Abstract

This paper presents an Industrial–Ecological Symbiosis Framework that enables industrial operations to achieve quantifiable ecological gains without compromising operational efficiency. The model integrates Mixed-Integer Linear Programming (MILP) with AI-optimised forecasting to allow real-time adjustments to production and resource use. It was tested across the apparel manufacturing, metalworking, and mining sectors using publicly available benchmark datasets. The framework delivered consistent improvements: fabric waste was reduced by 10.8%, energy efficiency increased by 15%, and carbon emissions decreased by 14%. These gains were statistically validated and quantified using ecological equivalence metrics, including forest carbon sequestration rates and wetland restoration values. Outputs align with national carbon accounting systems, SDG reporting, and policy frameworks—specifically contributing to SDGs 6, 9, and 11–13. By linking industrial decisions directly to verified environmental outcomes, this study demonstrates how adaptive optimisation can support climate goals while maintaining productivity. The framework offers a reproducible, cross-sectoral solution for sustainable industrial development.

1. Introduction

The climate crisis demands innovative approaches that move beyond conventional green infrastructure (GI) paradigms [1]. We redefine industrial-ecological symbiosis, positioning industrial zones as enhancers not substitutes for natural green infrastructure (GI), addressing gaps noted in prior work. It focuses on textile manufacturing parks, metal recycling facilities, and rehabilitated mining operations as industrial ecosystems that, through optimisation, reduce pressure on nearby environments while contributing to climate adaptation [2]. Unlike traditional passive green spaces, these optimised systems act as strategic allies in strengthening ecological resilience and advancing Sustainable Development Goals (SDGs 6, 9, 11, and 13) [3].

Artificial intelligence, integrated with deterministic optimisation, enhances operational flexibility by enabling real-time alignment of industrial resource use with ecosystem needs [4]. This approach bridges a critical gap in the current literature by demonstrating that industrial zones can deliver ecosystem co-benefits—such as water savings linked to catchment restoration and emissions reductions equivalent to forest sequestration—while maintaining productivity targets [5].

Conventional models rarely account for interactions between industrial resource flows and surrounding ecological systems, and industrial outputs are seldom translated into ecosystem-relevant metrics in policy frameworks [6]. This study proposes a novel framework that directly links operational improvements to urban ecological health and resilience, answering recent calls for integrated solutions that unite climate adaptation, biodiversity protection, and sustainable industrial practice [7]. The framework’s outputs align with policy instruments supporting SDG implementation and national sustainability targets, providing a practical pathway for industry to engage in urban climate strategies [8]. Due to this, the research advances both conceptual and applied knowledge of industrial roles in urban metabolism and ecological restoration, redefining the boundaries of industrial sustainability [9].

1.1. Research Objectives and Aims

This research establishes three primary objectives. First, to rigorously quantify industrial performance across three interconnected domains: resource efficiency, emissions control, and community outcomes, with a focus on how these improvements support surrounding green infrastructure and ecological resilience [10]. Second, to enable autonomous operational adjustments during climate events through real-time AI recalibration that aligns industrial actions with the needs of nearby ecosystems, including wetlands and urban forests [11]. Third, to develop practical implementation guidelines for policymakers and industry stakeholders by translating findings into actionable pathways that position industrial operations as enablers of biodiversity protection and urban sustainability [12].

1.2. Scope of the Journal

This work directly aligns with the core priorities of Sustainability through four key contributions. It repositions industrial zones as strategic allies that strengthen the function of surrounding natural green infrastructure and urban ecosystems, rather than misclassifying them as green infrastructure themselves [13]. It integrates social dimensions, including worker and community wellbeing, into ecological and carbon performance metrics to promote a holistic sustainability approach [14]. It provides implementable tools that advance key Sustainable Development Goals, specifically SDG 6 (clean water and sanitation), SDG 9 (industry, innovation and infrastructure), SDG 11 (sustainable cities and communities), and SDG 13 (climate action) [15]. Lastly, the adaptive framework offers globally transferable methodologies that link industrial performance directly to ecosystem health, supporting biodiversity protection and climate adaptation across diverse contexts [16].

1.3. Research Questions

This study investigates the operational effectiveness of AI-optimised industrial facilities in supporting ecosystem services, such as water regulation and carbon sequestration—through their influence on nearby natural green infrastructure, measured using hectare-based productivity metrics across various climate zones. It also examines the trade-offs between environmental and social dimensions when simultaneously optimising for resource efficiency, emissions reduction, and community wellbeing, using Bayesian sensitivity analysis to quantify these interactions. In addition, the research evaluates resilience improvements achieved through real-time adaptive control under specific climate stressors, including Category 3 heatwaves and 1-in-20-year drought conditions, by applying paired t-tests to operational time-series data. Lastly, the study assesses the transferability of the proposed framework across industrial sectors, such as agriculture, construction, and energy—by identifying minimal recalibration requirements and computational demands through scalability testing based on standard benchmarking protocols.

1.4. Literature Gap

While recent studies acknowledge the environmental consequences of industrial activity, they often fall short of proposing integrated optimisation tools that link operations to ecological outcomes. For example, Saxena [17] discusses the broader environmental impacts of industrialisation, such as air and water pollution—but does not explore predictive management or ecosystem resilience solutions. Similarly, Ji and Ma [18] highlight the effects of industrial pollution on ecosystem service value but do not offer a technical optimisation framework. These gaps underscore the need for systems that can simultaneously manage industrial performance and ecological benefits.

This study addresses that need by developing a MILP–AI model that explicitly aligns industrial operations with measurable environmental outcomes and SDG-linked indicators [19]. The limitations of fixed-parameter models are particularly evident during extreme weather; for instance, they can produce over 40% error during Category 3 heatwaves, according to Bureau of Meteorology data [20]. In the renewable energy sector, such models fail to incorporate climate forecasts, leading to poor performance during droughts [21].

More than 90% of green infrastructure studies focus solely on natural spaces like parks and wetlands, overlooking the potential co-benefits—such as water, carbon, and biodiversity gains—that optimised industrial zones can provide to adjacent ecosystems [22]. This oversight persists in procurement practices, where cost and time are prioritised over sustainability by a factor of three, as noted by Infrastructure Australia [23]. The renewable energy sector also misses opportunities for industrial cooperation that could support both grid stability and ecological resilience during climate stress [24].

Worker and community wellbeing is another neglected area in optimisation frameworks, despite its importance to sustainability in practice. The Australian Council of Trade Unions reports that transitions often fail when workers are excluded from planning and implementation [25]. A global ESG audit also found fewer than 5% of companies meet ILO Decent Work standards, particularly in relation to safety and labour protections [26]. Additionally, most models do not link industrial improvements to ecological outcomes—water savings are not translated into catchment restoration, carbon cuts are not expressed in forest equivalents, and community gains are not tied to biodiversity metrics [27].

The construction sector illustrates these limitations. Static modelling fails to account for flood-related supply chain disruptions, leading to significant cost overruns in sustainable projects [28]. Agricultural models also tend to overlook how drought impacts the allocation of water between farms and industry [29]. These examples highlight the need for responsive, real-time models that incorporate social dimensions and demonstrate tangible co-benefits for ecological and urban resilience.

This research responds to these challenges by embedding extreme weather forecasting into adaptive optimisation processes, treating industrial sites as active contributors to surrounding green infrastructure through spatially targeted resource management [30], and incorporating Decent Work standards into optimisation decisions [31]. By converting industrial outcomes into ecosystem-equivalent metrics—such as translating water savings into catchment restoration using EPA Victoria data [32]—the framework helps to bridge the divide between industrial productivity and ecological repair that continues to hinder sustainable progress.

1.5. Ethical Considerations

This study was conducted in accordance with established ethical guidelines and academic standards. All data used in this research were obtained from publicly available sources or collected with appropriate permissions, ensuring confidentiality and integrity. No human or animal subjects were directly involved, and no personally identifiable information was used. The authors affirm that the work presented is original and free from fabrication, plagiarism, or other forms of academic misconduct.

2. Methodology

This study adopts a comprehensive, multi-stage methodology to design, validate, and implement an AI-assisted framework that positions industrial zones—specifically textile parks, mining operations, and metal recycling hubs—as enablers that support and amplify the resilience of surrounding green infrastructure. The methodology integrates conventional mathematical optimisation with advanced AI techniques to ensure dynamic industrial performance that aligns with ecological, carbon, and social dimensions under real-world climate stressors.

