Integrating Noise Pollution into Life Cycle Assessment: A Comparative Framework for Concrete and Timber Floor Construction

Abstract

1. Introduction

1.1. Background

1.2. Recent Literature Review

1.3. Aim

1.4. Present Study

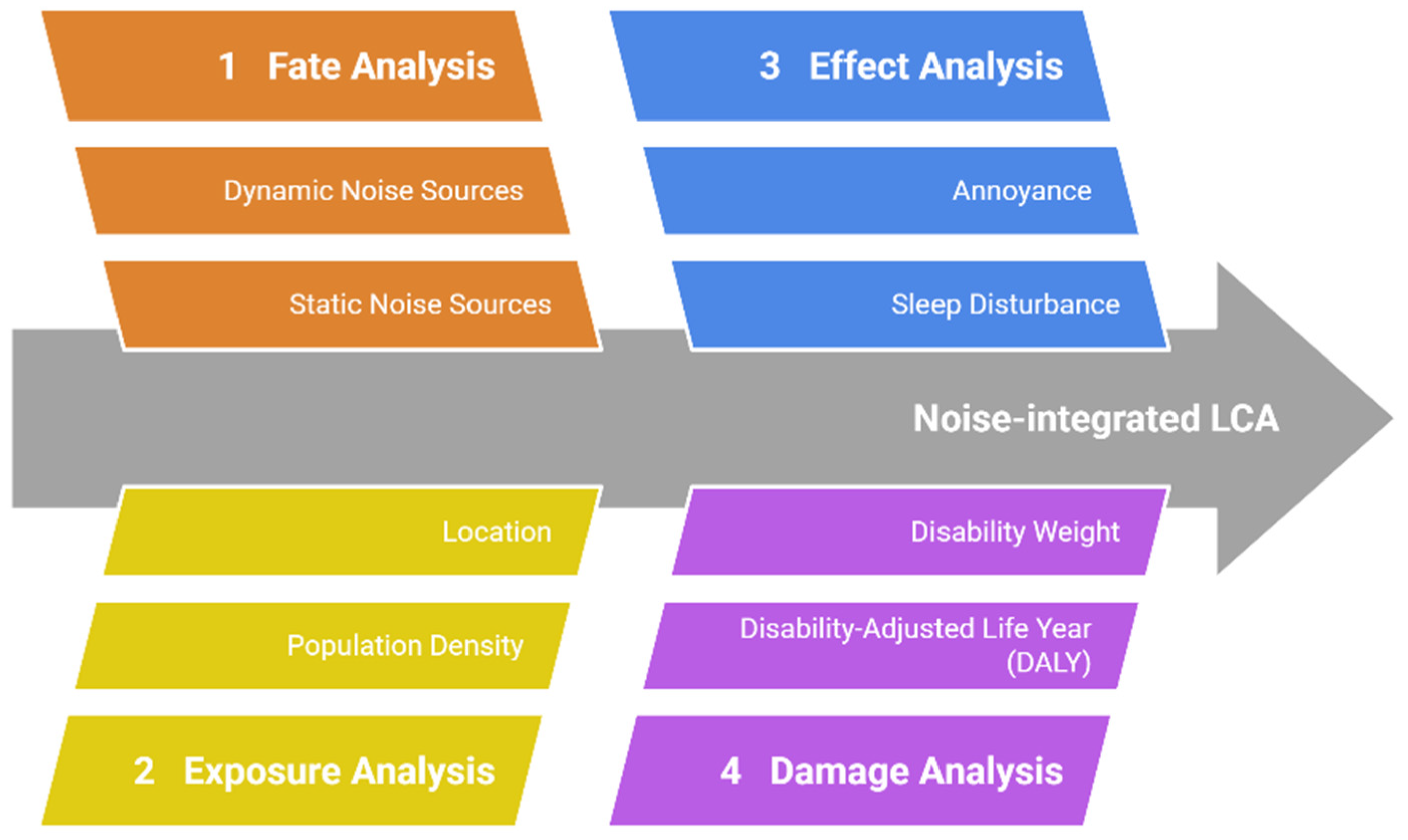

2. Methodology

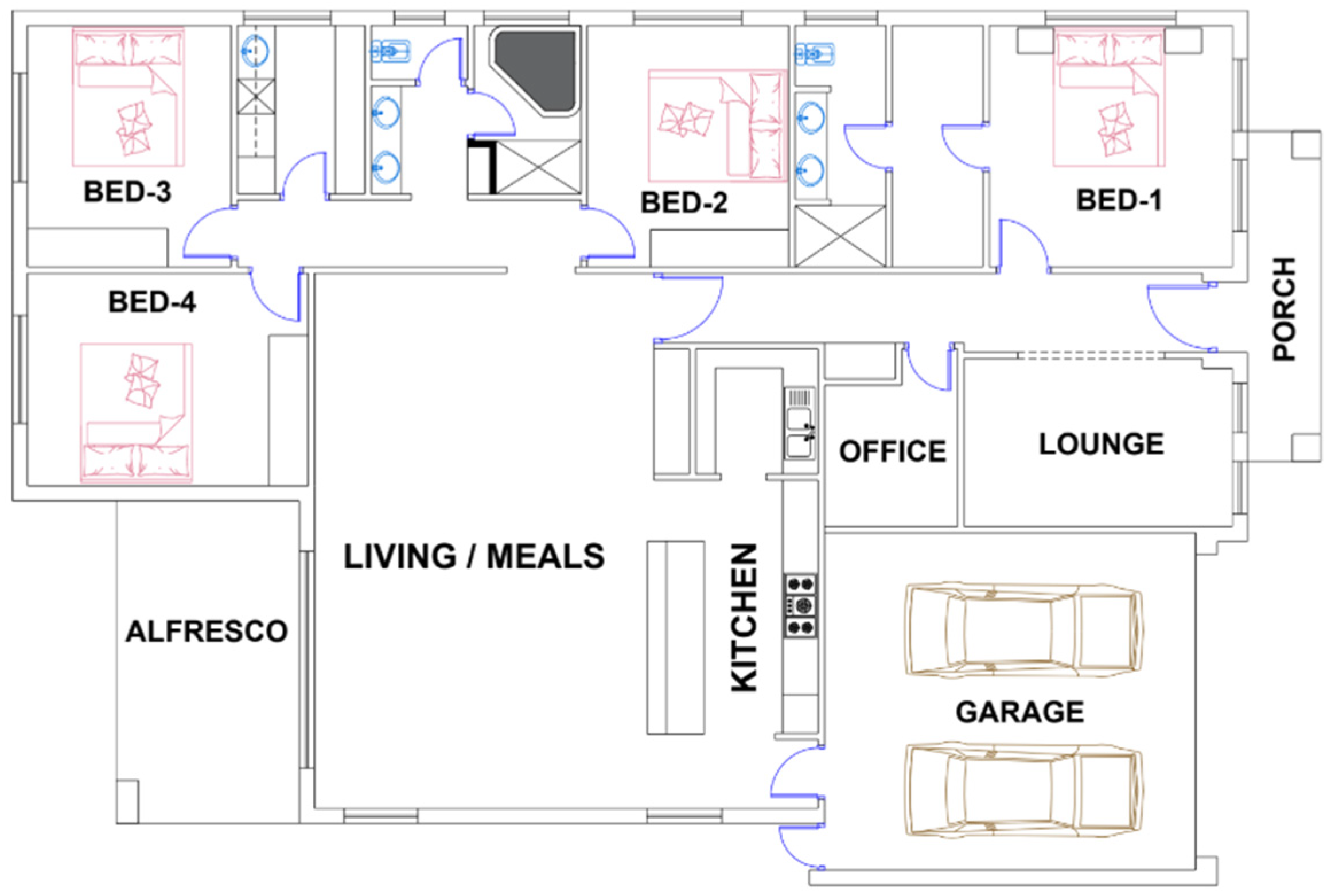

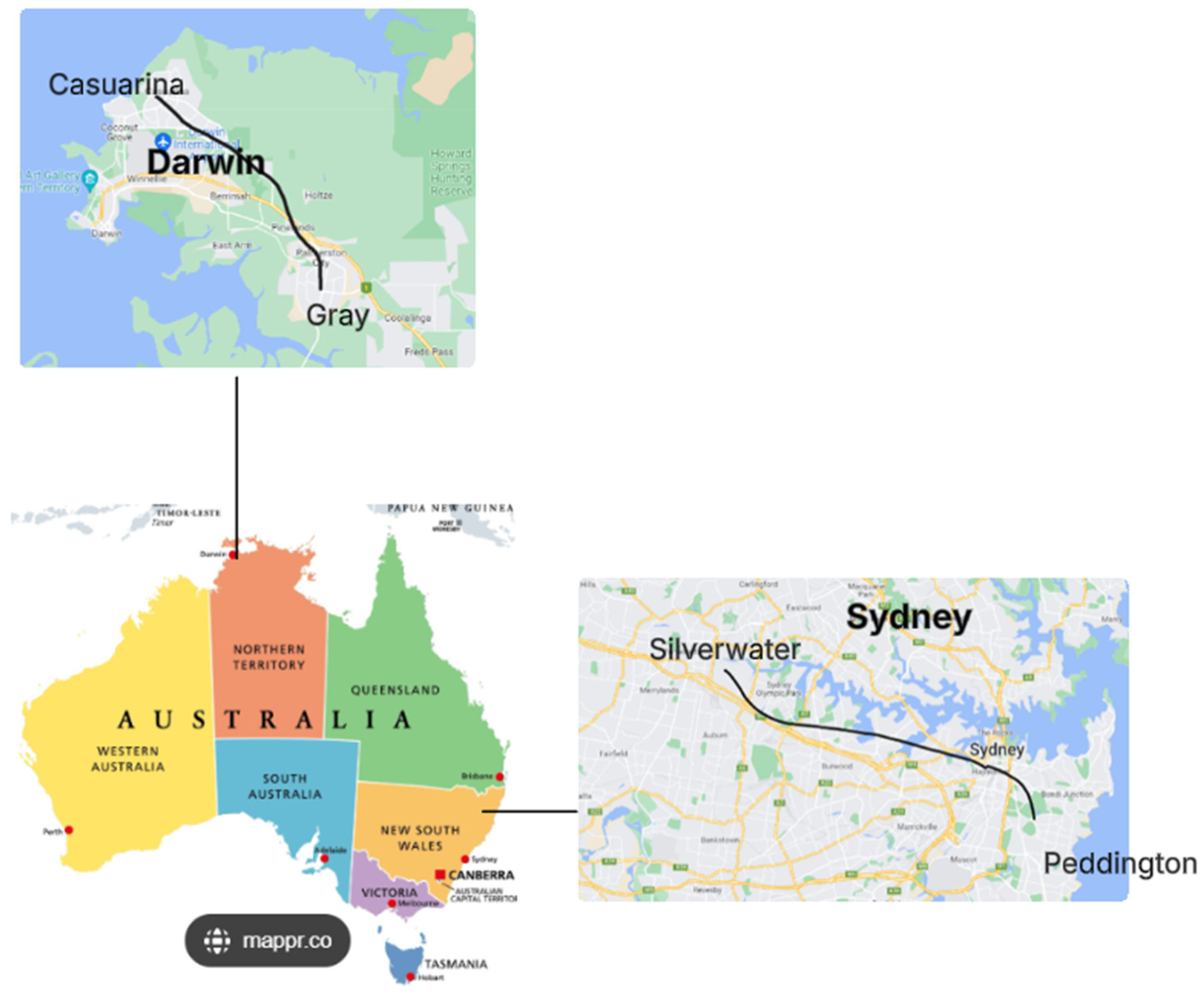

2.1. Goal and Scope Definition

2.2. Data Input/Inventory

2.3. Life Cycle Impact Assessment

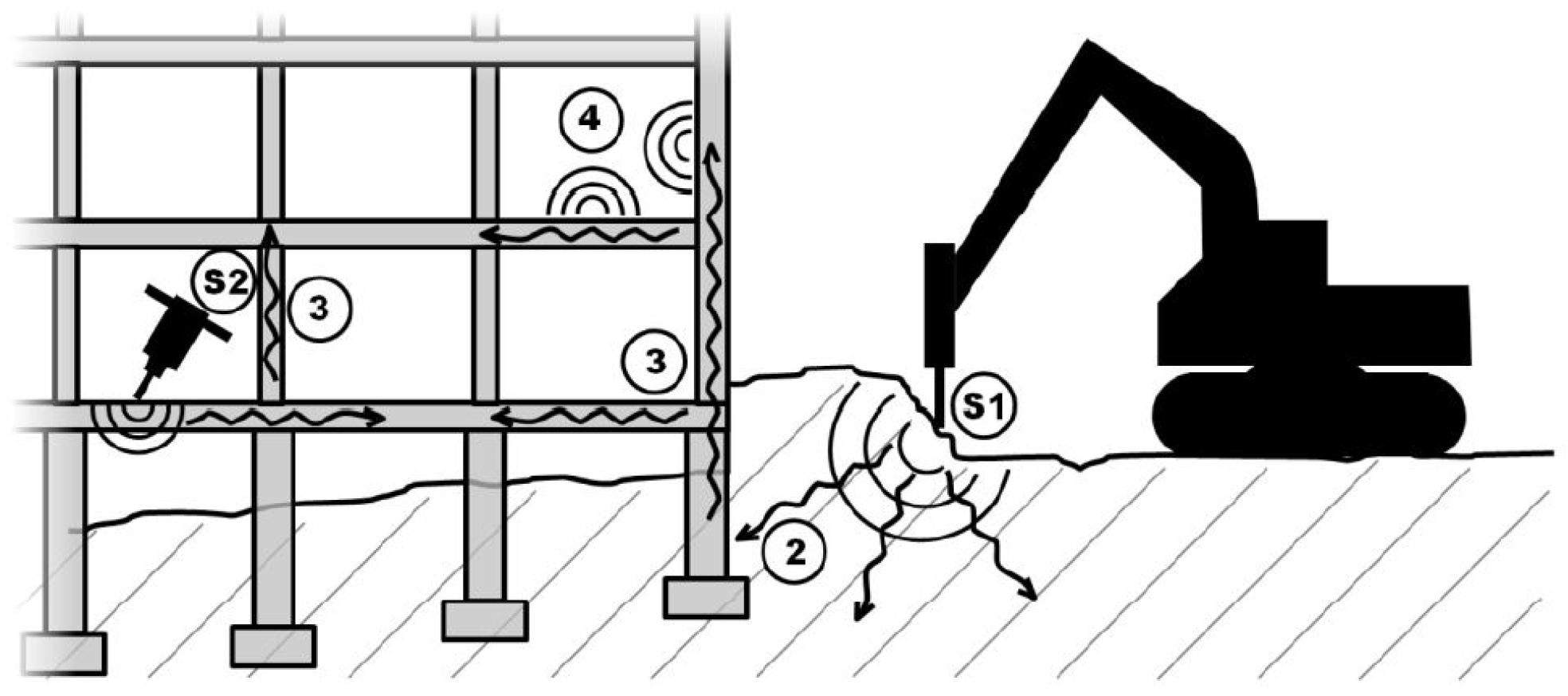

