Surface Moisture Control for Sustainable Manure Management: Reducing Ammonia Emissions and Preserving Nutrients

Abstract

1. Introduction

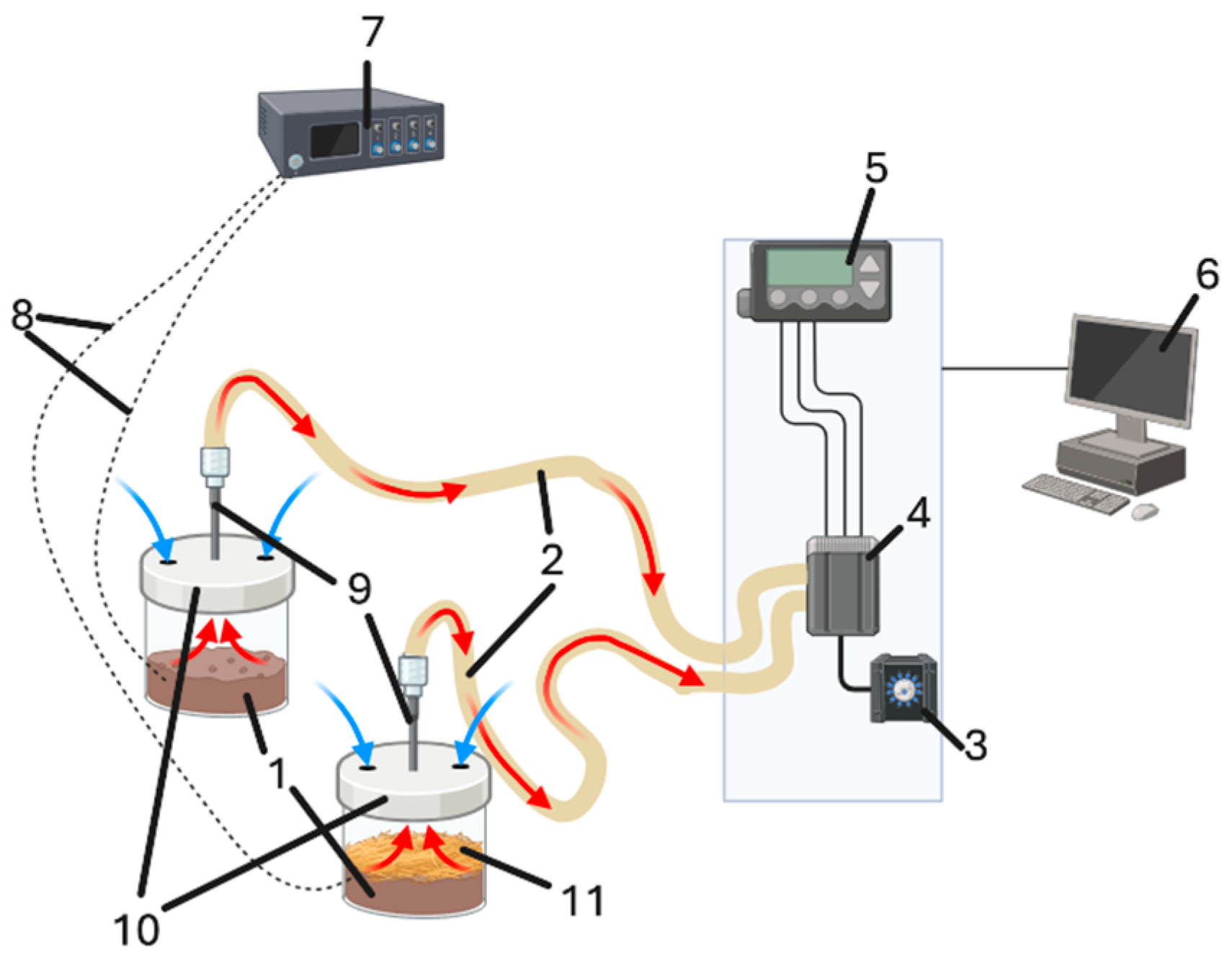

2. Materials and Methods

2.1. Methods

2.2. Cattle Housing System and Diet

2.3. Analysis of Manure Characteristics

2.4. Statistical Analysis

3. Results and Discussion

3.1. The Intensity of NH3 Emissions When Bio-Coatings Are Used

3.2. The Efficacy of Various Bio-Coatings

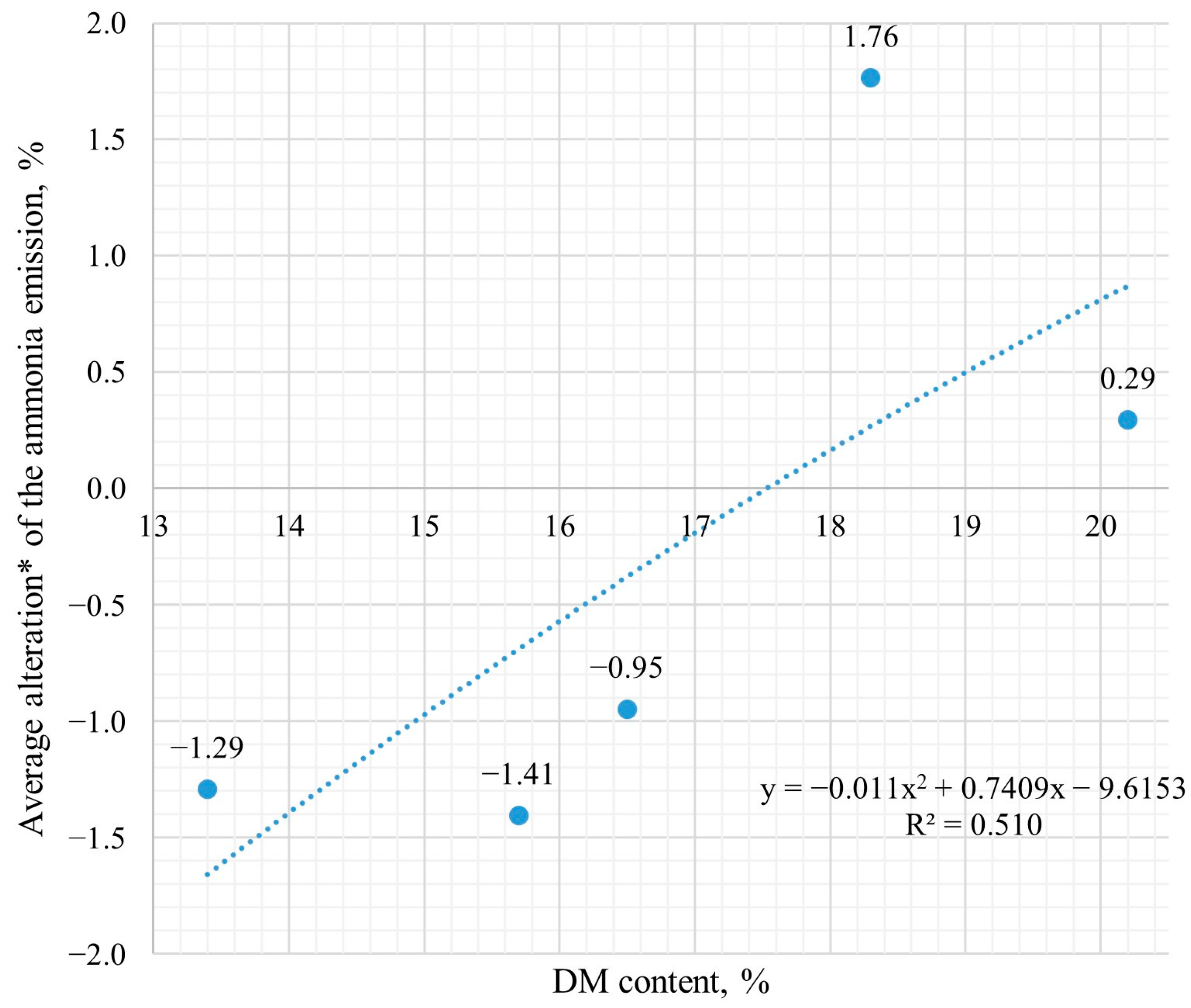

3.3. Impact of Precipitation and DM Content

4. Conclusions and Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DM | Dry matter |

| NH3 | Ammonia |

| NH4+ | Ammonium |

| NH3-N | Ammonia nitrogen |

| N | Nitrogen |

| TAN | Total ammoniacal nitrogen |

| VMU-AA | Vytautas Magnus University Agriculture Academy |

References

- Cao, X.; Reichel, R.; Brüggemann, N. Potential of High Organic Carbon Soil Amendments to Mitigate Greenhouse Gas and Ammonia Emissions from Pig and Cattle Slurry Treated Soils. Geophys. Res. Abstr. 2019, 21, 1. [Google Scholar]

