Abstract

Due to the increasing environmental concerns and the growing generation of electronic waste and plastic, sustainable waste management solutions are essential for the construction industry. This study explores the potential of using electronic waste toner powder (WTP) and recycled low-density polyethylene (LDPE), either individually or in combination as modifiers for asphalt binder to enhance pavement performance and reduce environmental impact. The analysis focused on three key components: (1) binder development and testing; (2) performance evaluation through Marshall stability, indirect tensile strength, and Dynamic Shear Rheometer (DSR) testing for rutting resistance; and (3) sustainability assessment in terms of carbon footprint reduction. The results revealed that the formulation of 25% WTP and 8% LDPE processed at 160 °C achieved the best mechanical performance and lowest carbon index, enhancing Marshall stability by 32% and rutting resistance by 41%. Additionally, this formulation reduced the carbon footprint by 27% compared to conventional asphalt. The study demonstrated that the combination of WTP and LDPE significantly improves the sustainability and performance of asphalt pavements, offering mechanical, environmental, and economic benefits. By providing a quantitative assessment of waste-modified asphalt, this study uniquely demonstrates the combined use of WTP and LDPE in asphalt, offering a novel dual-waste valorization approach that enhances pavement performance while promoting circular economy practices.

1. Introduction

The demand for sustainable construction materials has grown exponentially in response to increasing global concerns over climate change, non-renewable resource depletion, and environmental pollution. Among various infrastructural components, asphalt pavements consume a substantial volume of petroleum-based bitumen annually, contributing significantly to greenhouse gas emissions and environmental degradation during their lifecycle [1,2,3]. Bitumen production accounts for around 10% to 15% of global industrial CO2 emissions, with the crude oil extraction phase contributing 70% of its total global warming potential [4]. To address these concerns, the integration of waste-derived modifiers into asphalt binders has emerged as a promising avenue for enhancing pavement performance while mitigating environmental burdens [5,6,7].

One of the most critical challenges in the modern era is the management of solid waste, particularly electronic waste (e-waste) and plastic waste, which are accumulating at an alarming rate. According to the global e-waste monitor [8], the world generated approximately 53.6 million metric tonnes of e-waste in 2019, a figure expected to reach 74.7 million tonnes by 2030. Waste toner powder (WTP), a by-product of disposed printer cartridges, is a hazardous constituent of this waste stream, rich in thermoplastic polymers, styrene–acrylate copolymers, and carbon black [9,10]. If not properly managed, it poses severe risks to human health and the environment due to the presence of toxic heavy metals and organic compounds [11,12,13].

Similarly, waste plastics, particularly polyethylene (PE), polypropylene (PP), and polystyrene (PS), contribute to a growing environmental crisis due to their non-biodegradable nature and improper disposal practices. These materials, however, possess intrinsic thermoplastic and viscoelastic properties that make them attractive candidates for bitumen modification [14,15,16]. The reuse of these polymers in asphalt mixtures aligns well with the principles of the circular economy, wherein end-of-life products are reintroduced into production cycles to maximize resource efficiency and minimize environmental footprints [17,18].

In this context, the present study explores the synergistic use of waste toner and recycled LDPE as asphalt modifiers. While individual studies have investigated the use of plastics [19,20,21] and toner powder [22,23,24] in asphalt, limited research exists on their combined effect on the rheological, mechanical, and environmental properties of asphalt binders and mixtures. Moreover, past studies often overlook environmental impacts like carbon emissions and rarely optimize both material content and processing temperature together. This study addresses these gaps through a comprehensive performance and sustainability evaluation.

The novelty of this study lies in employing these two waste streams together through a response surface methodology (RSM) approach, providing a systematic optimization of key parameters including toner content, plastic content, and mixing temperature. The combination of waste toner and plastic waste leverages the complementary properties of both modifier toner contributes to increased stiffness and reduces the carbon footprint due to its high carbon content, while recycled plastics like LDPE enhance elasticity, durability, and resistance to deformation. Together, they offer a balanced improvement in mechanical and environmental performance, promoting circular economy principles in asphalt binder modification.

Furthermore, this research contributes to sustainable infrastructure development by reducing dependency on virgin materials and addressing critical waste management issues. The integration of recycled materials into road construction not only enhances the functional properties of asphalt but also contributes to carbon emission reduction, a key objective under global climate agreements such as the Paris accord [24]. The development of a CO2 index in this study further provides a quantifiable measure of environmental performance for modified asphalt formulations.

This study presents unique innovations by exploring the synergistic effects of combining two waste polymers (waste toner powder and recycled plastic) for asphalt binder modification, offering new insights into waste valorization. It integrates mechanical and environmental optimization using RSM, balancing both performance and carbon footprint reduction, which is a novel approach compared to traditional studies that address these factors separately. The introduction of a carbon performance index (CO2 index) to measure waste content impact on emissions is a pioneering step towards standardized environmental assessment in binder modification. Additionally, the study advocates for low-cost, environmentally friendly materials in line with circular economy principles, promoting sustainable infrastructure. Lastly, by optimizing mixing temperature alongside waste content, it identifies the best processing conditions to enhance both binder performance and carbon savings, a combination seldom explored concurrently in previous binder optimization studies.

2. Background

The global accumulation of solid waste, particularly non-biodegradable polymers, has escalated into a significant ecological and economic challenge, necessitating innovative recycling and upcycling strategies [25]. Among these waste materials, plastic products and printer consumables like waste toner powder (WTP) contribute substantially to environmental pollution due to their persistence and potential toxicity [26,27]. Traditional disposal methods, such as landfilling and incineration, are increasingly unsustainable, as they lead to soil contamination, greenhouse gas emissions, and resource depletion [26,28]. Consequently, researchers have explored integrating these waste materials into construction materials, particularly asphalt pavements, to promote a circular economy while enhancing material performance [29,30].

Asphalt pavements, primarily composed of bitumen and aggregates, are susceptible to deterioration from traffic loads, temperature fluctuations, and moisture infiltration [31,32]. Conventional bitumen often lacks the mechanical resilience required for modern infrastructure demands, prompting investigations into polymer-modified binders [33,34]. Styrene–butadiene–styrene (SBS) and ethylene–vinyl acetate (EVA) are widely used modifiers, but their high cost and reliance on virgin polymers limit sustainability [35,36,37,38]. In contrast, recycled plastics, such as low-density polyethylene (LDPE), offer a cost-effective alternative, improving asphalt’s high-temperature stability and rutting resistance [39,40,41]. Similarly, WTP comprising carbon powder, polymers, and nano-oxides (e.g., SiO2 and Fe3O4) has shown promise as a filler due to its high surface area and potential to enhance binder–aggregate adhesion [22,42,43]. However, inconsistencies in WTP composition and concerns over microplastic leaching necessitate rigorous performance and environmental assessments [26,44,45].

Recent studies highlight the synergistic potential of hybrid waste-modified asphalts. For instance, LDPE improves stiffness [16,46], while WTP’s nano-fillers enhance thermal and mechanical properties [47,48,49]. However, optimizing their combined use remains underexplored, particularly in balancing mechanical performance with environmental benefits. Response surface methodology (RSM) has emerged as a robust tool for such multi-objective optimization, enabling precise evaluation of interactions between variables like modifier content and mixing temperature [50,51,52].

A critical research gap exists in the optimization of asphalt binders combining waste toner powder (WTP) and recycled LDPE, as no previous studies have employed RSM to systematically evaluate their synergistic effects [48,53]. While both materials show promise as individual modifiers, their combined potential remains unexplored, particularly regarding three key aspects: (1) rheological performance and durability of the blended system; (2) standardized methods for carbon footprint assessment; and (3) quantitative optimization of formulation parameters. This study bridges these gaps through an integrated approach that develops a novel WTP-LDPE modified binder, employs RSM for multi-objective optimization, and establishes a quantitative CO2 index for environmental evaluation. The resulting framework advances sustainable pavement technology while demonstrating a practical application of circular economy principles in infrastructure materials development.

The Sustainable Development Goals (SDGs) provide a global roadmap toward achieving enhanced sustainability by 2030 [54]. These 17 interlinked goals, supported by 169 specific targets, are increasingly adopted by both public and private sectors worldwide to guide sustainable practices. Alongside the SDGs, the circular economy (CE) framework has gained prominence as a practical approach to sustainability at local, national, and international levels [55,56]. Various stakeholders, including governments, municipalities, and multinational corporations, actively promote CE initiatives to reduce waste and maximize resource efficiency [57]. The benefits of CE are presented in Figure 1a.

Although the literature directly linking CE and SDGs remains limited [58,59,60], emerging studies emphasize the role of CE strategies as effective tools for achieving multiple SDGs, especially in developing economies. Key synergies between CE initiatives and SDGs include:

- SDG 6: Clean water and sanitation promote resource recycling and pollution reduction.

- SDG 7: Affordable and clean energy emphasizes renewable and efficient energy use.

- SDG 8: Decent Work and Economic Growth advocates sustainable economic development.

- SDG 12: Responsible consumption and production focus on sustainable material use and waste reduction.

- SDG 15: Life on land aims to restore and preserve terrestrial ecosystems.

In the context of sustainable infrastructure, particularly asphalt pavement modification, the integration of e-waste toner and recycled plastic polymers exemplifies CE principles by valorizing post-consumer waste materials. This approach contributes primarily to SDG 12 by promoting sustainable production and consumption of materials, and to SDG 8 by fostering economic growth through innovative recycling industries. Additionally, by reducing reliance on virgin asphalt binder and minimizing waste disposal, this strategy indirectly supports SDG 13 (climate action) through reduced carbon footprints, as shown in Figure 1a.

