Performance Evaluation of Waste Toner and Recycled LDPE-Modified Asphalt Pavement: A Mechanical and Carbon Assessment-Based Optimization Approach Towards Sustainability

Abstract

1. Introduction

2. Background

- SDG 6: Clean water and sanitation promote resource recycling and pollution reduction.

- SDG 7: Affordable and clean energy emphasizes renewable and efficient energy use.

- SDG 8: Decent Work and Economic Growth advocates sustainable economic development.

- SDG 12: Responsible consumption and production focus on sustainable material use and waste reduction.

- SDG 15: Life on land aims to restore and preserve terrestrial ecosystems.

- Designing out waste and pollution by incorporating waste toner and recycled plastics into binder formulations.

- Keeping products and materials in use by enhancing pavement durability and recyclability.

- Regenerating natural systems by reducing demand for virgin fossil-based binders, thereby lowering environmental degradation.

3. Materials and Methods

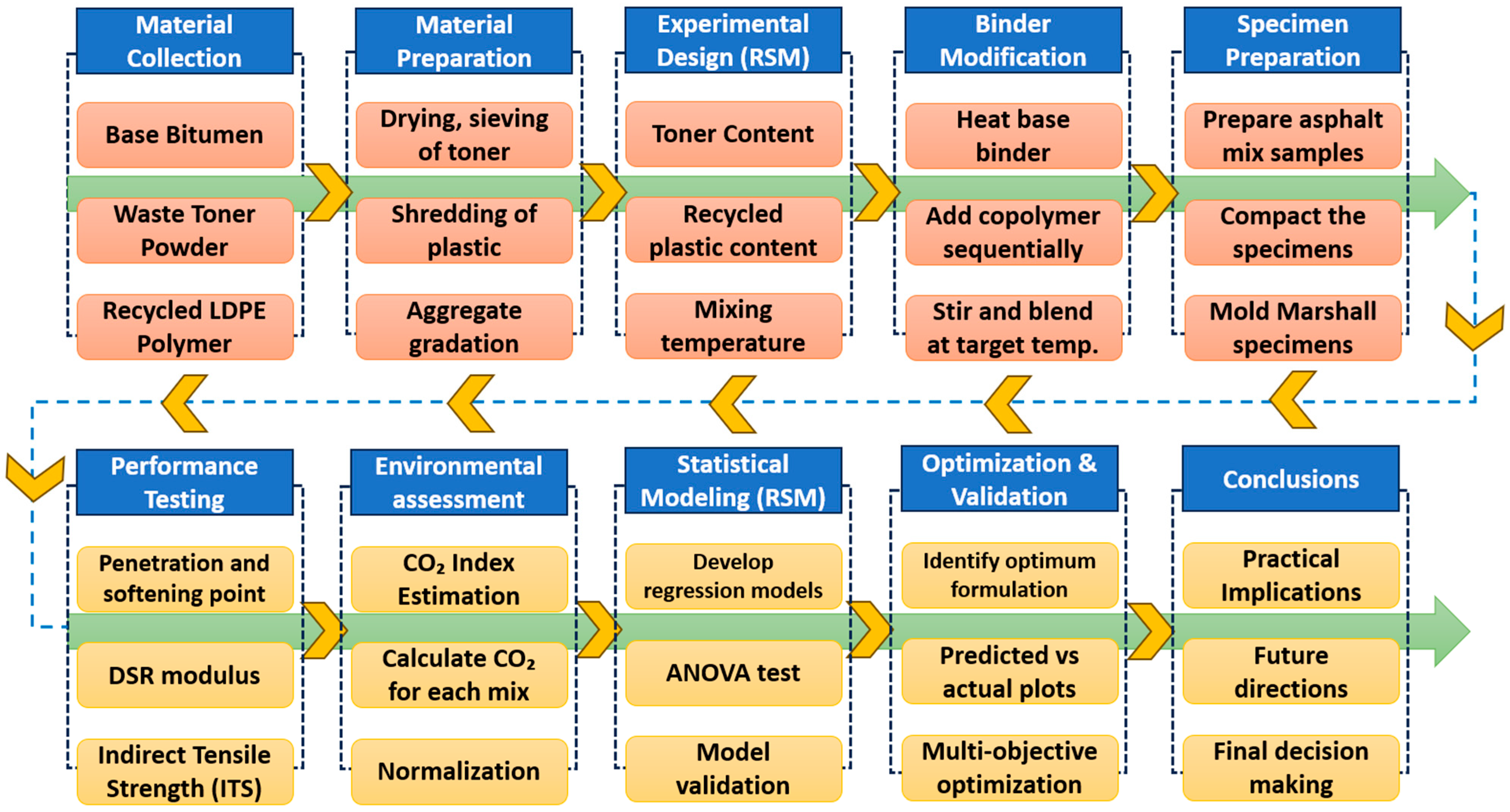

3.1. Research Methodology

3.2. Materials

3.2.1. Asphalt Binder

3.2.2. Waste Toner Powder (WTP)

3.2.3. Recycled Plastic Polymer

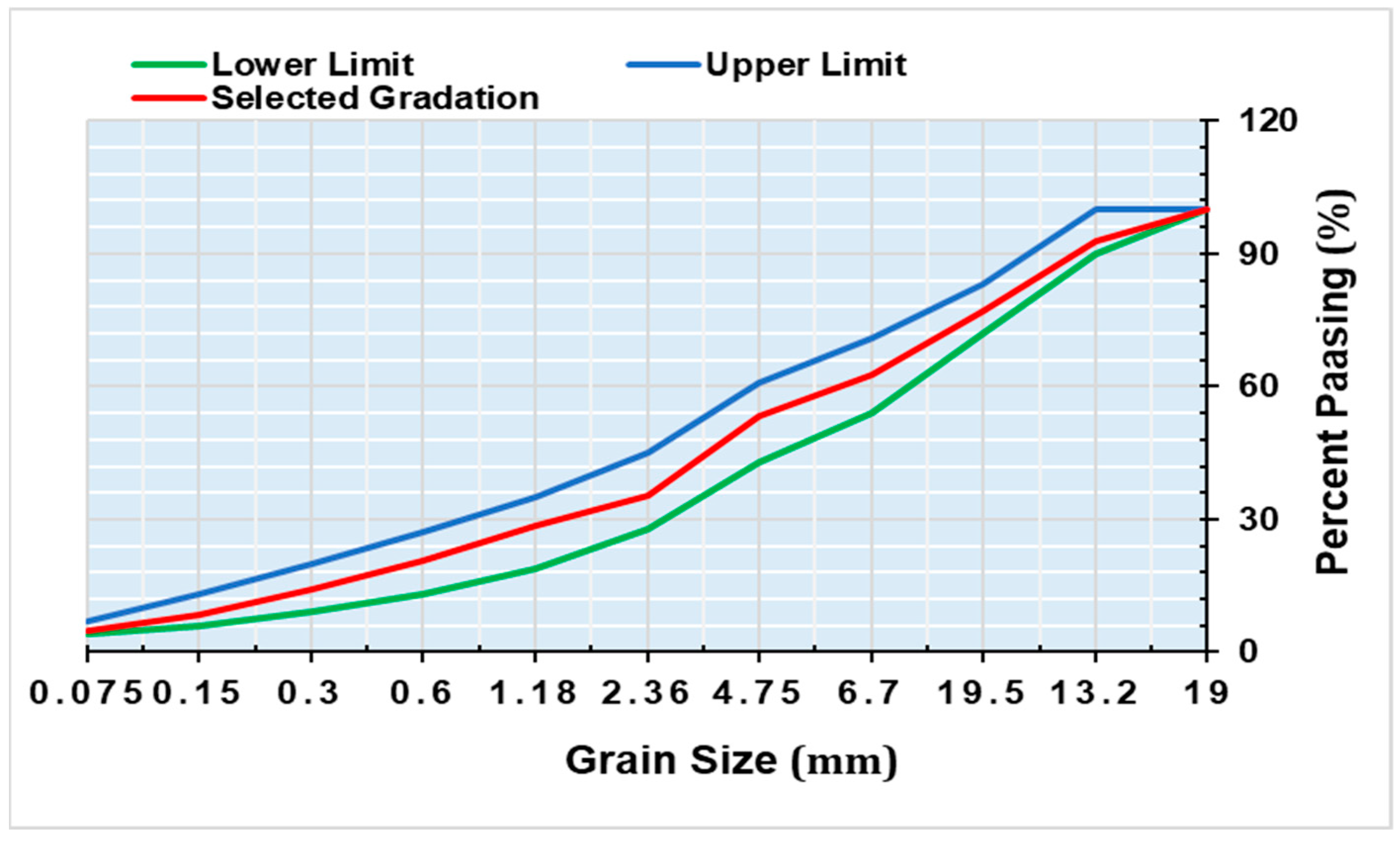

3.2.4. Aggregates

3.3. Experimental Design Using RSM

3.4. Sample Preparation

3.5. Testing Procedures

3.5.1. Penetration and Softening Point

3.5.2. Marshall Stability and Flow

3.5.3. Indirect Tensile Strength (ITS)

3.5.4. Dynamic Shear Rheometer (DSR)

3.6. Environmental Assessment

3.7. Statistical Analysis

4. Results and Discussions

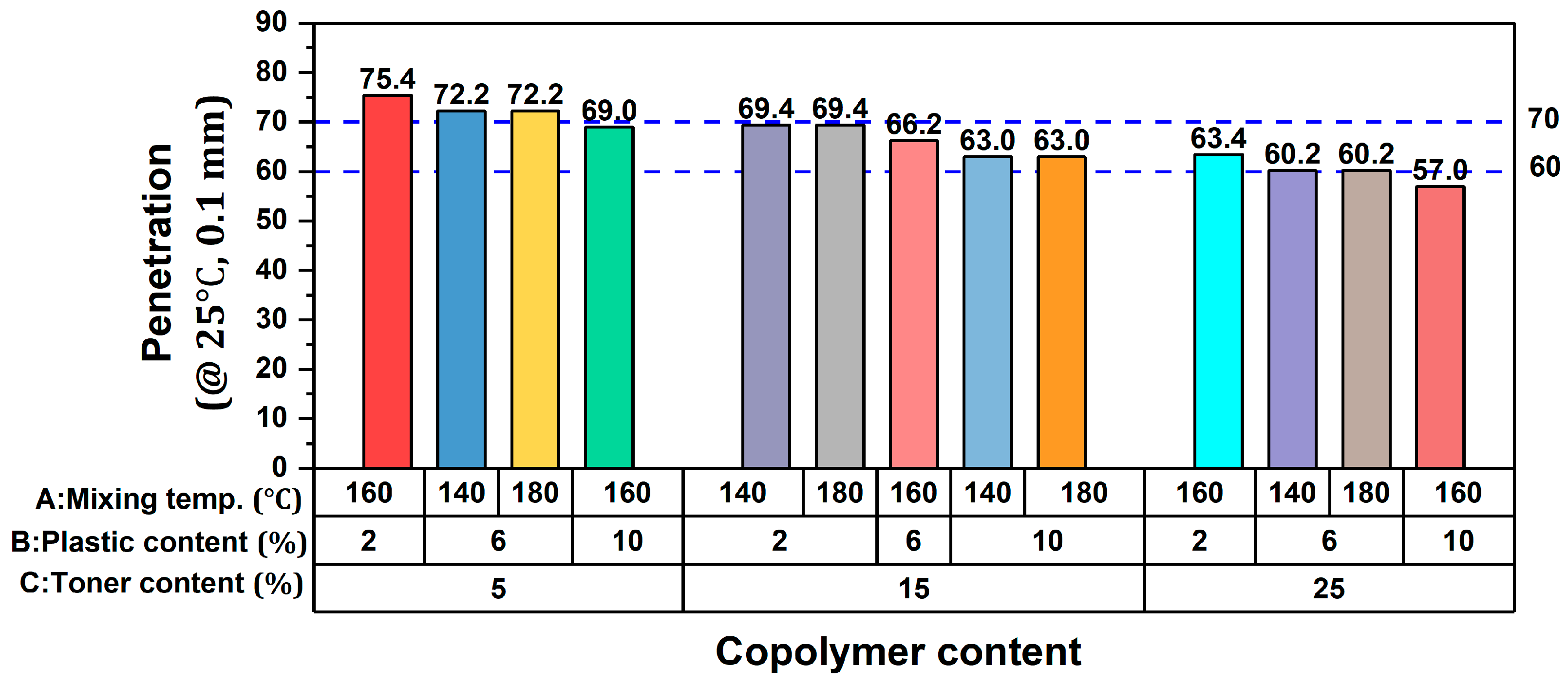

