1. Introduction

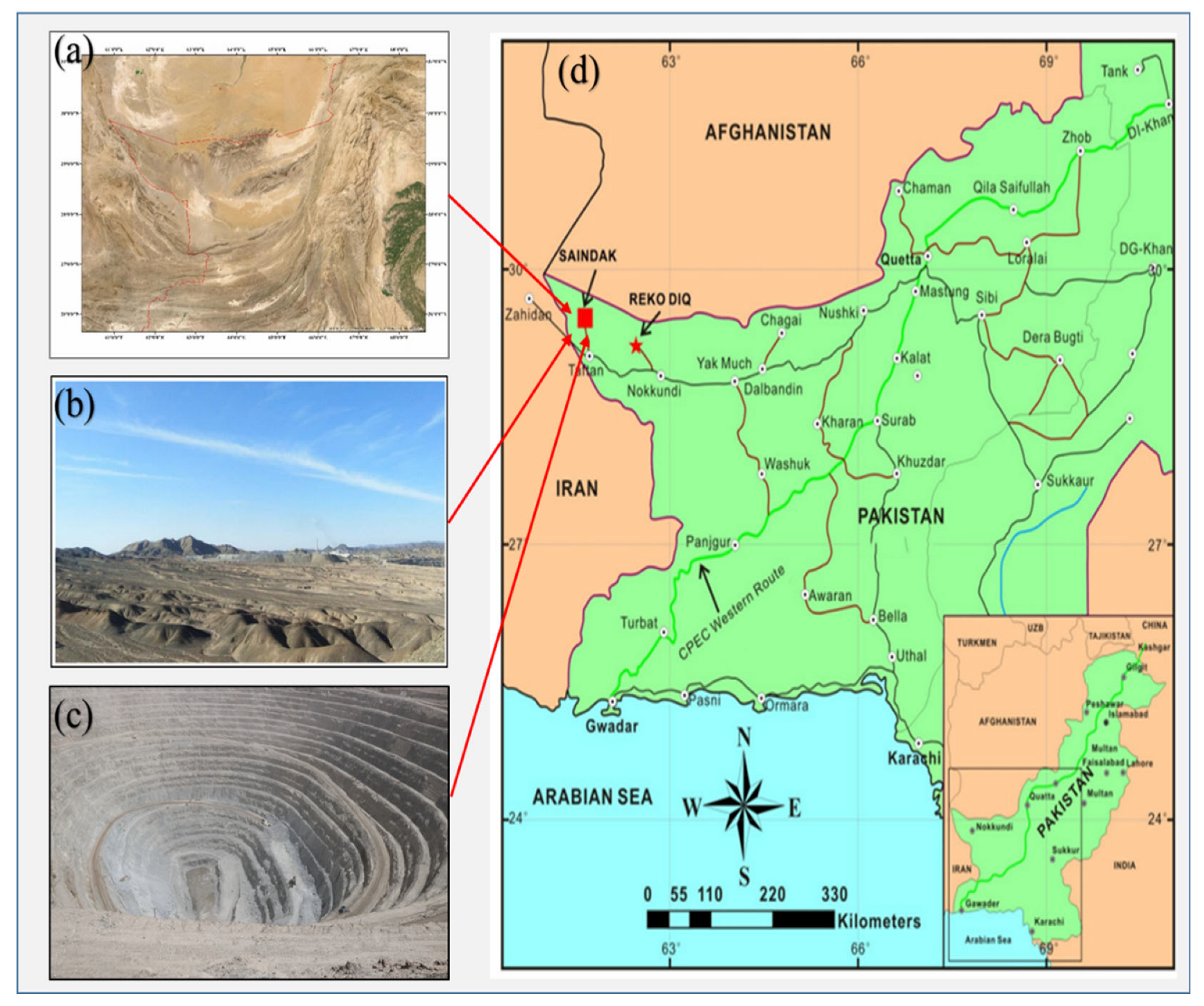

Blasting is widely recognized as one of the most effective and economical techniques for rock fragmentation and excavation in open-pit mining operations [

1,

2]. However, only approximately one-third of the explosive energy contributes to rock breakage, while the remaining energy is utilized as undesirable effects such as blast-induced ground vibration, backbreak, fly rock, noise, and airblast [

3,

4]. Among these, blast-induced ground vibration is particularly hazardous due to its potential to compromise the structural integrity of nearby infrastructure through ground wave-induced vibrations [

5]. The most commonly used parameter for quantifying blast-induced vibration is PPV, used to define permissible vibration limits based on the resonance characteristics of nearby structures and materials [

6]. To control blast-induced vibration, it is essential to determine the maximum charge per delay, typically by conducting a series of blasts and applying scaled distance equations. PPV is directly influenced by the maximum charge per delay and inversely related to the distance between the blast site and the monitoring point [

7]. Ultimately, the goal of blast-induced ground vibration assessment is to evaluate its impact on slope stability and nearby structures, thereby ensuring operational safety. This assessment depends on site-specific conditions, including the proximity of critical infrastructure. Open-pit slope stability is influenced by several factors such as the number of blast holes, hole diameter and depth, burden, spacing, explosive type and quantity, initiation pattern, delay timing, and the mechanical properties of the rock mass. While many studies have drawn parallels between blast vibrations and earthquake-induced seismic waves, it is important to note that blasting events are short lived yet repetitive, making their cumulative impact on slope stability significant [

8,

9].

The repetitive nature of production blasting exposes slopes to recurring dynamic loads, which must not be overlooked. Seismic or dynamic loading is a major contributor to slope instability and remains one of the most challenging issues in deep open-pit mining. There is ongoing debate among researchers regarding the most reliable methods for assessing slope stability under such dynamic conditions [

10]. Ignoring these effects can result in inaccurate evaluations and potential slope failures. Therefore, the proper evaluation and monitoring of blast-induced ground vibrations are crucial to maintaining slope stability and reducing the risk of accidents [

11]. Addressing these concerns is essential for the safe and efficient operation of open-pit mines. To assess the impact of blasting vibrations on slope stability, numerous studies have aimed to measure and mitigate the effects of these vibrations on rock slopes [

12,

13]. Bazzi et al. [

14] used a dynamic finite element method to analyze the effect of blasting vibrations on a faulted mine by evaluating acceleration-time waveforms. Similarly, Koo et al. [

15] assessed the stability of a soil slope subjected to blast-induced ground vibrations using a pseudo-static approach based on recorded PPV values. In the case of the Yejiagou Boron Iron Mine, Zhang et al. [

16] utilized GEOSLOPE (version 2012) and FLAC3D software (version 5.0) to simulate slope failure, while Li et al. [

17] analyzed the stability of steeply inclined layered carbonate rock, taking into account the presence of an underground goaf—a mined-out area left after the extraction of minerals, which can significantly affect rock mass stability.

Additionally, slope instability under strong earthquake-induced dynamic loading has been studied by Alimohammadlou et al. [

18] and Zhou et al. [

19]. Yilmaz and Unlu [

20] examined the effect of anisotropic in situ stresses and loading rates on damage zone behavior under seismic loads. The influence of blasting vibration parameters on slope stability was also explored by Wu et al. [

21], aiming to control and evaluate vibration effects during blasting. In another case, Jiang et al. [

22] investigated the effects of underground mining-induced vibrations at the Gol-E-Gohar Iron Mine using waveform superposition and UDEC software (version 6.0) to analyze single-hole blasting vibrations. Slope stability analysis can be carried out using static or dynamic approaches through either analytical or numerical methods to identify potential failure mechanisms [

23]. It is a crucial aspect of geotechnical engineering, particularly in hard rock excavation. Soren et al. [

24] emphasized the need for slope stability assessment during mine excavation, as openings can lead to instability. Marquez [

25] noted that slope stability has remained one of the most active areas of research in geotechnical engineering.

Over the past two decades, researchers have employed a variety of numerical and computational methods, including the LEM and the finite element method (FEM), to analyze slope behavior under different conditions [

26,

27]. Among these, LEM is the most widely used method in geotechnical engineering due to its simplicity, speed, and low computational complexity [

28,

29]. It evaluates the stability of a potential sliding mass by dividing it into slices and applying static or dynamic force/moment equilibrium principles. If the system reaches force closure, the slope is considered stable; otherwise, instability is inferred [

30]. LEM typically assumes the rock or soil behaves as a plastic material and computes the safety factor under both static and dynamic conditions [

31]. Although LEM treats seismic forces as time-independent inertial loads, in reality, seismic wave propagation is both time and space dependent [

30]. Nonetheless, LEM remains popular due to its adaptability, integration with advanced modeling tools, and ability to produce key outputs such as the factor of safety and potential slip surfaces.

