Mitigation of Alkali–Silica Reactivity of Greywacke Aggregate in Concrete for Sustainable Pavements

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

| ID | Description | Density [g/cm3] | Expansion * [%] | ||

|---|---|---|---|---|---|

| At 14 Days | At 28 Days | ||||

| D | coarse | Crushed greywacke | 2.71 | 0.31 | 0.52 |

| N | Crushed greywacke | 2.73 | 0.26 | 0.40 | |

| B | fine | Natural fossil sand | 2.65 | 0.09 | 0.23 |

| W | Natural river sand | 2.66 | 0.30 | 0.46 | |

| T | Natural fossil sand | 2.65 | 0.36 | 0.57 | |

| Constituent | Content [%] | ||||

|---|---|---|---|---|---|

| Greywacke (D) | Greywacke (N) | Sand (B) | Sand (W) | Sand (T) | |

| SiO2 | 58.27 | 63.22 | 87.15 | 93.52 | 89.98 |

| TiO2 | 0.74 | 0.659 | 0.075 | 0.035 | 0.1 |

| Al2O3 | 14.51 | 15.11 | 2.61 | 1.5 | 2.98 |

| Fe2O3 | 5.79 | 5 | 0.52 | 0.23 | 0.49 |

| MnO | 0.116 | 0.062 | 0.015 | 0.009 | 0.027 |

| MgO | 2.24 | 1.97 | 0.19 | 0.02 | 0.30 |

| CaO | 2 | 1.32 | 2.48 | 0.17 | 1.28 |

| Na2O | 2.08 | 2.93 | 0.49 | 0.29 | 0.57 |

| K2O | 2.78 | 3.01 | 0.95 | 0.54 | 1 |

| P2O5 | 0.189 | 0.152 | 0.06 | 0.017 | 0.028 |

| SO3 | 0.13 | <0.01 | <0.01 | <0.01 | <0.01 |

| Cl | 0.014 | 0.016 | 0.001 | 0.007 | <0.001 |

| F | <0.01 | <0.01 | <0.01 | 0.04 | <0.01 |

| LOI | 6.9 | 1.9 | 2.2 | <0.5 | 1.7 |

| total | 95.64 | 95.21 | 96.71 | 96.66 | 98.41 |

2.2. Methods

3. Results

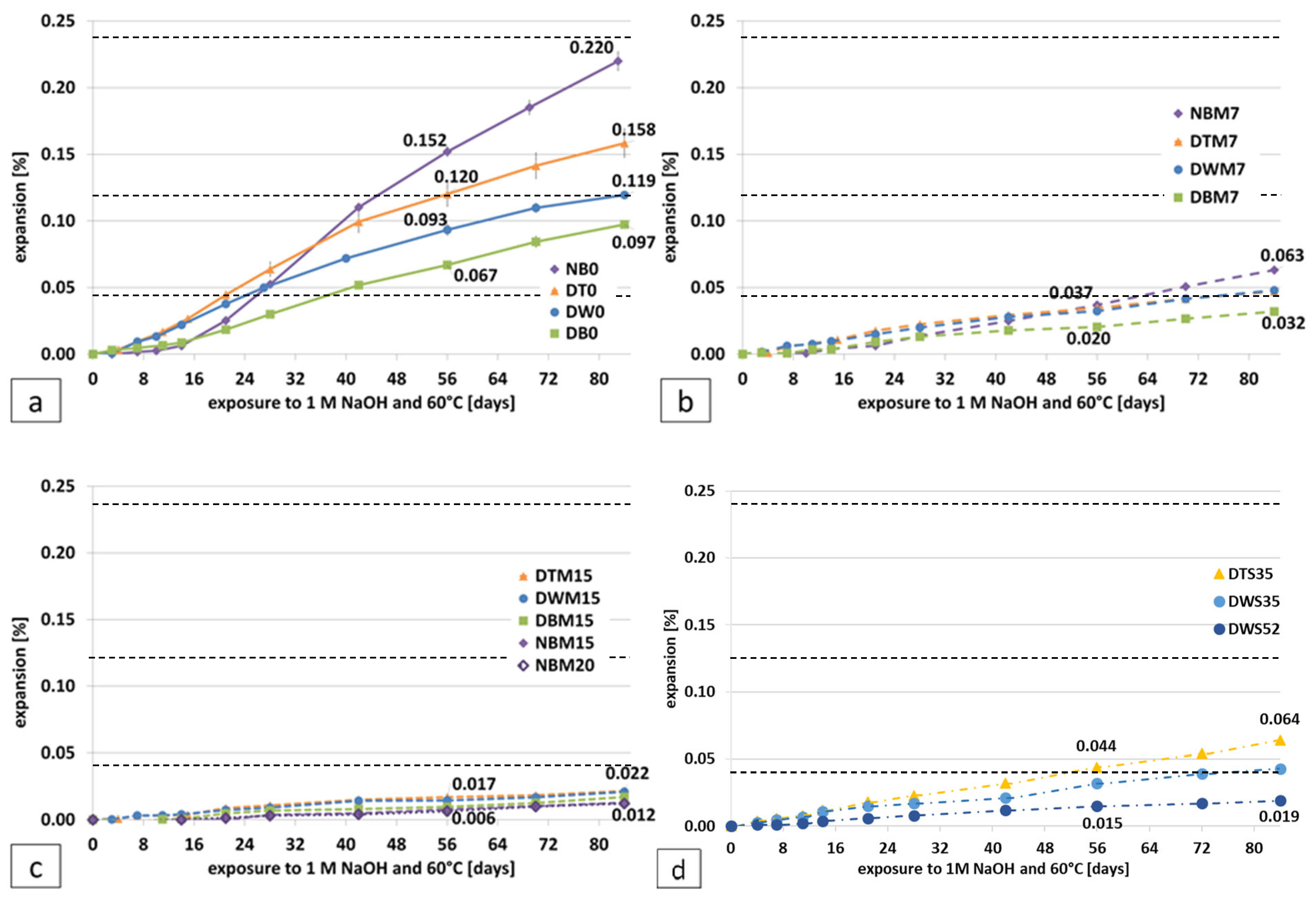

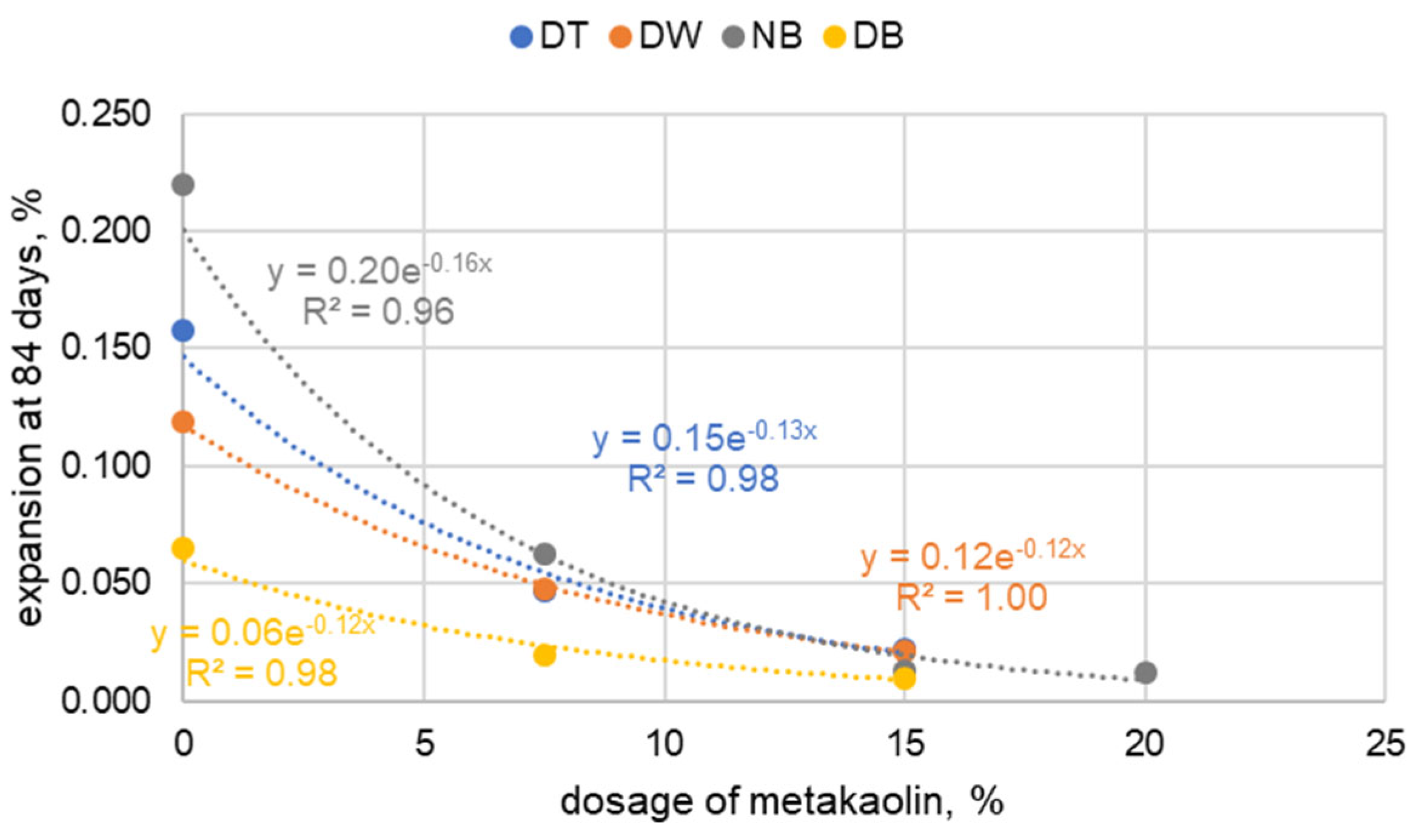

3.1. Expansion

3.2. Elastic Modulus and Compressive Strength

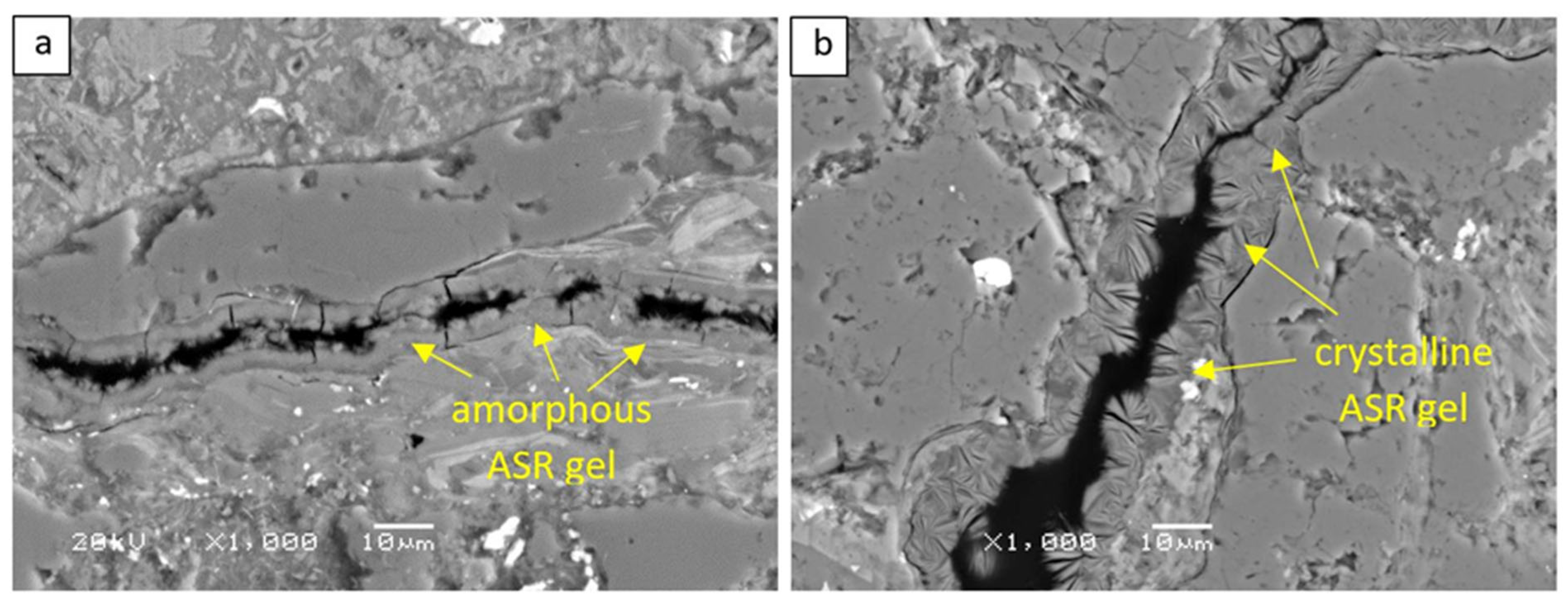

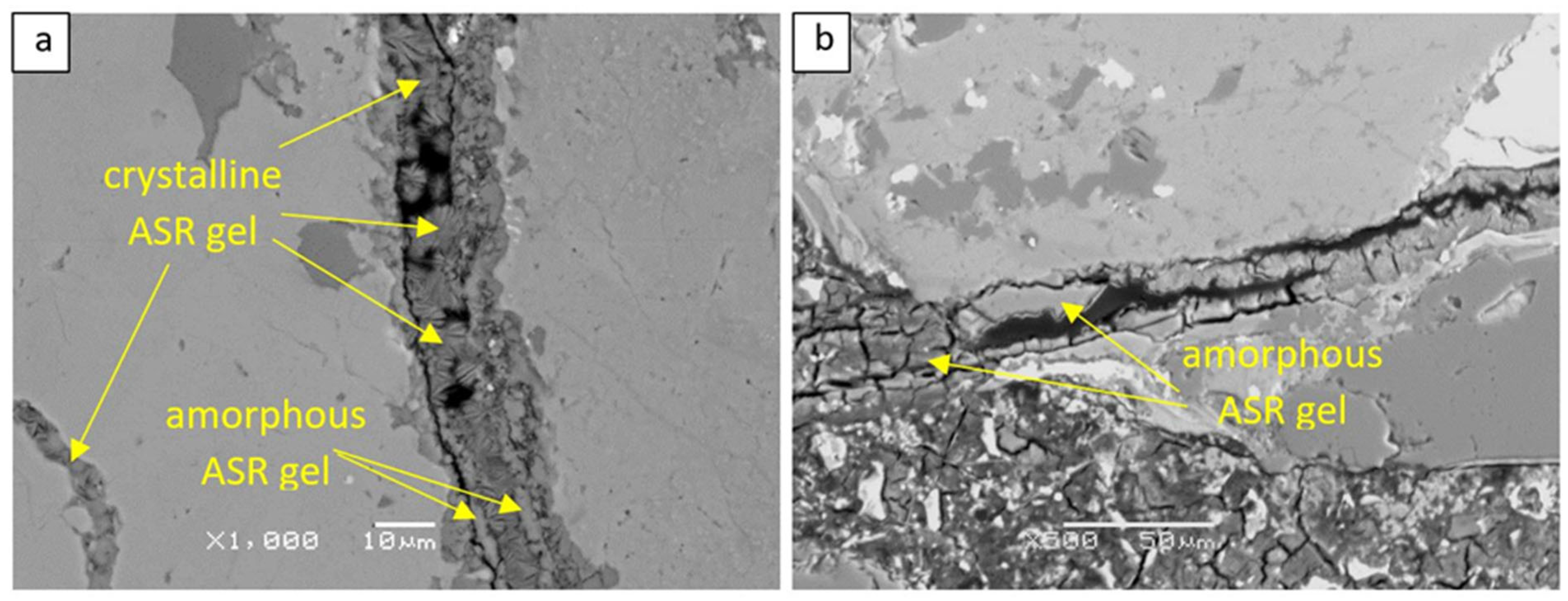

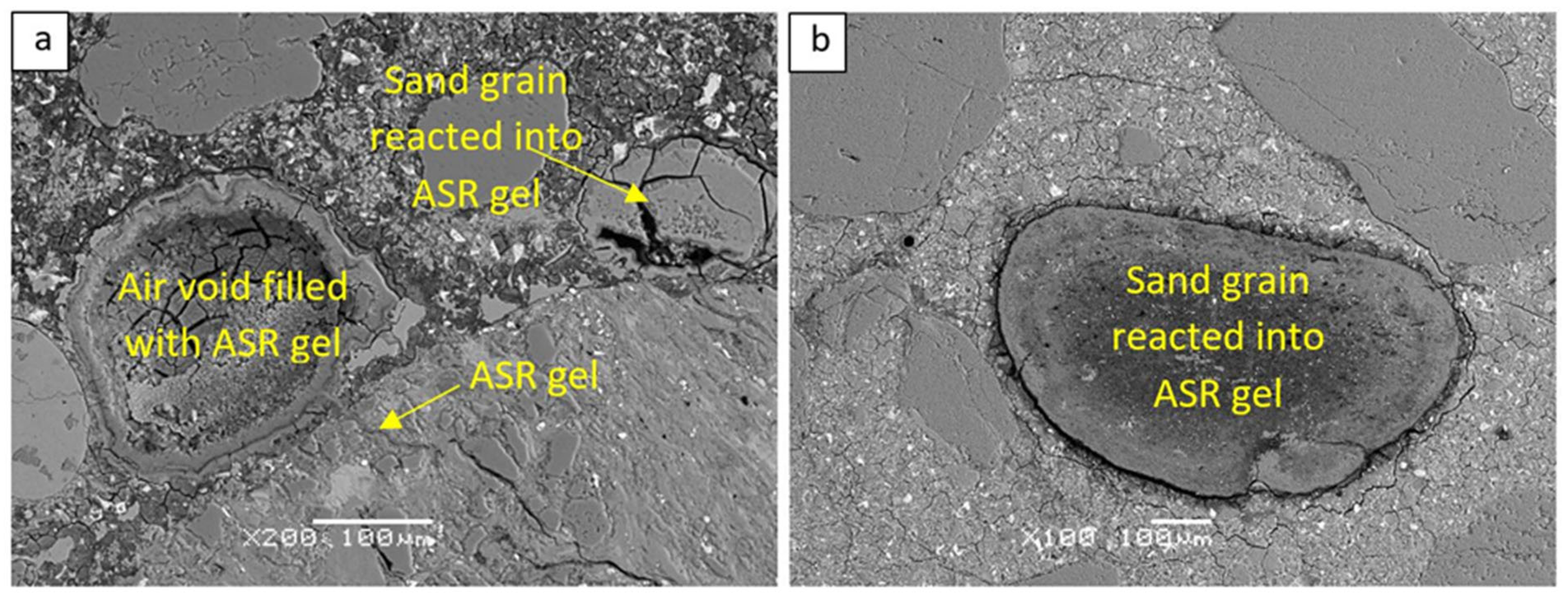