4.1. Effect of Polymer Modification and Temperature on Binder Consistency

4.1.1. Penetration Test

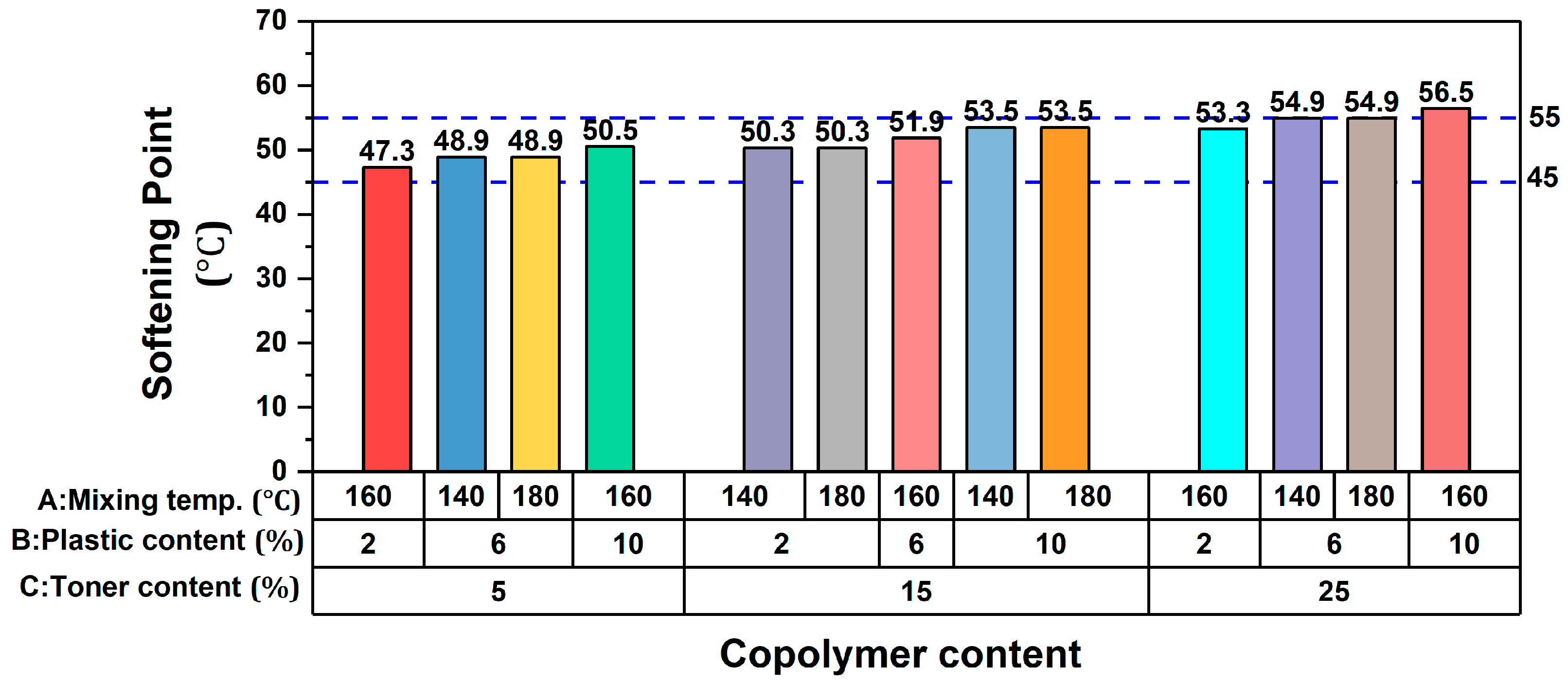

4.1.2. Softening Point Test

4.2. Effect of Polymer Binders on Marshall Flow

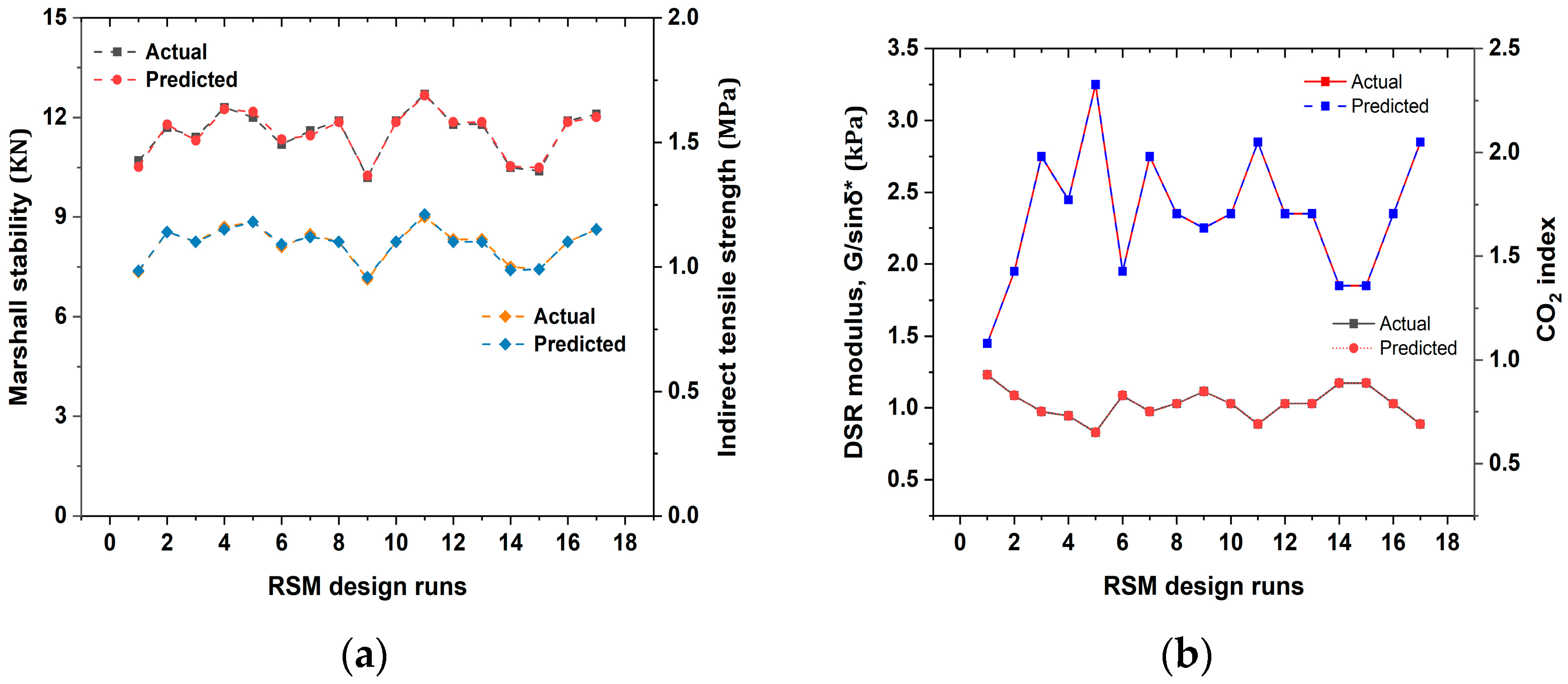

4.3. Response Surface Methodology Analysis and Model Validation

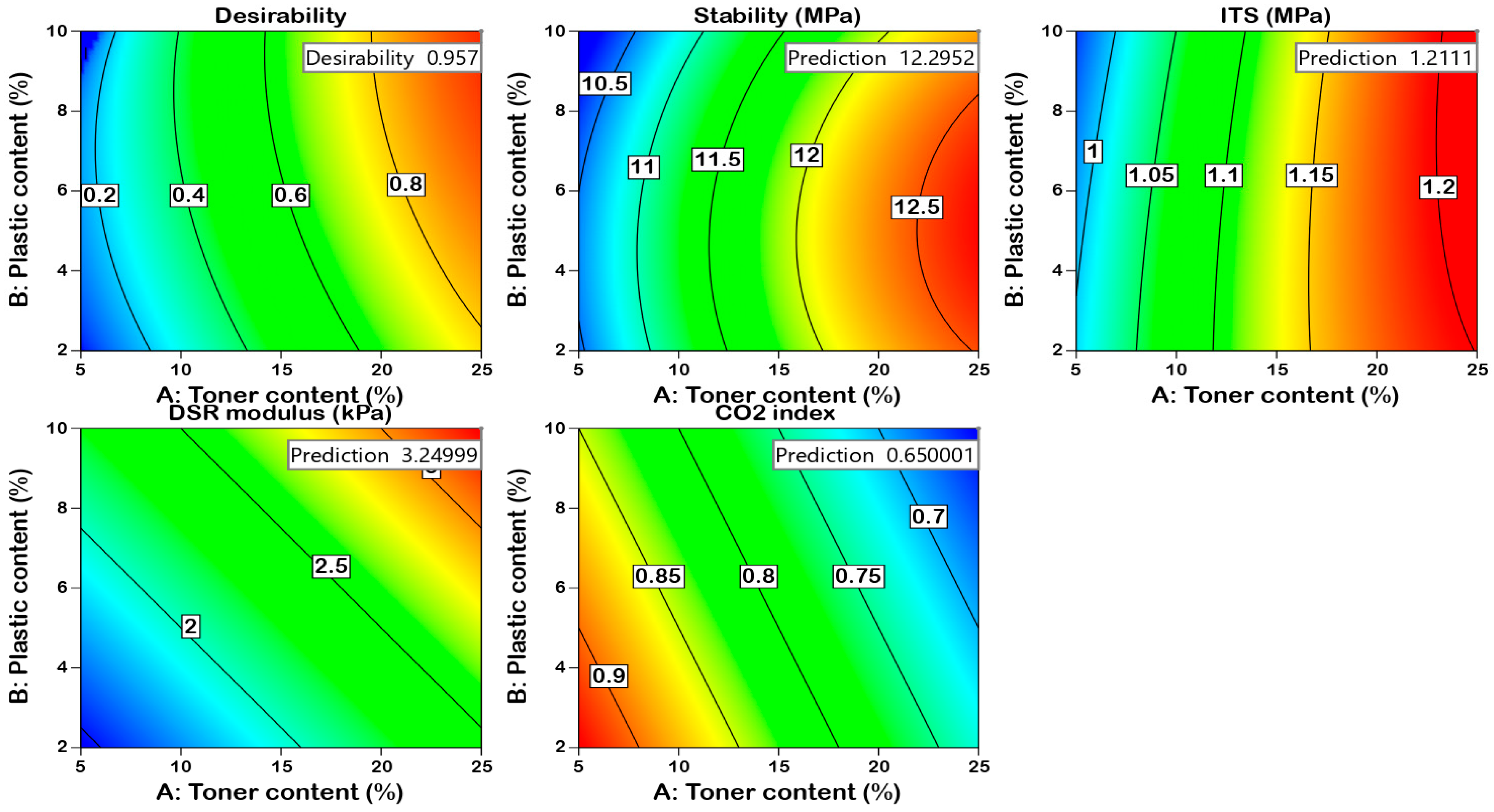

4.4. Response Surface Model Plots

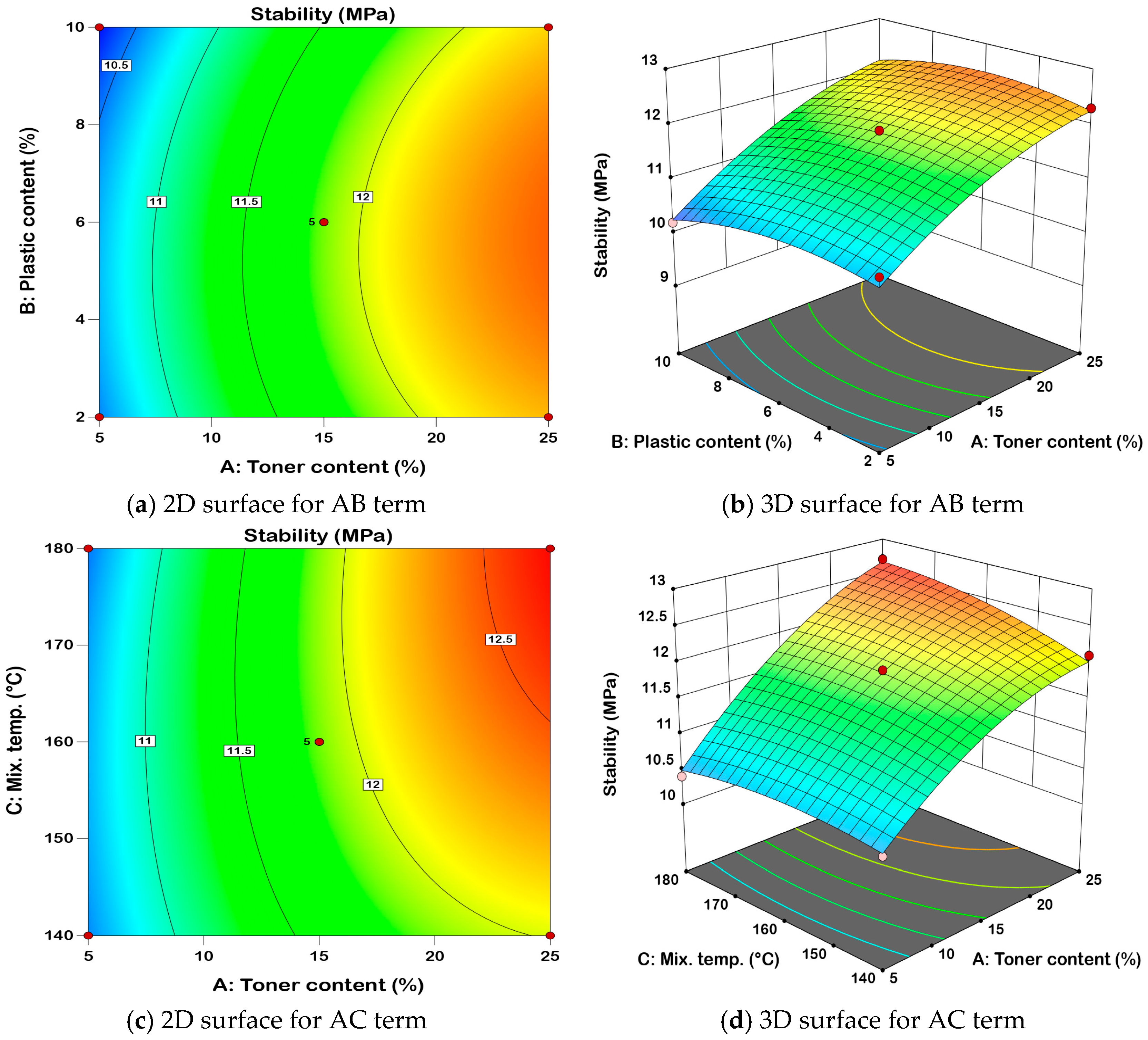

4.4.1. Marshall Stability Performance of Polymer-Modified Asphalt

4.4.2. ITS Performance Analysis of Polymer-Modified Asphalt

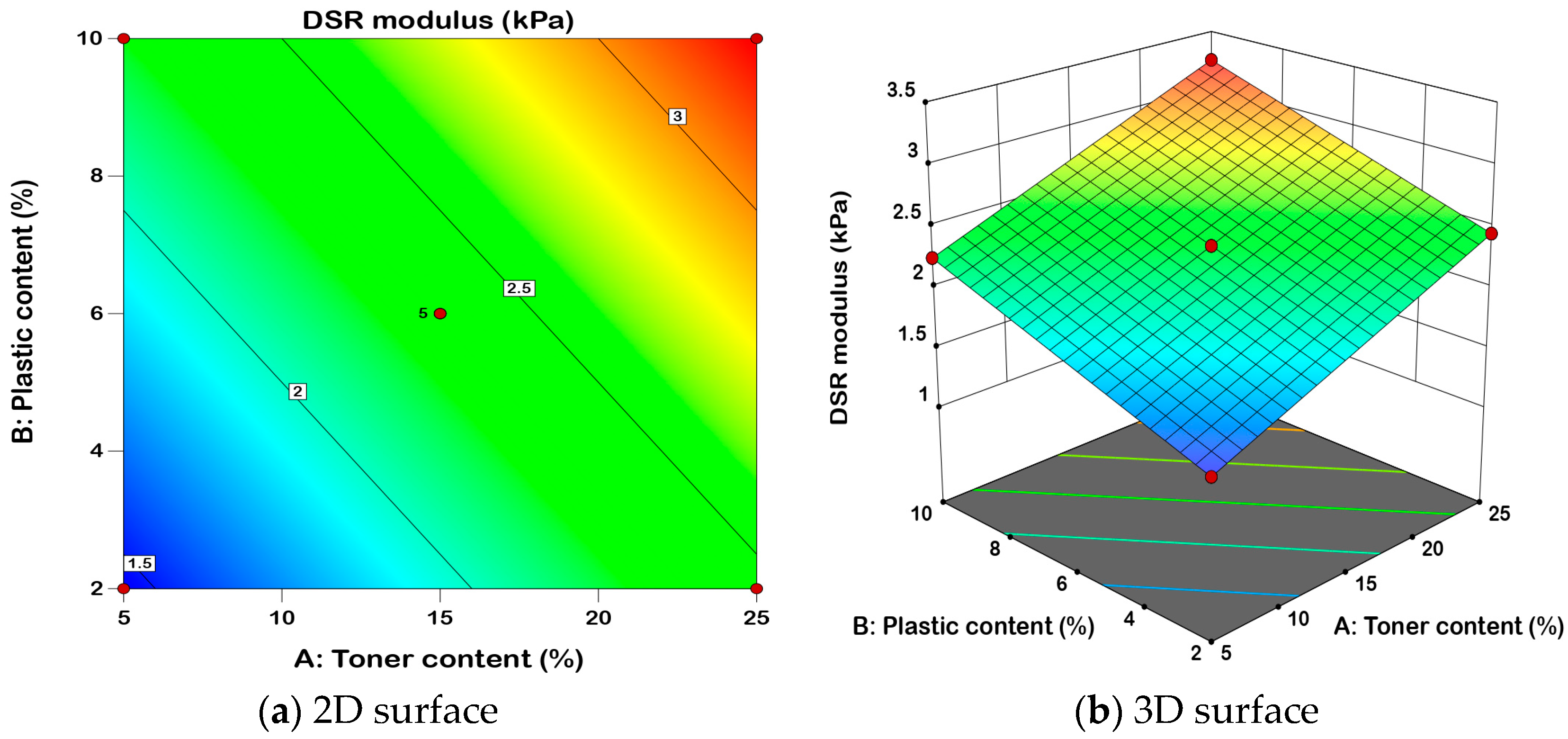

4.4.3. DSR Modulus Performance of Polymer-Modified Asphalt

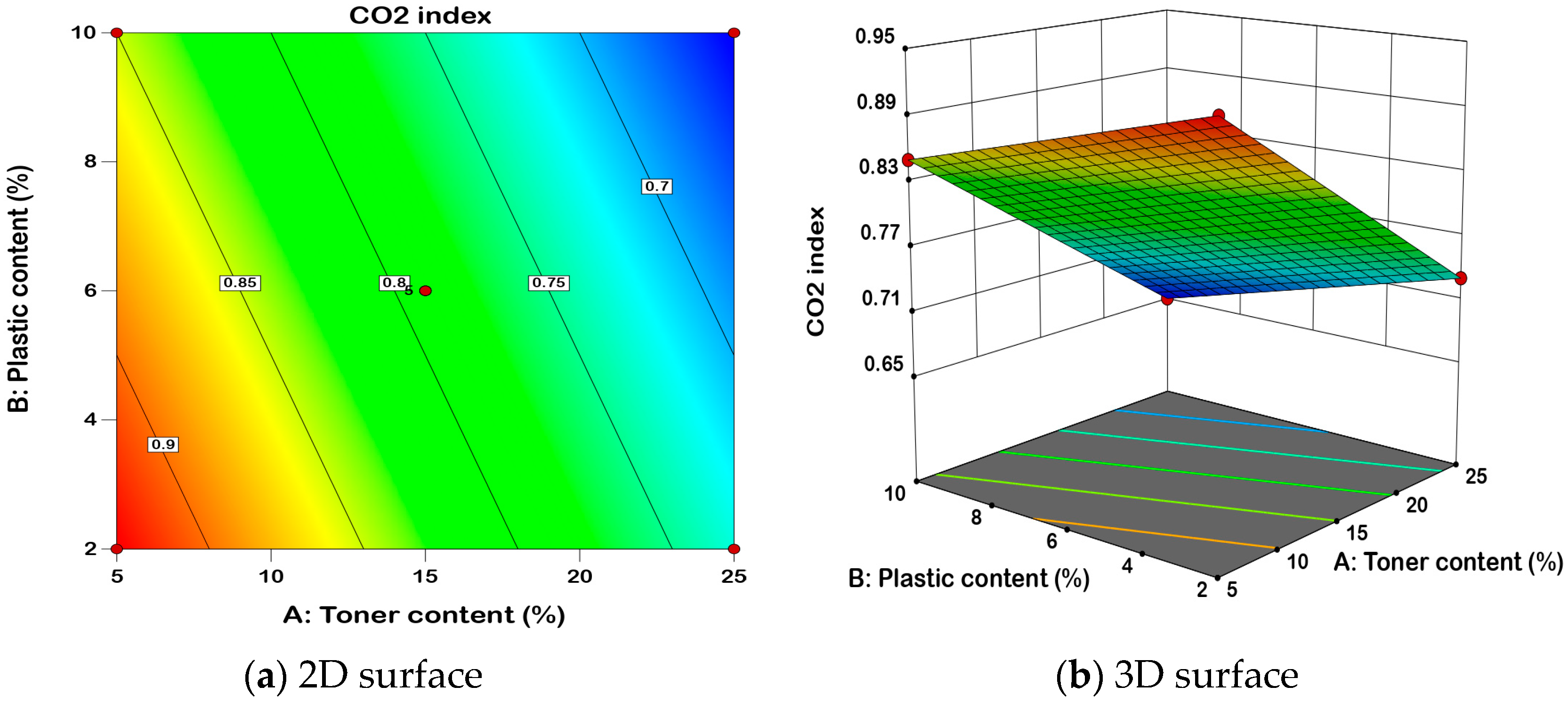

4.4.4. Environmental Assessment of Polymer-Modified Asphalt

4.5. Multi-Objective Performance Optimization and Desirability Analysis

5. Contribution to Circular Economy and Sustainability

6. Conclusions

- The addition of e-waste toner significantly improved Marshall stability and indirect tensile strength (ITS) of asphalt mixtures, especially when combined with moderate to high contents of recycled plastic. The optimum blend of 25% toner and 6% plastic at 180 °C yielded the highest stability (12.7 kN) and ITS (1.2 MPa).

- Dynamic shear rheometer (DSR) testing showed a marked increase in G*/sinδ values with rising e-waste toner and plastic content, indicating enhanced rutting resistance. A maximum of 3.25 kPa was achieved with 25% toner and 10% plastic.

