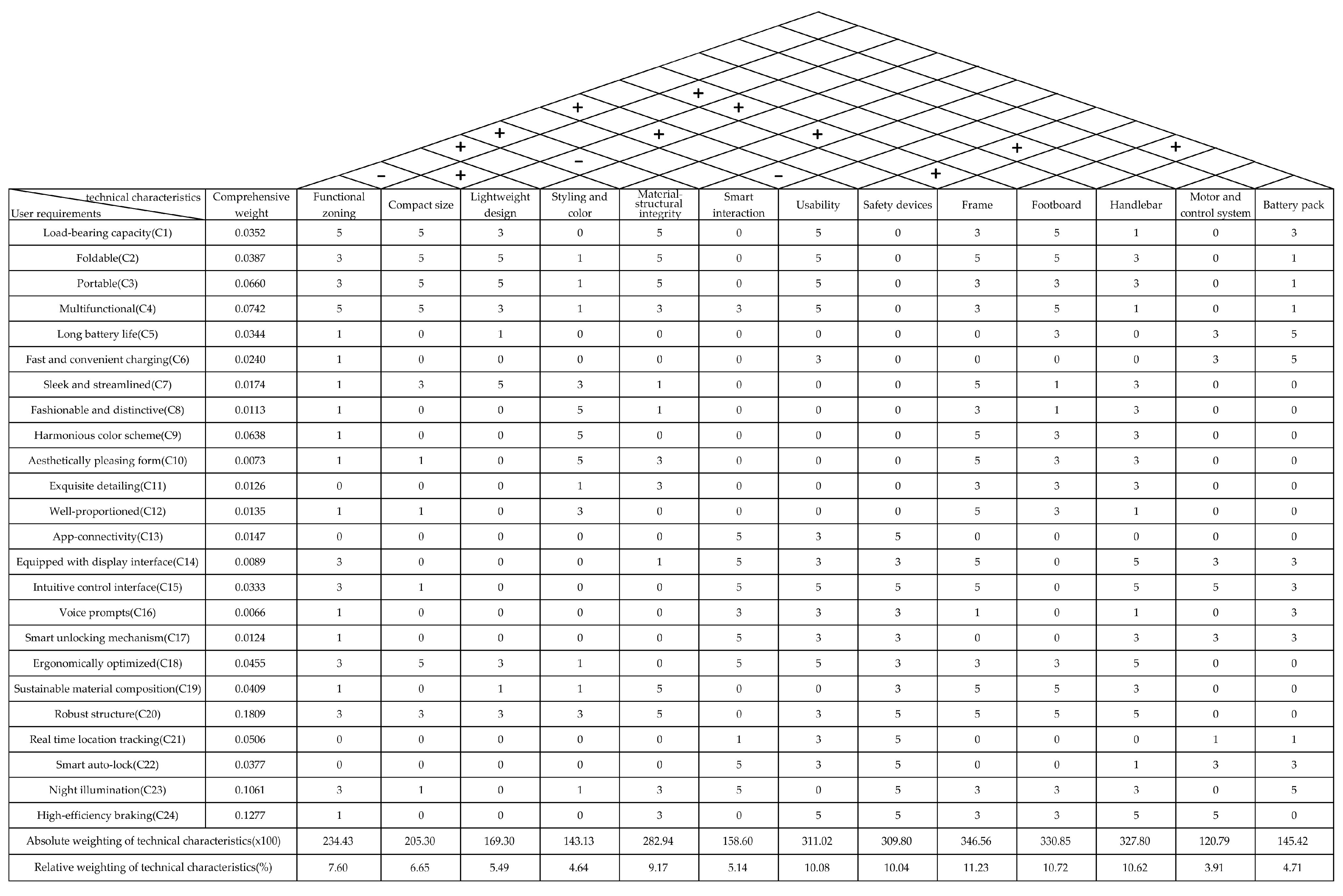

3.3. Electric Scooter Design Strategy Based on the Integrated Theory of QFD and TRIZ

3.3.1. Construction of HoQ Model for Electric Scooter Products

3.3.2. Contradiction Analysis Based on TRIZ Theory

- (1)

- Functional zoning versus compact size

- (2)

- Lightweight design versus material/structural integrity

- (3)

- Smart interaction versus usability

3.3.3. Conflict Resolution (TRIZ-Based Problem Solving)

- (1)