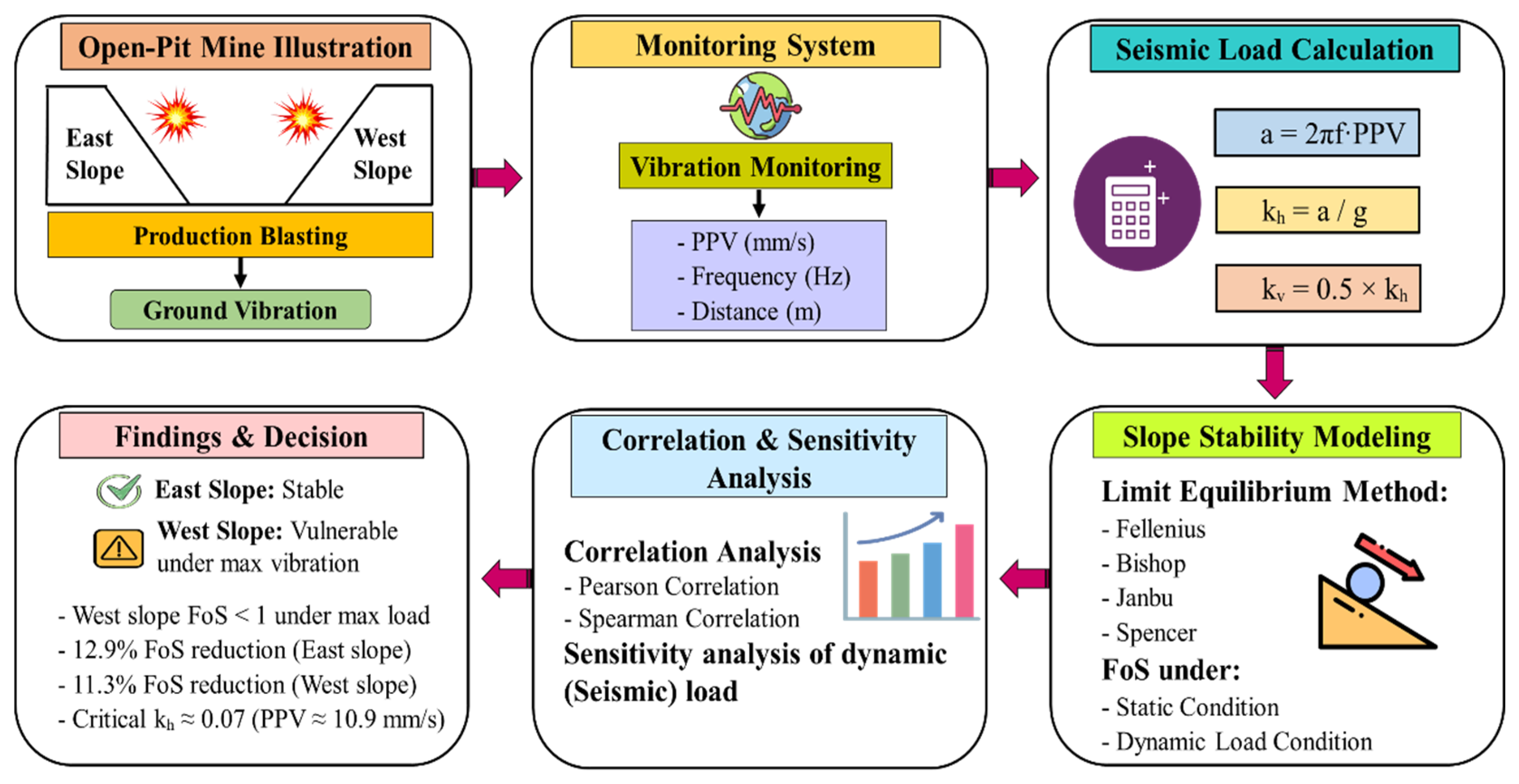

Although numerous studies have examined the impact of blasting on slope stability, many rely on assumed seismic inputs or simplified site conditions. There remains a significant gap in field-based research that integrates real-time ground vibration monitoring with numerical slope stability modeling, particularly in operational mine environments. This study addresses that gap by utilizing the actual field-monitored blast-induced ground vibration data to evaluate slope behavior at the dynamically sensitive and operationally complex Saindak Copper-Gold Open-Pit Mine. Both east and west pit slopes were assessed under static and dynamic loading conditions using the LEM, with particular emphasis on calculating the factor of safety (FoS), a key indicator of the balance between resisting and driving forces within a slope system. To investigate the influence of blasting parameters on FoS, both Pearson and Spearman correlation analyses were performed using OriginPro software (version 2022). Key input variables such as S, B, SL, and MCPD were examined to evaluate both linear and non-linear relationships with FoS of slope stability. This dual-approach correlation allowed for a robust statistical interpretation of how different blasting parameters affect the geotechnical response of pit slopes.

In addition, a sensitivity analysis was carried out to assess the effects of dynamic loading, specifically, blast-induced ground vibrations on slope stability by systematically varying the PPV and its corresponding horizontal seismic coefficient (kh). The analysis aimed to determine the cumulative distribution of slope failure and dynamic response frequency associated with increasing seismic load intensities. The primary objective was to identify how varying levels of ground motion influence failure probability and potential instability. Overall, this study contributes to sustainable blasting practices in seismically active mining zones by providing a field-based framework for assessing vibration-induced slope instability. It also highlights critical vibration thresholds that may compromise slope stability, thereby informing safer, more resilient, and sustainable mine operations.

3. Materials and Methods

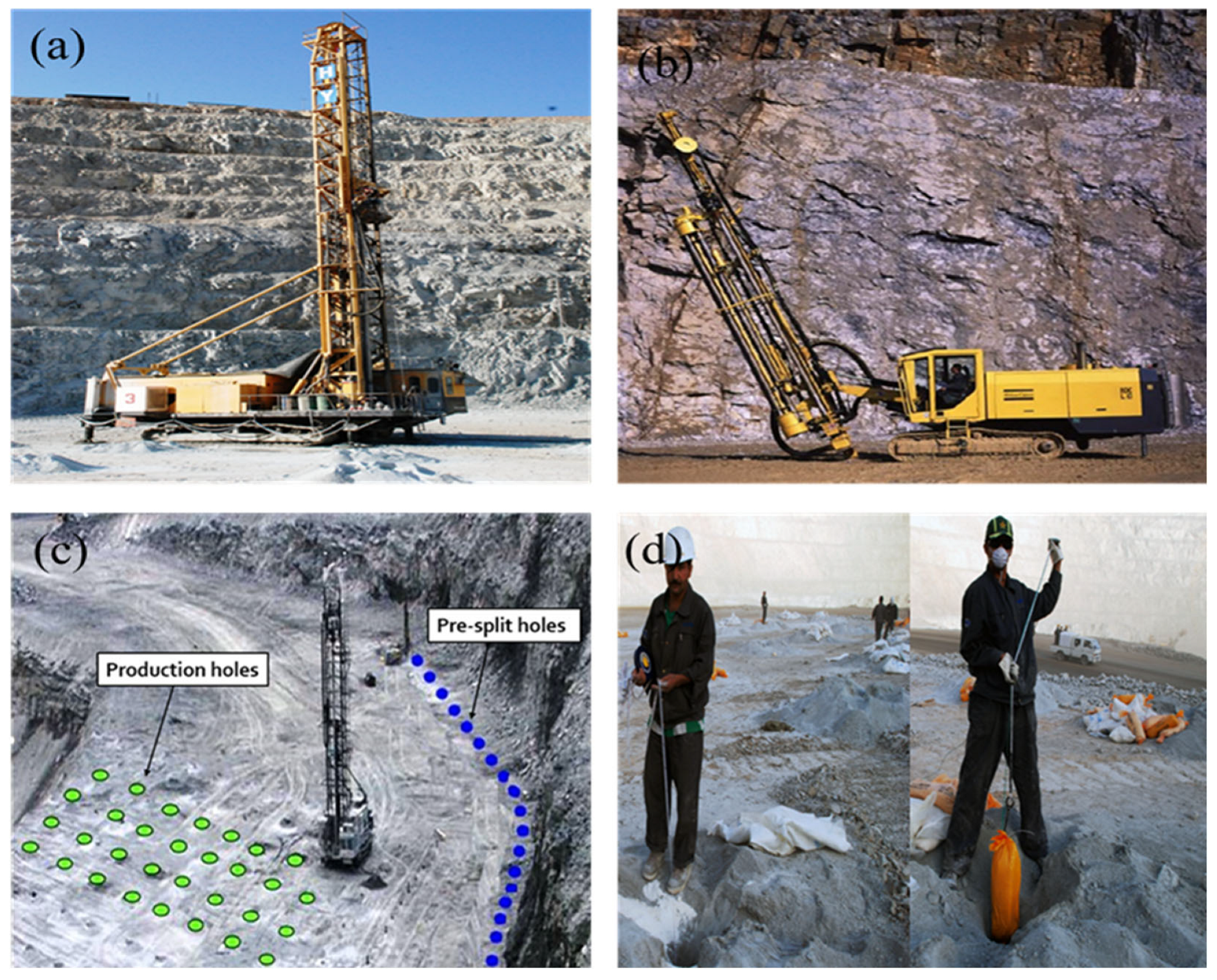

3.1. Blast-Induced Ground Vibration Monitoring Data

For this study, blasting data were collected from the Saindak Copper-Gold Open-Pit Mine in Pakistan. To assess the impact of blast-induced ground vibrations on slope stability, a total of ten blasting events were analyzed, five from the east slope and five from the west slope. Key blasting geometry parameters, including blast point location, blast hole diameter (mm), blast hole depth (mm), spacing (m), burden (m), stemming length (m), maximum charge per delay (kg), and distance from the blast point (m), were recorded. The average values of these parameters are presented in