The production phase of circularity in asphalt modification focuses on maximizing the reuse of recycled materials such as waste toner and recycled plastics, while minimizing value loss during processing and application. Consumption phase strategies include extending pavement service life through improved material performance, enabling repair and maintenance rather than complete replacement, and facilitating future recycling, all core CE activities that preserve material utility and reduce environmental impact.

Figure 1b illustrates the three fundamental principles of the circular economy alongside 17 SDGs, contextualized here to copolymer-modified asphalt binders and aligned with the relevant SDGs. These principles emphasize:

- Designing out waste and pollution by incorporating waste toner and recycled plastics into binder formulations.

- Keeping products and materials in use by enhancing pavement durability and recyclability.

- Regenerating natural systems by reducing demand for virgin fossil-based binders, thereby lowering environmental degradation.

By integrating waste toner and recycled plastic polymers in asphalt binders, this research advances a practical CE model that supports multiple SDGs, creating a sustainable, low-carbon, and circular infrastructure solution.

Figure 1.

(a) Circular economy (CE) benefits, (b) CE aligned with sustainable development goals (SDGs) [61,62].

3. Materials and Methods

3.1. Research Methodology

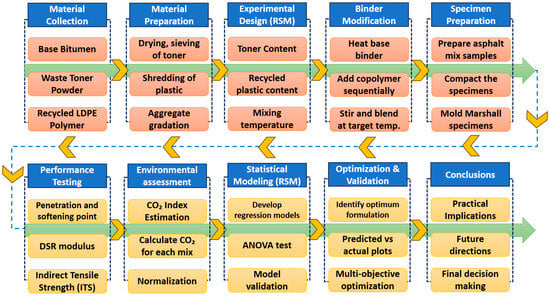

The research methodology in this study is divided into two main stages: modification of bitumen using polymer materials such as waste toner and recycled plastic polymers, followed by the preparation and testing of polymer-modified asphalt mixtures. Various contents of waste copolymers were evaluated through both fresh binder characterization, mechanical and environmental performance testing of the asphalt mixes. Key engineering properties, including Marshall stability, tensile strength, dynamic shear modulus and CO2 index, were thoroughly analyzed to assess the mixtures’ behavior and durability under local environmental and traffic conditions. The step-by-step research methodology is illustrated in the flowchart shown in Figure 2.

Figure 2.

Overview of the experimental procedure, including binder modification, mixture preparation, and testing workflow.

3.2. Materials

3.2.1. Asphalt Binder

The base asphalt binder utilized in this study was a conventional 60/70 penetration grade bitumen, widely used in road construction across various climatic zones. The binder was sourced from a regional refinery and was tested to comply with ASTM standards. The optimum binder content is 7% according to our preliminary studies. Key physical properties included a penetration value of 67 dmm, softening point of 49.8 °C, and dynamic shear modulus of 1.56 kPa, meeting the requirements of ASTM D5, ASTM D36 and ASTM D7175 [63,64,65]. The physical properties of pure binder are presented in Table 1.

Table 1.

Physical properties of pure binder.

3.2.2. Waste Toner Powder (WTP)

Waste toner powder (WTP) was sourced from discarded laser printer cartridges collected from electronic waste processing facilities. The toner mainly consisted of thermoplastic styrene–acrylate copolymers, carbon black, and trace amounts of ferrite and silica, as confirmed by Fourier transform infrared spectroscopy (FTIR) and energy dispersive X-ray spectroscopy (EDS), as presented in Table 2. The toner was dried and sieved to <75 µm to ensure uniform dispersion during mixing. The percentage of WTP was selected based on our prior study [48].

Table 2.

Physical properties of waste toner powder.

3.2.3. Recycled Plastic Polymer

Low-density polyethylene (LDPE) waste was obtained from post-consumer plastic packaging. The material was washed, shredded, and ground to a fine granulate (particle size ~2–3 mm). The LDPE polymer was selected for its favorable melting point (110–120 °C) and compatibility with asphalt binder rheology. The percentage of recycled plastic was selected based on the literature studies [53,66,67] to prepare the copolymer-modified asphalt binder.

3.2.4. Aggregates

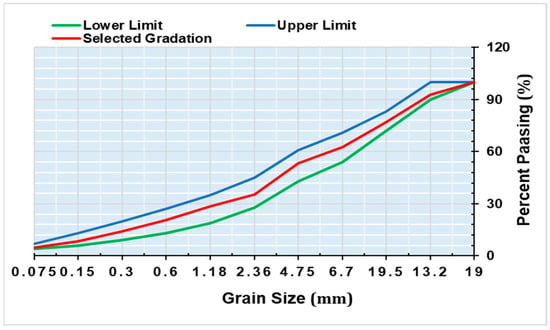

Crushed granite aggregates, conforming to ASTM D692 [68] specifications, were used in all mix designs as presented in Table 3. A standard dense-graded aggregate gradation was maintained across all samples. Aggregates were oven-dried at 105 ± 5 °C prior to mixing. Sieve analysis of the aggregate was performed in accordance with ASTM C136 [69]. As illustrated in Figure 3, the proposed gradation falls within the upper and lower specification limits, confirming compliance with standard requirements.

Table 3.

Physical properties of aggregates.

Figure 3.

Gradation curve of used aggregates.

3.3. Experimental Design Using RSM

A total of 17 modified binder samples were prepared based on a central composite design (CCD) under response surface methodology (RSM). The three factors, such as toner content, polymer content, and mixing temperature, were selected based on their critical influence on binder modification, workability, and environmental footprint. The study evaluated multiple responses, including Marshall stability (kN) and flow (mm), indirect tensile strength (MPa), dynamic shear rheometer (G*/sinδ, kPa), penetration (dmm), softening point (°C), and a CO2 emissions index, providing a comprehensive assessment of performance and sustainability. Waste toner (10–30%) enhances stiffness and contributes to carbon reduction, while polymer (2–10%) improves elasticity and rutting resistance. The mixing temperature range (140–180 °C) ensures effective blending without degrading the modifiers. These levels were selected based on previous literature studies [48,53,66,67] and preliminary trials for practical applicability. The design matrix involved three independent variables and their levels are presented in Table 4.

Table 4.

Independent variables and their levels.

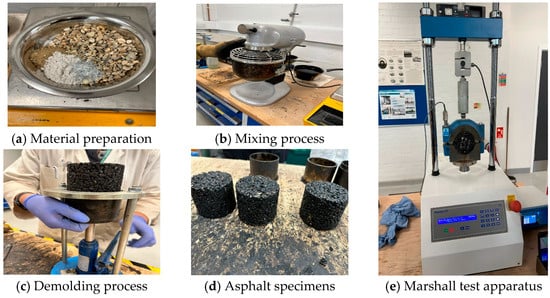

3.4. Sample Preparation

To prepare polymer-modified binder specimens, the base bitumen was first heated to approximately 130 °C to ensure a fluid state suitable for mixing. Based on our preliminary study, the optimum binder content for the control specimen was found to be 6%. Predetermined amounts of waste toner and LDPE polymer, based on the RSM design matrix, were gradually added in sequence under continuous mechanical stirring. The blend was further mixed at the target mixing temperature (140–180 °C) for 30 min to ensure uniform dispersion of the modifiers. For asphalt mixture specimens, the modified binder was combined with preheated aggregates and mixed thoroughly. Marshall specimens were compacted using standard procedures (75 blows per side) and cured at room temperature for 24 h prior to mechanical testing. This ensured consistency in specimen preparation and testing conditions across all design levels. The development and preparation of polymer-modified asphalt are presented in Figure 4.

Figure 4.

Development and preparation of copolymer-modified asphalt.

3.5. Testing Procedures

The selected tests, including penetration, softening point, Marshall stability, flow, indirect tensile strength (ITS), and Dynamic Shear Rheometer (DSR), are widely accepted standards for evaluating the mechanical and rheological performance of asphalt binders and mixtures. These tests collectively assess consistency, strength, resistance to deformation, and rutting behavior, which are critical for understanding the asphalt’s durability and performance under various traffic and environmental conditions. Additionally, the CO2 index was used to evaluate environmental impact, ensuring a comprehensive assessment of both performance and sustainability.

3.5.1. Penetration and Softening Point

Penetration was determined following ASTM D5, while softening point was measured using the ring-and-ball method (ASTM D36). These tests provided insights into the consistency and thermal susceptibility of the modified binders.

3.5.2. Marshall Stability and Flow

The Marshall specimens were prepared according to ASTM D6927 [75]. Cylindrical samples (101.6 mm diameter and 63.5 mm height) were compacted using 75 blows per face. The specimens were tested at 60 °C under a loading rate of 50 mm/min. The peak load was recorded as Marshall stability (kN), while the corresponding deformation was noted as Marshall flow (mm).

3.5.3. Indirect Tensile Strength (ITS)

ITS was evaluated on cylindrical specimens (101.6 mm diameter, 63.5 mm height) as per ASTM D6931 [76]. The tensile strength was computed from the peak load at failure using Equation (1).

where “ITS” is the indirect tensile strength (MPa), “P” is the maximum load (N), “d” is diameter (mm), and “t” is thickness (mm).

