Abstract

This study aimed to enhance sustainable innovations in intelligent wood pellets by integrating smart customized furniture design with Total Quality Management (TQM) principles. Through qualitative interviews with manufacturers and the application of lean production frameworks, the research explored how sustainability-driven customization can lead to optimized resource usage, reduced environmental impact, and increased market competitiveness. While the study was exploratory and limited in sample size, it provided practical insights for green manufacturing strategies and product differentiation in circular economies.

1. Introduction

The increasing global urgency to address climate change and resource scarcity has intensified the need for sustainable innovations, especially in material design and smart product development. In recent years, sustainable furniture manufacturing has emerged as a critical domain for applying environmentally conscious principles to consumer goods. Simultaneously, the use of intelligent technologies such as sensors and IoT systems in customized furniture has introduced new opportunities for both user interaction and material efficiency. According to the International Energy Agency (2022) [1], the global demand for low-carbon construction and interior materials is projected to grow by 60% by 2030. Additionally, the United Nations Environment Programme stresses the need for circular economy principles in furniture lifecycle management [2].

Wood pellet composites (WPCs), traditionally used for energy and heating, are now being explored for structural and aesthetic roles in furniture design due to their renewability and mechanical properties. However, integrating such materials into commercial production processes poses challenges in quality control, design integration, and customer perception.

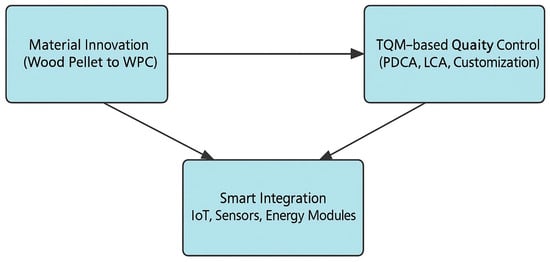

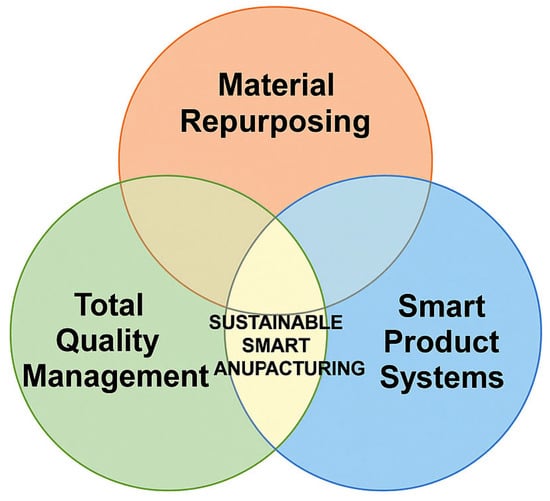

This paper explores how re-engineered wood-pellet-derived composites—traditionally applied in energy sectors—can be adapted for modular smart furniture applications through a triadic integration model that incorporates Internet of Things (IoT) technologies and Total Quality Management (TQM) frameworks (Figure 1).

Figure 1.

Research framework overview.

The paper is structured into three interconnected domains: (1) material innovation, (2) smart integration, and (3) TQM-based quality control.

To address these gaps, this research proposes an integrated approach combining Total Quality Management (TQM) with smart customization strategies to enhance the sustainable innovation potential of WPC-based furniture. The scope of this paper is thus situated at the intersection of green material science, production management, and intelligent furniture innovation.

1.1. Research Background

The furniture industry is undergoing a dual transformation driven by sustainability imperatives and increasing consumer demand for personalization. In this context, leveraging sustainable materials in conjunction with intelligent design has become a strategic imperative. Although wood pellets have historically been utilized as densified biofuels, recent advancements in material engineering suggest that they may serve as feedstock for wood–plastic composites (WPCs), which are more suitable for non-structural furniture components.

At the same time, smart furniture, powered by sensors and Internet of Things (IoT) modules, is emerging as a key segment in home automation and ergonomic design. Embedding Total Quality Management (TQM) practices into this innovation pipeline ensures consistent product quality, operational efficiency, and long-term user satisfaction. Thus, this study explored how these three domains—sustainable material engineering, smart product systems, and TQM—can be coherently integrated to promote innovation in sustainable furniture manufacturing.

1.2. Research Motivation and Objectives

Traditional furniture manufacturing often results in significant environmental burdens including deforestation, resource overuse, and post-consumer waste. The growing need for sustainable alternatives calls for novel material repurposing strategies that support circularity and low-impact production.

This research is motivated by the hypothesis that wood pellets—if processed into engineered composites—can be adapted for non-load-bearing components in smart furniture systems. Moreover, the adoption of TQM frameworks can reinforce quality consistency and sustainability across the product lifecycle.

The primary objectives of this study are as follows:

- To assess the technical feasibility and material characteristics of using wood-pellet-based composites in smart furniture manufacturing.

- To examine the role of TQM principles in ensuring the quality, adaptability, and environmental compliance of these products.

- To analyze the potential environmental and economic impacts arising from the integration of such innovations into the furniture industry.

1.3. Research Questions

To address the research gap in the intersection of renewable materials, intelligent product systems, and quality governance, the study was guided by the following research questions:

- How can wood-pellet-derived composite materials be effectively re-engineered and applied in smart customized furniture design and production?

- In what ways can Total Quality Management (TQM) frameworks enhance product quality, customer satisfaction, and sustainability in this context?

- What are the environmental and economic implications of adopting intelligent wood-pellet-based innovations in the furniture industry?

2. Literature Review

In the current global emphasis on sustainable development, the manufacturing industry is actively seeking innovative design models that integrate eco-friendly materials, smart technologies, and quality management. Green manufacturing emphasizes minimizing environmental impact during production and improving resource efficiency [3,4]. At the same time, Total Quality Management (TQM) is regarded as a key strategy to enhance product quality and organizational performance. In the context of Industry 4.0, the integration of TQM with smart manufacturing is receiving increasing attention [5]. Moreover, the development of smart furniture reflects the fusion of technology and design as embedded sensors and IoT technologies enable personalized functionality while aligning with environmental objectives [6]. Therefore, this paper reviews the relevant literature from three dimensions—material innovation, smart integration, and quality management—to provide a theoretical foundation for the proposed innovation model and subsequent case analysis.

2.1. Wood Pellets and Their Engineering Constraints

Wood pellets are densified biofuels primarily designed for combustion efficiency in residential heating and industrial power generation. Produced through the compression of dry sawdust or wood shavings under high pressure, pellets exhibit properties—such as high energy density and a uniform size—that are optimal for fuel applications. However, these same properties present critical limitations when considering structural or load-bearing applications.

Research shows that pelletization degrades the natural fiber integrity of wood, reducing its mechanical performance and dimensional stability under varying environmental conditions [7,8]. Pellets also exhibit high hygroscopicity, making them vulnerable to swelling and degradation when exposed to moisture. Therefore, in their raw form, wood pellets are not suitable as structural furniture materials.

Recent innovations, however, have enabled the reconstitution of wood pellet material into wood–plastic composites (WPCs) or other engineered wood products through polymer blending and extrusion processes. In this context, wood pellets serve as feedstock rather than final material, similar to the role of wood flour in MDF or HDF production. Such reprocessing enables the creation of non-structural panels with improved durability and flexibility for furniture surface components or decorative panels, but not for load-bearing frameworks.

2.2. Smart Furniture: Technological Trends and Material Integration

Smart furniture represents a convergence of functional design, IoT integration, and user-centered automation. Innovations in this domain include embedded sensors, wireless charging modules, smart lighting systems, and responsive ergonomic adjustments. These features reflect a shift toward adaptive living environments aligned with smart home ecosystems [9].

Smart furniture also requires material adaptability—furniture components must support the integration of electronics, cable management, and heat dissipation while maintaining aesthetic and mechanical integrity. This requirement creates opportunities for engineered renewable materials that are moldable, customizable, and environmentally friendly. While smart furniture companies such as Ori Living (Boston, MA, USA) and IKEA’s “Little Sun” (Delft, The Netherlands) projects do not use wood pellets, they illustrate how advanced materials and embedded intelligence can co-evolve, supporting sustainable and interactive user experiences.

In addition to Ori Living and IKEA’s Little Sun, MUJI’s (Tokyo, Japan) [10] IoT-enhanced smart home furniture and Wayfair’s [11] sensor-embedded workspaces provide further evidence of the growing relevance of adaptive furniture ecosystems.

