Physico-Mechanical Properties and Decay Susceptibility of Clay Bricks After the Addition of Volcanic Ash from La Palma (Canary Islands, Spain)

Abstract

1. Introduction

2. Materials and Methods

2.1. Study of the Pore System

2.2. Compactness, Compressive Strength and Thermal Conductivity

2.3. Color of the Bricks

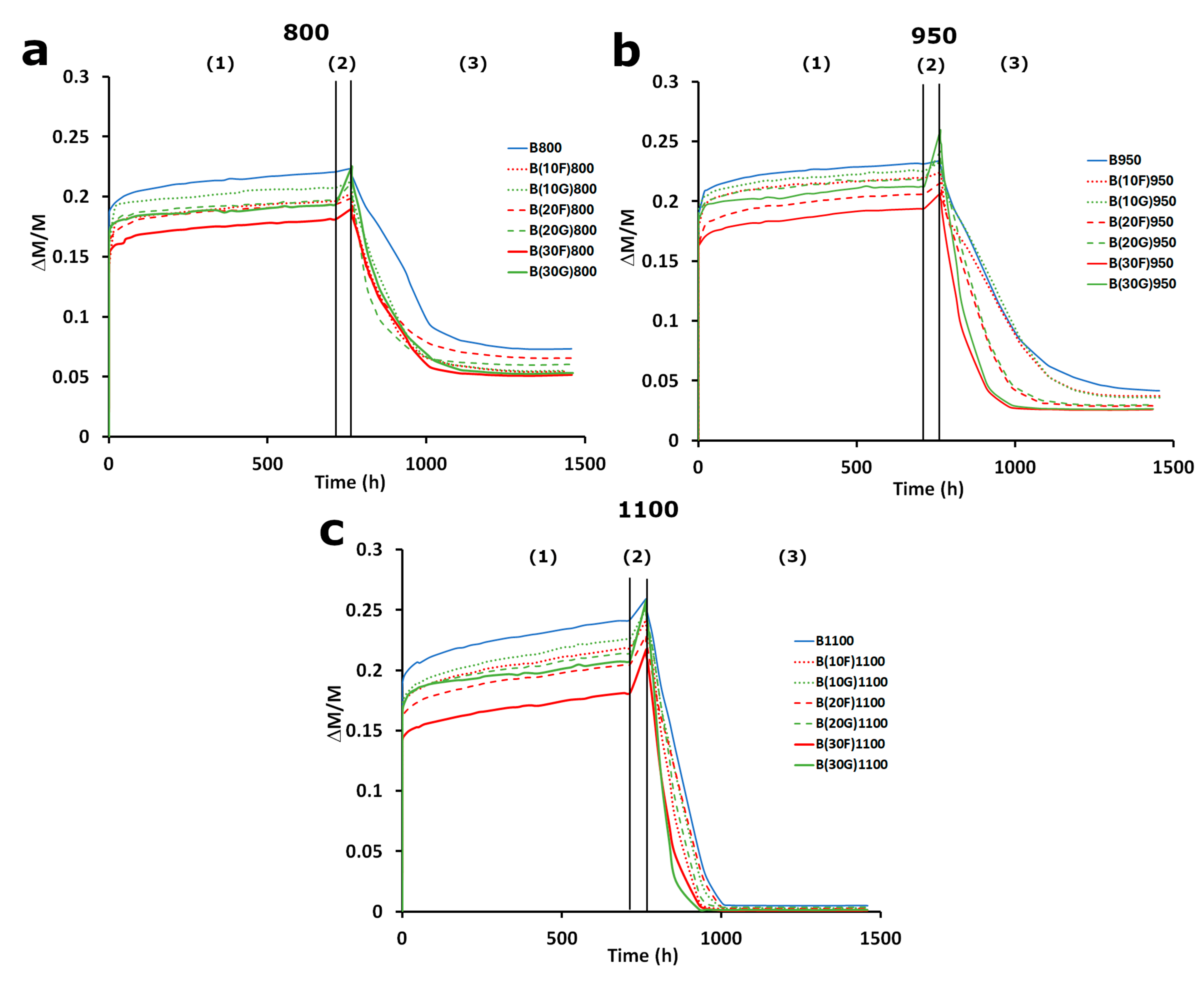

2.4. Durability by Salt Crystallization

3. Results and Discussion

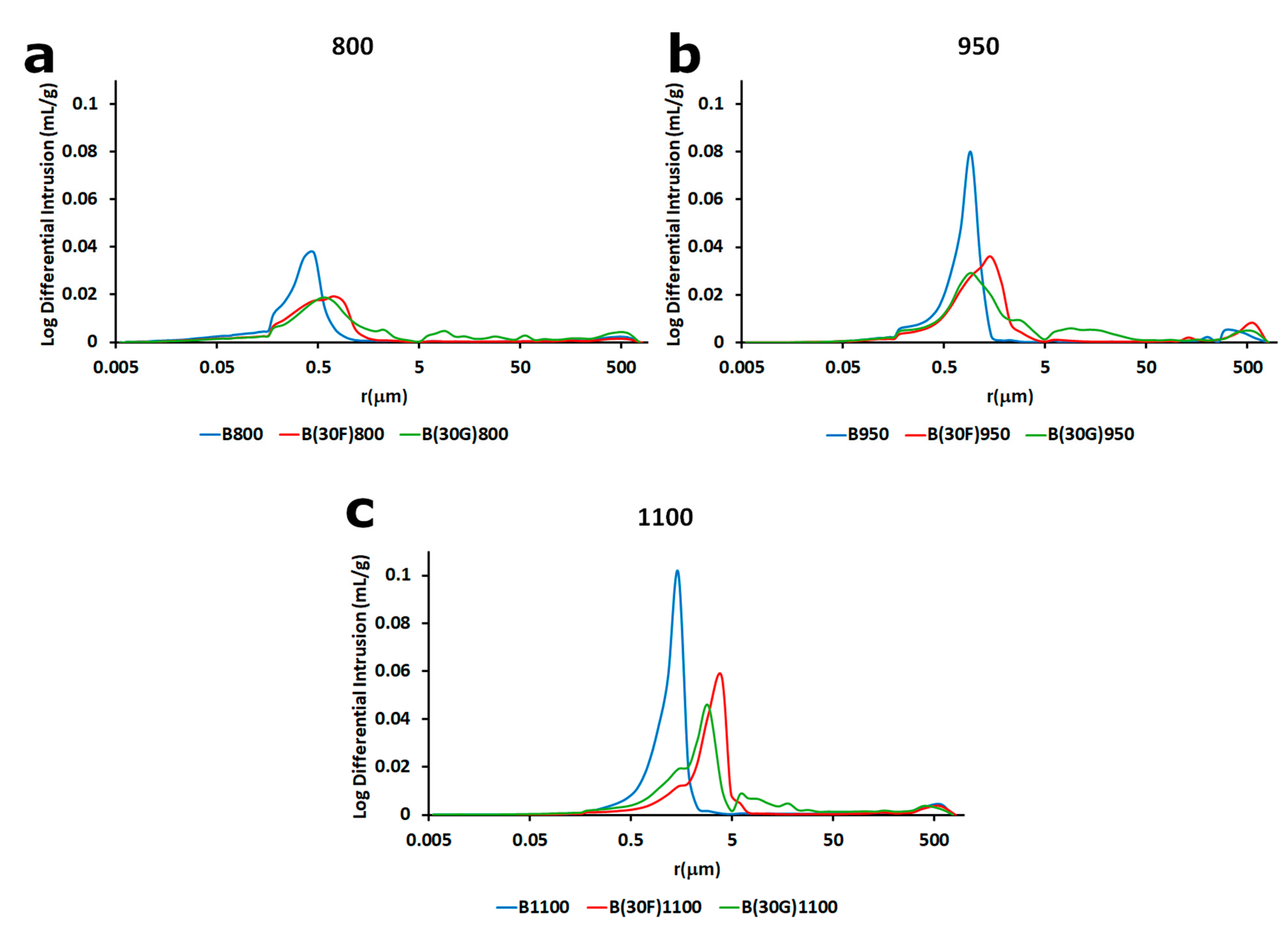

3.1. Study of the Pore System

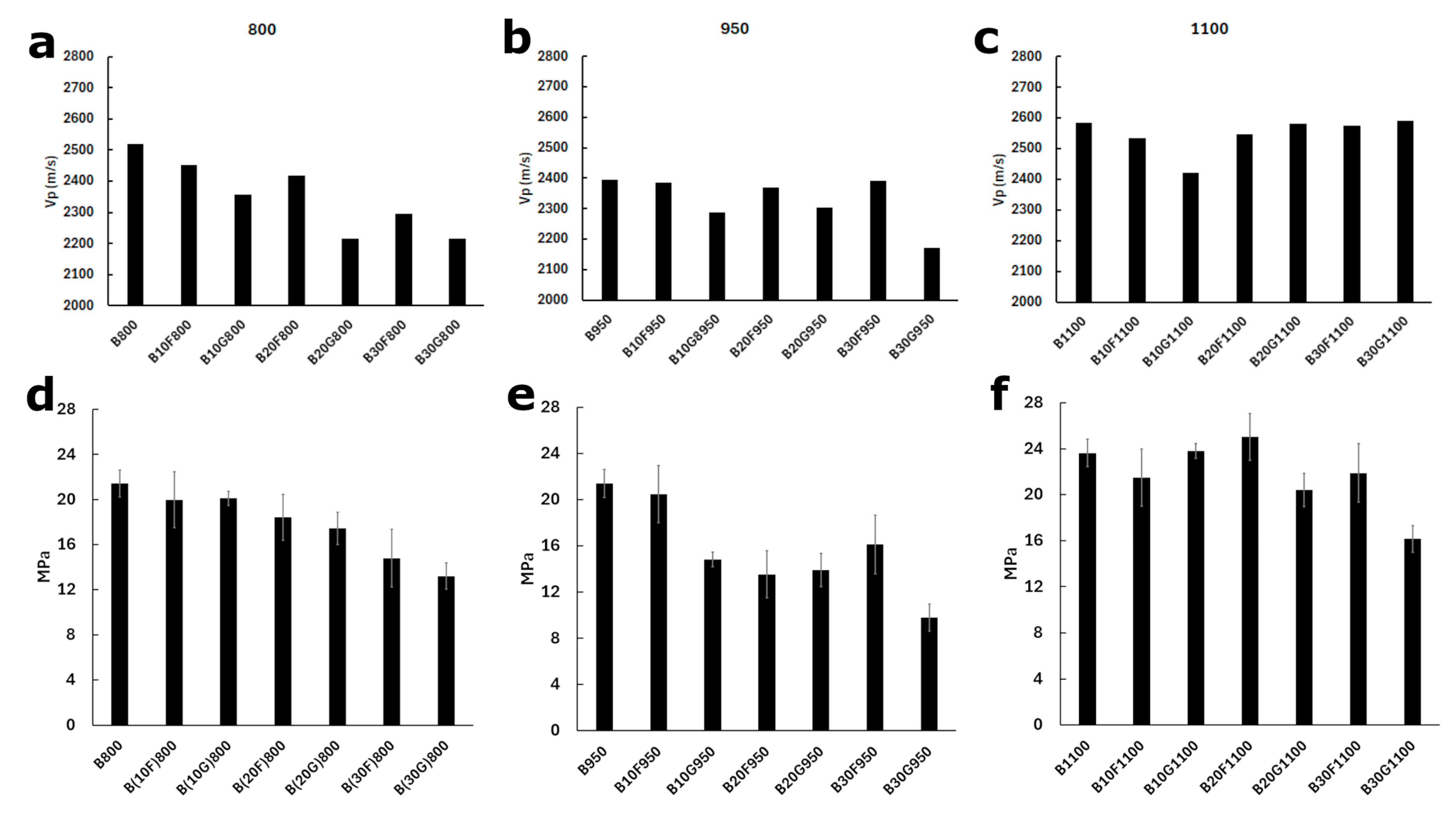

3.2. Compactness, Compressive Strength and Thermal Conductivity

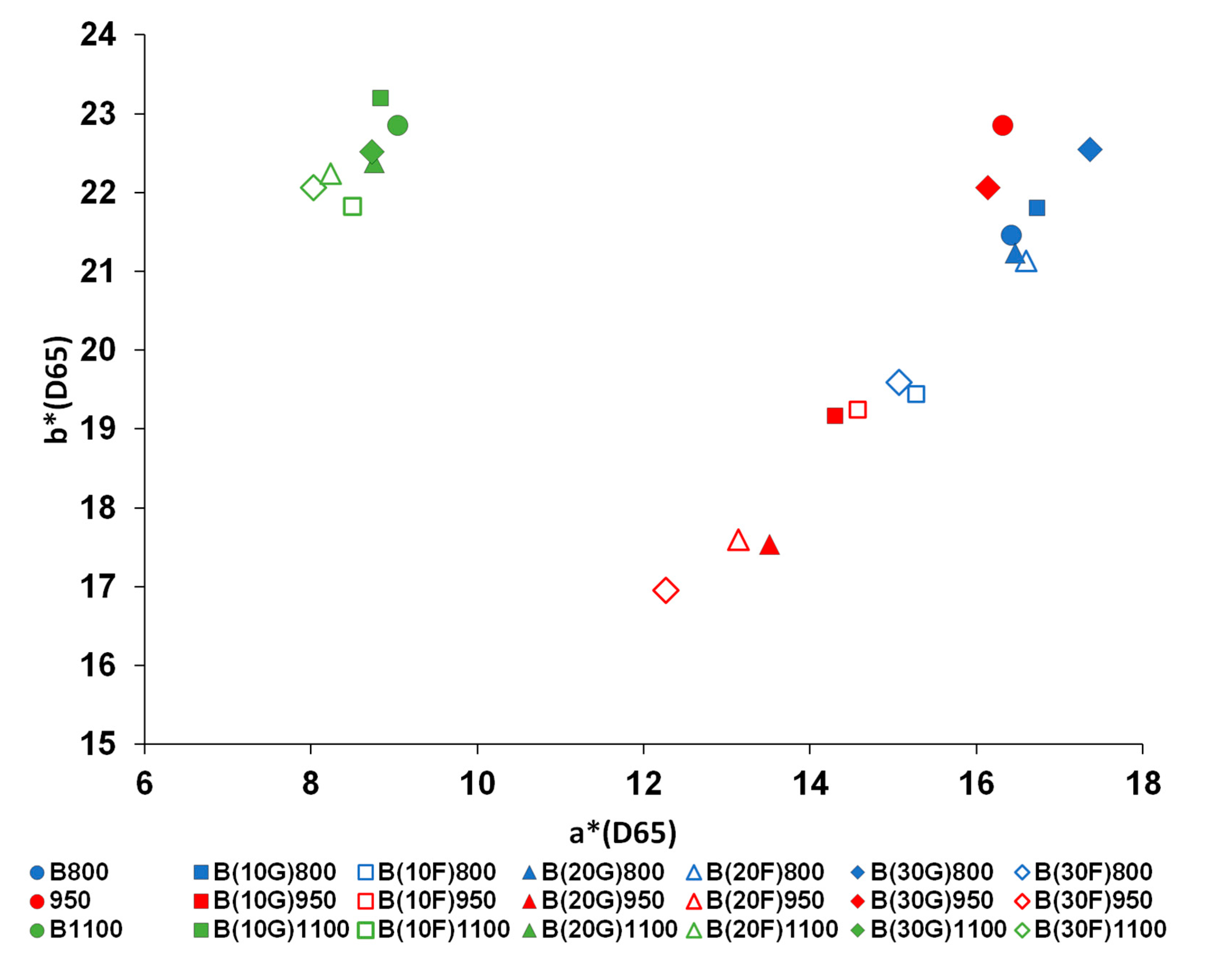

3.3. Color of the Bricks

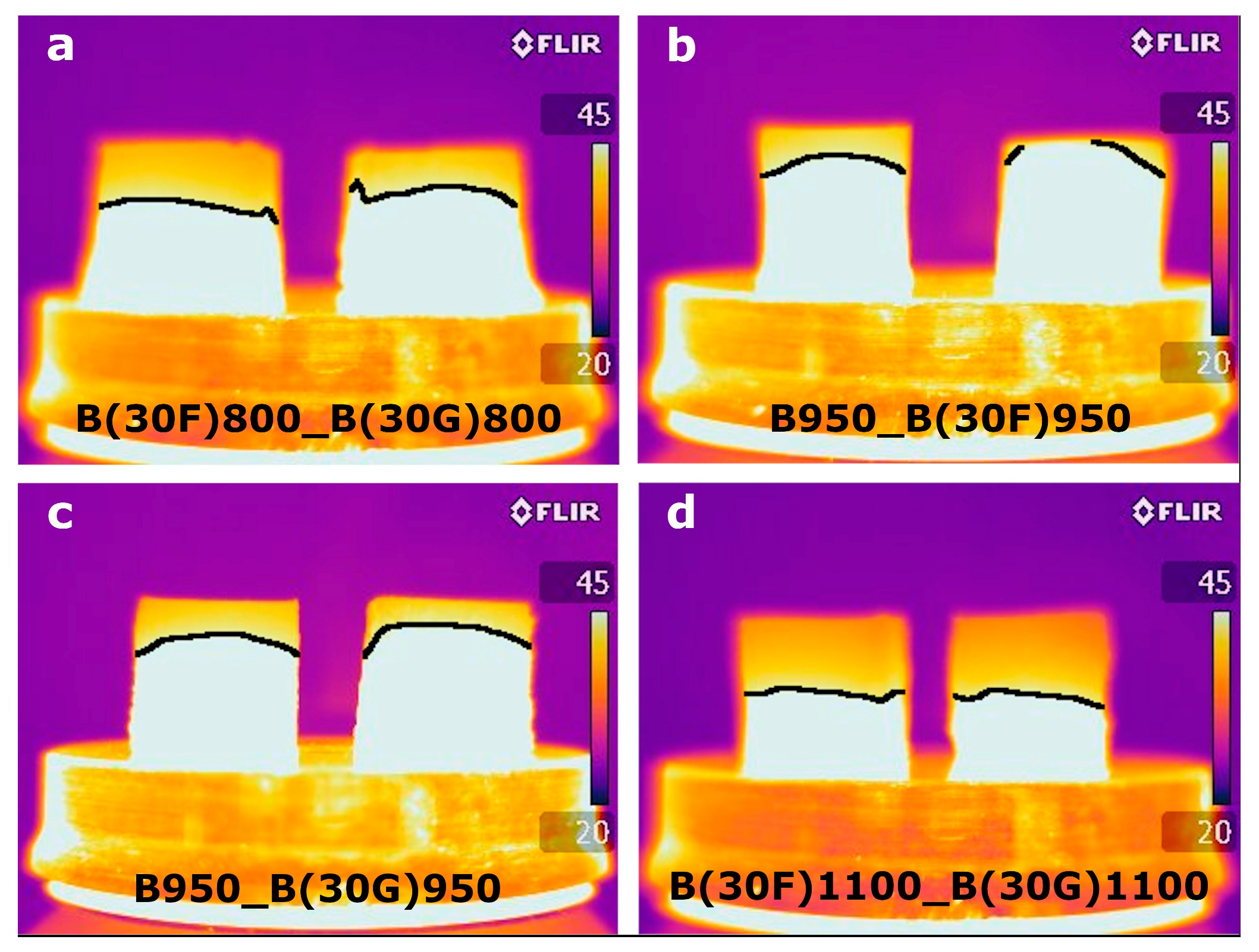

3.4. Durability of Bricks by Salt Crystallization

