Sustainability Assessment of Rural Biogas Production and Use Through a Multi-Criteria Approach: A Case Study in Colombia

Abstract

1. Introduction

2. Materials and Methods

2.1. Location of the Study

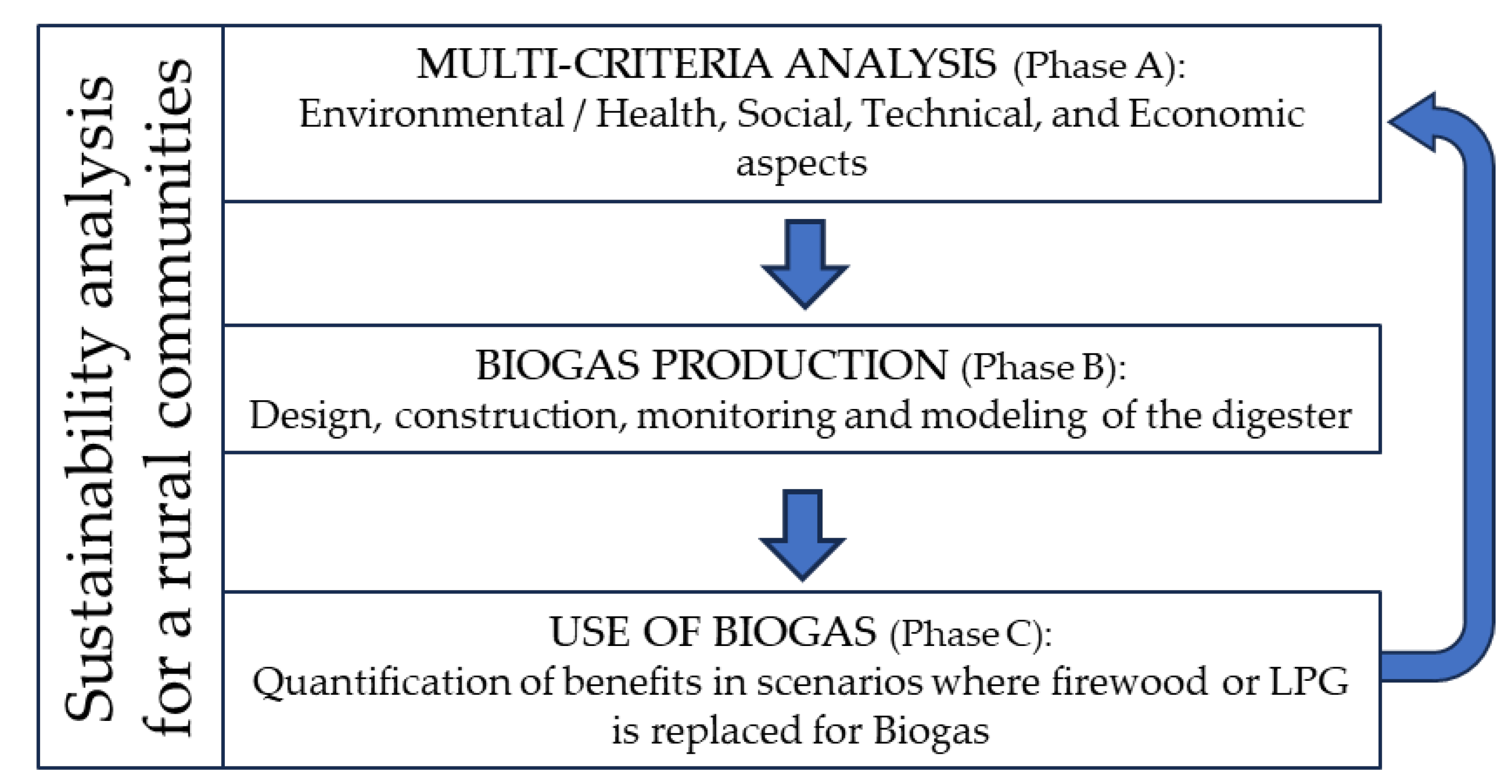

2.2. Structure of Analysis for Assessment Methodology

2.3. Ph-A—Multi-Criteria Analysis (MCA)

- i.

- Definition of the matrix, which represents general criteria (GC), C1 to C12. To identify GC, the criteria from other similar research were used and adapted to the context and territory. Table 1 lists the GC used for this case study.

- ii.

- Assignment of weights to the criteria by comparison in pairs (Wpi), to establish their importance. In pairwise comparison, each criterion is compared with the others by asking the following: How much more important is each criterion in relation to each other, concerning the overall goal? Importance is rated from 1 (equal) to 9 (absolute), with intermediate values [11,12].

- iii.

- Normalisation of the comparison criteria, is used to make the data in the matrix homogeneous and operational.

- iv.

- Weighting of the standardised values (Wsi), calculated for each of the criteria, by averaging the values of the specific standardised relative weights.

- v.

- The sensitivity analysis, performed by calculating the Consistency Index (CI) and the Coherence Coefficient (CR), consists of assessing whether the pairwise comparisons are logically consistent. For the case study matrix with number of criteria ni= 12, it is necessary to give as results CR < 0.1 and CI ≥ 11%, to conclude an adequate coherence in the comparisons. The calculation steps to determine CI and CR can be seen in Equations (1) and (2) [11,12].

- Ēi is average of the specific values of Ei = Σ(Wpi Wsi);

- RI is the Random Index; for ni = 12, it is 1.49.

- vi.

