Abstract

The environmental impact of first-generation biodiesel production, particularly deforestation and soil degradation caused by palm and soybean cultivation, has raised concerns about sustainability. In contrast, second-generation biodiesel utilizes waste as feedstock, offering a more sustainable alternative. Used cooking oil (UCO), a significant waste stream, represents a viable feedstock for biodiesel production, reducing pollution and mitigating economic, environmental, and social challenges. While Europe has demonstrated successful UCO waste management strategies, many regions lack efficient systems, leading to improper disposal that causes water eutrophication, soil degradation, and increased wastewater treatment costs. This study develops a comprehensive strategy for UCO management to optimize its energy potential in biodiesel production, using Barranquilla, Colombia, as a case study. Transesterification, identified as the most efficient conversion method, achieves conversion rates of up to 90%. A pilot project in the Barranquilla area estimates that 963,070.95 kg of UCO is generated annually, with the potential to produce 902,108.56 kg of biodiesel. These findings contribute to the advancement of circular economy principles, offering an adaptable framework for sustainable biofuel production in other regions.

1. Introduction

Used cooking oil (UCO) is a waste generated during food preparation. The annual worldwide generation of UCO is around 16 to 25 million tons of UCO. Approximately 15% of clean vegetable oil becomes waste after use, which makes UCO a highly polluting waste and continuous generation, so improper disposal can cause economic, environmental, and social problems [1,2].

Several life cycle studies on first- and second-generation biodiesel have highlighted significant environmental differences between them. The production of first-generation biodiesel often involves deforestation of extensive areas for palm and soybean cultivation. This practice leads to adverse effects, such as monoculture farming, soil degradation, and increased risks of food scarcity. Conversely, second-generation biodiesel relies on waste materials as feedstock, with UCO emerging as a highly viable option for its production [3].

The production of second-generation biodiesel is vital as it uses highly polluting waste, such as UCO, through transesterification processes with efficiencies reaching up to 98%, as described in [4]. In Thailand, the Energy Development Plan promotes the use of diverse renewable energy sources—including wind, photovoltaic, and biomass energy. Within this context, UCO presents substantial energy potential. Specifically, the process efficiencies for converting UCO into biodiesel in Thailand range from 85% to 92%, reflecting practical implementation outcomes within the country [5].

Studies in Europe have shown that proper management of UCO waste offers significant benefits. Researchers have found transesterification to be the most efficient process for producing biodiesel from UCO, with efficiencies of up to 90%. The optimal NaOH catalyst to oil ratio, based on trials, is 1:12 [6].

In South America, countries like Ecuador have actively explored environmentally friendly energy sources to promote sustainability. Research on the physicochemical properties of UCO and biodiesel has demonstrated that UCO possesses excellent characteristics for fuel production. These properties comply with international standards, including pH, acidity index (ISO 660:2020) [7], iodine index (ISO 3961:2024) [8], dynamic viscosity (ASTM D 6751) [9], saponification index (ISO 3657-2023) [10], and density (ISO 6883-2000) [11]. Such compliance ensures its suitability for applications in transportation and industry [12]. In Ecuador, a project focused on UCO management evaluated the technical and economic feasibility of its alternative uses, such as producing candles and soap. The study involved 47 gastronomic establishments in the city of Puyo, located in Pastaza Province. Findings revealed that candle manufacturing is the most profitable option, with an estimated revenue of 447,530.01 USD by 2022. The project reported a remarkable rate of return of 106.3% and an investment recovery period of only 0.7 years, highlighting its economic viability [13].

In Costa Rica, the Universidad Nacional conducted a diagnosis of the management of UCO waste in kitchens, finding inadequate practices in terms of filtration, useful life, use, and disposal temperatures. Additionally, the collected oils exhibited turbidity and odors compared to new oil, showing the need for pretreatment for valorization [14].

In Colombia, the national circular economy strategy has boosted research on the reincorporation of waste into the productive chain. Colombian regulations establish parameters for UCO proper management [15]. This regulation defines two key players: the generator, who produces the UCO, and the manager, who handles its use [1]. The country also has a national circular economy strategy [16], UCO regulations [15] and environmental sanctioning procedure [17], which establish guidelines for the use of waste and its reintegration into the production chain. Also, districts have their own regulations such as Barranquilla [18]. However, it does not address the potential of UCO to produce biofuels, a key area for the strategic management of its energy use. A study focusing on large UCO generators in Barranquilla (Colombia) revealed that restaurants constitute 79.5% of UCO-producing establishments. Among these, 60.4% deliver their used oil to authorized collection companies [19]. However, approximately 8.7% dispose of it with organic waste, and 12% sell it to unknown handlers, posing environmental and health risks.

Therefore, the current work presents a novel strategy developed for the management of UCO for its energetic use in the production of biodiesel, promoting actions that contribute to the circular economy in cities and highlighting its major contribution to the literature. The strategy for UCO management and its energy recovery for biodiesel production provides a valuable contribution to waste management. To support novel contribution, the research considered a literature review to identify previous works before proposing a strategy to promote the production of biodiesel in one of the principal cities of Colombia. This approach aligns with the energy policy and the Sustainable Development Goal that guarantees responsible production and consumption, aiming to reduce waste production through recycling, reduction, and reuse by 2030 [20].

2. Production of Biodiesel Based on Used Cooking Oil

2.1. Waste Management: Framework

Global waste generation is mainly influenced by three factors: population growth, industrialization, and consumerism. Therefore, ref. [21] analyzed the waste generated in different regions of the world, projecting data between 2001 and 2010. Their results showed that Sub-Saharan Africa experienced an exponential growth in waste generation, while Europe and Central Asia maintained low levels. On the other hand, Latin America and the Caribbean presented a moderate increase in waste generation [21].

To achieve proper waste management, it is crucial to evaluate the entire management chain, from the production of waste to the implementation of the stages of collection, transportation, storage, transformation, utilization, and manufacture of new materials. The implementation of these stages will vary according to the type of waste to be managed or recycled, as shown in Figure 1 [22].

Figure 1.

Phases to integral waste management.