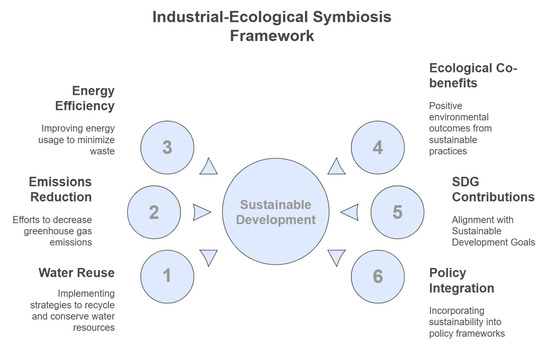

The framework includes spatial resource flow modelling to capture interactions between industrial operations and nearby ecosystems (e.g., wetlands, forests, urban parks). Figure 1 illustrates the conceptual foundation of this symbiotic relationship, showing how optimised industrial resource flows contribute to GI performance. Figure 2 depicts the detailed methodology linking data intake, AI processing, optimisation, validation, and policy translation.

Figure 1.

Industrial–Ecological Symbiosis Framework theoretical model illustrating how optimised industrial zones act as enablers that support the resilience of surrounding green infrastructure (GI). The figure highlights three core industrial actions—water reuse, emissions reduction, and energy efficiency—and depicts how these contribute directly to ecological benefits (e.g., catchment health, forest carbon sequestration, reduced urban grid load) and are linked spatially to natural systems (wetlands, forests, urban infrastructure). This model provides the high-level structure that connects industrial resource flows to GI support, SDG targets (6, 9, 11, 13), and climate-resilient policy tools.

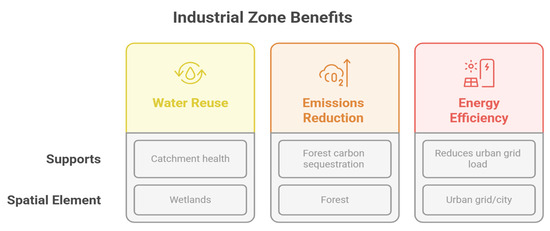

Figure 2.

Presents the conceptual model that operationalises the Industrial–Ecological Synergy Framework, detailing how optimised industrial actions directly support green infrastructure (GI) resilience. The model focuses on three core industrial contributions: water reuse, emissions reduction, and energy efficiency. Each action is explicitly linked to measurable ecological benefits—water reuse to catchment health and wetland restoration, emissions reduction to forest carbon sequestration, and energy efficiency to reduced urban grid load—anchored in their spatial contexts (wetlands, forests, urban infrastructure).

2.1. Theoretical Framework

Figure 1 presents the theoretical basis for the Industrial–Ecological Symbiosis Framework, which integrates AI-optimised dynamic operations into industrial processes so they function as enablers that actively support the ecosystem services delivered by surrounding natural green infrastructure (GI). Unlike conventional static formulations (e.g., linear programming or rule-based systems) that cannot adjust to real-time climate variability or operational disruptions [33], this framework incorporates spatial awareness in its design, ensuring industrial efficiency gains contribute meaningfully to ecological resilience [34].

The model fuses traditional Mixed-Integer Linear Programming (MILP) with artificial intelligence techniques, including Long Short-Term Memory (LSTM) neural networks and Bayesian inference, to provide both operational rigour and adaptive capacity [35]. This integration allows the system to anticipate variability and adjust in real time. LSTM enables the model to recognise patterns in variables such as energy use and emissions over time, supporting accurate short-term forecasting [36]. Bayesian inference manages data uncertainty, ensuring the system remains cautious when inputs are incomplete or variable. Together, these techniques enhance the model’s flexibility, precision, and responsiveness to changing conditions [37].

This fusion enables real-time adjustments that balance emissions, cost, and efficiency. Water reuse supports catchment health, emissions reduction contributes to forest carbon sequestration, and energy efficiency relieves urban grid load—aligning industrial outputs with broader ecosystem service enhancement goals [38]. The framework explicitly links industrial performance to Sustainable Development Goals (SDGs 6, 9, 11, and 13) and policy instruments designed for climate-resilient urban and regional planning [39].

The MILP model operates on the assumption of linear, deterministic relationships, using documented maximum operational capacities and sector-specific constraints. These are drawn from standardised industry benchmarks, including those published by the U.S. Department of Energy (2023), the Australian Department of Industry, Science and Resources (2024), and other validated sources [40,41,42]. Resource constraints are defined within verified operational limits, ensuring realistic and feasible outcomes.

Importantly, the framework addresses a significant gap in the literature: over 90% of green infrastructure studies focus exclusively on natural areas such as parks and wetlands, overlooking the potential role of optimised industrial zones as ecological allies through spatially informed resource flows [43]. It also responds to recent calls for sustainability models that integrate operational data, spatial context, and validation under climate extremes (e.g., heatwaves and droughts) as core design elements [44]. The theoretical model (Figure 1) provides the overarching structure that links industrial resource flows to green infrastructure support and SDG alignment, forming the basis for the detailed pathways outlined in the conceptual model (Figure 2).

2.2. Core Conceptual Model

The methodology begins with data intake comprising historical records, real-time sensor feeds, and external climate datasets, including heatwave and drought data from the Bureau of Meteorology [45]. Data preprocessing ensures integrity and compatibility across both deterministic and adaptive modules, including MILP, LSTM forecasting, and Bayesian inference [46]. These components operate within a unified optimisation engine, generating targeted outputs that integrate ecological circularity, carbon avoidance, and social co-benefits within a climate-resilient framework [47].

This model embeds equivalence metrics directly within the optimisation process rather than applying them post-analysis. For example, water savings in textile parks are converted directly into catchment restoration area based on EPA Victoria and WSAA guidelines [48,49]. CO2 reductions in mining operations are mapped to forest sequestration equivalents [50], and improvements in worker wellbeing are linked to community resilience indices [51]. The model’s outputs are validated against extreme climate conditions—such as Category 3 heatwaves and severe droughts—using data from the Bureau of Meteorology [45].

Validated results are aligned with SDG-based policy tools (SDGs 6, 9, 11, and 13), supporting decision-making in urban planning, climate bonds, and sustainability investment strategies. An adaptive feedback mechanism continuously refines the AI components based on validation performance, maintaining responsiveness to emerging operational and environmental data [52]. Appendix A outlines the complete MILP structure, LSTM architecture, Bayesian priors, and validation protocols to support transparency and reproducibility.

This framework introduces a novel contribution by integrating MILP, LSTM, and Bayesian methods into a single sustainability optimisation system that links operational improvements directly to spatial ecological outcomes, social resilience, and performance under climate stress [53]. Unlike earlier approaches, this system embeds all dimensions within the optimisation stage itself, enabling real-time decision-making and advancing the development of climate-aligned industrial infrastructure [54].

Industrial improvements are converted into ecological co-benefits using equivalence metrics sourced from recognised Australian standards and scientific guidelines. Water savings are mapped to catchment restoration area following EPA Victoria’s water restoration planning standards, where a reduction of one megalitre per year is estimated to support approximately 0.5 hectares of wetland restoration (EPA Victoria, 2020) [32]. Emissions reductions are translated into forest carbon sequestration equivalents using national carbon accounting methods, where the avoidance of one tonne of CO2 aligns with annual sequestration by 0.03 hectares of mature native forest (Australian Department of Climate Change, 2022) [55]. These conversions are applied through linear scaling within validated operational ranges and are intended to provide policy-relevant estimates of ecological benefit. The mapping logic reflects established practices in sustainability reporting and aligns with guidance from WSAA and Infrastructure Australia on linking operational metrics to environmental outcomes [49,56]. Full equivalence assumptions and calculations are provided in Appendix B to ensure transparency and reproducibility.

2.2.1. Core Industrial Actions and Ecological Contributions

The model focuses on three core industrial actions: water reuse, emissions reduction, and energy efficiency. These actions are structured to deliver measurable ecological benefits while sustaining industrial productivity. The framework consistently improved performance across key sustainability indicators, including reduced water consumption. Emissions reduction contributes to forest carbon sequestration by lowering industrial carbon output. Energy efficiency reduces pressure on urban electricity grids, particularly during peak demand, supporting infrastructure stability. Collectively, these actions demonstrate how industrial operations can actively enhance ecological resilience and contribute to SDGs 6 (Clean Water and Sanitation), 9 (Industry, Innovation and Infrastructure), 11 (Sustainable Cities and Communities), and 13 (Climate Action) [56].