- Final score for each alternative, the products of the score assigned to the alternative for each criterion, and the relative weight of that criterion are added together. In the case study, a scale of 0 to 3 is applied, as follows: 0: The criterion has a strong negative influence on the alternative; 1: The criterion has a negative influence; 2: The criterion has no influence; 3: The criterion has a positive influence; 4: The criterion has a strong positive influence. The best alternative is the one with the highest final score [11,12].

| Impact Category | Code | General Impact Criteria |

|---|---|---|

| Environmental [8,12,13,14] | C1 | Pollutant emissions in water, air, and soil. |

| C2 | Consumption of natural resources and raw materials (wood, water, fuel consumption, or non-renewable energy). | |

| C3 | Deforestation in areas with high biodiversity. | |

| Social/Health [4,11,18,23] | C4 | Effects on human health and local biodiversity. |

| C5 | Organisational culture of the local community. | |

| C6 | Living conditions of the local community over time. | |

| Technical [8,15,23] | C7 | Use of local resources and reproducibility. |

| C8 | Use of small-scale technologies and access for low cost. | |

| C9 | Ease of management. | |

| Economic [3,11,12,13] | C10 | Technological development and investment in infrastructure. |

| C11 | Generation of employment and development of the local economy. | |

| C12 | Incentive to the local market/biogas-based energy community. |

2.4. Ph-B—Characteristics of Swine-Rearing Wastewater (WWs) and Swine Biomass

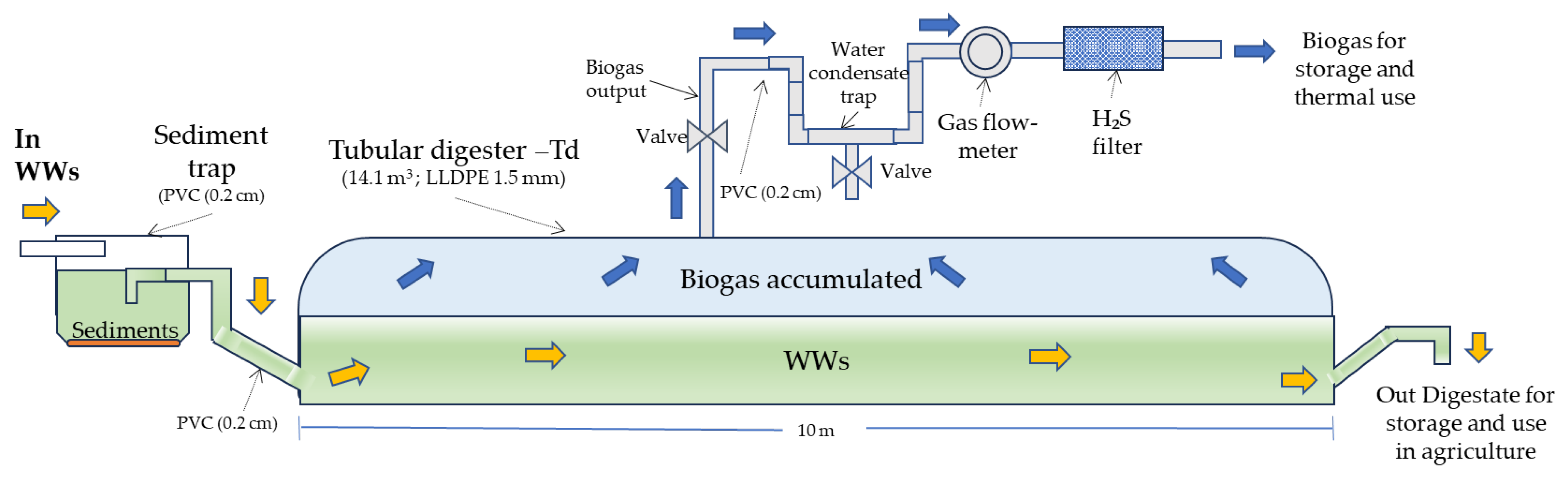

2.5. Ph-B—Pilot-Scale System—Tubular Digester (Td)

- = Daily volumetric flow of mix = 0.29 m3 d−1;

- QW = Daily quantity of water enters the digester = 275 kg d−1;

- QDS = Daily quantity of swine biomass enters the digester = 14.3 kg d−1;

- ρW = water density = 1000 kg m3 −1.

- VT = digestion chamber volume = 10.8 m3;

- = daily volumetric flow of mix = 0.29 m3 d−1;

- HRT = Hydraulic Retention Time = 30 day;

- x = gas volume ratio = 0.2 m3 biogas m3 −1.