2.2. Production of Second-Generation Biodiesel: A Literature Review

Biodiesel is an alternative fuel made from animal or vegetable fats. When it is produced using waste, it is classified as second-generation biodiesel, since its raw material comes from waste, which is given an energetic use, thus facilitating its reintegration into the production chain [14].

The main technique to produce second-generation biodiesel is the transesterification of fats. During this process, each triglyceride molecule present in the oil is converted into three long-chain fatty acid monoalkyl esters, also generating a glycerol molecule as a by-product of the reaction [23]. The stages of the biodiesel production process from UCO are as follows [9,23]:

- (1)

- Verification of the input parameters of the UCO;

- (2)

- Checking the acid number of the UCO—if it is higher than 1%, prior esterification is recommended;

- (3)

- Once the UCO is within the parameters, it is introduced into the reactor,

- (4)

- Alcohol is added in ratios of 12: 1, 9:1, or 6:1;

- (5)

- The reaction catalyst is incorporated, such as potassium hydroxide (KOH) and sodium hydroxide (NaOH), among others, recommending sodium hydroxide (NaOH) at 1% W/W, and an oil–alcohol ratio of 12:1;

- (6)

- The alcohol and catalyst are premixed;

- (7)

- The reaction temperature must be lower than the alcohol evaporation temperature to avoid losses—in the case of methanol (65 °C), the reaction is carried out at 60 °C and typical pressures of 20 Psi;

- (8)

- The optimum reaction time should be determined by experimentation;

- (9)

- The mixture should be stirred continuously during the reaction;

- (10)

- The reaction mixture is transferred to a settling tank to separate the glycerol phases;

- (11)

- The biodiesel phase is washed with distilled water at a ratio of one third of the water to one part biodiesel—the mixture is stirred and allowed to separate by decanting until the pH of the water approaches neutral;

- (12)

- The biodiesel is dried by heating it at approximately 110 °C to evaporate the remaining water;

- (13)

- Quality tests are performed to certify compliance with biodiesel specifications.

To demonstrate the success of biodiesel production, the review considered studies published between 2019 and 2024, using the following keywords in the SCOPUS database: “used cooking oil”, “transesterification”, “biodiesel”, “catalyst”, and “sodium hydroxide”. Table 1 presents the stoichiometric reaction yields achieved in biodiesel production from UCO, using the transesterification method, based on data from 33 articles identified through the proposed search strategy. The results show that, in previous studies, the reaction yields were no lower than 80%, with more than half of the papers reporting yields above 93%.

Table 1.

Efficiency of the reactions reached in previous work.

The paper analysis revealed that the range of the stoichiometric reaction to produce biodiesel by the fat transesterification method varied between 90% and 100%. This provides a solid basis for developing a management strategy that allows the valorization of the waste.

2.3. Analysis of the Efficiency and Quality of Biodiesel Generated from Cooking Oil Waste

Table 2 lists the parameters that must be analyzed to assess the quality of biodiesel, together with the corresponding technical standards and acceptable ranges for the analysis results as described in Table 1.

Table 2.

List of parameters and standards considered to evaluate biodiesel derived from UCO.

3. Materials and Methods

For the development of the Cooking Oil Waste Strategy to produce biodiesel, the authors considered context, energetic potential, and national policies, highlighting topics such as capabilities, barriers, and drivers to collect and process UCO in the department of Atlántico (Colombia). To evaluate the potential for utilization of UCO, its amount (in kilograms) managed in the city was used as a reference based on information reported to national regulators.

The potential for energy utilization was evaluated based on information provided in Table 1 and standard reviewed. Table 2 presents physicochemical parameters of UCO for biodiesel production feasibility. The research considered these parameters based on the literature reviewed and national recommendations to analyze the quality and efficiency of biodiesel derived from UCO.

The strategy considers within its implementation and monitoring framework the Colombian National Circular Economy Strategy and Resolution 316 of 2018 [15], which regulates activities related to the management of UCO in Colombia. To ensure the execution of the policies, the strategy considers the recycling process of the UCO, and involves generators, managers, and recyclers. In addition, it includes recovery techniques, establishes goals, performance indicators, and defines a governance framework to ensure effective implementation.

The research sample comprised the total UCO collected over one year of observation. It included seventeen companies registered in Barranquilla and twenty-three companies allowed to collect UCO in the department. Altogether, the total UCO collected contributions involved from forty companies. Companies use to report the collected UCO on kg/year of UCO.

4. Results from the Implemented Strategy for Guaranteed Management of Cooking Oil Waste for Energy Use in Biodiesel Production

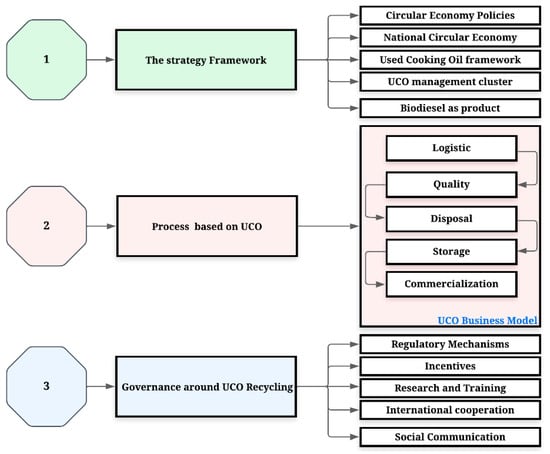

The strategy for managing cooking oil waste to use energy in biodiesel production involves three phases. The first phase corresponds to the strategy framework. Then, the business model considered evaluating the UCO Generation Rates. The last phase considers the utilization of mechanisms and governance of UCO recycling. Figure 2 summarizes each phase, and the following section describes each component.

Figure 2.

Conceptual strategy to use Cooking Oil Waste for Energy Use in Biodiesel Production.

4.1. Phase 1: The Strategy Framework

Table 3 outlines the conceptual framework, including circular economy definitions, national circular economy strategy, UCO Framework (generator, manager), and second-generation biodiesel framework. The phase points out the recycling process of UCO. This strategy focuses on creating a plan to manage UCO and produce biodiesel, ultimately driving economic growth. This plan consists of three key components. The first involves developing a strategic framework for UCO recycling, using Barranquilla and the Atlantic Department as reference case studies. The second outlines the process of converting UCO into biodiesel to support the business model. The third component addresses governance mechanisms surrounding UCO improvements to maintain and support the strategy, such as regulations, incentives, research, training, cooperation, and social communication.

