Clarifying the Taxonomy of Plastics and Bioplastics: Toward a ‘Zero-Trace Plastic’ (ZTP) Material Framework

Abstract

1. Introduction

2. Materials and Methods

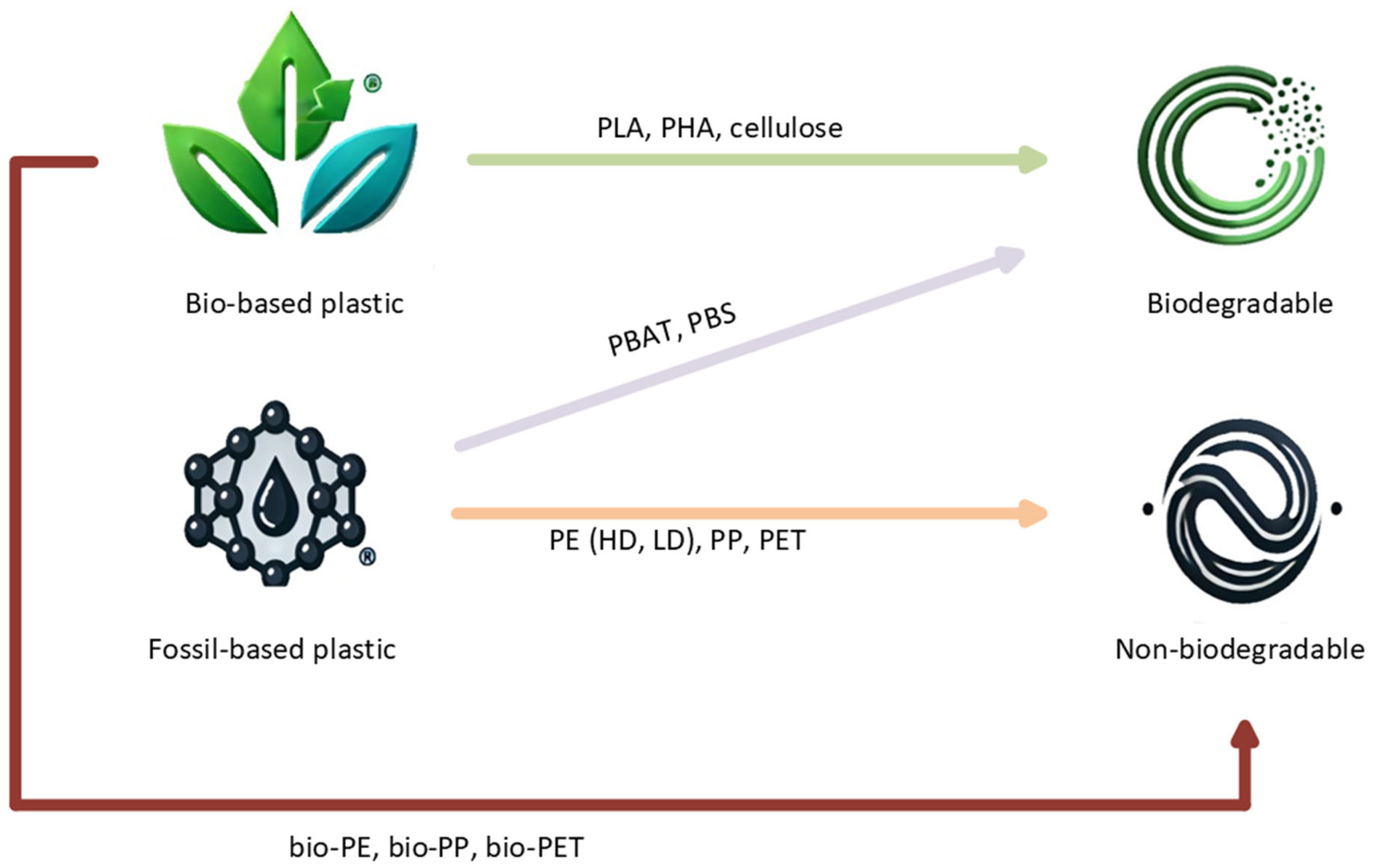

3. Challenges of Common Taxonomy and Terminologies of Plastics, Polymers, and Biopolymers

3.1. Plastic Alternatives Versus Plastic Substitutes