2.3.1. Fate Analysis

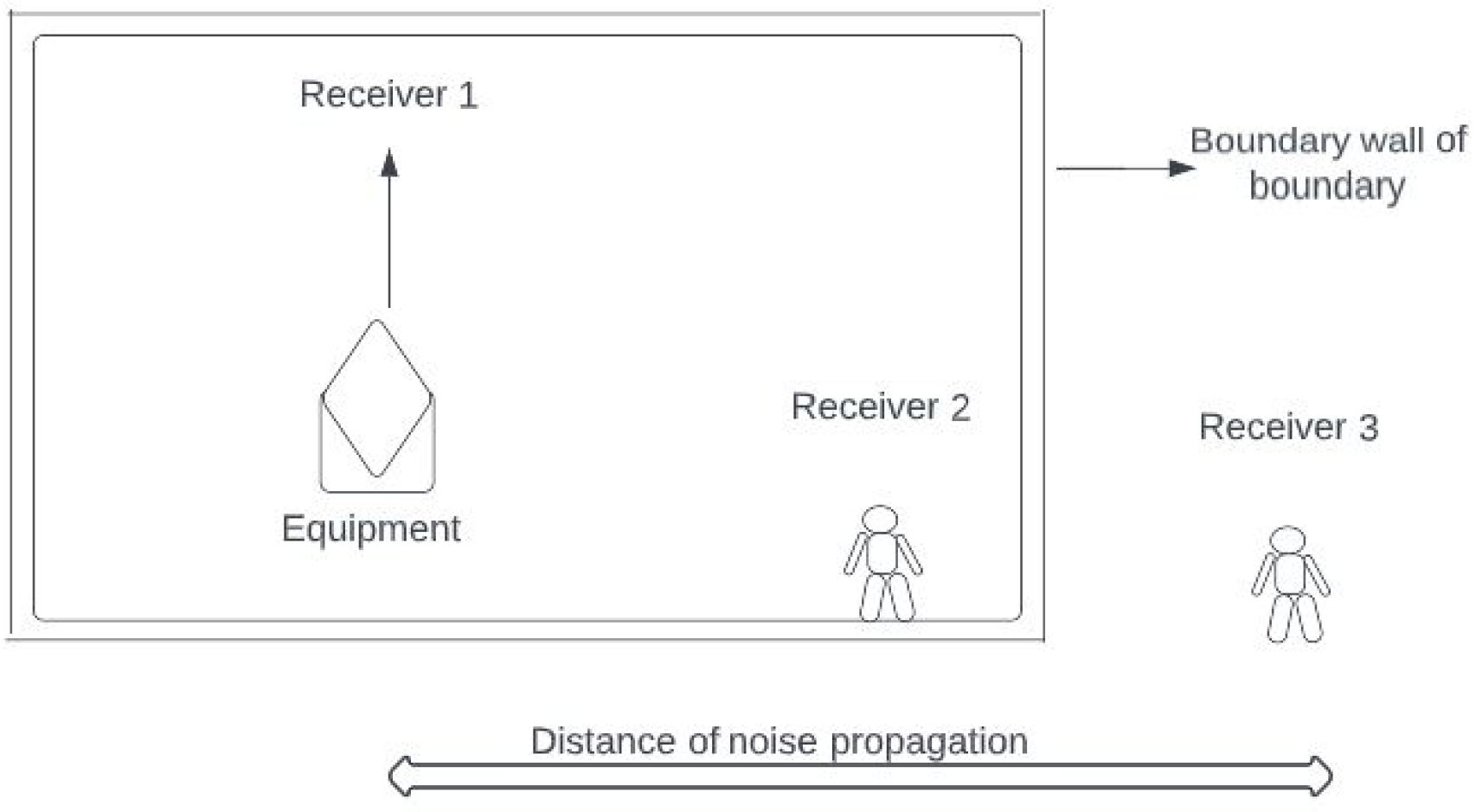

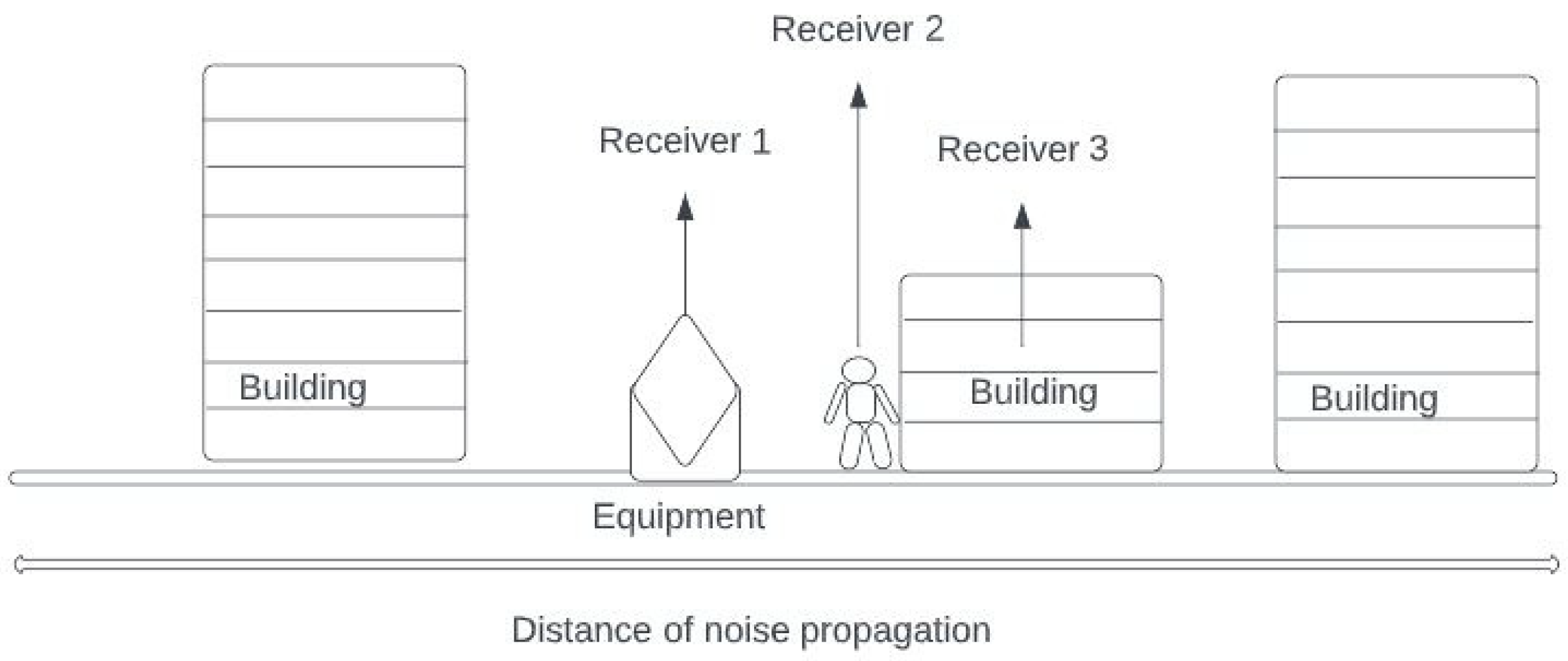

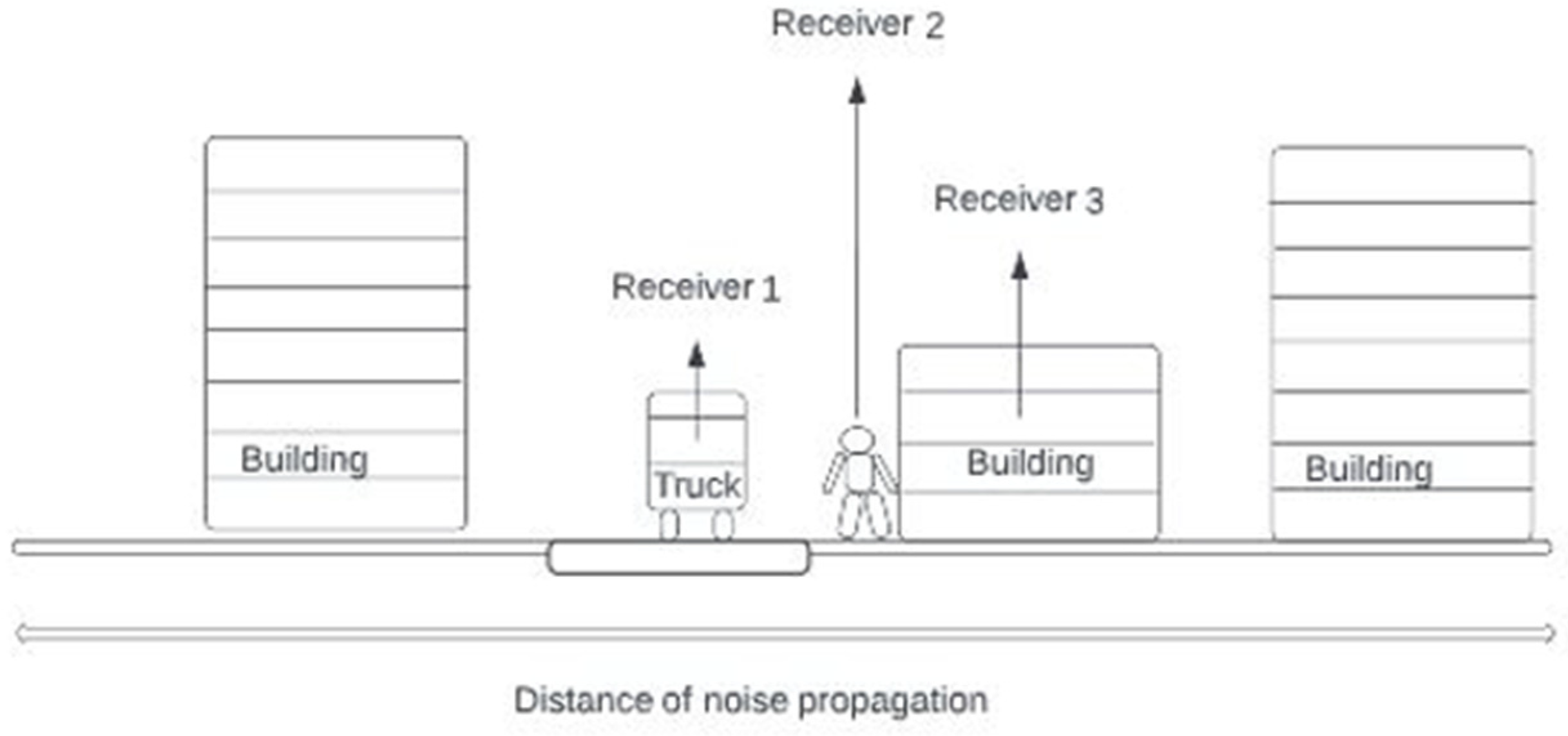

- Structural noise receiver: Individuals directly exposed to noise while using equipment, machinery, or transportation;

- Airborne noise receiver: Individuals situated 50 feet away from the noise source, capturing the impact of noise propagation;

- Indoor noise receiver: Occupants inside residential buildings affected by transmitted noise.