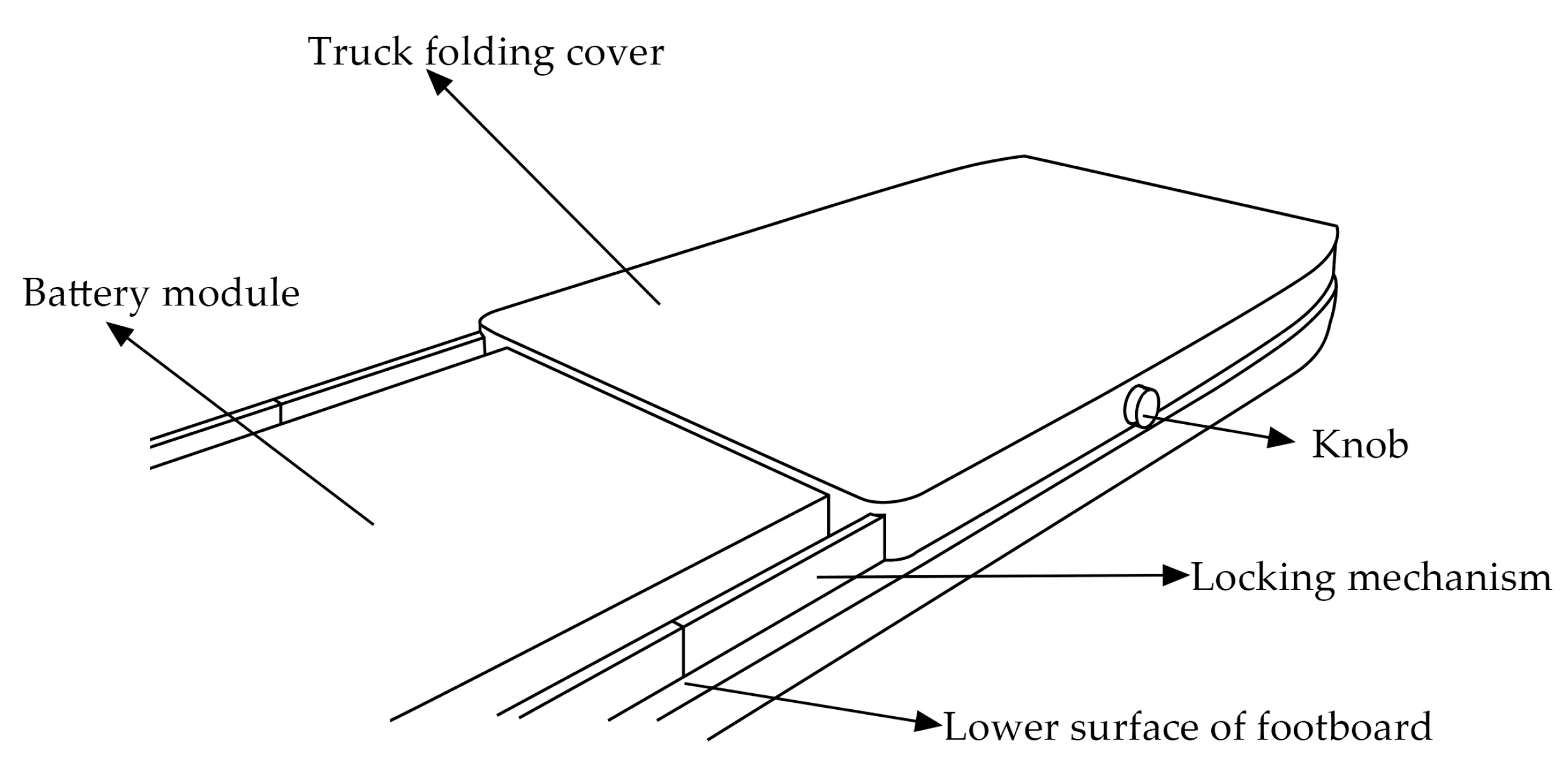

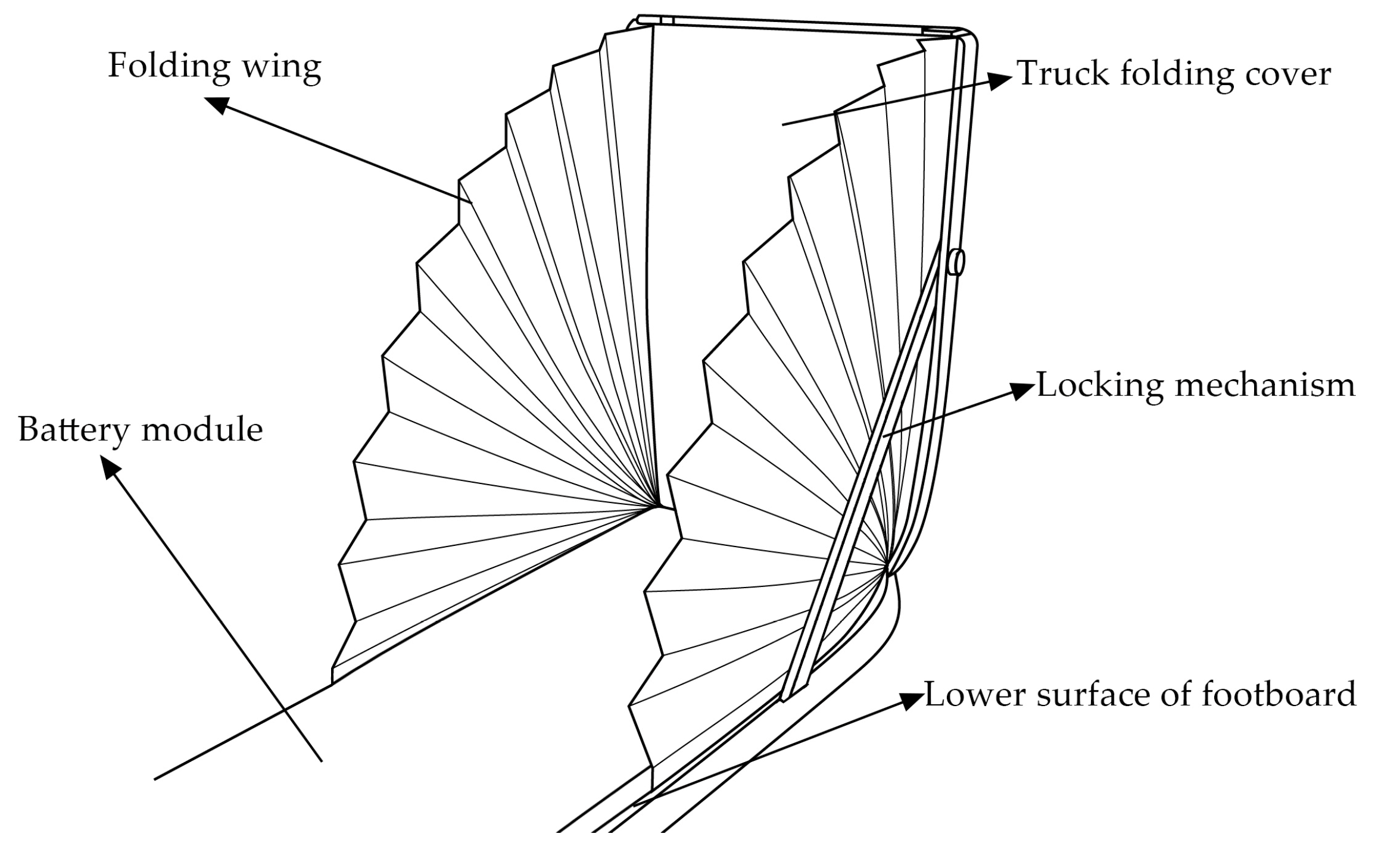

- Applying the Physical Contradiction Resolution Theory to Address the Tension Between Functional Zoning and Compact Size.

- (2)

- Application of Technical Contradiction Resolution Theory to Address the Dilemma Between Lightweight Design and Material/Structural Integrity.

- (3)

- Employing Technical Contradiction Resolution Theory to Reconcile the Tension Between Smart Interaction and Usability.