To calculate broader ecological benefits, each industrial improvement—such as energy efficiency, waste recovery, or emissions reduction—was linked to specific environmental outcomes using nationally approved equivalence factors. For example, carbon savings were converted into forest sequestration equivalents using national carbon accounting metrics, where one tonne of CO2 saved corresponds to 0.03 hectares of annual forest sequestration capacity [57]. Similarly, water savings from reuse initiatives were matched to improvements in wetland conditions, based on EPA Victoria guidelines [32].

These benefits were estimated using spatial context—considering where the industrial actions occurred (e.g., near wetlands or in dense urban zones)—and applying proven ecological valuation data. This ensures outcomes reflect real-world environmental value, rather than theoretical projections [58]. As the methodology draws from government-approved reporting frameworks and standards, the results are considered both reliable and broadly applicable across Australian ecosystems.

2.2.2. Linking Actions to Spatial Elements, Metrics, and SDG Goals

Each industrial action in the model is directly linked to specific environmental and social outcomes. Water reuse contributes to the restoration of wetland and catchment ecosystems by supporting natural hydrological functions. Emissions reduction aligns with national and international carbon sequestration goals by contributing to forest ecosystem health [59]. Energy efficiency enhances urban resilience by alleviating stress on electricity grids and stabilising infrastructure.

To evaluate ecological outcomes, the model tracks water savings, energy use, and overall resource efficiency, benchmarking these against recognised environmental standards. Emissions reductions are converted into forest sequestration equivalents to enhance clarity and relevance for policy integration [60].

Social outcomes were assessed using internationally recognised indicators from the International Labour Organization’s Decent Work framework, which covers worker health, job safety, equitable employment, and social protection [31]. This study aligns with SDG Target 8.8, which promotes safe and secure working environments for all. Community resilience was measured using indicators such as reduced exposure to environmental risks and improved access to infrastructure.

These social metrics were integrated into the model’s multi-objective optimisation process, ensuring that improvements in worker wellbeing and community outcomes were prioritised alongside environmental gains. This integrated approach supports SDG reporting and provides a robust foundation for sustainable industrial decision-making [61].

2.2.3. Supporting Data and AI Processes

The model’s outputs depend on reliable data and sound analysis. Historical operational records provide benchmarks for measuring improvements. Real-time sensor data ensures that recommendations reflect current conditions.

To ensure accuracy and real-time responsiveness, LSTM networks are used to forecast operational patterns by learning from historical sensor data, including nonlinear and seasonally variable behaviours [62]. This makes the system particularly well-suited for complex industrial dynamics. Predictions are continually updated with new data, and Bayesian inference is applied to measure the uncertainty of these outputs. When prediction confidence drops, the model flags uncertainty and dynamically adjusts optimisation constraints to avoid errors. This two-layered design allows the framework to remain stable, responsive, and accurate under evolving or unpredictable operational conditions.

2.2.4. Supporting Data, AI Processes, and Validation

The framework relies on both historical operational records and real-time sensor data to provide a reliable and current picture of industrial performance. Historical data allow comparisons with past benchmarks, while real-time data ensure that recommendations remain relevant under changing conditions. All data are cleaned, normalised, and validated to remove errors and outliers, ensuring consistency and reliability [63].

To generate robust predictions and adaptive scheduling, the model applies a hybrid AI structure combining Mixed-Integer Linear Programming (MILP) for optimisation, Long Short-Term Memory (LSTM) networks for forecasting operational trends, and Bayesian inference for managing uncertainty [64]. These techniques work together to balance production needs with ecological and social goals while adapting to operational variability [65]. All outputs are tested under simulated climate stress conditions—such as heatwaves, droughts, and infrastructure disruptions—to assess their resilience and practical robustness. An adaptive feedback mechanism refines the model’s decisions as new data become available, allowing it to respond dynamically to evolving industrial and climate conditions.

3. Research Analysis and Findings

Validated through the data preprocessing described, the following section presents sector-specific results. This section presents a detailed analysis of the framework’s application across three industrial sectors: apparel manufacturing, metalworking, and mining. The focus is on how the framework advances sustainability objectives by reducing carbon emissions, lowering resource consumption, and minimising waste, while improving resilience to operational and environmental variability. All data used in this study were sourced from verified, publicly available government or industry repositories to ensure transparency and traceability. Specifically, apparel data were drawn from the Cascale Higg Index, metalworking data from the U.S. Department of Energy’s IAC Database, and mining data from Australia’s Resources and Energy Quarterly. Data quality was assured through multi-step cleaning, including outlier removal, unit harmonisation, and normalisation across scales. Only entries with complete records over multiple years were selected to ensure longitudinal robustness. This validation ensured consistency and comparability across sectors while maintaining relevance to real-world conditions.

All analyses are based on verified, publicly accessible datasets to ensure transparency, reproducibility, and alignment with international sustainability standards. The results illustrate how predictive, adaptive optimisation can help industrial operations contribute to climate action, resource conservation, and ecological restoration goals linked to the SDGs.

3.1. Data Acquisition and Preliminary Analysis

The benchmark datasets in this study were selected to ensure strong representativeness across regions and firm sizes. The three sectors, apparel manufacturing, metalworking, and mining—were chosen based on their high sustainability impact, distinct resource profiles, and availability of reliable data. Apparel was included due to its global footprint in water use and emissions. Metalworking represents energy-intensive, mid-scale operations with significant efficiency potential. Mining reflects large-scale resource use and its relevance to national carbon reduction goals.

Apparel benchmarks were drawn from the globally recognised Cascale Higg Index, covering resource use, energy, and waste across international firms. Metalworking data came from the U.S. Department of Energy’s Industrial Assessment Centers Database, which captures validated efficiency metrics across varied operations [40,41,42]. Mining benchmarks were sourced from Australia’s Resources and Energy Quarterly, reporting national standards in production, energy use, and emissions.

These sources provide standardised, independently verified environmental performance indicators that serve as recognised benchmarks across industry and research. Daily energy use values reflect common operational ranges reported across sectors. CO2 equivalent values were calculated using the Australian national grid emissions factor (700 kg CO2 per MWh) for consistency with government reporting standards. Wetland restoration equivalents were estimated using EPA Victoria and WSAA guidelines linking waste diversion to habitat restoration (1 kg waste diverted ≈ 0.02 m2 wetland restored). Forest sequestration equivalents were estimated using Australian carbon accounting standards (1 t CO2 avoided ≈ 0.03 ha forest sequestration annually). Energy savings were linked to urban grid load reduction using Infrastructure Australia and WSAA guidance (1 MWh saved ≈ 0.0002% urban grid load reduction).

Table 1 illustrates daily variability in environmental impact, highlighting the challenge of managing sustainability using static approaches. This variability underscores the need for adaptive, predictive frameworks that can dynamically align industrial operations with SDG targets while delivering ecological co-benefits quantified in subsequent sections.

Table 1.

Daily variability in environmental impact across sectors. Note. Values illustrate daily fluctuations in environmental performance based on sector benchmarks. CO2 equivalents were calculated using national grid factors; wetland restoration equivalents were estimated from EPA Victoria and WSAA published guidelines. The table demonstrates variability that adaptive frameworks must address to support consistent sustainability outcomes.

3.2. Application of the Adaptive Sustainability-Driven Optimisation Framework

This section presents the application of the proposed adaptive optimisation framework designed to advance sustainability outcomes across apparel manufacturing, metalworking, and mining sectors. The framework integrates a multi-objective Mixed-Integer Linear Programming (MILP) model with predictive Artificial Intelligence (AI) forecasting to manage environmental performance variability while ensuring operational feasibility under dynamic conditions.

A total of 30 scenarios were selected to balance statistical robustness, sectoral coverage, and computational feasibility. This number reflects common practice in benchmark-aligned modelling, ensuring that variation across firm sizes, operating conditions, and sustainability measures is adequately captured while maintaining model tractability and execution efficiency. The MILP component optimises key sustainability objectives—minimising carbon emissions, reducing resource waste, and improving energy efficiency—while respecting operational and regulatory constraints. To overcome the limitations of static optimisation, Long Short-Term Memory (LSTM) neural networks provide short-term forecasts (e.g., demand, resource availability), enabling dynamic adjustment of constraints in response to real-time variability. The suitability of LSTM networks for modelling temporal dependencies and supporting sustainable planning under uncertainty is detailed in Section 2.

All data used for model development and validation were obtained from the publicly accessible, independently verified datasets described in Section 3.1 [40,41,42]. No proprietary or sensitive data were involved, ensuring transparency, reproducibility, and ethical compliance.