- Horrillo, A.; Gaspar, P.; Escribano, M. Organic Farming as a Strategy to Reduce Carbon Footprint in Dehesa Agroecosystems: A Case Study Comparing Different Livestock Products. Animals 2020, 10, 162. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Kumar, A.M.; Du, W.; Ren, X.; Lei, T.; Lv, J. Compost Supplementation with Nitrogen Loss and Greenhouse Gas Emissions during Pig Manure Composting. Bioresour. Technol. 2020, 297, 122435. [Google Scholar] [CrossRef] [PubMed]

- Murawska, A.; Prus, P. The Progress of Sustainable Management of Ammonia Emissions from Agriculture in European Union States Including Poland—Variation, Trends, and Economic Conditions. Sustainability 2021, 13, 1035. [Google Scholar] [CrossRef]

- European Environment Agency. Sources and Emissions of Air Pollutants in Europe. In Web Report; European Environment Agency: Copenhagen, Denmark, 2022. [Google Scholar]

- Ding, L.; Li, Q.; Wang, C.; Zhang, G.; Jiang, R.; Yu, L.; Zheng, W.; Gao, R.; Ma, W.; Zhang, S.; et al. Determination of the Mass Transfer Coefficient of Ammonia Emissions from Dairy Open Lots using a Scale Model. Biosyst. Eng. 2020, 190, 145–156. [Google Scholar] [CrossRef]

- Ni, J.; Erasmus, M.A.; Croney, C.C.; Li, C.; Li, Y. A Critical Review of Advancement in Scientific Research on Food Animal Welfare-Related Air Pollution. J. Hazard. Mater. 2021, 408, 124468. [Google Scholar] [CrossRef] [PubMed]