4. Conclusions

- The porosity of the bricks decreases with the addition of fine volcanic ash. The use of coarse volcanic ash decreases the brick porosity at low percentages, but its use in high percentages results in bricks with almost the same porosity as bricks without volcanic ash additives.

- Volcanic ash acts as a filler that decreases the microporosity of the bricks. This can be seen through the SSA values, as the addition of volcanic ash decreases the SSA, and so the microporosity of the bricks.

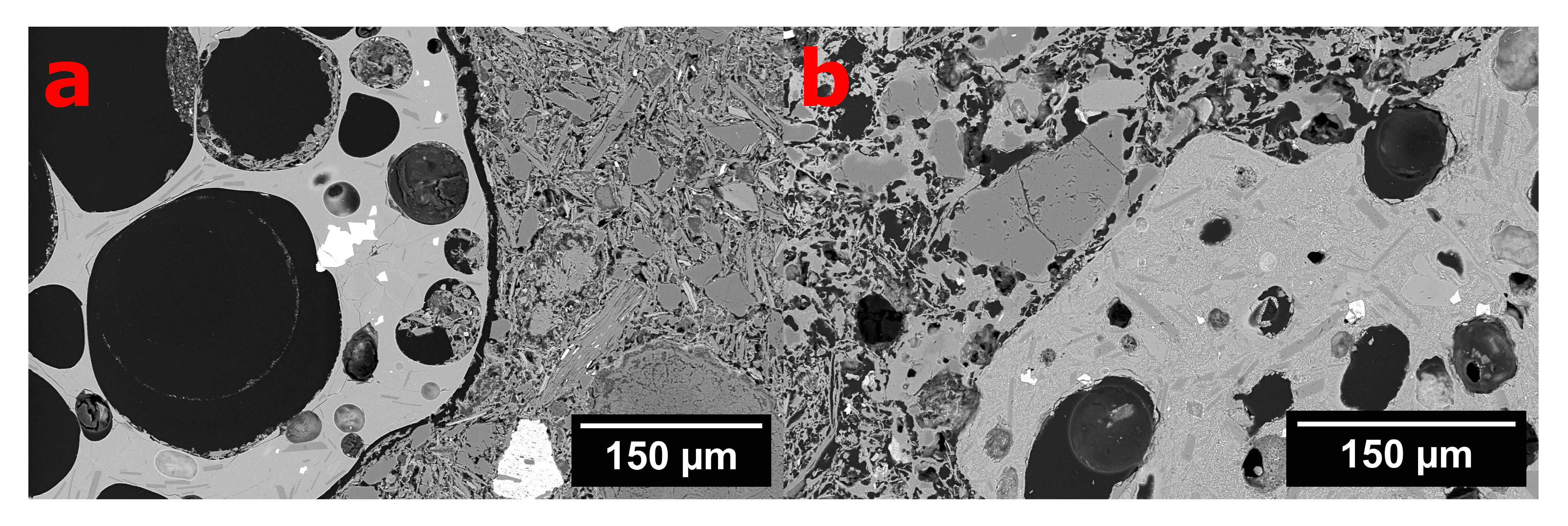

- Under SEM, the bricks fired at 800 °C present smaller and more irregular pores than the bricks fired at 1100 °C, due to the vitrification of the latter. Moreover, a better bond between the brick matrix and the volcanic ash additive was observed in the bricks fired at 1100 °C than in the bricks fired at 800 °C.

- The addition of volcanic ash at 800 and 950 °C decreases the compactness and the uniaxial compression strength of the bricks. This decrease is more noticeable when the coarse volcanic ash additive is used, due to the higher presence of vesicles that affect the compressive resistance of the bulk sample, and the poor bond between the brick matrix and the volcanic ash additive. The addition of coarse volcanic ash also decreases the compressive strength of bricks fired at 1100 °C, although this reduction is less significant than at the rest of the temperatures, due to the better bond between the volcanic ash and the melted matrix. The resistance of all bricks stands over or almost in reach (in the case of the sample with 30% of coarse volcanic ash and fired at 950 °C) of the values required to be used in construction (10 MPa) and all achieve the minimum resistance necessary for lightweight bricks (5 MPa), which means that they can be used for construction.

- No significant differences in the qualitative heat conductivity were detected between the bricks.

- The addition of volcanic ash causes dispersed a* and b* values in bricks fired at 800 and 950 °C because at these temperatures the volcanic ash maintains its black color. At 1100 °C, the a* and b* values between bricks with and without volcanic ash are more homogeneous because the volcanic ash changes its color from black to red, blending in better with the color of the brick matrix.