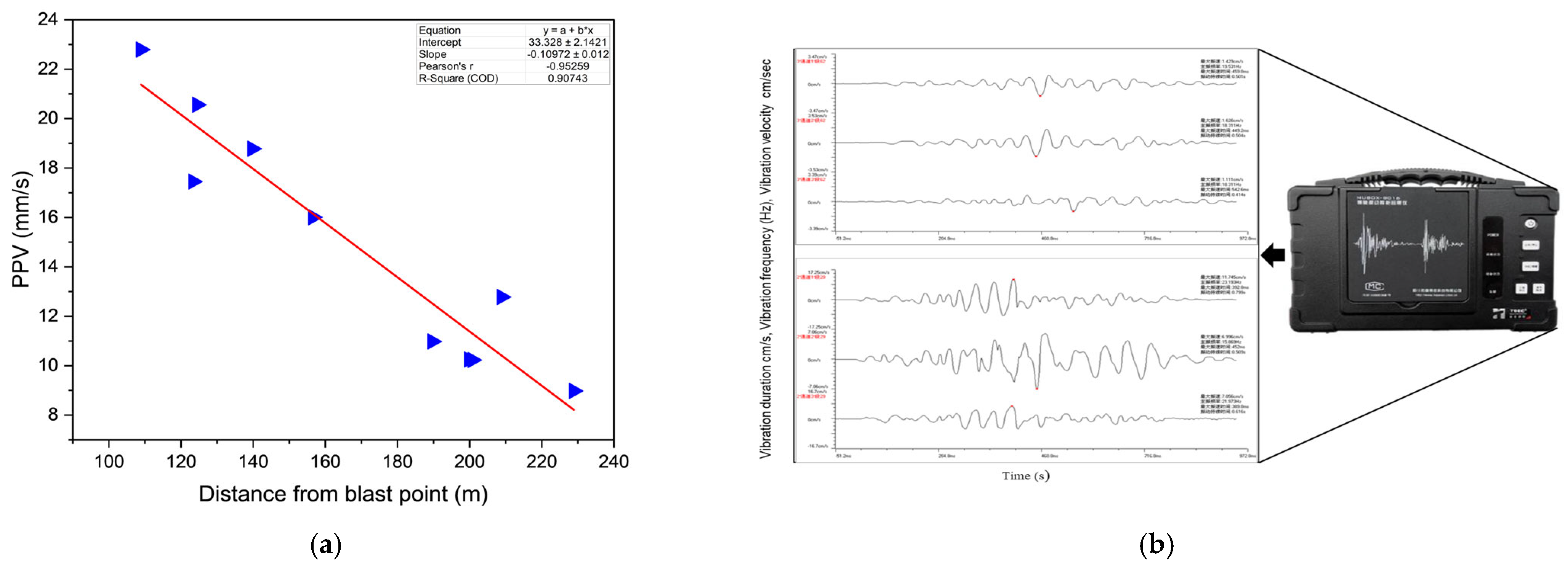

Table 1. Ground vibration data were measured in terms of PPV, frequency, duration, and vibration velocity. PPV values, initially recorded in mm/sec, were converted to m/sec using standard conversion formulas for simulation. All parameters for each blast event were compiled into a structured dataset for subsequent analysis. Additional slope-specific geotechnical parameters, such as volumetric weight, elastic modulus, Poisson’s ratio, cohesion, and internal friction angle, were obtained from the technical department. However, the laboratory testing was also conducted for cross-validation of these parameters. The equipment used for blast vibration monitoring is shown in

Figure 4.

The NUBOX-8016 vibration monitoring system also called intelligent vibration measuring instrument produced by a Chinese company SCTPCKKJ (Chengdu, China) was used to record blast-induced ground vibrations. One unit was installed on the east slope, with two additional sensors positioned near the northern and eastern toes of the pit. These were connected to a TP3V-4.5 three-dimensional velocity-type sensor via a specialized input signal cable. The sensor measured ground vibration magnitudes in three orthogonal directions. Historical monitoring records were provided by the site’s blasting vibration monitoring team.

Table 2 summarizes the complete range of vibration parameters recorded during the ten blast events, which served as critical input for evaluating the dynamic effects of blasting on the slope’s FoS. Detailed blasting design data collected for each event were crucial in understanding explosive energy distribution and its correlation with vibration characteristics, particularly PPV, frequency, and the resulting seismic coefficients used in dynamic slope stability assessments.

Figure 4a shows the linear regression fit between the actual blast-induced ground vibration PPV and the corresponding distances from the blast site, while

Figure 4b displays a photograph of the NUBOX-8016 vibration monitoring equipment used for measuring blast-induced ground vibrations.