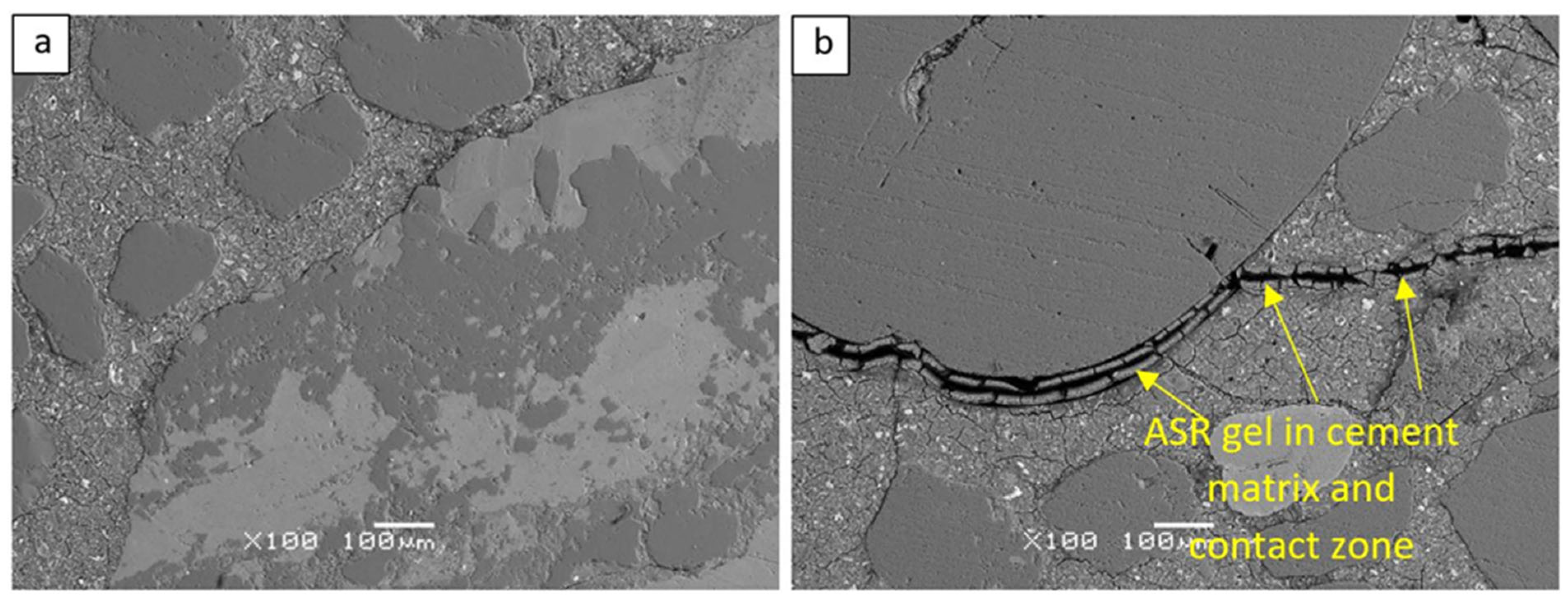

3.3. Reaction Products in Concrete Specimens

4. Discussion

5. Conclusions

- 1.

- A moderate alkaline reactivity of locally sourced greywacke aggregate was established using the MCPT method. The expansion, due to alkali–silica reaction, was increased by a factor 1.7–2.4 when greywacke coarse aggregate was blended with natural sand of moderate reactivity.

- 2.

- Alkali–silica reaction products in Portland cement concrete, both crystalline and amorphous, were detected in the cracks of greywacke grains, around greywacke grains, and in the cement matrix. In the blends with reactive fine aggregate, the alkali–silica reaction products filled the space previously occupied by reactive sand grains. The composition of reaction products in greywacke grains was characterized by the Ca/Si ratio