- Penetration and softening point tests confirmed that the modified binders became stiffer and more thermally stable, with lower penetration and higher softening point values. However, very high plastic content slightly compromised flow characteristics.

- The calculated CO2 index indicated that mixtures with higher waste content significantly reduced carbon impact. The lowest index (0.65) was achieved with the most heavily modified blends, showcasing the environmental sustainability of using industrial waste in asphalt production.

- The results suggest that a synergistic combination of 15–25% toner and 6–10% plastic can produce asphalt mixtures suitable for heavy-load and warm-climate conditions, contributing to circular economy goals and waste management efforts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LDPE | Low-density polyethylene |

| CO2 index | Carbon emission index |

| CE | Circular economy |

| LCA | Life cycle assessment |

| SDGs | Sustainable development goals |

| ITS | Indirect tensile strength |

| DSR | Dynamic shear modulus |

| RSM | Response surface methodology |

| MOPO | Multi-objective performance optimization |

| C-eff | Effective carbon emission |

| CCD | Central composite design |

| VOC | Volatile organic compounds. |

| SBS | Styrene–butadiene–styrene |

| EVA | Ethylene–vinyl acetate |

References

- Yaro, N.S.A.; Sutanto, M.H.; Baloo, L.; Habib, N.Z.; Usman, A.; Yousafzai, A.K.; Ahmad, A.; Birniwa, A.H.; Jagaba, A.H.; Noor, A. A comprehensive overview of the utilization of recycled waste materials and technologies in asphalt pavements: Towards environmental and sustainable low-carbon roads. Processes 2023, 11, 2095. [Google Scholar] [CrossRef]