4. Design Practice

4.1. Design Development

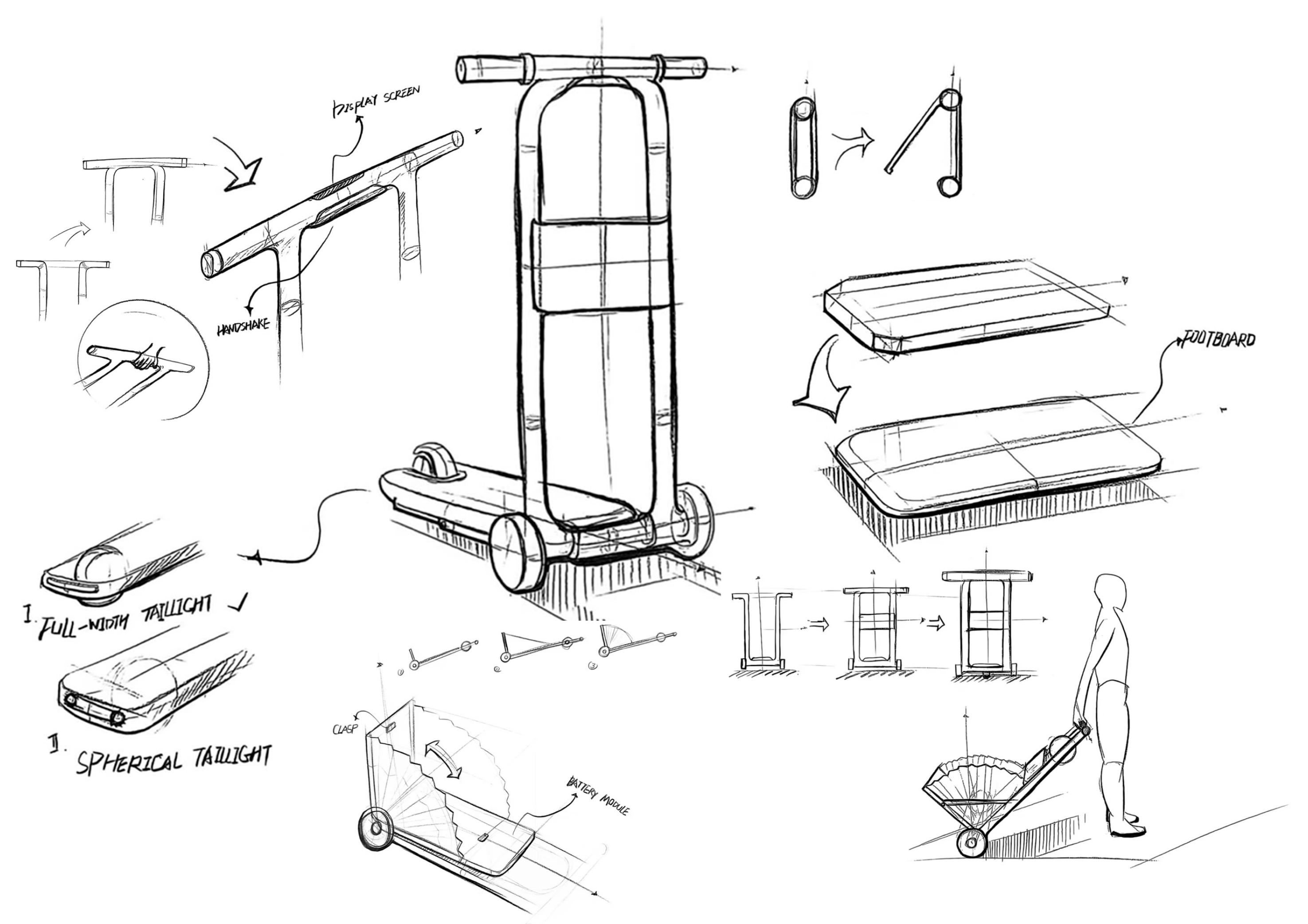

4.1.1. Conceptual Sketch Design

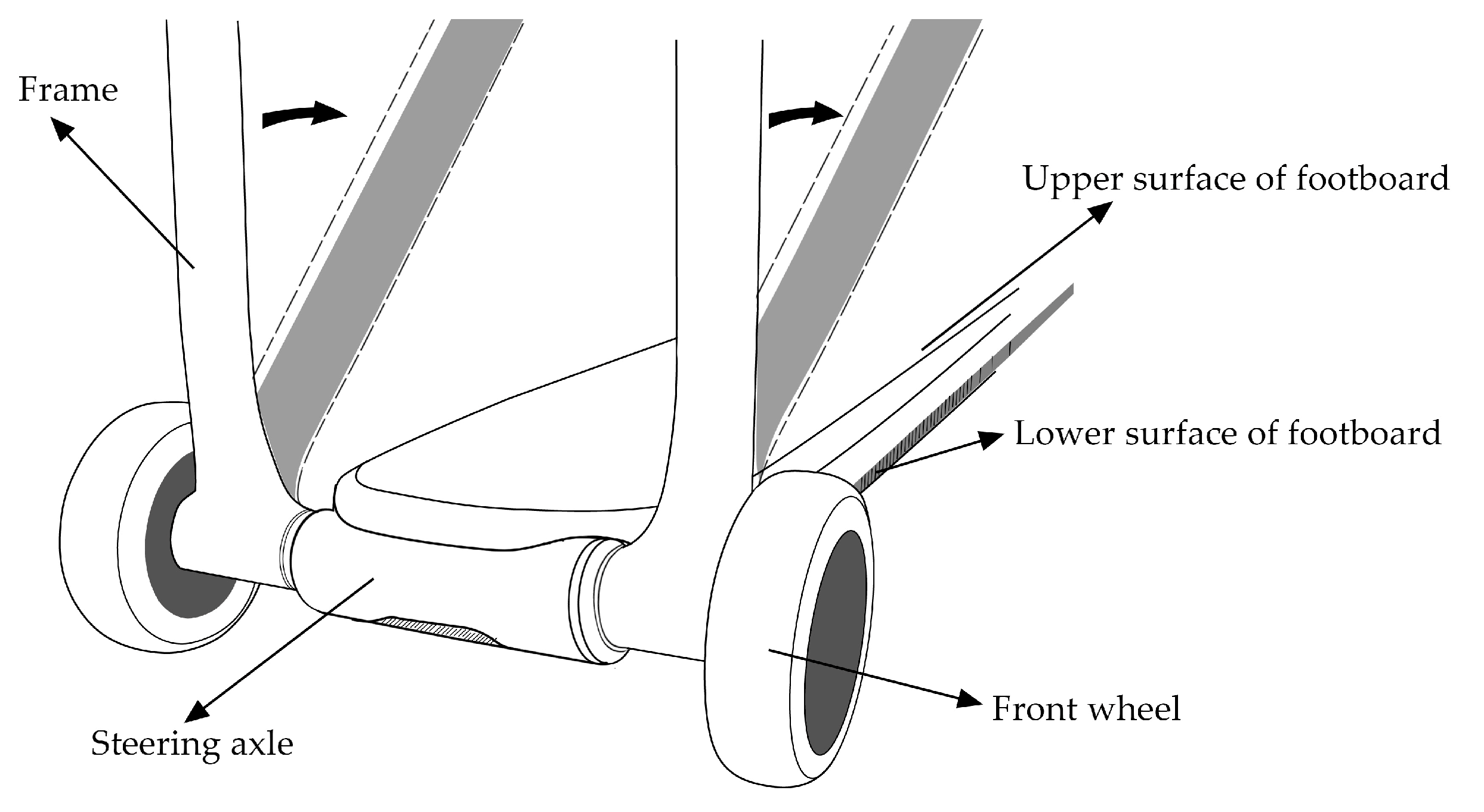

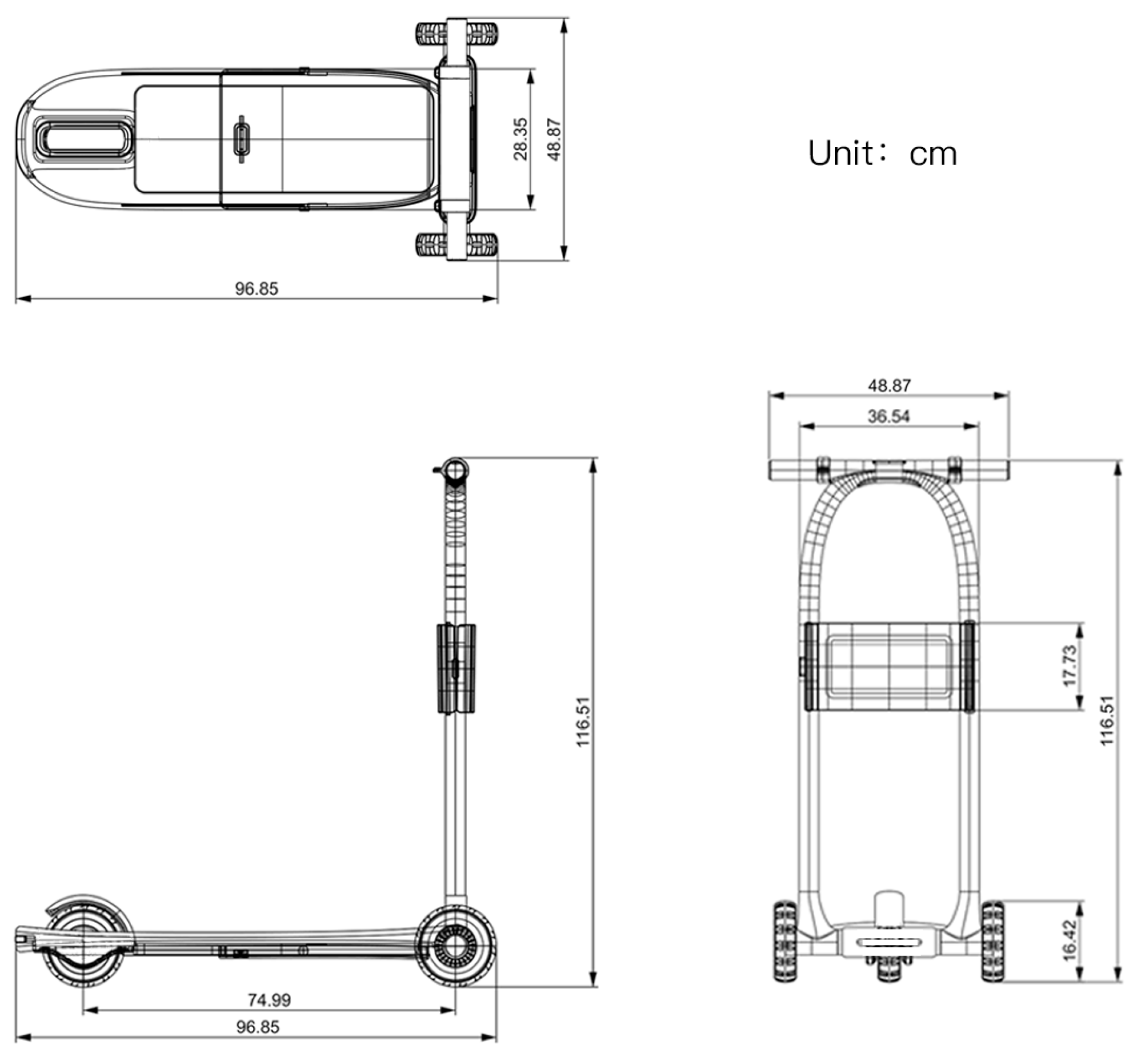

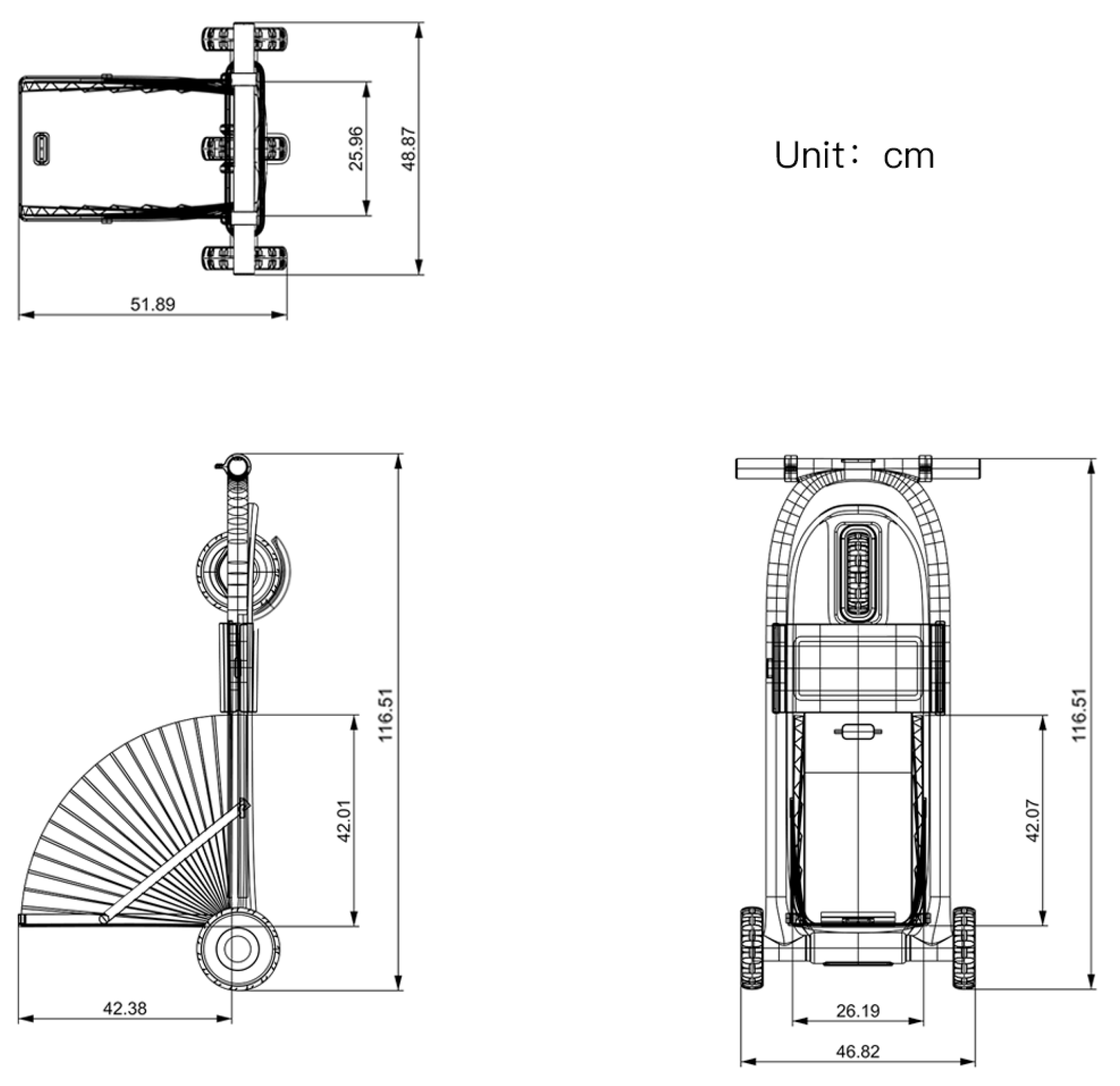

4.1.2. Ergonomic Analysis of Electric Scooter

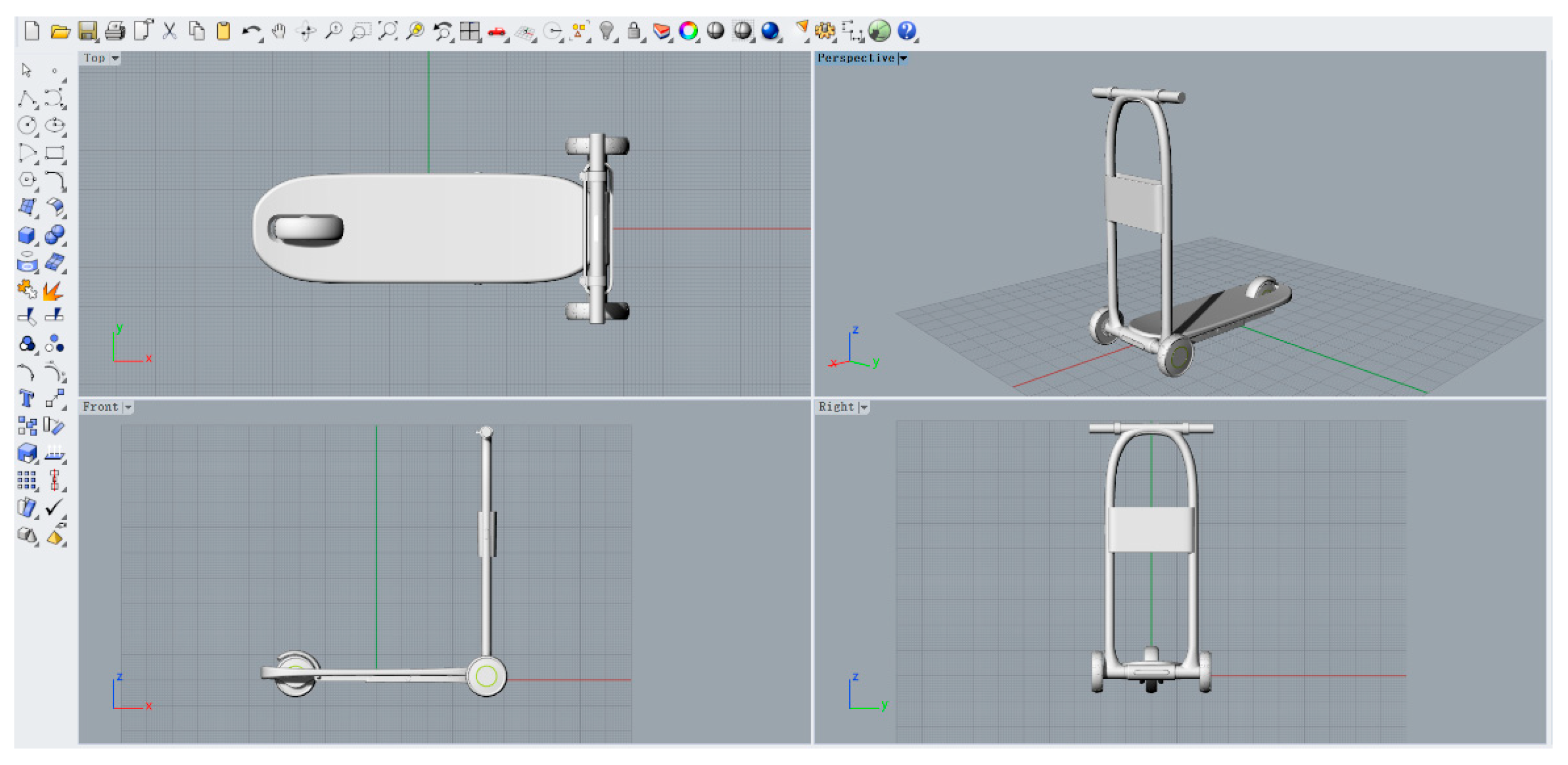

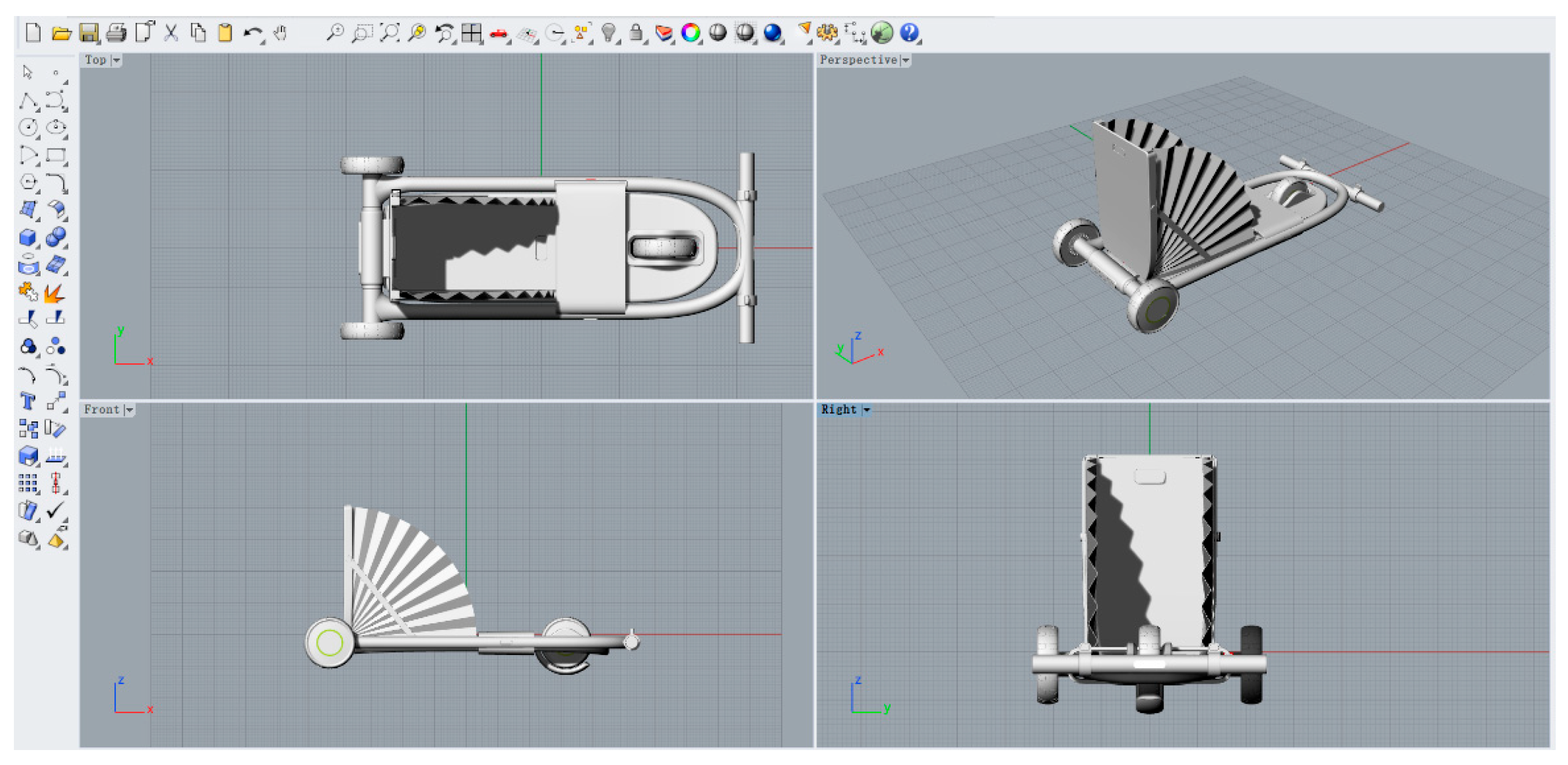

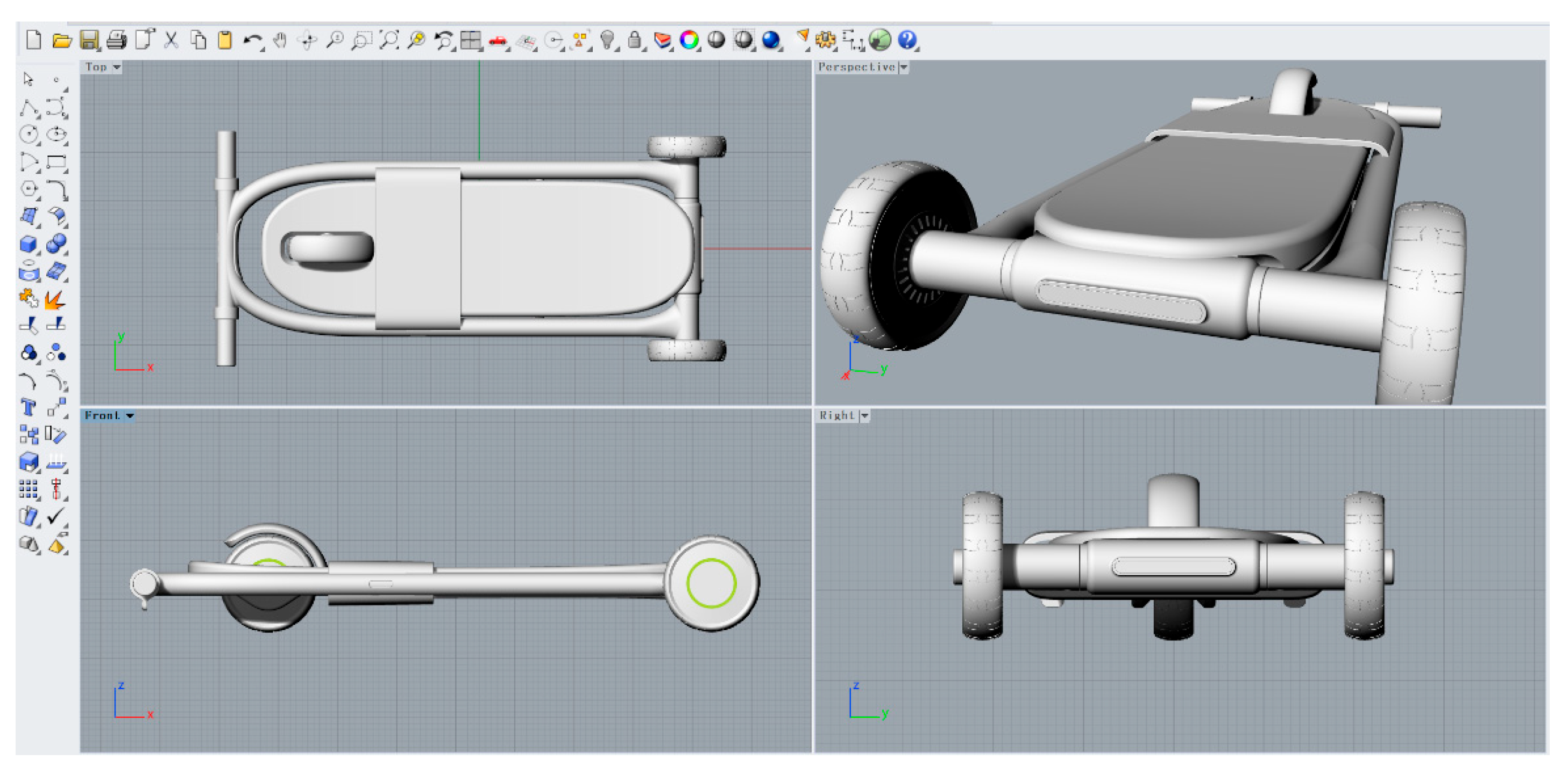

4.1.3. Digital Modeling of 2-in-1 Electric Scooter

4.2. Final Design

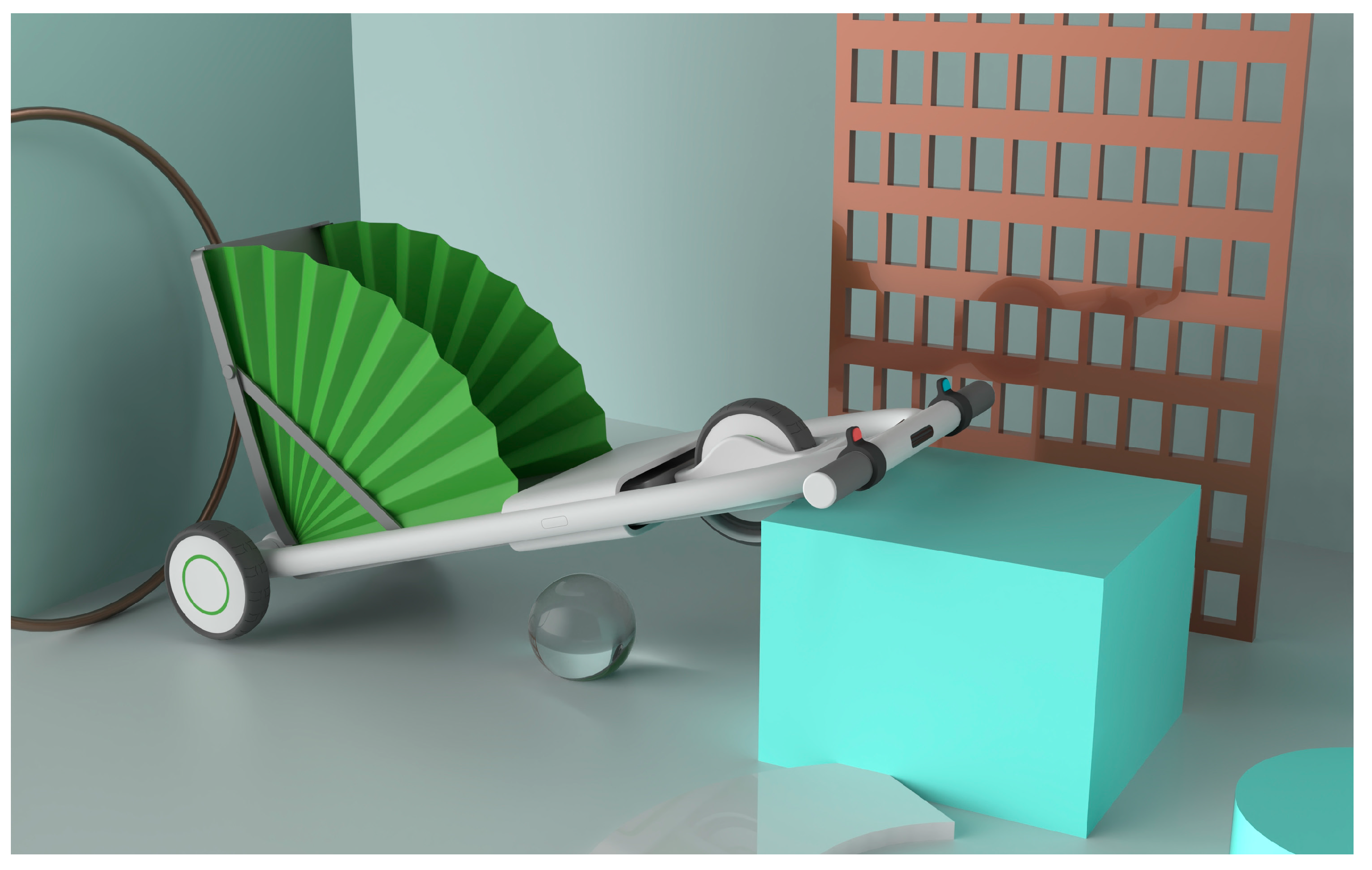

4.2.1. Design Outcomes

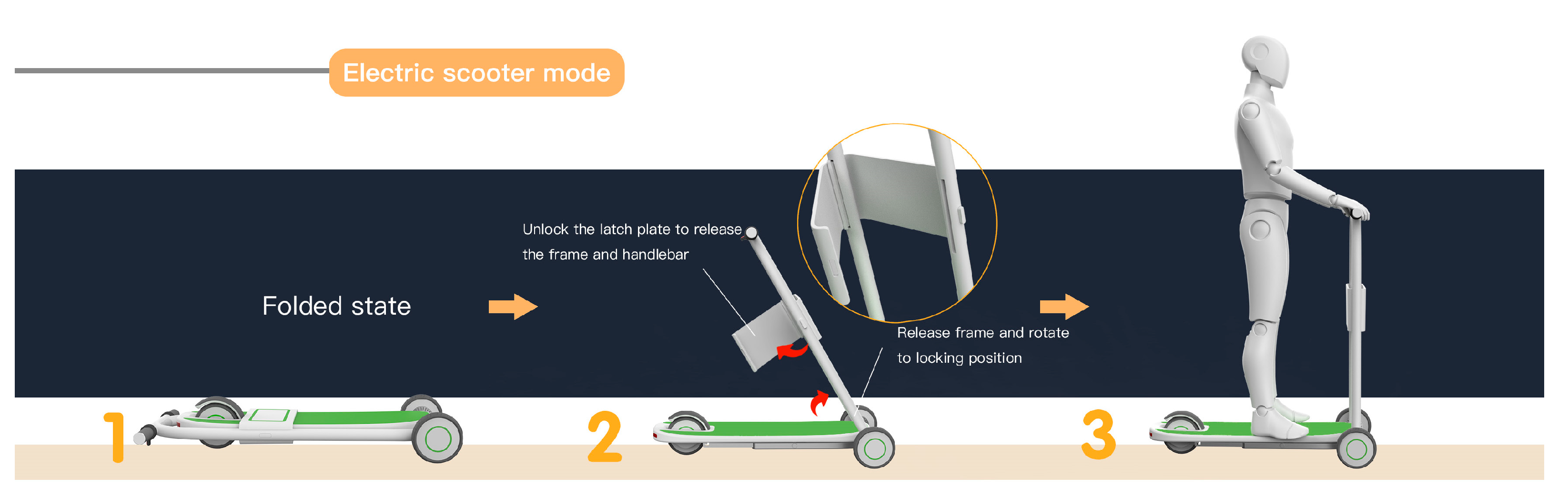

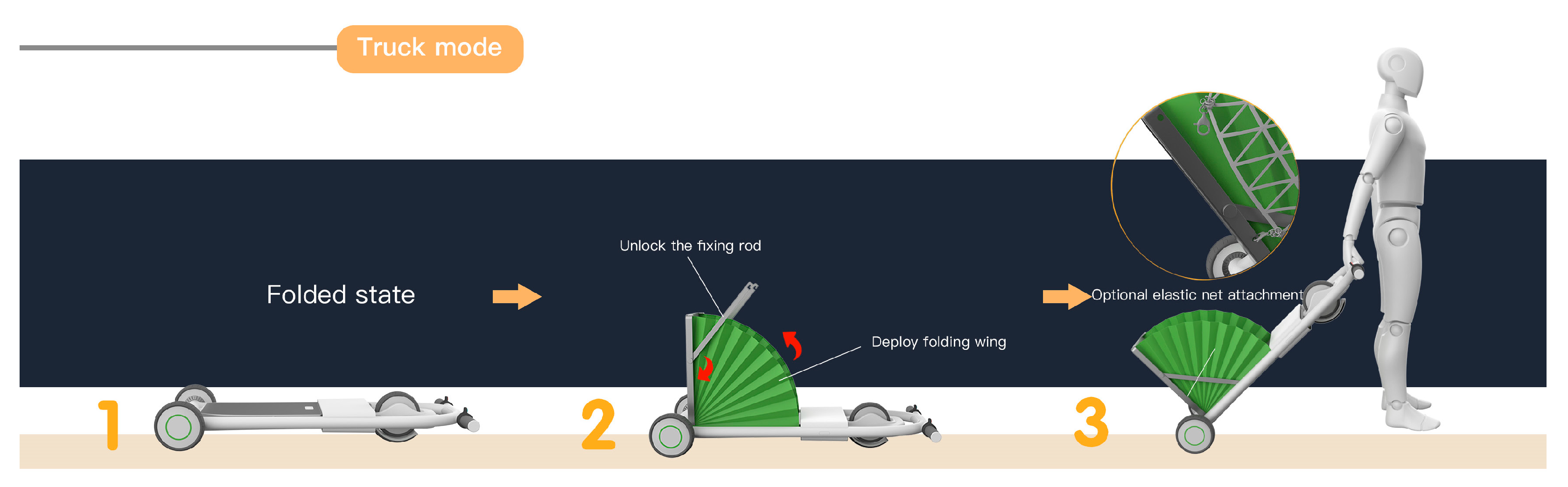

4.2.2. Mode Transition Diagram

5. Discussion

6. Conclusions

- (1)

- The application of objective analysis methods in industrial design to the research on electric scooter design has pioneered a new approach to product design research. It provides a scientific and effective methodological basis and theoretical guidance, from identifying problems, analyzing them, to solving them. It offers relatively objective research data for design practice, reducing subjectivity and blind adherence in design innovation, and enhancing the objectivity and accuracy of design work.

- (2)

- By reviewing the literature in the field of electric scooter design, this research comprehensively discusses the research progress trends and opportunities, and proposes innovative content for the dual-function integration of electric scooters.

- (3)

- Through quantitative data analysis, user needs for electric scooters are studied, resulting in user need indicators with different priorities. This enriches the data on user research in the electric scooter field and provides guidance and a basis for industry product positioning and design decision-making.

- (4)