3.5.4. Dynamic Shear Rheometer (DSR)

The rheological behavior was evaluated using a DSR (Anton Paar MCR series, Anton Paar GmbH, Graz, Austria), in accordance with AASHTO T315. Tests were conducted at 64 °C using 25 mm plates with a 1 mm gap. The DSR testing was conducted at 64 °C in alignment with Superpave binder specifications (AASHTO T 315) to evaluate high-temperature rutting resistance, a critical performance parameter for asphalt binders in warm climates. The complex shear modulus (G*) and phase angle (δ) were recorded, and the rutting resistance parameter G*/sin δ was computed.

3.6. Environmental Assessment

To calculate the CO2 index, the process begins by determining the baseline carbon emission (C0), which represents the carbon footprint of 100% virgin asphalt binder per unit volume or weight. For simplicity, it is assumed that “C0” equals 1.0. Next, the waste material carbon emission (C-waste) is considered. Since waste toner and plastic are made from recycled materials, they are assumed to have zero or negligible carbon emissions, making “C-waste” approximately 0.

The third step is to calculate the effective carbon emission (C-eff), which is proportional to the fraction of virgin binder that remains after replacement by waste toner and plastic. This can be calculated using the formula given below:

where “R” is the total replacement fraction of virgin binder by toner and plastic. If the toner content is “T%” and the plastic content is “P%”, then the total binder replacement “R” is calculated as in Equation (3).

Substituting into Equation (4) yields the final expression for effective carbon emission (C-eff).

where “C-eff” is the effective carbon emission, “C0” is the carbon emission, “T” is the toner content and “P” is the plastic content in percentage.

Finally, to normalize the CO2 index, the effective carbon emission is adjusted to keep values between 0 and 1. The formula used in Equation (3) is CO2 index. For example, if the toner content is 15% and the plastic content is 6%, the total replacement is 21%, and the CO2 index becomes 1 − 0.21 = 0.79. Similarly, for 25% toner and 10% plastic (35% total replacement), the CO2 index is 1 − 0.35 = 0.65. For 5% toner and 2% plastic (7% total replacement), the CO2 index is 1 − 0.07 = 0.93.

3.7. Statistical Analysis

All experimental data were analyzed using Design-Expert® software, version 13.0. Analysis of Variance (ANOVA) was performed to evaluate the significance of individual factors and their interactions on each response variable. A second-order polynomial regression model was developed for each response. Contour plots and desirability functions were used for multi-objective optimization of mechanical and environmental performance.

4. Results and Discussions

4.1. Effect of Polymer Modification and Temperature on Binder Consistency

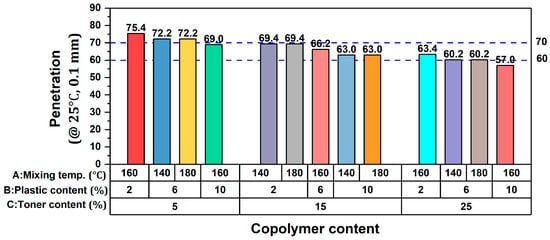

4.1.1. Penetration Test

Figure 5 presents the synergistic effects of polymer modification and mixing temperature on the penetration values. The penetration values ranged from 57 dmm to 75.4 dmm, as shown in Figure 5. A strong inverse relationship was observed between toner content and penetration value. Mixtures with 25% toner exhibited the lowest penetration values (57–63.4 dmm), indicating a harder binder. In contrast, mixes with 5% toner and higher plastic content had values exceeding 70 dmm, indicating a softer binder matrix.

Figure 5.

Effect of polymer modification on penetration.

The effect of mixing temperature also plays a crucial role in determining the binder’s penetration. Mixtures prepared at higher temperatures (e.g., 180 °C) generally show lower penetration values, reinforcing the idea that elevated temperatures tend to stiffen the binder. At higher mixing temperatures, the material’s viscosity increases, which can contribute to a more rigid structure and lower penetration. This is particularly evident in the 25% toner mixtures, where higher mixing temperatures (180 °C) resulted in slightly lower penetration values compared to those mixed at 160 °C.

This suggests that toner acts as a stiffening agent, reducing binder penetration, while plastic polymer content increases flexibility. A balanced formulation of 15% toner and 6% plastic yielded moderate penetration values around 66.2 dmm, suitable for a range of climates. These findings correlate with those of Zhu et al. [77], who observed reduced penetration in binders modified with carbon-rich polymer materials due to increased filler concentration and a stiffer binder matrix.

4.1.2. Softening Point Test

Figure 6 presents the synergistic effects of polymer modification and mixing temperature on the softening point values. Softening point results ranged from 47.3 °C to 56.5 °C, as shown in Figure 6. The highest values were recorded in binders containing 25% toner and 10% plastic, indicating enhanced thermal resistance (up to 56.5 °C). These results demonstrate that waste toner significantly increases binder stiffness at elevated temperatures, likely due to its fine particle size and glassy matrix.

Figure 6.

Effect of polymer modification on the softening point.

Interestingly, binders with only 5% toner had softening points as low as 47.3 °C, similar to unmodified bitumen. This confirms that toner content is the primary factor influencing softening point, while plastic polymer plays a secondary role by adjusting the flexibility of the matrix. The mixing temperature also played a crucial role in determining the softening point. At higher mixing temperatures (e.g., 180 °C), the softening point tended to increase, reflecting the enhanced binder rigidity. Specifically, mixtures prepared at 180 °C with 10% recycled plastic and 25% toner exhibited softening points of 53.5 °C, compared to those prepared at 160 °C, which were slightly lower. This indicates that higher mixing temperatures promote binder stiffness, further improving the thermal resistance of the mixture. This outcome is supported by studies [22,78], and found that toner-rich and recycled plastic content formulations improve thermal resistance and delay softening under high-temperature service conditions. The overall performance of copolymer-modified asphalt binders showed a promising result in improving overall binder properties.

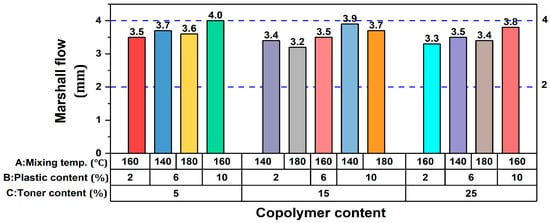

4.2. Effect of Polymer Binders on Marshall Flow

Figure 7 presents the synergistic effects of polymer modification and mixing temperature on the Marshall flow results. The Marshall flow results (Figure 7) revealed a range from 3.2 mm to 4.0 mm. Optimal flow values were found at moderate plastic and toner contents (e.g., 15% toner and 6% plastic), suggesting a balanced elastic and viscous response. Excessive plastic (10%) tended to increase flow values due to softening, while lower toner levels (5%) resulted in less structural rigidity, corroborating findings from previous studies on waste polymer modifiers [5,6]. Similarly, as the mixing temperature increases from 140 °C to 180 °C, the Marshall flow generally increases, especially at higher toner and plastic contents. This suggests that higher temperatures promote better binder flow, which enhances the mixture’s workability and flexibility. These findings align with the existing literature, such as studies by Li et al. [79], which shows that higher temperatures reduce viscosity and improve flow, and Andrews et al. [80], who suggest that increasing plastic content enhances the flexibility and cohesion of the mixture. Overall, the chart confirms that both higher mixing temperatures and higher recycled plastic and toner contents contribute to an increased Marshall flow, improving the overall performance of the asphalt mixture.

Figure 7.

Effect of polymer modification on the Marshall flow.

4.3. Response Surface Methodology Analysis and Model Validation

In this study, RSM was applied to optimize the performance of copolymer-modified asphalt incorporating waste toner and recycled plastic polymers. A total of 17 asphalt mixtures were prepared using a three-factor design with toner content, plastic content, and mixing temperature as variables.

Performance was evaluated through Marshall stability, indirect tensile strength (ITS), and G/sinδ* (kPa) from DSR testing. The study prioritizes mechanistic (Stability/ITS/DSR) and environmental (CO2) metrics over empirical tests (penetration/softening point), as they better capture modified asphalt behavior and align with performance-grade specifications during RSM modeling. A CO2 index was also introduced to assess environmental impact. Second-order polynomial models were developed for all responses except DSR and CO2 indices, with their validity confirmed through R2, adjusted R2, and ANOVA. The ANOVA results of all responses are presented in Table 5.

Table 5.

ANOVA results of RSM model.

The results indicated that all three factors significantly influenced both mechanical and environmental performance. The RSM approach successfully identified an optimal formulation that balances strength and carbon reduction, supporting the development of more sustainable asphalt materials.

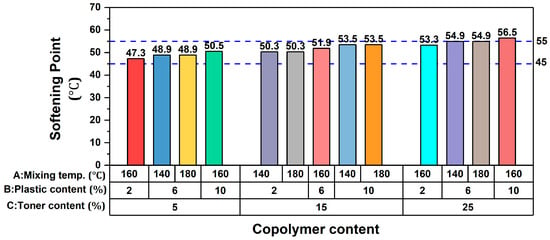

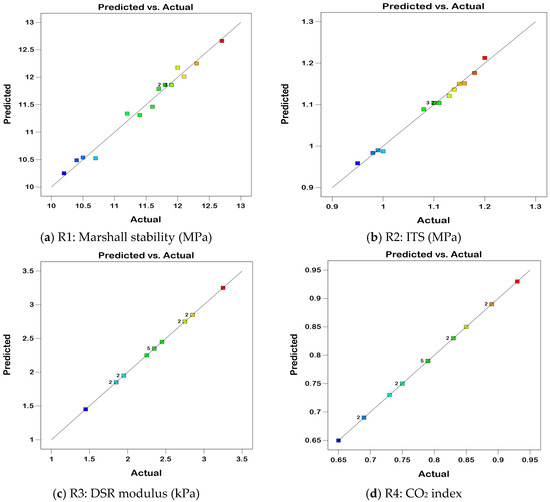

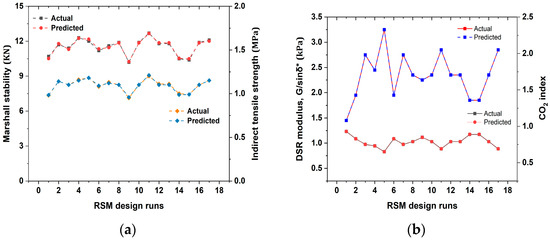

The four “predicted vs. actual” scatter plots presented in Figure 8a–d validate the predictive performance of the developed models for each response variable. In each plot, the predicted values are plotted against the corresponding actual experimental values, with data points color-coded to reflect the magnitude of the responses.