- Malluru, S.; Islam, S.M.I.; Saidi, A.; Baditha, A.K.; Chiu, G.; Mehta, Y. A State-of-the-Practice Review on the Challenges of Asphalt Binder and a Roadmap Towards Sustainable Alternatives—A Call to Action. Materials 2025, 18, 2312. [Google Scholar] [CrossRef] [PubMed]

- Praticò, F.G.; Perri, G.; De Rose, M.; Vaiana, R. Comparing bio-binders, rubberised asphalts, and traditional pavement technologies. Constr. Build. Mater. 2023, 400, 132813. [Google Scholar] [CrossRef]

- Asphalt Pro. Understanding the Environmental Impact of Bitumen: Insights from Eurobitume’s LCA 4.0. 2025. Available online: https://theasphaltpro.com/understanding-the-environmental-impact-of-bitumen-insights-from-eurobitumes-lca-4-0/?utm_source=chatgpt.com (accessed on 12 June 2025).

- Dong, Z.; Li, L.; Zhou, T.; Yang, H.; Cao, L.; Shan, L. Waste-modified asphalt for climate change mitigation: Carbon and pollution reduction. Transp. Res. Part D: Transp. Environ. 2025, 143, 104727. [Google Scholar] [CrossRef]

- Albatayneh, O. Paving the future: Breakthroughs in sustainable approaches to pavement. In Recent Developments and Innovations in the Sustainable Production of Concrete; Elsevier: Amsterdam, The Netherlands, 2025; pp. 511–531. [Google Scholar]

- Shacat, J.; Willis, R.; Ciavola, B. The Carbon Footprint of Asphalt Pavements; SIP-109; The Road Forward; National Asphalt Pavement Association: Greenbelt, MD, USA, 2024. [Google Scholar]