- Bricks with and without volcanic ash additives and fired at 800 and 950 °C show higher decay signs than those fired at 1100 °C, which is explained by a lesser crystallization of salt in the pores of bricks fired at 1100 °C and their better resistance to the salt crystallization pressure. The bricks with volcanic ash and fired at 800 and 950 °C also present decay signs after the test, which are explained by the lower compressive strength of bricks with volcanic ash compared with the control samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rodríguez-Losada, J.A.; Hernández-Gutiérrez, L.E.; Miranda-Hardisson, A.; González de Vallejo, L.I.; Cervigón-Tomico, G.; de los Ríos Díaz, H.; de Villepreux, E.; Álvarez-Hernández, A.; Afonso-Falcón, D. Evaluation of the Slopes Stability in the Lava Field of the 2021 Tajogaite Eruption (La Palma, Canary Islands) in Order to Recover the Territory for the Development of New Infrastructures. In Proceedings of the EGU General Assembly 2023, Vienna, Austria, 23–28 April 2023. EGU-13809. [Google Scholar] [CrossRef]

- Leoni, V.; Boto-García, D. The Effect of Natural Disasters on Hotel Demand, Supply and Labour Markets: Evidence from the La Palma Volcano Eruption. Environ. Resour. Econ. 2023, 86, 755–780. [Google Scholar] [CrossRef]

- PEVOLCA. Informe de Comité Científico: Actualización de La Actividad Volcánica En Cumbre Vieja (La Palma) 20/11/2021. 2021. Available online: https://www3.gobiernodecanarias.org/noticias/wp-content/uploads/2021/11/201121-INFORME-Comit%C3%A9-Cient%C3%ADfico-PEVOLCA1.pdf (accessed on 4 September 2024).

- Hayes, J.L.; Wilson, T.M.; Magill, C. Tephra Fall Clean-up in Urban Environments. J. Volcanol. Geotherm. Res. 2015, 304, 359–377. [Google Scholar] [CrossRef]

- Occhipinti, R.; Portale, S.; Lanzafame, G.; Gimeno, D.; Prašek, M.K.; Mazzoleni, P.; Barone, G. Alkali Activated Materials from Tajogaite Volcanic Ash (La Palma, Spain): A Green Recovery after the 2021 Eruption. Volcanica 2024, 7, 717–731. [Google Scholar] [CrossRef]

- RTVC. Tajogaite, el Volcán que Cambió a La Palma. Radio Televisión Canaria. 24 May 2024. Available online: https://rtvc.es/tajogaite-el-volcan-que-cambio-a-la-palma/ (accessed on 26 July 2024).

- Turrión, D.; Morcillo, L.; Alloza, J.A.; Vilagrosa, A. Innovative Techniques for Landscape Recovery after Clay Mining under Mediterranean Conditions. Sustainability 2021, 13, 3439. [Google Scholar] [CrossRef]

- Koščová, M.; Hellmer, M.; Anyona, S.; Gvozdkova, T. Geo-Environmental Problems of Open Pit Mining: Classification and Solutions. E3S Web Conf. 2018, 41, 01034. [Google Scholar] [CrossRef]

- Muñoz, P.; Letelier, V.; Muñoz, L.; Gencel, O.; Sutcu, M.; Vasic, M. Assessing Technological Properties and Environmental Impact of Fired Bricks Made by Partially Adding Bottom Ash from an Industrial Approach. Constr. Build. Mater. 2023, 396, 132338. [Google Scholar] [CrossRef]

- UN. Transforming Our World: The 2030 Agenda for Sustainable Development; UN: New York, NY, USA, 2015. [Google Scholar]

- USGS. Mineral Commodity Summaries 2025; U.S. Geological Survey: Reston, VA, USA, 2025. [CrossRef]

- Shaqour, E.N.; Abo Alela, A.H.; Rsheed, A.A. Improved Fired Clay Brick Compressive Strength by Recycling Wastes of Blacksmiths’ Workshops. J. Eng. Appl. Sci. 2021, 68, 5. [Google Scholar] [CrossRef]

- Abdeen, H.; Shihada, S. Properties of Fired Clay Bricks Mixed with Waste Glass. J. Sci. Res. Rep. 2017, 13, 1–9. [Google Scholar] [CrossRef]

- Riaz, M.H.; Khitab, A.; Ahmad, S.; Anwar, W.; Arshad, M.T. Use of Ceramic Waste Powder for Manufacturing Durable and Eco-Friendly Bricks. Asian J. Civ. Eng. 2020, 21, 243–252. [Google Scholar] [CrossRef]

- Arezki, S.; Chelouah, N.; Tahakourt, A. The Effect of the Addition of Ground Olive Stones on the Physical and Mechanical Properties of Clay Bricks. Mater. Constr. 2016, 66, e082. [Google Scholar] [CrossRef]

- Aramide, F.O. Production and Characterization of Porous Insulating Fired Bricks from Ifon Clay with Varied Sawdust Admixture. J. Miner. Mater. Charact. Eng. 2012, 11, 970–975. [Google Scholar] [CrossRef]

- Gencel, O. Characteristics of Fired Clay Bricks with Pumice Additive. Energy Build. 2015, 102, 217–224. [Google Scholar] [CrossRef]

- Cultrone, G. The Use of Mount Etna Volcanic Ash in the Production of Bricks with Good Physical-Mechanical Performance: Converting a Problematic Waste Product into a Resource for the Construction Industry. Ceram. Int. 2022, 48, 5724–5736. [Google Scholar] [CrossRef]

- Whitham, A.G.; Sparks, R.S.J. Pumice. Bull. Volcanol. 1986, 48, 209–223. [Google Scholar] [CrossRef]

- Belfiore, C.M.; Parisi, S.; Menta, S.; Mazzoleni, P. Use of Volcanic Ash and Chamotte as Substitute Temper in the Production of Ceramic Tiles. Appl. Clay Sci. 2024, 262, 107603. [Google Scholar] [CrossRef]

- López Gómez, M.; Cultrone, G. Study of the Mineralogical and Textural Properties of Bricks with Volcanic Ash Temper. Appl. Clay Sci. 2025, 266, 107690. [Google Scholar] [CrossRef]

- Lesher, C.E.; Spera, F.J. Chapter 5—Thermodynamic and Transport Properties of Silicate Melts and Magma. In The Encyclopedia of Volcanoes, 2nd ed.; Sigurdsson, H., Ed.; Academic Press: Amsterdam, The Netherlands, 2015; pp. 113–141. [Google Scholar] [CrossRef]

- UNE-EN 13755; Métodos de Ensayo Para Piedra Natural. Determinación de La Absorción de Agua a Presión Atmosférica. AENOR: Madrid, Spain, 2008.

