Abstract

Coal gangue, a major by-product of coal mining, poses significant environmental challenges due to its large-scale accumulation, land occupation, and potential for air and water pollution. This manuscript presents a comprehensive overview of continuous chamber gangue storage technology as a sustainable mining solution for coal mines. The principles of this approach emphasize minimizing disturbance to overlying strata, enabling uninterrupted mining operations, and reducing both production costs and environmental risks. By storing the surface or underground gangue in continuous chambers, the proposed method ensures the roof stability, maximizes the waste storage, and prevents the interaction between mining and waste management processes. Detailed storage sequences and excavation methods are discussed, including continuous and jump-back excavation strategies tailored to varying roof conditions. The process flows for both underground and ground-based chamber storage are described, highlighting the integration of gangue crushing, paste preparation, and pipeline transport for efficient underground storage. In a case study with annual storage of 500,000 t gangue, the annual economic benefit reached CNY 1,111,425,000. This technology not only addresses the urgent need for sustainable coal gangue management, but also aligns with the goals of resource conservation, ecological protection, and the advancement of green mining practices in the coal industry.

1. Introduction

Inner Mongolia encompasses a vast territory, covering most of northeast, north central, and the eastern part of northwest China. Coal-bearing strata are widely available, featuring nearly all major coal-accumulating periods. It is home to the world’s largest “open-pit coal mine” town [1]. In 2021, coal production in Inner Mongolia reached 1.07 billion tons, accounting for 26% of the national coal production, making it the second-largest producer in the country [2]. Coal gangue, a by-product of coal mining, is prevalent in Inner Mongolia. According to statistics from the Development and Reform Commission of the Inner Mongolia Autonomous Region, as of 2023, the cumulative stock of coal gangue in the region had reached 2 billion tons. A significant amount of coal gangue is piled in the open air, forming gangue mountains, and the harmful components and chemicals within can infiltrate the atmosphere, soil, surface, and groundwater, leading to environmental pollution. The repose angle of natural gangue is approximately 40°. It becomes susceptible to gravity disasters such as landslides and mudslides when it exceeds this angle, along with artificial excavation and high rainfall intensity. Gangue contains residual coal, and its surface is capable of absorbing oxygen. Under pressure, gangue generates high temperatures, easily leading to flammability and explosions. Gangue has become a “worry” for the government and enterprises [3,4,5]. The reuse of gangue has been incorporated into the country’s “14th Five-Year Plan” and has emerged as a crucial indicator for the development of national green mines.

Scholars have studied the comprehensive utilization technology of coal gangue across various fields [6,7,8]. The primary utilization methods include ecological restoration technology, heat and power generation, building materials, chemical products, recovery of valuable elements, and other products [9,10,11]. Amongst these, land reclamation, power generation, and building materials consume a large volume while other application methods have lower consumption rates. However, current disposal practices are inadequate to meet the demand for large-scale consumption, which is primarily reflected in the following aspects. First, local economic conditions and industrial layout constrain industries with high consumption volumes, such as building materials, mine backfilling, and combustion power generation. The demand in “waste-producing” areas is limited, and regions with substantial demand do not “produce waste”. Second, many technologies incur high costs during the application process. While the technology is feasible, its economic efficiency is poor due to factors such as transportation radius and market capacity, hindering its promotion. Third, some utilization technologies are theoretically possible but not yet mature; they lack large-scale demonstration and evaluation of practical application effects and support from a technical standard system, requiring further development. Fourth, the regional characteristics of coal gangue are pronounced, making it challenging to develop replicable and broadly applicable technologies, which restricts the widespread adoption of its comprehensive utilization technology [12].

This paper examines the green mining technology of gangue storage in continuous chambers within coal mines. Based on the generation and proportion of gangue during tunnel excavation, the coal mining process, and the surface coal washing process, this paper introduces a green mining technology for gangue storage in continuous chambers, wherein the gangue remains underground without being transported to the surface or stored above ground. The principles of this technology are explained, and a supporting process is designed, proposing a new path for gangue utilization and promoting safe, green mining practices in coal mines.

2. Progress on Green Mining Technology in Coal Mines

There are currently three main applications of coal gangue in ecological restoration: backfill mining, backfilling of collapsed areas, and land restoration. Among them, backfill mining is suitable for underground goafs formed by mining [13]. Goafs may cause ground collapse, and using coal gangue to fill them can effectively reduce the settlement of overlying rock strata while avoiding geological disasters. Currently, there are three filling methods: solid filling, paste filling, and slurry filling [14,15].

Gangue filling was initially primarily utilized in metal mines, with the earliest coal mines designed for gangue filling being North Lyell Mine in Australia and Mount Lyell Mine in Tasmania, which first implemented gangue for filling operations in 1915 [16]. Some longwall coal mines in the United States predominantly use solid waste for filling, including gangue filling. However, overall, few foreign mines utilise gangue for filling, leading to limited research on gangue filling. Foreign scholars mainly concentrate on the role of solid waste in goafs, while there is less investigation into related filling technologies. For example, Hollinderbaeumer et al. [17,18] evaluated solid waste filling in Germany. Lazorenko et al. proposed underground filling and utilization of coal gangue resources for coal mining.

In the 1960s and 1970s, China conducted experimental research on using gangue as a filling material in the goaf. However, due to the outdated gangue filling process and insufficient filling machinery, the filling efficiency was low, resulting in the slow development of gangue filling technology. In recent years, with the rapid growth of China’s economy, the significant industry demand has led to a swift increase in coal production, which has also caused many problems. Zhang et al. [19] proposed a pre-excavation fault processing technology that uses pre-excavated chambers as storage for gangue, allowing the gangue to be filled underground without mechanical crushing on the ground. This approach increases coal output and saves on processes and costs, representing a new clean filling technology. Zhang et al. [20] systematically discussed theoretical issues related to green mining of deep coal resources and established a technical system for rock filling. Lu Bin et al. [21] proposed a short-wall gangue cementation filling technology that effectively alleviated the drawbacks of longwall filling mining. Qi et al. [22] explored the “short filling and long mining” method, which effectively addressed the waste of coal pillars left in the mine and the accumulation of gangue discharged on the ground, constructing a new model of green mining. Wang and Zhang and others studied gangue filling methods and techniques [23,24]. Xu et al. conducted research on strip gangue filling in conjunction with field experiments [25].