- Huang, D.; Guo, H. Diurnal and Seasonal Variations of Odor and Gas Emissions from a Naturally Ventilated Free-Stall Dairy Barn on the Canadian Prairies. J. Air Waste Manag. Assoc. 2017, 67, 1092–1105. [Google Scholar] [CrossRef] [PubMed]

- Yi, Q.; Zhang, G.; König, M.; Janke, D.; Hempel, S.; Amon, T. Investigation of Discharge Coefficient for Wind-Driven Naturally Ventilated Dairy Barns. Energy Build. 2018, 165, 132–140. [Google Scholar] [CrossRef]

- Morsing, S.; Strøm, J.S.; Zhang, G.; Kai, P. Scale Model Experiments to Determine the Effects of Internal Airflow and Floor Design on Gaseous Emissions from Animal Houses. Biosyst. Eng. 2008, 99, 99–104. [Google Scholar] [CrossRef]

- Zhang, G.; Bjerg, B.; Strøm, J.S.; Morsing, S.; Kai, P.; Tong, G.; Ravn, P. Emission Effects of Three Different Ventilation Control strategies—A Scale Model Study. Biosyst. Eng. 2008, 100, 96–104. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, G.; Kai, P. Ammonia and Methane Emissions from Two Naturally Ventilated Dairy Cattle Buildings and the Influence of Climatic Factors on Ammonia Emissions. Atmos. Environ. (1994) 2012, 61, 232–243. [Google Scholar] [CrossRef]