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global e-Waste Monitor 2020; United Nations University (UNU): Bonn, Germany; International Telecommunication Union (ITU): Geneva, Switzerland; International Solid Waste Association (ISWA): Rotterdam, The Netherlands, 2020; Volume 120. [Google Scholar]

- Daniel-Mkpume, C.C.; Ahaiwe, R.C.; Ifenatuorah, C.L.; Ike-Eze, I.C.E.; Aigbodion, V.S.; Egoigwe, S.V.; Okonkwo, E.G. Potential end of life application of African star apple shell and waste toner powder as composite filler materials. J. Mater. Cycles Waste Manag. 2022, 24, 680–691. [Google Scholar] [CrossRef]

- Du, X.; Hu, K.; Zhang, F.; Liu, J.; Gillani, S.T.A. Characteristics of waste toner powder and its interaction effect on the physicochemical properties of asphalt binder. Constr. Build. Mater. 2025, 458, 139484. [Google Scholar] [CrossRef]

- Fernández, B.; Ayala, J.; Del Valle, E.; Martínez-Blanco, D.; Castañón, A.M.; Menéndez-Aguado, J.M. Recycling of waste toner powder as adsorbent to remove aqueous heavy metals. Materials 2022, 15, 4150. [Google Scholar] [CrossRef]

- Choudhary, D.; Kaithwas, S.; Sharma, R.; Mishra, A.; Singhai, S.; Powar, S.; Singh, A. Recycling of waste toner derived from exhausted printer cartridges as adsorbent for defluoridation of water. Environ. Technol. Innov. 2024, 34, 103572. [Google Scholar] [CrossRef]

- Nna Orji, C.; Olawore, Y.A. Well of hazards in e-waste: A review. Environment 2024, 13, 35–36. [Google Scholar]

- Movilla-Quesada, D.; Raposeiras, A.; Silva-Klein, L.; Lastra-González, P.; Castro-Fresno, D. Use of plastic scrap in asphalt mixtures added by dry method as a partial substitute for bitumen. Waste Manag. 2019, 87, 751–760. [Google Scholar] [CrossRef]