- Innovative design practice for electric scooters is completed. The design positioning of the product is established, with design efforts focused on functional innovation, structural design, color schemes, and so on.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Payne, C.; Smith, S.A.; Sappal, A.; Boorgula, R.; Taylor, K.A. Are e-scooters active transport? Measured physical activity outputs of e-scooter riding vs walking. J. Transp. Health 2025, 41, 101963. [Google Scholar] [CrossRef]

- Bozzi, A.D.; Aguilera, A. Shared E-Scooters: A Review of Uses, Health and Environmental Impacts, and Policy Implications of a New Micro-Mobility Service. Sustainability 2021, 13, 8676. [Google Scholar] [CrossRef]

- Shah, N.R.; Guo, J.; Han, L.D.; Cherry, C.R. Why do people take e-scooter trips? Insights on temporal and spatial usage patterns of detailed trip data. Transp. Res. Part A Policy Pract. 2023, 173, 103705. [Google Scholar] [CrossRef]

- Triviño-Cabrera, A.; Quiró, J.C.; González-González, J.M.; Aguado, J.A. Optimized design of a wireless charger prototype for an e-scooter. IEEE Access 2023, 11, 33014–33026. [Google Scholar] [CrossRef]

- Tappa, R.; Chowhan, S.A.S.; Shaik, A.; Maroju, A.; Talluri, S.R. Design and Development of a Micromobility Smart Electric Scooter to Revolutionize Urban Commuting. In Proceedings of the International Automotive CAE Conference–Road to Virtual World, Haryana, India, 17–18 October 2024. [Google Scholar]

- Moosavi, S.M.H.; Ma, Z.; Armaghani, D.J.; Aghaabbasi, M.; Ganggayah, M.D.; Wah, Y.C.; Ulrikh, D.V. Understanding and predicting the usage of shared electric scooter services on university campuses. Appl. Sci. 2022, 12, 9392. [Google Scholar] [CrossRef]

- Wu, Y.; Cheng, J. Continuous Fuzzy Kano Model and Fuzzy AHP Model for Aesthetic Product Design: Case Study of an Electric Scooter. Math. Probl. Eng. 2018, 2018, 62539. [Google Scholar] [CrossRef]

- Kwon, Y.W.; Eu, H.S. Proposal of a Portable Folding Electric Scooter Model and Manufacturing of the Prototype. Int. J. Adv. Smart Converg. 2019, 8, 58–64. [Google Scholar]

- Liu, K.-H.; Wang, S.-M. Design and evaluation of electric scooter innovative service. In Proceedings of the 2020 IEEE International Conference on Consumer Electronics-Taiwan (ICCE-Taiwan), Taoyuan, Taiwan, 28–30 September 2020; pp. 1–2. [Google Scholar]