3.2. Emergence of New Terminologies

4. The Proposed New Terminologies to Overcome Existing Challenges and Confusions

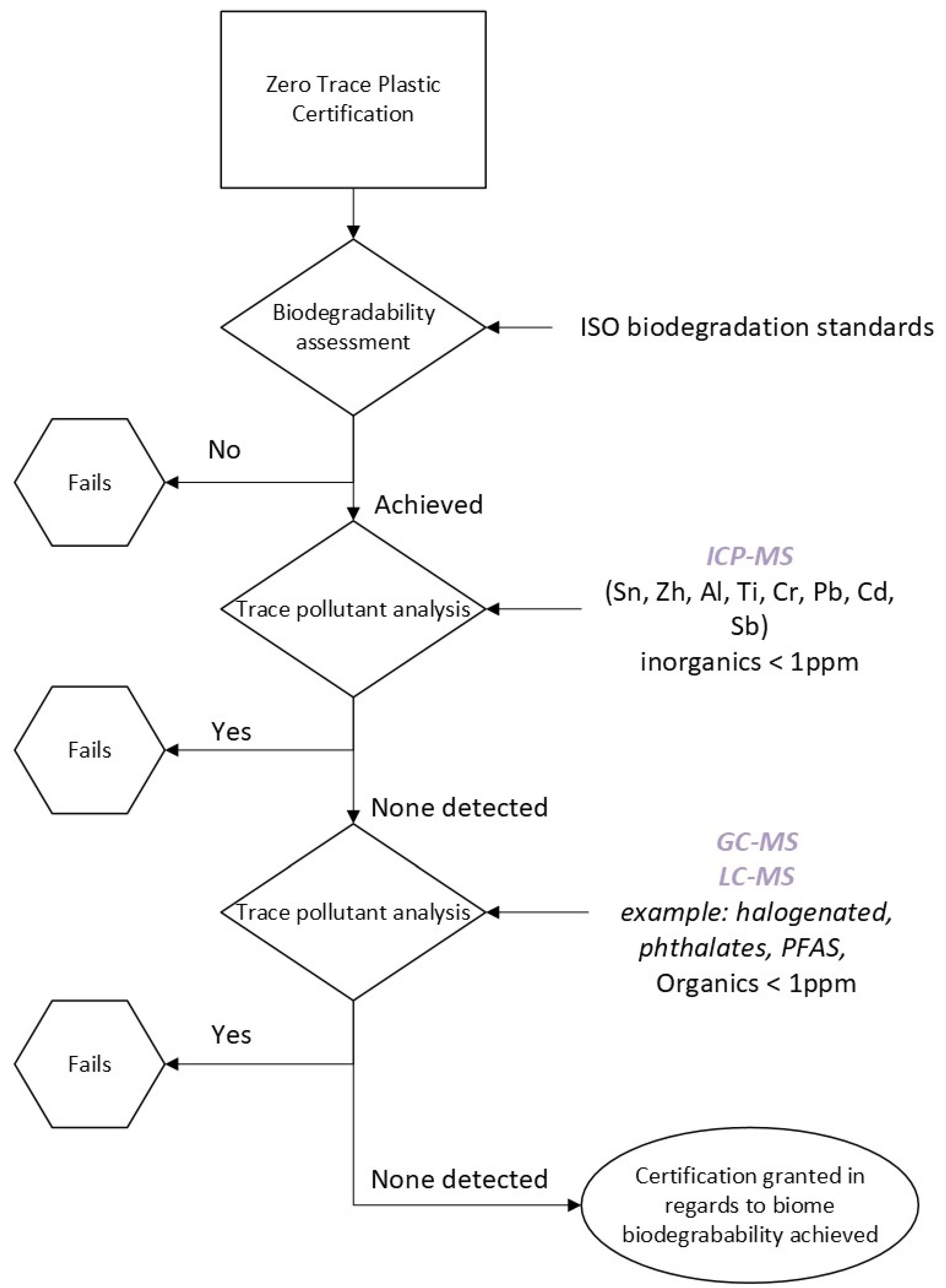

5. Proposed Validation and Certification Procedure

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rosenboom, J.-G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef]