- Ngwabie, N.M.; Jeppsson, K.-H.; Gustafsson, G.; Nimmermark, S. Effects of Animal Activity and Air Temperature on Methane and Ammonia Emissions from a Naturally Ventilated Building for Dairy Cows. Atmos. Environ. (1994) 2011, 45, 6760–6768. [Google Scholar] [CrossRef]

- Pereira, J.; Misselbrook, T.H.; Chadwick, D.R.; Coutinho, J.; Trindade, H. Effects of Temperature and Dairy Cattle Excreta Characteristics on Potential Ammonia and Greenhouse Gas Emissions from Housing: A Laboratory Study. Biosyst. Eng. 2012, 112, 138–150. [Google Scholar] [CrossRef]

- Van der Stelt, B.; Temminghoff, E.J.M.; Van Vliet, P.C.J.; Van Riemsdijk, W.H. Volatilization of Ammonia from Manure as Affected by Manure Additives, Temperature and Mixing. Bioresour. Technol. 2007, 98, 3449–3455. [Google Scholar] [CrossRef] [PubMed]

- Aguerre, M.J.; Wattiaux, M.A.; Powell, J.M. Emissions of Ammonia, Nitrous Oxide, Methane, and Carbon Dioxide during Storage of Dairy Cow Manure as Affected by Dietary Forage-to-Concentrate Ratio and Crust Formation. J. Dairy Sci. 2012, 95, 7409–7416. [Google Scholar] [CrossRef] [PubMed]

- Finzi, A.; Riva, E.; Bicoku, A.; Guido, V.; Shallari, S.; Provolo, G. Comparison of Techniques for Ammonia Emission Mitigation during Storage of Livestock Manure and Assessment of their Effect in the Management Chain. J. Agric. Eng. 2019, 50, 12–19. [Google Scholar] [CrossRef]

- Bleizgys, R.; Čėsna, J. Gyvulininkystės Technologijų Inžinerija: Mokomoji Knyga; Aleksandro Stulginskio Universiteto Leidybos Centras: Akademija, Lithuania, 2012. [Google Scholar]

- Kavolėlis, B. Galvijų Fermų Technologinio Projektavimo Taisyklės Ir Patarimai; Kavolėlis, P.B., Ed.; Lietuvos Žemės Ūkio Universiteto Žemės Ūkio Inžinerijos Institutas: Raudondvaris, Lithuania, 2006. [Google Scholar]

- Skurdenienė, I.; Bakutis, B.; Ribikauskas, V. Ekologinio Ūkio Privalumai Gyvulininkystėje: [Ūkininkaujantiems Ekologiškai]; Lututė: Kaunas, Lithuania, 2007. [Google Scholar]

- Loyon, L.; Guiziou, F. Ammonia Volatilization from Different Pig Slurries Applied on Wheat Stubble using Different Land Spreading Techniques Under French Conditions. Agric. Ecosyst. Environ. 2019, 280, 114–117. [Google Scholar] [CrossRef]

- Bleizgys, R.; Bagdoniene, I. Control of Ammonia Air Pollution through the Management of Thermal Processes in Cowsheds. Sci. Total Environ. 2016, 568, 990–997. [Google Scholar] [CrossRef] [PubMed]

- Bleizgys, R.; Naujokienė, V. Ammonia Emissions from Cattle Manure Under Variable Moisture Exchange between the Manure and the Environment. Agronomy 2023, 13, 1555. [Google Scholar] [CrossRef]

- Bagdonienė, I.; Bleizgys, R. Ammonia Emissions from Dairy Cattle Manure Under Variable Ventilation Rates. Ann. Anim. Sci. 2014, 14, 141–151. [Google Scholar] [CrossRef]

- Kavolėlis, B. Amoniako Emisija Karvidėse, 1st ed.; Žemės Ūkio Mokslai; Vytauto Didžiojo Universiteto Žemės ūkio Akademija: Kaunas, Lithuania, 2004; p. 46. [Google Scholar]