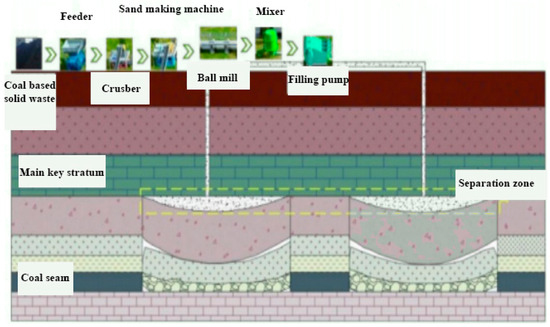

Academician Qian et al. [26] first proposed the theory of key layers of stope overburden in 1996 and established criteria for identifying these layers. From the 1980s to the late 1990s, based on theoretical research on key layers, some scholars introduced the overburden separation grouting filling technology to address the demand for surface subsidence control after coal seam mining. As shown in Figure 1, overburden separation grouting filling technology involves using high-pressure grouting to fill the separation area formed in the overburden to control subsidence, thereby slowing down surface subsidence. The advantage of this method is that the grouting system is constructed on the well without altering the existing development system, making it easy to achieve efficient production, reduce resource waste, and support the strategic goal of green mining [27].

Figure 1.

Principle of overburden separation grouting technology.

To meet the needs of large-scale disposal of gangue in major mines, some scholars in China have begun to study and explore the grouting filling technology for goaf areas and have gradually carried out industrial experiments at Huangling No. 2 Mine and Dahaize Coal Mine [28]. The technical principle of goaf grouting filling technology is to fill the space between the remaining coal pillars to create a complete filling bearing layer. Compared to the areas without filling, its bearing capacity is significantly increased, which can prevent the coal pillars and surrounding rocks from being damaged and reduce the impact of surface collapse caused by the movement of the overlying rock strata [29]. Currently, research on grouting filling technology in goaf areas by both domestic and international scholars mainly focuses on the layout of the grouting filling system and the management of grouting filling disasters in goaf areas.

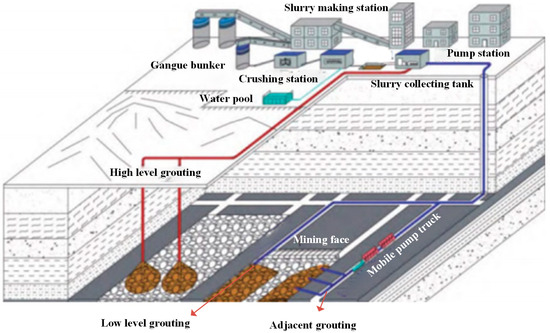

Regarding the layout of the grouting filling system in the goaf, both domestic and international scholars have conducted extensive innovative research on the system layout of grouting filling technology in the goaf [30,31,32]. Based on key factors such as the location of the grouting filling station, the relationship between the grouting and grouting layers, and the design of the grouting pipeline, they have proposed various goaf grouting-filling system layout methods that are suitable for different geological and production conditions in mines, including high-position grouting on the surface of the same layer, low-position grouting on the adjacent surface of the same layer, grouting from the upper coal seam to the lower coal seam, etc. [33]. The layout of the grouting filling system in the goaf is illustrated in Figure 2.

Figure 2.

Layout of goaf grouting system.

In terms of disaster management through grouting filling in goaf, grouting filling in goaf can be employed to achieve the goals of controlling mining pressure on the working face, preventing and extinguishing fires in goaf, and controlling water inrush underground [34]. By applying the method of grouting filling in the goaf to the mining of steeply inclined coal seams under water bodies, the researchers examined the mechanism of grouting filling. They accomplished multiple objectives, such as controlling roof subsidence, inhibiting the expansion of water-conducting fracture zones, and delaying the manifestation of mine pressure [35]. For the abnormally high temperature area of the goaf in the 12,315-working face of Huojitu Well in Daliuta Coal Mine, the researchers utilized ground drilling grouting, goaf closed measure-hole grouting, underground high-position drilling, and artificial grouting. They performed goaf fire prevention and extinguishing treatment, successfully achieving safe mining of the working face. The researchers employed grouting of stop walls to manage water, ensuring that the construction conditions of the tunnel were suitable for subsequent support, and used long pipe sheds combined with steel supports for robust reinforcement, applying shotcrete to the surrounding rock, resulting in positive outcomes [36]. The researchers proposed point grouting technology, analyzed the mechanism of controlling residual deformation in old goafs through point grouting, strip grouting, and full grouting methods, and outlined the design principles of grouting column size and grouting hole layout [37].

In summary, scholars have studied the green technology of underground gangue storage, but the underground spaces used for gangue storage are either goafs or overlying strata rather than chambers. There are issues limited by the technical process, such as insufficient utilization of mining space and time–space interference between filling and mining. Therefore, it is urgent to develop new underground green storage and research technologies to achieve the multiple goals of all underground gangue disposal, storage, and research, as well as chamber excavation, while protecting the ecological environment of the mining area.

3. Principles of Green Mining by Gangue Storage in Continuous Chambers in Coal Mines

3.1. Sources of Coal Mining Waste

Gangue is the solid waste generated during coal mining and processing. It primarily consists of rocks mixed with coal seams and non-coal materials separated during coal extraction and washing. These non-coal materials include rocks, soil, and other impurities. They are mined alongside coal but separated in the subsequent processing stage, forming gangue. Gangue can be classified into three categories according to its source [38,39].