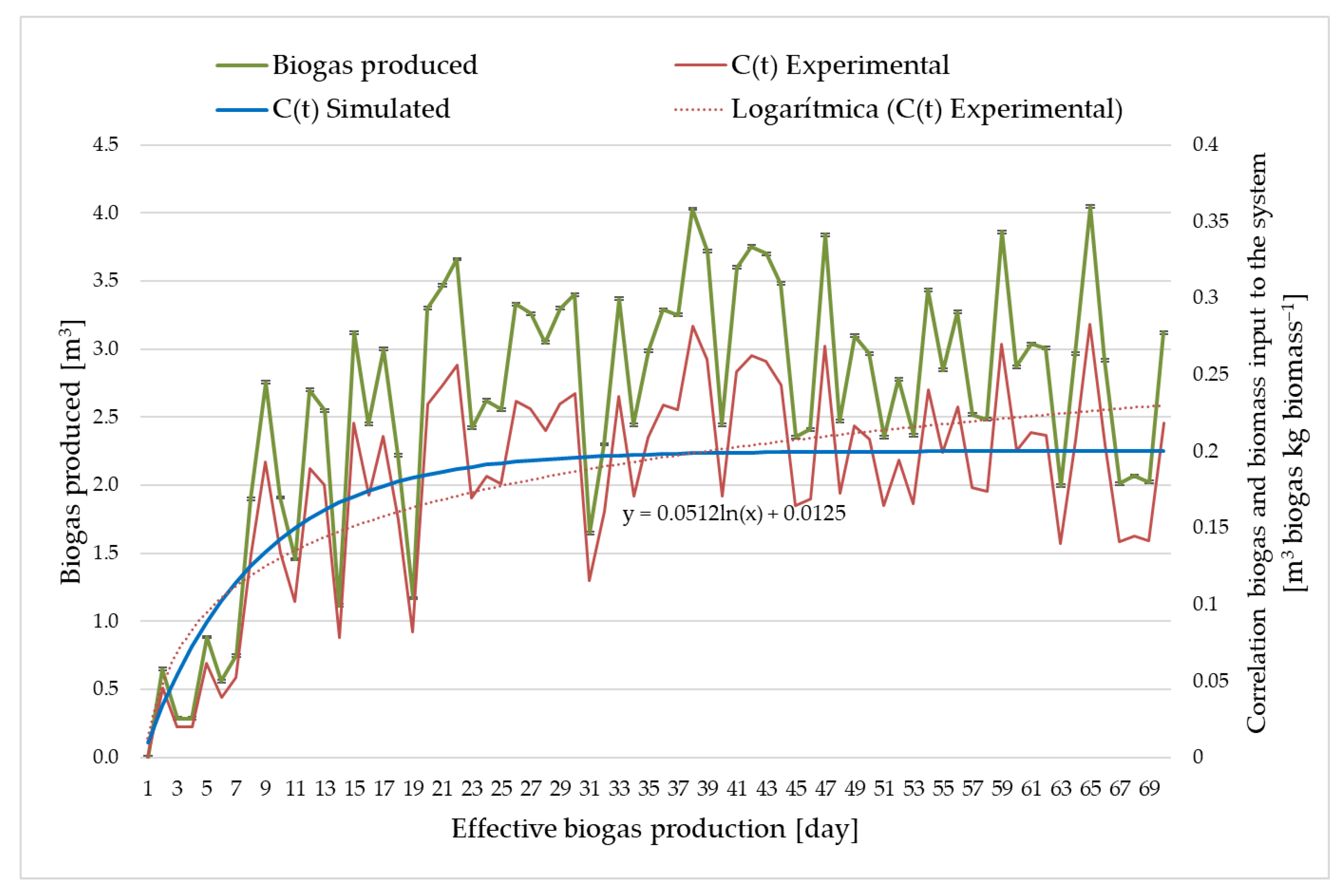

2.6. Ph-B: Biogas Production Model for Td (Continuous Biogas/Biomass Flow and Non-Stationary Systems—BgMod)

2.7. Ph-C: Quantification of the Environmental Benefits of Replacing Wood or LPG with Biogas

3. Results and Discussion

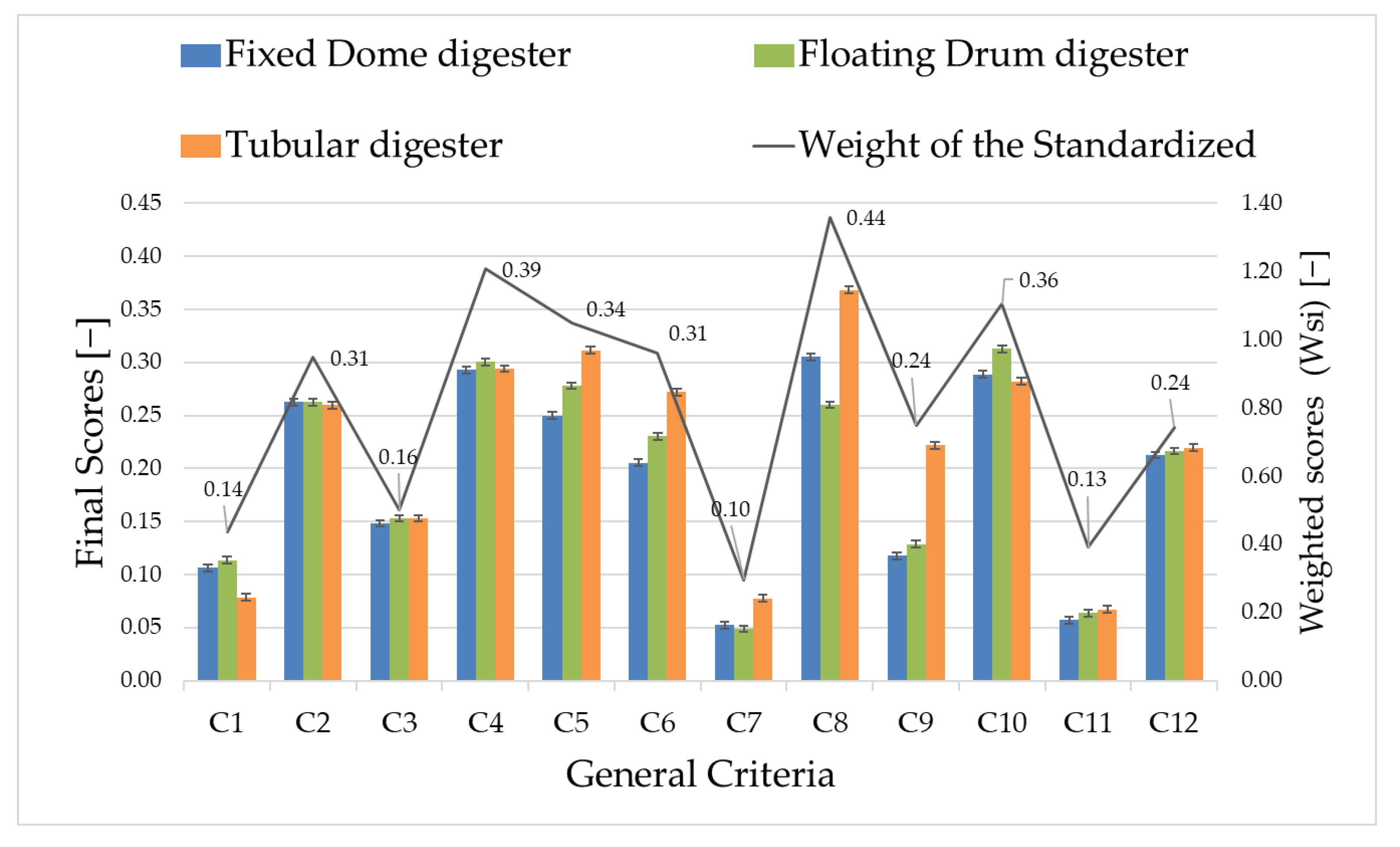

3.1. Ph-A—Results of the Multi-Criteria Analysis MCA

3.2. Ph-B—Results of the Characterisation of the Biogas Production Model for Td (Continuous Biomass Flow and Non-Stationary Systems—BgMod)

3.3. Ph-C— Quantification of Environmental, Social/Health, Technical, and Economic Benefits from the Implementation of Biogas in the Case Study

3.4. Framework for Implementing Appropriate Biogas Technologies on Rural Communities/Rural Farms

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AD | Anaerobic Digestion |

| BOD | Biological Oxygen Demand |

| BgMod | Continuous Biogas flow and non-stationary system Model |

| COD | Chemical oxygen demand |

| GC | General criteria |

| HRT | Hydraulic retention time |

| LPG | Liquefied Petroleum Gas |

| MCA | Multi-Criteria Analysis |

| OLR | Organic Load Rate |

| Tb | Tubular biodigester |

| WWs | Swine Wastewater |

| ZRC-VRC | Peasant Reserve Zone of the Cimitarra River Valley |

Appendix A

| Impact Category | Code | General Impact Criteria | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Environmental | C1 | Pollutant emissions in water, air, and soil. | 1.0 | 0.4 | 4.0 | 0.5 | 0.3 | 0.2 | 0.3 | 0.3 | 0.2 | 2.0 | 1.5 | 0.3 |

| C2 | Consumption of natural resources and raw materials (wood, water, fuel consumption, or non-renewable energy). | 2.5 | 1.0 | 1.13 | 1.0 | 1.0 | 0.7 | 1.0 | 3.0 | 0.4 | 3.5 | 2.5 | 2.0 | |