- Misura Dell’indice Di Asciugamento (Drying Index); NORMAL 29/88; ICR-CNR: Roma, Italy, 1988.

- RILEM. Recommended Test to Measure the Deterioration of Stone and to Assess the Differences of Treatment Methods. Mater Struct 1980, 13, 175–253. [Google Scholar]

- Cultrone, G.; Sebastián, E.; Elert, K.; de la Torre, M.J.; Cazalla, O.; Rodriguez–Navarro, C. Influence of Mineralogy and Firing Temperature on the Porosity of Bricks. J. Eur. Ceram. Soc. 2004, 24, 547–564. [Google Scholar] [CrossRef]

- UNE-EN 12878; Pigmentos Para la Coloración de Materiales de Construcción Fabricados a Partir de Cemento y/o Cal. Especificaciones y Métodos de Ensayo. AENOR: Madrid, Spain, 2014.

- UNE-EN 12370; Métodos de Ensayo Para Piedra Natural. Determinación de La Resistencia a La Cristalización de Las Sales. AENOR: Madrid, Spain, 2020.

- Lopez-Arce, P.; Garcia-Guinea, J. Weathering Traces in Ancient Bricks from Historic Buildings. Build. Environ. 2005, 40, 929–941. [Google Scholar] [CrossRef]

- Pankhurst, M.J.; Scarrow, J.H.; Barbee, O.A.; Hickey, J.; Coldwell, B.C.; Rollinson, G.K.; Rodríguez-Losada, J.A.; Lorenzo, A.M.; Rodríguez, F.; Hernández, W.; et al. Rapid Response Petrology for the Opening Eruptive Phase of the 2021 Cumbre Vieja Eruption, La Palma, Canary Islands. Volcanica 2022, 5, 1–10. [Google Scholar] [CrossRef]

- Lafhaj, Z.; Goueygou, M.; Djerbi, A.; Kaczmarek, M. Correlation between Porosity, Permeability and Ultrasonic Parameters of Mortar with Variable Water/Cement Ratio and Water Content. Cem. Concr. Res. 2006, 36, 625–633. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Lv, C.; Zhang, G.; Yin, Y. A Predictive Model of the Effective Tensile and Compressive Strengths of Concrete Considering Porosity and Pore Size. Constr. Build. Mater. 2018, 170, 520–526. [Google Scholar] [CrossRef]

- Pliego General de Condiciones Para La Recepción de Los Ladrillos Cerámicos En Las Obras de Construcción; RL-88; Minist. Obras Públicas Transp. Medio Ambiente: Madrid, Spain, 1988.

- Bhattacharjee, B.; Krishnamoorthy, S. Permeable Porosity and Thermal Conductivity of Construction Materials. J. Mater. Civ. Eng. 2004, 16, 322–330. [Google Scholar] [CrossRef]

- Cultrone, G.; Aurrekoetxea, I.; Casado, C.; Arizzi, A. Sawdust Recycling in the Production of Lightweight Bricks: How the Amount of Additive and the Firing Temperature Influence the Physical Properties of the Bricks. Constr. Build. Mater. 2020, 235, 117436. [Google Scholar] [CrossRef]

- Nodari, L.; Marcuz, E.; Maritan, L.; Mazzoli, C.; Russo, U. Hematite Nucleation and Growth in the Firing of Carbonate-Rich Clay for Pottery Production. J. Eur. Ceram. Soc. 2007, 27, 4665–4673. [Google Scholar] [CrossRef]

- Kreimeyer, R. Some Notes on the Firing Colour of Clay Bricks. Appl. Clay Sci. 1987, 2, 175–183. [Google Scholar] [CrossRef]

- Vasić, M.V.; Radovanović, L.; Pezo, L.; Radojević, Z. Raw Kaolinitic–Illitic Clays as High-Mechanical-Performance Hydraulically Pressed Refractories. J. Therm. Anal. Calorim. 2023, 148, 1783–1803. [Google Scholar] [CrossRef]

- Sousa, S.J.G.; Holanda, J.N.F. Characterization of Non-Calcareous “Thin” Red Clay from South-Eastern Brazil: Applicability in Wall Tile Manufacture. Cerâmica 2012, 58, 29–35. [Google Scholar] [CrossRef]

- Maniatis, Y.; Simopoulos, A.; Kostikas, A. Moessbauer Study of the Effect of Calcium Content on Iron Oxide Transformations in Fired Clays. J. Am. Ceram. Soc. 1981, 64, 263–269. [Google Scholar] [CrossRef]

- Mokrzycki, W.S.; Talot, M. Colour Difference ΔE. A Survey. Mach Graph Vis. 2021, 20, 383–411. [Google Scholar]

- Benavente, D.; Linares-Fernández, L.; Cultrone, G.; Sebastián, E. Influence of Microstructure on The Resistance to Salt Crystallisation Damage in Brick. Mater. Struct. 2006, 39, 105–113. [Google Scholar] [CrossRef]

| Temperature (°C) | Control Samples | Bricks with Volcanic Ash | ||

|---|---|---|---|---|

| % | Fine | Coarse | ||

| 800 | B800 | 10 | B(10F)800 | B(10G)800 |

| 20 | B(20F)800 | B(20G)800 | ||

| 30 | B(30F)800 | B(30G)800 | ||

| 950 | B950 | 10 | B(10F)950 | B(10G)950 |

| 20 | B(20F)950 | B(20G)950 | ||

| 30 | B(30F)950 | B(30G)950 | ||

| 1100 | B1100 | 10 | B(10F)1100 | B(10G)1100 |

| 20 | B(20F)1100 | B(20G)1100 | ||

| 30 | B(30F)1100 | B(30G)1100 | ||

| Sample | Ab | Af | Ax | Di | S | Po | ρa | ρr | PoMIP | ρaMIP | ρrMIP | SSA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B800 | 22.07 | 22.34 | 1.23 | 0.920 | 87.23 | 36.04 | 1.61 | 2.52 | 36.51 | 1.61 | 2.53 | 6.84 |