- (1)

- Gangue generated by tunnel excavation

A large amount of rock waste will be generated during the tunnelling process. The main production stages of rock tunnelling include drilling, blasting, loading, support, transportation, and more. During the tunnelling process, explosives are required for blasting, or a fully mechanized tunnelling machine is utilized to crush the rock. The resulting rock waste is classified as gangue which accounts for 60% to 70% of coal gangue. This gangue primarily consists of mudstone, shale, siltstone, sandstone, conglomerate, limestone, and other materials [40].

- (2)

- Gangue is produced during coal mining.

Gangue extracted from the roof, floor, and interlayer during coal mining accounts for 10% to 30% of the coal gangue. These rocks include mudstone, siltstone, sandstone, and conglomerate [40].

- (3)

- Gangue on surface

It primarily consists of gangue produced during the coal washing process. Coal washing is a processing technology that utilizes differences in the physical and chemical properties of coal and impurities (such as grinding stone) to effectively separate coal from impurities through physical, chemical, or microbial separation methods, transforming these into coal products with a uniform quality and various uses. The primary aim of this process is to remove impurities from coal, reduce ash content, enhance coal quality, and satisfy user requirements [41]. The gangue extracted constitutes about 5% of the coal gangue during coal washing. These gangues are mainly composed of kaolinite, clay rock, and pyrite, among other materials.

3.2. The Goal of Gangue Storage in Continuous Chambers

In response to the gangue emitted from coal production, this study researched green mining technology for gangue storage in continuous chambers within coal mines. The principle of this technology is that through underground storage and research technologies, the gangue is temporarily stored underground to thoroughly clean the surface gangue, while ensuring that the underground gangue is not brought to the surface. In the future, with advancements in science and technology, the gangue will be deeply developed and utilized as a resource.

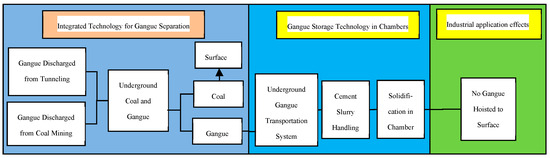

Theme 1: No gangue is hoisted to the surface.

Gangue discharged from underground excavation and coal mining is sorted underground using gangue sorting technology, and the screened gangue is transported to the gangue storage chamber via a belt conveyor system, then cemented and stored to meet the goal of not lifting gangue to the surface, as shown in Figure 3.

Figure 3.

Schematic diagram of underground gangue chamber storage technology.

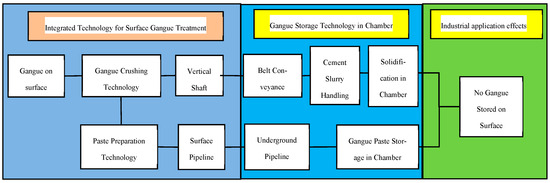

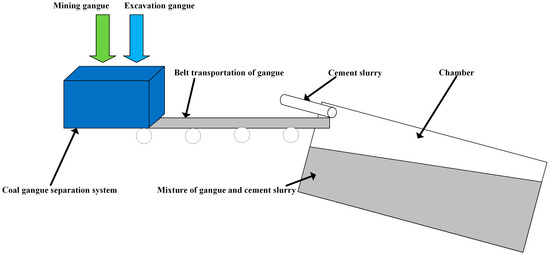

Theme 2: No gangue is stored on the surface.

The ground gangue is physically crushed using integrated gangue processing technology, and the coarsely crushed gangue (raw gangue) is transported to the gangue storage chamber through shafts and belts, cemented, and stored. The finely crushed gangue is made into a paste and transported to the storage chamber using a pipeline system to achieve no ground gangue, as shown in Figure 4.

Figure 4.

Schematic diagram of ground gangue storage chamber technology.

3.3. Principle of Gangue Storage in Continuous Chambers

Longwall gangue storage can reduce the need for underground gangue storage space. Additionally, roof maintenance is challenging and demands high standards for storage equipment, making it economically impractical for gangue storage. Therefore, we propose a method of gangue storage in continuous chambers. The technical principle of this method involves excavating a chamber within the coal seam to store gangue or gangue paste. Implementing continuous chamber storage can effectively remove surface gangue and eliminate the need to lift underground gangue. This technology addresses the ecological impacts of traditional methods and promotes green mining. Therefore, the principles of gangue storage design in continuous chambers are as follows:

- (1)

- Minimize the impact of disturbance on the overlying rock strata

The “longwall mining + caving method” for managing the roof has a greater destructive effect on the roof, and large-scale rock collapse reduces the gangue storage space [42]. Therefore, chamber excavation can minimize the disturbance to the overlying rock strata, thereby increasing the storage space for gangue.

- (2)

- Uninterrupted and continuous excavation operations

Continuous excavation accompanied by waste rock storage can significantly enhance work efficiency. By employing a constant advancement method, excavation equipment can perform excavation operations without interruption, avoiding the drawbacks of traditional intermittent excavation methods and cutting down on excavation time and costs. Simultaneously, the timely storage of waste rock in chambers can diminish issues such as the instability of the surrounding rock.

- (3)

- Reduce production costs and risks as much as possible

Ongoing research into continuous advancement and follow-up gangue storage can reduce reliance on excavation equipment and decrease maintenance and replacement costs for machinery. Additionally, it alleviates problems such as surrounding rock instability while minimizing risks to personnel and equipment. Furthermore, underground chamber gangue storage can lessen its impact on groundwater and reduce adverse effects on the surrounding environment and community.

- (4)

- Minimize environmental damage

Continuous advancement and follow-up gangue storage can protect the environment. The impact on the surrounding environment and community is minimized by implementing timely waste rock storage. Additionally, this technology reduces the effects on the surface and the consumption of land resources. Furthermore, it lowers the emission of noise and dust, further safeguarding the surrounding environment.

- (5)

- Mining and storage do not interfere with each other

During continuous gangue storage, excavation and storage co-occur without interfering with each other.

- (6)

- Gangue storage should be as close to the top as possible

The gangue should be stored as close to the roof as possible. On the one hand, it can prevent the roof from sinking and the two sides from deforming. On the other hand, it can maximize the capacity for waste rock storage.