- Wang, H.; Zhang, X.; Ma, Y.; Hou, Y. Mitigation Potential for Carbon and Nitrogen Emissions in Pig Production Systems: Lessons from the North China Plain. Sci. Total Environ. 2020, 725, 138482. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, Q.H.; Le, P.D.; Chim, C.; Le, N.D.; Fievez, V. Potential to Mitigate Ammonia Emission from Slurry by Increasing Dietary Fermentable Fiber through Inclusion of Tropical Byproducts in Practical Diets for Growing Pigs. Asian-Australas. J. Anim. Sci. 2019, 32, 574–584. [Google Scholar] [CrossRef] [PubMed]

- Hempel, S.; Saha, C.K.; Fiedler, M.; Berg, W.; Hansen, C.; Amon, B.; Amon, T. Non-Linear Temperature Dependency of Ammonia and Methane Emissions from a Naturally Ventilated Dairy Barn. Biosyst. Eng. 2016, 145, 10–21. [Google Scholar] [CrossRef]

- Sanchis, E.; Calvet, S.; Prado, A.D.; Estellés, F. A Meta-Analysis of Environmental Factor Effects on Ammonia Emissions from Dairy Cattle Houses. Biosyst. Eng. 2019, 178, 176–183. [Google Scholar] [CrossRef]

- Pedersen, J.; Nyord, T.; Feilberg, A.; Labouriau, R. Analysis of the Effect of Air Temperature on Ammonia Emission from Band Application of Slurry. Environ. Pollut. 2021, 282, 117055. [Google Scholar] [CrossRef] [PubMed]

- VanderZaag, A.C.; Gordon, R.J.; Glass, V.M.; Jamieson, R.C. Floating Covers to Reduce Gas Emissions from Liquid Manure Storages: A Review. Appl. Eng. Agric. 2008, 24, 657–671. [Google Scholar] [CrossRef]

- Scotto di Perta, E.; Mautone, A.; Oliva, M.; Cervelli, E.; Pindozzi, S. Influence of Treatments and Covers on NH3 Emissions from Dairy Cow and Buffalo Manure Storage. Sustainability 2020, 12, 2986. [Google Scholar] [CrossRef]

- Zhuang, M.; Shan, N.; Wang, Y.; Caro, D.; Fleming, R.M.; Wang, L. Different Characteristics of Greenhouse Gases and Ammonia Emissions from Conventional Stored Dairy Cattle and Swine Manure in China. Sci. Total Environ. 2020, 722, 137693. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Li, L.; Dong, H.; Wang, Y. Ammonia and Greenhouse Gas Emissions of Different Types of Livestock and Poultry Manure during Storage. Trans. ASABE 2020, 63, 1723–1733. [Google Scholar] [CrossRef]

- Chadwick, D.R. Emissions of Ammonia, Nitrous Oxide and Methane from Cattle Manure Heaps: Effect of Compaction and Covering. Atmos. Environ. 2005, 39, 787–799. [Google Scholar] [CrossRef]

- Emmerling, C.; Krein, A.; Junk, J. Meta-Analysis of Strategies to Reduce NH3 Emissions from Slurries in European Agriculture and Consequences for Greenhouse Gas Emissions. Agronomy 2020, 10, 1633. [Google Scholar] [CrossRef]

- Kriška, T.; Škarpa, P.; Antošovský, J. Effect of Natural Liquid Hydroabsorbents on Ammonia Emission from Liquid Nitrogen Fertilizers and Plant Growth of Maize (Zea Mays L.) Under Drought Conditions. Plants 2023, 12, 728. [Google Scholar] [CrossRef] [PubMed]

- Schmidhalter, U. 15 N Mass Balance Technique for Measuring Ammonia Losses from Soil Surface-applied Slurries Containing various Additives. J. Plant Nutr. Soil Sci. 2024, 187, 443–453. [Google Scholar] [CrossRef]

- Ellersiek, N.C.T.; Olfs, H. An Incubation System for the Simulation of Ammonia Emissions from Soil Surface-Applied Slurry: Effect of pH and Acid Type. Agronomy 2024, 14, 1078. [Google Scholar] [CrossRef]