Table 3.

Conceptual frameworks for a circular economy strategy in UCO management.

A successful transition from a linear economy to a circular economy requires implementing comprehensive guidelines, policies, and regulations, such as described in [17]. These should engage producers, marketers, distributors, recovery agents, and managers throughout the production chain. The strategy is supported by the National Circular Economy Strategy, launched in 2019 by Colombia’s Ministry of Environment and Sustainable Development, which provides policies and guidelines [16]. Its goals include promoting resource valorization, managing material, water, and energy cycles, and fostering new business creation. Additionally, the strategy encourages industrial collaboration and sustainable urban development to enhance production and consumption efficiency, reduce water and carbon footprints, and meet SDGs 8, 9, 11, 12, and 13 [20].

Vegetable oils are food products derived from plant sources, primarily composed of fatty acid glycerides, with potential traces of free fatty acids and other lipids. These oils are commonly used in households and industries for frying and marinating foods. However, prolonged exposure to high temperatures degrades the oils, producing triglycerides and lipid by-products, thus creating pollutant waste. According to national regulations [15], a UCO generator is any individual or commercial, industrial, or service entity using edible vegetable oil in food preparation. The household of UCO generators must follow usage guidelines provided by vegetable oil marketers and dispose of UCO at designated clean points managed by certified entities. A UCO manager is a natural or legal entity responsible for collecting, transporting, storing, and processing UCO in accordance with regulations. UCO managers are also required to install clean points for household UCO collection and maintain a contingency plan for transport, storage, and treatment. Vehicles must be equipped with spill prevention kits and modified to prevent waste leakage during transport [15,19].

Second-generation biodiesel refers to fuel produced from non-food-based raw materials, particularly agro-industrial residues and high-biomass energy crops. Among the most relevant agro-industrial residues are animal fats derived from meat processing industries (such as tallow, poultry fat, and slaughterhouse by-products), waste from food processing activities (including UCO, spent bleaching earth, and fruit or vegetable pulp), and lipid-rich waste from municipal and industrial wastewater treatment facilities. The use of these residues not only diverts organic waste from landfills and wastewater systems but also mitigates environmental impacts associated with improper disposal. Furthermore, second-generation biodiesel production reduces reliance on edible feedstocks, promoting a more sustainable and circular economic approach for urban and rural waste streams alike. Its production process is more complex than that of first-generation biodiesel. The primary distinction between these biodiesel types is in feedstock; second-generation biodiesel uses used oils and non-food materials, unlike first-generation biodiesel.

4.2. Phase 2: Process Based on UCO

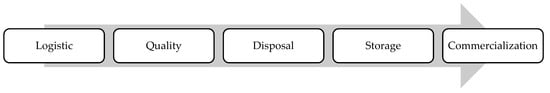

This model outlines a comprehensive process for the collection, analysis, storage, and commercialization of UCO as a resource for biodiesel production (Figure 3). By establishing clean points and involving local communities, the model promotes sustainable waste management practices while creating economic opportunities. It adheres to regulatory standards for transport, storage, and quality control, ensuring both environmental protection and alignment with national and international market demands. The process includes five steps.

Figure 3.

The five steps to manage the UCO.

4.2.1. Step 1: UCO Management Logistics

Used oil collection requires specialized containers that prevent spillage and restrict unauthorized access. Once collected, the oil must be transported to a recovery facility. Additionally, clean points should be installed where users, including residents, schools, and stores, can safely deposit UCO. Transportation from clean points to the processing plant must follow the same safety procedures applied to standard containers. Transportation should employ cargo vehicles specifically designed for waste storage. During daily operations, vehicles should collect UCO from designated areas based on a fixed schedule or supplier requests. The process should avoid transferring or handling the oil directly; instead, the oil drum should be replaced with a clean one.

4.2.2. Step 2: UCO Quality Analysis

To assess UCO quality for biodiesel production, the following parameters should be evaluated, as summarized in Table 2. The most used technique in the biodiesel production industry is the transesterification of fats. This process involves the reaction of triglycerides present in UCO with a short-chain alcohol, typically methanol or ethanol, resulting in the production of biodiesel and glycerin [64]. To ensure high-quality biodiesel, this process requires stringent control of reaction conditions such as temperature, catalyst concentration, and alcohol-to-oil ratio. Proper purification steps are also critical to meet international quality standards, minimizing impurities and optimizing fuel performance.

4.2.3. Step 3: Clean Points for UCO Disposal

Clean points are essential for collecting UCO at a community level, and should be strategically located in shopping centers, residential complexes, schools, universities, and stores. Containers must be safe, user-friendly, and accessible to children, adolescents, and adults, with designs minimizing spill risk and preventing issues such as vector proliferation and physical damage. To maximize community engagement, clean points should be accessible to all, regardless of disability or socioeconomic status. Outreach initiatives are necessary to inform users about the clean points, addressing topics such as the definition of UCO, the purpose of clean points, recycling, environmental and health impacts of improper UCO disposal, and instructions for clean point usage.

UCO should be received at the plant either in bulk (in containers such as barrels or isotanks) or directly offloaded from tank cars into storage tanks.

The filtration process involves two stages: initially, UCO is passed through a sieve upon arrival to remove large cooking residues. The second stage occurs in storage tanks, where the oil naturally settles, allowing sludge and moisture to separate over time.

Tests for pH, acid number (ISO 660-2009) [7], iodine number (ISO 3961-2009) [8], dynamic viscosity (ASTM D 6751) [65], saponification number (ISO 3657-2023) [10], density (ISO 6883-2000) [11], gas chromatography, and peroxide number (ISO 3960-2010) [66], should be conducted to determine UCO suitability for biodiesel production.

4.2.4. Step 4: UCO Storage

Storage tanks should be located within a containment dike capable of retaining 100% of the tank’s volume in case of a spill. Valves and appropriate pumping systems are also recommended for efficient handling. The facility must have a comprehensive contingency plan that includes preventive, corrective, and operational protocols for managing emergencies. This plan should follow the national guidelines, and essential components must include objectives, scope, roles and responsibilities, process descriptions, environmental and climatic considerations, risk analysis and mitigation, operational plan, emergency response priorities, organizational structure for emergencies, response services, support agencies, emergency preparedness and strategic planning, information dissemination, and medical evacuation plans.

