Multidimensional Evaluation of Local Rye Bread Fortified with Whey as a Model for Food Waste Valorization: From Recipe Development to Consumer Acceptance

Abstract

1. Introduction

2. Materials and Methods

2.1. Whey Preparation from Fresh Cheese Production

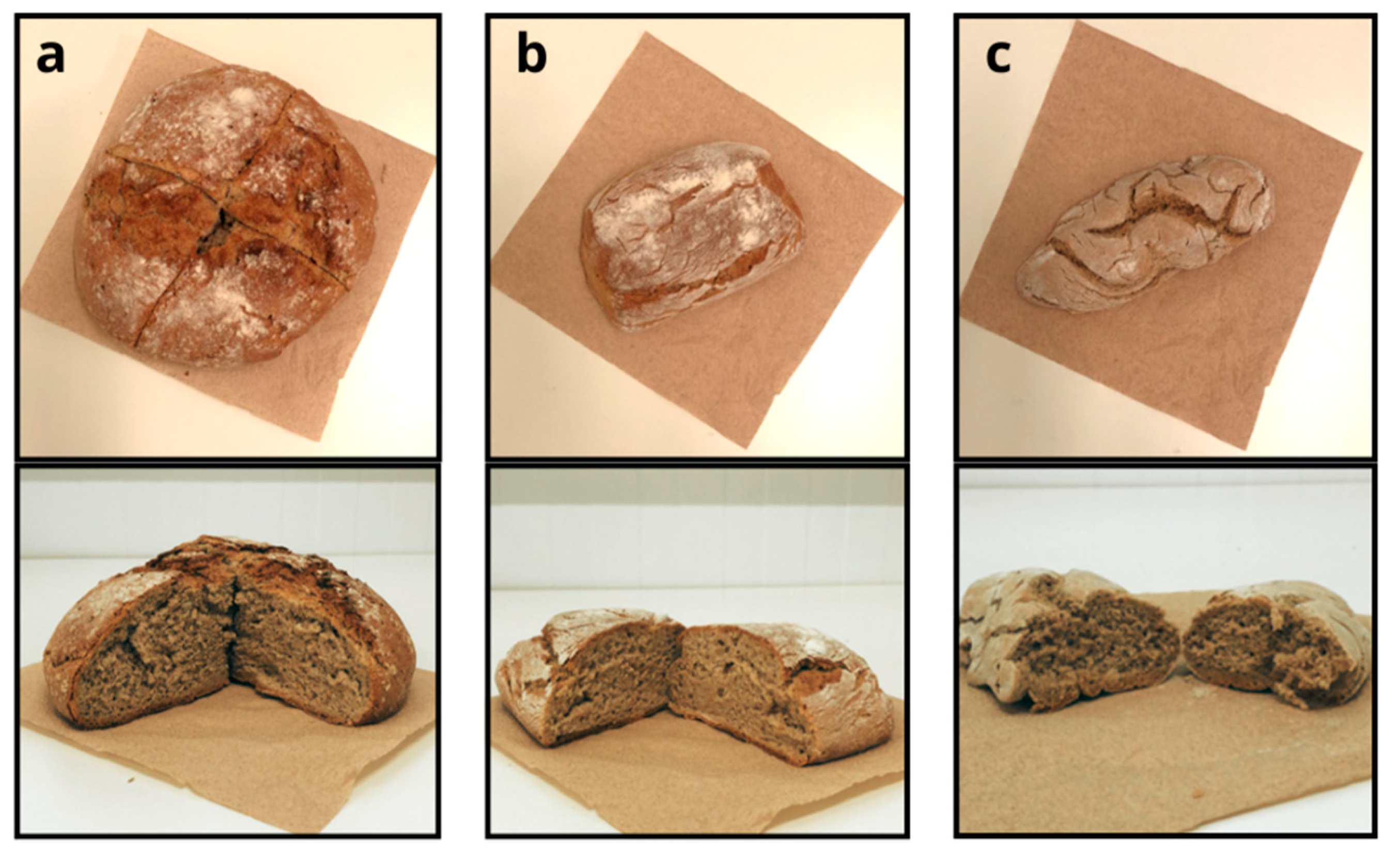

2.2. Formulation and Preparation of Rye-Based Breads

2.3. Nutritional Analysis

2.4. Microbiological Analysis