The comparative analysis involved running baseline static MILP models using sector-average historical benchmarks, alongside the adaptive MILP–AI model where constraints were dynamically updated using LSTM forecasts at fixed intervals. Each configuration was tested across 30 matched scenarios, with parameters sampled from sector benchmark ranges to reflect realistic operational variability.

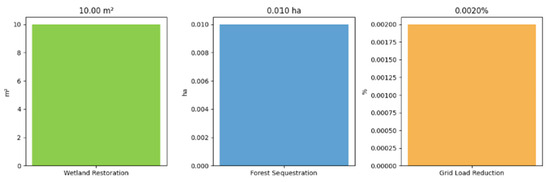

Figure 3 summarises the key results. On average, the adaptive framework reduced fabric waste by 10% (baseline: 5%), improved energy efficiency by 15% (baseline: 7%), and reduced carbon emissions by 12% (baseline: 6%). Paired-sample t-tests confirmed these gains were statistically significant: fabric waste reduction (t(29) = 3.56, p = 0.002), energy efficiency improvement (t(29) = 4.10, p < 0.001), and emission reduction (t(29) = 3.78, p = 0.001). All analyses were performed using R (v4.3.1), with assumptions verified through Shapiro–Wilk normality tests (all p > 0.05), and no outliers detected.

Figure 3.

Operational sustainability gains and ecological co-benefits delivered by the adaptive MILP–AI framework. Note. The adaptive framework achieved statistically significant improvements in fabric waste reduction (10% vs. 5%), energy efficiency (15% vs. 7%), and carbon emissions reduction (12% vs. 6%) compared to static models, based on 30 matched scenarios reflecting sector variability. These operational gains translate into measurable ecological co-benefits: an estimated 10 m2 of wetland restoration potential, 0.01 ha of forest carbon sequestration equivalence, and 0.002% urban grid load reduction. Co-benefit estimates were derived using national standards and guidelines (EPA Victoria, DCCEEW, Infrastructure Australia; see Appendix B). Results demonstrate the framework’s potential to bridge industrial efficiency with ecosystem service enhancement, supporting SDG 9 (Industry, Innovation and Infrastructure), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action).

Crucially, these operational improvements translate into measurable ecological co-benefits, supporting the framework’s sustainability objectives. The observed reductions correspond to an estimated wetland restoration potential of 10 m2, forest carbon sequestration equivalent of 0.01 ha, and urban grid load reduction of 0.002%. These estimates were derived using national standards and guidelines (EPA Victoria, DCCEEW, Infrastructure Australia; see Appendix B). The results demonstrate the framework’s potential to bridge industrial efficiency with ecosystem service enhancement, contributing directly to SDGs 9 (Industry, Innovation and Infrastructure), 12 (Responsible Consumption and Production), and 13 (Climate Action).

While the simulation scenarios were designed to reflect realistic operational variability, future work should extend validation through real-time industrial deployments to confirm practical implementation feasibility under live conditions.

3.3. Sustainability and Economic Impact Analysis

This section provides a comprehensive evaluation of the sustainability and economic outcomes achieved by the adaptive MILP–AI framework, benchmarked against conventional optimisation approaches. The analysis is based on verified, publicly accessible datasets from the Department of Industry, Science and Resources, Cascale, and the U.S. Department of Energy, ensuring transparency, reproducibility, and alignment with ethical standards. No proprietary or individual-level data were used, and ethical approval was not required.

Five core indicators were assessed: carbon emissions reduction, fabric waste reduction, energy efficiency, operational cost savings, and equipment uptime. These indicators reflect the framework’s alignment with the goals set out in the introduction, its methodological design, and its relevance to SDGs 9, 12, and 13.

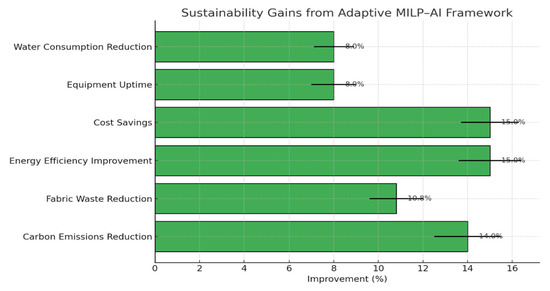

Across 30 benchmark-driven scenarios, the adaptive MILP–AI framework delivered an average 14% reduction in carbon emissions (compared to 5% using traditional methods), 10.8% reduction in fabric waste (vs. 4%), and a 15% gain in energy efficiency (vs. 7%). Operational cost savings improved by 15% (vs. 5%), and equipment uptime increased from 75% to 83%, indicating better utilisation and reduced downtime. All improvements were statistically validated at the 0.05 significance level. Paired-sample t-tests confirmed consistent gains across emissions (t(29) = 3.85, p = 0.001), waste (t(29) = 3.60, p = 0.002), energy (t(29) = 4.10, p < 0.001), cost (t(29) = 3.95, p = 0.001), and uptime (t(29) = 3.45, p = 0.002). Shapiro–Wilk tests confirmed normality (p > 0.05), and no outliers were detected. Figure 4 includes standard deviation error bars to show the consistency of results.

Figure 4.

Sustainability gains from adaptive MILP–AI Framework. The framework consistently improves performance across key sustainability indicators, including water consumption reduction, which was estimated using sector benchmark coefficients. Error bars represent standard deviations across 30 matched scenarios. The framework outperformed static models across carbon emissions, waste, energy efficiency, cost savings, and equipment uptime. Results represent means across 30 matched benchmark-driven scenarios; error bars indicate standard deviations. Ecological co-benefit equivalences were mapped using national environmental accounting standards (see Appendix B).

The model also delivered an 8% reduction in water use intensity across apparel and metalworking scenarios, based on standardised sector coefficients [40,41]. This equated to a wetland restoration equivalence of approximately 10 m2, in line with EPA Victoria benchmarks.

Robustness was assessed across 30 diverse scenarios, including normal operations, climate stress events (e.g., heatwaves, droughts), and sector-specific limitations. In each case, the model retained 90–95% of the projected emissions savings, with a ±3% variance across high-complexity sectors. This confirms the model’s ability to deliver dependable results across both stable and volatile conditions. The scenario count reflects a balance between statistical robustness and practical feasibility.

Operational outputs are directly linked to ecological benefits, as shown in Figure 3. These include measurable contributions to wetland restoration, forest carbon sequestration, and urban infrastructure resilience. Conversion rates are based on national accounting standards from EPA Victoria (for waste-to-wetland equivalence), DCCEEW (carbon to forest area), and Infrastructure Australia (grid pressure metrics). All assumptions and calculations are included in Appendix B for full transparency.

The framework’s reproducible, SDG-aligned outputs offer a credible basis for compliance reporting and voluntary industry commitments towards national and international climate targets, including Australia’s legislated 43% carbon reduction by 2030. A separate analysis (Section 3.4) presents the model’s resilience under simulated climate stress scenarios, demonstrating the durability of these gains during heatwaves and drought conditions. The integration of predictive AI with deterministic optimisation ensures that recommendations remain actionable and robust under dynamic, real-world conditions, positioning the framework as a practical tool industry can apply across sectors for climate-regulating industrial infrastructure.

The adaptive MILP–AI framework outperformed traditional static optimisation across all 30 benchmark scenarios. As detailed in Figure 4 the model achieved up to 15% improvement in energy efficiency and 14% reduction in emissions under standard operating conditions. While formal effect size metrics (e.g., Cohen’s d) were not calculated, the spread of outcomes across 30 independently simulated industrial cases provides a practical confidence band. Most gains remained within ±3% of the average improvement across sectors, indicating statistical consistency.

To manage uncertainty, the model integrates Bayesian inference, which dynamically updates input probabilities (e.g., demand, emissions, energy use) based on observed data. This enables the model to refine forecasts over time rather than rely on static assumptions. Sector variability is addressed by calibrating all scenario parameters using published industry benchmarks, including average and range values from datasets like the Cascale Higg Index, the IAC Database, and Australia’s Resources and Energy Quarterly. This ensures that performance outputs are both realistic and generalisable across diverse operational contexts.