Figure 8.

Predicted vs. actual response surface plots.

In Figure 8a, the predicted values for Marshall stability range from approximately 10 to 13 MPa, closely aligning along the 45° reference line. The color gradient from dark blue to red indicates increasing response values, helping to compare predicted and actual data trends. This strong linear relationship demonstrates excellent model accuracy, further supported by a high R2 value of 0.9814, indicating that over 98% of the variability in stability is explained by the model. Similarly, Figure 8b for ITS (MPa) shows a tight clustering of points along the diagonal line, with actual values ranging from 0.9 to 1.3 MPa. The high R2 of 0.9905 and the low standard deviation signify a robust predictive fit with minimal error.

In Figure 8c, the DSR modulus (G/sinδ)* ranges from 1.0 to 3.5 kPa, and the model once again demonstrates strong predictive capability with data points adhering closely to the reference line. The R2 value of 0.9912 confirms that the developed model accurately captures the rheological behavior of the binder in response to compositional changes. Lastly, Figure 8d for the CO2 index shows an almost perfect correlation between predicted and actual values, with values ranging from 0.65 to 0.95. The R2 value of 1.00 suggests that the model predicts this environmental performance metric with exceptional precision and zero deviation. Collectively, the visual and statistical results from these plots confirm the reliability and accuracy of the RSM-based models across all mechanical and environmental responses. The close alignment of predicted values with experimental results highlights the effectiveness of the modeling approach in capturing complex material behaviors influenced by copolymer content and mixing temperature.

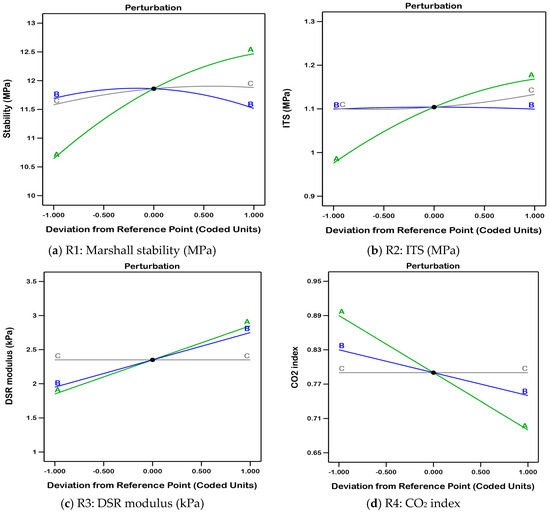

The perturbation plots presented in Figure 9a–d provide insights into the influence of the variables A (toner content), B (plastic content), and C (interaction between toner and plastic content) on the material properties of the developed model. These plots help to evaluate the sensitivity of the model to variations in each variable. For R1: Marshall stability (MPa) in Figure 9a, plastic content (B) shows the most significant negative effect, where increasing plastic content leads to a reduction in stability. Toner content (A) has minimal impact on stability, as the curve remains nearly flat. The interaction between the two variables (C) also shows little effect on stability.

Figure 9.

Perturbation response surface plots for each response.

In Figure 9b, for R2: ITS (MPa), plastic content (B) again dominates, positively influencing ITS. Higher plastic content increases ITS, while toner content (A) has a negligible effect, reflected by the near-horizontal curve. The interaction term (C) has a slight influence but is secondary to the effect of plastic content. For R3: DSR modulus (kPa) in Figure 9c, toner content (A) has a moderate positive impact, increasing the DSR modulus as its content rises. Plastic content (B) also increases the modulus, but to a lesser degree. The interaction (C) does not significantly affect the DSR modulus.

In Figure 9d, for R4: CO2 index, toner content (A) shows a slight positive effect, whereas plastic content (B) negatively impacts the CO2 index. Higher toner content reduces the CO2 index, while more plastic increases it. The interaction term (C) has minimal influence on the CO2 index. Overall, plastic content is the most influential variable on Marshall stability and ITS, while toner content is more significant for DSR modulus. The interaction between the two variables has minimal impact.

4.4. Response Surface Model Plots

4.4.1. Marshall Stability Performance of Polymer-Modified Asphalt

The performance of the polymer-modified asphalt was statistically analyzed using RSM to model the effect of toner content (A), plastic content (B), and mixing temperature (C) on Marshall stability. A quadratic regression model was developed, yielding the following predictive equation in terms of coded variables:

This model demonstrates the influence of both linear and interaction terms, as well as quadratic components, on the mechanical response of the asphalt mixtures, as shown in Table 6. The developed quadratic regression model for Marshall stability exhibited strong statistical significance, with an F-value of 40.94 and a p-value of less than 0.0001, indicating that the model is highly reliable in explaining the variability of the data. Among the input variables, toner content (A) emerged as the most influential factor (p < 0.0001), demonstrating a substantial positive effect on the stability of polymer-modified asphalt. Mixing temperature (°C) also showed a statistically significant impact (p = 0.0229), suggesting that higher temperatures can moderately enhance the material’s stability. Additionally, the interaction between toner and temperature (AC), along with the quadratic terms A2 and B2, was found to be significant, indicating a nonlinear relationship and the presence of optimal dosage levels for toner and plastic contents. In contrast, plastic content (B) alone did not show a statistically significant effect (p = 0.1342), and other interactions (AB, BC, C2) also remained insignificant. Effect sizes (η2) were calculated to assess the practical significance of each factor. Toner content showed the highest effect (η2 = 0.831), followed by A2 (0.0489) and B2 (0.0342), indicating toner’s dominant influence on Marshall stability.

Table 6.

RSM-based ANOVA results of Marshall stability.

Although the model’s Lack of Fit was significant (p = 0.0118), which typically suggests that some variation in the data remains unexplained, the overall model still captured the key trends and factor influences effectively. This analysis underscores toner content as the dominant factor enhancing Marshall stability in the polymer-modified asphalt, aligning with the goal of improving mechanical performance while integrating recycled materials.

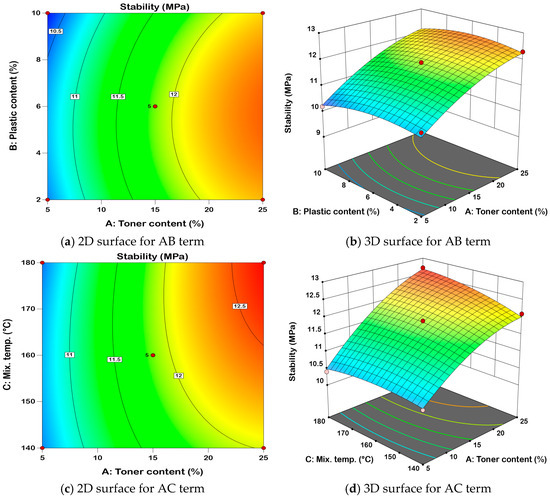

Figure 10 presents the 2D and 3D response surface plots illustrating the influence of toner and plastic content at various mixing temperatures on the Marshall stability of the polymer-modified asphalt. It was observed that an increase in toner content from 5% to 25% led to a notable improvement in stability, with a maximum value of 12.7 kN recorded at 25% toner, 6% plastic, and 180 °C (Run 11). This enhancement is attributed to the filler effect and the stiffening action imparted by toner particles, which improve the internal structure of the asphalt matrix [43,81,82]. Recycled plastic also contributed to binder stiffness, particularly evident at higher plastic contents (6–10%), which, in combination with toner, promoted higher Marshall stability. This is in agreement with observations by White [83] and Al-Saffar et al. [84], who found that hybrid modifiers enhance structural integrity and cohesion of bitumen matrices.

Figure 10.

The 2D and 3D response surface plots of Marshall stability for polymer-modified asphalt, with values increasing from dark blue to red.

4.4.2. ITS Performance Analysis of Polymer-Modified Asphalt

The performance of polymer-modified asphalt was further evaluated using RSM to examine the influence of e-waste toner content (A), plastic content (B), and mixing temperature (C) on indirect tensile strength (ITS). A quadratic regression model was formulated, and the coded equation is as follows:

This model incorporated both linear and interaction terms, along with quadratic components, capturing the nonlinear behavior of the asphalt mixtures (see Table 7). The analysis of variance (ANOVA) confirmed the model’s statistical significance, with an F-value of 81.16 and a p-value < 0.0001, suggesting a highly reliable fit to the experimental data. Among the variables, toner content (A) was the most influential factor (p < 0.0001), significantly enhancing ITS. Mixing temperature (°C) also showed a significant effect (p = 0.0035), indicating its role in improving internal cohesion and bonding within the mixture. Interaction effects, particularly between toner and temperature (AC), were statistically significant (p = 0.0260), emphasizing the importance of temperature control when using recycled additives. Additionally, the quadratic terms A2 and C2 were significant (p < 0.05), reflecting the existence of optimal dosage ranges and reinforcing the nonlinear relationship between input variables and ITS. Effect sizes (η2) for indirect tensile strength revealed that toner content had the strongest influence (η2 = 0.3187), followed by A2 (0.0185) and mixing temperature (0.0090), indicating toner’s dominant role in improving tensile performance.