2.5. Sensorial Analysis

2.5.1. Sensory Evaluation of Rye Bread by Quantitative Descriptive Analysis (QDA)

2.5.2. Consumer Evaluation

2.6. Statistical Analysis

3. Results

3.1. Nutritional Composition

3.2. Microbiological Analysis

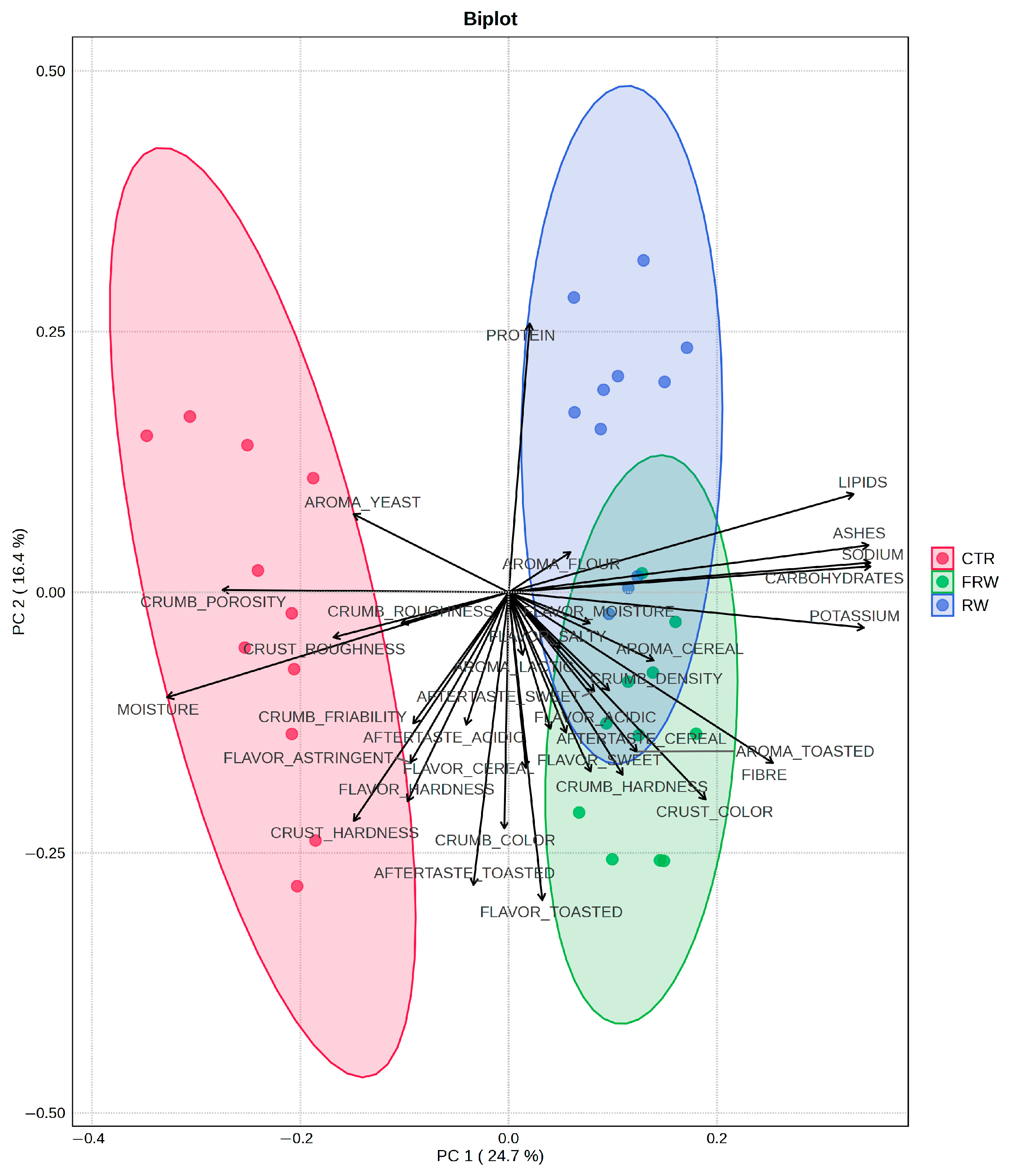

3.3. Sensory Profile Characterization

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AOAC | Association of Official Analytical Collaboration |