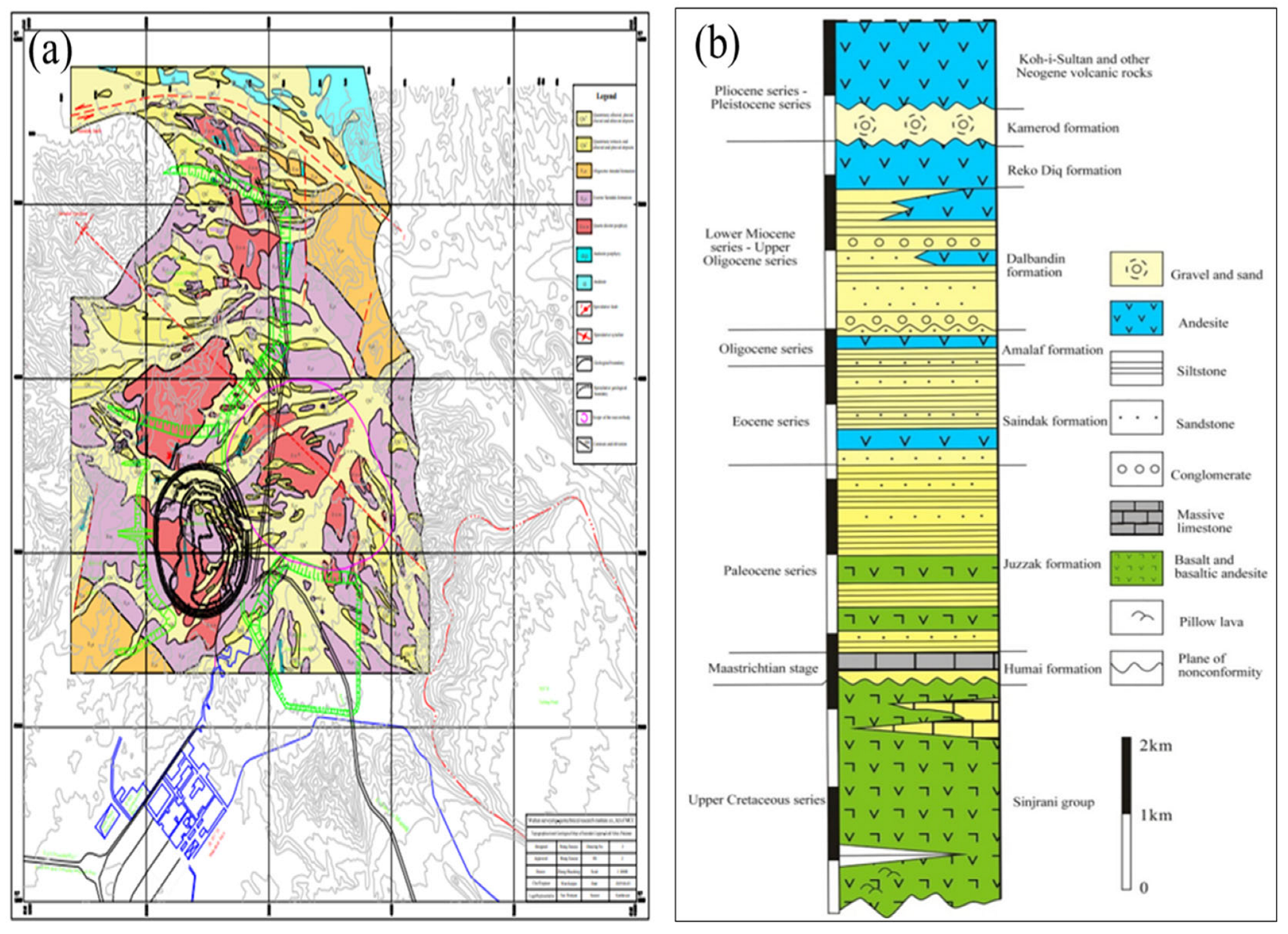

3.2. Slope Geometry and Material Assignment

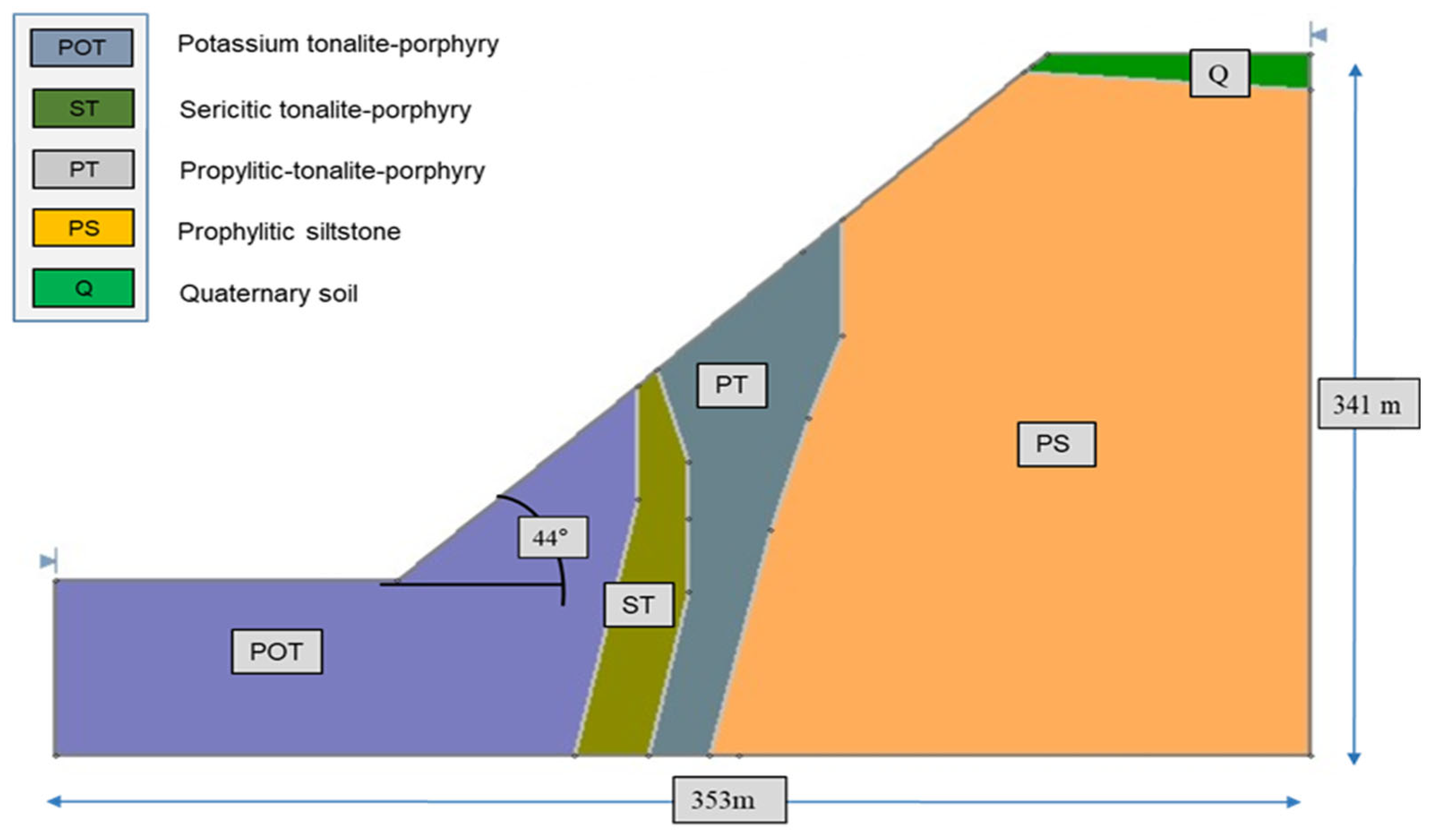

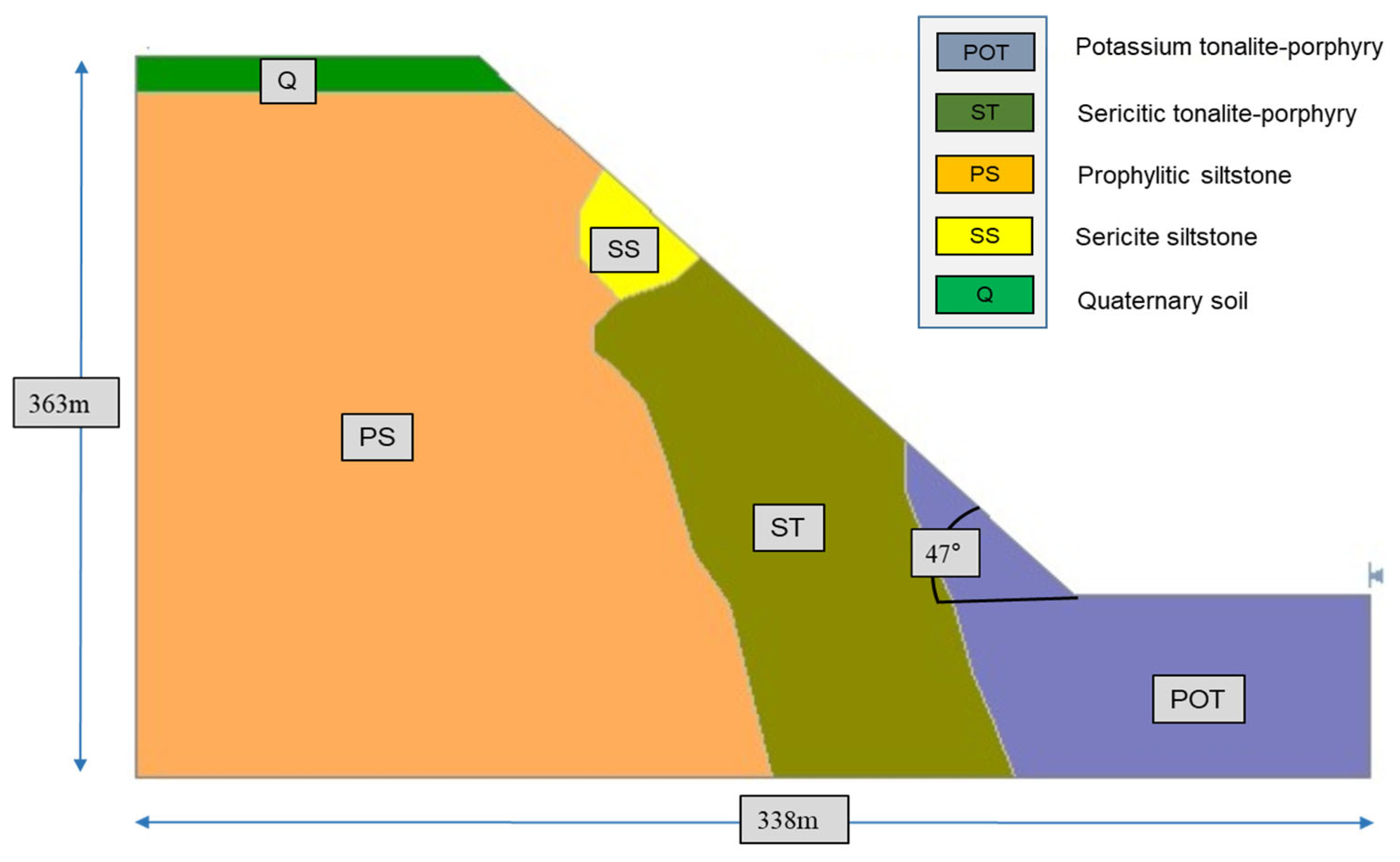

In this case study, two slopes, namely east and west of the south ore body at the Saindak Copper-Gold Mine, were selected for slope stability analysis under both static and dynamic loading conditions. Accurately defining slope geometry is essential for conducting a detailed stability assessment, as geometric parameters directly influence stress distribution, potential failure mechanisms, and overall slope behavior. Accordingly, both slopes were thoroughly surveyed during field investigations. The pit bottom lies at an elevation of approximately 950 m, with the vertical height of the east slope measuring 341 m and the west slope 363 m. The base length of the east slope is 353 m, while that of the west slope is 338 m. The overall slope lengths are 491 m for the east and 496 m for the west. The east slope consists of 28 benches, and the west slope comprises 30 benches. Each bench has an average height of 12 m; however, in the final pit stage, two working benches were merged to create a wider haul road or ramp for accommodating large-diameter mining equipment. The dominant rock types within both slopes include andesite, limestone, and faulted breccia zones. The primary engineering geological formations observed are Quaternary loose soil, Propylitic Siltstone, Sericite Siltstone, Potassium Siltstone, Propylitic-Tonalite-Porphyry, Sericitic-Tonalite-Porphyry, and Potassium-Tonalite-Porphyry. The slopes were divided into discrete material zones based on lithological classification. Each zone was assigned geotechnical properties, including unit weight (kN/m3), cohesion (kPa), internal friction angle (°), elastic modulus (GPa), and Poisson’s ratio. These parameters were obtained from geological records and further validated through laboratory testing.

Slope profiles were developed based on detailed field surveys. While the engineering properties of both slopes are broadly similar, minor differences exist in the lithological composition. These two slopes were selected for detailed analysis due to their increased susceptibility to potential failure. The rock mass in the area is generally strong and massive, exhibiting high internal strength. Overall slope angles range from 44° to 47°, with the east slope averaging 44° and the west slope 47°, depending on bench geometry and rock type. This geometric profile was modeled in SLIDE2 (version 6.0) to evaluate the FoS under different loading conditions and to assess the risk of slope failure induced by blasting operations.