- Hsiao, S.-W.; Chang, C.-H. Concurrent Design Strategy in Modeling and Structure of Electric Scooter for Taiwan. In Proceedings of the 2017 International Conference on Organizational Innovation (ICOI 2017), Weihai, China, 18–20 July 2017; pp. 250–256. [Google Scholar]

- Ye, J.; Gou, Y.; Liang, H.; Yuan, F.; Yang, C. A Design Method for Shared Two-Wheeled Electric Scooters (STWESs), Integrating Context Theory and Kansei Engineering. Sustainability 2025, 17, 3315. [Google Scholar] [CrossRef]

- Gu, J.; Sungpil, L. A Basic Study on the New Creative Thinking Process: Modified from the KJ Method. Int. J. Contents 2024, 20, 38–47. [Google Scholar] [CrossRef]

- Liang, Y.; Luo, J. Research on Innovative Interactive Pet Toy Design Based on Analytic Hierarchy Process. In Proceedings of the International Conference on Human-Computer Interaction, Washington, DC, USA, 29 June–4 July 2024; pp. 235–253. [Google Scholar]

- Liu, X. Research on Function Optimization of Electric Vehicle Charging Stations Based on User Demand Analysis: An Empirical Study Using the Kano Model and AHP Method. Sustainability 2024, 16, 10783. [Google Scholar] [CrossRef]

- Cabała, P. Proces analitycznej hierarchizacji w ocenie wariantów rozwiązań projektowych. Przedsiębiorstwo We Współczesnej Gospod. Teor. I Prakt. 2018, 24, 23–33. [Google Scholar]

- Glavinovic, R.; Vukic, L.; Peronja, I. Analysis of Management Models of Regional Ports in the Republic of Croatia. J. Mar. Sci. Eng. 2023, 11, 332. [Google Scholar] [CrossRef]

- Kotecki, K.; Paslawski, J.O. Poznań Metropolitan Railway-Development Opportunities Based on Comparative Analysis. Sustainability 2025, 17, 1986. [Google Scholar] [CrossRef]

- De Regge, M.; Gemmel, P.; Ackaert, L.; Dillen, L.; Pype, P.; van den Noortgate, N.; Meijboom, B.; Eeckloo, K. Addressing integration in the organization of palliative care in belgium: A multilevel ecosystems approach using the analytic hierarchy process (AHP) method. Bmc Palliat. Care 2024, 23, 266. [Google Scholar]