| BOD | Biochemical Oxygen Demand |

| COD | Chemical Oxygen Demand |

| CTR | Control |

| EU | European Union |

| FRW | Full Rye Whey |

| ICP-MS | Inductively Coupled Plasma Mass Spectrometry |

| ISO | International Organization for Standardization |

| NMR | Nuclear Magnetic Resonance |

| QDA | Quantitative Descriptive Analysis |

| RW | Rye Whey |

| SCFAs | Short-Chain Fatty Acids |

| USD | United States Dollar |

| UTAD | University of Trás-os-Montes and Alto Douro |

References

- Innova Market Insights. Top Food Trends 2025. Available online: https://www.innovamarketinsights.com/trends/top-food-trends-2025/ (accessed on 17 June 2025).

- Ligarda-Samanez, C.A.; Huamán-Carrión, M.L.; Calsina-Ponce, W.C.; Cruz, G.D.l.; Calderón Huamaní, D.F.; Cabel-Moscoso, D.J.; Garcia-Espinoza, A.J.; Sucari-León, R.; Aroquipa-Durán, Y.; Muñoz-Saenz, J.C.; et al. Technological Innovations and Circular Economy in the Valorization of Agri-Food By-Products: Advances, Challenges and Perspectives. Foods 2025, 14, 1950. [Google Scholar] [CrossRef]

- Berbeć, A.K.; Wyzińska, M. From Nutrition to Energy: Evaluating the Role of Rye (Secale cereale L.) Grain in Sustainable Food Systems and Biofuel Applications. Foods 2025, 14, 1971. [Google Scholar] [CrossRef]

- Monteiro, F.; Vidigal, P.; Barros, A.B.; Monteiro, A.; Oliveira, H.R.; Viegas, W. Genetic Distinctiveness of Rye In situ Accessions from Portugal Unveils a New Hotspot of Unexplored Genetic Resources. Front. Plant Sci 2016, 7, 1334. [Google Scholar] [CrossRef]

- Dziki, D. Rye Flour and Rye Bran: New Perspectives for Use. Processes 2022, 10, 293. [Google Scholar] [CrossRef]

- Iversen, K.N.; Dicksved, J.; Zoki, C.; Fristedt, R.; Pelve, E.A.; Langton, M.; Landberg, R. The Effects of High Fiber Rye, Compared to Refined Wheat, on Gut Microbiota Composition, Plasma Short Chain Fatty Acids, and Implications for Weight Loss and Metabolic Risk Factors (the RyeWeight Study). Nutrients 2022, 14, 1669. [Google Scholar] [CrossRef] [PubMed]

- Guan, Z.-W.; Yu, E.-Z.; Feng, Q. Soluble Dietary Fiber, One of the Most Important Nutrients for the Gut Microbiota. Molecules 2021, 26, 6802. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Grijalva, E.P.; Ambriz-Pére, D.L.; Leyva-López, N.; Castillo-López, R.I.; Heredia, J.B. Dietary phenolic compounds, health benefits and bioaccessibility. Arch. Latinoam Nut. 2016, 66, 87–1000. [Google Scholar]

- Cronin, P.; Joyce, S.A.; O’Toole, P.W.; O’Connor, E.M. Dietary Fibre Modulates the Gut Microbiota. Nutrients 2021, 13, 1655. [Google Scholar] [CrossRef]

- Randeni, N.; Bordiga, M.; Xu, B. A Comprehensive Review of the Triangular Relationship among Diet–Gut Microbiota–Inflammation. Int. J. Mol. Sci. 2024, 25, 9366. [Google Scholar] [CrossRef]