- (7)

- Store the waste rock promptly after excavating the chamber.

If the chamber is left unattended for an extended period after excavation, it will deform, impacting the storage capacity for waste rock. Furthermore, it will cause the overlying rock strata to sink, detrimental to controlling surface deformation.

- (8)

- The location of the gangue storage should be accurately marked on the excavation plan

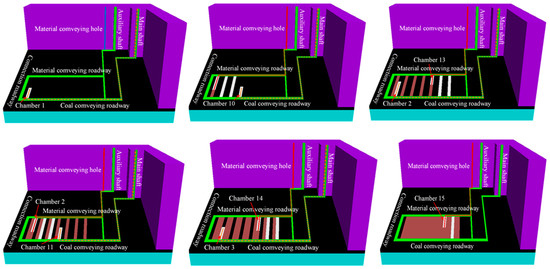

With advancements in science and technology, gangue could become a resource that can be developed and utilized. To support future development and utilization, the storage locations of the gangue should be marked for efficient mining and use later. Based on these principles and technical guidelines, a 3D display of the gangue storage scheme in continuous chambers is designed, as shown in Figure 5. There are numerous methods for continuous storage green mining solutions for chamber gangue. This design serves as a schematic diagram. The detailed design relies on the principles mentioned earlier, taking into account the production, geological conditions, and production capacity of the mine.

Figure 5.

Three-dimensional display diagram of the continuous chamber storage scheme for gangue or gangue paste.

3.4. The Method of Gangue Storage in a Continuous Chamber

The “Interval Chamber Excavation and Continuous Storage and Research” method is adopted to facilitate gangue storage in continuous chambers. A specific underground section is selected to construct the material conveying tunnel, coal transport tunnel, and connecting tunnel, forming a system. The storage chamber, which runs parallel to the network tunnel, is constructed at designated intervals. Underground or surface coal gangue is transported to the safety port via the conveying system. At the same time, cement slurry is sent from the surface to the chamber entrance to aid in transporting the coal gangue into the chamber, consolidating it into a solid mass. The front chamber is excavated while the gangue is stored in the back chamber. Subsequently, the coal pillars between the chambers are removed, allowing for additional gangue storage, thereby perpetuating the cycle until the block section is completed. Once the gangue storage for this block section is finished, storage proceeds to the next section, continuing the cycle until the area is fully developed with gangue storage. The specific gangue storage process is illustrated in Figure 6.

Figure 6.

Flowchart for the process of gangue storage in continuous chambers.

- (1)

- Gangue storage sequence

The designated area is excavated by a piece of excavation equipment inside and outside in sections. After the construction of Chamber One is completed, the door opening point is promptly blocked. Once the blocking is complete, Chamber One is filled with gangue. After the gangue storage of the excavated chamber is finalized and the cement or solid body solidifies (the solidification period is one week), Chamber Two of this section is excavated from inside to outside. After the excavation of Chamber Two is completed, the outermost chamber of this section acts as the connecting tunnel, which is then blocked with the inner material conveying tunnel and the coal transporting tunnel, after which the next section is filled. Each section is the length of two scraper conveyors. Proceeding to the next section is strictly forbidden before filling out the current section.

- (2)

- Excavation of odd-numbered chamber

The chamber excavation is carried out in a continuous or jump-back manner.

When the roof of the construction chamber is intact, the continuous retreat excavation method is employed. The continuous retreat method means that excavation of the chambers in the designated area occurs sequentially from the inside to the outside without interruption.

When the roof of the construction chamber is detached or broken, the jump-back excavation method is adopted.

One example of the jump-back method is as follows: a chamber and the adjacent chambers are considered a unit. From the inside to the outside, first excavate units 1, 2, and 3; leave units 4 and 5, then excavate units 6, 7, and 8, and leave units 9 and 10. When excavating the chambers in the designated area, continuously construct three chambers while leaving two chambers without construction to protect the coal pillars. Then, continue to construct three chambers and leave two chambers without construction. Repeat this process; in other words, construct three odd-numbered chambers for every two odd-numbered chambers, that is, “dig three every two.”

- (3)

- Excavation of even-numbered chambers

The chamber excavation is carried out in a continuous or jump-back manner.

When the roof of the construction chamber remains intact, the continuous backward excavation method is employed. Continuous backward excavation means that the excavation of the chamber in the designated area occurs continuously from the inside to the outside.

When the roof of the construction chamber is detached or broken, the jumping backwards excavation method is adopted.

The jump-back manner is as follows: from the inside to the outside, first excavate chambers 2#, 4#, and 6#, leaving chambers 8# and 10# unexcavated. Then, excavate chambers 12#, 14#, and 16#. When excavating the chambers in the designated area, continuously construct three even-numbered chambers and leave two even-numbered chambers unconstructed as protective coal pillars. Repeat this process by continuously constructing three even-numbered chambers for every two that are left unexcavated, that is, “dig three every two.”

The jump-back parameters need to be mechanically justified or designed using an empirical formula. Engineering calculations are necessary to ensure the stability of the chamber system under variable load, especially when the roof is weakened.

3.5. Matching Equipment for Gangue Storage in Continuous Chambers

The excavation, loading, transportation, and support production process of the chamber is constructed using excavation equipment and its supporting equipment. EBZ160 excavation equipment, a 40 T scraper conveyor, and ZL30EFB(C) explosion-proof loader are selected to complete the coal cutting and loading process. The MQT-120 anchor drilling rig is used to carry out the drilling and installation of anchors in both odd-numbered and even-numbered chambers. Circular excavation and anchor support technology are employed for construction. The ZL30EFB(C) explosion-proof loader is chosen to facilitate the opening of odd-numbered and even-numbered chambers and coal transportation during normal excavation. The 40T scraper conveyor and DSJ100/63/2×75 belt conveyor are selected to handle the transportation work. An RBW80/20 emulsification pump is selected to execute the single hydraulic support. The ZL30EFB(C) explosion-proof loader is utilized to manage the transportation and removal of materials and equipment, as well as the cleaning of floating coal in the chamber. This results in a production system where all processes of digging, loading, supporting, and transporting during chamber excavation are mechanized.