- Coppola, G.; Gaudio, M.T.; Lopresto, C.G.; Calabro, V.; Curcio, S.; Chakraborty, S. Bioplastic from Renewable Biomass: A Facile Solution for a Greener Environment. Earth Syst. Environ. 2021, 5, 231–251. [Google Scholar] [CrossRef]

- Faizan, M.; Nadeem, H.; Arif, A.; Zaheer, W. Bioplastics from Biopolymers: An Eco-Friendly and Sustainable Solution of Plastic Pollution. Polym. Sci. Ser. C 2021, 63, 47–63. [Google Scholar] [CrossRef]

- Yu, Y.; Flury, M. Unlocking the Potentials of Biodegradable Plastics with Proper Management and Evaluation at Environmentally Relevant Concentrations. npj Mater. Sustain. 2024, 2, 9. [Google Scholar] [CrossRef]

- Ansink, E.; Wijk, L.; Zuidmeer, F. No clue about bioplastics. Ecol. Econ. 2022, 191, 107245. [Google Scholar] [CrossRef]

- Gruter, G.-J.M. Using carbon above the ground as feedstock to produce our future polymers. Curr. Opin. Green Sustain. Chem. 2023, 40, 100743. [Google Scholar] [CrossRef]

- Mhaddolkar, N.; Tischberger-Aldrian, A.; Astrup, T.F.; Vollprecht, D. Consumers confused ‘Where to dispose biodegradable plastics?’: A study of three waste streams. Waste Manag. Res. 2024, 42, 776–787. [Google Scholar] [CrossRef]

- Luckachan, G.E.; Pillai, C.K.S. Biodegradable Polymers—A Review on Recent Trends and Emerging Perspectives. J. Polym. Environ. 2011, 19, 637–676. [Google Scholar] [CrossRef]

- Bhatia, S. (Ed.) Natural Polymers vs Synthetic Polymer. In Natural Polymer Drug Delivery Systems: Nanoparticles, Plants, and Algae; Springer International Publishing: Cham, Switzerland, 2016; pp. 95–118. [Google Scholar]

- Elango, J.; Zamora-Ledezma, C.; Maté-Sánchez de Val, J. Natural vs Synthetic Polymers: How Do They Communicate with Cells for Skin Regeneration—A Review. J. Compos. Sci. 2023, 7, 385. [Google Scholar] [CrossRef]

- Behr, A.; Seidensticker, T. (Eds.) Plastics from Nature—Biopolymers. In Chemistry of Renewables: An Introduction; Springer: Berlin/Heidelberg, Germany, 2020; pp. 323–339. [Google Scholar]

- Siracusa, V.; Blanco, I. Bio-polyethylene (Bio-PE), Bio-polypropylene (Bio-PP) and Bio-poly(ethylene terephthalate) (Bio-PET): Recent developments in bio-based polymers analogous to petroleum-derived ones for packaging and engineering applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef]

- ISO 472:2013; Plastic—Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2013.

- Bioplastics, E. What are Bioplastics. Available online: https://www.european-bioplastics.org/ (accessed on 1 February 2025).

- IUPAC. Nomenclature and Terminology. Available online: https://iupac.org/nomenclature-and-terminology/ (accessed on 1 February 2025).

- Fortin, S.G.; Uhlig, K.; Hale, R.C.; Song, B. Microplastic biofilms as potential hotspots for plastic biodegradation and nitrogen cycling: A metagenomic perspective. FEMS Microbiol. Ecol. 2025, 101, fiaf035. [Google Scholar] [CrossRef]

- Di Leto, Y.; Mineo, A.; Capri, F.C.; Puccio, G.; Mercati, F.; Alduina, R.; Gallo, G.; Mannina, G. The role of carbon and nitrogen ratio on sewage sludge microbiota for producing polyhydroxyalkanoates. J. Environ. Manag. 2025, 375, 124240. [Google Scholar] [CrossRef]