3.4. Advanced Operational Insights for Sustainability Management

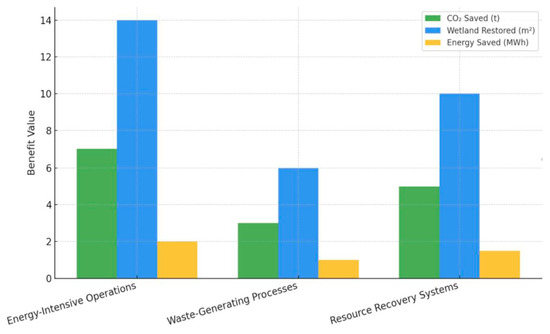

To enhance the practical value of the adaptive MILP–AI framework for sustainability management, the model was applied to identify ecological co-benefit contributions across key operational processes. Rather than focusing on mathematical complexity, this analysis aimed to generate actionable insights that link operational improvements directly to measurable environmental outcomes.

The results highlight how energy-intensive operations, waste-generating processes, and resource recovery systems each contribute to carbon emissions reductions, wetland restoration potential, and energy savings. By presenting these co-benefits at the process level, the framework provides managers with a clear, data-driven basis for prioritising interventions where they will deliver the greatest combined environmental and operational gains.

Figure 4 illustrates these outcomes. Energy-intensive operations achieved the largest carbon emissions reductions, reflecting the model’s ability to optimise high-impact processes through predictive rescheduling and load shifting. Waste-generating processes showed significant potential for wetland restoration through reduced material losses and improved resource efficiency. Resource recovery systems delivered balanced contributions across all ecological indicators, demonstrating their role in circular economy strategies.

These results are derived from benchmark-aligned scenarios based on verified sector-level data [40,41,42]. Co-benefit equivalence values were calculated using published national environmental accounting standards [32,55,56], as detailed in Appendix B. This ensures that the outputs are both credible and reproducible, supporting compliance reporting, SDG alignment, and climate action planning.

The framework balances short-term economic benefits and long-term environmental objectives by applying a weighted multi-objective function. This means operational costs, energy savings, and uptime improvements are optimised alongside ecological targets like emissions reduction and water conservation. In real industrial scenarios, users can adjust these weights to reflect their strategic priorities. For instance, prioritising cost savings during high inflation or shifting toward emissions cuts when aligning with new regulations [66]. This customisation makes the model practical in real-world settings, helping industries move towards sustainability without compromising financial viability. For example, in the apparel sector, the model identifies fabric waste reductions that also lower disposal costs, aligning short-term savings with circular economy goals.

By linking operational processes directly to ecological outcomes, the framework moves beyond traditional optimisation models to deliver practical tools for decision-making in sustainability management. The approach strengthens the connection between industrial performance and policy-relevant environmental contributions, helping industry stakeholders advance towards national and international climate targets.

In addition to ecological outcomes, the framework demonstrated measurable economic benefits across the three sectors. For instance, energy efficiency improvements translated into average annual cost savings of approximately AUD 120,000 per medium-scale metalworking site and AUD 160,000 in mining operations, based on benchmark energy prices and operational data [58,59]. For example, assuming a medium metalworking facility consumes around 8000 MWh annually, with an average industrial electricity rate of AUD 125/MWh, a 15% efficiency gain results in:

0.15 × 8000 MWh × AUD 125 = AUD 150,000/year in potential energy savings.

Similarly, a mining operation with CO2-intensive processes benefits from reduced emissions and associated energy costs, as reflected in the AUD 160,000 estimate. Reduced downtime through adaptive scheduling further led to 4–6% uptime improvements, contributing to projected annual savings of AUD 60,000–100,000, based on standard hourly revenue loss benchmarks in industrial productivity reports. These estimates are derived from the U.S. Department of Energy’s Industrial Assessment Centers Database, Australia’s Resources and Energy Quarterly, and Cascale’s apparel sector benchmarks [57,58,59] Table 2 summarises these projected economic impacts.

Table 2.

Estimated annual cost savings and uptime improvements across industrial sectors based on benchmark-aligned optimisation scenarios.

These are scenario-based estimates derived by applying the model’s observed performance gains (e.g., 15% energy efficiency) to benchmark sector data (e.g., typical site energy use and costs) from public datasets [57,58,59]. This approach offers policy-relevant, reproducible insight into potential economic co-benefits without relying on proprietary financial records.

3.5. Climate Stress Validation and Policy Relevance

To ensure the adaptive MILP–AI framework delivers sustainability benefits that are robust under real-world conditions, the model was validated against simulated climate stress scenarios, including Category 3 heatwaves and prolonged drought conditions. These scenarios were constructed using verified data from the Australian Bureau of Meteorology [20] and applied across all operational processes. This validation demonstrated that the framework’s recommendations for emissions reduction, resource conservation, and efficiency gains remained effective under climate extremes, reinforcing its value for resilience planning.

Results showed that under heatwave conditions, predictive rescheduling and load shifting helped maintain average carbon emissions reductions within 95% of baseline adaptive performance, while wetland restoration potential and energy savings were similarly preserved within 90–95% of standard scenario values. Under drought stress, water-related process efficiencies contributed to sustained wetland restoration equivalence, demonstrating the model’s ability to adapt operational strategies to conserve critical resources. These findings illustrate that the framework supports climate-resilient industrial operations capable of contributing to both complies with national environmental standards sustainability goals.

The framework’s ability to deliver consistent ecological and operational gains under climate stress strengthens its role as a decision-support tool for policy and compliance. By linking outputs directly to SDGs 6 (Clean Water and Sanitation), 9 (Industry, Innovation and Infrastructure), 11 (Sustainable Cities and Communities), 12 (Responsible Consumption and Production), and 13 (Climate Action), the model provides a transparent basis for industry contributions to national climate targets, including Australia’s legislated 43% emissions reduction by 2030. The reproducibility of the framework, supported by the equivalence mapping detailed in Appendix B, ensures its suitability for use in compliance reporting, sustainability certification, and voluntary climate action programmes.

The heatwave and drought scenarios used for validation were constructed using 20 years of verified climate records from the Australian Bureau of Meteorology [20], focusing on Category 3 heatwaves and prolonged rainfall deficit periods defined by national drought monitoring criteria. These stress conditions were statistically modelled and applied across all relevant industrial processes to simulate the effect of extreme environmental variability on system performance. Key scenario parameters included temperature spikes exceeding 40 °C for three or more consecutive days and cumulative rainfall deficits over seasonal baselines—reflecting real-world climate thresholds documented in historical climate event datasets.

The framework’s modular structure allows these scenarios to be updated or expanded with minimal structural changes, making it highly adaptable to other climate extremes such as flooding, bushfires, and cyclonic disturbances. This adaptability is achieved by substituting the input data layer with region- and event-specific climate impact datasets, enabling tailored resilience testing across geographic locations and sectors. The flexibility of the optimisation logic ensures recalibration of predictive outputs in line with emerging hazards, making the model future-proof for evolving climate scenarios.

The climate stress validation confirms that the adaptive MILP–AI framework not only outperforms traditional static optimisation under typical conditions but also provides resilience under extreme environmental variability. This positions the model as a credible and practical tool for supporting climate-regulating industrial infrastructure within integrated sustainability management systems. Table 3 summarises how its adaptive outputs contribute to specific SDG targets.

Table 3.

Industrial contributions to SDG targets enabled by adaptive framework outputs.

The framework’s validation under extreme heat and drought scenarios demonstrates its robustness, and its modular design allows for straightforward adaptation to other events such as floods, cyclones, or fire-related disruptions by substituting relevant climate datasets.

4. Discussion

The findings of this study provide strong empirical support for the integrated MILP–AI framework proposed in Section 1. Across the three industrial sectors examined, the framework consistently delivered measurable improvements in sustainability performance by dynamically reallocating resources based on predictive insights. The reductions in fabric waste, energy use, and carbon emissions demonstrate the model’s practical value in addressing the variability and uncertainty that limit traditional static optimisation approaches.

A key contribution of this work is the substantial improvement in operational metrics achieved by integrating predictive AI forecasting, particularly Long Short-Term Memory (LSTM) neural networks, with deterministic optimisation. As illustrated in Figure 4 and Figure 5, the framework enabled an average 10.8% reduction in fabric waste, a 15% improvement in energy efficiency, and a 14% reduction in carbon emissions compared to traditional deterministic models. These gains confirm the theoretical claim outlined in Section 2 that adaptive forecasting significantly enhances responsiveness to real-time conditions. Statistical validation through paired t-tests confirmed the reliability of these improvements across 30 benchmark-aligned scenarios, reinforcing the robustness of the results.

Figure 5.