| C3 | Deforestation in areas with high biodiversity. | 0.3 | 2.2 | 1.0 | 0.4 | 0.3 | 0.4 | 0.3 | 0.7 | 0.4 | 1.5 | 1.5 | 0.7 | |

| Social/ Health | C4 | Effects on human health and local biodiversity. | 2.0 | 1.0 | 3.0 | 1.0 | 1.0 | 1.0 | 0.7 | 1.5 | 0.7 | 3.0 | 2.5 | 2.0 |

| C5 | Organisational culture of the local community. | 3.0 | 1.0 | 3.0 | 1.0 | 1.0 | 0.7 | 1.5 | 1.5 | 0.5 | 3.5 | 3.5 | 2.0 | |

| C6 | Living conditions of the local community. | 4.0 | 1.5 | 3.0 | 1.0 | 1.5 | 1.0 | 1.0 | 1.5 | 1.50 | 3.5 | 3.0 | 2.0 | |

| Technical | C7 | Use of local resources and reproducibility. | 4.0 | 1.0 | 3.0 | 1.5 | 0.7 | 1.0 | 1.0 | 1.5 | 1.0 | 4.0 | 2.5 | 2.0 |

| C8 | Use of small-scale technologies and access for low cost. | 4.0 | 0.3 | 2.0 | 0.7 | 0.7 | 0.7 | 0.7 | 1.0 | 0.3 | 3.0 | 2.0 | 1.2 | |

| C9 | Ease of management. | 5.5 | 2.5 | 3.0 | 2.0 | 2.0 | 0.7 | 1.0 | 3.0 | 1.0 | 3.5 | 3.0 | 1.0 | |

| Economic | C10 | Technological development and investment in infrastructure. | 0.6 | 0.3 | 0.7 | 0.3 | 0.3 | 0.3 | 0.2 | 0.3 | 0.3 | 1.0 | 0.7 | 0.6 |

| C11 | Generation of employment and development of the local economy. | 0.7 | 0.4 | 0.7 | 0.4 | 0.3 | 0.3 | 0.4 | 0.5 | 0.3 | 1.5 | 1.0 | 1.2 | |

| C12 | Incentive to the local market/Biogas-based energy community | 3.0 | 0.7 | 1.5 | 0.7 | 0.7 | 0.7 | 0.7 | 1.2 | 1.0 | 2.5 | 1.7 | 1.0 |

| Impact Category | General Criteria | Normalised Value for Each Criterion | Average of Weighting Factor by Each Criterion | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | |||

| Environmental | C1 | 0.096 | 0.097 | 0.476 | 0.145 | 0.100 | 0.101 | 0.093 | 0.048 | 0.076 | 0.201 | 0.190 | 0.065 | 0.141 |