- Roman, E.K.B.; Ramos, M.A.; Tomazetto, G.; Foltran, B.B.; Galvão, M.H.; Ciancaglini, I.; Tramontina, R.; de Almeida Rodrigues, F.; da Silva, L.S.; Sandano, A.L.H.; et al. Plastic-degrading microbial communities reveal novel microorganisms, pathways, and biocatalysts for polymer degradation and bioplastic production. Sci. Total Environ. 2024, 949, 174876. [Google Scholar] [CrossRef] [PubMed]

- Oluwasina, O.O.; Akinyele, B.P.; Olusegun, S.J.; Oluwasina, O.O.; Mohallem, N.D.S. Evaluation of the effects of additives on the properties of starch-based bioplastic film. SN Appl. Sci. 2021, 3, 421. [Google Scholar] [CrossRef]

- Oluwasina, O.O.; Olaleye, F.K.; Olusegun, S.J.; Oluwasina, O.O.; Mohallem, N.D.S. Influence of oxidized starch on physicomechanical, thermal properties, and atomic force micrographs of cassava starch bioplastic film. Int. J. Biol. Macromol. 2019, 135, 282–293. [Google Scholar] [CrossRef] [PubMed]

- Fauziah, A.N.; Adriana, R.; Hayati, A.T.; Marlina, A.; Yustinah; Ndruru, S.T.C.L. Physical performance of glycerol-plasticized cassava peel starch-carboxymethyl cellulose bioplastic. Emergent Mater. 2025, 1–19. [Google Scholar] [CrossRef]

- Zhang, H.; Su, Z.; Wang, X. Starch-Based Rehealable and Degradable Bioplastic Enabled by Dynamic Imine Chemistry. ACS Sustain. Chem. Eng. 2022, 10, 8650–8657. [Google Scholar] [CrossRef]

- Agustin, M.B.; Ahmmad, B.; Alonzo, S.M.M.; Patriana, F.M. Bioplastic based on starch and cellulose nanocrystals from rice straw. J. Reinf. Plast. Compos. 2014, 33, 2205–2213. [Google Scholar] [CrossRef]

- He, M.; Lu, T.; Jia, Z.; Tian, H.; Feng, M.; Zhang, X.; Zhang, M.; Wang, C.; Zhao, Y.; Qiu, J. Fabrication and properties of novel chitosan/ZnO composite bioplastic. Cellulose 2022, 29, 233–243. [Google Scholar] [CrossRef]

- Albar, N.; Anuar, S.T.; Azmi, A.A.; Soh, S.K.C.; Bhubalan, K.; Ibrahim, Y.S.; Khalik, W.M.A.W.M.; Abdullah, N.S.; Yahya, N.K.E.M. Chemical, Mechanical, and Wettability Properties of Bioplastic Material from Manihot esculenta Cassava–Chitosan Blends as Plastic Alternative. Die Stärke 2025, 77, 2300278. [Google Scholar] [CrossRef]

- Bhat, S.G.; Thivaharan, V.; Divyashree, M.S. Sustainable Opportunities in the Downstream Processing of the Intracellular Biopolymer Polyhydroxyalkanoate. ChemBioEng Rev. 2024, 11, 79–94. [Google Scholar] [CrossRef]

- Li, D.; Li, J.; Ma, X. Accumulation of bioplastic polyhydroxyalkanoate with different substrate forms from pretreated waste lignocellulose hydrolysate. Ind. Crops Prod. 2021, 172, 114061. [Google Scholar] [CrossRef]

- ASTM D6400-21; Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities. ASTM International: West Conshohocken, PA, USA, 2021.

- BS EN 13432:2000; Packaging. Requirements for Packaging Recoverable Through Composting and Biodegradation. Test Scheme and Evaluation Criteria for the Final Acceptance of Packaging. British Standards Institution: London, UK, 2000.