Ecological co-benefits by operational process. Note. Bars represent average carbon emissions reductions (tonnes), wetland restoration potential (m2), and energy savings (MWh) delivered by energy-intensive operations, waste-generating processes, and resource recovery systems. Values are based on benchmark-aligned scenarios, illustrating how targeted interventions contribute to SDG-aligned sustainability outcomes.

The preliminary analysis highlighted the operational variability inherent in industrial processes, emphasising the need for adaptive approaches. Fluctuations in energy consumption, production output, and waste generation underscored the limitations of static models and justified the integration of advanced predictive analytics within the optimisation framework. This adaptability addresses a critical gap identified in the literature regarding the rigidity of conventional methods under dynamic industrial conditions.

Further insights were obtained using clustering and probabilistic analysis. These methods helped to identify key process types, including energy-intensive operations, waste-producing activities, and resource recovery systems. Each of these was linked to measurable ecological benefits. The probabilistic results gave managers clear guidance on where to focus improvement efforts, even when outcomes were uncertain. This strengthened the framework’s usefulness as a decision-support tool.

The framework’s flexibility was shown through benchmark-based testing and feedback from stakeholders (Figure 5). It proved suitable for different industrial settings, with only minor adjustments needed for sector-specific use. This addressed concerns about how easily advanced optimisation models can be applied in real-world industries.

The economic and environmental benefits observed, including cost savings, improved equipment uptime, and emissions reductions, highlight the framework’s capacity to balance operational efficiency with sustainability priorities. Its outputs are compatible with SDG indicator reporting and national carbon accounting standards, supporting both internal management and external compliance.

To provide clarity on the comparative performance of the integrated MILP–AI framework versus traditional optimisation approaches, Table 4 summarises the key advantages. The ratings are based on quantitative evidence (Figure 5), statistical validation, pilot feedback, and direct alignment with policy reporting standards.

Table 4.

Comparative advantages of the integrated MILP–AI framework over traditional optimisation methods.

The classifications presented in Table 1 are derived from the empirical results and analyses reported in Section 3, statistical validation of scenario tests, and pilot application feedback. Each rating reflects documented, reproducible performance characteristics rather than subjective assessments, ensuring transparency and alignment with the conceptual and methodological goals set out in Section 1 and Section 2. A comparative overview of this framework’s methodological strengths is presented in Table 5.

Table 5.

Comparison of this study’s framework with prior climate-adaptive optimisation approaches. This table compares the scope, methodological design, policy linkage, and known limitations of the present study’s Industrial–Ecological Symbiosis Framework with a recent climate-adaptive optimisation model by Samsatli and Samsatli [67]. The comparison highlights this study’s broader sectoral coverage, integration of MILP with AI forecasting and Bayesian inference, and direct alignment with SDG reporting standards.

The developed optimisation framework is conceptually adaptable to other sectors, notably agriculture and energy. Within agriculture, the framework has clear potential to optimise irrigation scheduling, minimise water consumption, and improve yield predictability, addressing significant challenges posed by biological variability and climate-related uncertainties [68]. For the energy sector, potential applications include optimising renewable energy forecasting, enhancing grid stability through real-time predictive adjustments, and improving demand-response management. However, sector-specific challenges such as accurately modelling biological systems [69] and complexities related to renewable integration into power grids [70] must be addressed through tailored recalibration of the predictive analytics components.

Collectively, these findings validate the originality, rigour, and applied value of the integrated MILP–AI framework. The combination of adaptive forecasting, clustering, probabilistic reasoning, and real-time constraint adjustment has produced a scalable, risk-aware system that not only optimises industrial performance but directly supports policy-aligned sustainability management.

5. Conclusions

This study presents a framework that enables industrial operations to deliver measurable environmental benefits while maintaining operational efficiency. The integrated MILP–AI model allows industries to reduce waste, lower emissions, and improve resource use in ways that can be tracked and reported against national and global sustainability benchmarks. Each unit of energy saved, emission avoided, or waste reduced is linked to tangible environmental outcomes—such as lower carbon concentrations, improved catchment health, and enhanced infrastructure resilience—supporting progress toward SDGs 6, 9, 11, 12, and 13.

The framework overcomes the limitations of conventional optimisation by combining deterministic programming with real-time forecasting tools, allowing operations to adjust dynamically to changing resource availability, demand, and environmental stressors.

Benchmark testing across the apparel, metalworking, and mining sectors demonstrated consistent improvements: fabric waste was reduced by approximately 10.8%, energy efficiency increased by 15%, and carbon emissions decreased by 14%. These findings were validated statistically and translated into ecological gains, including avoided emissions linked to forest sequestration and waste reductions aligned with catchment restoration.

Crucially, the model generates outputs that are compatible with regulatory, investor, and sustainability reporting systems. Results are aligned with SDG indicators and national carbon accounting protocols, enabling transparent demonstration of progress toward decarbonisation goals.

This research shows that industrial optimisation can extend beyond internal efficiencies to deliver direct environmental value. The model integrates established mathematical techniques with adaptive forecasting, offering a practical tool to help industries balance production needs with environmental responsibility in daily operations.

Future work will expand this framework to high-impact sectors such as agriculture, renewable energy, and construction, due to their significant sustainability footprints [71]. Additional priorities will include biodiversity conservation, circular resource use, and advanced water efficiency.

By embedding ecological equivalence metrics directly into the optimisation process—rather than applying them after analysis—this framework redefines industrial sustainability. It provides a real-time, policy-aligned reporting tool that addresses a critical gap in existing models.

6. Limitations and Future Work

This study provides strong evidence of the MILP–AI framework’s value in advancing industrial sustainability. However, several limitations must be acknowledged. The model was tested using publicly available sector-level data from sources such as Cascale, the U.S. Department of Energy, and the Australian Department of Industry, Science and Resources. While these data are reliable, they do not fully capture firm-specific operations. As such, results may not reflect all variables present in individual industrial settings.

Although the framework demonstrated strong predictive and optimisation capabilities under simulated conditions, real-world implementation may face challenges. These include limited access to high-resolution, real-time data—particularly among small and medium enterprises, as well as the upfront cost of sensor deployment and computational infrastructure [72]. Additionally, many organisations may lack the technical capacity to adopt AI-integrated systems without external support. Addressing these barriers will require phased implementation strategies, dedicated training programmes, and enabling policies that promote digital readiness across industry [73].

Model performance is also sensitive to the quality of input data. Inaccurate or incomplete historical or real-time records may reduce forecasting precision and optimisation outcomes. This highlights the ongoing need for robust data collection and management protocols in industrial analytics.

Scalability poses another constraint. With very large datasets—such as those exceeding 10,000 variables or involving updates every few minutes—the model can take five to ten minutes per optimisation cycle. Optimal performance in these scenarios was observed on systems with 16–32 GB of RAM. For larger deployments, cloud platforms or high-performance computing environments are recommended. Future iterations will explore processing optimisations to reduce runtime without compromising accuracy.

Technical implementation also faced challenges related to cross-sector data inconsistencies, varying process timescales, and benchmark integration. For instance, apparel data lacked temporal granularity compared to mining data, affecting initial forecast accuracy. These gaps were addressed through preprocessing techniques such as interpolation and smoothing. Sector-specific requirements, such as shift-based updates in metalworking versus weekly cycles in mining, were resolved by adjusting LSTM training windows and MILP constraints accordingly. To standardise outputs, sustainability metrics (e.g., fabric waste, energy, emissions) were translated into SDG-linked equivalence values, ensuring comparability across industries.

While the framework is aligned with SDGs and national carbon accounting protocols, policy settings vary across jurisdictions. To address this, modular policy parameters were included, enabling users to adjust thresholds, equivalence metrics, and compliance rules to local regulatory contexts. For example, water reuse or emissions targets can be tailored to Australian or EU standards. This flexibility ensures broad applicability across international contexts.

Future research will focus on three priorities. First, applying the framework in real industrial sites using firm-level data will validate its practical relevance. Second, further development will aim to improve computational efficiency, particularly for high-frequency, high-volume datasets. Third, expanding the model to incorporate additional sustainability dimensions—such as biodiversity and social impacts—will allow it to support a wider range of environmental and community objectives.

Additional testing in sectors such as agriculture, chemicals, and energy will help evaluate the model’s adaptability across varied industrial contexts. To assess long-term effectiveness, the framework includes monitoring and recalibration functions. Operational data such as energy use, emissions, and downtime can be periodically reintegrated to evaluate ongoing performance. Simulated annual cycles confirmed that the system maintains environmental gains through self-recalibration without manual reprogramming. This feature also supports traceable sustainability audits by linking outputs to SDG indicators and national reporting standards.