Table 7.

RSM-based ANOVA results of ITS.

In contrast, plastic content (B) and its associated interaction and quadratic terms were found to be statistically insignificant (p > 0.1), suggesting a minimal direct contribution to tensile strength in this formulation. Although the model exhibited a significant Lack of Fit (p = 0.0405), it still effectively captured the major trends in ITS behavior. This analysis highlights toner content and appropriate mixing temperature as key parameters in improving the tensile performance of polymer-modified asphalt, demonstrating the viability of incorporating waste materials without compromising mechanical integrity.

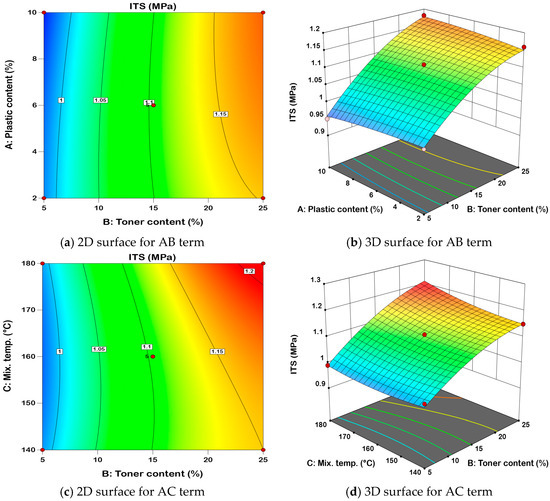

Figure 11 presents the 2D and 3D response surface plots illustrating the influence of toner and plastic content at various mixing temperatures on the ITS of the polymer-modified asphalt. The ITS improved significantly with higher toner content, peaking at 1.2 MPa with 25% toner and 6% plastic at 180 °C. This supports the theory that toner enhances interparticle bonding and matrix cohesion, which are essential for resisting tensile cracking under load [10]. The use of recycled plastic enhanced the ductility and crack-bridging ability of the binder, especially at elevated temperatures. Combinations of 15–25% toner and 6% plastic provided an optimum balance between stiffness and flexibility.

Figure 11.

The 2D and 3D response surface plots of ITS for polymer-modified asphalt, with values increasing from dark blue to red.

4.4.3. DSR Modulus Performance of Polymer-Modified Asphalt

The analysis of the DSR modulus response revealed that both copolymer materials such as e-waste toner content (A) and plastic content (B) exhibited a positive linear influence on the viscoelastic stiffness of the asphalt binder. The final regression equation in terms of coded factors was:

where “A” represents toner content, “B” is plastic content. The ANOVA results of DSR are presented in Table 8. Among these, toner content showed the most significant contribution to increasing the DSR modulus (+0.50), followed by plastic content (+0.40), whereas mixing temperature exhibited a negligible effect (+0.00) within the experimental range of 140–180 °C. The total sum of squares (3.28) was entirely explained by the model with no residual error, and both lack-of-fit and pure error terms were zero, indicating a statistically robust and well-fitted model. Effect size (η2) analysis showed that toner content contributed the most to both DSR modulus (η2 ≈ 0.61) and CO2 index (η2 ≈ 0.61), while plastic content followed with moderate impact (η2 ≈ 0.39). Mixing temperature had a negligible influence on both responses.

Table 8.

RSM-based ANOVA results of DSR modulus (kPa) and CO2 index.

Approximately 61% of the variance in DSR modulus was attributed to toner addition, affirming its critical role in enhancing the high-temperature rutting resistance of the binder. The absence of a temperature effect suggests that the modification process can be effective at lower energy input, aligning with circular economy and low-carbon processing goals. These results emphasize that increasing waste toner and polymer dosage is more influential for rheological performance enhancement than thermal conditions during mixing.

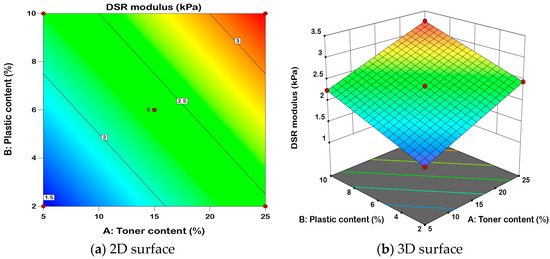

The contour and 3D surface plots illustrate the interactive effects of toner content (A) and plastic content (B) on the DSR modulus (G/sin δ, in kPa), an indicator of high-temperature rutting resistance in asphalt binders. Both plots reveal a clear positive correlation between the additive contents and the DSR modulus.

As shown in the contour plot in Figure 12, the modulus increases steadily from approximately 1.5 kPa at low e-waste toner (5%) and recycled plastic (2%) contents to a maximum of around 5.0 kPa at 25% toner and 10% plastic. The 3D surface plot further confirms this trend, illustrating a smooth incline in modulus with increasing levels of both modifiers.

Figure 12.

The 2D and 3D response surface plots of DSR modulus (kPa) for copolymer-modified asphalt, with values increasing from dark blue to red.

The experimental data support this visual trend. For instance, the combination of 25% toner and 10% plastic at 160 °C yielded the highest DSR modulus of 3.25 kPa, compared to only 1.45 kPa at 5% toner and 2% plastic. These findings demonstrate that incorporating higher proportions of waste toner and LDPE plastic significantly improves the binder’s viscoelastic response under high-temperature loading, thus enhancing rutting resistance. This outcome affirms the synergistic effect of the polymer system, contributing to both performance enhancement and sustainable material utilization in line with circular economy goals.

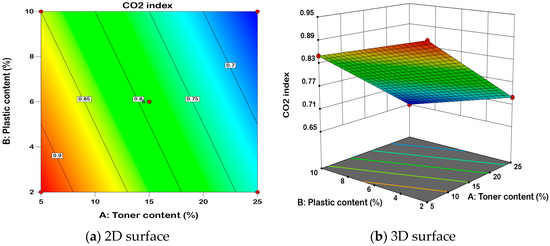

4.4.4. Environmental Assessment of Polymer-Modified Asphalt

The CO2 index, which reflects the normalized carbon footprint of the modified binder, was modeled using a linear regression Equation (8) in coded terms:

where “A” is toner content, “B” is plastic content, and “C” is mixing temperature. The negative coefficients of “A” and “B” indicate that increasing the proportions of waste toner and recycled plastic polymer contributes to a lower carbon index, thereby enhancing the binder’s environmental performance. The coefficient for toner content (−0.10) was larger than that for plastic content (−0.04), highlighting toner’s comparatively greater role in carbon reduction.

In Table 8, the ANOVA results showed the total variance (0.0928) was entirely explained by the model, with zero residual, lack-of-fit, and pure error terms, confirming an excellent model fit. Notably, mixing temperature had no effect on the CO2 index, suggesting that the environmental benefits are primarily material-driven rather than process-dependent. These findings affirm that increasing waste-derived content in asphalt binders can meaningfully reduce carbon impact, aligning with the study’s circular economy objectives.

The contour plots for the CO2 index (a measure of environmental impact) reveal a negative correlation between both toner content and plastic content with the CO2 index values (Figure 13). The analysis of the CO2 index demonstrates a clear inverse relationship between the content of waste toner and recycled plastic polymers and the environmental impact of the modified asphalt binder. As both toner and plastic content increase, the CO2 index consistently decreases, indicating enhanced carbon efficiency. For instance, a mix containing 25% toner and 10% plastic exhibited one of the lowest CO2 index values at 0.65, compared to 0.93 for a mix with just 5% toner and 2% plastic. This trend suggests that the incorporation of higher levels of waste materials helps to significantly reduce the reliance on virgin fossil-based binders, thereby lowering the overall carbon footprint. These findings align with the principles of circular economy and confirm that the co-utilization of waste toner and recycled plastic not only improves material performance but also contributes to environmental sustainability by promoting carbon-efficient infrastructure development.

Figure 13.

The 2D and 3D response surface plots of CO2 index for copolymer-modified asphalt, with values increasing from dark blue to red.

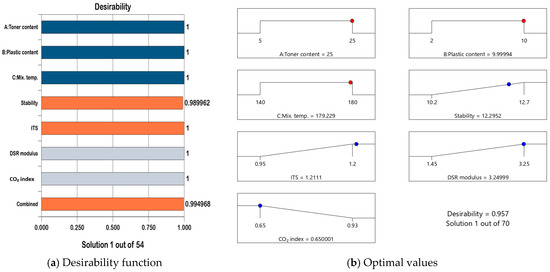

4.5. Multi-Objective Performance Optimization and Desirability Analysis

The multi-objective performance optimization (MOPO) approach used in this study highlights the ability of RSM to fine-tune material formulations by simultaneously maximizing mechanical performance and minimizing environmental impact. The optimization targeted four key responses: Marshall stability (R1), indirect tensile strength (ITS, R2), DSR modulus (G/sinδ, R3), and the CO2 index (R4), each influenced by toner content (A), plastic content (B), and mixing temperature (C).