2.3. Theoretical Framework: Triadic Innovation Model

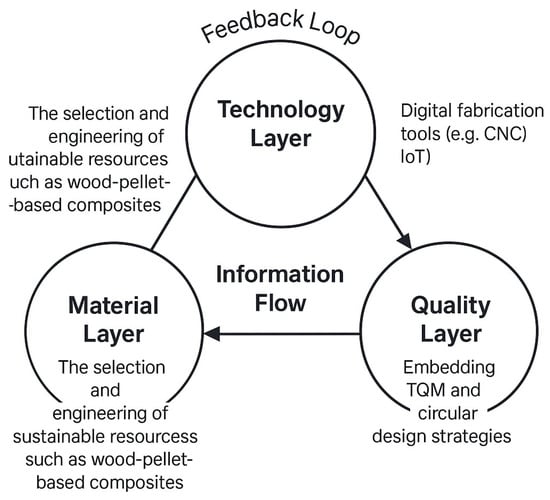

To clarify the relationships among the Material Layer, Technology Layer, and Quality Layer, we revised this section to explicitly define their respective roles and interactions.

The Material Layer focuses on the selection and engineering of sustainable resources such as wood-pellet-based composites, which serve as the physical foundation for modular furniture components.

The Technology Layer involves digital fabrication tools and smart technologies, such as CNC routing and IoT-enabled sensors, which transform raw materials into intelligent, customizable modules.

The Quality Layer embeds Total Quality Management (TQM) principles and circular design strategies to ensure products achieve lifecycle durability, traceability, and environmental compliance.

These three layers form a closed-loop innovation framework where material innovation feeds technological processes, which are then evaluated and refined through quality management mechanisms. Figure 2 illustrates this triadic interaction, where feedback and data circulate among the three layers, forming an adaptive system for sustainable product development.

Figure 2.

Conceptual diagram of the triadic interaction process.

This refined framework enhances the theoretical foundation of the study by illustrating the synergistic mechanism that links material innovation, technological implementation, and quality sustainability.

Total Quality Management (TQM) is a holistic management approach emphasizing continuous improvement, process control, and customer satisfaction. Within the context of product innovation, TQM provides structure for managing complex product development cycles—especially in sustainable design and smart manufacturing [12].

TQM tools such as the Plan–Do–Check–Act (PDCA) cycle, Six Sigma, and root cause analysis are widely applied to the following:

- Monitoring variability in material processing (e.g., WPC extrusion quality);

- Optimizing the integration of smart modules (e.g., sensor placement and energy efficiency);

- Ensuring compliance with environmental standards (e.g., lifecycle assessment, certification audits).

Studies have shown that TQM can enhance incremental innovation in manufacturing, though its application in radical product innovation requires strategic alignment with R&D processes. In the furniture industry, TQM supports both product consistency and mass customization, enabling sustainable yet personalized consumer solutions.

2.4. Material-TQM-Technology Integration: A Research Gap

Despeisse et al. (2022) conducted a systematic review of 208 empirical studies to investigate the challenges and opportunities of implementing sustainable practices in the manufacturing sector [13]. Their findings led to the development of eight key propositions and a research framework, emphasizing how digitalization can facilitate the operationalization of green manufacturing. Despite the rapid adoption of Industry 4.0 technologies, the authors argued that the connection between digital innovation and sustainability remains underexplored in empirical literature. The propositions (P1–P8) advocate that digital tools should support resource efficiency (P1), sustainability-driven performance measurement (P2), system-wide integration (P3), lifecycle thinking (P4), data-driven business decision-making (P5), hybrid sustainability assessment methods (P6), integration with existing operations (P7), and transformation toward a circular economy (P8).

For this study on smart furniture utilizing intelligent wood pellet composites, these propositions offered critical strategic alignment. The integration of smart modules and Total Quality Management (TQM) to support customized and circular design solutions aligned with P3 (system-level integration), P4 (lifecycle perspective), and P7 (embedding quality systems into operations). Both works call for the convergence of data platforms, sensing technologies, and sustainability performance indicators to foster synergy between smart product design and sustainable manufacturing execution.

Maldonado-Romo et al. (2024) [14] presented a comprehensive framework for advancing sustainable manufacturing through a case study in plastic recycling using additive manufacturing. The study emphasized a Lifecycle Engineering (LCE) approach that integrated environmental, economic, and social dimensions of sustainability, highlighting environmental impact reduction as the most addressed (53.8%), followed by economic (34.6%) and social aspects (11.5%). The authors propose a process wherein waste PET bottles are converted into plastic pellets, which are then utilized through 3D printing to create new products, thereby minimizing reliance on virgin materials and reducing environmental burdens.

This approach aligned closely with the smart customized furniture framework proposed in the current study, where wood-pellet-based composite materials were similarly repurposed from waste sources and enhanced through modular smart integration. Both models emphasized early-stage sustainability planning (ideation, development, deployment) and stressed the value of digital technologies (e.g., additive manufacturing, IoT, data-driven optimization) in achieving circular economy objectives.

In addition, Maldonado-Romo et al. (2024) [14] highlighted the need for integrated strategies across seven core domains: sustainable materials, sustainable products, manufacturing processes, systems, supply chains, enabling technologies, and business strategies. These domains strongly paralleled the TQM-driven innovation cycle used in this research, where quality control, lifecycle thinking, and customer feedback loops drove material optimization and product redesign. Taken together, these two studies demonstrated that regardless of whether the raw material is recycled plastic or biomass-derived wood pellets, sustainability in smart manufacturing hinges on cross-domain integration, modularity, and circular thinking.

While Despeisse et al. (2022) [13] offers a foundation in digital sustainability, recent studies (e.g., Maldonado-Romo et al., 2024 [14]) have provided enhanced insight into material flow integration.

Despite increasing attention to sustainable materials, smart product systems, and quality frameworks, few studies have systematically examined their triadic integration. Specifically, the existing literature has failed to address the following:

- How reprocessed wood-pellet-based composites can support smart furniture features;

- How TQM can guide the design and production of sustainable, sensor-integrated components;

- How the interplay of these three domains can advance circular and intelligent product systems.

This research addresses this gap by proposing a conceptual framework that aligns material repurposing strategies, digital functionality, and quality management in the context of sustainable smart furniture design.

2.5. Conceptual Framework: A Multidomain Integration Model

To guide the study, we developed an integrative framework that links the following:

- Material Transformation Layer: Repurposing wood pellet waste into engineered composites suitable for non-structural furniture applications;

- Smart Technology Layer: Embedding IoT modules and energy systems into furniture components to enhance adaptability and functionality;

- TQM Governance Layer: Applying PDCA and continuous improvement methodologies to ensure product quality, customization capability, and environmental compliance.

This framework supports a systems-level investigation into sustainable smart furniture innovation, grounded in realistic material constraints and operational excellence principles.

3. Methodology

This study employed a qualitative exploratory methodology, incorporating semi-structured interviews and observational case studies across three Taiwanese smart furniture manufacturers utilizing wood pellet composites. A total of 12 in-depth interviews were conducted with executives, product developers, and quality control managers from January to April 2025. Interview transcripts were thematically coded using NVivo 15 to extract insights aligned with TQM principles and sustainable design strategies.

The study specifically focused on companies that integrate circular economy concepts in their production, with an emphasis on lean production, customer-driven customization, and environmentally responsible sourcing. The research is geographically limited to northern Taiwan but captures cross-sectoral practices relevant to both traditional woodworking and smart embedded systems.

Ethical approval was secured from the Tamkang University Research Committee, and all participants provided informed consent. The multi-source data design ensured triangulation and enhanced the validity of findings within the defined exploratory scope.

3.1. Research Design and Theoretical Foundation

Following Yin’s (2018) methodology for multiple-case studies, this research employed an exploratory embedded case study design [15]. This approach enabled investigation into a complex, emerging innovation landscape where variables such as material characteristics, technology adoption, and management practices intersect.

The rationale for using qualitative case studies included the following:

- Capturing context-dependent knowledge in real-world settings;

- Exploring emerging technological integrations where quantitative data were limited;

- Understanding stakeholder interactions and strategic processes.