of about 0.31 (± 0.03), the (Na + K)/Si ratio of about 0.25 (± 0.03), and 0.21 (± 0.03) for crystalline and amorphous products, respectively.

- 3.

- Metakaolin used for partial replacement of Portland cement and ground-granulated blast furnace slag used as a constituent of blended cements were found effective in mitigating the expansion of concrete containing greywacke aggregate and moderately reactive quartz sand. The required level of ASR mitigation is obtained for the replacement of 15% of Portland cement by metakaolin or the use of CEM III/A cement containing about 52% of slag.

- 4.

- The expansion of concrete containing greywacke aggregate was associated with a trend of the reduction of the resonant elastic modulus by 15 to 24%. The use of metakaolin or slag-blended cements resulted in stabilization of the compressive strength of concrete and limiting the deterioration of elastic modulus below 10%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASR | Alkali–silica reaction |

| MCPT | Miniature concrete prism test |

| D | Coarse crushed greywacke |

| N | Coarse crushed greywacke |

| B | Natural fossil sand |

| W | Natural river sand |

| T | Natural fossil sand |

| XYZA | Mix ID, where X—type of coarse aggregate, Y—type of fine aggregate, Z—mitigating compound, and A—dosage of mitigating compound |

| XRF | X-ray Fluorescence |

References

- Rens, L. European Guide for Design of “Jointed Plain Concrete Pavements”, Concrete Paving Association, Brussels. 2020. Available online: https://www.eupave.eu/wp-content/uploads/EUPAVE-Guide-for-the-design-of-jointed-plain-concrete-pavements-April-2020.pdf (accessed on 26 May 2025).