To maintain an expansive solution space and ensure realistic process control, toner and plastic contents were allowed to vary within their experimental ranges, while three fixed mixing temperature levels of 140 °C, 160 °C, and 180 °C were individually set for distinct optimization goals. These goals were formulated to determine the optimal conditions under which the highest performance could be achieved with the lowest environmental burden.

Based on the statistical results, a response surface model was developed for each index, and the predicted values were compared with the experimental data, as shown in Figure 14a,b. The high correlation between predicted and measured values confirms that the models reliably analyze and predict the key performance and environmental indicators.

Figure 14.

RSM-based predicted vs. actual plots: (a) predicted vs. actual values comparison for Marshall stability and ITS; (b) predicted vs. actual values comparison for DSR modulus and CO2 index.

The desirability function was employed to quantify the optimization outcomes, as validated by other studies [85]. The desirability value ranged between 0 and 1 [86,87]. As shown in Figure 15a, the individual desirability scores for each response approached 1.0, indicating optimal alignment with the set goals. The overall composite desirability value of 0.995 confirms the model’s robustness and effectiveness in achieving a balanced solution that satisfies all performance and sustainability objectives. Similarly, Figure 15b presents the specific optimal values of the key input variables toner content, plastic content, and mix temperature under a slightly different scenario, yielding a still highly effective composite desirability of 0.957. These high values affirm the model’s predictive reliability and practical relevance in optimizing copolymer-modified asphalt binder formulations.

Figure 15.

(a) Desirability and (b) optimal response values plots based on multi-objective optimization.

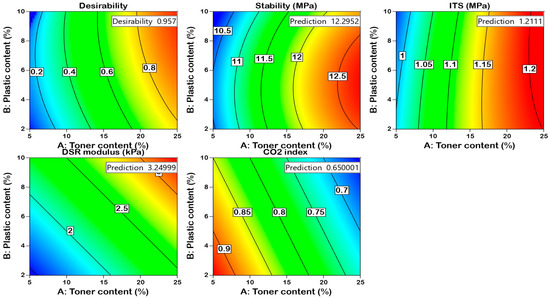

Figure 16 presents 3D contour plots showing the interaction effects of toner content (A) and recycled plastic content (B) on the predicted response values. For Marshall stability and DSR modulus, both variables show a positive synergistic effect, with plastic content slightly more influential on stability and toner content enhancing modulus. In ITS, toner content has a more significant impact, while plastic content plays a lesser role. For the CO2 index, higher toner content helps reduce emissions, whereas plastic content has a modest positive effect.

Figure 16.

Predicted contour plots based on multi-objective performance optimization, with values increasing from dark blue to red.

The predicted contour plots in Figure 16 also reveal that a maximum desirability of 0.957 is achieved at higher levels of both toner and plastic content, reflecting an optimal balance between performance and sustainability. Stability increases from 10.5 to 12.5 MPa, ITS from 1.0 to 1.2 MPa, and DSR modulus from 2 to 3.5 kPa. The CO2 index rises from 0.65 to 0.90, particularly with more plastic, highlighting a performance emissions trade-off. The optimum mix for balanced performance and low CO2 consists of 25% toner, 6–10% plastic, and a mixing temperature of 160–180 °C, achieving high stability, stiffness, and the lowest environmental impact.

These findings confirm that waste toner content is especially effective in improving mechanical properties and lowering environmental impact, while plastic content enhances stability. RSM and MOPO provide a valuable framework for optimizing binder design toward high performance and low carbon emissions in line with circular economy goals.

5. Contribution to Circular Economy and Sustainability

The integration of polymer-modified binders such as waste toner and recycled plastic polymers into asphalt binder systems aligns closely with the principles of the circular economy, which emphasize the reuse, recycling, and valorization of waste materials to reduce resource consumption and environmental degradation [88]. In this study, significant quantities of two commonly landfilled waste streams, toner cartridges and plastic polymers, were repurposed as functional modifiers, contributing to a more sustainable asphalt pavement solution.

By partially replacing virgin binder with waste-based materials, the environmental burden associated with asphalt production is significantly reduced. The decrease in the CO2 index, particularly in mixes containing 25% toner and 6–10% plastic, reflects a quantifiable reduction in greenhouse gas emissions. This suggests a dual benefit: enhanced material performance and reduced life-cycle environmental impact, a core tenet of circular material management [89].

Moreover, the improved mechanical and rheological performance of the modified binders—such as enhanced stability, reduced flow, and improved DSR G*/sinδ values indicates that the use of these waste materials not only diverts them from landfills but also results in technically superior products. This approach supports the transition from a linear “take–make–dispose” model to a regenerative model that maintains the value of materials and products for as long as possible [90].

In the broader context of infrastructure development, this innovation contributes to sustainable development goals (SDGs), especially SDG 9 (Industry, Innovation, and Infrastructure) and SDG 12 (Responsible Consumption and Production), by promoting the use of industrial by-products and consumer waste in high-volume applications such as road construction. The methodology developed in this study also provides a replicable framework for incorporating other polymeric and carbon-based wastes into infrastructure materials.

Future studies should extend this framework by integrating life cycle assessment (LCA) and techno-economic analysis to further quantify the sustainability benefits and economic viability of these waste-derived binders. Such multidimensional assessments are vital for policy-level endorsements and widespread adoption in road infrastructure projects.

6. Conclusions

This study investigated the combined effects of polymer binders such as e-waste toner and recycled plastic polymers on the fresh, mechanical, rheological, and environmental performance of asphalt binders. Through comprehensive laboratory testing and environmental analysis, the following key conclusions were drawn:

- The addition of e-waste toner significantly improved Marshall stability and indirect tensile strength (ITS) of asphalt mixtures, especially when combined with moderate to high contents of recycled plastic. The optimum blend of 25% toner and 6% plastic at 180 °C yielded the highest stability (12.7 kN) and ITS (1.2 MPa).

- Dynamic shear rheometer (DSR) testing showed a marked increase in G*/sinδ values with rising e-waste toner and plastic content, indicating enhanced rutting resistance. A maximum of 3.25 kPa was achieved with 25% toner and 10% plastic.

- Penetration and softening point tests confirmed that the modified binders became stiffer and more thermally stable, with lower penetration and higher softening point values. However, very high plastic content slightly compromised flow characteristics.

- The calculated CO2 index indicated that mixtures with higher waste content significantly reduced carbon impact. The lowest index (0.65) was achieved with the most heavily modified blends, showcasing the environmental sustainability of using industrial waste in asphalt production.

- The results suggest that a synergistic combination of 15–25% toner and 6–10% plastic can produce asphalt mixtures suitable for heavy-load and warm-climate conditions, contributing to circular economy goals and waste management efforts.

For future research, it is recommended to evaluate long-term field performance and conduct a comprehensive life-cycle assessment. In addition, long-term field performance evaluations under varying traffic and climate conditions are essential to validate laboratory findings. While single-temperature DSR testing in this study at 64 °C is standard for rutting assessment, future testing over a wider temperature range (e.g., using temperature sweep or multiple high/intermediate temperatures) could offer a more detailed rheological profile. Moreover, future work will investigate the physio-chemical and microstructural behavior of the copolymer-modified binder using techniques such as FTIR, SEM, and XRD to better understand the modification mechanisms and optimize the formulation for practical applications. Future studies should also investigate the variability in WTP composition from different printer sources to assess its impact on asphalt performance and develop standardization guidelines for scalable applications.

Author Contributions

Conceptualization, M.U.S. and M.K.A.; methodology M.U.S. and M.K.A.; software, M.K.A. and J.J.; validation, F.H.A. and J.J.; formal analysis, M.K.A. and M.A.Q.; investigation, F.H.A. and J.J. writing—original draft preparation, M.U.S. and M.K.A.; writing—review and editing, F.H.A. and M.A.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be available on suitable demand.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| LDPE | Low-density polyethylene |

| CO2 index | Carbon emission index |

| CE | Circular economy |

| LCA | Life cycle assessment |

| SDGs | Sustainable development goals |

| ITS | Indirect tensile strength |

| DSR | Dynamic shear modulus |

| RSM | Response surface methodology |

| MOPO | Multi-objective performance optimization |

| C-eff | Effective carbon emission |

| CCD | Central composite design |

| VOC | Volatile organic compounds. |

| SBS | Styrene–butadiene–styrene |

| EVA | Ethylene–vinyl acetate |

References

- Yaro, N.S.A.; Sutanto, M.H.; Baloo, L.; Habib, N.Z.; Usman, A.; Yousafzai, A.K.; Ahmad, A.; Birniwa, A.H.; Jagaba, A.H.; Noor, A. A comprehensive overview of the utilization of recycled waste materials and technologies in asphalt pavements: Towards environmental and sustainable low-carbon roads. Processes 2023, 11, 2095. [Google Scholar] [CrossRef]

- Malluru, S.; Islam, S.M.I.; Saidi, A.; Baditha, A.K.; Chiu, G.; Mehta, Y. A State-of-the-Practice Review on the Challenges of Asphalt Binder and a Roadmap Towards Sustainable Alternatives—A Call to Action. Materials 2025, 18, 2312. [Google Scholar] [CrossRef] [PubMed]

- Praticò, F.G.; Perri, G.; De Rose, M.; Vaiana, R. Comparing bio-binders, rubberised asphalts, and traditional pavement technologies. Constr. Build. Mater. 2023, 400, 132813. [Google Scholar] [CrossRef]

- Asphalt Pro. Understanding the Environmental Impact of Bitumen: Insights from Eurobitume’s LCA 4.0. 2025. Available online: https://theasphaltpro.com/understanding-the-environmental-impact-of-bitumen-insights-from-eurobitumes-lca-4-0/?utm_source=chatgpt.com (accessed on 12 June 2025).