- Mhaddolkar, N.; Astrup, T.F.; Tischberger-Aldrian, A.; Pomberger, R.; Vollprecht, D. Challenges and opportunities in managing biodegradable plastic waste: A review. Waste Manag. Res. 2025, 43, 911–934. [Google Scholar] [CrossRef] [PubMed]

- Billmeyer, F.W. Textbook of Polymer Science, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1984. [Google Scholar]

- Koltzenburg, S.; Maskos, M.; Nuyken, O. Polymer Chemistry, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Kumar, R.; Sadeghi, K.; Jang, J.; Seo, J. Mechanical, chemical, and bio-recycling of biodegradable plastics: A review. Sci. Total Environ. 2023, 882, 163446. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Sustainability of biodegradable plastics: New problem or solution to solve the global plastic pollution? Curr. Res. Green Sustain. Chem. 2022, 5, 100273. [Google Scholar] [CrossRef]

- Döhler, N.; Wellenreuther, C.; Wolf, A. Market dynamics of biodegradable bio-based plastics: Projections and linkages to European policies. EFB Bioecon. J. 2022, 2, 100028. [Google Scholar] [CrossRef]

- Piao, Z.; Agyei Boakye, A.A.; Yao, Y. Environmental impacts of biodegradable microplastics. Nat. Chem. Eng. 2024, 1, 661–669. [Google Scholar] [CrossRef]

- Brydson, J.A. Plastics Materials, 7th ed.; Butterworth-Heinemann: Oxford, UK, 1999. [Google Scholar]

- Nicholson, J.W. Chemistry of Polymers, 5th ed.; Royal Society of Chemistry: London, UK, 2017. [Google Scholar]

- Odian, G. Principles of Polymerization, 4th ed.; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Grossman, R.F.; Lutz, J.T., Jr. Polymer Modifiers and Additives; Chapman and Hall/CRC: Boca Raton, FL, USA, 2000. [Google Scholar]

- Bula, K.; Klapiszewski, Ł.; Jesionowski, T. A novel functional silica/lignin hybrid material as a potential bio-based polypropylene filler. Polym. Compos. 2015, 36, 913–922. [Google Scholar] [CrossRef]

- Yang, H.; Wentao, L. Bio-based Polyamide 56: Recent advances in basic and applied research. Polym. Eng. Sci. 2023, 63, 2484–2497. [Google Scholar] [CrossRef]

- Pang, J.; Zheng, M.; Sun, R.; Wang, A.; Wang, X.; Zhang, T. Synthesis of ethylene glycol and terephthalic acid from biomass for producing PET. Green Chem. 2016, 18, 342–359. [Google Scholar] [CrossRef]

- Tavanaie, M.A.; Ghahari, A.H. A study on melt recycling of bio-based polypropylene/thermoplastic starch compound. J. Appl. Polym. Sci. 2021, 138, 51282. [Google Scholar] [CrossRef]

- Cundari, F. NaturALL Bottle Alliance—Danone, Nestle and PepsiCo partner with Origin Materials to develop an innovative packaging solution. Knowledge Hub. 4 January 2023. Available online: https://knowledge-hub.circle-economy.com/article/22121?n=NaturALL-Bottle-Alliance---Danone%2C-Nestle-and-PepsiCo-partner-with-Origin-Materials-to-develop-an-innovative-packagin... (accessed on 21 July 2025).

- Ciriminna, R.; Pagliaro, M. Biodegradable and Compostable Plastics: A Critical Perspective on the Dawn of their Global Adoption. ChemistryOpen 2020, 9, 8–13. [Google Scholar] [CrossRef] [PubMed]

- Tenhaef, N.; Hermann, A.; Müller, M.F.; Görtz, J.; Marienhagen, J.; Oldiges, M.; Wiechert, W.; Bott, M.; Jupke, A.; Hartmann, L.; et al. From Microbial Succinic Acid Production to Polybutylene Bio-Succinate Synthesis. Chem. Ing. Tech. 2023, 95, 587–595. [Google Scholar] [CrossRef]

- Savitha, K.S.; Senthil Kumar, M.; Jagadish, R.L. Novel hydrolytically stable Lewis acidic ionic liquid catalyst system for polybutylene succinate (PBS) synthesis. Mater. Adv. 2022, 3, 8132–8136. [Google Scholar] [CrossRef]