- Glinicki, M.A. Concrete durability evaluation in new built pavement sections of expressways in Poland. Cement Wapno Beton 2023, 28, 105–119. [Google Scholar] [CrossRef]

- Rudnicki, T. The impact of the aggregate used on the possibility of reducing the carbon footprint in pavement concrete. Sustainability 2022, 14, 16478. [Google Scholar] [CrossRef]

- Van Dam, T.; Taylor, P.; Fick, G.; VanGeem, M.; Lorenz, E. Sustainable Concrete Pavements: A Manual of Practice; Institute for Transportation, Iowa State University: Ames, IA, USA, 2012. [Google Scholar]

- Rudnicki, T.; Stałowski, P. Performance research of cement concrete pavements with a lower carbon footprint. Materials 2024, 17, 3162. [Google Scholar] [CrossRef]

- Wang, F.; Xie, J.; Wu, S.; Li, J.; Barbieri, D.M.; Zhang, L. Life cycle energy consumption by roads and associated interpretative analysis of sustainable policies. Renew. Sustain. Energy Rev. 2021, 141, 110823. [Google Scholar] [CrossRef]

- Smith, S.H.; Durham, S.A. A cradle to gate LCA framework for emissions and energy reduction in concrete pavement mixture design. Int. J. Sustain. Built Environ. 2016, 5, 23–33. [Google Scholar] [CrossRef]

- EN 1097-8; Tests for Mechanical and Physical Properties of Aggregates–Part 8: Determination of the Polished Stone Value. CEN: Brussels, Belgium, 2020.

- EN 1097-1; Tests for Mechanical and Physical Properties of Aggregates–Part 1: Determination of the Resistance to Wear (Micro-Deval). CEN: Brussels, Belgium, 2011.

- EN 1097-2; Tests for Mechanical and Physical Properties of Aggregates–Part 2: Methods for the Determination of Resistance to Fragmentation. CEN: Brussels, Belgium, 2020.

- General Directorate for National Roads and Highways (GDDKiA). Conditions for the Execution and Acceptance of Construction Works D- 05.03.04 v02. Cement Concrete Pavements. Available online: https://www.gov.pl/web/gddkia/nawierzchnie (accessed on 26 May 2025). (In Polish)

- Fernandes, I.; Ribeiro, A.M.; Broekmans, M.; Sims, I. Petrographic Atlas: Characterisation of Aggregates Regarding Potential Reactivity to Alkalis. RILEM TC 219-ACS Recommended Guidance AAR-1.2, for Use with the RILEM AAR-1.1 Petrographic Examination Method; Springer: Dordrecht, The Netherlands, 2016. [Google Scholar]

- Shayan, A.; Quick, G.W.; Lancucki, C.J.; Way, S.J. Investigation of some greywacke aggregates for alkali silica reactivity. In Proceedings of the 9th International Conference on Alkali-Aggregate Reaction in Concrete, London, UK, 27–32 July 1992. [Google Scholar]

- Moffatt, E.G.; Thomas, M.D.A.; Hayman, S.; Fournier, B.; Ideker, J.; Fletcher, J. Remediation Strategies Intended for the Reconstruction of the ASR-Induced Mactaquac Dam. In Proceedings of the 15th International Conference on Alkali-Aggregate Reaction in Concrete, Sao Paulo, Brazil, 3–7 July 2016. [Google Scholar]

- Thomas, M.; Dunster, A.; Nixon, P.; Blackwell, B. Effect of fly ash on the expansion of concrete due to alkali-silica reaction—Exposure site studies. Cem. Concr. Compos. 2011, 33, 359–367. [Google Scholar] [CrossRef]

- Tremblay, C.; Bérubé, M.A.; Fournier, B.; Thomas, M.D.; Folliard, K.J. Experimental investigation of the mechanisms by which LiNO3 is effective against ASR. In Proceedings of the 13th International Conference on Alkali-Aggregate Reaction in Concrete, Trondheim, Norway, 16–20 June 2008. [Google Scholar]

- Ramlmochan, T.; Thomas, M.; Gruber, K.A. The effect of metakaolin on alkali–silica reaction in concrete. Cem. Concr. Res. 2000, 30, 339–344. [Google Scholar] [CrossRef]

- Richardson, M. Minimising the risk of deleterious alkali-silica reaction in Irish concrete practice. Constr. Build. Mater. 2005, 19, 654–660. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D.; Antolik, A.; Dziedzic, K.; Gméling, K.; Bogusz, K. Laboratory investigations on fine aggregates used for concrete pavements due to the risk of ASR. Road Mater. Pavement Des. 2021, 22, 2883–2895. [Google Scholar] [CrossRef]

- EN 206; Concrete–Specification, Performance, Production and Conformity. CEN: Brussels, Belgium, 2013.

- Dziedzic, K.; Glinicki, M.A. Risk assessment of reactive local sand use in aggregate mixtures for structural concrete. Constr. Build. Mater. 2023, 408, 133826. [Google Scholar] [CrossRef]

- ASTM C1260; Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method). ASTM International: West Conshohocken, PA, USA, 2023.

- AASHTO T 380-2019; Standard Method of Test for Potential Alkali Reactivity of Aggregates and Effectiveness of ASR Mitigation Measures (Miniature Concrete Prism Test, MCPT). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- ASTM C215-14; Standard Test Method for Fundamental Transverse, Longitudinal, and Torsional Resonant Frequencies of Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2014.