| C2 | 0.240 | 0.232 | 0.134 | 0.289 | 0.299 | 0.304 | 0.348 | 0.544 | 0.162 | 0.444 | 0.317 | 0.392 | 0.309 | |

| C3 | 0.026 | 0.522 | 0.119 | 0.109 | 0.100 | 0.152 | 0.116 | 0.121 | 0.146 | 0.190 | 0.190 | 0.147 | 0.161 | |

| Social/Health | C4 | 0.192 | 0.232 | 0.357 | 0.289 | 0.299 | 0.405 | 0.261 | 0.272 | 0.259 | 0.381 | 0.317 | 0.392 | 0.305 |

| C5 | 0.288 | 0.232 | 0.357 | 0.289 | 0.299 | 0.304 | 0.522 | 0.272 | 0.195 | 0.444 | 0.444 | 0.392 | 0.337 | |

| C6 | 0.384 | 0.348 | 0.357 | 0.289 | 0.448 | 0.405 | 0.348 | 0.272 | 0.584 | 0.444 | 0.381 | 0.392 | 0.388 | |

| Technical | C7 | 0.384 | 0.232 | 0.357 | 0.434 | 0.224 | 0.405 | 0.348 | 0.272 | 0.389 | 0.507 | 0.317 | 0.392 | 0.355 |

| C8 | 0.384 | 0.077 | 0.238 | 0.217 | 0.224 | 0.304 | 0.261 | 0.181 | 0.130 | 0.381 | 0.254 | 0.245 | 0.241 | |

| C9 | 0.528 | 0.580 | 0.357 | 0.579 | 0.597 | 0.304 | 0.348 | 0.544 | 0.389 | 0.444 | 0.381 | 0.196 | 0.437 | |

| Economic | C10 | 0.064 | 0.068 | 0.089 | 0.096 | 0.087 | 0.118 | 0.093 | 0.060 | 0.113 | 0.127 | 0.095 | 0.123 | 0.095 |

| C11 | 0.072 | 0.097 | 0.089 | 0.121 | 0.087 | 0.135 | 0.145 | 0.091 | 0.130 | 0.190 | 0.127 | 0.229 | 0.126 | |

| C12 | 0.288 | 0.155 | 0.178 | 0.193 | 0.199 | 0.270 | 0.232 | 0.227 | 0.389 | 0.317 | 0.222 | 0.196 | 0.239 | |

| Impact Category | Cod. | General Impact Criteria | Weighting Factor by Each Criterion | Fixed Dome Digester (Score) | Floating Drum Digester | Tubular Digester | Fixed Dome Digester (Final Score) | Floating Drum Digester (Final Score) | Tubular Digester (Final Score) |

|---|---|---|---|---|---|---|---|---|---|

| Environmental | C1 | Pollutant emissions in water, air, and soil. | 0.141 | 2.35 | 2.51 | 1.74 | 0.33 | 0.35 | 0.24 |

| C2 | Consumption of natural resources and raw materials (wood, water, fuel consumption, or non-renewable energy). | 0.309 | 2.87 | 2.68 | 2.65 | 0.82 | 0.82 | 0.81 | |

| C3 | Deforestation in areas with high biodiversity. | 0.161 | 2.86 | 2.95 | 2.95 | 0.46 | 0.48 | 0.48 | |

| Social/Health | C4 | Effects on human health and local biodiversity. | 0.305 | 2.45 | 2.41 | 2.13 | 0.91 | 0.93 | 0.91 |

| C5 | Organisational culture of the local community. | 0.337 | 2.51 | 2.67 | 2.38 | 0.78 | 0.86 | 0.97 | |

| C6 | Living conditions of the local community. | 0.388 | 2.07 | 2.35 | 2.74 | 0.64 | 0.72 | 0.85 | |

| Technical | C7 | Use of local resources and reproducibility. | 0.355 | 1.73 | 1.61 | 2.56 | 0.16 | 0.15 | 0.24 |

| C8 | Use of small-scale technologies and access for low cost. | 0.241 | 2.17 | 1.85 | 2.52 | 0.95 | 0.81 | 1.15 | |

| C9 | Ease of management. | 0.437 | 1.22 | 1.66 | 2.86 | 0.37 | 0.40 | 0.69 | |

| Economic | C10 | Technological development and investment in infrastructure. | 0.095 | 2.53 | 2.74 | 2.47 | 0.90 | 0.97 | 0.88 |

| C11 | Generation of employment and development of the local economy. | 0.126 | 1.41 | 1.58 | 1.66 | 0.18 | 0.20 | 0.21 | |

| C12 | Incentive to the local market/Biogas-based energy community | 0.239 | 2.77 | 2.82 | 2.86 | 0.66 | 0.67 | 0.68 | |

| Final score total: | 7.15 | 7.37 | 8.11 | ||||||

References

- World Health Organization (WHO). Household Air Pollution and Health. 2021. Available online: https://www.who.int/news-room/fact-sheets/detail/household-air-pollution-and-health (accessed on 17 May 2025).

- Gould, C.F.; Urpelainen, J. LPG as a clean cooking fuel: Adoption, use, and impact in rural India. Energy Policy 2018, 122, 395–408. [Google Scholar] [CrossRef]

- Garfí, M.; Ferrer-Martí, L.; Velo, E.; Ferrer, I. Evaluating benefits of low-cost household digesters for rural Andean communities. Renew. Sustain. Energy Rev. 2012, 16, 575–581. [Google Scholar] [CrossRef]

- Cellini, M.; Loos, S.; Mirenda, C.; Pisacane, L.; Striebing, C.; Tagliacozzo, S. Exploring the nexus of gender and energy transitions: A systematic literature review. Energy Res. Soc. Sci. 2024, 119. [Google Scholar] [CrossRef]

- Miller, C.; Pereira Coronel, L.C.; Pirelli, T.; Morese, M. Stocktaking Paper—Regional Analysis of Biogas Value Chains; FAO: Rome, Italy, 2020; Available online: https://www.fao.org/3/cc7032en/cc7032en.pdf (accessed on 15 May 2025).