4.2.5. Step 5: Commercialization of UCO

The UCO has a potential market in exportation and national uses. To achieve international commercialization of UCO, it is essential to establish a robust supply chain that integrates sustainable collection methods, stringent quality control measures, and efficient processing technologies to meet international standards. Building partnerships with local restaurants, food industries, and waste management companies can ensure a steady supply of UCO, while certifications such as International Sustainability and Carbon Certification can enhance market credibility. Additionally, leveraging trade agreements and promoting the environmental benefits of UCO-derived products, such as biodiesel, can attract stakeholders across industries. A comprehensive marketing strategy, combined with compliance with international regulations, will ensure competitive positioning in the global market.

4.3. Phase 3: Governance Around UCO Recycling

For phase 3, the process for obtaining biodiesel used by the industry was described, which is called transesterification of fats. This consists of the reaction between the fats (triglycerides) present in the UCO with a short-chain alcohol that is generally methanol or ethanol, obtaining biofuel and glycerin as products [64].

For the management mechanisms, innovation in regulations, incentives for waste pickers, research and training, international cooperation, information and communication and citizen culture are planted as fundamental tools for the implementation of this strategy, in such a way as to guarantee the recovery of waste.

For the governance of this strategy, regulatory tools are available such as Decree 1076 of 2015, which establishes the “Single Regulatory Decree of the Environment and Sustainable Development Sector as of the date of its issuance”, Resolution 316 of 2018, which defines provisions for the management of UCO and establishes other regulations, and the National Circular Economy Strategy.

4.3.1. Regulatory Mechanisms

It is essential to develop additional regulations to Resolution 316 of 2018 that not only focus on sanctions but also address the regulatory needs in the UCO economy. These new regulations must involve private companies that generate and market edible vegetable oil, commercial, industrial and UCO service generators, as well as managers and recyclers by trade. In addition, an adequate socialization of government policies must be ensured.

Before implementing the new legal framework, it is necessary to train all the actors involved, including government agencies such as the Mining-Energy Planning Unit (UPME), the Superintendence of Residential Public Services (SSPD), the National Environmental Licensing Authority (ANLA), the Regional Autonomous Corporations (CAR), and public environmental establishments. Standards should be clear on definitions, responsibilities, obligations, inclusion of the public and private sector, and UCO recycling standards.

4.3.2. Incentives

It is essential to create specialized lines of credit for entrepreneurs interested in businesses related to UCO recycling, as well as for Used Oil Recycling Companies (ECAS) and other trade recycler organizations. These lines of credit should offer affordable repayment plans and favorable interest rates, providing technical support and initial capital. In addition, tax incentives should be considered in accordance with Law 2099 of 2021, which promotes the energy transition, the revitalization of the energy market, and economic reactivation [67].

Additional incentives should also be implemented, such as entrepreneurship and innovation competitions, carbon tax exemptions for the use of clean products, and exemptions for the import or generation of clean technology. To encourage investments in the circular economy in Colombia, the Ministry of Environment and Sustainable Development and the Ministry of Finance are promoting impact funds with operations in the country, such as Inversor and UCOmen. Likewise, Bancóldex and the Ministry of Finance are expanding sustainable credit lines and managing seed capital for sustainable ventures.

4.3.3. Research and Training

Research is crucial in a circular economy, encompassing the generation of new knowledge, waste recovery, implementation of clean technologies, analysis of product life cycles, and the creation of products from waste. Although the government has the Green Business Office of the Ministry of Environment and Sustainable Development and the National Center for Cleaner Production, it is necessary to advance in the development of innovative technologies, valuation of materials, and new methods of recycling and energy production.

4.3.4. International Cooperation

The circular economy is a global goal reflected in Sustainable Development Goals 11 and 12 [20]. Therefore, export agencies and local investment promotion agencies must promote products, services, and technologies that promote this economic model in international markets. Given the growing interest in UCO in Europe, it is essential to develop policies that facilitate the opening of new markets [68].

Organizations must report the circularity of its economy to the OECD. To this end, advanced cooperation with international agencies, such as the Presidential Agency for International Cooperation (APC), the Inter-American Development Bank (IDB), the European Union’s Directorate-General for the Environment, the World Bank, and the Andean Development Corporation (CAF), is required to promote a circular economy in the country.

4.3.5. Social Communication

It is necessary to establish a consolidated mechanism for the collection and dissemination of UCO reports issued to the environmental authorities by generators and managers. This would enable accurate tracking of recycling data and support the development of public policies and research initiatives aimed at strengthening this economic sector, which provides social and environmental benefits.

Strategies must be created to socialize programs aimed at strengthening the economy of recycling UCO. These strategies should focus on UCO management companies, as well as ECAS and trade recyclers’ associations.

In addition, efforts must be coordinated between the Ministry of Environment and Sustainable Development, the Regional Autonomous Corporations, environmental public establishments, UCO managers, ECAS and associations of professional recyclers, and companies that generate and market vegetable oils. This will allow campaigns to be carried out aimed at household, industrial, commercial, and service generators, raising awareness of the importance of recycling UCO and the adverse effects of improper disposal of waste on natural resources.

5. Study Case

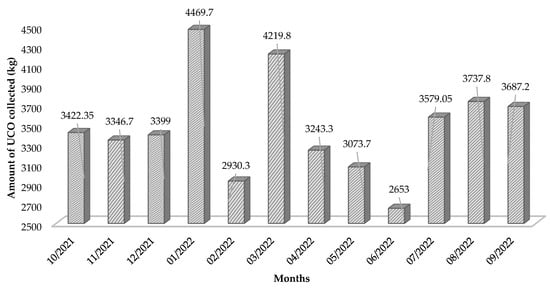

The data for each company were evaluated between October 2021 and September 2022. Within the collecting strategy, the reception of UCO at plants and residential complexes were predominant.