- Elias Guckert, F.; Sayer, C.; de Oliveira, D.; Hermes de Araújo, P.H.; Francisco Oechsler, B. Synthesis of polybutylene succinate via Lipase-Catalyzed Transesterification: Enzyme Stability, reuse and PBS properties in bulk polycondensations. Eur. Polym. J. 2022, 179, 111573. [Google Scholar] [CrossRef]

- Labet, M.; Thielemans, W. Synthesis of polycaprolactone: A review. Chem. Soc. Rev. 2009, 38, 3484–3504. [Google Scholar] [CrossRef]

- Lee, J.; Park, C.; Tsang, Y.F.; Lin, K.-Y.A. Towards Sustainable Production of Polybutylene Adipate Terephthalate: Non-biological Catalytic Syntheses of Biomass-derived Constituents. ChemSusChem 2024, 17, e202401070. [Google Scholar] [CrossRef]

- Jiang, Z.; Hou, F.; Chen, J.; Wang, B.; Song, S.; Li, J.; Huang, L.; Wang, C.; Wang, H. Synthesis and properties of biodegradable PBAT prepared from PBT chemically recycled resources. Polymer 2024, 307, 127326. [Google Scholar] [CrossRef]

- Bao, Q.; Zhang, Z.; Yu, B.; Sun, H.; Leung, P.H.m.; Tao, X. Synthesis of Polylactic Acid Oligomers for Broad-Spectrum Antimicrobials. Polymers 2022, 14, 4399. [Google Scholar] [CrossRef]

- Zhuang, Q.; Wang, Q.; Liang, Q.; Qi, Q. Synthesis of polyhydroxyalkanoates from glucose that contain medium-chain-length monomers via the reversed fatty acid β-oxidation cycle in Escherichia coli. Metab. Eng. 2014, 24, 78–86. [Google Scholar] [CrossRef]

- Volova, T.; Kiselev, E.; Zhila, N.; Shishatskaya, E. Synthesis of Polyhydroxyalkanoates by Hydrogen-Oxidizing Bacteria in a Pilot Production Process. Biomacromolecules 2019, 20, 3261–3270. [Google Scholar] [CrossRef]

- Anitha, R.; Jayakumar, K.; Samuel, G.V.; Joice, M.E.; Sneha, M.; Seeli, D.S. Synthesis and Characterization of Starch-Based Bioplastics: A Promising Alternative for a Sustainable Future. Eng. Proc. 2024, 61, 30. [Google Scholar] [CrossRef]

- Zimmermann, L.; Dombrowski, A.; Völker, C.; Wagner, M. Are bioplastics and plant-based materials safer than conventional plastics? In vitro toxicity and chemical composition. Environ. Int. 2020, 145, 106066. [Google Scholar] [CrossRef]

- Goossen, C.P.; Schattman, R.E.; MacRae, J.D. Evidence of compost contamination with per- and polyfluoroalkyl substances (PFAS) from “compostable” food serviceware. Biointerphases 2023, 18, 030501. [Google Scholar] [CrossRef]

- Beyondplastics. The False Promise of Bioplastics and Compostable Plastics. Available online: https://www.beyondplastics.org/ (accessed on 20 February 2025).

- Atiwesh, G.; Mikhael, A.; Parrish, C.C.; Banoub, J.; Le, T.-A.T. Environmental impact of bioplastic use: A review. Heliyon 2021, 7, e07918. [Google Scholar] [CrossRef]

- Piemonte, V.; Gironi, F. Land-use change emissions: How green are the bioplastics? Environ. Prog. Sustain. Energy 2011, 30, 685–691. [Google Scholar] [CrossRef]

- Tsiropoulos, I.; Faaij, A.P.C.; Lundquist, L.; Schenker, U.; Briois, J.F.; Patel, M.K. Life cycle impact assessment of bio-based plastics from sugarcane ethanol. J. Clean. Prod. 2015, 90, 114–127. [Google Scholar] [CrossRef]

- Weiss, M.; Haufe, J.; Carus, M.; Brandão, M.; Bringezu, S.; Hermann, B.; Patel, M.K. A Review of the Environmental Impacts of Biobased Materials. J. Ind. Ecol. 2012, 16, S169–S181. [Google Scholar] [CrossRef]