- Lappa, I.K.; Papadaki, A.; Kachrimanidou, V.; Terpou, A.; Koulougliotis, D.; Eriotou, E.; Kopsahelis, N. Cheese Whey Processing: Integrated Biorefinery Concepts and Emerging Food Applications. Foods 2019, 8, 347. [Google Scholar] [CrossRef]

- Chourasia, R.; Phukon, L.C.; Abedin, M.M.; Padhi, S.; Singh, S.P.; Rai, A.K. Whey valorization by microbial and enzymatic bioprocesses for the production of nutraceuticals and value-added products. Bioresour. Technol. Rep. 2022, 19, 101144. [Google Scholar] [CrossRef]

- Pires, A.F.; Marnotes, N.G.; Rubio, O.D.; Garcia, A.C.; Pereira, C.D. Dairy By-Products: A Review on the Valorization of Whey and Second Cheese Whey. Foods 2021, 10, 1067. [Google Scholar] [CrossRef]

- Horizon Grand View Research. Europe Whey Protein Market Size & Outlook, 2024–2030. Available online: https://www.grandviewresearch.com/horizon/outlook/whey-protein-market/europe (accessed on 17 June 2025).

- Minj, S.; Anand, S. Whey Proteins and Its Derivatives: Bioactivity, Functionality, and Current Applications. Dairy 2020, 1, 233–258. [Google Scholar] [CrossRef]

- Barba, F.J. An Integrated Approach for the Valorization of Cheese Whey. Foods 2021, 10, 564. [Google Scholar] [CrossRef]

- Pedrali, D.; Scarafoni, A.; Giorgi, A.; Lavelli, V. Binary Alginate-Whey Protein Hydrogels for Antioxidant Encapsulation. Antioxidants 2023, 12, 1192. [Google Scholar] [CrossRef] [PubMed]

- Ramu Ganesan, A.; Hoellrigl, P.; Mayr, H.; Martini Loesch, D.; Tocci, N.; Venir, E.; Conterno, L. The Rheology and Textural Properties of Bakery Products Upcycling Brewers’ Spent Grain. Foods 2023, 12, 3524. [Google Scholar] [CrossRef] [PubMed]

- Ryan, M.P.; Walsh, G. The biotechnological potential of whey. Rev. Environ. Sci. Biotechnol. 2016, 15, 479–498. [Google Scholar] [CrossRef]

- European Commission. Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the Provision of Food Information to Consumers, Amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and Repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004; Official Journal of the European Union: Luxembourg, 2011; Volume L 304, pp. 18–63. [Google Scholar]

- Association of Official Analytical Chemists. Total Dietary Fiber in Foods Enzymatic-Gravimetric Method; AOAC Official Method 985.29; Association of Official Analytical Chemists: Rockville, MD, USA, 1986. [Google Scholar]

- FAO; WHO. Food Energy–Methods of Analysis and Conversion Factors; Food and Nutrition Paper; FAO: Rome, Italy, 2003; Volume 77. [Google Scholar]

- ISO 4833-1; Microbiology of the Food Chain–Horizontal Method for the Enumeration of Microorganisms–Part 1: Colony Count at 30 °C by the Pour Plate Technique. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 15214; Microbiology of Food and Animal Feeding Stuffs–Horizontal Method for the Enumeration of Mesophilic Lactic Acid Bacteria–Colony-Count Technique at 30 Degrees C. International Organization for Standardization: Geneva, Switzerland, 1998.

- NP 3277-1; Food Microbiology–Counting of Yeasts and Moulds–Part 1: Incubation at 25 °C. Instituto Português da Qualidade: Lisbon, Portugal, 1988.

- ISO 8589; Sensory Analysis–General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2007.