4. The Process of Green Mining Through Gangue Storage in Continuous Chambers Within Coal Mines

4.1. The Process of Gangue Storage in Underground Chambers

Gangue produced by mining and excavation is the primary source of coal gangue, with excavation gangue accounting for 60% to 70% of the total, while mining gangue makes up 10% to 30%. To manage the gangue generated from these processes, an underground gangue chamber storage method is utilized. The gangue is transported to the gangue concentration area via a belt for sorting, after which the sorted coal is lifted to the surface. Subsequently, the gangue is moved to the entrance of the gangue storage chamber using a belt transportation system, and then cement slurry is employed to transport the gangue into the chamber for solidification and storage. The specific storage process is depicted in Figure 7.

Figure 7.

Schematic diagram of the underground gangue storage process in a continuous chamber.

The continuous chamber underground gangue storage process mainly includes gangue sorting, belt transportation, and chamber gangue storage. Among these, the underground gangue sorting uses the heavy medium coal preparation process, which requires a systematic coal flow design, lump raw coal preparation, lump raw coal sorting, and uniform feeding, as well as medium removal and recovery, coal slurry water treatment, gangue discharge, transportation and storage, and the support design of a large-section chamber in the coal gangue separation system to ensure the efficient and safe storage of continuous chamber underground gangue.

4.2. Chambered Storage Technology for Ground Coal Gangue

For existing coal gangue on the ground, it is stored in the chamber through “crushing, drilling, conveying, cement slurry, consolidation” or “crushing, mixing, making paste, pipeline transportation, consolidation”. For each link of the chamber storage of gangue, the processes of coal gangue crushing and sorting, paste preparation, and transportation have been developed to facilitate the chamber storage of coal gangue.

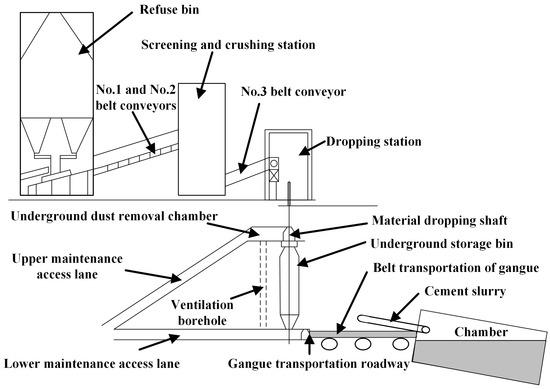

4.2.1. Chamber Storage Processes for Ground Raw Gangue

The ground raw gangue is loaded into the gangue bin, and the gangue in the bin is then transported to the gangue crushing station via No. 1 and No. 2 belt conveyors. In the gangue crushing station, a jaw crusher coarsely crushes and screens the gangue, while a hammer crusher finely crushes and screens the grinding stone. The gangue materials that are crushed and screened to meet the storage requirements are transported to the gangue delivery station through No. 3 belt conveyor and then delivered to the underground gangue material storage bin. The gangue materials in the storage bin are subsequently transported to the underground continuous chamber entrance via the underground belt and then moved to the two chambers by cement slurry, as shown in Figure 8.

Figure 8.

Schematic diagram illustrating the storage process of raw gangue on the ground within the continuous chamber.

The storage process of raw gangue on the ground within the continuous chamber involves waste rock crushing, a shaft, an underground waste rock storage bin, belt transportation, and chamber storage and research. Among these, waste rock crushing requires determining the structure and crushing parameters of both the jaw crusher and hammer crusher. The shaft diameter and delivery speed must be established to design the shaft delivery efficiency. The waste rock material moves at high speed when vertically delivered to the underground storage bin through the delivery shaft. To prevent falling waste rock from damaging the storage bin, a buffer must be installed underground. The belt needs to transport materials at a uniform speed, and its transportation speed is adjusted according to the storage and research capacity.

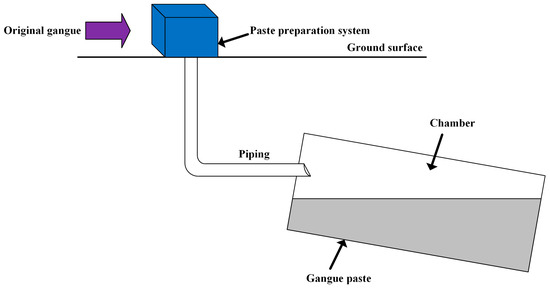

4.2.2. Chamber Storage Process of Ground Raw Gangue Paste

The storage of the paste in the underground continuous chemical chamber of the ground raw gangue is illustrated in Figure 9. The ground gangue is crushed on the surface, converted into paste, and then transported to the underground continuous chamber through pipelines for storage.

Figure 9.

Schematic diagram of the paste storage line in the underground continuous chamber of the raw gangue on the surface.

The surface gangue in the underground continuous chamber paste-storage process includes gangue paste preparation, a pumping system, a pipeline transportation system, and chamber storage. Among these, the gangue paste preparation system requires the design of a gangue crushing system and an intelligent control system. The paste preparation system necessitates determining the process parameters of the storage system along with the proportioning and mixing system. The pumping system involves selecting the rated capacity of the delivery pump, emergency pump, and auxiliary equipment and facilities. The pipeline transportation system requires determining the composition of the pipeline system and the layout of the delivery pipeline.

5. Economic Benefits of a Case Study

The technology of gangue storage in continuous chambers was applied in a coal mine of in Inner Mongolia. The annual storage of gangue is 500,000 tons, which is effectively solving the problem of coal gangue and achieving the goal of no gangue hoisted to the surface and no gangue stored on the surface, realizing green mining.

The economic benefits of using the technology of gangue storage in continuous chambers mainly include saving environmental protection fees, saving gangue processing costs, gangue discharge costs, and increasing coal production rate. However, gangue storage costs were added in the whole process.