- Villamor, G.B. Gender and Water-Energy-Food Nexus in the Rural Highlands of Ethiopia: Where Are the Trade-Offs? Land 2023, 12, 585. [Google Scholar] [CrossRef]

- Shrestha, R.P.; Jirakiattikul, S.; Chapagain, B.; Katuwal, H.; Gyawali, S.; Shrestha, M. Biogas adoption and its impact on women and the community: Evidence from Nepal. Int. J. Environ. Stud. 2024, 81, 537–553. [Google Scholar] [CrossRef]

- Garfí, M.; Martí-Herrero, J.; Garwood, A.; Ferrer, I. Household anaerobic digesters for biogas production in Latin America: A review. Renew. Sustain. Energy Rev. 2016, 60, 599–614. [Google Scholar] [CrossRef]

- Surendra, K.C.; Takara, D.; Jasinski, J.; Khanal, S.K. Household anaerobic digester for bioenergy production in developing countries: Opportunities and challenges. Environ. Technol. 2013, 34, 1671–1689. [Google Scholar] [CrossRef]

- Tavera-Ruiz, C.; Martí-Herrero, J.; Mendieta, O.; Jaimes-Estévez, J.; Gauthier-Maradei, P.; Azimov, U.; Escalante, H.; Castro, L. Current understanding and perspectives on anaerobic digestion in developing countries: Colombia case study. Renew. Sustain. Energy Rev. 2023, 173, 113097. [Google Scholar] [CrossRef]

- Nzila, C.; Dewulf, J.; Spanjers, H.; Tuigong, D.; Kiriamiti, H.; van Langenhove, H. Multi criteria sustainability assessment of biogas production in Kenya. Appl. Energy 2012, 93, 496–506. [Google Scholar] [CrossRef]

- Garfì, M.; Ferrer-Martí, L. Decision-making criteria and indicators for water and sanitation projects in developing countries. Water Sci. Technol. 2011, 64, 83–101. [Google Scholar] [CrossRef]

- Garfì, M.; Tondelli, S.; Bonoli, A. Multi-criteria decision analysis for waste management in Saharawi refugee camps. Waste Manag. 2009, 29, 2729–2739. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Gomez, F.H.; Caccamo, F.M.; Sorlini, S. Reduction of pathogens in greywater with biological and sustainable treatments selected through a multicriteria approach. Environ. Sci. Pollut. Res. 2022, 30, 38239–38254. [Google Scholar] [CrossRef]

- Gomez, F.H.; Pelegri, N.; Lopez, J.G.; Torres, K.C.; Vaccari, M. Impact of Artisanal Gold Mining in Community Conserved Areas with High Biodiversity Using a Multi-Criteria Approach: A Case Study in Colombia. Pollutants 2024, 4, 276–290. [Google Scholar] [CrossRef]

- Luna-Delrisco, M.; González, C.A.; Mendoza-Hernández, S.; Vanegas-Trujillo, E.; Meneses, L.d.R.; Rio, J.S.-D.; Castillo-Meza, L.E.; Santos-Ballardo, D.U.; Montoya, J.P.G. Evaluating the socio-economic drivers of household adoption of biodigester systems for domestic energy in rural Colombia. Sustain. Energy Technol. Assess. 2024, 73, 104146. [Google Scholar] [CrossRef]

- Kinyua, M.N.; Rowse, L.E.; Ergas, S.J. Review of small-scale tubular anaerobic digesters treating livestock waste in the developing world. Renew. Sustain. Energy Rev. 2016, 58, 896–910. [Google Scholar] [CrossRef]

- Martí-Herrero, J.; Chipana, M.; Cuevas, C.; Paco, G.; Serrano, V.; Zymla, B.; Heising, K.; Sologuren, J.; Gamarra, A. Low cost tubular digesters as appropriate technology for widespread application: Results and lessons learned from Bolivia. Renew. Energy 2014, 71, 156–165. [Google Scholar] [CrossRef]

- Alvarez, R.; Lidén, G. Semi-continuous co-digestion of solid slaughterhouse waste, manure, and fruit and vegetable waste. Renew. Energy 2008, 33, 726–734. [Google Scholar] [CrossRef]

- Garfí, M.; Gelman, P.; Comas, J.; Carrasco, W.; Ferrer, I. Agricultural reuse of the digestate from low-cost tubular digesters in rural Andean communities. Waste Manag. 2011, 31, 2584–2589. [Google Scholar] [CrossRef]

- Esposito, G.; Frunzo, L.; Liotta, F.; Panico, A.; Pirozzi, F. Bio-Methane Potential Tests to Measure the Biogas Production from The Digestion and Co-Digestion of Complex Organic Substrates. Open Environ. Eng. J. 2012, 5, 1–8. [Google Scholar] [CrossRef]

- Rajendran, K.; Aslanzadeh, S.; Taherzadeh, M.J. Household Biogas Digesters—A Review. Energies 2012, 5, 2911–2942. [Google Scholar] [CrossRef]

- Surendra, K.; Takara, D.; Hashimoto, A.G.; Khanal, S.K. Biogas as a sustainable energy source for developing countries: Opportunities and challenges. Renew. Sustain. Energy Rev. 2014, 31, 846–859. [Google Scholar] [CrossRef]

- Martí-Herrero, J. Reduced hydraulic retention times in low-cost tubular digesters: Two issues. Biomass Bioenergy 2011, 35, 4481–4484. [Google Scholar] [CrossRef]