- Zhu, H.; Zuo, F.; Dong, H.; Luan, D. Effects of Covering Materials and Sawdust Covering Depths on Ammonia and Greenhouse Gase Emissions from Cattle Manure during Storage. Trans. Chin. Soc. Agric. Eng. 2015, 31, 223–229. [Google Scholar] [CrossRef]

- Turbí, M.A.T.; Gómez-Garrido, M.; El bied, O.; Bencosme, J.G.C.; Cano, Á.F. Preliminary Results on the use of Straw Cover and Effective Microorganisms for Mitigating GHG and Ammonia Emissions in Pig Slurry Storage Systems. Agriculture 2024, 14, 1788. [Google Scholar] [CrossRef]

- Matulaitis, R.; Juskiene, V.; Juska, R. The Effect of Floating Covers on Gas Emissions from Liquid Pig Manure. Chil. J. Agric. Res. 2015, 75, 232–238. [Google Scholar] [CrossRef]

- Kim, S.; Shim, S.; Won, S.; Ra, C. Assessment of a Novel Real-Time Bio-Liquor Circulation System for Manure Management and Mitigation of Odor Potential in Swine Farming. Animals 2023, 13, 3849. [Google Scholar] [CrossRef] [PubMed]

- Kupper, T.; Häni, C.; Neftel, A.; Kincaid, C.; Bühler, M.; Amon, B.; VanderZaag, A. Ammonia and Greenhouse Gas Emissions from Slurry Storage—A Review. Agric. Ecosyst. Environ. 2020, 300, 106963. [Google Scholar] [CrossRef]

- Lemes, Y.M.; Nyord, T.; Feilberg, A.; Kamp, J.N. Effect of Covering Deep Litter Stockpiles on Methane and Ammonia Emissions Analyzed by an Inverse Dispersion Method. ACS Agric. Sci. Technol. 2023, 3, 399–412. [Google Scholar] [CrossRef]

- Chen, G.; Wu, P.; Dong, J.; Zheng, J.; Wang, E. Use of a Wheat Straw Covering to Reduce Nitrogen Loss during Pig Slurry Storage and Reuse of the Straw Covering in Biochar Production for Nitrogen Retention in the Slurry. Waste Manag. 2023, 168, 406–412. [Google Scholar] [CrossRef] [PubMed]

- Mohankumar, S.E.P.; Winiwarter, W.; Amon, B. Greenhouse Gas and Ammonia Emissions from Different Stages of Liquid Manure Management Chains: Abatement Options and Emission Interactions. J. Environ. Qual. 2018, 47, 30–41. [Google Scholar] [CrossRef] [PubMed]

- de-Jiménez-Santiago, D.E.; Ovejero, J.; Antúnez, M.; Bosch-Serra, A.D. Ammonia Volatilization from Pig Slurries in a Semiarid Agricultural Rainfed Area. Sustainability 2024, 16, 238. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knoknerienė, I.; Bleizgys, R.; Naujokienė, V. Surface Moisture Control for Sustainable Manure Management: Reducing Ammonia Emissions and Preserving Nutrients. Sustainability 2025, 17, 6617. https://doi.org/10.3390/su17146617

Knoknerienė I, Bleizgys R, Naujokienė V. Surface Moisture Control for Sustainable Manure Management: Reducing Ammonia Emissions and Preserving Nutrients. Sustainability. 2025; 17(14):6617. https://doi.org/10.3390/su17146617

Chicago/Turabian StyleKnoknerienė, Ieva, Rolandas Bleizgys, and Vilma Naujokienė. 2025. "Surface Moisture Control for Sustainable Manure Management: Reducing Ammonia Emissions and Preserving Nutrients" Sustainability 17, no. 14: 6617. https://doi.org/10.3390/su17146617

APA StyleKnoknerienė, I., Bleizgys, R., & Naujokienė, V. (2025). Surface Moisture Control for Sustainable Manure Management: Reducing Ammonia Emissions and Preserving Nutrients. Sustainability, 17(14), 6617. https://doi.org/10.3390/su17146617