2.3.2. Exposure Analysis

2.3.3. Effect Analysis

2.3.4. Damage Analysis

3. Result and Discussion

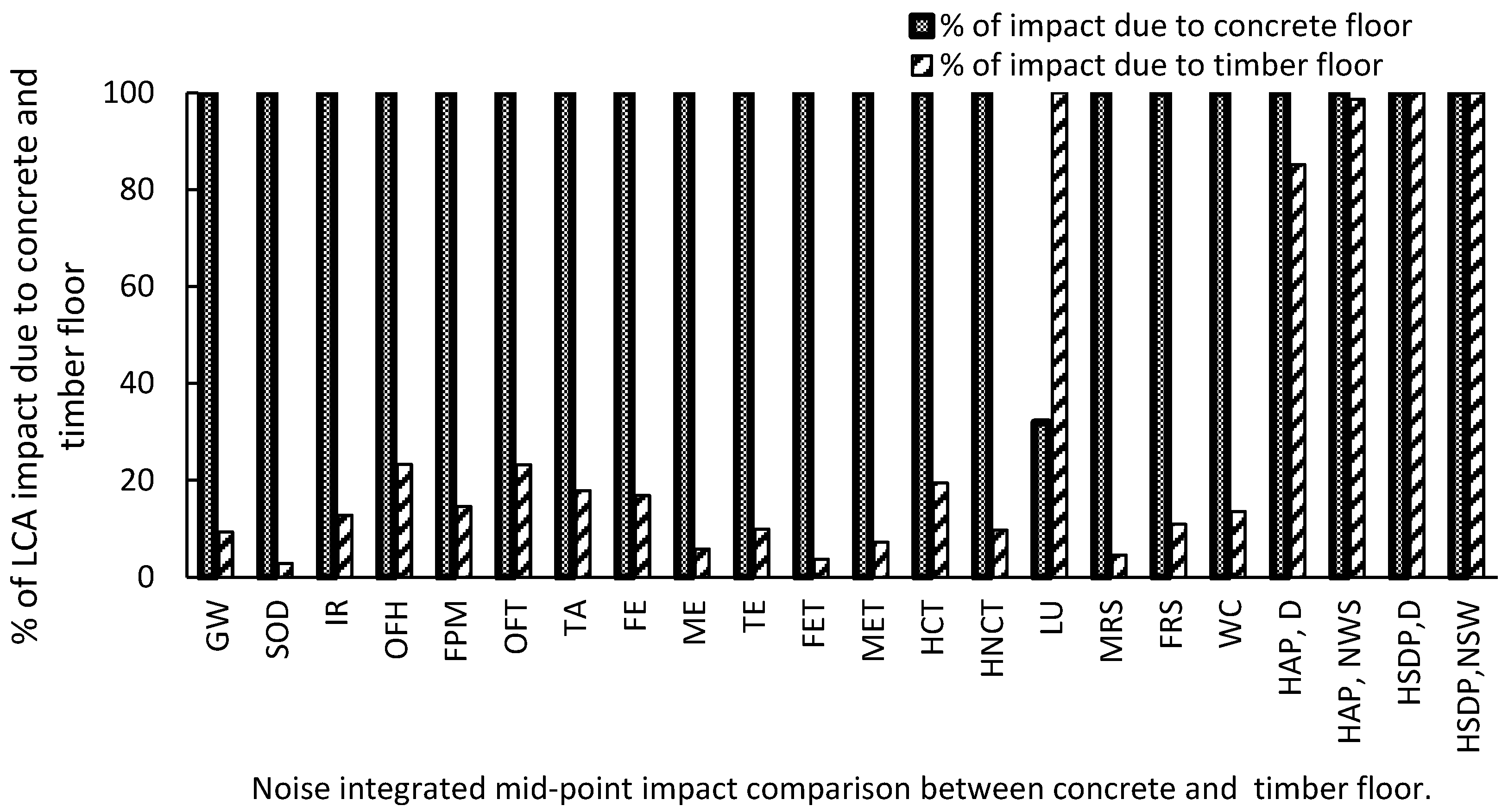

3.1. Midpoint Impact Assessment

3.1.1. Impact of Concrete and Timber Floors (Material and Associated Traffic)

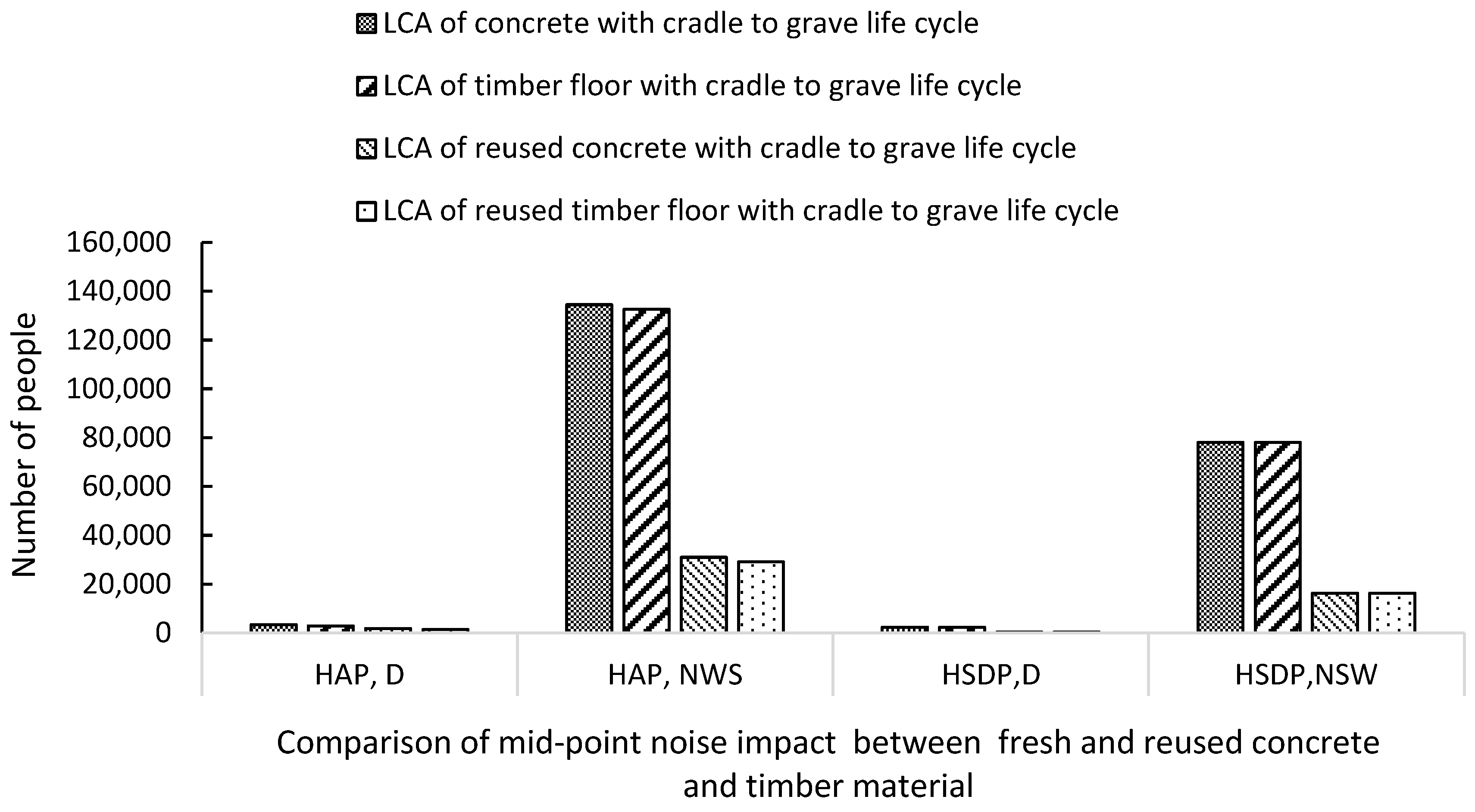

3.1.2. Circular Economy Scenarios: Reuse, Recycling, and Transport Distance Reduction

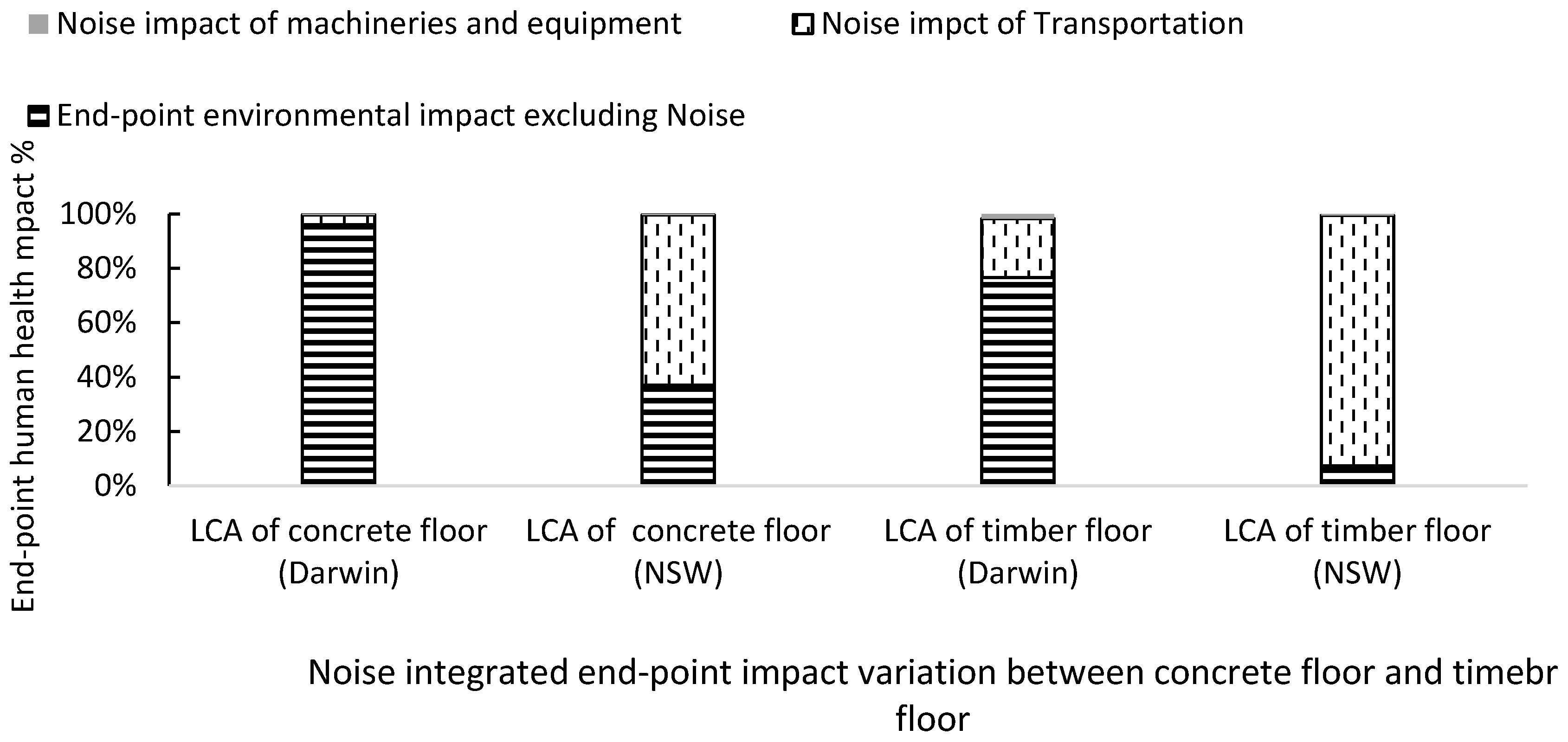

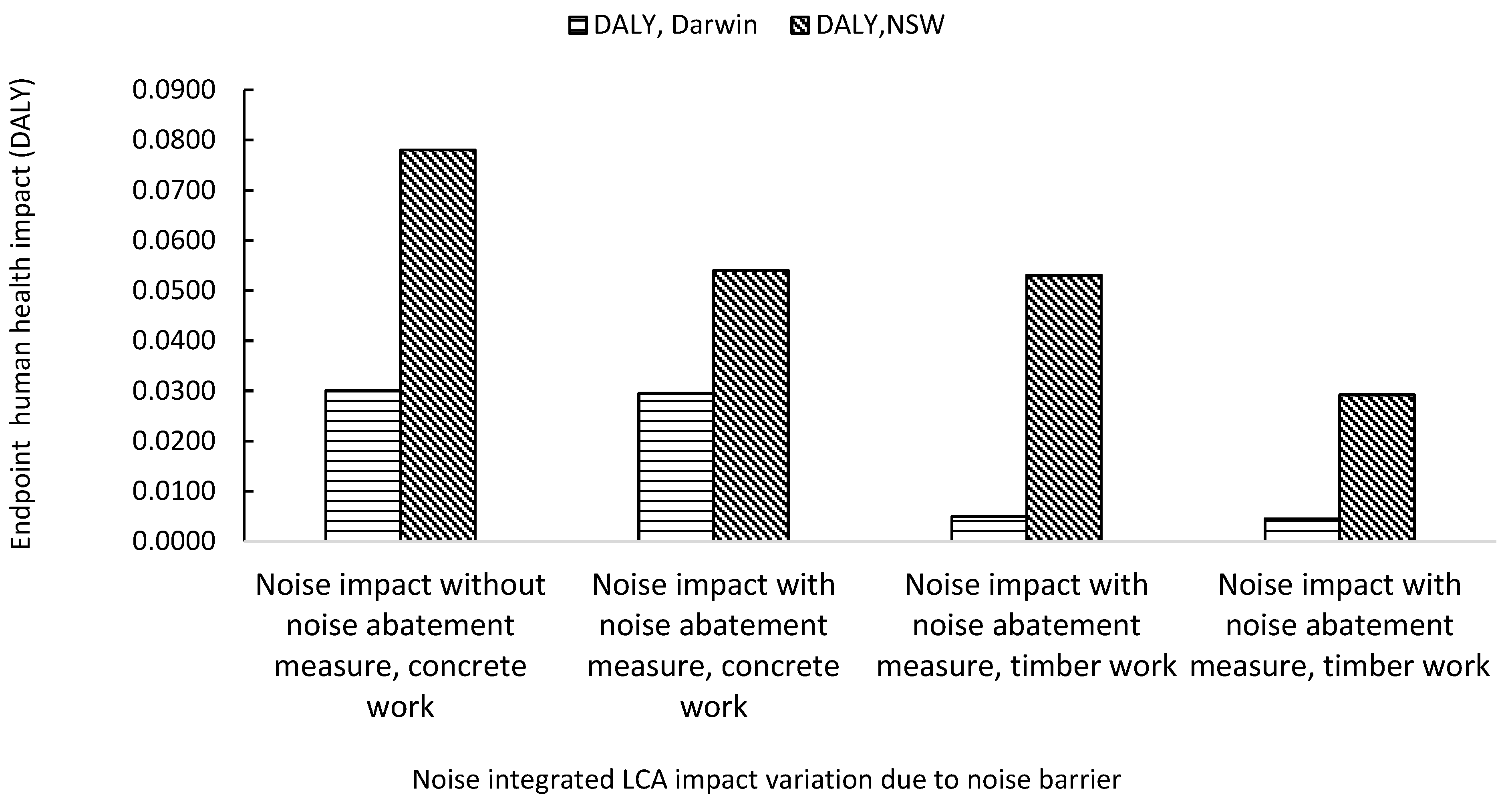

3.2. Endpoint Impact Assessment

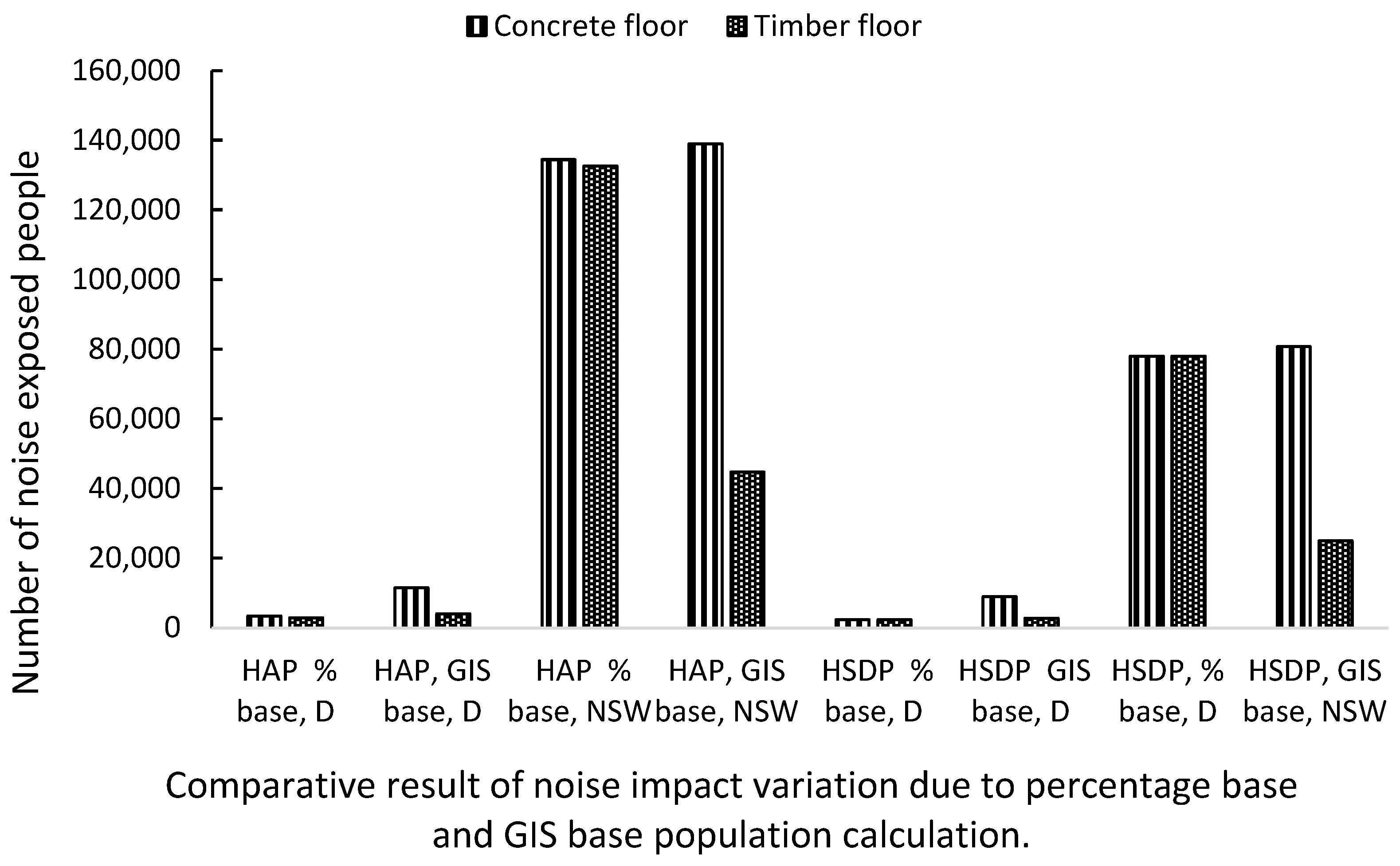

3.3. Sensitivity Analysis

3.4. Results Validation

3.4.1. Material Impact, Specifically Carbon Emission

3.4.2. Traffic Noise Validation

3.4.3. Construction Nosie Validation

4. Limitations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| LCA | life cycle assessment |

| LCIA | life cycle impact assessment |

| DALYs | disability-adjusted life years |

| BIM | building information modeling |

| ISO | International Organization for Standardization |

| DW | disability weight |

| HAP | highly annoyed person |

| HSDP | highly sleep-disturbed person |

| vkm | vehicle-kilometer |

Appendix A

Appendix A.1. Estimation of the Noise Level of the Point/Stationary/Static Source

Appendix A.2. Noise Level Calculation

Appendix A.2.1. Noise Level in Construction Area

Noise Level for Concrete Work

Noise Level for Timber Work

Appendix A.2.2. Estimation of the Noise Level of the Mobile Source

Traffic Data Input

Appendix A.3. Computation of Characterization Factors (CFs)

Appendix A.4. List of the Tables

| Type of Work | Name of Material | Quantity of Material | Service Time |

|---|---|---|---|

| Trenching | Soil digging | 40 m3 | |

| reinforcement | 1100 kg | 100 years | |

| 6 mm laminated floor panel | 1.044 m3 | 20 years | |

| Wooden floor maintenance | Sanding, vacuuming | 10 years | |

| Oil-based polyurethane | 20 L | 10 years |

| Type of Work | Name of Material | Quantity of Material | Service Time |

|---|---|---|---|

| Wooden floor | Structural timber of floor foundation | 3.4 m3 | 100 years |