| 0.34 | 0.33 | 0.09 | 0.001 | 1.77 | 0.52 | 0.00 | 0.02 | |||||

| B(10F)800 | 19.61 | 20.24 | 3.09 | 0.910 | 90.26 | 33.85 | 1.67 | 2.53 | 35.75 | 1.66 | 2.59 | 4.67 |

| 0.28 | 0.38 | 1.66 | 0.006 | 2.70 | 0.51 | 0.01 | 0.01 | |||||

| B(10G)800 | 20.73 | 21.22 | 2.32 | 0.908 | 92.12 | 34.67 | 1.63 | 2.50 | 37.00 | 1.63 | 2.59 | 6.78 |

| 0.15 | 0.08 | 0.68 | 0.006 | 1.41 | 0.13 | 0.00 | 0.01 | |||||

| B(20F)800 | 19.31 | 19.89 | 2.90 | 0.917 | 85.94 | 33.93 | 1.71 | 2.58 | 35.91 | 1.69 | 2.63 | 4.59 |

| 0.25 | 0.32 | 0.59 | 0.003 | 0.66 | 0.43 | 0.01 | 0.01 | |||||

| B(20G)800 | 19.73 | 21.12 | 6.58 | 0.905 | 85.25 | 35.14 | 1.66 | 2.56 | 35.44 | 1.65 | 2.56 | 6.09 |

| 0.12 | 0.20 | 0.33 | 0.005 | 0.46 | 0.22 | 0.01 | 0.00 | |||||

| B(30F)800 | 18.10 | 18.97 | 4.61 | 0.916 | 84.22 | 33.15 | 1.75 | 2.61 | 32.15 | 1.83 | 2.69 | 4.23 |

| 0.14 | 0.14 | 0.72 | 0.002 | 1.11 | 0.29 | 0.01 | 0.02 | |||||

| B(30G)800 | 19.38 | 22.49 | 13.82 | 0.903 | 79.53 | 37.32 | 1.66 | 2.65 | 35.35 | 1.66 | 2.57 | 4.22 |

| 0.15 | 0.41 | 1.01 | 0.005 | 0.92 | 0.62 | 0.00 | 0.02 | |||||

| B950 | 23.15 | 23.41 | 1.10 | 0.910 | 90.51 | 36.78 | 1.57 | 2.49 | 42.53 | 1.53 | 2.66 | 2.19 |

| 0.10 | 0.09 | 0.77 | 0.003 | 1.41 | 0.13 | 0.00 | 0.01 | |||||

| B(10F)950 | 21.93 | 22.40 | 2.11 | 0.910 | 90.11 | 35.96 | 1.61 | 2.51 | 40.81 | 1.60 | 2.71 | 1.75 |

| 0.13 | 0.24 | 0.83 | 0.004 | 0.53 | 0.31 | 0.01 | 0.01 | |||||

| B(10G)950 | 22.54 | 23.26 | 3.14 | 0.909 | 89.24 | 36.80 | 1.58 | 2.50 | 41.40 | 1.56 | 2.67 | 2.03 |

| 0.14 | 0.15 | 0.22 | 0.000 | 0.43 | 0.28 | 0.00 | 0.02 | |||||

| B(20F)950 | 20.63 | 21.56 | 4.30 | 0.897 | 86.96 | 35.90 | 1.66 | 2.60 | 39.47 | 1.62 | 2.68 | 1.75 |

| 0.21 | 0.09 | 0.55 | 0.003 | 1.19 | 0.03 | 0.01 | 0.01 | |||||

| B(20G)950 | 21.85 | 24.14 | 9.50 | 0.889 | 84.58 | 38.47 | 1.59 | 2.59 | 40.28 | 1.58 | 2.64 | 1.71 |

| 0.16 | 0.14 | 0.23 | 0.000 | 0.56 | 0.19 | 0.00 | 0.01 | |||||

| B(30F)950 | 19.41 | 20.68 | 6.16 | 0.891 | 84.33 | 35.35 | 1.71 | 2.64 | 41.27 | 1.75 | 2.97 | 1.51 |

| 0.26 | 0.28 | 0.95 | 0.001 | 1.92 | 0.27 | 0.01 | 0.01 | |||||

| B(30G)950 | 21.25 | 25.92 | 18.01 | 0.874 | 77.04 | 41.61 | 1.61 | 2.75 | 40.95 | 1.57 | 2.66 | 1.92 |

| 0.11 | 0.21 | 0.69 | 0.001 | 0.77 | 0.21 | 0.00 | 0.00 | |||||

| B1100 | 24.17 | 25.89 | 6.65 | 0.876 | 77.74 | 40.21 | 1.55 | 2.60 | 43.99 | 1.53 | 2.73 | 1.05 |

| 0.06 | 0.04 | 0.15 | 0.006 | 0.10 | 0.17 | 0.01 | 0.02 | |||||

| B(10F)1100 | 21.85 | 24.16 | 9.57 | 0.874 | 74.35 | 38.90 | 1.61 | 2.63 | 42.15 | 1.57 | 2.71 | 0.79 |

| 0.05 | 0.10 | 0.55 | 0.003 | 0.20 | 0.12 | 0.00 | 0.00 | |||||

| B(10G)1100 | 22.64 | 25.09 | 9.76 | 0.875 | 73.22 | 39.80 | 1.59 | 2.64 | 41.28 | 1.60 | 2.72 | 0.85 |

| 0.01 | 0.21 | 0.77 | 0.004 | 0.48 | 0.26 | 0.01 | 0.01 | |||||

| B(20F)1100 | 20.49 | 22.87 | 10.37 | 0.885 | 73.56 | 37.95 | 1.66 | 2.67 | 40.05 | 1.63 | 2.72 | 0.68 |

| 0.12 | 0.14 | 0.29 | 0.003 | 0.04 | 0.07 | 0.01 | 0.01 | |||||

| B(20G)1100 | 21.46 | 25.36 | 15.39 | 0.873 | 70.82 | 40.65 | 1.60 | 2.70 | 39.97 | 1.59 | 2.65 | 0.82 |

| 0.39 | 0.17 | 1.21 | 0.001 | 1.56 | 0.26 | 0.00 | 0.01 | |||||

| B(30F)1100 | 18.17 | 21.74 | 16.41 | 0.879 | 68.94 | 37.44 | 1.72 | 2.75 | 35.26 | 1.67 | 2.58 | 0.59 |

| 0.25 | 0.36 | 2.34 | 0.006 | 2.28 | 0.44 | 0.01 | 0.01 | |||||

| B(30G)1100 | 20.81 | 25.77 | 19.24 | 0.861 | 70.07 | 41.70 | 1.62 | 2.78 | 38.93 | 1.61 | 2.64 | 0.8 |