- Dong, Z.; Li, L.; Zhou, T.; Yang, H.; Cao, L.; Shan, L. Waste-modified asphalt for climate change mitigation: Carbon and pollution reduction. Transp. Res. Part D: Transp. Environ. 2025, 143, 104727. [Google Scholar] [CrossRef]

- Albatayneh, O. Paving the future: Breakthroughs in sustainable approaches to pavement. In Recent Developments and Innovations in the Sustainable Production of Concrete; Elsevier: Amsterdam, The Netherlands, 2025; pp. 511–531. [Google Scholar]

- Shacat, J.; Willis, R.; Ciavola, B. The Carbon Footprint of Asphalt Pavements; SIP-109; The Road Forward; National Asphalt Pavement Association: Greenbelt, MD, USA, 2024. [Google Scholar]

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global e-Waste Monitor 2020; United Nations University (UNU): Bonn, Germany; International Telecommunication Union (ITU): Geneva, Switzerland; International Solid Waste Association (ISWA): Rotterdam, The Netherlands, 2020; Volume 120. [Google Scholar]

- Daniel-Mkpume, C.C.; Ahaiwe, R.C.; Ifenatuorah, C.L.; Ike-Eze, I.C.E.; Aigbodion, V.S.; Egoigwe, S.V.; Okonkwo, E.G. Potential end of life application of African star apple shell and waste toner powder as composite filler materials. J. Mater. Cycles Waste Manag. 2022, 24, 680–691. [Google Scholar] [CrossRef]

- Du, X.; Hu, K.; Zhang, F.; Liu, J.; Gillani, S.T.A. Characteristics of waste toner powder and its interaction effect on the physicochemical properties of asphalt binder. Constr. Build. Mater. 2025, 458, 139484. [Google Scholar] [CrossRef]

- Fernández, B.; Ayala, J.; Del Valle, E.; Martínez-Blanco, D.; Castañón, A.M.; Menéndez-Aguado, J.M. Recycling of waste toner powder as adsorbent to remove aqueous heavy metals. Materials 2022, 15, 4150. [Google Scholar] [CrossRef]

- Choudhary, D.; Kaithwas, S.; Sharma, R.; Mishra, A.; Singhai, S.; Powar, S.; Singh, A. Recycling of waste toner derived from exhausted printer cartridges as adsorbent for defluoridation of water. Environ. Technol. Innov. 2024, 34, 103572. [Google Scholar] [CrossRef]

- Nna Orji, C.; Olawore, Y.A. Well of hazards in e-waste: A review. Environment 2024, 13, 35–36. [Google Scholar]

- Movilla-Quesada, D.; Raposeiras, A.; Silva-Klein, L.; Lastra-González, P.; Castro-Fresno, D. Use of plastic scrap in asphalt mixtures added by dry method as a partial substitute for bitumen. Waste Manag. 2019, 87, 751–760. [Google Scholar] [CrossRef]

- Othman, A.M. Effect of low-density polyethylene on fracture toughness of asphalt concrete mixtures. J. Mater. Civ. Eng. 2010, 22, 1019–1024. [Google Scholar] [CrossRef]

- Kakar, M.R.; Mikhailenko, P.; Piao, Z.; Bueno, M.; Poulikakos, L. Analysis of waste polyethylene (PE) and its by-products in asphalt binder. Constr. Build. Mater. 2021, 280, 122492. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Selection criteria for building materials and components in line with the circular economy principles in the built environment—A review of current trends. Infrastructures 2021, 6, 49. [Google Scholar] [CrossRef]

- Liu, Z.; Kringos, N. Transition from linear to circular economy in pavement engineering: A historical review. J. Clean. Prod. 2024, 449, 141809. [Google Scholar] [CrossRef]

- Jan, H.; Aman, M.Y.; Tawab, M.; Ali, K.; Ali, B. Performance evaluation of hot mix asphalt concrete by using polymeric waste polyethylene. In Modeling, Simulation, and Optimization; Springer: Cham, Switzerland, 2018; pp. 91–99. [Google Scholar]

- Noor, A.; Rehman, M.A.U. A mini-review on the use of plastic waste as a modifier of the bituminous mix for flexible pavement. Clean. Mater. 2022, 4, 100059. [Google Scholar] [CrossRef]

- Rincón-Estepa, J.A.; González-Salcedo, E.V.; Rondón-Quintana, H.A.; Reyes-Lizcano, F.A.; Bastidas-Martínez, J.G. Mechanical behavior of low-density polyethylene waste modified hot mix asphalt. Sustainability 2022, 14, 4229. [Google Scholar] [CrossRef]

- Huang, J.; Kumar, G.S.; Sun, Y. Evaluation of workability and mechanical properties of asphalt binder and mixture modified with waste toner. Constr. Build. Mater. 2021, 276, 122230. [Google Scholar] [CrossRef]

- Khedaywi, T.; Haddad, M.; Al-Masaeid, H.; Mharib, I.A.; Hawari, S. Characterization of binder and asphalt mixture modified with waste toner. Int. J. Transp. Sci. Technol. 2025, in press. [Google Scholar] [CrossRef]

- Itoua, P.; Sun, D.; Shen, S. Investigating the Properties of Asphalt and Asphalt Mixture Based on the Effect of Waste Toner. Carbon 2024, 59, 55.88. [Google Scholar]

- Acharya, B.; Behera, A.; Deshmukh, K.; Moharana, S. Plastic Waste Management During and Post COVID-19 Pandemic: Challenges and Strategies. Plast. Waste Manag. Methods Appl. 2024, 4, 173–199. [Google Scholar]

- Parthasarathy, M. Challenges and emerging trends in toner waste recycling: A review. Recycling 2021, 6, 57. [Google Scholar] [CrossRef]

- Shahib, M.I.; Dsouza, G.C.; Vijayakumar, R. A review on end-of-life waste toner powder: Recovery, utilization and upcycling. Waste Manag. 2025, 204, 114911. [Google Scholar] [CrossRef]

- Ruan, J.; Li, J.; Xu, Z. An environmental friendly recovery production line of waste toner cartridges. J. Hazard. Mater. 2011, 185, 696–702. [Google Scholar] [CrossRef]

- Khan, W.S.; Asmatulu, E.; Uddin, M.N.; Asmatulu, R. Recycling and Reusing of Engineering Materials: Recycling for Sustainable Developments; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Santolini, E.; Tarsi, G.; Torreggiani, D.; Sangiorgi, C. Towards more sustainable infrastructures through circular processes: Environmental performance assessment of a case study pavement with recycled asphalt in a life cycle perspective. J. Clean. Prod. 2024, 448, 141380. [Google Scholar] [CrossRef]

- Pérez-Acebo, H.; Mindra, N.; Railean, A.; Rojí, E. Rigid pavement performance models by means of Markov Chains with half-year step time. Int. J. Pavement Eng. 2019, 20, 830–843. [Google Scholar] [CrossRef]

- Merbold, G. Sensitivity of Water Absorption on the Performance Properties of RCA and RMA Stabilised with Bitumen Emulsion; Stellenbosch University: Stellenbosch, South Africa, 2022. [Google Scholar]

- Mostafa, A.Z. Improving the Performance of Highways and Airports Flexible Pavement to Resist the Effect of Octahedral Shear Stresses; Faculty of Engineering, Cairo University: Giza, Egypt, 2022. [Google Scholar]

- Prasad, C.S.R.; Reddy, S.N. Eco-Innovation In Road Construction: Development And Application Of Waste Polymer Modified Binder. Educ. Adm. Theory Pract. 2024, 30, 7819–7828. [Google Scholar] [CrossRef]

- Bai, M. Investigation of low-temperature properties of recycling of aged SBS modified asphalt binder. Constr. Build. Mater. 2017, 150, 766–773. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Analysis of styrene-butadiene-styrene polymer modified bitumen using fluorescent microscopy and conventional test methods. J. Hazard. Mater. 2008, 150, 424–432. [Google Scholar] [CrossRef]

- Masri, T.D.K.A.; Ferdaus, R.; Ramadhansyah, P. Sustainable use of polymer in asphalt mixture: A review. Construction 2022, 2, 12–21. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Boom, Y.J.; Giustozzi, F. Sustainable polymers from recycled waste plastics and their virgin counterparts as bitumen modifiers: A comprehensive review. Polymers 2021, 13, 3242. [Google Scholar] [CrossRef]

- Li, H.; Han, Y.; Guangxun, E.; Sun, Y.; Wang, L.; Liu, X.; Ren, J.; Lin, Z. Recycling of waste polyethylene in asphalt and its performance enhancement methods: A critical literature review. J. Clean. Prod. 2024, 451, 142072. [Google Scholar] [CrossRef]

- Singh, A.; Gupta, A. Mechanical and economical feasibility of LDPE Waste-modified asphalt mixtures: Pathway to sustainable road construction. Sci. Rep. 2024, 14, 25311. [Google Scholar] [CrossRef]

- Shahbazi, R.; Rajabipour, A.; Yaghoubi, E.; Bazli, M.; Diaz, L.H.; Dlugogorski, B.Z. Rubber and plastic waste-modified asphalt binders and mixtures: Performance against environmentally induced distresses—A review. J. Traffic Transp. Eng. (Engl. Ed.) 2025, in press. [Google Scholar]