- Dolci, G.; Rigamonti, L.; Grosso, M. The challenges of bioplastics in waste management. Waste Manag. Res. 2023, 41, 1281–1282. [Google Scholar] [CrossRef]

- Purkiss, D.; Allison, A.L.; Lorencatto, F.; Michie, S.; Miodownik, M. The Big Compost Experiment: Using citizen science to assess the impact and effectiveness of biodegradable and compostable plastics in UK home composting. Front. Sustain. 2022, 3, 942724. [Google Scholar] [CrossRef]

- Allison, A.L.; Lorencatto, F.; Michie, S.; Miodownik, M. Barriers and Enablers to Food Waste Recycling: A Mixed Methods Study amongst UK Citizens. Int. J. Environ. Res. Public Health 2022, 19, 2729. [Google Scholar] [CrossRef]

- Allison, A.L.; Purkiss, D.; Lorencatto, F.; Miodownik, M.; Michie, S. Improving compostable plastic disposal: An application of the Behaviour Change Wheel intervention development method. Front. Sustain. 2022, 3, 968152. [Google Scholar] [CrossRef]

- Taneepanichskul, N.; Purkiss, D.; Miodownik, M. A Review of Sorting and Separating Technologies Suitable for Compostable and Biodegradable Plastic Packaging. Front. Sustain. 2022, 3, 901885. [Google Scholar] [CrossRef]

- Chong, Z.K.; Hofmann, A.; Haye, M.; Wilson, S.; Sohoo, I.; Alassali, A.; Kuchta, K. Lab-scale and full-scale industrial composting of biodegradable plastic blends for packaging. Open Res. Eur. 2024, 2, 101. [Google Scholar] [CrossRef] [PubMed]

- Taneepanichskul, N.; Hailes, H.C.; Miodownik, M. Automatic identification and classification of compostable and biodegradable plastics using hyperspectral imaging. Front. Sustain. 2023, 4, 1125954. [Google Scholar] [CrossRef]

- EN 14995:2006; Plastics—Evaluation of compostability—Test scheme and specifications. Comite Europeen de Normalisation: Brussels, Belgium, 2006.

- Sustainable Manufacturing and Environmental Pollution (SMEP). Plastic Reduction & Management Summary of Recommendations. ECOS. 2024. Available online: https://unctad.org/system/files/non-official-document/plastic-reduction-and-management-summary-of-recommendations.pdf (accessed on 21 July 2025).

- Gazeau, B.; Zaman, A.; Minunno, R.; Shaikh, F. Developing Traceability Systems for Effective Circular Economy of Plastic: A Systematic Review and Meta-Analysis. Sustainability 2024, 16, 9973. [Google Scholar] [CrossRef]

- Nova-Institute. Biodegradable Polymer in Various Environments. Available online: https://www.biocycle.net/wp-content/uploads/2024/10/poster_l.jpg (accessed on 8 March 2024).

- Shekhar, N.; Mondal, A. Synthesis, properties, environmental degradation, processing, and applications of Polylactic Acid (PLA): An overview. Polym. Bull. 2024, 81, 11421–11457. [Google Scholar] [CrossRef]

- Niu, Y.; Pan, F.; Shen, K.; Yang, X.; Niu, S.; Xu, X.; Zhou, H.; Fu, Q.; Li, X. Status and Enhancement Techniques of Plastic Waste Degradation in the Environment: A Review. Sustainability 2024, 16, 9395. [Google Scholar] [CrossRef]

- Kaur, R.; Chauhan, I. Biodegradable plastics: Mechanisms of degradation and generated bio microplastic impact on soil health. Biodegradation 2024, 35, 863–892. [Google Scholar] [CrossRef]

- ISO 14855; Determination of the Ultimate Aerobic Biodegradability of Plastic Materials Under Controlled Composting Conditions—Method by Analysis of Evolved Carbon Dioxide. ISO: Geneva, Switzerland, 2012.

- ISO 17088; Plastics—Organic Recycling—Specifications for Compostable Plastics. ISO: Geneva, Switzerland, 2021.