Figure 4 presents the monthly reception of UCO at each company. During analysis, it was observed that the month with the highest amount of waste collected was January, with a total of 4469.7 kg. This increase was related to vacations. The occupation in restaurants, hotels, and other commercial establishments is the highest, which increases the production of UCO. The daily average of storage for each company varies between 57.67 kg and 97.17 kg of UCO, which represents a significant amount.

Figure 4.

Behavior of the UCO reception in a company over one year (October 2021 to September 2022).

The statistical information shows that a company can manage at least a total of 41,872.65 kg of UCO annually. This figure was projected to estimate the waste production of the Department of Atlántico (Colombia), considering the number of registered companies, resulting in 1,674,906 kg per year (711,835.05 kg per year for Barranquilla and 963,070.95 kg per year for Atlántico).

The literature revealed that the mean performance of the stoichiometric reaction to produce biodiesel by the fat transesterification method is 93.67%. With this yield, it is estimated that approximately 666,775.89 kg of biodiesel could be produced in Barranquilla and 902,108.56 kg in Atlántico, for a total of 1,568,881.45 kg of biodiesel. These results support the hypothesis of this research, which establishes that UCO has an energy recovery potential greater than 70% to produce biodiesel.

To develop this strategy, a diagnosis was conducted on UCO generation rates in Barranquilla and the Atlántico department. A representative sample was analyzed and extrapolated to the total companies registered as UCO managers with environmental authorities in both jurisdictions. Results showed that 711,835.05 kg of UCO are recovered annually in Barranquilla, and 963,070.95 kg are managed annually in Atlántico.

6. Conclusions

The improper disposal of UCO poses significant environmental and infrastructure challenges. These include the reduction of soil exchange capacity, eutrophication of water bodies, sanitary system blockages, and an increase in biological and chemical oxygen demand in wastewater, which leads to higher treatment costs. Addressing these issues requires the development of a comprehensive UCO management strategy. Such a strategy must involve all key stakeholders, including private companies in the edible oil industry, UCO generators in commercial and industrial sectors, and waste managers and recyclers, to ensure efficient recovery and reuse of UCO.

This study confirms that UCO serves as a viable feedstock for producing second-generation biodiesel through transesterification, as extensively supported by the reviewed literature. Transitioning to UCO-based biodiesel reduces reliance on first-generation biodiesel derived from vegetable oils, such as palm oil. Large-scale cultivation of these oils has caused significant environmental degradation, including deforestation, desertification, greenhouse gas emissions, and soil erosion.

The 12-month collection trial conducted in this study highlights the critical need for public policies that support UCO recycling. The trial revealed several operational challenges faced by recyclers, including a lack of regulatory permits, insufficiently equipped vehicles, inadequate social security measures, and the absence of personal protective equipment. Addressing these barriers will ensure safe, efficient, and scalable UCO collection and processing systems.

The proposed UCO management strategy and its potential for energy recovery through biodiesel production contribute significantly to sustainable waste management. By engaging all stakeholders in the UCO value chain, this approach aligns with technical governance documents under the National Circular Economy Strategy [16]. This information is useful for areas with many businesses that produce UCO, like restaurants and hotels. These sectors could directly benefit from implementing UCO management initiatives, contributing to a circular economic model while addressing environmental concerns.

Future research should focus on measuring the environmental, economic, and social impacts of producing first-generation biofuels from palm oil versus second-generation biodiesel from UCO. Such studies will help identify which pathway offers greater contributions to sustainability, aligning with the commitments outlined in the Sustainable Development Goals (SDG) reports. Future works should conduct detailed cost–benefit analyses of implementing UCO recycling systems in other regions. This includes estimating collection, processing, and logistics costs against the economic benefits of biodiesel production. Such analyses will help policymakers prioritize resource allocation.

Examine how UCO recycling programs affect local employment, public health, and social equity. Understanding these impacts will strengthen the case for widespread adoption of such strategies. Finally, UCO management can evolve into a globally scalable solution, reducing waste, promoting sustainability, and contributing to energy transition goals outlined in the Sustainable Development Goals (SDG) framework.

Author Contributions

Conceptualization, R.C.-R. and C.M.-R.; Methodology, R.C.-R.; Validation, P.T.-S. and J.R.-A.; Formal analysis, M.S.-B. and C.M.-B.; Investigation, M.S.-B. and J.S.-O.; Resources, J.R.-A.; Writing—review & editing, J.S.-O. and P.T.-S.; Visualization, M.S.-B.; Project administration, J.S.-O. and J.R.-A.; Funding acquisition, R.C.-R. and P.T.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rodríguez-Flórez, J.S. Estudio de Factibilidad para el Aprovechamiento de ACUs en la Ciudad de Bogotá. Master’s Dissertation, National University of Colombia, Bogotá, Colombia, 2020. [Google Scholar]

- Eremeeva, A.M.; Ilyushin, Y.V. Automation of the Control System for Drying Grain Crops of the Technological Process for Obtaining Biodiesel Fuels. Sci. Rep. 2023, 13, 14956. [Google Scholar] [CrossRef] [PubMed]

- Dey, P.; Ray, S.; Newar, A. Defining a Waste Vegetable Oil-Biodiesel Based Diesel Substitute Blend Fuel by Response Surface Optimization of Density and Calorific Value. Fuel 2021, 283, 118978. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Nizami, A.-S.; Kalogirou, S.A.; Gupta, V.K.; Park, Y.-K.; Fallahi, A.; Sulaiman, A.; Ranjbari, M.; Rahnama, H.; Aghbashlo, M.; et al. Environmental Life Cycle Assessment of Biodiesel Production from Waste Cooking Oil: A Systematic Review. Renew. Sustain. Energy Rev. 2022, 161, 112411. [Google Scholar] [CrossRef]

- Nutongkaew, P.; Waewsak, J.; Riansut, W.; Kongruang, C.; Gagnon, Y. The Potential of Palm Oil Production as a Pathway to Energy Security in Thailand. Sustain. Energy Technol. Assess. 2019, 35, 189–203. [Google Scholar] [CrossRef]

- Lombardi, L.; Mendecka, B.; Carnevale, E. Comparative Life Cycle Assessment of Alternative Strategies for Energy Recovery from Used Cooking Oil. J. Environ. Manag. 2018, 216, 235–245. [Google Scholar] [CrossRef]

- ISO 660:2020; Animal and Vegetable Fats and Oils—Determination of Acid Value and Acidity. ISO: Geneva, Switzerland, 2020; pp. 1–12.