- Melnjak, I.; Vučinić, A.A.; Radetić, L.; Grčić, I. Waste Toner Powder in Concrete Industry: An Approach Towards Circular Economy. Environ. Eng. Manag. J. 2019, 18, 1897–1906. [Google Scholar] [CrossRef]

- Itoua, P.I.; Sun, D.; Li, P.; Shen, S. Influence of waste toner on asphalt binder: Chemical and rheological characterization. Molecules 2023, 28, 2794. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Park, W.; Kim, H.; Park, Y.; Byun, Y.; Cho, S.; Hahn, S.K.; Han, H.; Kwon, W. Waste toner–derived carbon dots for bioimaging and photodynamic therapy. Dye. Pigment. 2023, 217, 111441. [Google Scholar] [CrossRef]

- Lim, S.M.; Ng, T.C.A.; He, M.; Amio, B.E.C.; Hao, G.; Zulkati, A.; Kapilan, S.; Ng, H.Y.; Ong, G.P. Refining leaching protocols of waste-plastic incorporated asphalt mixes for environmental impact assessment. J. Clean. Prod. 2025, 487, 144610. [Google Scholar] [CrossRef]

- Jordan, J.L.; Casem, D.T.; Bradley, J.M.; Dwivedi, A.K.; Brown, E.N.; Jordan, C.W. Mechanical properties of low density polyethylene. J. Dyn. Behav. Mater. 2016, 2, 411–420. [Google Scholar] [CrossRef]

- Notani, M.A.; Mokhtarnejad, M. Investigating the rheological and self-healing capability of toner-modified asphalt binder. Proc. Inst. Civ. Eng. Constr. Mater. 2020, 173, 123–131. [Google Scholar] [CrossRef]

- Shah, S.A.R.; Hussan, S.; Kahla, N.B.; Anwar, M.K.; Baluch, M.A.; Nawaz, A. Performance Evaluation and Optimization of Binder-Toner and Mixing Efficiency Ratios in an E-Waste Toner-Modified Composite Mixture Using Response Surface Methodology. Infrastructures 2024, 9, 200. [Google Scholar] [CrossRef]

- Showkat, B.; Suresha, S.; Akhandappagol, N. Study of rheological and creep recovery properties of asphalt binder modified with waste toner. J. Mater. Civ. Eng. 2020, 32, 04020331. [Google Scholar] [CrossRef]

- Obaid, H.A.; Eltwati, A.; Hainin, M.R.; Al-Jumaili, M.A.; Enieb, M. Modeling and design optimization of the performance of stone matrix asphalt mixtures containing low-density polyethylene and waste engine oil using the response surface methodology. Constr. Build. Mater. 2024, 446, 138037. [Google Scholar] [CrossRef]

- Vatanparast, M.; Sarkar, A.; Sahaf, S.A. Optimization of asphalt mixture design using response surface method for stone matrix warm mix asphalt incorporating crumb rubber modified binder. Constr. Build. Mater. 2023, 369, 130401. [Google Scholar] [CrossRef]

- Zakerzadeh, M. Optimising Mix Design and Performance of Crumb Rubber Modified Stone Mastic Asphalt (SMA): An Experimental Study for Enhanced Durability and Sustainability; UNSW Sydney: Sydney, NSW, Australia, 2025. [Google Scholar]

- Genet, M.B.; Sendekie, Z.B.; Jembere, A.L. Investigation and optimization of waste LDPE plastic as a modifier of asphalt mix for highway asphalt: Case of Ethiopian roads. Case Stud. Chem. Environ. Eng. 2021, 4, 100150. [Google Scholar] [CrossRef]

- Krannich, A.-L.; Reiser, D. The United Nations sustainable development goals 2030. In Encyclopedia of Sustainable Management; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–5. [Google Scholar]

- Anwar, M.K.; Shah, S.A.R.; Alhazmi, H. Recycling and utilization of polymers for road construction projects: An application of the circular economy concept. Polymers 2021, 13, 1330. [Google Scholar] [CrossRef] [PubMed]

- Hussain, S.; Zhou, X.; Shah, S.A.R.; Ahmad, N.; Anwar, M.K.; Basheer, M.A. Utilization of radium-bead material for road safety: An application of the circular economy concept. Polymers 2021, 13, 3708. [Google Scholar] [CrossRef]

- Knudsen, M.S.; Kaivo-oja, J. Bridging Industry 4.0 and Circular Economy: A New Research Agenda for Finland. Tulevaisuuden Tutkimuskeskuksen Blogi. 2018. Available online: https://ffrc.wordpress.com/2018/09/12/bridging-industry-4-0-and-circulareconomy (accessed on 13 May 2022).

- Schroeder, P.; Anggraeni, K.; Weber, U. The relevance of circular economy practices to the sustainable development goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef]

- Valverde, J.-M.; Avilés-Palacios, C. Circular economy as a catalyst for progress towards the sustainable development goals: A positive relationship between two self-sufficient variables. Sustainability 2021, 13, 12652. [Google Scholar] [CrossRef]

- Mushtaq, F.; Huang, Z.; Shah, S.A.R.; Zhang, Y.; Gao, Y.; Azab, M.; Hussain, S.; Anwar, M.K. Performance optimization approach of polymer modified asphalt mixtures with pet and pe wastes: A safety study for utilizing eco-friendly circular economy-based SDGs concepts. Polymers 2022, 14, 2493. [Google Scholar] [CrossRef]

- EurekAlert. A Comparison Between the Concepts of Linear and Circular Economy Models. 2025. Available online: https://www.eurekalert.org/multimedia/946513 (accessed on 14 June 2025).

- UN Trade and Devlopment. Circular Economy: The Silver Bullet for Emissions? 2017. Available online: https://unctad.org/news/circular-economy-silver-bullet-emissions (accessed on 14 June 2025).

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- ASTM D36; Standard Test Method for Softening Point of Bitumen (Ring-Andball Apparatus). American Association of State and Highway Transportation Officials: Washington, DC, USA, 2014.

- ASTM D7175-15; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- Xu, F.; Zhao, Y.; Li, K. Using waste plastics as asphalt modifier: A review. Materials 2021, 15, 110. [Google Scholar] [CrossRef]

- Haider, S.; Hafeez, I.; Ullah, R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr. Build. Mater. 2020, 235, 117496. [Google Scholar] [CrossRef]

- ASTM D692–00; Standard Specification for Coarse Aggregate for Bituminous Paving Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- ASTM C136-06; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- ASTM C127-01; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM C29/C29M-23; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- ASTM D5821-13; Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM D4791-19; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- ASTM C131-06; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- ASTM D6927-15; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- ASTM D6931-17; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2025.

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, Y.; Yang, Y.; Guo, R. Study on the Physical and Rheological Characterisation of Low-Density Polyethylene (LDPE)/Recycled Crumb Rubber (RCR) on Asphalt Binders. Molecules 2024, 29, 716. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Ding, Z.; Ma, L.X.; Feng, Z.G. Analysis of viscous flow properties of asphalt in aging process. Constr. Build. Mater. 2016, 124, 631–638. [Google Scholar] [CrossRef]

- Andrews, K.; Dernayka, S.; Mir, M.A.; Khasawneh, M.A. Review of the utilization of plastic waste in asphalt pavements in hot climate conditions—KSA as a case study. Mater. Today Proc. 2023, 5, 463. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Martínez, M.; Mas-Giner, I.; Verdejo, R.; López-Manchado, M.A.; Santana, M.H. New recyclable and self-healing elastomer composites using waste from toner cartridges. Compos. Sci. Technol. 2023, 244, 110292. [Google Scholar] [CrossRef]

- Shah, P.M. Study on use of recycled waste materials on the performance of asphalt binder and mixes: A comprehensive review. Prog. Rubber Plast. Recycl. Technol. 2024. [Google Scholar] [CrossRef]

- White, G. Evaluating recycled waste plastic modification and extension of bituminous binder for asphalt. In Proceedings of the Eighteenth Annual International Conference on Pavement Engineering, Asphalt Technology and Infrastructure, Liverpool, UK, 27–28 February 2019. [Google Scholar]

- Al-Saffar, Z.H.; Hasan, H.G.M.; Alamri, M.; Al-Attar, A.A.; Hamad, A.J.; Abdulmawjoud, A.A.; Mezaal, M.R.; Elmagarhe, A. Assessing the effects of copolymer modifier addition on asphalt attributes: Towards achieving performance optimization. Constr. Build. Mater. 2024, 420, 135645. [Google Scholar] [CrossRef]

- Adamu, M.; Ibrahim, Y.E.; Alanazi, H. Optimization of sustainable concrete properties modified with blends of date palm ash and eggshell powder using response surface methodology. Dev. Built Environ. 2024, 17, 100359. [Google Scholar] [CrossRef]

- Hamada, H.M.; Al-Attar, A.; Shi, J.; Yahaya, F.; Al Jawahery, M.S.; Yousif, S.T. Optimization of sustainable concrete characteristics incorporating palm oil clinker and nano-palm oil fuel ash using response surface methodology. Powder Technol. 2023, 413, 118054. [Google Scholar] [CrossRef]

- Liu, C.; Yang, H. Multi-objective optimization of a concrete thermal energy storage system based on response surface methodology. Appl. Therm. Eng. 2022, 202, 117847. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Spani, R.C. The New Circular Economy Action Plan (1 July 2020). FEEM Policy Brief No. 09-2020. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3711331 (accessed on 12 June 2025).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).