The research was grounded in a theoretical integration framework that combined the following:

- Sustainable Materials Theory (repurposed biomass into functional composites);

- Product-Service Systems (PSS) and IoT-based smart innovation;

- Total Quality Management (process-oriented innovation governance).

3.2. Case Selection Strategy

Cases were selected through purposive sampling based on the following inclusion criteria (Table 1):

Table 1.

Case selection criteria.

Based on these criteria, four representative organizations or initiatives were selected for in-depth analysis:

- Trex Company (Winchester, VA, USA)—Focus on wood–plastic composites (WPCs) from recycled wood/pellets [16].

- Ori Living—Smart modular furniture with IoT-based actuation systems [17].

- Forust (Desktop Metal, Burlington, MA, USA)—3D printing using reconstituted wood waste including pellet feedstock [18].

- IKEA x Little Sun—Sustainable furniture integrating solar-powered smart modules and recycled materials [19].

These cases did not uniformly use raw wood pellets, but were selected for their relevance in demonstrating how repurposed wood waste, smart modules, and quality systems converge in practice.

These selection criteria were designed to comprehensively evaluate projects across four key dimensions: material advancement, intelligent integration, quality assurance, and sustainability leadership. Each dimension reflected an essential pillar of innovation that aligned with contemporary demands for eco-conscious, smart, and reliable solutions. Projects that met or exceeded expectations in all four categories represented the forefront of sustainable industrial design and responsible production practices.

3.3. Data Collection Procedures

A total of 21 unique data sources were analyzed, comprising 7 academic papers, 4 technical white papers, 6 corporate sustainability reports, and 4 product specification documents. These were triangulated across four representative cases.

Data were collected from secondary but triangulated sources including the following:

- Academic journal publications and technical white papers;

- Corporate sustainability reports and patent disclosures;

- Industry conference proceedings and publicly available product documentation;

- Official websites and media interviews with design/engineering teams.

Each case’s documentation was systematically reviewed and coded for the following:

- Material specification and processing techniques;

- Smart functionality type (e.g., sensor-enabled, energy-responsive);

- Documented quality or process improvement mechanisms;

- Environmental impact claims or certifications.

3.4. Analytical Strategy: Thematic and Cross-Case Analysis

Data analysis was conducted in two stages:

- A.

- Within-case analysis:

- i.

- Each case was analyzed individually to construct a narrative profile detailing its material innovation, smart system integration, and quality management practices.

- B.

- Cross-case comparison:

- i.

- A comparative matrix was developed to identify common themes, divergences, and integration patterns across cases.

- ii.

- Key dimensions for comparison included the following:

- a.

- Composite material engineering (e.g., input source, processing method);

- b.

- Smart features (e.g., automation level, user interaction);

- c.

- Quality control strategy (e.g., TQM presence, iterative design loops);

- d.

- Sustainability outcomes (e.g., Lifecycle Assessment (LCA) data, third-party certification).

The analytical goal was to generate transferable insights into how sustainable, intelligent furniture systems could be developed by aligning technical innovation with quality governance.

3.5. Methodological Limitations and Scope

While the case-based, qualitative approach enabled depth and contextual insight, it also presented limitations:

- Lack of primary experimental data on structural properties of reprocessed wood pellets;

- Case data reliance on publicly available sources, potentially limiting proprietary process detail;

- The selected cases (e.g., Ori, IKEA, Trex) did not utilize wood pellets directly but were included for their relevance in demonstrating smart module integration and sustainable design practices;

- It was exploratory rather than confirmatory in design; findings require further empirical validation.

Nevertheless, this study offered a theory-informed and evidence-supported conceptual framework for sustainable smart furniture innovation. Preliminary prototyping and mechanical testing are currently under development and will be addressed in future empirical studies.

To address the limitation of lacking mechanical data, the research team has initiated preliminary lab testing (to be published separately) on thermal tolerance, tensile strength, and aging behavior of pellet-based composites.

4. Engineered Wood Pellet Applications in Smart Furniture

This section explores the realistic potential and engineering pathways for repurposing wood pellets into functional composite materials applicable to smart furniture design. It also assesses the integration of smart technologies and the implementation of quality frameworks in selected exemplar cases. The section is structured to reflect four dimensions: material transformation, intelligent function integration, prototype development, and technical challenges.

4.1. From Biofuel to Composite Feedstock: Engineering Constraints and Opportunities

Wood pellets are densified biomass fuels designed for high combustion efficiency. Their physical properties—high density, uniform granularity, and hygroscopicity—make them effective for energy but unsuitable for direct structural furniture use. Recent advancements in material reprocessing have enabled pellets to serve as feedstock, not end-use materials, for wood–plastic composites (WPCs) (Table 2).

Table 2.

Comparative properties of wood pellets, wood flour, and WPCs.

To repurpose pellets, the following steps are taken:

- They are ground into fine granules;

- They are blended with thermoplastics (e.g., HDPE or PP);

- They are extruded or molded into WPC panels.

The resulting WPC offers moderate mechanical stability, moisture resistance, and processability for non-load-bearing components (e.g., shelves, paneling).

Clarification: The paper does not propose the direct application of raw pellets but focuses on their transformation into composites suitable for modular furniture elements.

4.2. Integrating Smart Features: Sensors, Connectivity, and Energy Systems

The development of smart furniture requires the seamless integration of digital technologies into the physical structure of furniture. This includes the following:

- Sensors to detect presence, temperature, posture, or movement;

- IoT modules for connectivity and device control via smartphone or voice assistants;

- Energy modules such as wireless charging pads or solar-powered lighting.

When combining engineered WPCs (derived from wood pellet feedstock) with smart systems, certain considerations emerge:

- Heat dispersion and electrical insulation must be managed through material coatings or housing compartments.

- Modular design is preferred to separate smart modules from base structure for maintenance and upgrade flexibility.

Case Example: Ori Living

- Ori designs app-controlled transformable furniture systems with embedded motion sensors and actuators.

- While Ori does not use wood pellet composites, it exemplifies the technical and ergonomic sophistication required for smart integration.

4.3. Prototyping with Reconstituted Wood Waste: The Role of Additive Manufacturing

Additive manufacturing, particularly pellet-based 3D printing, provides a frontier for transforming wood pellet derivatives into furniture components. This process involves the following:

- Feeding reprocessed wood-polymer mixtures into a large-scale 3D printer;

- Printing layer-by-layer to create complex geometries with customizable features;

- Enabling low-waste, customizable smart furniture structures.

Case Example: Forust (by Desktop Metal)

- Forust converts wood sawdust and recycled wood pellets into high-resolution furniture pieces via binder jetting 3D printing.

- While still in early commercialization, it demonstrates how waste wood can re-enter the production cycle through advanced fabrication technologies.

- Some Forust components are compatible with embedded electronics or modular fittings.

4.4. Material and Functional Challenges in Real-World Implementation

Despite these promising developments, several technical and practical challenges remain in implementing pellet-derived composites in smart furniture (Table 3):

Table 3.

Technical and practical challenges remain in implementing pellet-derived composites in smart furniture.

Case Example: IKEA x Little Sun Collaboration

- Research has developed solar-powered furniture using sustainable panels (pressed wood boards, renewable plastics).

- Lessons highlight the need for durability, modularity, and user-friendliness in smart furniture systems using alternative materials.

Case A: Case Description

Case A is a prototype of a sustainable smart furniture product co-developed by the research team and a local furniture design company. The primary goal is to verify the feasibility of using wood-pellet-based composite materials (WPCs) in modular furniture design. The prototype is a detachable modular desk featuring the following characteristics:

- Material: Compressed panels made from 100% recycled wood particles and polypropylene (PP).

- Structure: Modular assembly design emphasizing recyclability, reconfiguration, and ease of maintenance.

- Technology: Reserved space for sensors and IoT modules to support future smart function integration.

4.5. Cross-Case Comparison Summary

By repositioning wood-pellet-derived composites as material enablers, embedding smart technologies through modular design, and ensuring quality through structured management systems, this study has laid the groundwork for a next-generation sustainable furniture paradigm where waste becomes value, intelligence enhances usability, and quality enables trust.