3.3. Slope Stability Analysis Using SLIDE Software

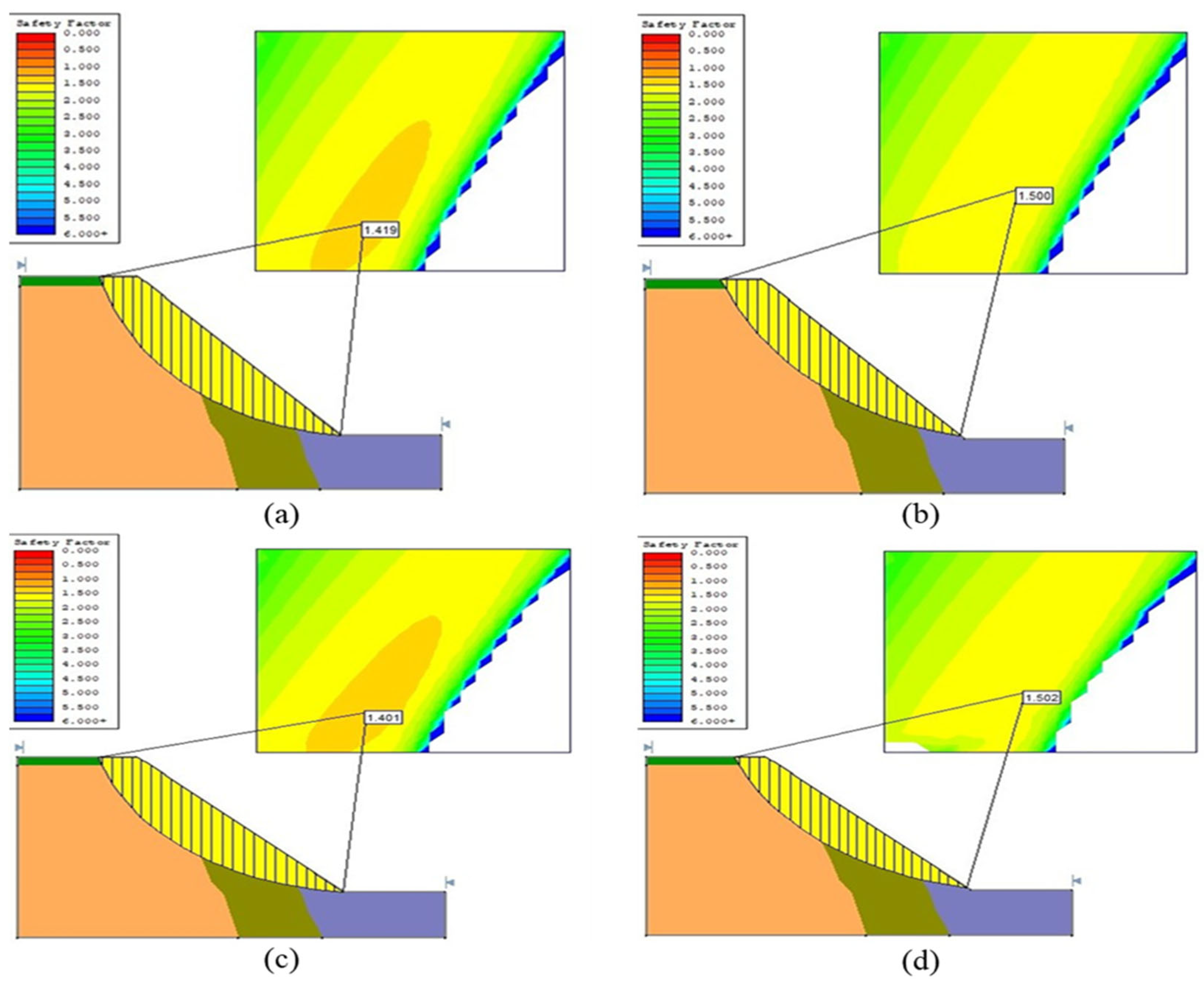

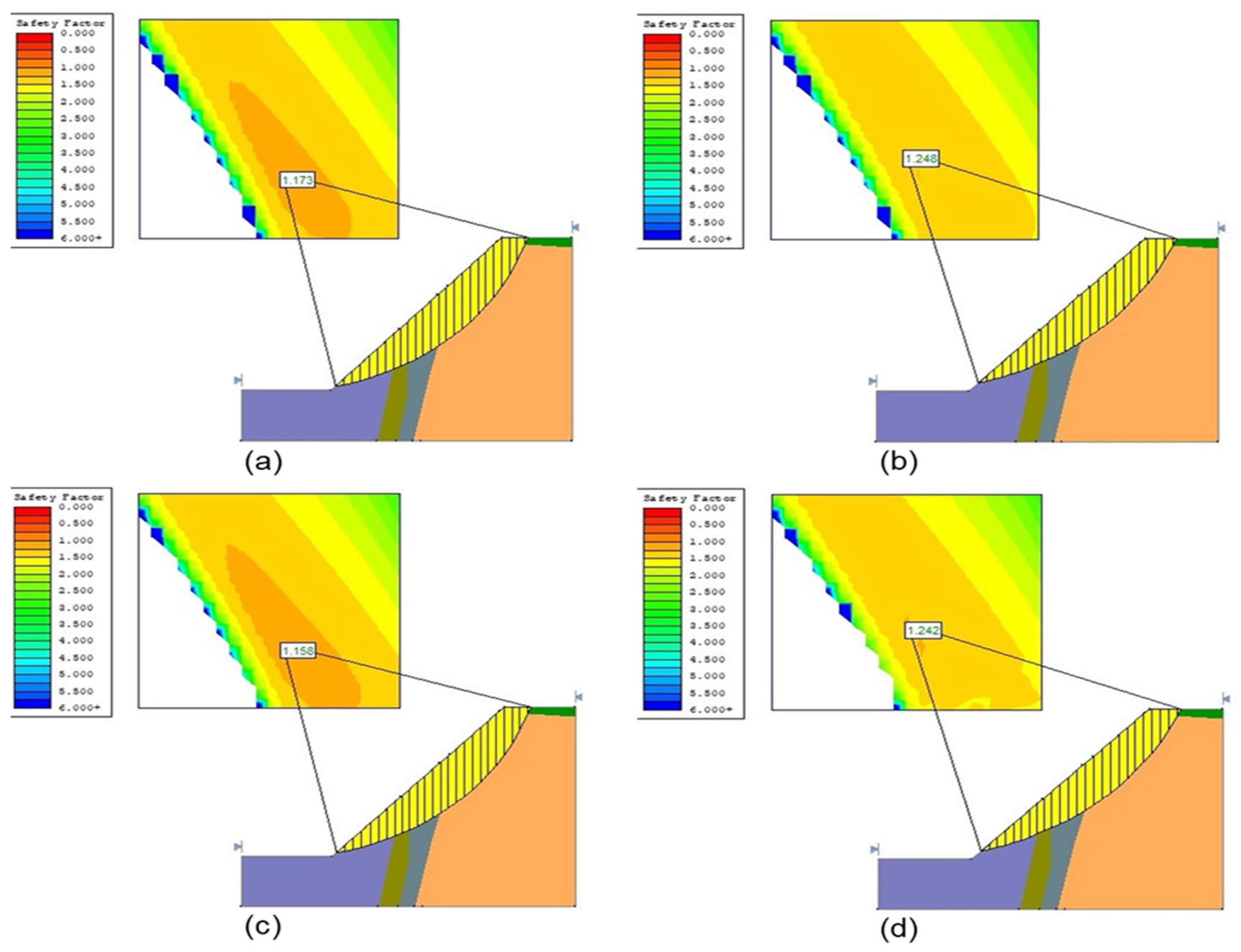

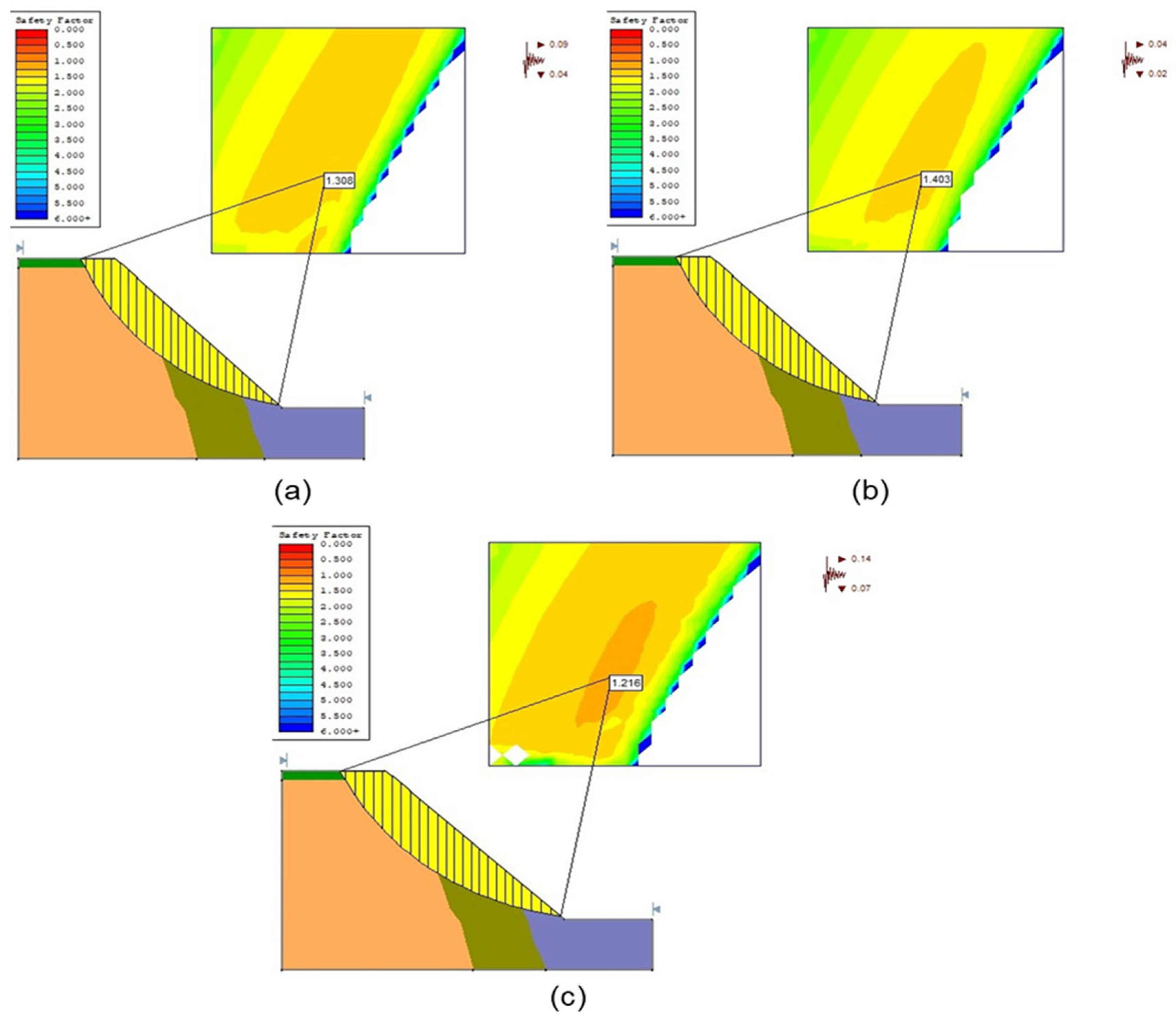

This section outlines the methodology used to evaluate slope stability using SLIDE2 version 6.0, a two-dimensional (2D) limit equilibrium software developed by Rocscience. The software was employed to analyze the FoS under both static and dynamic loading conditions, incorporating actual blast-induced ground vibration data to assess its impact on slope performance. Two slopes from the open-pit mine, designated as the east slope and west slope, were selected for analysis based on recommendations from mine officials. These slopes were identified as the most vulnerable to potential failure due to their geometric configuration and exposure to frequent blasting activities. SLIDE 6.0 supports a wide range of LEMs for analyzing both circular and non-circular slip surfaces and allows for detailed modeling of slope geometry, material zoning, pore water pressure, support systems, and external loading, including seismic forces. The analysis employed four widely recognized LEM techniques available in SLIDE: the Fellenius, Bishop Simplified, Janbu Simplified, and Spencer methods. These were initially applied under static conditions to determine the baseline FoS values for both slopes.