- ISO 3961:2024; Animal and Vegetable Fats and Oils—Determination of Iodine Value. ISO: Geneva, Switzerland, 2024; pp. 1–11.

- ASTM D6751-20a; Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels. ASTM International: West Conshohocken, PA, USA, 2020; pp. 1–33.

- ISO 3657:2023; Animal and Vegetable Fats and Oils—Determination of Saponification Value. ISO: Geneva, Switzerland, 2023; pp. 1–10.

- ISO 6883:2017; Animal and Vegetable Fats and Oils—Determination of Conventional Mass per Volume (Litre Weight in Air). ISO: Geneva, Switzerland, 2017; pp. 1–11.

- Garcia-Muentes, S.A.; Lafargue-Pérez, F.; Labrada-Vázquez, B.; Díaz-Velázquez, M.; Sánchez del Campo-Lafita, A.E. Physicochemical Properties of Oil and Biodiesel Produced from Jatropha curcas L. in the Province of Manabí, Ecuador. Rev. Cuba. Quim. 2018, 30, 142–158. [Google Scholar]

- Prieto-Guerrero, M.E.; Robalino-Zambrano, D.A.; Sarduy-Pereira, L.B.; Villavicencio-Montoya, J.F.; Diéguez Santana, K. Evaluación de Estrategias de Gestión de Aceites de Cocina Usados. Caso de Estudio Puyo, Amazonia Ecuatoriana. Rev. EIA 2022, 19, 3813. [Google Scholar] [CrossRef]

- Cisneros-Lopez, M.; García-Salzar, J.; Mora-Flores, J.; Martinez-Damian, M.; García-Sanchez, R.; Valdez-Lazalde, J.; Portillo-Vásquez, M. Economic Evaluation with Real Options: Second Generation Bioethanol Biorefinery in Veracruz, México. Agric. Soc. Desarrollo 2020, 17, 397–413. [Google Scholar] [CrossRef]

- Ministerio de Ambiente y Desarrollo Sostenible. Resolución 0316 de 2018. Disposiciones Relacionadas con la Gestión de los Aceites de Cocina Usados; Ministerio de Ambiente y Desarrollo Sostenible: Bogotá, Colombia, 2018; pp. 1–8.

- Gobierno de la República de Colombia Estrategia Nacional de Economía Circular. Cierre de Ciclos de Materiales, Innovación Tecnológica, Colaboración y Nuevos Modelos de Negocio Estrategia Nacional de Economía Circular Contenido; Gobierno de la República de Colombia Estrategia Nacional de Economía Circular: Bogotá, Colombia, 2019. [Google Scholar]

- Gobierno de la República de Colombia. Ley 1333 de 2009. Procedimiento Sancionatorio Ambiental y otras disposiciones; Departamento Administrativo de la Función Pública: Bogotá, Colombia, 2009; pp. 1–23. [Google Scholar]

- Barranquilla Verde; Alcadlía de Barranquilla. Resolución 0393 de 2017. Regulaciones para la Generación, Recolección, Tratamiento, Aprovecamiento y/o Transporte Adecuado del Aceite Vegetal Usado en el Distrito de Barranquilla; Barranquilla Verde; Alcadlía de Barranquilla: Barranquilla, Colombia, 2017; pp. 1–15. [Google Scholar]

- Jiménez Rojano, D.A.; Mejía Castro, L.V.; Márquez Santiago, J.A. Characterization of the Generation and Disposal of Used Cooking Oil (UCO) of Large Producers over an Urban Sector; Universidad del Norte: Barranquilla, Colombia, 2019. [Google Scholar]

- United Nations. The 17 Goals. Available online: https://sdgs.un.org/goals (accessed on 25 November 2024).

- Banco de Desarrollo de América Latina. Economía Circular e Innovación Tecnológica en Residuos Sólidos. Oportunidades en América Latina, 1st ed.; Corporación Andina de Fomento: Buenos Aires, Argentina, 2018; ISBN 978-980-422-092-0. [Google Scholar]

- Ochoa-Miranda, M. Gestión Integral de Residuos. Análisis Normativo y Herramientas para su Implementación; 1st ed.; Universidad del Rosario: Bogotá, Colombia, 2016. [Google Scholar]

- Tapanwong, M.; Punsuvon, V. Production of Ethyl Ester Biodiesel from Used Cooking Oil with Ethanol and Its Quick Glycerol-Biodiesel Layer Separation Using Pure Glycerol. Int. J. GEOMATE 2019, 17, 109–114. [Google Scholar] [CrossRef]

- Bousba, D.; Sobhi, C.; Zouaoui, E.; Rouibah, K.; Boublia, A.; Ferkous, H.; Haddad, A.; Gouasmia, A.; Avramova, I.; Mohammed, Z.; et al. Efficient Biodiesel Production from Recycled Cooking Oil Using a NaOH/CoFe2O4 Magnetic Nano-Catalyst: Synthesis, Characterization, and Process Enhancement for Sustainability. Energy Convers. Manag. 2024, 300, 118021. [Google Scholar] [CrossRef]

- Cheikh, F.Z.B.; Zobeidi, A.; Belkhalfa, H.; Douadi, A.; Nacer, S.N.; Ghernaout, D.; Elboughdiri, N. Transforming Waste Cooking Oil into Environmentally Friendly Biodiesel: A Comparative Analysis of Three Transesterification Methods. Int. J. Oil Gas Coal Technol. 2023, 34, 413–427. [Google Scholar] [CrossRef]

- Omidkar, A.; Xu, H.; Li, Z.; Haddadian, K.; Song, H. Techno-Economic and Life Cycle Assessment of Renewable Diesel Production via Methane-Assisted Catalytic Waste Cooking Oil Upgrading. J. Clean. Prod. 2023, 414, 137512. [Google Scholar] [CrossRef]

- Garg, N.K.; Pal, A. Microwave-based Transesterification of Waste Cooking Oil using Waste Aluminium Foil (NaOH/γ-Al2O3) as Catalyst. Indian J. Eng. Mater. Sci. 2023, 30, 249–255. [Google Scholar] [CrossRef]