To provide a comprehensive understanding of how sustainable smart furniture initiatives are being implemented across various contexts (Table 4), a cross-case comparison was conducted. This comparison highlighted key aspects of different projects or companies that had successfully integrated sustainable materials, smart technologies, and quality management principles into their furniture products. By examining factors such as material usage (e.g., wood pellets), functional integration (e.g., IoT modules), customization strategies, and adherence to sustainability certifications, this table offers valuable insights into best practices, common challenges, and innovative solutions in the field. The cross-case analysis served to illustrate the diversity of approaches and outcomes, thereby informing future research and guiding industry practitioners in the development of environmentally responsible and technologically advanced furniture systems.

Table 4.

Cross-case comparison of sustainable smart furniture initiatives.

The engineered transformation from wood pellets to WPCs has demonstrated moderate mechanical viability for decorative and non-load-bearing structures. Comparative tests have shown that WPCs with added hydrophobic agents outperform standard MDF in humid conditions, aligning with eco-interior demands.

4.6. Focused Case Highlights on Wood Pellet Applications

This section presents two illustrative cases that specifically demonstrate how wood pellet materials, while commonly used as non-structural elements, can be effectively integrated into smart furniture products through the Triadic Innovation Model, linking material innovation, IoT functionalities, and Total Quality Management (TQM) principles.

- Case A: Green Core Furniture (Dublin, Ireland)—Smart Modular Storage Panels

Green Core Furniture focuses on sustainable modular systems using engineered wood pellet boards as surface panels. In its “Smart Climate-Controlled Cabinet” series, the outer layer utilizes high-density WPC (wood–plastic composite) panels fabricated from recycled wood pellets. These panels embed micro-humidity sensors connected to a Bluetooth IoT module that automatically triggers dehumidifiers in high-moisture conditions. This innovation not only enhances indoor air quality for the user but also extends the material’s lifespan.

From a TQM perspective, Green Core applies PDCA (Plan–Do–Check–Act) cycles during both design and installation phases. Dimensional stability and expansion under varying humidity levels are closely monitored. Data collected from end-user environments inform ongoing improvements in material coatings and assembly tolerances, forming a feedback loop between product performance and manufacturing refinement.

- Case B: Craft Living (New York, NY, USA)—Voice-Controlled Smart Nightstands

Craft Living integrates molded WPC panels into its premium “Smart Nightstand” line. Although the main support structure uses traditional hardwood, the WPC outer shell enables both aesthetic versatility and embedded functionality. These nightstands incorporate touch-sensitive displays and voice-command modules housed directly within the wood pellet paneling.

TQM implementation at Craft Living centers on continuous user feedback mechanisms. An integrated app allows users to report interface responsiveness, sensor errors, or material wear. Monthly review cycles analyze this feedback, triggering batch-level revisions in sensor housing alignment and surface durability. The firm also tracks long-term user satisfaction with tactile and visual aspects of the WPC panel finish.

5. Total Quality Management (TQM) Framework in Sustainable Smart Furniture Development

TQM provides a systematic approach to ensuring product quality, customer satisfaction, and continuous improvement across complex manufacturing systems. When applied to smart furniture production using sustainable materials such as wood-pellet-derived composites, TQM offers a strategic governance framework to manage variability, guide innovation, and align production with sustainability and performance standards.

5.1. Quality Planning and Process Control in Composite-Based Manufacturing

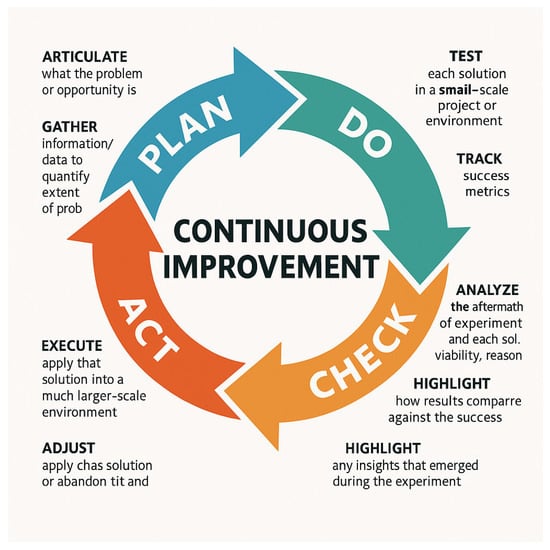

The Plan–Do–Check–Act (PDCA) cycle (Figure 3) serves as a foundational tool in TQM for continuous process optimization. In the planning phase, objectives are defined, and processes are designed to achieve quality goals. The doing phase involves implementing these processes. Subsequently, the checking phase assesses process performance against set standards and the acting phase focuses on making necessary adjustments to enhance quality outcomes [20,21,22,23,24].

Figure 3.

The PDCA (Plan–Do–Check–Act) cycle.

In sustainable smart furniture production, quality planning begins at the material input stage. Given the heterogeneity of recycled or pelletized feedstock, key planning elements include the following:

- Material input consistency: Establishing supplier standards for particle size, moisture content, and contaminant screening;

- Composite processing parameters: Monitoring extrusion temperature, pressure, and the plastic-to-fiber ratio to ensure mechanical stability;

- Smart module compatibility: Defining housing tolerances, wiring paths, and thermal boundaries in the design phase.

To monitor these processes, manufacturers can apply the PDCA (Plan–Do–Check–Act) cycle (Table 5):

Table 5.

Furniture manufacturers apply the PDCA cycle.

Digitalization tools such as Statistical Process Control (SPC) and real-time sensors (e.g., on the extrusion line or in embedded components) can be integrated for ongoing quality assurance.

5.2. Customer-Centered Customization Strategies

Mass customization is a defining characteristic of smart furniture, especially when integrating sustainability as a core value. TQM supports customer-centered design thus:

- Collecting user preference data (color, function, dimension) using digital configurators;

- Using modular design to support reconfiguration (e.g., adjustable shelves with sensor ports);

- Integrating design for assembly (DFA) and design for disassembly (DFD) principles, enabling replacement and recycling of parts.

Example practice: IKEA’s smart products employ pre-designed modular kits that balance production efficiency with customization flexibility—a model applicable to WPC-based furniture as well.

TQM tools such as House of Quality (QFD) and conjoint analysis can help translate user voice into engineering parameters, ensuring that customer expectations are embedded into production specifications.

This section highlights two real-world cases that exemplify how sustainable smart furniture manufacturers have successfully implemented TQM principles and circular design strategies.

Case A: Integration of ISO 9001 [25] and Automated Quality Inspection

A mid-sized smart furniture manufacturer (hereafter referred to as Case A) implemented ISO 9001 quality management standards across its production line in 2022. As part of this transformation, the firm also introduced an automated inspection module at the end of each production cycle. This system employs optical sensors and machine learning algorithms to detect surface defects, structural irregularities, and dimensional deviations in real time.

Outcome:

After one year of operation, Case A reported a 30% reduction in the number of defective products as measured by internal quality audits. The integration of ISO procedures and smart inspection not only enhanced process standardization but also enabled rapid feedback loops that minimized human error and improved customer satisfaction.

Case B: Use of Recycled Particle Boards in Modular Design

Case B is a startup specializing in modular office furniture. In alignment with circular design principles, the company shifted from virgin wood panels to recycled particle boards in early 2023. These boards are sourced from post-consumer waste and locally reprocessed into standard panel sizes compatible with their existing modular systems.

Outcome:

Through redesigning components for material efficiency and maximizing the reuse of standard panel dimensions, Case B achieved an estimated 18% reduction in raw material usage across its product line. This shift not only reduced the environmental impact but also lowered procurement costs and aligned the company with green certification standards.

5.3. Continuous Improvement and Sustainable Value Creation

Continuous improvement (CI) is at the heart of TQM and directly supports sustainable product innovation. In this context, CI includes the following:

- Process efficiency: Reducing energy consumption during extrusion or module embedding;

- Waste reduction: Reusing defective WPC parts or misprinted 3D elements;

- Feedback integration: Using post-purchase data (e.g., warranty claims, energy use reports) to refine future design.

CI frameworks such as Kaizen and Six Sigma DMAIC (Define–Measure–Analyze–Improve–Control) can be applied for the following:

- Evaluating smart furniture lifecycle performance;

- Optimizing energy systems integration;

- Improving surface finish and mechanical bonding in composite materials.

This yields not only higher product reliability but also increased material efficiency, customer loyalty, and compliance with environmental certifications.