- Anjamrooz, T.; El-Sayegh, S.M.; Romdhane, L. Key Portfolio Selection Criteria for Sustainable Construction. Buildings 2024, 14, 1777. [Google Scholar] [CrossRef]

- Ransikarbum, K.; Chanthakhot, W.; Glimm, T.; Janmontree, J. Evaluation of sourcing decision for hydrogen supply chain using an integrated multi-criteria decision analysis (MCDA) tool. Resources 2023, 12, 48. [Google Scholar] [CrossRef]

- Cheng, Q.; Li, Q. The application of grey statistical method and analytic hierarchy process in the evaluation of community park rehabilitation landscapes. Humanit. Soc. Sci. Commun. 2025, 12, 158. [Google Scholar] [CrossRef]

- Montella, L.; Liu, X.; Monaco, R.; Murino, T.; Nielsen, P.S. An integrated multi-criteria decision making framework for industrial excess heat recovery and utilization. Energy 2025, 318, 134721. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, X. An optimization method for handling incomplete and conflicting opinions in quality function deployment based on consistency and consensus reaching process. Comput. Ind. Eng. 2024, 187, 109779. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, X.; Zhang, B.; Zhang, H. Consensus-driven methodology to managing diversity and complex linguistic ratings in quality function deployment: An optimization-based approach. J. Oper. Res. Soc. 2023, 74, 2165–2186. [Google Scholar] [CrossRef]

- Li, H.; Gu, H.; Chen, W.; Zhu, Q. Improving Massive Open Online Course Quality in Higher Education by Addressing Student Needs Using Quality Function Deployment. Sustainability 2023, 15, 15678. [Google Scholar] [CrossRef]

- Tsang, N.K.F.; Au, W.C.W. Smart Tourism Experience Design in Amusement Parks: A Quality Function Deployment (QFD) Application. J. Hosp. Tour. Res. 2024, 48, 1051–1066. [Google Scholar] [CrossRef]

- Li, J.; Kim, K. Kano-QFD-based analysis of the influence of user experience on the design of handicraft intangible cultural heritage apps. Herit. Sci. 2023, 11, 59. [Google Scholar] [CrossRef]