- Komeroski, M.R.; Oliveira, V.R.d. Influence of the Amount and Type of Whey Protein on the Chemical, Technological, and Sensory Quality of Pasta and Bakery Products. Foods 2023, 12, 2801. [Google Scholar] [CrossRef]

- Camargo, L.R.; Silva, L.M.; Komeroski, M.R.; Kist, T.B.L.; Rodrigues, C.E.; Rios, A.d.O.; Silva, M.M.; Doneda, D.; Schmidt, H.d.O.; Oliveira, V.R. Effect of whey protein addition on the nutritional, technological and sensory quality of banana cake. Int. J. Food Sci. Technol. 2018, 53, 2617–2623. [Google Scholar] [CrossRef]

- Wani, S.H.; Amir, G.; Farhana, A.; Safapuri, T.A. Effects of incorporation of whey protein concentrate on physicochemical, texture, and microbial evaluation of developed cookies. Cogent Food Agric. 2015, 1, 1092406. [Google Scholar] [CrossRef]

- Tsermoula, P.; Khakimov, B.; Nielsen, J.H.; Engelsen, S.B. WHEY–The waste-stream that became more valuable than the food product. Trends Food Sci. Technol. 2021, 118, 230–241. [Google Scholar] [CrossRef]

- Verma, D.K.; Patel, A.R.; Tripathy, S.; Gupta, A.K.; Singh, S.; Shah, N.; Utama, G.L.; Chávez-González, M.L.; Zongo, K.; Banwo, K.; et al. Processing and formulation technology of nutritional and functional food products by utilizing cheese and/or paneer whey: A critical review. J. King Saud Univ. Sci. 2024, 36, 103508. [Google Scholar] [CrossRef]

- Soares, J.P.; Marques, G.D.A.; Magalhães, C.S.D.; Santos, A.B.; José, J.F.B.D.S.; Silva, D.A.; Silva, E.M.M.D. Efeito da adição de proteína do soro do leite como substituto do trigo na formulação de bolos sem adição de açúcar. Braz. J. Food Technol. 2017, 21, e2016190. [Google Scholar] [CrossRef]

- Jyotsna, R.; Soumya, C.; Swati, S.; Prabhasankar, P. Rheology, texture, quality characteristics and immunochemical validation of millet based gluten free muffins. J. Food Meas. Charact. 2016, 10, 762–772. [Google Scholar] [CrossRef]

- Monteiro, C.; Martins, Z.; Pinho, O.; Gonçalves, C.S. Impact of salt reduction on bread on sensory preference and physicochemical parameters. J. Microbiol. Biotechnol. Food Sci. 2021, 11, e2701. [Google Scholar] [CrossRef]

- Komeroski, M.R.; Homem, R.V.; Schmidt, H.d.O.; Rockett, F.C.; de Lira, L.; Vitória da Farias, D.; Kist, T.L.; Doneda, D.; Rios, A.d.O.; Ruffo de Oliveira, V. Effect of whey protein and mixed flours on the quality parameters of gluten-free breads. Int. J. Gastron. Food Sci. 2021, 24, 100361. [Google Scholar] [CrossRef]

- Tița, M.A.; Moga, V.-M.; Constantinescu, M.A.; Bătușaru, C.M.; Tița, O. Harnessing the Potential of Whey in the Creation of Innovative Food Products: Contributions to the Circular Economy. Recycling 2024, 9, 79. [Google Scholar] [CrossRef]

- Pillai, A.T.; Morya, S.; Kasankala, L.M. Emerging Trends in Bioavailability and Pharma-Nutraceutical Potential of Whey Bioactives. Int. J. Nutr. Metab. 2024, 2024, 8455666. [Google Scholar] [CrossRef]

- PortFIR. Composição de Alimentos: Pão de Centeio. Available online: https://portfir-insa.min-saude.pt (accessed on 18 July 2025).