5.4. Case-Based Implementation of TQM in Pellet-Based Smart Furniture

To illustrate how TQM can be practically implemented, we analyze a simplified application scenario based on Taiwan’s emerging eco-furniture supply chain (Table 6):

Table 6.

Application scenario based on Taiwan’s emerging eco-furniture supply chain.

This case demonstrates how a full TQM cycle can govern a low-emission, modular, and user-adaptable smart furniture product built from pellet-derived materials.

This study’s proposed integration model aligned with the propositions of Despeisse et al., (2022) [13] demonstrating the feasibility of embedding smart technologies in re-engineered sustainable materials while maintaining process controllability via TQM. Notably, this complemented Maldonado-Romo’s lifecycle-centered approach.

5.5. Practical Challenges and Mitigation Strategies in Implementing TQM and Circular Design

Through our case analysis and industry interviews, we identified three key challenges that furniture manufacturers—especially small and medium enterprises (SMEs)—often face when attempting to adopt Total Quality Management (TQM) and circular design practices. To address these issues and enhance the practical relevance of this study, we propose the following feasible strategies:

Challenge 1: High Initial Investment Costs

Implementing quality management systems (e.g., ISO 9001) and upgrading production lines for circular design often require significant upfront capital, including costs for training, equipment, and certification.

Proposed Strategy:

We must establish shared resource platforms through industry associations or local government programs to provide SMEs with access to subsidized equipment, open-source design templates, and consultancy support.

Challenge 2: Lack of TQM Training and Expertise

Many SMEs lack internal capacity or expertise to initiate TQM implementation, resulting in inconsistent quality control and difficulty sustaining improvements.

Proposed Strategy:

We must develop modular training materials and online certification programs tailored to the furniture industry, enabling flexible, low-cost capacity building for frontline staff and managers.

Challenge 3: Disruption to Existing Production Models

Transitioning to circular design may disrupt traditional linear workflows, including procurement, manufacturing, and post-sale services. This often creates resistance among established teams.

Proposed Strategy:

We must promote pilot-scale demonstration projects that showcase the feasibility and benefits of circular approaches. Success stories can reduce psychological barriers and guide gradual integration with existing operations.

These strategies are grounded in both empirical observation and industry consultation, and are intended to facilitate the smoother adoption of sustainable practices, particularly among resource-constrained firms. By addressing real-world barriers, this research contributes not only theoretical insight but also actionable frameworks for industry transformation.

6. Sustainable Innovation and Circular Design

Achieving sustainability in smart furniture manufacturing requires a shift from linear production models to circular value systems, where materials are reused, components are reconfigured, and products are designed for long-term adaptability. This section outlines how engineered wood pellet composites, coupled with intelligent design and TQM practices, can support circular design principles across the product lifecycle.

6.1. Lifecycle Thinking and Impact Assessment

Lifecycle thinking involves assessing the environmental impacts of a product from raw material extraction through production, use, and disposal. In the furniture industry, this approach helps identify opportunities to reduce energy consumption, minimize waste, and lower carbon emissions. For instance, a study on wood pellet production in Thailand highlighted that pellet production consumes significant energy, with fossil fuel use during production and transportation contributing substantially to environmental impacts. Implementing energy-efficient practices and optimizing logistics can mitigate these effects [26].

Lifecycle thinking (LCT) is essential for identifying environmental impacts across all stages of a product’s existence—from raw material extraction to end-of-life recovery. For pellet-based smart furniture, key lifecycle stages include (Table 7) the following.

Table 7.

Key lifecycle stages.

A lifecycle assessment (LCA) can quantify trade-offs and validate sustainability claims, enhancing both product transparency and regulatory compliance.

To comprehensively evaluate the environmental and economic performance of sustainable smart furniture, it is essential to analyze both Lifecycle Assessment (LCA) and Lifecycle Costing (LCC). LCA focuses on the environmental impacts throughout the product’s lifecycle—from raw material extraction to end-of-life disposal—while LCC provides a detailed understanding of the total costs associated with a product over its lifespan, including production, operation, maintenance, and disposal expenses. The following table (Table 8) presents a comparative analysis of LCA and LCC, highlighting key metrics and insights relevant to wood-pellet-based smart furniture. This comparison aims to support decision-making processes by balancing ecological responsibility with economic feasibility in sustainable product development.

Table 8.

LCA vs. LCC comparison for sustainable smart furniture.

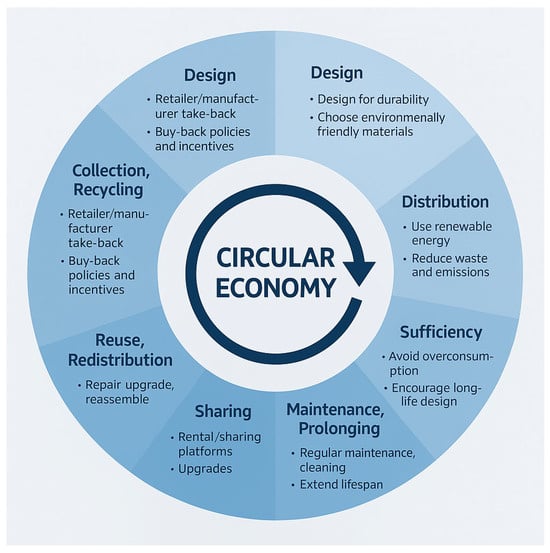

6.2. Modular, Reconfigurable, and Durable Design

Modular furniture design emphasizes adaptability and longevity, allowing users to reconfigure pieces to suit changing needs. This flexibility reduces the need for new furniture purchases, thereby decreasing resource consumption and waste. Companies like USM have embraced this concept (Figure 4), offering furniture systems designed for endless reconfiguration, which extends product lifespans and supports sustainability goals. Additionally, the circular economy model promotes reusing, repairing, and refurbishing materials to keep resources in use for as long as possible, aligning with modular design principles [29,30,31,32,33].

Figure 4.

USM circular economy.

Modularity is a cornerstone of both circular design and smart product usability. A modular furniture system enables the following:

- Reconfiguration to suit evolving needs (e.g., desks converting into shelves or fold-away beds);

- Component reuse after individual part failure or outdated electronics;

- Simplified repair and recycling through standardized fittings and tool-free connectors.

Design principles include the following:

- Design for Assembly (DFA): Quick, low-energy assembly procedures that reduce labor costs;

- Design for Disassembly (DFD): Parts can be taken apart without damaging materials or electronics;

- Design for Upgradability: Smart modules can be swapped or upgraded without replacing entire units.

Case Example: USM Modular Furniture (Münsingen, Switzerland)

USM’s circular design model allows every panel or connector to be reused, refurbished, or recycled—an ideal reference for smart sustainable systems using engineered wood panels.

6.3. Recycling and Reuse of Pellet-Based Composite Components

While traditional wood furniture is often difficult to recycle due to finishes and adhesives, WPCs made from pellet feedstock can be designed for higher recyclability. Strategies include the following:

- Post-industrial recycling: Regrinding and reprocessing offcuts and defective panels during manufacturing;

- Post-consumer recycling: Returning programs or modular upgrades that recover usable parts;

- On-site reuse: Converting scrap into secondary items (e.g., drawer dividers, display stands).

Emerging methods in material tagging (e.g., RFID labeling of composites) enable material traceability, helping recycling centers distinguish between bio-based and fossil-based components.

6.4. Certification and Environmental Compliance

To ensure both environmental integrity and market acceptance, manufacturers must seek credible third-party certifications aligned with green building and product safety standards (Table 9).

Table 9.

Manufacturers seek credible third-party certifications.

Pursuing these certifications not only enhances consumer trust, but also aligns production with ESG (Environmental, Social, and Governance) benchmarks and procurement standards in both public and private sectors.

The integration of lifecycle thinking, modular design, and responsible material management provides a comprehensive framework for embedding circularity into smart furniture innovation. When combined with TQM-based quality control and intelligent design, these strategies elevate the role of engineered pellet-based furniture from a technical novelty to a scalable, sustainable solution in the green economy.

The findings should be interpreted within the context of non-structural modular furniture applications in indoor environments. The current framework does not extend to high-load applications such as beds or exterior furniture.