- Rocha-Meneses, L.; Luna-Delrisco, M.; González, C.A.; Moncada, S.V.; Moreno, A.; Rio, J.S.-D.; Castillo-Meza, L.E. An Overview of the Socio-Economic, Technological, and Environmental Opportunities and Challenges for Renewable Energy Generation from Residual Biomass: A Case Study of Biogas Production in Colombia. Energies 2023, 16, 5901. [Google Scholar] [CrossRef]

- Pizarro-Loaiza, C.; Antón, A.; Torrellas, M.; Torres-Lozada, P.; Palatsi, J.; Bonmatí, A. Environmental, social and health benefits of alternative renewable energy sources. Case study for household biogas digesters in rural areas. J. Clean. Prod. 2021, 297, 126722. [Google Scholar] [CrossRef]

- Lazaro, L.L.B.; de Aquino Neiva, S.; Serrani, E. Energy Poverty, Justice, and Gender in Latin America—Understanding the Intersection. In Energy Poverty, Justice and Gender in Latin America; Lazaro, L.L.B., Neiva, S.d.A., Serrani, E., Eds.; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Deublein, D.; Steinhauser, A. Anaerobic Digestion of Biowaste in Developing Countries: Practical Information and Case Studies; IWA Publishing: Dübendorf, Switzerland, 2011; Available online: https://www.eawag.ch/fileadmin/Domain1/Abteilungen/sandec/publikationen/SWM/Anaerobic_Digestion/biowaste.pdf (accessed on 15 May 2025).

- ACVC. Asociación Campesina del Valle del Río Cimitarra, Instituto Colombiano de Desarrollo Rural,; Corporación Desarrollo y Paz del Magdalena Medio. Actualización del Plan de Desarrollo Sostenible ZRC-VRC. Barrancabermeja (Colombia). 2012. Available online: https://reservacampesinariocimitarra.org/wp-content/uploads/2022/07/PLAN-DE-DESARROLLO-ZRC-VALLE-RIO-CIMITARRA-2_compressed.pdf (accessed on 1 June 2025).

- ACVC. Asociación Campesina del Valle del Río Cimitarra, UNDP and Soluterra. Estudio Participativo de Tenencia de la Tierra y el Territorio, Usos y Conflictos en La Zona de Reserva Campesina Del Valle Del Río Cimitarra—Cartografía. BARRANCA-BERMEJA—Colombia. 2014. Available online: https://reservacampesinariocimitarra.org/wp-content/uploads/2022/07/Informe-final-PNUD-ACVC-20072014-4_compressed.pdf (accessed on 2 June 2025).

- ACVC. Asociación Campesina del Valle del Río Cimitarra, Fondo Acción, Conserva Colombia. Biodiversity Assessment of the Caño Negro and Cimitarra River Marsh Complex in the Cimitarra River Valley Peasant Reserve Zone. Colombia. Barranca-bermeja. Junio de 2017. 2017. Available online: https://reservacampesinariocimitarra.org/informe-caracterizacion-biologica-de-la-zona-de-cienagas-del-valle-del-rio-cimitarra-colombia/ (accessed on 2 June 2025).

- Arbeláez-Cortés, E.; Villamizar-Escalante, D.; Trujillo-Arias, N. New voucher specimens and tissue samples from an avifaunal survey of the Middle Magdalena Valley of Bolívar, Colombia, bridge geographical and temporal gaps. Wilson J. Ornithol. 2020, 132, 773–779. [Google Scholar] [CrossRef]

- Trujillo-Arias, N.; Serrano-Cardozo, V.H.; Ramirez-Pinilla, M.P. Role of a Campesine Reserve Zone in The Magdalena Valley (Colombia) in The Conservation of Endangered Tropical Rainforests. Nat. Conserv. Res. 2023, 8, 1–15. [Google Scholar] [CrossRef]

- Duarte, J.; Mantilla, A.; Castaño, F. Diversity of Plant Uses by a Farming Community of Northwestern Colombia: A Quantitative Approach. Econ. Bot. 2023, 77, 153–168. [Google Scholar] [CrossRef]

- Molina, A. The Cimitarra River Valley Rural Reserve Zone: An Unfinished Exercise in Citizen Participation and Collective Management of Territory. Rev. Colomb. De Geogr. 2011, 20, 21–33. [Google Scholar] [CrossRef]

- Quijano-Mejia, C.M.; Linares-García, J. Zonas de Reserva Campesina: Territorialidades en disputa. El caso del Valle del río Cimitarra, Colombia. Prospectiva 2017, 225–251. [Google Scholar] [CrossRef]

- Falla, J.T.; Castrillón, C.A.R. The new rural dynamics in peasants reserve zones in Colombia. Perspect. Geogr. 2018, 23. [Google Scholar] [CrossRef]

- Ferrer, I.; Gamiz, M.; Almeida, M.; Ruiz, A. Pilot project of biogas production from pig manure and urine mixture at ambient temperature in Ventanilla (Lima, Peru). Waste Manag. 2009, 29, 168–173. [Google Scholar] [CrossRef]

- Lüer, M. Installation manual for Low-Cost Polyethylene Tube Digesters. 2010. Available online: https://energypedia.info/images/1/19/Low_cost_polyethylene_tube_installation.pdf (accessed on 5 February 2025).