- Zandona, E.; Blažić, M.; Režek Jambrak, A. Whey Utilization: Sustainable Uses and Environmental Approach. Food Technol. Biotechnol. 2021, 59, 147–161. [Google Scholar] [CrossRef]

- El-Aidie, S.A.M.; Khalifa, G.S.A. Innovative applications of whey protein for sustainable dairy industry: Environmental and technological perspectives—A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13319. [Google Scholar] [CrossRef]

- Iuga, M.; Boestean, O.; Ghendov-Mosanu, A.; Mironeasa, S. Impact of Dairy Ingredients on Wheat Flour Dough Rheology and Bread Properties. Foods 2020, 9, 828. [Google Scholar] [CrossRef]

| Composition | CTR | RW | FRW | p |

|---|---|---|---|---|

| Moisture (g/100 g) | 40.23 ± 1.19 a | 28.27 ± 4.29 b | 31.80 ± 1.93 b | 0.005 |

| Ashes (g/100 g) | 1.55 ± 0.05 b | 2.10 ± 0.13 a | 2.06 ± 0.05 a | <0.001 |

| Lipids (g/100 g) | 0.70 ± 0.04 b | 0.96 ± 0.05 a | 0.89 ± 0.07 a | 0.003 |

| Fiber (g/100 g) | 4.77 ± 0.12 b | 5.33 ± 0.40 b | 6.96 ± 0.15 a | <0.001 |

| Protein (g/100 g) | 5.66 ± 0.15 b | 6.54 ± 0.28 a | 5.05 ± 0.16 c | <0.001 |

| Carbohydrates (g/100 g) | 47.13 ± 1.21 b | 53.17 ± 1.76 a | 53.27 ± 1.65 a | 0.005 |