- Cong, J.; Chen, C.-H.; Meng, X.; Xiang, Z.; Dong, L. Conceptual design of a user-centric smart product-service system using self-organizing map. Adv. Eng. Inform. 2023, 55, 101857. [Google Scholar] [CrossRef]

- Guo, Z.; Song, M.; Fang, X.; Lin, C.; Zhang, H.; Li, X.; Wang, W. Exploring synergies between AIGC and TRIZ in the optimisation of road cone design through integrated innovation methods. J. Eng. Des. 2025, 36, 256–275. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Z.; Feng, L.; Lin, K.-Y.; Liu, P. Development of technology opportunity analysis based on technology landscape by extending technology elements with BERT and TRIZ. Technol. Forecast. Soc. Change 2023, 191, 122481. [Google Scholar] [CrossRef]

- Shie, A.-J.; Xu, E.-M.; Wang, Y.; Yang, M.; Wu, Y.J. Emotional needs and service process optimization in combined medical and elder care: A TRIZ approach. Technovation 2025, 143, 103224. [Google Scholar] [CrossRef]

- Yao, K.-C.; Chen, L.-Y.; Li, K.-Y.; Chang, Y.-N.; Xu, J.-R.; Huang, W.-L.; Ho, W.-S. An Innovative Design for Cleansing, Deodorization, and Pest Control in Drain Covers: Application of the TRIZ Method and Human Factors Engineering. Machines 2024, 12, 621. [Google Scholar] [CrossRef]

- Yu, S.; Liu, M.B.; Chen, L.P.; Chen, Y.M.; Yao, L. Emotional Design and Evaluation of Children’s Furniture Based on AHP-TOPSIS. Bioresources 2024, 19, 7418–7433. [Google Scholar] [CrossRef]

- Desai, S.; Mantha, S.; Phalle, V. TRIZ and AHP in early design stage of a novel reconfigurable wheelchair. J. Mech. Eng. 2019, 16, 123–141. [Google Scholar] [CrossRef]

- Su, J.; Wei, J. Design of rosebud picking machine based on AHP/QFD/TRIZ. J. Mach. Des 2020, 37, 121–126. [Google Scholar]

- Wei, W.; Tang, S.; Huang, R. The design of a community new energy vehicle shared charging service system based on the KJ-AHP method. In Proceedings of the International Conference on Human-Computer Interaction, Copenhagen, Denmark, 23–28 July 2023; pp. 436–449. [Google Scholar]

- Liu, W.; Li, Y.; Cai, J. Research on Aging Design of Passenger Car Center Control Interface Based on Kano/AHP/QFD Models. Electronics 2024, 13, 5004. [Google Scholar] [CrossRef]

- Miao, Y.; Xie, X.; Wang, H.; Xu, W. A study on the design of literacy toy for children with parent-child interactions. Sci. Rep. 2025, 15, 6793. [Google Scholar] [CrossRef] [PubMed]

- Hameed, A.Z.; Kandasamy, J.; Raj, S.A.; Baghdadi, M.A.; Shahzad, M.A. Sustainable Product Development Using FMEA ECQFD TRIZ and Fuzzy TOPSIS. Sustainability 2022, 14, 14345. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, Q. Two Stepped Innovation Design Method of Products Based on the QFD. J. Graph. 2016, 37, 394–399. [Google Scholar]

- GB/T 10000-2023; National Standard of Human Dimensions for Chinese Adults. Standardization Administration of China: Beijing, China, 2023.

- GB/T 12985-1991; General Principles for Applying Body Dimensions Percentiles in Product Design. Standardization Administration of China: Beijing, China, 1991.

- Xu, Y.N.; Won, L.S. Analysis of design elements of educational toys for preschool children aged 3~6 years old Taking KANO-AHP model as the core. Des. Res. 2023, 8, 76–90. [Google Scholar]

- Xie, Q.; Liu, Q. Application of TRIZ Innovation Method to In-Pipe Robot Design. Machines 2023, 11, 912. [Google Scholar] [CrossRef]

- Wang, L.; Gong, Y.H.; Niu, S.F.; Ren, Z.X. Cultural Symbols Migration and User Perception: Innovation in Chinese-Style Furniture Design. Bioresources 2025, 20, 3476–3496. [Google Scholar] [CrossRef]

| Scale | Definition |

|---|---|

| 1 | Indicates that two elements are of equal importance. |

| 3 | Indicates that the former is slightly more important than the latter. |

| 5 | Indicates that the former is significantly more important than the latter. |

| 7 | Indicates that the former is strongly more important than the latter. |

| 9 | Indicates that the former is extremely more important than the latter. |

| 2, 4, 6, 8 | Intermediate values representing compromises between adjacent judgments. |

| Reciprocals (1–9) | Indicates the inverse importance when comparing the elements in reverse order. |

| Order | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| RI | 0.00 | 0.00 | 0.58 | 0.89 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 |

| No. | Interview Questions |

|---|---|

| Q1 | What is your age? |

| Q2 | What is your occupation? |

| Q3 | What is your highest level of education attained? |

| Q4 | How frequently do you use electric scooters? |

| Q5 | In what scenarios do you typically use electric scooters? |

| Q6 | What inconveniences have you encountered during usage or storage? |

| Q7 | What factors matter most to you when using electric scooters? |

| Q8 | What are the main shortcomings of current electric scooters in your opinion? |

| Q9 | What additional features would you like electric scooters to have? |

| First-Level Requirements | Second-Level Requirement | Third-Level Requirements |

|---|---|---|

| Electric Scooter User Requirements | Functional requirements | Load-bearing capacity; Foldable; Portable; Multifunctional; Long battery life; Fast and convenient charging |

| Aesthetic requirements | Sleek and streamlined; Fashionable and distinctive; Harmonious color scheme; Aesthetically pleasing form; Exquisite detailing; Well proportioned | |

| Human–machine interaction requirements | App-connectivity; Equipped with display interface; Intuitive control interface; Voice prompts; Smart unlocking mechanism; Ergonomically optimized | |

| Safety requirements | Sustainable material composition; Robust structure; Real-time location tracking; Smart auto-lock; Night illumination; High-efficiency braking |

| Expert ID | Academic/ Professional Title | Years of Experience | Affiliation | Conflict of Interest Statement |

|---|---|---|---|---|

| E1 | Professor | 20 | [Anonymized] School of Design, China | No conflict of interest |

| E2 | Professor | 14 | [Anonymized] School of Design, China | No conflict of interest |

| E3 | Senior Industrial Designer | 8 | [Anonymized] Industrial Design Company, China | No conflict of interest |

| E4 | Senior Engineer | 12 | [Anonymized] Electric scooter Manufacturer, China | No conflict of interest |