To simulate dynamic conditions, seismic loading was introduced using horizontal and vertical seismic coefficients. In line with standard mine safety practices [

37], the vertical component was assumed to be 50% of the horizontal force. The seismic coefficient (K) was calculated using measured ground vibration frequency and gravitational acceleration. The Mohr–Coulomb failure criterion was adopted for all materials, and slope-specific mechanical properties were defined separately for the east and west slopes to account for lithological variability. The modeling process in SLIDE involved several stages, including defining slope geometry, assigning boundary conditions, inputting geotechnical parameters, and incorporating key topographic and geometric features such as slope height, and surface profiles. The geological profile and geometry of the stratified formations along the east and west slopes are illustrated in

Figure 5 and

Figure 6. The external model boundaries were constructed based on field survey data and coordinate measurements. After completing both static and dynamic simulations, FoS values were computed for each method using average, minimum, and maximum ground vibration inputs. The results were compiled and compared for both slopes to quantify the reduction in stability under dynamic conditions.

3.4. The Limit Equilibrium Method

LEM is one of the most widely used and fundamental approaches for slope stability analysis due to its simplicity, low computational complexity, ease of implementation, and fast processing time [

30,

38]. It is effectively applied under both static and dynamic conditions, in two-dimensional and three-dimensional slope geometries, using either block or slice-based analysis techniques. LEM estimates the FoS by evaluating the equilibrium conditions of a potential sliding mass along a predefined failure surface. The method assumes equilibrium by balancing either forces or moments and can handle both circular and non-circular slip surfaces [

39]. Several LEM techniques have been developed, with the most commonly used methods being Fellenius (Ordinary), Bishop Simplified, Janbu Simplified, and Spencer. These approaches typically yield closely matching FoS results, with differences generally less than 6% [

40]. The basic form of the FoS calculation in LEMs is:

A key feature of LEM is its reliance on the Mohr–Coulomb failure criterion to estimate shear strength and resistance along potential failure surfaces. This criterion, based on total or effective stress parameters (cohesion and internal friction angle), is widely regarded as applicable for analyzing slope stability in both soil and rock. In this study, slope stability was evaluated under blast-induced dynamic loading using LEM, assuming a circular failure surface passing through the critical sections of the east and west pit slopes. The Bishop, Janbu, Fellenius, and Spencer methods were employed to calculate the FoS and identify likely failure mechanisms under dynamic conditions [

35].

3.4.1. The Fellenius Method

The Fellenius method, also known as the Ordinary Method of Slices, was introduced in 1927. It is the simplest form of LEM and involves dividing the potential sliding mass into vertical slices [

26]. This method can be used under both static and seismic loading conditions [

41]. The equation for calculating FoS in this method is:

where

W′ represents the effective weight of the sliding mass, typically acting normal to the slope surface.

α is the angle of the base of the potential sliding surface (i.e., the slope angle), while

φ denotes the internal friction angle of the slope material (in degrees). c refers to the cohesion of the material, and

L is the base length of the potential slip surface. The term

stands for the horizontal seismic coefficient, used to represent the dynamic load due to blast-induced ground vibrations. In this equation, the numerator represents the resisting forces contributed by cohesion and friction, whereas the denominator accounts for the driving forces, including gravitational and seismic effects.

3.4.2. The Bishop Simplified Method

The Bishop Simplified method considers interslice normal forces and assumes negligible shear forces between slices. It provides accurate FoS estimates even though it does not fully satisfy all static equilibrium equations [

42,

43]. The FoS is calculated using:

where

ψₚ represents the inclination angle of the base of the sliding slice or failure surface,

μ pore water pressure, and

υ denotes the velocity-related dynamic coefficient. Other symbols as previously defined.

3.4.3. The Janbu Simplified Method

The Janbu method is effective for non-circular failure surfaces. It assumes that normal forces act at the center of the slice base and neglects interslice shear [

44,

45]. The FoS is given by:

where

Nγ describes the bearing capacity factor related to the unit weight of the material

(γ), and

γ unit weight of the soil or rock.

describes the material strength parameters.

3.4.4. The Spencer Method

The Spencer method assumes both force and moment equilibrium and applies a constant ratio between interslice shear and normal forces. It offers high accuracy for both circular and complex non-circular slip surfaces [

46,

47]. The FoS is calculated as:

where

represent the rock strength properties, and

B and

D denote the width and length of the slip surface.

3.5. Seismic Coefficient Calculation

PPV data were collected in the field using vibration monitoring equipment for each blast event, recorded in millimeters per second (mm/s). To compute the corresponding horizontal seismic coefficients

for use in pseudo-static slope stability analysis, the peak particle acceleration (PPA) was first calculated using the formula:

where

f is the dominant vibration frequency (Hz) and PPV is converted to meters per second. The pseudo-static horizontal seismic coefficient

was then obtained as:

where

g = 9.81 m/s

2 is gravitational acceleration. A conservative vertical seismic coefficient

was adopted for the dynamic analysis, assuming it to be half the horizontal seismic coefficient. This approach follows the recommendation by Morales et al. [

48], who demonstrated that such an assumption has minimal impact on stability results under typical seismic conditions. The final calculated dynamic load values for each blast event are presented in

Table 3.

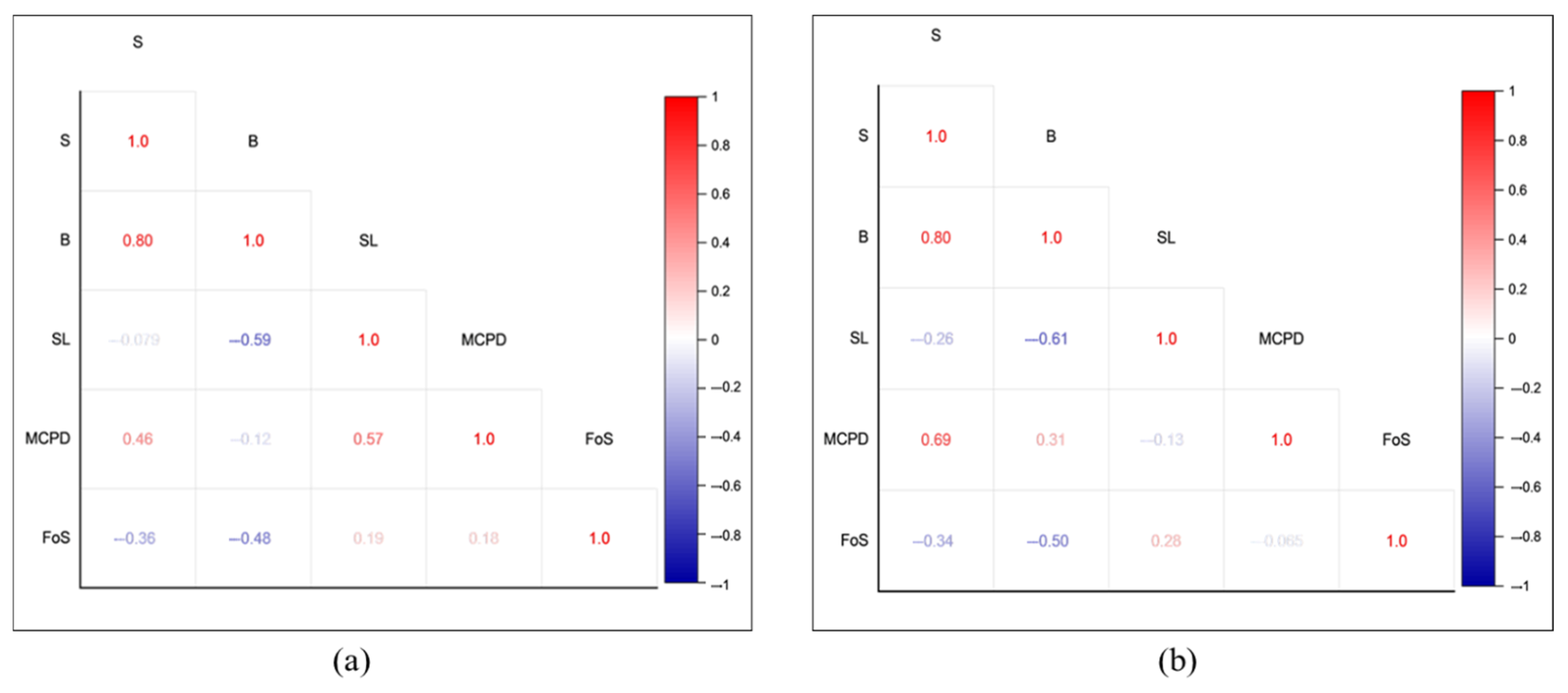

3.6. Correlation Analysis

In this study, two statistical correlation techniques, namely Pearson correlation coefficient (PCC) and Spearman rank correlation coefficient (SCC) were employed to assess the relationship between blasting parameters and slope stability, measured by the FoS. The Pearson correlation coefficient measures the strength and direction of a linear relationship between two continuous variables and is suitable for normally distributed data [

49,

50]. It is defined by the following formula:

where

and

are the individual sample points, and

and

are the mean of variables

x and

y, respectively.

The Spearman rank correlation coefficient is a non-parametric measure that evaluates the monotonic relationship between two variables, without assuming normal distribution or linearity [

51,

52]. It is computed using:

where

is the difference between the ranks of each pair, and n is the number of observations.

These correlation methods were applied to identify both linear and non-linear associations between blasting variables including spacing (S), burden (B), stemming length (SL), maximum charge per delay (MCPD) and the corresponding FoS values. The correlation coefficients range from −1 to +1, where +1 indicates a perfect positive correlation, −1 indicates a perfect negative correlation, 0 implies no correlation. Higher absolute values of the correlation coefficients suggest stronger relationships between the variables. The results help determines whether variations in blasting parameters significantly influence slope stability.