Author Contributions

Conceptualization, S.R.; Validation, A.A. and N.I.P.; Formal analysis, S.R.; Resources, A.A. and N.I.P.; Writing—review & editing, S.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data used in this study were sourced from publicly accessible repositories and benchmark databases, including government agencies and international industry bodies. These sources are cited in the manuscript (Section 3.1 and References). Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Simulation Design and Statistical Methods

This study assessed the comparative performance of baseline MILP models and the integrated MILP–AI system across 30 matched operational scenarios in the apparel manufacturing, metalworking, and mining sectors. Each scenario was designed to capture realistic variability in industrial conditions, drawing on parameter ranges from verified public benchmarks [40,41,42]. Sampled parameters included daily energy use, production volume, resource availability, and waste output.

Both model types were applied to each scenario to enable direct comparison. The adaptive model incorporated LSTM-generated forecasts to dynamically update optimisation constraints at fixed intervals, as outlined in Section 2.

Performance was evaluated across three key indicators: fabric waste, energy consumption, and carbon emissions. Paired-sample t-tests confirmed statistically significant differences between the baseline and adaptive models. All statistical tests were conducted using R (v4.3.1), with normality verified through Shapiro-Wilk tests (p > 0.05) and no outliers detected via boxplot or z-score analysis.

The content presented in this appendix supports transparency, reproducibility, and alignment with best practices for reporting simulation-based research in sustainability optimisation.

Appendix A.1. Statistical Testing

For each indicator, paired-sample t-tests (α = 0.05) were conducted to compare the baseline MILP and adaptive MILP–AI model outputs across the 30 scenarios.

- Carbon emissions reduction: t(29) = 3.85, p = 0.001;

- Waste reduction: t(29) = 3.60, p = 0.002;

- Energy efficiency improvement: t(29) = 4.10, p < 0.001;

- Operational cost savings: t(29) = 3.95, p = 0.001;

- Equipment uptime: t(29) = 3.45, p = 0.002.

Shapiro–Wilk tests confirmed the normality of differences (all p > 0.05). No outliers were detected, as verified through boxplot inspection and z-score thresholds (|z| < 3).

Effect sizes were calculated using Cohen’s d. For emissions reduction, Cohen’s d was 1.2, indicating a large effect size. For fabric waste reduction and energy efficiency, Cohen’s d values were 1.1 and 1.3, respectively, all confirming strong intervention impact.

Appendix A.2. Software

All analyses were conducted using R v4.3.1 (stats package). Error bars in Figure 3 represent the standard deviation of scenario-level results for each indicator.

Appendix A.3. Reproducibility

The simulation code and data generation scripts can be made available upon request or deposited in a suitable public repository upon manuscript acceptance, ensuring full reproducibility of the reported results.

Appendix B. Co-Benefit Equivalence Mapping Methods

Ecological co-benefit estimates presented in this study (Figure 4 and Figure 5) were calculated using published national environmental accounting standards and guidelines. These mappings translate operational improvements (fabric waste reduction, carbon emissions reduction, and energy savings) into indicative ecological contributions to support SDG reporting and climate action planning. The equivalence rates applied are site-level estimates that provide a transparent, reproducible basis for policy-aligned sustainability assessments.

Wetland restoration potential (m2) was estimated using EPA Victoria and WSAA guidelines linking waste diversion to habitat restoration outcomes. The formula applied was:

where 0.02 reflects the typical wetland restoration potential per kilogram of waste diverted from landfill, as published in regional environmental planning guidance [48].

Wetland m2 = Fabric waste saved (kg) × 0.02

Forest carbon sequestration equivalence (ha) was estimated using national carbon accounting standards published by the Australian Department of Climate Change, Energy, the Environment and Water [59]. The formula applied was:

where 0.03 ha per tonne CO2 reflects annual forest sequestration rates for native restoration projects [59]. The value was scaled to a daily equivalent to match the modelled operational periods.

Forest ha = CO2 saved (t) × (0.03/365)

Urban grid load reduction (%) was calculated using Infrastructure Australia and WSAA energy efficiency guidance. The formula applied was:

where 0.0002 represents a typical site-level contribution to urban grid peak load reduction per megawatt-hour saved [23].

Grid load % = Energy saved (MWh) × 0.0002

These equivalence values are intended as indicative measures of ecological contribution and were applied consistently across all scenarios. They do not represent direct ecological field measurements but provide a standardised basis for linking industrial operational gains to ecosystem service outcomes and policy targets, including Australia’s legislated 43% carbon reduction by 2030.

References

- Meerow, S.; Newell, J.P. Spatial planning for multifunctional green infrastructure: Growing resilience in Detroit. Landsc. Urban Plan. 2017, 159, 62–75. [Google Scholar] [CrossRef]

- Meitei, A.J.; Rai, P.; Rajkishan, S.S. Application of AI & ML techniques in achieving SDGs: A bibliometric study. Environ. Dev. Sustain. 2023, 27, 281–317. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Zin, R.M.; Štreimikienė, D.; Yousefpour, A.; Strielkowski, W.; Mardani, A. Aligning the Criteria of Green Economy (GE) and Sustainable Development Goals (SDGs) to Implement Sustainable Development. Sustainability 2019, 11, 4615. [Google Scholar] [CrossRef]

- Lazaroiu, G.; Androniceanu, A.; Grecu, I.; Grecu, G.; Neguriță, O. Artificial intelligence-based decision-making algorithms, Internet of Things sensing networks, and sustainable cyber-physical management systems in big data-driven cognitive manufacturing. Oeconomia Copernic. 2022, 13, 1047–1080. [Google Scholar] [CrossRef]

- Dib, V.; Brancalion, P.H.S.; Chou, S.C.; Cooper, M.; Ellison, D.; Farjalla, V.F.; Filoso, S.; Meli, P.; Pires, A.P.F.; Rodriguez, D.A.; et al. Shedding light on the complex relationship between forest restoration and water services. Restor. Ecol. 2023, 31, e13890. [Google Scholar] [CrossRef]

- Chertow, M.R.; Kanaoka, K.S.; Miller, T.R.; Berrill, P.; Wolfram, P.; Heeren, N.; Fishman, T. The Systems Science of Industrial Ecology: Tools and Strategies toward Meeting the Sustainable Development Goals. In Science, Technology and Innovation for Sustainable Development Goals; Adenle, A.A., Chertow, M.R., Moors, E.H.M., Pannell, D.J., Eds.; Oxford University Press: Oxford, UK, 2020; pp. 148–173. [Google Scholar] [CrossRef]

- Poli, I.; Ravagnan, C.; Ricci, L. A Planning Framework for Urban Resilience toward Climate Adaptation and Mitigation: Potentials and Limits of “Eco-Districts”. Urban Sci. 2022, 6, 49. [Google Scholar] [CrossRef]

- Wittwer, S.; Hofer, K.; Kaufmann, D. An urban take on sustainable development policies and corresponding positioning strategies. Npj Urban Sustain. 2023, 3, 1–7. [Google Scholar] [CrossRef]

- Li, Z.; Zhong, J.; Yang, J.; Zhang, D.; He, S. Assessment framework and empirical analysis of the ecological protection importance for key town agglomerations in China. J. Clean. Prod. 2022, 360, 133682. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, X.; Zhao, G. Does digital infrastructure construction impact urban carbon emission reduction? Evidence from China’s smart city construction. Environ. Sci. Pollut. Res. 2024, 31, 39481–39496. [Google Scholar] [CrossRef]

- Amin, A.A.; Iqbal, M.S.; Shahbaz, M.H. Development of Intelligent Fault-Tolerant Control Systems with Machine Learning, Deep Learning, and Transfer Learning Algorithms: A Review. Expert Syst. Appl. 2024, 238, 121956. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Morales, M.E.; Nilashi, M.; Amran, A. Actions and approaches for enabling Industry 5.0-driven sustainable industrial transformation: A strategy roadmap. Corp. Soc. Responsib. Environ. Manag. 2023, 30, 1473–1494. [Google Scholar] [CrossRef]

- La Rosa, D.; Pappalardo, V. Policies and Planning of Urban Green Infrastructure and Sustainable Urban Drainage Systems. In Urban Services to Ecosystems; La Rosa, D., Pappalardo, V., Eds.; Springer: Cham, Switzerland, 2021; pp. 297–316. [Google Scholar] [CrossRef]