| B1 | B2 | B3 | B4 | |

|---|---|---|---|---|

| B1 | 1 | 7 | 3 | 1/2 |

| B2 | 1/7 | 1 | 1/3 | 1/8 |

| B3 | 1/3 | 3 | 1 | 1/4 |

| B4 | 2 | 8 | 4 | 1 |

| B1 | B2 | B3 | B4 | |

|---|---|---|---|---|

| B1 | 1 | 6 | 3 | 1 |

| B2 | 1/6 | 1 | 1/3 | 1/4 |

| B3 | 1/3 | 3 | 1 | 1/4 |

| B4 | 1 | 4 | 4 | 1 |

| B1 | B2 | B3 | B4 | |

|---|---|---|---|---|

| B1 | 1 | 7 | 1 | 1/3 |

| B2 | 1/7 | 1 | 1/5 | 1/9 |

| B3 | 1 | 5 | 1 | 1/3 |

| B4 | 3 | 9 | 3 | 1 |

| B1 | B2 | B3 | B4 | |

|---|---|---|---|---|

| B1 | 1 | 2 | 4 | 1/6 |

| B2 | 1/2 | 1 | 2 | 1/9 |

| B3 | 1/4 | 1/2 | 1 | 1/9 |

| B4 | 6 | 9 | 9 | 1 |

| B1 | B2 | B3 | B4 | |

|---|---|---|---|---|

| B1 | 1 | 4.924298 | 2.449490 | 0.408248 |

| B2 | 0.203075 | 1 | 0.459150 | 0.140149 |

| B3 | 0.408248 | 1/2 | 1 | 0.219346 |

| B4 | 2.449490 | 7.135243 | 4.559014 | 1 |

| C1 | C2 | C3 | C4 | C5 | C6 | |

|---|---|---|---|---|---|---|

| C1 | 1 | 0.795271 | 0.422107 | 0.577350 | 1.203801 | 1.565085 |

| C2 | 1.257433 | 1 | 0.789690 | 0.562341 | 0.930605 | 1.106682 |

| C3 | 2.369096 | 1.266320 | 1 | 0.840896 | 2.300327 | 2.702400 |

| C4 | 1.732051 | 1.778279 | 1.189207 | 1 | 2.783158 | 3.201086 |

| C5 | 0.830702 | 1.074570 | 0.434721 | 0.359304 | 1 | 2.059761 |

| C6 | 0.638943 | 0.903602 | 0.370041 | 0.312394 | 0.485492 | 1 |

| C7 | C8 | C9 | C10 | C11 | C12 | |

|---|---|---|---|---|---|---|

| C7 | 1 | 1.967990 | 3.130169 | 1.446254 | 1.000000 | 0.945742 |

| C8 | 0.508133 | 1 | 2.645751 | 1.800103 | 0.945742 | 1.124683 |

| C9 | 0.319472 | 0.377964 | 1 | 0.500000 | 0.250986 | 0.359304 |

| C10 | 0.691442 | 0.555524 | 2.000000 | 1 | 0.508133 | 0.537285 |

| C11 | 1.000000 | 1.057371 | 3.984283 | 1.967990 | 1 | 0.622333 |

| C12 | 1.057371 | 0.889140 | 2.783158 | 1.861210 | 1.606857 | 1 |

| C13 | C14 | C15 | C16 | C17 | C18 | |

|---|---|---|---|---|---|---|

| C13 | 1 | 2.407603 | 0.440056 | 2.149140 | 1.106682 | 0.260847 |

| C14 | 0.415351 | 1 | 0.241498 | 1.812825 | 0.795271 | 0.193049 |

| C15 | 2.272439 | 4.140825 | 1 | 5.634626 | 2.912951 | 0.594604 |

| C16 | 0.465302 | 0.551625 | 0.177474 | 1 | 0.438691 | 0.219346 |

| C17 | 0.903602 | 1.257433 | 0.343295 | 2.279507 | 1 | 0.268642 |

| C18 | 3.833659 | 5.180040 | 1.681793 | 4.559014 | 3.722419 | 1 |

| C19 | C20 | C21 | C22 | C23 | C24 | |

|---|---|---|---|---|---|---|

| C19 | 1 | 0.260847 | 0.866025 | 1.057371 | 0.268642 | 0.379918 |

| C20 | 3.833659 | 1 | 4.486046 | 4.486046 | 2.059767 | 1.235931 |

| C21 | 1.154701 | 0.222913 | 1 | 1.861210 | 0.594604 | 0.290715 |

| C22 | 0.945702 | 0.222913 | 0.537285 | 1 | 0.386097 | 0.343295 |

| C23 | 3.722419 | 0.485492 | 1.681793 | 2.590020 | 1 | 0.903602 |

| C24 | 2.632148 | 0.809107 | 3.439791 | 2.912951 | 1.106682 | 1 |

| Primary Indicators | Weight | Secondary Indicator | Relative Weight | Comprehensive Weight | Rank |

|---|---|---|---|---|---|

| B1 | 0.2724 | C1 | 0.1293 | 0.0352 | 12 |

| C2 | 0.1419 | 0.0387 | 10 | ||

| C3 | 0.2422 | 0.0660 | 5 | ||

| C4 | 0.2723 | 0.0724 | 4 | ||

| C5 | 0.1262 | 0.0344 | 13 | ||

| C6 | 0.0882 | 0.0240 | 15 | ||

| B2 | 0.0623 | C7 | 0.2799 | 0.0174 | 16 |

| C8 | 0.1809 | 0.0113 | 21 | ||

| C9 | 0.0638 | 0.0638 | 6 | ||

| C10 | 0.1174 | 0.0073 | 23 | ||

| C11 | 0.2015 | 0.0126 | 19 | ||

| C12 | 0.2166 | 0.0135 | 18 | ||

| B3 | 0.1214 | C13 | 0.1214 | 0.0147 | 17 |

| C14 | 0.0729 | 0.0089 | 22 | ||

| C15 | 0.2746 | 0.0333 | 14 | ||

| C16 | 0.0540 | 0.0066 | 24 | ||

| C17 | 0.1022 | 0.0124 | 20 | ||

| C18 | 0.3749 | 0.0455 | 8 | ||

| B4 | 0.5439 | C19 | 0.0752 | 0.0409 | 9 |

| C20 | 0.3326 | 0.1809 | 1 | ||

| C21 | 0.0930 | 0.0506 | 7 | ||

| C22 | 0.0693 | 0.0377 | 11 | ||

| C23 | 0.1951 | 0.1061 | 3 | ||

| C24 | 0.2348 | 0.1277 | 2 |

| Contradiction | Conflict Type | Improving Parameter | Worsening Parameter |

|---|---|---|---|

| Functional zoning vs. Compact size | Physical conflict | —— | —— |

| Lightweight design vs. Material/structural integrity | Technical conflict | Weight of moving object | Stability of structure |

| Smart interaction vs. Usability | Technical conflict | Ease of operation | Complexity of device |

| Separation Principle | Definition |

|---|---|

| Spatial Separation | Separating contradictory properties into distinct spatial domains through distance or intermediate media. |

| Temporal Separation | Applied when contradictory properties appear exclusively in different time periods. |

| Whole-Part Separation | Resolving conflicting requirements by distinguishing between macro (system-level) and micro (component-level) characteristics. |

| Condition-based Separation | Separation achieved by altering environmental parameters (e.g., temperature, pressure) to satisfy opposing requirements under different conditions. |

| No. | Inventive Principle | Definition |

|---|---|---|

| 1 | Segmentation | Divide an object into independent parts or make it modular. |

| 2 | Extraction | Remove an interfering part or property from an object, or extract only the necessary part. |

| 3 | Local Quality | Transition from a uniform structure to non-uniform composition or optimize different zones for different functions. |

| 4 | Asymmetry | Replace symmetrical forms with asymmetrical ones to enhance functionality. |

| 7 | Nesting | Designing a system or object to be embedded within another system or object. |

| 13 | Inversion | Applying reverse thinking to flip or reposition objects, systems, or operational processes. |

| 17 | Dimensionality Change | Altering an object’s motion or configuration across 1D, 2D, or 3D spaces to achieve varied functional effects. |

| 24 | Intermediary | Introducing a mediator (temporary or permanent) between interacting objects or systems. |

| 26 | Copying | Substituting unsuitable materials with low-cost, readily available, or redesigned alternatives. |

| 30 | Flexible Shells | Replacing rigid structures with flexible enclosures or membranes to isolate or protect systems. |

| No. | Principle | Definition |

|---|---|---|

| 1 | Segmentation | Applying decomposition methodology to divide an integrated system into multiple distinct subsystems for redesign purposes. |

| 35 | Parameter Changes | Modifying physical states (solid/liquid/gas) or adjusting parameters such as concentration, temperature, and pressure. |

| 19 | Periodic Action | Converting continuous actions into rhythmic periodic operations, or altering existing periodic frequencies. |

| 39 | Inert Environment | Substituting normal environments with inert ones, or introducing inert elements into object systems. |

| No. | Principle | Definition |

|---|---|---|

| 32 | Color Changes | Altering the color, transparency, or other visual attributes of an object or environment to enhance visibility. |

| 26 | Copying | Replacing an unsuitable material system with a low-cost, readily available, or redeveloped material system. |

| 12 | Equipotentiality | Modifying working conditions or redesigning the object/environment to counteract inherent system stresses. |

| 17 | Transition to Another Dimension | Changing the spatial dimensions (1D, 2D, or 3D) of an object or its motion to achieve different application effects. |

| Gender | Age Range | Percentile | Functional Hand Heigh | Foot Length | Foot Width |

|---|---|---|---|---|---|

| Male | 18–70 | 1st | 649 | 224 | 85 |

| Male | 18–70 | 5th | 681 | 232 | 89 |

| Male | 18–70 | 10th | 696 | 236 | 91 |

| Male | 18–70 | 50th | 750 | 250 | 98 |

| Male | 18–70 | 90th | 806 | 264 | 104 |

| Male | 18–70 | 95th | 823 | 269 | 106 |

| Male | 18–70 | 99th | 854 | 278 | 110 |

| Female | 18–70 | 1st | 617 | 208 | 77 |

| Female | 18–70 | 5th | 644 | 215 | 82 |

| Female | 18–70 | 10th | 658 | 218 | 83 |

| Female | 18–70 | 50th | 705 | 230 | 90 |

| Female | 18–70 | 90th | 753 | 243 | 96 |

| Female | 18–70 | 95th | 767 | 247 | 98 |

| Female | 18–70 | 99th | 797 | 256 | 102 |

| Category | Definition | Body Dimension Percentiles | Examples |

|---|---|---|---|

| Type I | Dual-limit design: Adjustable products to accommodate users of different body sizes | Upper limit: /Lower limit: or | Car seats, rearview mirrors |

| Type IIA | Large-size design: Products only need to accommodate users with maximum body dimensions | Upper limit: , or | Doors, cup handles |

| Type IIB | Small-size design: Products only need to accommodate users with minimum body dimensions | Lower limit: , or | Bookshelves, fan grilles |

| Type III | Average-size design: Products where user size is irrelevant or limit-based design is not applicable | ( male + female)/2 | Door handles, public seating |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Jiang, X.; Niu, S.; Zhang, Y. Research on Innovative Design of Two-in-One Portable Electric Scooter Based on Integrated Industrial Design Method. Sustainability 2025, 17, 7121. https://doi.org/10.3390/su17157121

Zhang Y, Jiang X, Niu S, Zhang Y. Research on Innovative Design of Two-in-One Portable Electric Scooter Based on Integrated Industrial Design Method. Sustainability. 2025; 17(15):7121. https://doi.org/10.3390/su17157121

Chicago/Turabian StyleZhang, Yang, Xiaopu Jiang, Shifan Niu, and Yi Zhang. 2025. "Research on Innovative Design of Two-in-One Portable Electric Scooter Based on Integrated Industrial Design Method" Sustainability 17, no. 15: 7121. https://doi.org/10.3390/su17157121

APA StyleZhang, Y., Jiang, X., Niu, S., & Zhang, Y. (2025). Research on Innovative Design of Two-in-One Portable Electric Scooter Based on Integrated Industrial Design Method. Sustainability, 17(15), 7121. https://doi.org/10.3390/su17157121