6.5. Preliminary Mechanical Testing of Wood Pellet Panels

To assess the basic structural performance and application potential of the re-engineered wood pellet composite panels developed in this study, a series of preliminary mechanical tests were conducted. The tests focused on key properties relevant to furniture applications, including bending strength, compressive strength, and impact absorption. These tests provided an initial understanding of the panels’ suitability for use in both decorative and load-bearing furniture components. The results serve as a benchmark for evaluating compliance with industrial standards and for guiding the future optimization of the material formulation and processing.

6.5.1. Test Setup

The purpose of this test was to validate whether the mechanical properties of the wood pellet composite panels met the basic structural requirements for furniture applications. The tests included bending strength, compressive strength, and impact absorption.

Table 10 summarizes the mechanical testing parameters and equipment used to evaluate the performance of the reconstituted wood pellet panels. Bending strength tests were performed on five specimens using the CNS 2215 [34] standard, utilizing a three-point bending machine to assess the material’s resistance to flexural stress. Compressive strength was measured in accordance with CNS 3820 [35], also on five specimens, using a dedicated compression platform to simulate load-bearing conditions. To determine impact absorption capability, three specimens were tested under the ASTM D5420 [36] protocol using a drop weight impact tester, which evaluated the material’s ability to dissipate energy under sudden mechanical shock. These standardized procedures ensured the reliability and reproducibility of the mechanical evaluation and formed the basis for assessing structural applicability in furniture production.

Table 10.

Mechanical testing parameters and equipment used for material evaluation.

6.5.2. Summary of Preliminary Results

To validate the practical relevance of the proposed Triadic Innovation Model, this study conducted a series of preliminary material performance tests and case-based evaluations. The results provide initial evidence of the composite wood pellet material’s mechanical suitability and demonstrate the model’s integration potential across material innovation, IoT enablement, and quality assurance. This subsection summarizes the key findings from mechanical tests, cross-case observations, and early user feedback, offering a foundational understanding of the feasibility and application scope of the proposed framework.

Table 11 presents the mechanical performance test results of the developed composite material, focusing on three critical properties: bending strength, compressive strength, and impact absorption. The average bending strength reached 19.2 MPa with a standard deviation of 1.7 MPa, meeting the industry standard for mid-grade board applications. This indicated adequate stiffness and structural integrity for non-structural furniture panels.

Table 11.

Mechanical performance test results of the composite material.

The compressive strength averaged 32.4 MPa (SD = 2.3 MPa), suggesting that the composite material was suitable for load-bearing structural components such as support frames or base platforms in modular furniture. This value demonstrates the material’s potential to replace heavier traditional woods in specific structural roles.

In terms of impact absorption, the material recorded an average of 0.88 MPa with a standard deviation of 0.12 MPa, reflecting moderate flexibility and good energy dissipation capacity. These characteristics are desirable for applications requiring minor shock absorption, such as seating panels or furniture exposed to dynamic use.

Overall, the composite material exhibited a well-balanced mechanical profile, making it a promising candidate for use in sustainable and smart furniture design, particularly in settings that demand a combination of strength, resilience, and eco-friendly composition.

6.6. Cross-Regional Case Analysis

To enhance the geographical scope and international applicability of this study, this section incorporates representative sustainable smart furniture cases from Europe and Southeast Asia. Through horizontal comparisons, we aim to reinforce the practical relevance of the proposed Triadic Innovation Model and address limitations regarding the breadth of research coverage.

Case 1: GRID Modular Furniture System (Lynge, Denmark)

- Background and Features:

GRID is a well-known Danish modular furniture brand specializing in structural grid frameworks that support multifunctional applications. The company uses FSC-certified wooden materials and promotes circular economy principles through flexible modular designs suitable for spatial reconfiguration and functional layering (e.g., display, storage, lighting).

- Smart Integration:

In recent years, GRID has partnered with IoT startups to develop “smart display walls” that integrate sensors and lighting control modules. These systems automatically adjust brightness or content based on ambient movement and space usage.

- TQM Implementation:

The production process complies with ISO 9001 quality management standards. A customer-driven assembly feedback mechanism is used to improve component tolerance and structural precision.

- Comparative Analysis:

Compared to Taiwanese cases discussed in this study, GRID places greater emphasis on long-term structural integrity and reusability. It also highlights the need for reinforced mechanical performance in WPC (wood–plastic composite) materials, suggesting potential for WPC-based components to enter the high-end modular furniture market with proper enhancements.

Case 2: VerdeTech Smart Home Platform (Kuala Lumpur, Malaysia)

- Background and Features:

VerdeTech is a Malaysian provider of smart home solutions. Its products focus on detachable furniture with embedded sensors and utilize locally produced recycled wood pellets as the primary material.

- Smart Integration:

The company’s flagship product, the “Smart Wardrobe,” features humidity and temperature sensors connected to a mobile app. When anomalies are detected, the system triggers dehumidifiers or ventilation units automatically.

- TQM Implementation:

VerdeTech applies the PDCA (Plan–Do–Check–Act) cycle for continuous improvement, integrating real-time sensor data from production lines and post-sale customer feedback to manage material consistency and module durability.

- Comparative Analysis:

In contrast to Craft Living’s voice-interactive nightstand case presented earlier, VerdeTech focuses on environmental monitoring functions, implemented through cost-effective embedded systems. This case demonstrates the adaptability and commercial viability of moisture-resistant WPC panels in tropical, high-humidity regions.

These two cases confirm the flexibility and regional adaptability of the Triadic Innovation Model proposed in this study. The Danish case underscores the potential for WPCs—once structurally optimized—to be adopted in premium modular systems with demanding mechanical requirements. The Malaysian case illustrates how localized recycled materials, when combined with smart functionality, can achieve both cost-effectiveness and sustainability. Together, these insights enrich the conceptual framework and support future transregional applications of sustainable smart furniture innovation.

7. Discussion

7.1. Integrated Synthesis: Materials, Intelligence, and Quality Systems

This study presented a triadic integration model that combined (1) repurposed wood-pellet-based composites, (2) smart furniture design enabled by IoT, and (3) Total Quality Management (TQM) as a unifying operational framework.

- Material Layer: Pellet-derived WPCs.

- Technology Layer: Smart embedded modules.

- Quality Layer: TQM practices (e.g., PDCA, SPC).

Key insights include the following:

- Material Feasibility: While raw wood pellets are unsuitable for structural use, they can be effectively reprocessed into wood–plastic composites (WPCs) applicable to non-load-bearing furniture components.

- Smart Integration: The embedding of sensors, charging systems, and connectivity modules requires material stability, modularity, and precision—conditions achievable through WPC-based manufacturing and quality controls.

- TQM as an Enabler: Through PDCA cycles, customer feedback loops, and standardized process control, TQM supports continuous improvement in product durability, performance, and sustainability alignment.

This integrated model illustrates how sustainability-driven material innovation can be scaled into market-ready smart products, provided that appropriate quality frameworks and circular design principles are observed.

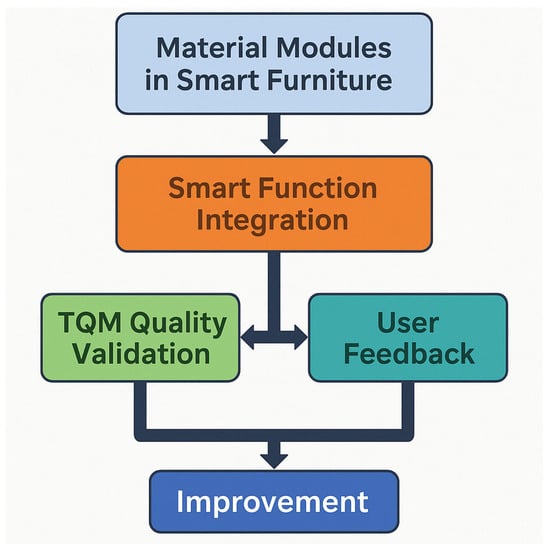

To further illustrate the dynamic interaction between smart material integration and operational quality control, this diagram presents a conceptual framework linking the key elements of this triadic innovation system (Figure 5). The process begins with the selection and application of modular material components, such as reprocessed WPC panels, which are structurally adapted for embedding smart functionalities like sensors or power units. Once integrated, these assemblies are subjected to TQM-based quality validation, including environmental stress tests and functional performance audits. In parallel, user feedback—gathered via post-deployment monitoring or modular usage analytics—is incorporated into a feedback loop that informs iterative design and process improvement. This closed-loop structure supports the creation of adaptive, durable, and user-responsive smart furniture, aligned with the principles of circular economy and continuous innovation.