| Nail for timber foundation | 6.9 kg | 100 years | |

| 20 mm wooden floor panel | 3.3 m3 | 50 years | |

| Aluminum nail | 10 kg | 50 years | |

| Wooden floor maintenance | Sanding, vacuuming | 10 years | |

| Oil-based polyurethane | 20 L | 10 years |

| Product Stage | Material Information |

|---|---|

| Packaging material: | Concrete information: For 110,000 kg of reinforced concrete, 15,400 kg of cement, 30,800 kg of sand, 61,600 kg of crushed stone, 1100 kg of steel, and 6600 kg of water were used. A 18.64 kw machine will operate for 8 h for concrete production. A 16–32 metric ton lorry, EURO4|Cut-off, U will travel 800 km from the mining place to the industry and 50 km to the construction site. For 60,000 kg earth excavations, 18.64 kw machines will operate for 8 h. Timber information: For 3.4 m3 of timber footing, glue-laminated timber is used, and a 6.9 kg aluminum nail is used for fixing. Cross-laminated timber is used for 3.3 m3 of timber floor, and a 10 kg aluminum nail is used for fixing. A 16–32 metric ton lorry, EURO4|Cut-off, U will travel 50 km distance. For 30,000 kg earth excavations, an 18.64 kw machine will operate for 4 h. |

| During the construction stage: | One kWh of electricity vibrates the concrete. Seventy kg of polyurethane rigid foam acts as a vapor barrier underneath the concrete. A 2800 kg vinyl floor covers the floor. Hammer guns and hand saw machines are used for timber work. |

| Maintenance and repair stage: | An amount of 200 kg of anionic resin is used to maintain the floor covering, and 100 kg of wood preservative is used to protect the wooden floor. |

| Deconstruction and disposal stage: | Landfill scenario: The concrete demolishing hammer is used for 8 h for concrete work, and leftover concrete will go to a landfill. The landfill location is 100 km away from the construction site. Reinforcement will be gone in the landfill, too. The timber will be demolished by an 18.64 kW machine for 4 h and transferred to 100 km for landfill. Reuse scenario: The concrete is demolished with the machine for 16 h and will