- ISO 16679; Plastics—Determination of Aerobic Biodegradation of Non-Floating Plastic Materials in a Seawater/Sediment Interface—Method by Analysis of Evolved Carbon Dioxide. ISO: Geneva, Switzerland, 2020.

- ISO 18830; Plastics—Determination of Aerobic Biodegradation of Non-Floating Plastic Materials in a Seawater/Sandy Sediment Interface—Method by Measuring the Oxygen Demand in Closed Respirometer. ISO: Geneva, Switzerland, 2016.

- ISO 22404; Plastics—Determination of the Aerobic Biodegradation of Non-Floating Materials Exposed to Marine Sediment—Method by Analysis of Evolved Carbon Dioxide. ISO: Geneva, Switzerland, 2019.

- ISO 17556; Plastics—Determination of the Ultimate Aerobic Biodegradability of Plastic Materials in Soil by Measuring the Oxygen Demand in a Respirometer or the Amount of Carbon Dioxide Evolved. ISO: Geneva, Switzerland, 2019.

- ASTM D5988; Determining Aerobic Biodegradation of Plastic Materials in Soil. ASTM: West Conshohocken, PA, USA, 2018.

| Term | Carbon Source | Polymer Structure | Degradability | Examples | References |

|---|---|---|---|---|---|

| Plastic. | Fossil or bio-based. | Synthetic, long chain. | Often persistent. | PE, PET, PS. | ISO 472:2013 [13]. |

| Bioplastic. | Bio or fossil-based. | Synthetic. | Varies (PLA versus bio-PE). | PLA, bio-PE, PBAT. | European Bioplastics [14], IUPAC [15]. |

| Biopolymer. | Natural (Bio-based). | Produced by organisms. | Typically biodegradable. | Starch, PHA, chitosan. | IUPAC [15], academic sources [16,17,18,19,20,21,22,23,24,25,26,27]. |

| Compostable Plastic. | Fossil or bio-based. | Synthetic or blended. | Degradable in industrial conditions. | PLA, PBAT. | ASTM D6400 [28], EN 13432 [29]. |

| Zero-Trace Plastic (ZTP). | Bio-based. | Engineered or natural. | Fully mineralising under target conditions. | PHA, future materials. | This study proposed a framework. * |

| Aspect. | Plastic Alternatives (‘Better Plastic’) | Plastic Substitutes (‘Non-Plastic Materials’) |

|---|---|---|

| Composition. | May include plastics (bio-based, or biodegradable). | Does not include plastics; entirely non-plastic materials. |

| Environmental Goal. | Reduce reliance on virgin fossil-based plastics. | Eliminate plastics entirely, reduce downstream impact. |

| Examples. | PLA, PHA, bio-PET. | Paper, bamboo, glass, metals, jute. |

| End-of-Life. | Requires proper recycling or industrial composting facilities. | Often biodegradable, erodible recyclable. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gazeau, B.; Zaman, A.; Pacini, H.; Khan, M.A. Clarifying the Taxonomy of Plastics and Bioplastics: Toward a ‘Zero-Trace Plastic’ (ZTP) Material Framework. Sustainability 2025, 17, 6763. https://doi.org/10.3390/su17156763

Gazeau B, Zaman A, Pacini H, Khan MA. Clarifying the Taxonomy of Plastics and Bioplastics: Toward a ‘Zero-Trace Plastic’ (ZTP) Material Framework. Sustainability. 2025; 17(15):6763. https://doi.org/10.3390/su17156763

Chicago/Turabian StyleGazeau, Benjamin, Atiq Zaman, Henrique Pacini, and Mubarak Ahmad Khan. 2025. "Clarifying the Taxonomy of Plastics and Bioplastics: Toward a ‘Zero-Trace Plastic’ (ZTP) Material Framework" Sustainability 17, no. 15: 6763. https://doi.org/10.3390/su17156763

APA StyleGazeau, B., Zaman, A., Pacini, H., & Khan, M. A. (2025). Clarifying the Taxonomy of Plastics and Bioplastics: Toward a ‘Zero-Trace Plastic’ (ZTP) Material Framework. Sustainability, 17(15), 6763. https://doi.org/10.3390/su17156763