- Glinicki, M.A.; Litorowicz, A. Crack system evaluation in concrete elements at mesoscale. Bull. Pol. Acad. Sci.-Tech. Sci. 2006, 54, 371–379. [Google Scholar]

- Borchers, I. Leistungsbasiertes Konzept Für Einen Ausreichenden AKR-Widerstand Von Beton (Performance-Based Concept for Sufficient ASR Resistance of Concrete). Ph.D. Thesis, Technischen Universität Clausthal, Clausthal-Zellerfeld, Germany, 2023. [Google Scholar]

- Glinicki, M.A.; Jóźwiak-Niedźwiedzka, D.; Antolik, A.; Dziedzic, K.; Gibas, K. Susceptibility of selected aggregates from sedimentary rocks to alkali-aggregate reaction. Roads Bridges Drog. I Mosty 2019, 18, 5–24. [Google Scholar] [CrossRef]

- Kawabata, Y.; Dunant, C.; Nakamura, S.; Yamada, K.; Kawakami, T. Effects of temperature on expansion of concrete due to the alkali-silica reaction: A simplified numerical approach. Mater. De Construcción 2022, 72, e282. [Google Scholar] [CrossRef]

- Freitag, S.A.; St John, D.A.; Goguel, R. ASTM C1260 and the alkali reactivity of New Zealand greywackes. In Proceedings of the 11th International Conference on Alkali-Aggregate Reaction in Concrete, Quebec City, QC, Canada, 11–16 June 2000. [Google Scholar]

- Leemann, A.; Shi, Z.; Lindgård, J. Characterization of amorphous and crystalline ASR products formed in concrete aggregates. Cem. Concr. Res. 2000, 137, 106190. [Google Scholar] [CrossRef]

- Hünger, K.J. The contribution of quartz and the role of aluminum for understanding the AAR with greywacke. Cem. Concr. Res. 2007, 37, 1193–1205. [Google Scholar] [CrossRef]

- Shi, Z.; Lothenbach, B. Role of Aluminum and Lithium in Mitigating Alkali-Silica Reaction–A Review. Front. Mater. 2022, 8, 796396. [Google Scholar] [CrossRef]

- Konduru, H.; Rangaraju, P.R.; Amer, O. Reliability of Miniature Concrete Prism Test in Assessing Alkali-Silica Reactivity of Moderately Reactive Aggregates. Transp. Res. Rec. 2020, 2674, 23–29. [Google Scholar] [CrossRef]

- National Academies of Sciences, Engineering, and Medicine. Alkali-Silica Reactivity Potential and Mitigation: Test Methods and State of Practice; The National Academies Press: Washington, DC, USA, 2023. [Google Scholar] [CrossRef]

- Leemann, A.; Merz, C. Long-term efficiency of silica fume and fly ash to suppress ASR in field structures. Mater. De Construcción 2022, 72, e285. [Google Scholar] [CrossRef]

- Deschenes, R.A.; Giannini, E.R.; Drimalas, T.; Fournier, B.; Hale, W.M. Effects of moisture, temperature, and freezing and thawing on alkali-silica reaction. ACI Mater. J. 2018, 115, 575–584. [Google Scholar] [CrossRef]

- Glinicki, M.A. Methods of qualitative and quantitative assessment of concrete air entrainment. Cem. Wapno Beton 2014, 19, 359–369. [Google Scholar]

- Gong, F.; Takahashi, Y.; Segawa, I.; Maekawa, K. Mechanical properties of concrete with smeared cracking by alkali-silica reaction and freeze-thaw cycles. Cem. Concr. Compos. 2020, 111, 103623. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Jóźwiak-Niedźwiedzka, D.; Antolik, A.; Dziedzic, K.; Dąbrowski, M.; Bogusz, K. Diagnosis of ASR damage in highway pavement after 15 years of service in wet-freeze climate. Case Stud. Constr. Mater. 2022, 17, e01226. [Google Scholar] [CrossRef]

| Mix ID | Cement | Coarse Aggregate | Fine Aggregate | Mitigating Compound | Dosage |