be reused. The reuse mechanism factory is 100 km away from the construction site. Reinforcement will be reused, too. The timber will be demolished by an 18.64 kW machine for 8 h and transferred to 100 km for landfill. Nail scrap will be separated and sent to the factory. Steel: Steel, low-alloyed {GLO}|market for|Cut-off, U Transport, freight, lorry 16-32 metric ton, euro4 {RoW}| Brick: Clay brick {GLO}|market for|Cut-off, U Transport, freight, lorry 16–32 metric ton, euro4 {RoW}| Insulation: Glass wool mat {GLO}|market for|Cut-off, U Transport, freight, lorry 3.5–7.5 metric ton, euro6 {RER}| Wood-based insulation: cellulose fiber {RoW}|market for cellulose fiber|Cut-off, U Transport, freight, lorry 3.5–7.5 metric ton, euro5 {RoW}| Paint: Alkyd paint, white, without solvent, in 60% solution state {RER}|market for alkyd paint, white, without solvent, in 60% solution state|APOS, S Plasterboard: Gypsum plasterboard {GLO}|market for|Cut-off, U Door: Door, outer, wood-glass {GLO}|market for|Cut-off, S Window: Transport, freight, lorry 16–32 metric ton, EURO6|Cut-off, U |

| Name of Point Source | Decibel |

|---|---|

| Concrete work-related equipment | |

| Rock drill | 97 |

| Steel reinforcement forming for concrete | 90 |

| Aluminum forming and processing | 80 |

| Vibrating roller | 106 |

| Concrete mixer | 86 |

| Jackhammer | 87 |

| Construction lift | 93 |

| Pump | 100 |

| Crawler excavators 0.9–9 tons | 97 |

| Crawler excavators 12–40 tons | 103 |

| Crawler piling rig | 110 |

| Skid-steer loaders | 101 |

| Excavator with a demolition hammer | 114 |

| Excavator | 76 |

| Timber work-related equipment | |

| Timber harvester | 75 |

| Forwarder | 82 |

| Self-loading tractor | 91 |

| Grapple skidder | 78 |

| Forest loader | 82 |

| Chainsaw | 100 |

| Timber lifting crane | 87 |

| Jackhammer | 87 |

| Excavator | 76 |

| Type of Vehicle | Traveled from | Travel to | Total Distance | Traffic Velocity | Traveling Time |

|---|---|---|---|---|---|

| Heavy vehicle (truck) | Mining | Industry | (800 + 800) = 1600 km | 80 km/h | 20 h |