- Jain, S.; Kumar, N.; Singh, V.P.; Mishra, S.; Sharma, N.K.; Bajaj, M.; Khan, T.M.Y. Transesterification of Algae Oil and Little Amount of Waste Cooking Oil Blend at Low Temperature in the Presence of NaOH. Energies 2023, 16, 1293. [Google Scholar] [CrossRef]

- Darwin; Harahap, R.A.M.; Pratama, A.; Thifal, M.; Fayed, M.A.A. Enhanced Biodiesel Production from Waste Cooking Oils Catalysed by Sodium Hydroxide Supported on Heterogeneous Co-Catalyst of Bentonite Clay. Res. Agric. Eng. 2023, 69, 124–131. [Google Scholar] [CrossRef]

- Torres, Y.D.; Gullo, P.; Herrera, H.H.; Torres del Toro, M.; Guerra, M.A.Á.; Ortega, J.I.S.; Speerforck, A. Statistical Analysis of Design Variables in a Chiller Plant and Their Influence on Energy Consumption and Life Cycle Cost. Sustainability 2022, 14, 10175. [Google Scholar] [CrossRef]

- Nada, S.S.; Hawash, S.I.; Zahran, M.A.; Ahmed, E.M. Preparation of Poly (AAc/AAm)/NaOH Hydrogel as a Catalyst for Electrolysis Production of Biodiesel from Waste Cooking Oil. Egypt. J. Chem. 2022, 65, 919–931. [Google Scholar] [CrossRef]

- Abusweireh, R.S.; Rajamohan, N.; Vasseghian, Y. Enhanced Production of Biodiesel Using Nanomaterials: A Detailed Review on the Mechanism and Influencing Factors. Fuel 2022, 319, 123862. [Google Scholar] [CrossRef]

- da Silva, C.A.; dos Santos, R.N.; Oliveira, G.G.; de Souza Ferreira, T.P.; de Souza, N.L.G.D.; Soares, A.S.; de Melo, J.F.; Colares, C.J.G.; de Souza, U.J.B.; de Araújo-Filho, R.N.; et al. Biodiesel and Bioplastic Production from Waste-Cooking-Oil Transesterification: An Environmentally Friendly Approach. Energies 2022, 15, 1073. [Google Scholar] [CrossRef]

- Yusof, I.; Tajuddin, N.A.; Samad, W.Z.; Hamzah, N. Effect of Sodium Hydroxide on a Bentonite Support as Catalyst for Transesterification of Waste Cooking Oil into Biodiesel. Malays. J. Chem. 2022, 24, 177–183. [Google Scholar]

- Suzihaque, M.U.H.; Syazwina, N.; Alwi, H.; Ibrahim, U.K.; Abdullah, S.; Haron, N. A Sustainability Study of the Processing of Kitchen Waste as a Potential Source of Biofuel: Biodiesel Production from Waste Cooking Oil (WCO). Mater. Today Proc. 2022, 63 (Suppl. S1), S484–S489. [Google Scholar] [CrossRef]

- Vera-Rozo, J.R.; Riesco-Avila, J.M.; Elizalde-Blanca, F.; Cano-Andrade, S. Optimization of the Real Conversion Efficiency of Waste Cooking Oil to Fame. Therm. Sci. 2022, 26, 653–665. [Google Scholar] [CrossRef]

- Helmi, M.; Hemmati, A. Synthesis of magnetically solid base catalyst of NaOH/Chitosan-Fe3O4 for biodiesel production from waste cooking oil: Optimization, kinetics and thermodynamic studies. Energy Convers. Manag. 2021, 248, 114807. [Google Scholar] [CrossRef]

- Abukhadra, M.R.; Othman, S.I.; Allam, A.A.; Elfayoumi, H. Insight into the Catalytic Properties Zeolitized Kaolinite/Diatomite Geopolymer as an Environmental Catalyst for the Sustainable Conversion of Spent Cooking Oil into Biodiesel; Optimization and Kinetics. Sustain. Chem. Pharm. 2021, 22, 100473. [Google Scholar] [CrossRef]

- Wongjaikham, W.; Wongsawaeng, D.; Ratnitsai, V.; Kamjam, M.; Ngaosuwan, K.; Kiatkittipong, W.; Hosemann, P.; Assabumrungrat, S. Low-Cost Alternative Biodiesel Production Apparatus Based on Household Food Blender for Continuous Biodiesel Production for Small Communities. Sci. Rep. 2021, 11, 13827. [Google Scholar] [CrossRef]

- Hamed, H.H.; Mohammed, A.E.; Habeeb, O.A.; Ali, O.M.; Aljaf, O.H.S.; Abdulqader, M.A. Biodiesel Production from Waste Cooking Oil Using Homogeneous Catalyst. Egypt. J. Chem. 2021, 64, 2827–2832. [Google Scholar] [CrossRef]

- Abdullah, R.F.; Rashid, U.; Ibrahim, M.L.; Hazmi, B.; Alharthi, F.A.; Nehdi, I.A. Bifunctional Nano-Catalyst Produced from Palm Kernel Shell via Hydrothermal-Assisted Carbonization for Biodiesel Production from Waste Cooking Oil. Renew. Sustain. Energy Rev. 2021, 137, 110638. [Google Scholar] [CrossRef]

- Guo, M.; Jiang, W.; Chen, C.; Qu, S.; Lu, J.; Yi, W.; Ding, J. Process Optimization of Biodiesel Production from Waste Cooking Oil by Esterification of Free Fatty Acids Using La3+/ZnO-TiO2 Photocatalyst. Energy Convers. Manag. 2021, 229, 113745. [Google Scholar] [CrossRef]

- Mercy Nisha Pauline, J.; Sivaramakrishnan, R.; Pugazhendhi, A.; Anbarasan, T.; Achary, A. Transesterification Kinetics of Waste Cooking Oil and Its Diesel Engine Performance. Fuel 2021, 285, 119108. [Google Scholar] [CrossRef]