|---|---|---|---|---|---|

| DB0 | CEM I 52.5R | Greywacke (D) | Non-reactive sand (B) | None | - |

| DBM7 | Metakaolin | 7.5% | |||

| DBM15 | Metakaolin | 15% | |||

| DW0 | CEM I 52.5R | Greywacke (D) | Reactive sand (W) | None | - |

| DWS35 | CEM II/B-S 42.5R | GGBS (as cement constituent) | ca. 35% | ||

| DWS52 | CEM III/A 42.5N | GGBS (as cement constituent) | ca. 52% | ||

| DWM7 | CEM I 52.5R | Metakaolin | 7.5% | ||

| DWM15 | CEM I 52.5R | Metakaolin | 15% | ||

| DT0 | CEM I 52.5R | Greywacke (D) | Reactive sand (T) | None | - |

| DTS35 | CEM II/B-S 42.5R | GGBS (as cement constituent) | ca. 35% | ||

| DTM7 | CEM I 52.5R | Metakaolin | 7.5% | ||

| DTM15 | CEM I 52.5R | Metakaolin | 15% | ||

| NB0 | CEM I 52.5R | Greywacke (N) | Non-reactive sand (B) | None | - |

| NBM7 | Metakaolin | 7.5% | |||

| NBM15 | Metakaolin | 15% | |||

| NBM20 | Metakaolin | 20% |

| Mix ID | Average Expansion [%] | |||

|---|---|---|---|---|

| 56 Days | Rel. Reduction [%] | 84 Days | Rel. Reduction [%] | |

| DB0 | 0.067 | - | 0.097 | - |

| DBM7 | 0.020 | 70.1 | 0.032 | 67.0 |

| DBM15 | 0.010 | 85.1 | 0.017 | 82.5 |

| DW0 | 0.093 | - | 0.119 | - |

| DWS35 | 0.032 | 65.6 | 0.043 | 63.9 |

| DWS52 | 0.015 | 83.9 | 0.019 | 84.0 |

| DWM7 | 0.032 | 65.6 | 0.048 | 59.7 |

| DWM15 | 0.014 | 84.9 | 0.021 | 82.4 |

| DT0 | 0.120 | - | 0.158 | - |

| DTS35 | 0.044 | 63.3 | 0.064 | 59.4 |

| DTM7 | 0.035 | 70.8 | 0.047 | 70.3 |

| DTM15 | 0.017 | 85.8 | 0.022 | 86.1 |

| NB0 | 0.152 | - | 0.220 | - |

| NBM7 | 0.037 | 75.7 | 0.063 | 71.4 |

| NBM15 | 0.008 | 94.7 | 0.013 | 94.1 |

| NBM20 | 0.006 | 96.1 | 0.012 | 94.5 |

| Mix ID | Compressive Strength [MPa] * | Resonance Elastic Modulus [GPa] ** | ||||

|---|---|---|---|---|---|---|

| NaOH 60 °C | H2O 20 °C | Rel. Loss [%] | NaOH 60 °C | H2O 20 °C | Rel. Loss [%] | |

| DB0 | 57.2 ± 2.9 | 59.0 ± 1.5 | 3.1 | 41.5 | 49.0 | 15.3 |

| DBM7 | 57.0 ± 1.9 | 61.5 ± 1.3 | 7.4 | 46.7 | 48.1 | 2.9 |

| DBM15 | 56.5 ± 1.5 | 59.8 ± 0.8 | 5.4 | 48.4 | 44.9 | −7.7 |

| DW0 | 64.3 ± 3.5 | 73.1 ± 4.8 | 12.0 | 37.6 | 49.5 | 24.0 |

| DWS35 | 64.7 ± 3.6 | 63.3 ± 1.7 | −2.2 | 44.5 | 47.4 | 6.1 |

| DWS52 | 58.9 ± 2.1 | 54.6 ± 2.6 | −7.9 | 44.2 | 48.2 | 8.3 |

| DWM7 | 73.2 ± 2.8 | 69.9 ± 5.4 | −4.7 | 43.2 | 46.5 | 7.1 |

| DWM15 | 67.8 ± 3.4 | 72.6 ± 4.7 | 6.6 | 42.8 | 47.1 | 9.1 |

| DT0 | 64.2 ± 2.1 | 73.9 ± 1.9 | 13.2 | 38.9 | 49.9 | 22.0 |

| DTS35 | 65.1 ± 2.4 | 65.8 ± 0.9 | 1.0 | 47.1 | 49.5 | 4.8 |

| DTM7 | 72.5 ± 2.8 | 72.5 ± 3.9 | 0.0 | 44.3 | 47.3 | 6.3 |

| DTM15 | 67.0 ± 3.1 | 72.3 ± 3.5 | 7.3 | 43.8 | 48.5 | 9.7 |

| NB0 | 63.4 ± 2.5 | 80.2 ± 3.5 | 20.9 | N/A *** | N/A *** | - |

| NBM7 | 71.5 ± 1.8 | 74.0 ± 1.6 | 3.4 | 44.0 | 54.0 | 18.5 |

| NBM15 | 64.1 ± 1.8 | 65.6 ± 3.4 | 2.2 | 45.0 | 48.4 | 7.0 |

| NBM20 | 61.7 ± 2.7 | 66.7 ± 1.8 | 7.5 | 47.4 | 47.9 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dziedzic, K.; Brachaczek, A.; Nowicki, D.; Glinicki, M.A. Mitigation of Alkali–Silica Reactivity of Greywacke Aggregate in Concrete for Sustainable Pavements. Sustainability 2025, 17, 6825. https://doi.org/10.3390/su17156825

Dziedzic K, Brachaczek A, Nowicki D, Glinicki MA. Mitigation of Alkali–Silica Reactivity of Greywacke Aggregate in Concrete for Sustainable Pavements. Sustainability. 2025; 17(15):6825. https://doi.org/10.3390/su17156825

Chicago/Turabian StyleDziedzic, Kinga, Aneta Brachaczek, Dominik Nowicki, and Michał A. Glinicki. 2025. "Mitigation of Alkali–Silica Reactivity of Greywacke Aggregate in Concrete for Sustainable Pavements" Sustainability 17, no. 15: 6825. https://doi.org/10.3390/su17156825

APA StyleDziedzic, K., Brachaczek, A., Nowicki, D., & Glinicki, M. A. (2025). Mitigation of Alkali–Silica Reactivity of Greywacke Aggregate in Concrete for Sustainable Pavements. Sustainability, 17(15), 6825. https://doi.org/10.3390/su17156825