- Martí-Herrero, J.; Cipriano, J. Design methodology for low cost tubular digesters. Bioresour. Technol. 2012, 108, 21–27. [Google Scholar] [CrossRef]

- Mayerle, S.F.; de Figueiredo, J.N. Designing optimal supply chains for anaerobic bio-digestion/energy generation complexes with distributed small farm feedstock sourcing. Renew. Energy 2016, 90, 46–54. [Google Scholar] [CrossRef]

- Qiao, W.; Yan, X.; Ye, J.; Sun, Y.; Wang, W.; Zhang, Z. Evaluation of biogas production from different biomass wastes with/without hydrothermal pretreatment. Renew. Energy 2011, 36, 3313–3318. [Google Scholar] [CrossRef]

- Giraldi, D.; de Michieli Vitturi, M.; Iannelli, R. FITOVERT: A dynamic numerical model of subsurface vertical flow constructed wetlands. Environ. Model. Softw. 2010, 25, 633–640. [Google Scholar] [CrossRef]

- Gomez, F.H.; Collivignarelli, M.C.; Bellazzi, S.; Torres, K.C.; Sorlini, S.; Vaccari, M. Mercury removal from mining wastewater by bioaccumulation and thermal separation in Eichhornia crassipes. Environ. Sci. Pollut. Res. 2024, 32, 798–810. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Miino, M.C.; Gomez, F.H.; Torretta, V.; Rada, E.C.; Sorlini, S. Horizontal Flow Constructed Wetland for Greywater Treatment and Reuse: An Experimental Case. Int. J. Environ. Res. Public Health 2020, 17, 2317. [Google Scholar] [CrossRef]

- Jiménez-González, C.; Kim, S.; Overcash, M.R. Methodology for developing gate-to-gate Life cycle inventory information. Int. J. Life Cycle Assess. 2000, 5, 153–159. [Google Scholar] [CrossRef]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories—Volume 4: Agriculture, Forestry and Other Land Use. Chapter 10: Emissions from Livestock and Manure Management. Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/pdf/4_Volume4/19R_V4_Ch10_Livestock.pdf (accessed on 9 July 2025).

- Food and Agriculture Organization (FAO). Biogas from Anaerobic Digestion: Powering Green Growth; Technical Report; FAO: Rome, Italy, 2013; Available online: https://www.fao.org/4/i1273e/i1273e.pdf (accessed on 9 July 2025).

| Impact Category | S1: For kitchen energy needs by family: Wood-fired: 468 kg monthly or 1 LPG = 0.03 m3 monthly. Percentage of firewood substitution by biogas 83.1% | S2: For 0.5-ton citronella essential oil plant: Wood-fired 1500 kg monthly. Percentage of firewood substitution by biogas 24.1% | Actions/Recommendations to be developed |

| Environmental | Stop consuming the following amount of firewood per month= 388.4 kg. Emissions to the atmosphere would be avoided in one month by optimising the anaerobic process = 48.4 m3 CH4. Equivalent to tons of carbon dioxide (CO2) per month = 0.52 Ton CO2eq. Treatment of livestock wastewater that, if left untreated, will be a source of pollution and a health risk. | The use of local organic waste improves circularity and resource sustainability, while proper digestate management and methane monitoring ensure environmental protection and system efficiency. | |

| Social/Health | Improvements in Quality of Life: Effective reduction of indoor pollution from firewood use, reflected in the prevalence of chronic obstructive pulmonary disease (COPD), primarily among women. | Biogas substitution for firewood improves indoor air quality and health, especially for women. Promoting women’s involvement in system management enhances gender equity and supports community-led energy transitions. | |

| Technical | Use of the biogas produced (2.6 m3 d−1) for heat requirements in household or productive activities. Monthly energy potential of the biogas produced = 520,516 Kcal month−1. Production of treated digestate: 275 L d−1 to be used as liquid fertiliser for forage crops or protein bank or the same citronella crop. | Locally adapted systems using available materials and skills enable decentralised implementation. Simplified procedures and training foster user autonomy, while documenting pilot cases supports replication and technical scaling. Routine maintenance of rural pig waste biodigesters, particularly desludging to remove sediment, is typically required every 12 to 24 months [48]. | |

| Economic | Monthly savings on LPG purchase (1 cylinder of 40 pounds for a household): USD 30. Commercial fertilisers derived from hydrocarbons would no longer be consumed and would be replaced by coproducts derived from bioprocesses. Approximate monthly savings of USD 60 approx. | Financial sustainability requires microfinancing, cost-sharing, and co-benefit valuation (e.g., fuel savings, biofertilisers). Cooperative models enhance scalability and community ownership. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gomez, F.H.; Vasquez, N.J.; Torres, K.C.; Meza, C.M.; Vaccari, M. Sustainability Assessment of Rural Biogas Production and Use Through a Multi-Criteria Approach: A Case Study in Colombia. Sustainability 2025, 17, 6806. https://doi.org/10.3390/su17156806

Gomez FH, Vasquez NJ, Torres KC, Meza CM, Vaccari M. Sustainability Assessment of Rural Biogas Production and Use Through a Multi-Criteria Approach: A Case Study in Colombia. Sustainability. 2025; 17(15):6806. https://doi.org/10.3390/su17156806

Chicago/Turabian StyleGomez, Franco Hernan, Nelson Javier Vasquez, Kelly Cristina Torres, Carlos Mauricio Meza, and Mentore Vaccari. 2025. "Sustainability Assessment of Rural Biogas Production and Use Through a Multi-Criteria Approach: A Case Study in Colombia" Sustainability 17, no. 15: 6806. https://doi.org/10.3390/su17156806

APA StyleGomez, F. H., Vasquez, N. J., Torres, K. C., Meza, C. M., & Vaccari, M. (2025). Sustainability Assessment of Rural Biogas Production and Use Through a Multi-Criteria Approach: A Case Study in Colombia. Sustainability, 17(15), 6806. https://doi.org/10.3390/su17156806