| 0.54 | 0.42 | 1.21 | 0.002 | 1.25 | 0.39 | 0.01 | 0.01 |

| L* | a* | b* | C* | h° | ΔE* | L* | a* | b* | C* | h° | ΔE* | L* | a* | b* | C* | h° | ΔE* | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B800 | 61.20 | 16.42 | 21.46 | 27.02 | 52.58 | - | 950 | 62.27 | 16.32 | 22.86 | 28.08 | 54.48 | - | B1100 | 66.56 | 9.04 | 22.85 | 24.58 | 68.43 | - |

| 0.42 | 0.26 | 0.24 | 0.34 | 0.17 | 0.80 | 0.71 | 0.76 | 1.03 | 0.28 | 0.15 | 0.13 | 0.10 | 0.07 | 0.34 | ||||||

| B(10F) 800 | 60.78 | 15.29 | 19.43 | 24.73 | 51.76 | 2.36 | B(10F) 950 | 63.51 | 14.59 | 19.23 | 24.14 | 52.82 | 4.21 | B(10F) 1100 | 66.19 | 8.51 | 21.82 | 23.42 | 68.70 | 1.22 |

| 1.58 | 1.33 | 2.23 | 2.58 | 0.75 | 0.80 | 0.47 | 0.69 | 0.82 | 0.38 | 0.95 | 0.36 | 1.01 | 1.06 | 0.37 | ||||||

| B(10G) 800 | 60.77 | 16.74 | 21.80 | 27.49 | 52.48 | 0.64 | B(10G) 950 | 63.15 | 14.31 | 19.15 | 23.91 | 53.22 | 4.30 | B(10G) 1100 | 66.00 | 8.85 | 23.19 | 24.82 | 69.11 | 0.68 |

| 0.54 | 0.41 | 0.59 | 0.72 | 0.19 | 1.56 | 0.62 | 1.17 | 1.30 | 0.63 | 0.79 | 0.37 | 0.17 | 0.12 | 0.89 | ||||||

| B(20F) 800 | 59.34 | 16.59 | 21.13 | 26.87 | 51.87 | 1.90 | B(20F) 950 | 65.06 | 13.14 | 17.60 | 21.97 | 53.25 | 6.75 | B(20F) 1100 | 65.10 | 8.23 | 22.24 | 23.72 | 69.68 | 1.78 |

| 1.21 | 0.96 | 1.07 | 1.43 | 0.39 | 0.68 | 0.25 | 0.48 | 0.51 | 0.53 | 0.93 | 0.19 | 0.35 | 0.33 | 0.55 | ||||||

| B(20G) 800 | 60.73 | 16.46 | 21.23 | 26.87 | 52.18 | 0.52 | B(20G) 950 | 63.98 | 13.52 | 17.53 | 22.14 | 52.37 | 6.26 | B(20G) 1100 | 66.00 | 8.76 | 22.38 | 24.04 | 68.63 | 0.78 |

| 0.73 | 0.92 | 1.64 | 1.86 | 0.60 | 0.73 | 0.15 | 0.29 | 0.29 | 0.37 | 1.43 | 0.36 | 0.27 | 0.26 | 0.88 | ||||||

| B(30F) 800 | 60.26 | 15.07 | 19.59 | 24.72 | 52.45 | 2.49 | B(30F) 950 | 64.75 | 12.27 | 16.95 | 20.92 | 54.10 | 7.58 | B(30F) 1100 | 63.59 | 8.03 | 22.06 | 23.48 | 69.99 | 3.24 |

| 0.49 | 0.62 | 0.60 | 0.86 | 0.34 | 0.90 | 0.43 | 0.54 | 0.69 | 0.15 | 0.96 | 0.18 | 0.11 | 0.07 | 0.47 | ||||||

| B(30G) 800 | 58.72 | 17.36 | 22.55 | 28.46 | 52.40 | 2.87 | B(30G) 950 | 61.57 | 16.14 | 22.07 | 27.34 | 53.82 | 1.07 | B(30G) 1100 | 63.51 | 8.74 | 22.52 | 24.16 | 68.80 | 3.08 |

| 1.07 | 1.02 | 1.53 | 1.83 | 0.26 | 0.21 | 0.02 | 0.10 | 0.08 | 0.15 | 1.03 | 0.11 | 0.11 | 0.07 | 0.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López Gómez, M.; Cultrone, G. Physico-Mechanical Properties and Decay Susceptibility of Clay Bricks After the Addition of Volcanic Ash from La Palma (Canary Islands, Spain). Sustainability 2025, 17, 6545. https://doi.org/10.3390/su17146545

López Gómez M, Cultrone G. Physico-Mechanical Properties and Decay Susceptibility of Clay Bricks After the Addition of Volcanic Ash from La Palma (Canary Islands, Spain). Sustainability. 2025; 17(14):6545. https://doi.org/10.3390/su17146545

Chicago/Turabian StyleLópez Gómez, María, and Giuseppe Cultrone. 2025. "Physico-Mechanical Properties and Decay Susceptibility of Clay Bricks After the Addition of Volcanic Ash from La Palma (Canary Islands, Spain)" Sustainability 17, no. 14: 6545. https://doi.org/10.3390/su17146545

APA StyleLópez Gómez, M., & Cultrone, G. (2025). Physico-Mechanical Properties and Decay Susceptibility of Clay Bricks After the Addition of Volcanic Ash from La Palma (Canary Islands, Spain). Sustainability, 17(14), 6545. https://doi.org/10.3390/su17146545