- Othman, A.M. Effect of low-density polyethylene on fracture toughness of asphalt concrete mixtures. J. Mater. Civ. Eng. 2010, 22, 1019–1024. [Google Scholar] [CrossRef]

- Kakar, M.R.; Mikhailenko, P.; Piao, Z.; Bueno, M.; Poulikakos, L. Analysis of waste polyethylene (PE) and its by-products in asphalt binder. Constr. Build. Mater. 2021, 280, 122492. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Selection criteria for building materials and components in line with the circular economy principles in the built environment—A review of current trends. Infrastructures 2021, 6, 49. [Google Scholar] [CrossRef]

- Liu, Z.; Kringos, N. Transition from linear to circular economy in pavement engineering: A historical review. J. Clean. Prod. 2024, 449, 141809. [Google Scholar] [CrossRef]

- Jan, H.; Aman, M.Y.; Tawab, M.; Ali, K.; Ali, B. Performance evaluation of hot mix asphalt concrete by using polymeric waste polyethylene. In Modeling, Simulation, and Optimization; Springer: Cham, Switzerland, 2018; pp. 91–99. [Google Scholar]

- Noor, A.; Rehman, M.A.U. A mini-review on the use of plastic waste as a modifier of the bituminous mix for flexible pavement. Clean. Mater. 2022, 4, 100059. [Google Scholar] [CrossRef]

- Rincón-Estepa, J.A.; González-Salcedo, E.V.; Rondón-Quintana, H.A.; Reyes-Lizcano, F.A.; Bastidas-Martínez, J.G. Mechanical behavior of low-density polyethylene waste modified hot mix asphalt. Sustainability 2022, 14, 4229. [Google Scholar] [CrossRef]

- Huang, J.; Kumar, G.S.; Sun, Y. Evaluation of workability and mechanical properties of asphalt binder and mixture modified with waste toner. Constr. Build. Mater. 2021, 276, 122230. [Google Scholar] [CrossRef]

- Khedaywi, T.; Haddad, M.; Al-Masaeid, H.; Mharib, I.A.; Hawari, S. Characterization of binder and asphalt mixture modified with waste toner. Int. J. Transp. Sci. Technol. 2025, in press. [Google Scholar] [CrossRef]

- Itoua, P.; Sun, D.; Shen, S. Investigating the Properties of Asphalt and Asphalt Mixture Based on the Effect of Waste Toner. Carbon 2024, 59, 55.88. [Google Scholar]

- Acharya, B.; Behera, A.; Deshmukh, K.; Moharana, S. Plastic Waste Management During and Post COVID-19 Pandemic: Challenges and Strategies. Plast. Waste Manag. Methods Appl. 2024, 4, 173–199. [Google Scholar]

- Parthasarathy, M. Challenges and emerging trends in toner waste recycling: A review. Recycling 2021, 6, 57. [Google Scholar] [CrossRef]

- Shahib, M.I.; Dsouza, G.C.; Vijayakumar, R. A review on end-of-life waste toner powder: Recovery, utilization and upcycling. Waste Manag. 2025, 204, 114911. [Google Scholar] [CrossRef]

- Ruan, J.; Li, J.; Xu, Z. An environmental friendly recovery production line of waste toner cartridges. J. Hazard. Mater. 2011, 185, 696–702. [Google Scholar] [CrossRef]

- Khan, W.S.; Asmatulu, E.; Uddin, M.N.; Asmatulu, R. Recycling and Reusing of Engineering Materials: Recycling for Sustainable Developments; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Santolini, E.; Tarsi, G.; Torreggiani, D.; Sangiorgi, C. Towards more sustainable infrastructures through circular processes: Environmental performance assessment of a case study pavement with recycled asphalt in a life cycle perspective. J. Clean. Prod. 2024, 448, 141380. [Google Scholar] [CrossRef]

- Pérez-Acebo, H.; Mindra, N.; Railean, A.; Rojí, E. Rigid pavement performance models by means of Markov Chains with half-year step time. Int. J. Pavement Eng. 2019, 20, 830–843. [Google Scholar] [CrossRef]

- Merbold, G. Sensitivity of Water Absorption on the Performance Properties of RCA and RMA Stabilised with Bitumen Emulsion; Stellenbosch University: Stellenbosch, South Africa, 2022. [Google Scholar]

- Mostafa, A.Z. Improving the Performance of Highways and Airports Flexible Pavement to Resist the Effect of Octahedral Shear Stresses; Faculty of Engineering, Cairo University: Giza, Egypt, 2022. [Google Scholar]

- Prasad, C.S.R.; Reddy, S.N. Eco-Innovation In Road Construction: Development And Application Of Waste Polymer Modified Binder. Educ. Adm. Theory Pract. 2024, 30, 7819–7828. [Google Scholar] [CrossRef]

- Bai, M. Investigation of low-temperature properties of recycling of aged SBS modified asphalt binder. Constr. Build. Mater. 2017, 150, 766–773. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Analysis of styrene-butadiene-styrene polymer modified bitumen using fluorescent microscopy and conventional test methods. J. Hazard. Mater. 2008, 150, 424–432. [Google Scholar] [CrossRef]

- Masri, T.D.K.A.; Ferdaus, R.; Ramadhansyah, P. Sustainable use of polymer in asphalt mixture: A review. Construction 2022, 2, 12–21. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Boom, Y.J.; Giustozzi, F. Sustainable polymers from recycled waste plastics and their virgin counterparts as bitumen modifiers: A comprehensive review. Polymers 2021, 13, 3242. [Google Scholar] [CrossRef]

- Li, H.; Han, Y.; Guangxun, E.; Sun, Y.; Wang, L.; Liu, X.; Ren, J.; Lin, Z. Recycling of waste polyethylene in asphalt and its performance enhancement methods: A critical literature review. J. Clean. Prod. 2024, 451, 142072. [Google Scholar] [CrossRef]

- Singh, A.; Gupta, A. Mechanical and economical feasibility of LDPE Waste-modified asphalt mixtures: Pathway to sustainable road construction. Sci. Rep. 2024, 14, 25311. [Google Scholar] [CrossRef]

- Shahbazi, R.; Rajabipour, A.; Yaghoubi, E.; Bazli, M.; Diaz, L.H.; Dlugogorski, B.Z. Rubber and plastic waste-modified asphalt binders and mixtures: Performance against environmentally induced distresses—A review. J. Traffic Transp. Eng. (Engl. Ed.) 2025, in press. [Google Scholar]

- Melnjak, I.; Vučinić, A.A.; Radetić, L.; Grčić, I. Waste Toner Powder in Concrete Industry: An Approach Towards Circular Economy. Environ. Eng. Manag. J. 2019, 18, 1897–1906. [Google Scholar] [CrossRef]

- Itoua, P.I.; Sun, D.; Li, P.; Shen, S. Influence of waste toner on asphalt binder: Chemical and rheological characterization. Molecules 2023, 28, 2794. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Park, W.; Kim, H.; Park, Y.; Byun, Y.; Cho, S.; Hahn, S.K.; Han, H.; Kwon, W. Waste toner–derived carbon dots for bioimaging and photodynamic therapy. Dye. Pigment. 2023, 217, 111441. [Google Scholar] [CrossRef]

- Lim, S.M.; Ng, T.C.A.; He, M.; Amio, B.E.C.; Hao, G.; Zulkati, A.; Kapilan, S.; Ng, H.Y.; Ong, G.P. Refining leaching protocols of waste-plastic incorporated asphalt mixes for environmental impact assessment. J. Clean. Prod. 2025, 487, 144610. [Google Scholar] [CrossRef]

- Jordan, J.L.; Casem, D.T.; Bradley, J.M.; Dwivedi, A.K.; Brown, E.N.; Jordan, C.W. Mechanical properties of low density polyethylene. J. Dyn. Behav. Mater. 2016, 2, 411–420. [Google Scholar] [CrossRef]

- Notani, M.A.; Mokhtarnejad, M. Investigating the rheological and self-healing capability of toner-modified asphalt binder. Proc. Inst. Civ. Eng. Constr. Mater. 2020, 173, 123–131. [Google Scholar] [CrossRef]