- (1)

- Save environmental protection fees

According to regulations, solid waste generated needs to pay environmental protection fees at a rate of CNY 5 /ton. After the implementation of the technology, the case-studied project reduced the annual discharge of 439,000 tons of gangue, which saved environmental protection fees of CNY 2.195 million annually.

- (2)

- Save gangue treatment costs

According to surveys, the cost of discharging, transporting, and processing gangue is approximately CNY 30,626 /ton. After the implementation of the technology, the case-studied project reduced the annual discharge 439,000 t of gangue, which saved gangue treatment costs of CNY 13.4448 million annually.

- (3)

- Increase raw coal production rate

By adopting the technology of gangue storage in underground continuous chambers, an additional 439,000 tons of raw coal can be produced annually. The main coal type in the case-studied coal seam is gas coal, which contains an average 40% of gangue. After coal washing and processing, 175,600 tons of clean coal with a calorific value of 5000 kcal were produced. Taking the average market price of thermal coal as CNY 400 /ton, the benefit increased by CNY 70.24 million annually.

- (4)

- Add gangue storage costs

The cost of gangue storage is about CNY 53 /t, and gangue processing is 439,000 t annually, which requires a total cost of CNY 23,267 million.

Taking into account all of the above factors, the comprehensive annual economic benefit is CNY 1,111,425 million.

6. Future Studies

This paper delivered the main concept of the technology of gangue storage in continuous chambers in coal mines. However, there are some detailed technical parameters required to determine in a defined case if the technology should be put into application. Future studies will focus on the following contents:

- (1)

- Gangue composition varies significantly by region and affects its suitability for paste preparation or cementation. If applying the gangue paste storage process, fundamental material properties such as composition, slurry rheology, set time, or long-term strength need to be investigated to prepare qualified paste [43].

- (2)

- To ensure the safety of the gangue storage in continuous chamber technology, numerical simulations, mechanical modeling, or geotechnical computations are essential to support the stability of the continuous chambers. For instance, modeling spatiotemporal transport behavior of gangue slurries and solidification dynamics [44] and the numerical modeling of mining-fill coupling and support systems [45].

- (3)

- Different gangue storage methods influence the choice of the chamber design. The proposed system scales with mining depth, chamber length, storage volume per 1 m3 of mined space, storage density, permissible feed rate, and the maximum production capacity must be determined in the future. Also, assessments of the risk of massif destruction and design of a fall control system are essential to develop to enhance the resilience of the technology.

- (4)

- This paper assumes that the chamber roof remains stable throughout excavation and filling but has not accounted for the dynamic response under stress redistribution or operational disturbances. This issue is particularly critical in deep mining scenarios. It is of great significance that the perspective on structural behavior under dynamic loads and backfill interaction should be studied [46,47].

7. Conclusions

This paper examines and develops the principles and processes of green mining technology for continuous chamber coal mines with gangue storage, and presents the following conclusions:

- (1)

- The principle of green mining technology for gangue storage in continuous chambers in coal mines is that gangue is temporarily stored in underground chambers through mining and storage technology to thoroughly clean the surface gangue. At the same time, the underground gangue is not brought up to the surface, ensuring there is no gangue on the ground.

- (2)

- The principles of continuous chamber storage of gangue involve minimizing disturbance to the overlying rock strata, maintaining uninterrupted excavation operations, reducing production costs and risks, minimizing environmental damage, avoiding interference with excavation and storage, storing gangue as close to the top as feasible, depositing gangue promptly after chamber excavation, and accurately marking the gangue storage location on the excavation plan.

- (3)

- Continuous chamber storage of waste rock employs the chamber segmentation method for its storage. Once the waste rock storage in the current section is completed, storage in the next section will commence, and this cycle will continue until the waste rock storage in the designated area is finished.

- (4)

- The process of underground gangue chamber storage involves sorting the gangue produced by underground mining and excavation, transporting it to the entrance of the gangue storage chamber using a belt conveyor system, and then moving the gangue into the chamber with cement slurry for solidification and storage.

- (5)

- The process of storing ground gangue in chambers can involve crushing and screening the ground gangue, placing it in the underground gangue material storage bin through a vertical shaft, and then transporting it to the entrance of the continuous chamber to flush it into the chamber with cement slurry. Additionally, the ground gangue can be crushed on the surface into a paste and then transported to an underground continuous chamber through a pipeline for storage.

Author Contributions

Conceptualization, J.L. (Jinha Liu); methodology, J.L. (Jinhai Liu) and S.Z.; validation, Z.Y. and S.Z.; Resources, Z.Y.; formal analysis, J.L. (Jinhai Liu) and Y.W.; data curation, Y.W.; investigation, D.N.; writing—original draft preparation, J.L. (Jinhai Liu); writing—review and editing, J.L. (Jiajie Li) and D.N.; supervision, M.H.; funding acquisition, J.L. (Jiajie Li). All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key R&D Program of China (2023YFC3805103), the Natural Science Foundation of China (52374076), the Fundamental Research Funds for the Central Universities (FRF-KP-25-009), and the 111 Project (B20041).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yang, X.W.; Wang, Y.; Liu, X.; Yu, H.X.; Zhang, Z.A.; Tian, Y. Current Situation and Prospect of Open-pit Coal Mines in China. China Coal 2023, 49, 126–133. [Google Scholar] [CrossRef]

- The Annual Report of the Coal Industry in 2021 was Released. China Coal News, 2 April 2022; 007. [CrossRef]

- Zheng, Q.; Zhou, Y.; Liu, X.; Liu, M.; Liao, L.; Lv, G. Environmental hazards and comprehensive utilization of solid waste coal gangue. Prog. Nat. Sci.·Mater. Int. 2024, 34, 223–239. [Google Scholar] [CrossRef]

- Li, Y. Review of Coal Gangue Characteristics and Ecological Restoration Management Technology. IOP Conf. Ser. Earth Environ. Sci. 2021, 781, 032033. [Google Scholar] [CrossRef]