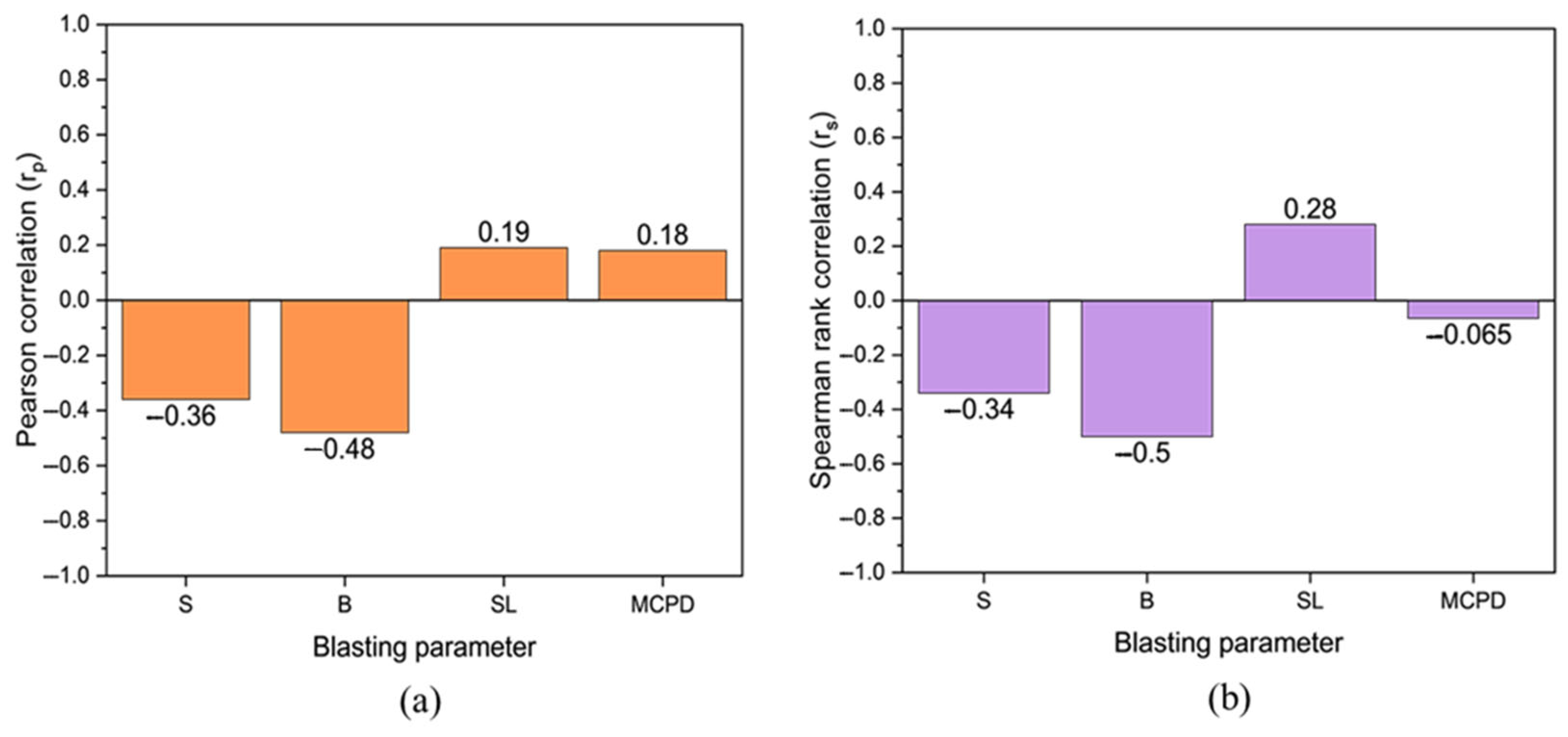

Figure 7 presents the correlation matrix plots for both Pearson and Spearman analyses across all input variables and FoS.

3.7. The Study Workflow and the Methodological Framework

This section outlines the systematic approach adopted in this study to evaluate the effects of blasting-induced ground vibrations on slope stability. The workflow integrates field data collection, laboratory testing (validation), numerical modeling, correlation, and statistical analysis to assess the FoS under both static and dynamic conditions. A step-by-step methodology was developed, as illustrated in

Figure 8, to ensure consistency and reliability in the analysis. This framework serves as the basis for all subsequent modeling, correlation, and sensitivity evaluations discussed in later sections.

5. Conclusions

Blasting is a widely adopted and cost-effective technique for rock fragmentation and excavation in open-pit mining. However, uncontrolled or poorly executed blasting operations can produce excessive ground vibrations, which may compromise slope stability and pose risks to nearby infrastructure, equipment, and personnel. Therefore, evaluating the impact of blast-induced ground vibrations on slope stability is essential for ensuring safe and sustainable mining operations. This study presents a comprehensive field investigation conducted at the Saindak Copper-Gold Open-Pit Mine in Pakistan, focusing on slope performance under both static and dynamic (pseudo-static) loading conditions. The investigation incorporated detailed field data, including pit geometry, lithological characteristics, blast design parameters, and ground vibration records. Laboratory testing was conducted on rock samples to validate the geomechanical properties used in the analysis. Slope stability was assessed using SLIDE2 6.0 software, and the influence of key blasting parameters on slope behavior was quantified using both Pearson and Spearman correlation analyses. Four standard limit equilibrium methods (LEMs)—Fellenius, Bishop, Janbu, and Spencer, based on the Mohr–Coulomb failure criterion, were employed to evaluate the FoS under varying load scenarios. Additionally, a sensitivity analysis was performed to determine the cumulative distribution of slope failure and dynamic response frequency under increasing seismic loads. The key findings and recommendations derived from this analysis are summarized below:

All the blasting geometry parameters, including spacing, burden, stemming length, charge per delay, and distance from the blast point, were incorporated into the analysis. The average recorded ground vibration values were: PPV = 14.88 mm/s, frequency = 9.43 Hz, duration = 1.51 s, and vibration velocity = 14.29 mm/s.

Field investigations revealed that the pit slopes are primarily composed of moderate to strong rock types, such as Propylitic Siltstone, Sericite Siltstone, Potassium Siltstone, and various Tonalite-Porphyry formations, with a thin Quaternary layer at the surface. These materials exhibit moderate to high strength, contributing to overall slope stability.

Under static conditions, both the east and west slopes exhibited stable behavior, with all FoS values exceeding 1.0. The east slope showed slightly higher stability, with FoS ranging from 1.401 to 1.502, compared to 1.158 to 1.242 for the west slope primarily due to a lower average slope angle (44° vs. 47°).

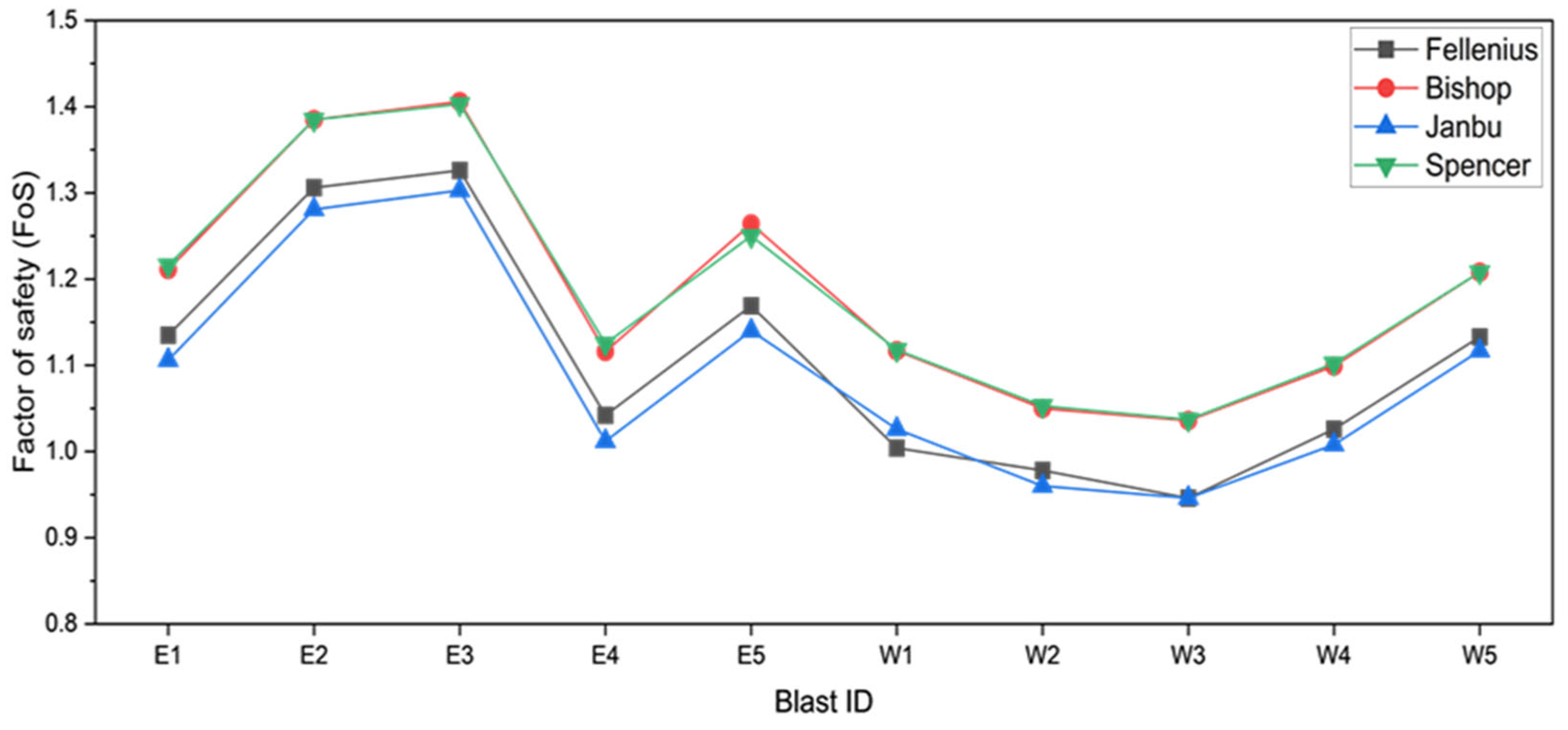

Under average blast-induced dynamic loading, both slopes remained stable (FoS > 1). However, under maximum seismic loading, the west slope became potentially unstable, with FoS values falling below 1.0 in the Janbu and Fellenius methods only with values of 0.961 and 0.979, respectively. The Spencer method consistently produced the highest FoS under dynamic conditions (1.308 for east, 1.102 for west), confirming its robustness in seismic analysis. Slope angle was found to be a significant factor in stability performance. Dynamic loading resulted in a reduction in FoS by approximately 12.9% for the east slope and 11.3% for the west slope, emphasizing the need for slope angle optimization in design phases.