| Sodium (g/100 g) | 0.30 ± 0.02 | 0.36 ± 0.02 | 0.36 ± 0.04 | 0.070 |

| Potassium (g/100 g) | 0.20 ± 0.01 c | 0.32 ± 0.01 b | 0.36 ± 0.01 a | <0.001 |

| Microorganisms | CTR | RW | FRW | p | Whey |

|---|---|---|---|---|---|

| Mesophilic | 7.74 ± 0.27 | 7.64 ± 0.00 | 7.23 ± 0.08 | 0.086 | 3.15 ± 0.07 |

| Molds and Yeasts | 8.66 ± 0.08 | 8.59 ± 0.03 | 8.03 ± 0.10 | 0.650 | ----- |

| LAB | 7.74 ± 0.15 | 7.57 ± 0.13 | 7.29 ± 0.05 | 0.075 | ----- |

| Domains | Descriptors | CTR | RW | FRW | p |

|---|---|---|---|---|---|

| Crust | Color | 3.2 ± 1.3 a | 3.6 ± 0.7 a | 4.7 ± 0.5 b | 0.001 |

| Hardness | 4.7 ± 0.5 a | 2.2 ± 0.9 a | 4.7± 0.6 b | <0.001 | |

| Roughness | 4.0 ± 0.9 a | 2.9 ± 1.1 a,b | 3.3 ± 0.9 b | 0.044 | |

| Crumb | Color | 2.9 ± 1.0 a,b | 2.0 ± 0.8 a | 3.6 ± 1.3 b | 0.006 |

| Hardness | 2.7 ± 1.2 a | 2.5 ± 0.9 a | 3.8 ± 0.6 b | 0.007 | |

| Friability | 3.5 ± 0.8 | 2.7 ± 1.2 | 3.1 ± 1.5 | 0.420 | |

| Roughness | 2.5 ± 0.8 | 2.2 ± 0.8 | 1.9 ± 1.1 | 0.367 | |

| Density | 2.7 ± 1.0 | 2.6 ± 1.0 | 3.5 ± 1.3 | 0.142 | |

| Porosity | 4.0 ± 0.8 a | 2.6 ± 0.7 b | 1.9 ± 0.8 b | <0.001 | |

| Aroma | Yeast | 3.1 ± 1.0 | 2.7 ± 0.8 | 2.3 ± 1.0 | 0.073 |

| Toasted | 2.1 ± 1.1 | 2.3 ± 1.2 | 3.0 ± 1.1 | 0.089 | |

| Flour | 2.2 ± 1.2 | 2.5 ± 1.0 | 2.6 ± 1.0 | 0.715 | |

| Cereal | 2.7 ± 0.9 | 3.4 ± 0.9 | 3.2 ± 0.8 | 0.169 | |

| Lactic | 1.7 ± 0.6 | 2.0 ± 0.8 | 1.5 ± 0.7 | 0.329 | |

| Flavor | Moisture | 2.5 ± 1.0 | 3.1 ± 1.2 | 2.9 ± 1.1 | 0.543 |

| Hardness | 4.0 ± 1.0 a | 2.5 ± 0.7 b | 4.0 ± 1.3 a | 0.002 | |

| Sweet | 2.0 ± 1.1 | 2.4 ± 1.1 | 2.6 ± 1.4 | 0.497 | |

| Salty | 2.1 ± 0.7 | 2.5 ± 0.8 | 2.0 ± 1.1 | 0.378 | |

| Acidic | 1.7 ± 0.8 | 1.9 ± 1.0 | 1.9 ± 1.1 | 0.959 | |

| Astringent | 2.1 ± 1.0 | 1.5 ± 0.7 | 1.7 ± 1.0 | 0.313 | |

| Cereal | 3.0 ± 1.1 | 2.7 ± 1.1 | 3.4 ± 1.0 | 0.362 | |

| Toasted | 3.2 ± 1.3 a,b | 2.6 ± 1.2 a | 4.0 ± 0.9 b | 0.028 | |

| Aftertaste | Sweet | 2.1 ± 1.2 | 2.5 ± 0.9 | 2.6 ± 1.3 | 0.534 |

| Acidic | 1.9 ± 0.9 | 1.6 ± 0.7 | 1.8 ± 1.1 | 0.829 | |

| Cereal | 2.7 ± 1.1 | 2.8 ± 1.2 | 3.1 ± 1.1 | 0.743 | |

| Toasted | 3.4 ± 1.2 | 2.4 ± 1.4 | 3.6 ± 1.0 | 0.060 |

| Scale | Appearance | Aroma | Flavor | Texture | Overall Liking |

|---|---|---|---|---|---|

| 1 | 0% | 0% | 0% | 0% | 0% |

| 2 | 0% | 5% | 5% | 8% | 0% |

| 3 | 9% | 15% | 11% | 13% | 7% |

| 4 | 56% | 50% | 48% | 44% | 63% |

| 5 | 35% | 31% | 37% | 35% | 29% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moura-Alves, M.; Mota, J.; Lameirão, D.; Teixeira, A.F.; Saraiva, C.; Romero-Rodríguez, M.Á.; Vilela, A.; Gonçalves, C. Multidimensional Evaluation of Local Rye Bread Fortified with Whey as a Model for Food Waste Valorization: From Recipe Development to Consumer Acceptance. Sustainability 2025, 17, 6710. https://doi.org/10.3390/su17156710

Moura-Alves M, Mota J, Lameirão D, Teixeira AF, Saraiva C, Romero-Rodríguez MÁ, Vilela A, Gonçalves C. Multidimensional Evaluation of Local Rye Bread Fortified with Whey as a Model for Food Waste Valorization: From Recipe Development to Consumer Acceptance. Sustainability. 2025; 17(15):6710. https://doi.org/10.3390/su17156710

Chicago/Turabian StyleMoura-Alves, Márcio, João Mota, Diogo Lameirão, Ana Francisca Teixeira, Cristina Saraiva, María Ángeles Romero-Rodríguez, Alice Vilela, and Carla Gonçalves. 2025. "Multidimensional Evaluation of Local Rye Bread Fortified with Whey as a Model for Food Waste Valorization: From Recipe Development to Consumer Acceptance" Sustainability 17, no. 15: 6710. https://doi.org/10.3390/su17156710

APA StyleMoura-Alves, M., Mota, J., Lameirão, D., Teixeira, A. F., Saraiva, C., Romero-Rodríguez, M. Á., Vilela, A., & Gonçalves, C. (2025). Multidimensional Evaluation of Local Rye Bread Fortified with Whey as a Model for Food Waste Valorization: From Recipe Development to Consumer Acceptance. Sustainability, 17(15), 6710. https://doi.org/10.3390/su17156710