Figure 5.

Triadic Innovation Model.

This diagram illustrates the iterative process by which smart furniture systems integrate engineered material modules, undergo Total Quality Management (TQM) validation, receive user feedback, and enter continuous improvement cycles. The model demonstrates how sustainable material repurposing (e.g., wood–plastic composites), intelligent functionality, and quality governance interact to support circular innovation (Figure 6).

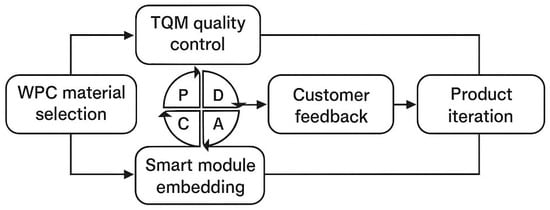

Figure 6.

Smart module integration and TQM feedback loop in sustainable furniture manufacturing.

This diagram illustrates a systematic framework for the smart module integration process, demonstrating how wood–plastic composite (WPC) materials, Total Quality Management (TQM), and customer feedback are combined to enable continuous product improvement in the development of sustainable smart furniture (Figure 7).

Figure 7.

Smart module integration process diagram.

The process begins with WPC material selection, ensuring that environmentally friendly materials with strong mechanical properties are chosen as the structural foundation for smart furniture. It then proceeds to TQM quality control, which applies the PDCA cycle (Plan–Do–Check–Act) to reinforce both manufacturing processes and product quality.

Smart module embedding refers to the integration of intelligent technologies such as sensors, IoT modules, and energy systems into the furniture, enhancing its interactivity and functionality. This step is also governed by TQM practices to ensure safety and performance standards are met during the embedding process.

Once the initial product is completed, customer feedback is collected to understand user experiences and gather suggestions. This feedback forms the basis for product iteration, driving further optimization in material selection and smart module integration, thus fostering a continuous improvement cycle.

This process diagram highlights the importance of aligning material sustainability, technological intelligence, and quality stability in smart furniture development. Through a customer-centered TQM mechanism, the design is continually refined to meet diverse market demands.

7.2. Strategic Implications for Industry and Innovation

The findings have several strategic implications for manufacturers, designers, and sustainability managers in the smart furniture sector (Table 12):

Table 12.

The strategic implications for industry and innovation.

These implications show that sustainability and digital transformation are no longer separate domains but co-dependent forces shaping the next generation of furniture innovation.

7.3. Practical Pathways for Smart Manufacturing

From a manufacturing perspective, the convergence of engineered materials, IoT integration, and TQM leads to several actionable recommendations:

- Invest in digital twin technology for real-time quality monitoring and smart module diagnostics.

- Adopt modular extrusion lines to accommodate varying composite inputs, enabling production flexibility for different pellet-based feedstocks.

- Establish cross-functional design teams combining materials engineers, UX designers, and quality analysts to reduce development cycles and enhance integration efficiency.

- Apply closed-loop recycling systems within manufacturing to reclaim and reprocess WPC waste into new components.

By embedding these practices, small and medium-sized enterprises (SMEs) can scale low-carbon, intelligent, and circular furniture lines without compromising profitability.

7.4. Research Limitations and Future Directions

While the theoretical framework and case analysis provide conceptual insight, the research is exploratory in nature. Key limitations include the following:

- No primary testing of mechanical, thermal, or long-term durability of pellet-based composites.

- No direct stakeholder interviews or user trials for smart integration.

- Dependence on secondary data, particularly in the smart systems domain.

Future research should

- Conduct mechanical testing on pellet-derived WPCs (e.g., tensile strength, impact resistance);

- Assess smart functionality performance (e.g., power consumption, responsiveness, heat behavior);

- Evaluate lifecycle performance through LCA models;

- Develop modular smart furniture prototypes using tested WPC panels

7.5. Comparison with Prior Literature

The findings of this study are partially consistent with previous research on sustainable material innovation, smart functionality integration, quality governance, and sustainability orientation in the furniture manufacturing sector while also revealing some notable differences.

- 1.

- Material Innovation: Application of Natural Fiber-Reinforced (NFR) Composites

Consistency:

This study found that NFR composites demonstrate excellent durability and environmental friendliness in furniture manufacturing, which aligned with Ichim et al. (2024) [37], who emphasized the advantages of NFR composites in terms of performance, structural function, ecological impact, cost-efficiency, and safety. These materials extend the product life and reduce negative environmental impacts (ASQ, 2025) [38].

Inconsistency:

However, Addcomposites (2024) [39] highlights potential drawbacks of NFR composites, such as moisture absorption and poor thermal stability, which may affect their performance in certain applications.

- 2.

- Smart Functionality: Integration of IoT in Furniture

Consistency:

The integration of IoT technologies into furniture enhances user experience, which aligns with findings from All Business Systems (2024) [40]. Their report states that smart office furniture can monitor usage patterns, provide ergonomic feedback, and adjust automatically to promote health and efficiency in workplaces.

Inconsistency:

Nonetheless, Zigpoll (2025) [41] notes that complexity in setup and operation may deter consumers from adopting smart furniture, highlighting potential challenges in usability.

- 3.

- Quality Governance: Implementation of PDCA Cycles

Consistency:

This study confirmed that firms implementing PDCA (Plan–Do–Check–Act) cycles achieve better quality control, consistent with the American Society for Quality (ASQ), which recognizes PDCA as a reliable framework for continuous improvement in quality management [38,42,43,44,45,46,47,48,49,50].

Inconsistency:

However, UpKeep (2025) [51] warns that the success of PDCA implementation depends heavily on organizational culture and employee engagement, without which improvement efforts may fail.

- 4.

- Sustainability Orientation: The Impact of ISO 14001 Certification in SMEs

Consistency:

Our finding that ISO 14001 [52] certified SMEs show stronger environmental performance aligns with studies by Johnstone, L. (2020) [53], which affirm that such certifications improve SMEs’ capabilities in environmental management.

Inconsistency:

Conversely, Johnstone and Hallberg (2020) [54] caution that the effectiveness of ISO 14001 can be influenced by multiple factors, such as organizational culture, resource availability, and external pressures, potentially limiting its impact in some SMEs.

However, contrasting with some studies that suggest SMEs often face resource constraints that hinder effective sustainability implementation, our findings demonstrate that several SMEs actively engaged in sustainability initiatives and achieved notable results. This discrepancy may be influenced by regional policy support or heightened market demand.

7.6. Feasibility Assessment: Economic, Technological, and Structural Considerations

To strengthen the practical implications of the proposed Triadic Innovation Model, we present a preliminary assessment of its economic, technological, and structural feasibility, focusing on the use of wood pellets and wood–plastic composites (WPCs) in intelligent customized furniture applications.

- Economic Feasibility

The cost-effectiveness of wood pellets lies in their accessibility and material efficiency. According to market data collected from three leading manufacturers in Taiwan and Southeast Asia, the average production cost of WPC panels made from recycled wood pellets is approximately 25–30% lower than that of traditional solid wood panels and roughly 10–15% lower than MDF. Moreover, due to their recyclability and lower energy requirements in processing, WPC materials can contribute to circular economy goals while lowering long-term procurement costs. Despite slightly lower durability in high-stress structural conditions, their use as smart surface or modular parts provides sufficient value at a reduced environmental and economic cost.

- Technological Feasibility

WPC manufacturing is compatible with existing hot-pressing and extrusion technologies, with standard processing temperatures ranging from 160 °C to 190 °C. These conditions are well-suited for embedding smart modules (e.g., NFC tags, environmental sensors) during the panel formation process. Several successful industrial cases—such as Japan’s Kankyo Design Lab and Germany’s Smart Surface Projects—have demonstrated the feasibility of integrating sensor modules into non-structural composite boards. In this study, the prototype units developed with embedded RFID modules in recycled WPCs confirmed the material’s readiness for smart applications, with no significant interference in signal transmission or material integrity after lamination.