Correlation analysis revealed that stemming length (SL) positively influences slope stability, while burden (B) and spacing (S) are negatively correlated with the FoS. Among all parameters, burden showed the strongest negative impact on FoS, identifying it as a critical factor in blast-induced slope vulnerability. Among all parameters, burden showed the strongest negative effect on FoS, identifying it as a critical factor in blast-induced slope vulnerability.

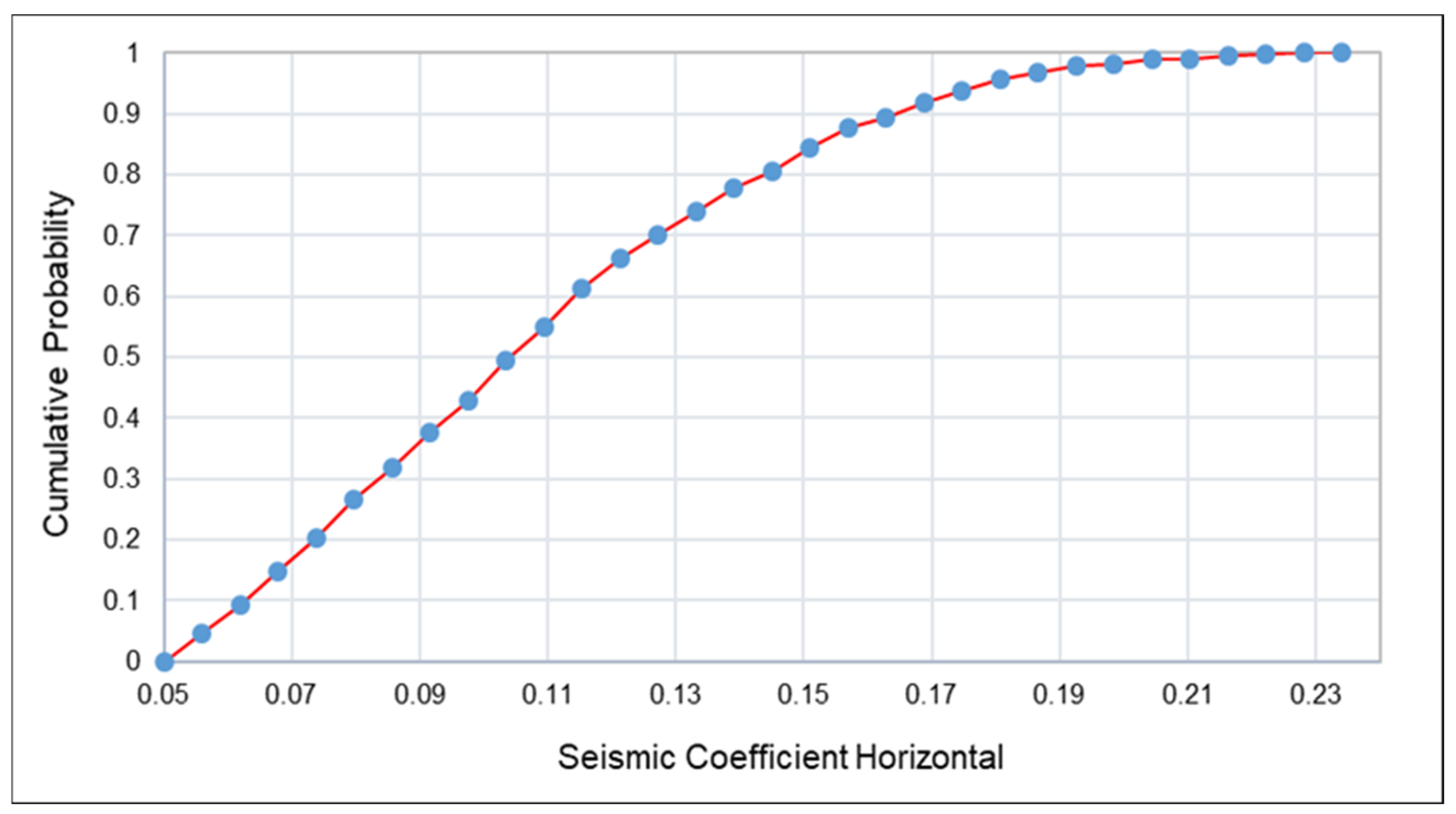

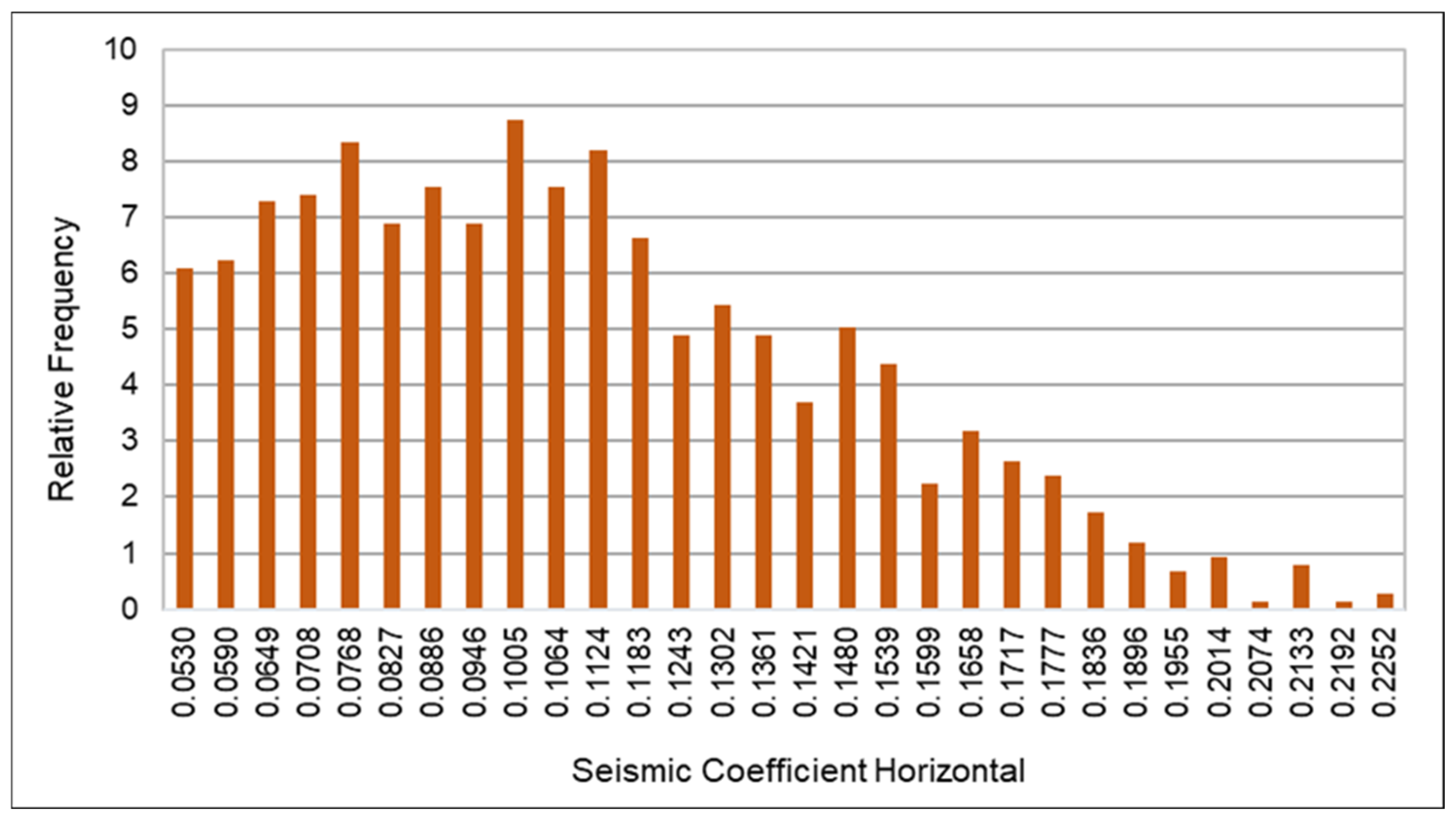

Sensitivity analysis further revealed that slope stability deteriorates rapidly when the horizontal seismic coefficient (kₕ) exceeds 0.07, corresponding to a PPV of approximately 10.9 mm/s within a vibration frequency range of 8.76 to 9.31 Hz. These thresholds represent critical design limits for ensuring safe blasting operations and informing future vibration control strategies. This underscores the importance of precisely managing blasting parameters, particularly the maximum charge per delay, to prevent exceeding critical vibration levels, especially on the more sensitive west slope.

While this study provides valuable insights into slope behavior under blast-induced dynamic loads using field-monitored data and multiple LEM techniques, it employs a pseudo-static approach that simplifies the transient nature of blasting. The use of two-dimensional models and a limited dataset may not fully capture the three-dimensional complexity and in situ variability of rock mass behavior.

Future research should focus on integrating three-dimensional and time-history dynamic modeling to more accurately simulate real blast conditions. Expanding vibration monitoring networks and datasets will enhance predictive capability. Moreover, optimizing blast design in relation to slope geometry and rock mass properties will be essential for minimizing vibration impacts and ensuring long-term slope stability, and promoting sustainability in dynamic environments.