- Li, Q.; Li, J.; Zhang, S.; Huang, X.; Wang, X.; Wang, Y.; Ni, W. Research Progress of Low Carbon Cementitious Materials Based on Synergistic Industrial Wastes. Energies 2023, 16, 2376. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, S.; Wang, Y.; Li, J.; Li, K.; Zhang, C. Exploration of silica fume effect on solid waste based backfilling material: Mechanical properties, hydration mechanism and economic benefits. Process Saf. Environ. Prot. 2025, 197, 107042. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, S.; Yang, T.; Wang, Y.; Li, J.; Li, K. The influence of coal gangue dosage and concentration on the properties and hydration mechanism of fly ash-based cemented filling materials. J. Clean. Prod. 2025, 492, 144903. [Google Scholar] [CrossRef]

- Li, J.; Fu, P.; Zhang, S.; Li, J.; Liu, Y.; Wu, C.; Ni, W. Enhanced leaching control of chromium, antimony, and chlorine utilizing CO2-curing slag-fly ash-based agent. J. Environ. Chem. Eng. 2024, 12, 114606. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Y.; Xu, K.; Bai, L.; Guo, N.; Li, S. A short review of the sustainable utilization of coal gangue in environmental applications. RSC Adv. 2024, 14, 39285–39296. [Google Scholar] [CrossRef]

- Cui, R.X.; Huo, P.X.; Zhou, B.J.; Hu, Y.Y.; Yang, Y.Q.; Yang, F.L.; Di, Z.C. Spatial Distribution Characteristics and Graded Utilization Path of Coal Gangue in China. Environ. Sci. 2025, 46, 2281–2291. [Google Scholar] [CrossRef]

- Wang, Y. An Overview of Coal Gangue Resource Utilisation: A Brief Study. Adv. Res. 2025, 26, 351–354. [Google Scholar] [CrossRef]

- Zhu, L.; Gu, W.Z.; He, Z.W.; Liu, C.Y.; Zhao, M.Y.; Song, T.Q.; Zhang, Y.; Wu, Y.Y.; Liu, Z.C.; Zhang, X.F.; et al. Current situation of comprehensive utilization of coal gangue and exploration of ways of high-value utilization: A case study of China National Coal Group Corporation. Coal Sci. Technol. 2025, 53, 104–124. [Google Scholar] [CrossRef]

- Li, J.; Wang, J. Comprehensive utilization and environmental risks of coal gangue: A review. J. Clean. Prod. 2019, 239, 117946. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, K.; He, X.; Zhao, X.; Wei, Z.; He, S. Research status of comprehensive utilization of coal-based solid waste (CSW) and key technologies of filling mining in China: A review. Sci. Total Environ. 2024, 926, 171855. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.Y.; Zhang, B.; Wang, M.; Qiu, H.F.; Zhang, X.Y. Evolution Process and Basic Categories of Mine Backfilling Technology. Met. Mine 2021, 03, 724–732. [Google Scholar] [CrossRef]

- Yu, X.; Yang, K.; He, X.; Hou, Y.; Fang, J.; He, S. Research progress on multi-source coal-based solid waste (MCSW) resource utilization and backfill mining basic theory: A systematic literature review. Process Saf. Environ. Prot. 2025, 195, 106670. [Google Scholar] [CrossRef]

- Hollinderbäumer, E.W.; Mez, W. Viscosity Controlled Production of High Concentration Backfill Pastes. In Proceedings of the Sixth International Symposium on Mining with Backfill, Brisbane, Australia, 19–23 April 1998; pp. 43–47. [Google Scholar]

- Lazorenko, G.; Kasprzhitskii, A.; Yatsenko, E.A.; Wensheng, L.; Chaudhary, S. Towards coal mining waste valorization: Gangue as resource for the production of geopolymer and related alkali-activated materials. Green Technol. Sustain. 2025, 3, 100205. [Google Scholar] [CrossRef]

- Zhang, D.S.; Zhang, J.X.; Xu, J.H. Technology of Pre-drilled Roadway Passing through Faults and Underground Treatment of Gangue. J. China Univ. Min. Technol. 2004, 33, 54–58. [Google Scholar]

- Zhang, J.X.; Zhang, Q.; Ju, F.; Zhou, N.; Li, M.; Sun, Q. Theory and Technology of Green Mining of Mining, Dressing and Backfilling for Deep Coal Resources. J. China Coal Soc. 2018, 43, 377–389. [Google Scholar] [CrossRef]

- Lu, B.; Zhang, X.G.; Li, F.; Zhang, B.L.; Pang, Z.Z. Technology and Application of Short-wall Cemented Gangue Backfill Mining. J. China Coal Soc. 2017, 42, 7–15. [Google Scholar] [CrossRef]

- Qi, H.G.; Zhang, N.; Li, J.; Zheng, Z.Y.; Zhu, L.; Guan, Z.L. Study on the Scientific Mining Mode of "Short-distance Backfilling and Long-distance Mining" in Coal Mines. Coal Sci. Technol. 2019, 47, 1–11. [Google Scholar] [CrossRef]

- Wang, Y.J. Direct Gangue Backfilling and Its Benefit Analysis. J. Liaoning Tech. Univ. 2003, 22, 70–71. [Google Scholar]

- Zhang, J.X.; Zhou, N.; Gao, F.; Yan, H. Gangue Grouting Backfilling Method for the Subsequent Space in Coal Mine Mining. J. China Coal Soc. 2023, 48, 150–162. [Google Scholar] [CrossRef]

- Li, X.S.; Xu, J.L.; Zhu, W.B.; Wang, X.Z. Theoretical Study on Grouting Backfilling Technology in the Caving Area of Strip Mining. J. China Coal Soc. 2008, 11, 1205–1210. [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Study on the Key Stratum Theory in Rock Mass Control. J. China Coal Soc. 1996, 03, 2–7. [Google Scholar]