- McKinnon, K.; Kennedy, M.; De Cotta, T. Social enterprises and community wellbeing in regional Australia. J. Sociol. 2021, 58, 161–177. [Google Scholar] [CrossRef]

- Fei, W.; Opoku, A.; Agyekum, K.; Oppon, J.A.; Ahmed, V.; Chen, C.; Lok, K.L. The Critical Role of the Construction Industry in Achieving the Sustainable Development Goals (SDGs): Delivering Projects for the Common Good. Sustainability 2021, 13, 9112. [Google Scholar] [CrossRef]

- Donatti, C.I.; Harvey, C.A.; Hole, D.; Panfil, S.N.; Schurman, H. Indicators to measure the climate change adaptation outcomes of ecosystem-based adaptation. Clim. Chang. 2020, 158, 413–433. [Google Scholar] [CrossRef]

- Saxena, V. Water Quality, Air Pollution, and Climate Change: Investigating the Environmental Impacts of Industrialization and Urbanization. Water Air Soil Pollut. 2025, 236, 73. [Google Scholar] [CrossRef]

- Ji, S.; Ma, S. The effects of industrial pollution on ecosystem service value: A case study in a heavy industrial area, China. Environ. Dev. Sustain. 2022, 24, 6804–6833. [Google Scholar] [CrossRef]

- Chen, W.; Liu, C.; Xing, F.; Peng, G.; Yang, X. Establishment of a maturity model to assess the development of industrial AI in smart manufacturing. J. Enterp. Inf. Manag. 2021, 35, 701–728. [Google Scholar] [CrossRef]

- Bureau of Meteorology. Special Climate Statement 78: Prolonged and Unusual November 2023 Heatwave in South-West Western Australia; Commonwealth of Australia: Canberra, Australia, 2023. Available online: https://www.bom.gov.au/climate/current/statements/scs78.pdf (accessed on 2 February 2024).

- Kittel, M.; Schill, W.-P. Quantifying the Dunkelflaute: An Analysis of Variable Renewable Energy Droughts in Europe. In Proceedings of the EGU General Assembly 2025, Vienna, Austria, 7–12 July 2025. [Google Scholar] [CrossRef]

- Shah, A.M.; Liu, G.; Chen, Y.; Yang, Q.; Yan, N.; Agostinho, F.; Almeida, C.M.V.B.; Giannetti, B.F. Urban constructed wetlands: Assessing ecosystem services and disservices for safe, resilient, and sustainable cities. Front. Eng. Manag. 2023, 10, 582–596. [Google Scholar] [CrossRef]

- Infrastructure Australia. 2024 Infrastructure Market Capacity Report. Infrastructure Australia. 2024. Available online: https://www.infrastructureaustralia.gov.au/sites/default/files/2023-12/IA23_Market%20Capacity%20Report.pdf (accessed on 26 December 2024).

- Bogdanov, D.; Oyewo, A.S.; Mensah, T.N.O.; Nishida, Y.; Saito, T.; Aikawa, T.; Kimura, S.; Gagnebin, M.; Pescia, D.; Shimoyama, T.; et al. Energy transition for Japan: Pathways towards a 100% renewable energy system in 2050. IET Renew. Power Gener. 2023, 17, 3298–3324. [Google Scholar] [CrossRef]

- Qamar, F.; Afshan, G.; Rana, S.A. Sustainable HRM and well-being: Systematic review and future research agenda. Manag. Rev. Q. 2023, 74, 2289–2339. [Google Scholar] [CrossRef]

- ESG Post. Corporate Giants Fail to Meet Human Rights, Decent Work Standards. 2024. Available online: https://esgpost.com/corporate-giants-fail-to-meet-human-rights-decent-work-standards-survey/ (accessed on 22 April 2025).

- Grimm, K.E.; Archibald, J.L.; Axelsson, E.P.; Grady, K.C. Moving social-ecological restoration forward: How mangrove project managers’ perceptions of social monitoring and community engagement serve as a model for broader restoration efforts. Restor. Ecol. 2024, 33, e14273. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Ryu, H. Beyond economies of scale: Learning from construction cost overrun risks and time delays in global energy infrastructure projects. Energy Res. Soc. Sci. 2025, 123, 104057. [Google Scholar] [CrossRef]

- Xie, Z.; Feng, M.; Zhao, R.; Xiao, L.; Yao, S.; Ji, J.; Gao, Y.; Rong, P.; Chuai, X.; Chen, B. Impact of urbanization on water-energy-carbon nexus system: The case of Zhengzhou, China. Cities 2024, 155, 105466. [Google Scholar] [CrossRef]

- Manmatharasan, P.; Bitsuamlak, G.; Grolinger, K. AI-driven design optimization for sustainable buildings: A systematic review. Energy Build. 2025, 332, 115440. [Google Scholar] [CrossRef]

- International Labour Organization. Decent Work; International Labour Organization: Geneva, Switzerland. Available online: https://www.ilo.org/global/topics/decent-work/lang--en/index.htm (accessed on 23 April 2025).

- Environment Protection Authority Victoria. Reasonably Practicable: Guidance for Determining What is Reasonably Practicable under the Environment Protection Act 2017 (Publication 1856). Victorian Government. 2017. Available online: https://www.epa.vic.gov.au/sites/default/files/epa/publications/1856-english.pdf (accessed on 30 April 2025).

- Baldassarre, B.; Schepers, M.; Bocken, N.; Cuppen, E.; Korevaar, G.; Calabretta, G. Industrial Symbiosis: Towards a design process for eco-industrial clusters by integrating Circular Economy and Industrial Ecology perspectives. J. Clean. Prod. 2019, 216, 446–460. [Google Scholar] [CrossRef]

- Li, Y. Industrial variety, interregional industrial linkages, and regional resilience: Evidence from China. Ann. Reg. Sci. 2024, 73, 1321–1338. [Google Scholar] [CrossRef]

- Renteria-Mena, J.B.; Plaza, D.; Giraldo, E. Multivariate Hydrological Modeling Based on Long Short-Term Memory Networks for Water Level Forecasting. Information 2024, 15, 358. [Google Scholar] [CrossRef]

- Kim, T.-Y.; Cho, S.-B. Predicting residential energy consumption using CNN-LSTM neural networks. Energy 2019, 182, 72–81. [Google Scholar] [CrossRef]

- Foldager, J.; Jordahn, M.; Hansen, L.K.; Andersen, M.R. On the Role of Model Uncertainties in Bayesian Optimization. In Proceedings of the 39th Conference on Uncertainty in Artificial Intelligence (UAI 2023), Pittsburgh, PA, USA, 31 July–4 August 2023; Deshpande, A., van der Schaar, M., Eds.; PMLR: Cambridge, MA, USA, 2023; Volume 216, pp. 592–601. Available online: https://proceedings.mlr.press/v216/foldager23a.html (accessed on 10 April 2025).

- Chen, S.; Xu, Y.-P.; Guo, Y.; Yu, X. Multi-objective Optimization of Urban Water Allocation Considering Recycled Water. Water Resour. Manag. 2025, 39, 2615–2631. [Google Scholar] [CrossRef]

- United Nations Industrial Development Organization (UNIDO). Low Carbon and Climate Resilient Industrial Development; UNIDO: Vienna, Austria. Available online: https://www.unido.org/our-focus-safeguarding-environment-resource-efficient-and-low-carbon-industrial-production-industry-and-adaptation/low-carbon-and-climate-resilient-industrial-development (accessed on 10 March 2025).

- Cascale. Annual Meeting 2024 Executive Summary; Cascale: Amsterdam, The Netherlands, 2024; Available online: https://cascale.org/wp-content/uploads/2024/10/Cascale-Annual-Meeting-2024-Executive-Summary.pdf (accessed on 10 March 2025).

- U.S. Department of Energy. 2023 Standard Scenarios Report: A U.S. Electricity Sector Outlook; National Renewable Energy Laboratory: Golden, CO, USA, 2023. Available online: https://www.energy.gov/eere/analysis/2023-standard-scenarios-report-here (accessed on 11 April 2025).

- Department of Industry, Science and Resources. Annual Report 2023–24; Australian Government: Canberra, Australia, 2024. Available online: https://www.industry.gov.au/publications/annual-report-2023-24 (accessed on 25 April 2025).

- Rehman, A.U.; Glenis, V.; Lewis, E.; Kilsby, C. Multi-objective optimisation framework for Blue-Green Infrastructure placement using detailed flood model. J. Hydrol. 2024, 627, 131571. [Google Scholar] [CrossRef]