- Hsiao, M.-C.; Liao, P.-H.; Lan, N.V.; Hou, S.-S. Enhancement of Biodiesel Production from High-Acid-Value Waste Cooking Oil via a Microwave Reactor Using a Homogeneous Alkaline Catalyst. Energies 2021, 14, 437. [Google Scholar] [CrossRef]

- Shazwani, S.S.; Noraini, H.; Nazrizawati, A.T. Conversion of Waste Cooking Oil to Biodiesel Catalysed by ZnAl Layered Double Hydroxide. ASM Sci. J. 2021, 16, 1–8. [Google Scholar] [CrossRef]

- Brito, G.M.; Chicon, M.B.; Coelho, E.R.C.; Faria, D.N.; Freitas, J.C.C. Eco-Green Biodiesel Production from Domestic Waste Cooking Oil by Transesterification Using LiOH into Basic Catalysts Mixtures. J. Renew. Sustain. Energy 2020, 12, 043101. [Google Scholar] [CrossRef]

- Abdollahi Asl, M.; Tahvildari, K.; Bigdeli, T. Eco-Friendly Synthesis of Biodiesel from WCO by Using Electrolysis Technique with Graphite Electrodes. Fuel 2020, 270, 117582. [Google Scholar] [CrossRef]

- Chinglenthoiba, C.; Das, A.; Vandana, S. Enhanced Biodiesel Production from Waste Cooking Palm Oil, with NaOH-Loaded Calcined Fish Bones as the Catalyst. Environ. Sci. Pollut. Res. 2020, 27, 15925–15930. [Google Scholar] [CrossRef]

- Khedri, B.; Mostafaei, M.; Safieddin Ardebili, S.M. Flow-Mode Synthesis of Biodiesel under Simultaneous Microwave–Magnetic Irradiation. Chin. J. Chem. Eng. 2019, 27, 2551–2559. [Google Scholar] [CrossRef]

- Bunushree, B.; Ravichandra, B.; Rangabhashiyam, S.; Jayabalan, R.; Balasubramanian, P. Qualitative Analysis of Biodiesel Produced by Alkali Catalyzed Transesterification of Waste Cooking Oil Using Different Alcohols. Indian J. Chem. Technol. 2019, 26, 330–336. [Google Scholar]

- Rafati, A.; Tahvildari, K.; Nozari, M. Production of Biodiesel by Electrolysis Method from Waste Cooking Oil Using Heterogeneous MgO-NaOH Nano Catalyst. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 1062–1074. [Google Scholar] [CrossRef]

- Bargole, S.; George, S.; Kumar Saharan, V. Improved Rate of Transesterification Reaction in Biodiesel Synthesis Using Hydrodynamic Cavitating Devices of High Throat Perimeter to Flow Area Ratios. Chem. Eng. Process. Process Intensif. 2019, 139, 1–13. [Google Scholar] [CrossRef]

- García-Martín, J.F.; Alés-Álvarez, F.J.; López-Barrera, M.D.C.; Martín-Domínguez, I.; Álvarez-Mateos, P. Cetane Number Prediction of Waste Cooking Oil-Derived Biodiesel Prior to Transesterification Reaction Using near Infrared Spectroscopy. Fuel 2019, 240, 10–15. [Google Scholar] [CrossRef]

- Dimian, A.C.; Kiss, A.A. Eco-Efficient Processes for Biodiesel Production from Waste Lipids. J. Clean. Prod. 2019, 239, 118073. [Google Scholar] [CrossRef]

- Jeyakumar, N.; Narayanasamy, B.; Balasubramaniam, V. Optimization of Used Cooking Oil Methyl Ester Production Using Response Surface Methodology. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 2313–2325. [Google Scholar] [CrossRef]

- ASTM D 1298-99; Standard Test Method for Density, Relative Density (Specific Gravity), or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method. ASTM International: West Conshohocken, PA, USA, 1999; pp. 1–8.

- ASTM D 664; Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration. ASTM International: West Conshohocken, PA, USA, 2011; pp. 1–15.

- ASTM D 445-09; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids. ASTM International: West Conshohocken, PA, USA, 2009; pp. 1–11.

- ASTM D 93; Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester. ASTM International: West Conshohocken, PA, USA, 2020; pp. 1–13.

- ASTM D 6890; Standard Test Method for Determination of Ignition Delay and Derived Cetane Number (DCN) of Diesel Fuel Oils by Combustion in a Constant Volume Chamber. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D 4951; Standard Test Method for Determination of Additive Elements in Lubricating Oils by Inductively Coupled Plasma Atomic Emission Spectrometry. ASTM International: West Conshohocken, PA, USA, 2019; pp. 1–8.

- UNE-EN 14110; Fat and Oil Derivatives–Fatty Acid Methyl Esters (FAME)–Determination of Methanol Content. AENOR: Madrid, Spain, 2003.

- ASTM D 6584; Standard Test Method for Determination of Total Acid Number of Biodiesel (B100) and Biodiesel Blends by Potentiometric Titration. ASTM International: West Conshohocken, PA, USA, 2007; pp. 1–9.

- Reategui-Romero, W.; Salas-Barrera, F.J. Estudio Del Proceso de Transesterificación Para La Obtención de Biodiesel a Partir Del Aceite de Palma En Un Reactor Por Lotes. Prod. + Limpia 2013, 8, 119–134. [Google Scholar]

- ASTM D 6751:2020; Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels. ASTM International: West Conshohocken, PA, USA, 2020; pp. 1–11.

- ISO 3960:2010; Determination of Peroxide Value. ISO: Geneva, Switzerland, 2010; pp. 1–10.

- República de Colombia. Ley 2099 de 2021. Disposiciones para la Transición Energética, la Dinamización del Mercado Energético, la Reactivación Económica del País y se Dictan Otras Disposiciones. 2021, pp. 1–11. Available online: https://russellbedford.com.co/disposiciones-para-la-transicion-energetica-dinamizacion-de-mercado-energetico-la-reactivacion-economica-y-otras (accessed on 19 May 2025).

- Rojas-Ramírez, H.A. Caracterización de La Logística de Recolección, Tratamiento y Exportación de Aceite de Cocina Usado En Colombia. Thesis to obtain the title of National and International Commercial Logistics Management Specialist, University of Bogota Jorge Tadeo Lozano, Bogotá, Colombia, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).