- Liu, Y.C.; Lin, B.Q.; Gong, X.M.; Liu, T.; Li, Y.J.; He, J.H.; Yang, J.Y. Influence of overburden separation grout filling on the evolution characteristics of spontaneous combustion hazard zones in the goaf. Environ. Earth Sci. 2025, 84, 57. [Google Scholar] [CrossRef]

- Xie, S.R.; Pan, H.; Gu, W.Z.; Zhu, L.; Dong, Y.; Chen, D.D.; Song, T.Q.; Jiang, Z.S. Technology and engineering test of filling goaf with coal gangue slurry. Sci. Rep. 2025, 13, 20536. [Google Scholar] [CrossRef]

- Jiang, N.; Zhao, J.; Sun, X.; Bai, L.; Wang, C. Use of fly-ash slurry in backfill grouting in coal mines. Heliyon 2017, 3, e00470. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; He, H.; Jin, X.; Qu, Y.; Guo, H. Research on Key Factors Influencing Surface Subsidence of Paste Backfilling Mining in Thick Coal Seam of Deep Mine. Adv. Civ. Eng. 2021, 2021, 6634331. [Google Scholar] [CrossRef]

- Liu, J.; Wen, Z.D. Research on Partial Backfill Mining Technology Based on Controlling Coal Mine Mining Subsidence. Inn. Mong. Coal Econ. 2023, 10, 28–30. [Google Scholar] [CrossRef]

- Wu, G.; Nie, X.; Zhao, L.; Li, Z. Study on the stability of waste rock filling in goaf based on dynamic comprehensive analysis method. Heliyon 2024, 10, e41023. [Google Scholar] [CrossRef]

- Zhu, L.; Gu, W.Z.; Yuan, C.F.; Liu, C.Y.; Pan, H.; Song, T.Q.; Sheng, F.T. Application and Prospect of Coal Gangue Slurry Filling Technology. Coal Sci. Technol. 2024, 52, 93–104. [Google Scholar] [CrossRef]

- Gupta, A.K.; Paul, B. A review on utilisation of coal mine overburden dump waste as underground mine filling material: A sustainable approach of mining. Int. J. Min. Miner. Eng. 2015, 6, 172–186. [Google Scholar] [CrossRef]

- Liu, C.Y.; Yang, J.X.; Wu, F.F. A Proposed Method of Coal Pillar Design, Goaf Filling, and Grouting of Steeply Inclined Coal Seams Under Water-Filled Strata. Mine Water Environ. 2015, 34, 87–94. [Google Scholar] [CrossRef]

- Gao, D.Y. Application of High-level Borehole Grouting Technology in Fire Prevention and Extinguishing of Goaf. Coal Technol. 2017, 36, 121–123. [Google Scholar] [CrossRef]

- Wang, L.; Guo, G.L.; Zhang, X.N.; Zha, J.F. A New Point Pillar Grouting Method for Longwall Gently Inclined Old Goaf. Saf. Coal Mines 2016, 47, 85–88+92. [Google Scholar] [CrossRef]

- Sun, Y.; Bai, B.; Yang, X.; Zhu, S.; Tian, J.; Wang, Z.; Xu, L.; Xu, L.; Shen, B. Coal Gangue Utilization: Applications, Challenges, and Sustainable Development Strategies. Energies 2025, 18, 444. [Google Scholar] [CrossRef]

- Li, C.; Xu, R.X.; Wang, L.P.; Wang, Y.W.; Zhao, Y.H.; Cui, Y.J.; Li, X.Y. Research Progress in Comprehensive Utilization of Coal Gangue. Appl. Chem. Ind. 2021, 50, 209–214+231. [Google Scholar] [CrossRef]

- Fan, X.P.; Liu, J.; Kang, Z.; Dong, X.G. Strategic Thinking on the Comprehensive Utilization of Coal Gangue and Mine Ecological Restoration. Environ. Sanit. Eng. 2023, 31, 8–15. [Google Scholar] [CrossRef]

- Li, D.; Wu, D.; Xu, F.; Lai, J.; Shao, L. Literature overview of Chinese research in the field of better coal utilization. J. Clean. Prod. 2018, 185, 959–980. [Google Scholar] [CrossRef]

- He, X.; Zhang, C.; Yang, K.; Liu, S.; Han, P. Cooperative failure of overburden-surface and its control measures in longwall mining. Geotech. Geol. Eng. 2023, 41, 3587–3604. [Google Scholar] [CrossRef]

- Luo, B.; Su, Y.; Ding, X.; Chen, Y.; Liu, C. Modulation of initial CaO/Al2O3 and SiO2/Al2O3 ratios on the properties of slag/fly ash-based geopolymer stabilized clay: Synergistic effects and stabilization mechanism. Mater. Today Commun. 2025, 47, 113295. [Google Scholar] [CrossRef]

- Ding, X.-H.; Luo, B.; Zhou, H.-T.; Chen, Y.-H. Generalized solutions for advection–dispersion transport equations subject to time-and space-dependent internal and boundary sources. Comput. Geotech. 2025, 178, 106944. [Google Scholar] [CrossRef]

- Wang, M.; Su, J.S.; Qin, H.Y.; Shang, L.Y.; Kang, J.X.; Liu, W.W.; Li, M.; Zhang, F.; Li, X.; Fang, Z.Z. Research on active advanced support technology of backfilling and mining face. Rock Mech. Rock Eng. 2024, 57, 7623–7642. [Google Scholar] [CrossRef]

- Chen, Y.H.; Zhang, L.; Xu, L.R.; Shuai, Z.; Luo, B.; Kui, D. In-situ investigation on dynamic response of highway transition section with foamed concrete. Earthq. Eng. Eng. Vib. 2025, 24, 547–563. [Google Scholar] [CrossRef]

- Wang, M.; Li, X.; Su, J.S.; Liu, W.W.; Fang, Z.Z.; Wang, S.; Kang, J.X.; Yu, W.G. A study on the reasonable width of narrow coal pillars in the section of hard primary roof hewing along the air excavation roadway. Energy Sci. Eng. 2024, 12, 2746–2765. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).