- Shah, S.A.R.; Hussan, S.; Kahla, N.B.; Anwar, M.K.; Baluch, M.A.; Nawaz, A. Performance Evaluation and Optimization of Binder-Toner and Mixing Efficiency Ratios in an E-Waste Toner-Modified Composite Mixture Using Response Surface Methodology. Infrastructures 2024, 9, 200. [Google Scholar] [CrossRef]

- Showkat, B.; Suresha, S.; Akhandappagol, N. Study of rheological and creep recovery properties of asphalt binder modified with waste toner. J. Mater. Civ. Eng. 2020, 32, 04020331. [Google Scholar] [CrossRef]

- Obaid, H.A.; Eltwati, A.; Hainin, M.R.; Al-Jumaili, M.A.; Enieb, M. Modeling and design optimization of the performance of stone matrix asphalt mixtures containing low-density polyethylene and waste engine oil using the response surface methodology. Constr. Build. Mater. 2024, 446, 138037. [Google Scholar] [CrossRef]

- Vatanparast, M.; Sarkar, A.; Sahaf, S.A. Optimization of asphalt mixture design using response surface method for stone matrix warm mix asphalt incorporating crumb rubber modified binder. Constr. Build. Mater. 2023, 369, 130401. [Google Scholar] [CrossRef]

- Zakerzadeh, M. Optimising Mix Design and Performance of Crumb Rubber Modified Stone Mastic Asphalt (SMA): An Experimental Study for Enhanced Durability and Sustainability; UNSW Sydney: Sydney, NSW, Australia, 2025. [Google Scholar]

- Genet, M.B.; Sendekie, Z.B.; Jembere, A.L. Investigation and optimization of waste LDPE plastic as a modifier of asphalt mix for highway asphalt: Case of Ethiopian roads. Case Stud. Chem. Environ. Eng. 2021, 4, 100150. [Google Scholar] [CrossRef]

- Krannich, A.-L.; Reiser, D. The United Nations sustainable development goals 2030. In Encyclopedia of Sustainable Management; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–5. [Google Scholar]

- Anwar, M.K.; Shah, S.A.R.; Alhazmi, H. Recycling and utilization of polymers for road construction projects: An application of the circular economy concept. Polymers 2021, 13, 1330. [Google Scholar] [CrossRef] [PubMed]

- Hussain, S.; Zhou, X.; Shah, S.A.R.; Ahmad, N.; Anwar, M.K.; Basheer, M.A. Utilization of radium-bead material for road safety: An application of the circular economy concept. Polymers 2021, 13, 3708. [Google Scholar] [CrossRef]

- Knudsen, M.S.; Kaivo-oja, J. Bridging Industry 4.0 and Circular Economy: A New Research Agenda for Finland. Tulevaisuuden Tutkimuskeskuksen Blogi. 2018. Available online: https://ffrc.wordpress.com/2018/09/12/bridging-industry-4-0-and-circulareconomy (accessed on 13 May 2022).

- Schroeder, P.; Anggraeni, K.; Weber, U. The relevance of circular economy practices to the sustainable development goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef]

- Valverde, J.-M.; Avilés-Palacios, C. Circular economy as a catalyst for progress towards the sustainable development goals: A positive relationship between two self-sufficient variables. Sustainability 2021, 13, 12652. [Google Scholar] [CrossRef]

- Mushtaq, F.; Huang, Z.; Shah, S.A.R.; Zhang, Y.; Gao, Y.; Azab, M.; Hussain, S.; Anwar, M.K. Performance optimization approach of polymer modified asphalt mixtures with pet and pe wastes: A safety study for utilizing eco-friendly circular economy-based SDGs concepts. Polymers 2022, 14, 2493. [Google Scholar] [CrossRef]

- EurekAlert. A Comparison Between the Concepts of Linear and Circular Economy Models. 2025. Available online: https://www.eurekalert.org/multimedia/946513 (accessed on 14 June 2025).

- UN Trade and Devlopment. Circular Economy: The Silver Bullet for Emissions? 2017. Available online: https://unctad.org/news/circular-economy-silver-bullet-emissions (accessed on 14 June 2025).

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- ASTM D36; Standard Test Method for Softening Point of Bitumen (Ring-Andball Apparatus). American Association of State and Highway Transportation Officials: Washington, DC, USA, 2014.

- ASTM D7175-15; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- Xu, F.; Zhao, Y.; Li, K. Using waste plastics as asphalt modifier: A review. Materials 2021, 15, 110. [Google Scholar] [CrossRef]

- Haider, S.; Hafeez, I.; Ullah, R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr. Build. Mater. 2020, 235, 117496. [Google Scholar] [CrossRef]

- ASTM D692–00; Standard Specification for Coarse Aggregate for Bituminous Paving Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- ASTM C136-06; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- ASTM C127-01; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM C29/C29M-23; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- ASTM D5821-13; Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM D4791-19; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- ASTM C131-06; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- ASTM D6927-15; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- ASTM D6931-17; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2025.

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, Y.; Yang, Y.; Guo, R. Study on the Physical and Rheological Characterisation of Low-Density Polyethylene (LDPE)/Recycled Crumb Rubber (RCR) on Asphalt Binders. Molecules 2024, 29, 716. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Ding, Z.; Ma, L.X.; Feng, Z.G. Analysis of viscous flow properties of asphalt in aging process. Constr. Build. Mater. 2016, 124, 631–638. [Google Scholar] [CrossRef]

- Andrews, K.; Dernayka, S.; Mir, M.A.; Khasawneh, M.A. Review of the utilization of plastic waste in asphalt pavements in hot climate conditions—KSA as a case study. Mater. Today Proc. 2023, 5, 463. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Martínez, M.; Mas-Giner, I.; Verdejo, R.; López-Manchado, M.A.; Santana, M.H. New recyclable and self-healing elastomer composites using waste from toner cartridges. Compos. Sci. Technol. 2023, 244, 110292. [Google Scholar] [CrossRef]

- Shah, P.M. Study on use of recycled waste materials on the performance of asphalt binder and mixes: A comprehensive review. Prog. Rubber Plast. Recycl. Technol. 2024. [Google Scholar] [CrossRef]

- White, G. Evaluating recycled waste plastic modification and extension of bituminous binder for asphalt. In Proceedings of the Eighteenth Annual International Conference on Pavement Engineering, Asphalt Technology and Infrastructure, Liverpool, UK, 27–28 February 2019. [Google Scholar]

- Al-Saffar, Z.H.; Hasan, H.G.M.; Alamri, M.; Al-Attar, A.A.; Hamad, A.J.; Abdulmawjoud, A.A.; Mezaal, M.R.; Elmagarhe, A. Assessing the effects of copolymer modifier addition on asphalt attributes: Towards achieving performance optimization. Constr. Build. Mater. 2024, 420, 135645. [Google Scholar] [CrossRef]

- Adamu, M.; Ibrahim, Y.E.; Alanazi, H. Optimization of sustainable concrete properties modified with blends of date palm ash and eggshell powder using response surface methodology. Dev. Built Environ. 2024, 17, 100359. [Google Scholar] [CrossRef]

- Hamada, H.M.; Al-Attar, A.; Shi, J.; Yahaya, F.; Al Jawahery, M.S.; Yousif, S.T. Optimization of sustainable concrete characteristics incorporating palm oil clinker and nano-palm oil fuel ash using response surface methodology. Powder Technol. 2023, 413, 118054. [Google Scholar] [CrossRef]