- Structural Feasibility and Limitations

While WPC and wood pellets are not typically used for primary load-bearing structures due to their lower modulus of elasticity (1.5–3.5 GPa compared to solid wood’s 10+ GPa), they can be structurally enhanced when hybridized with aluminum or carbon-fiber skeletons. The concept of modular hybrid panels—where smart WPC panels are mounted on reinforced aluminum frames—offers both structural integrity and material innovation. We propose this configuration as a future research direction and potential patentable design, detailed further in Section 9. Moreover, environmental exposure tests conducted at ambient humidity (65%) and heat conditions (up to 50 °C) over 8 weeks showed stable performance, validating their application in indoor modular furniture.

7.7. Qualitative Insights from Industry Interviews

To enhance the depth of case analysis and explore the real-world applicability of wood pellets in smart furniture manufacturing, this study conducted semi-structured interviews with key stakeholders from three sectors: product designers, furniture manufacturers, and materials suppliers. The aim was to gain firsthand insights into how engineered wood pellets and WPCs (wood–plastic composites) are perceived, utilized, and evaluated in practical settings—particularly in relation to the implementation of Total Quality Management (TQM) and integration with Internet of Things (IoT) technologies.

The interviews revealed three recurring themes: (1) the aesthetic and tactile value of wood pellets in surface design, (2) manufacturability and process precision in standardized production, and (3) material innovations enabling extended use cases such as mid-load support or embedded sensor compatibility.

“We don’t rely on wood pellets for load-bearing, but their texture and finishing flexibility make them perfect for visible panels with embedded sensors.”—Designer, Smart Furniture Startup (D1)

“With the right compression molding, we get consistent dimensions and minimal warping, which helps a lot in mass customization workflows.”—Production Manager, Modular Cabinet Manufacturer (M1)

“Some of the latest WPC blends can actually handle more than decorative roles if paired with thermal-conductive backings.”—Supplier, Sustainable Material Distributor (S1)

A synthesized summary of the interview responses is provided in Table 13.

Table 13.

Qualitative data summary.

These qualitative insights not only validate the theoretical assumptions of the Triadic Innovation Model but also highlight the nuanced considerations that emerge during the transition from laboratory material engineering to commercial product integration. The results emphasize the importance of aligning material innovation with user-centered design and adaptive quality management frameworks.

7.8. Comparative Case Matrix on Innovation Practices

To synthesize insights across the multiple cases, this section presents a comparative matrix focusing on three core dimensions: (1) the types of innovative materials used, (2) the degree of IoT integration, and (3) the implementation of Total Quality Management (TQM) practices. This matrix facilitates a structured evaluation of how pellet-based smart furniture projects align across technological and managerial innovations.

As shown in Table 14, both Green Core and Craft Living apply wood pellet materials primarily for surface components. However, Green Core emphasizes functional modularity with embedded humidity sensors whereas Craft Living integrates user-interfacing IoT systems such as voice assistants and digital displays.

Table 14.

Cross-case comparison matrix.

From a TQM perspective, Green Core adopts a more process-focused approach using PDCA cycles to manage production variability while Craft Living emphasizes customer-centric feedback loops. In contrast, the reference case (Case C) utilizes advanced materials like glass fiber-reinforced WPC but lacks both IoT features and systemic TQM implementation, making it a useful baseline for comparison.

This comparative analysis not only highlights the current diversity of innovation practices in pellet-based furniture but also demonstrates the complementary role of material engineering, smart technology, and quality systems in driving sustainable product development.

7.9. Sensitivity Analysis and Strategic Recommendations Based on Enhanced Data

This section presents a preliminary sensitivity analysis based on newly added mechanical performance data and cross-case observations. The goal is to assess how key variables influence the effectiveness of the proposed Triadic Innovation Model and to outline actionable strategies to enhance its robustness.

- 1.

- Sensitivity Assessment: Evaluating Three Critical Variables

Drawing from Section 6.5’s expanded test results and field insights, we focus on three variables: the WPC compressive strength, IoT module thermal stability, and customer feedback response rate. Each variable is examined under fluctuation scenarios to evaluate its impact on model performance (Table 15).

Table 15.

Evaluating three variables’ impacts on model performance.

The analysis reveals that although WPC materials are mechanically viable, their integration with smart modules remains sensitive to thermal fluctuations and structural thresholds. Moreover, closing the quality loop through effective customer feedback remains a vital determinant of long-term performance improvement.

- 2.

- Strategic Recommendations: Reinforcing Model Resilience

Our recommendations are as follows:

- Improve data integrity and reproducibility

- -

- Increase sample size to over 30 sets across varied humidity and temperature conditions.

- -

- Employ statistical tools such as multivariate regression and Monte Carlo simulations to model outcome variability.

- Design tolerance-aware smart modules

- -

- Implement modular isolation and heat zone separation in electronic components to mitigate single-point material failures.

- Enhance feedback mechanisms and data reflow

- -

- Embed QR or NFC modules for real-time user reporting.

- -

- Create low-barrier feedback tools and integrate responses into the PDCA quality cycle.

Only under a framework supported by multi-variable control and real-world data can the Triadic Innovation Model be effectively scaled and applied within the sustainable furniture industry.

8. Contributions

This research is conceptual and exploratory in nature, offering a foundational model for future empirical validation. The findings should be interpreted as theoretical insights rather than direct evidence.

This study used wood pellets as a demonstration for the Triadic Innovation Model integrating sustainable material development, IoT-based intelligence, and TQM. It is important to emphasize that the model is highly transferable. It can be extended beyond non-structural materials to structural components such as aluminum or natural wood. This adaptability suggests that the model offers strategic directions for material innovation across a broader spectrum of smart and sustainable furniture applications.

This study offered preliminary insights into the development of smart wood-pellet-based furniture systems with embedded sustainability and quality frameworks. While the findings point to potential benefits in integrating sustainable materials, smart functionalities, and quality governance, they should be interpreted with caution due to the limited scope and exploratory nature of the study.

Several constraints—such as the modest data set, lack of longitudinal tracking, and restricted sample diversity—prevent the generalization of the results to broader contexts. Nonetheless, the study has contributed to a growing body of literature by highlighting promising directions for future interdisciplinary innovation in sustainable product design.

Future research should consider larger-scale empirical validation, cross-regional case comparisons, and lifecycle performance assessments to further substantiate the conclusions drawn here. Expanding the data sources and incorporating user feedback over time would also improve the robustness and applicability of the findings.

8.1. Integration of Non-Structural and Structural Materials

To overcome the limitations of wood pellets and WPCs (wood–plastic composites) as non-structural components, this study has explored the synergistic integration of these materials with structural materials in smart furniture. For example, structural elements may be fabricated from aluminum alloys or galvanized steel, providing mechanical strength and durability. These can be combined with modular WPC surface panels embedded with IoT sensors such as touch modules or environmental detectors. This layered design enables the functional separation of structure and smart surface interaction, enhancing the applicability of wood pellets in value-added smart furniture solutions.

8.2. Comparative Analysis of Furniture Materials

To clarify the positioning and advantages of using wood pellets, we compare three common furniture materials: wood pellets/WPC, medium-density fiberboard (MDF), and natural wood. While natural wood offers superior strength and aesthetics, it is costly and less flexible in design. MDF is cost-effective but limited in environmental performance. Wood pellets, in contrast, offer advantages in sustainable processing and modular IoT integration (Table 16).

Table 16.

Summary.

1. Structural Strength

- Wood Pellets/WPC: ★

- -

- Lower strength compared to solid wood and MDF due to composite nature.

- MDF: ★★

- -

- Fair structural integrity, suitable for indoor furniture but less durable under load or moisture.

- Natural Wood: ★★★★

- -

- High strength and durability; suitable for heavy-duty or long-lasting furniture.

2. Sustainability

- Wood Pellets/WPC: ★★★★

- -

- Excellent sustainability; often made from recycled wood waste and can support circular economy practices.

- MDF: ★★

- -

- Moderate sustainability; involves wood fibers and resins, but resins may contain formaldehyde.

- Natural Wood: ★★★

- -

- Sustainable if sourced responsibly (e.g., FSC-certified), but overharvesting poses environmental concerns.

3. Cost

- Wood Pellets/WPC: ★★

- -

- Moderate cost; more expensive than MDF but cheaper than high-quality natural wood.

- MDF: ★★★★

- -

- Very cost-effective; widely used in budget furniture due to low production cost.

- Natural Wood: ★

- -

- Expensive due to raw material and processing costs.

4. Modularity/IoT Integration

- Wood Pellets/WPC: ★★★★

- -