- Liu, C.; Yang, H. Multi-objective optimization of a concrete thermal energy storage system based on response surface methodology. Appl. Therm. Eng. 2022, 202, 117847. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Spani, R.C. The New Circular Economy Action Plan (1 July 2020). FEEM Policy Brief No. 09-2020. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3711331 (accessed on 12 June 2025).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

| Tests | Unit | Standard | Results | Range | Remarks |

|---|---|---|---|---|---|

| Penetration | 0.1 mm | ASTM D5 | 67 | 60–70 | ok |

| Softening point | °C | ASTM D36 | 49.8 | ≥46 | ok |

| G*/sinδ | kPa | ASTM D7175 | 1.42 | ≥1.0 | ok |

| Component | Content (%) | Function/Risk | Image |

|---|---|---|---|

| Polymer resins | 30–60 | Binder; microplastic hazard |  |

| Carbon black | 15–30 | Pigment; nanoparticle risk | |

| Iron oxide (Fe3O4) | 5–20 | Magnetic component; recyclable | |

| Silica (SiO2) | 1–10 | Flow agent; respiratory hazard | |

| Heavy metals | <1 (trace) | Toxic (Pb, Cd, Hg); leaching risk |  |

| Plastic additives | Variable | Non-biodegradable waste | |

| VOCs | Trace | Air pollution during processing |

| Tests | Unit | Standard | Results | Range | Remarks |

|---|---|---|---|---|---|

| Water absorption | % | ASTM C127 [70] | 1.84 | <2 | ok |

| Bulk density | Kg/m3 | ASTM C29 [71] | 2 | \ | ok |

| Specific gravity | \ | ASTM C127 [70] | 2.23 | 2–3 | ok |

| Aggregate crushing | % | ASTM D5821-13 [72] | 25 | <30 | ok |

| Elongation index | % | ASTM D 4791 [73] | 29 | <45 | ok |

| Flakiness index | % | ASTM D 4791 [73] | 22 | <30 | ok |

| Aggregate impact value | % | ASTM C131 [74] | 21 | <27 | ok |

| Los Angeles abrasion | % | ASTM C131 [74] | 29 | <35 | ok |

| Factor | Unit | Symbol | Level −1 | Level 0 | Level +1 |

|---|---|---|---|---|---|

| Toner content | % | A | 5 | 15 | 25 |

| Recycled plastic content | % | B | 2 | 6 | 10 |

| Mixing temperature | °C | C | 140 | 160 | 180 |

| Statistical Index | Criteria | Stability (MPa) | ITS (MPa) | G/sinδ* (kPa) | CO2 Index |

|---|---|---|---|---|---|

| R2 value | 0–1 | 0.9814 | 0.9905 | 0.9912 | 1.00 |

| adjusted R2 | 0–1 | 0.9574 | 0.9783 | 0.9981 | 1.00 |

| predicted R2 | 0–1 | 0.9323 | 0.8688 | 0.9921 | 1.00 |

| Adeq. precision | 21.5239 | 31.0453 | \ | \ | |

| Std. Dev. | Lower | 0.1461 | 0.0107 | 0.00 | 0.00 |

| Mean | \ | 11.54 | 1.09 | 2.35 | 0.79 |

| C.V. % | 1.27 | 0.9751 | 0.00 | 0.00 | |

| F-value | Higher | 12.67 | 14.62 | \ | \ |

| p-value | 0.0032 | 0.0021 | \ | \ | |

| LOF-p-value | 0.0118 | 0.0405 | \ | \ |

| Response-R1 | Variables | Sum of Sq. | dF | Mean Sq. | F-Value | p-Value | η2 | Remarks |

|---|---|---|---|---|---|---|---|---|

| R1: Marshall stability (KN) | Model | 7.87 | 9 | 0.8744 | 40.94 | <0.0001 | \ | Significant |

| A-Toner content | 6.66 | 1 | 6.66 | 311.90 | <0.0001 | 0.831 | ||

| B-Plastic content | 0.0612 | 1 | 0.0612 | 2.87 | 0.1342 | 0.0076 | ||

| C-Mix. temp. | 0.1800 | 1 | 0.1800 | 8.43 | 0.0229 | 0.0224 | ||

| AB | 0.0100 | 1 | 0.0100 | 0.4682 | 0.5158 | 0.0012 | ||

| AC | 0.1225 | 1 | 0.1225 | 5.74 | 0.0478 | 0.0153 | ||

| BC | 0.0225 | 1 | 0.0225 | 1.05 | 0.3389 | 0.0028 | ||

| A2 | 0.3917 | 1 | 0.3917 | 18.34 | 0.0036 | 0.0489 | ||

| B2 | 0.2738 | 1 | 0.2738 | 12.82 | 0.0090 | 0.0342 | ||

| C2 | 0.0712 | 1 | 0.0712 | 3.33 | 0.1107 | 0.0089 | ||

| Residual | 0.1495 | 7 | 0.0214 | \ | \ | \ |

| Response-R2 | Variables | Sum of Sq. | dF | Mean Sq. | F-Value | p-Value | η2 | Remarks |

|---|---|---|---|---|---|---|---|---|

| R2: Indirect tensile strength (KN) | Model | 0.0830 | 9 | 0.0092 | 81.16 | <0.0001 | \ | Significant |

| A-Toner content | 0.0741 | 1 | 0.0741 | 652.56 | <0.0001 | 0.3187 | ||

| B-Plastic content | 0.0000 | 1 | 0.0000 | 0.0000 | 1.0000 | 0.0000 | ||

| C-Mix. temp. | 0.0021 | 1 | 0.0021 | 18.60 | 0.0035 | 0.0090 | ||

| AB | 0.0006 | 1 | 0.0006 | 5.50 | 0.0514 | 0.0026 | ||

| AC | 0.0009 | 1 | 0.0009 | 7.92 | 0.0260 | 0.0039 | ||

| BC | 0.0002 | 1 | 0.0002 | 1.98 | 0.2021 | 0.0009 | ||

| A2 | 0.0043 | 1 | 0.0043 | 37.96 | 0.0005 | 0.0185 | ||

| B2 | 0.0001 | 1 | 0.0001 | 0.7507 | 0.4149 | 0.0004 | ||

| C2 | 0.0007 | 1 | 0.0007 | 6.27 | 0.0408 | 0.0030 | ||

| Residual | 0.1495 | 7 | 0.0214 | \ | \ | \ |

| Responses-R3 and R4 | Variables | Sum of Sq. | dF | Mean Sq. | η2 | Remarks |

|---|---|---|---|---|---|---|

| R3: DSR modulus, G/sinδ* (kPa) | Model | 3.28 | 3 | 1.09 | \ | Significant |

| A-Toner content | 2.00 | 1 | 2.00 | 0.61 | R2 = 0.99, adjusted R2 = 0.998, predicted R2 = 0.992, mean = 2.35 | |

| B-Plastic content | 1.28 | 1 | 1.28 | 0.39 | ||

| C-Mix. temp. | 0.0000 | 1 | 0.0000 | 0.00 | ||

| Residual | 3.28 | 4 | 0.0000 | |||

| R4: CO2 index | Model | 3.28 | 3 | 1.09 | Significant | |

| A-Toner content | 2.00 | 1 | 2.00 | 0.61 | R2 = 1.0, adjusted R2 = 1.0, predicted R2 = 1.0, mean = 0.79 | |

| B-Plastic content | 1.28 | 1 | 1.28 | 0.39 | ||

| C-Mix. temp. | 0.0000 | 1 | 0.0000 | 0.00 | ||

| Residual | 3.28 | 4 | 0.0000 | \ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siddiq, M.U.; Anwar, M.K.; Almansour, F.H.; Javed, J.; Qurashi, M.A. Performance Evaluation of Waste Toner and Recycled LDPE-Modified Asphalt Pavement: A Mechanical and Carbon Assessment-Based Optimization Approach Towards Sustainability. Sustainability 2025, 17, 7003. https://doi.org/10.3390/su17157003

Siddiq MU, Anwar MK, Almansour FH, Javed J, Qurashi MA. Performance Evaluation of Waste Toner and Recycled LDPE-Modified Asphalt Pavement: A Mechanical and Carbon Assessment-Based Optimization Approach Towards Sustainability. Sustainability. 2025; 17(15):7003. https://doi.org/10.3390/su17157003

Chicago/Turabian StyleSiddiq, Muhammad Usman, Muhammad Kashif Anwar, Faris H. Almansour, Jahanzeb Javed, and Muhammad Ahmed Qurashi. 2025. "Performance Evaluation of Waste Toner and Recycled LDPE-Modified Asphalt Pavement: A Mechanical and Carbon Assessment-Based Optimization Approach Towards Sustainability" Sustainability 17, no. 15: 7003. https://doi.org/10.3390/su17157003

APA StyleSiddiq, M. U., Anwar, M. K., Almansour, F. H., Javed, J., & Qurashi, M. A. (2025). Performance Evaluation of Waste Toner and Recycled LDPE-Modified Asphalt Pavement: A Mechanical and Carbon Assessment-Based Optimization Approach Towards Sustainability. Sustainability, 17(15), 7003. https://doi.org/10.3390/su17157003