| Industry | Construction site | (25 + 25) = 50 km | 50 km/h | 1 h | |

| Maintenance material factory | Construction site | (25 + 25) = 50 km | 50 km/h | 1 h | |

| Construction site | Landfill | (50 + 50) = 100 km | 50 km/h | 2 h | |

| Passenger car | Mining | 5 | (25 + 25) = 50 km | 50 km/h | 5 h |

| Industry | 5 | (25 + 25) = 50 km | 50 km/h | 5 h | |

| Construction site | 5 | (25 + 25) = 50 km | 50 km/h | 5 h | |

| Maintenance time | 2 | (25 + 25) = 50 km | 50 km/h | 2 h | |

| Demolition time | 2 | (25 + 25) = 50 km | 50 km/h | 2 h | |

| EOL factory | 5 | (25 + 25) = 50 km | 50 km/h | 5 h |

| Impact Category | Unit | LCA of Concrete with Cradle-to-Grave Life Cycle | LCA of Timber Floor with Cradle-to-Grave Life Cycle | % of Impact Due to Concrete Flooring | % of Impact Due to Timber Flooring | |

|---|---|---|---|---|---|---|

| Global warming | GW | kg CO2 eq | 71,584.59 | 6717.785 | 100 | 9.384401 |

| Stratospheric ozone depletion | SOD | kg CFC11 eq | 0.129747 | 0.00374 | 100 | 2.8825329 |

| Ionic radiation | IR | kg Co-60 eq | 256.4087 | 32.88057 | 100 | 12.8235 |

| Ozone formation, human health | OFH | kg NOx eq | 238.5943 | 55.68097 | 100 | 23.337091 |

| Fine particulate matter formation | FPM | kg PM 2.5 eq | 34.9953 | 5.096214 | 100 | 14.562567 |

| Ozone formation, terrestrial ecosystems | OFT | kg NOx eq | 245.0896 | 56.95245 | 100 | 23.2374 |

| Terrestrial acidification | TA | Kg SO2 eq | 183.2309 | 32.7833 | 100 | 17.891797 |

| Freshwater eutrophication | FE | kg P eq | 1.565374 | 0.263861 | 100 | 16.8561 |

| Marine eutrophication | ME | kg N eq | 1.735597 | 0.101414 | 100 | 5.8431767 |

| Terrestrial ecotoxicity | TE | kg 1,4-DCB | 217,716.9 | 21,668.13 | 100 | 9.9524336 |

| Freshwater ecotoxicity | FET | kg 1,4-DCB | 305.2816 | 11.31409 | 100 | 3.7061159 |

| Marine ecotoxicity | MET | kg 1,4-DCB | 177.7454 | 12.82773 | 100 | 7.2169125 |

| Human carcinogenic toxicity | HCT | kg 1,4-DCB | 63.21805 | 12.3086 | 100 | 19.470072 |

| Human non-carcinogenic toxicity | HNCT | kg 1,4-DCB | 1368.211 | 132.7463 | 100 | 9.7021804 |

| Land use | LU | m2a crop eq | 3343.709 | 10,476.46 | 31.9164 | 100 |

| Mineral resource scarcity | MRS | kg Cu eq | 448.0035 | 20.583 | 100 | 4.5943837 |

| Fossil resource scarcity | FRS | kg oil eq | 18,034.2 | 1968.984 | 100 | 10.918056 |

| Water consumption | WC | m3 | 422.643 | 57.28129 | 100 | 13.553115 |

| Noise, highly annoyed people, Darwin | HAP, D | HAP | 3411 | 2906 | 100 | 85.184221 |

| Noise, highly annoyed people, NSW | HAP, NWS | HAP | 134,405 | 132,552 | 100 | 98.621674 |

| Noise, highly sleep-deprived people, Darwin | HSDP, D | HSDP | 2323 | 2323 | 100 | 100 |

| Noise, highly sleep-deprived people, NSW | HSDP, NSW | HSDP | 78,027 | 78,027 | 100 | 100 |

| Impact Category | Unit | LCA of Concrete with Cradle-to-Grave Life Cycle | LCA of Timber Floor with Cradle-to-Grave Life Cycle | LCA of Reused Concrete with Cradle-to-Grave Life Cycle | LCA of Reused Timber Floor with Cradle-to-Grave Life Cycle |

|---|---|---|---|---|---|

| Global warming | kg CO2 eq | 71,584.59 | 6717.785 | 1225.318 | 199.1238 |

| Stratospheric ozone depletion | kg CFC11 eq | 0.129747 | 0.00374 | 0.000376 | 6.36 × 10−5 |

| Ionic radiation | kg Co-60 eq | 256.4087 | 32.88057 | 4.452854 | 0.725207 |

| Ozone formation, human health | kg NOx eq | 238.5943 | 55.68097 | 8.670905 | 1.401802 |

| Fine particulate matter formation | kg PM 2.5 eq | 34.9953 | 5.096214 | 0.739111 | 0.116319 |

| Ozone formation, terrestrial ecosystems | kg NOx eq | 245.0896 | 56.95245 | 8.861374 | 1.431817 |

| Terrestrial acidification | Kg SO2 eq | 183.2309 | 32.7833 | 5.306071 | 0.837611 |

| Freshwater eutrophication | kg P eq | 1.565374 | 0.263861 | 0.030383 | 0.004391 |

| Marine eutrophication | kg N eq | 1.735597 | 0.101414 | 0.003791 | 0.00058 |

| Terrestrial ecotoxicity | kg 1,4-DCB | 217,716.9 | 21,668.13 | 7284.772 | 1044.376 |

| Freshwater ecotoxicity | kg 1,4-DCB | 305.2816 | 11.31409 | 2.991508 | 0.437 |

| Marine ecotoxicity | kg 1,4-DCB | 177.7454 | 12.82773 | 2.742173 | 0.399516 |

| Human carcinogenic toxicity | kg 1,4-DCB | 63.21805 | 12.3086 | 0.450204 | 0.175154 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | 1368.211 | 132.7463 | 23.47352 | 3.873507 |

| Land use | m2a crop eq | 3343.709 | 10,476.46 | 120.8077 | 17.19549 |

| Mineral resource scarcity | kg Cu eq | 448.0035 | 20.583 | 2.402292 | 0.359573 |

| Fossil resource scarcity | kg oil eq | 18,034.2 | 1968.984 | 399.8294 | 64.52096 |

| Water consumption | m3 | 422.643 | 57.28129 | 4.085829 | 0.598325 |

| Noise, highly annoyed people, Darwin | HAP, D | 3411 | 2906 | 1838 | 1332 |

| Noise, highly annoyed people, NSW | HAP, NWS | 134,405 | 132,552 | 30,979 | 29,126 |

| Noise, highly sleep-deprived people, Darwin | HSDP, D | 2323 | 2323 | 328 | 328 |

| Noise, highly sleep-deprived people, NSW | HSDP, NSW | 78,027 | 78,027 | 16,283 | 16,283 |

| Midpoint LCA Impact | Mix Ratio of Concrete Impact | Mix Ratio of Timber Impact |

|---|---|---|

| kg CO2 eq | 15,297.17 | 1502.86 |

| kg CFC11 eq | 0.03 | 0.00 |

| kg Co-60 eq | 54.84 | 7.16 |

| kg NOx eq | 54.66 | 12.26 |

| kg PM 2.5 eq | 7.59 | 1.11 |

| kg NOx eq | 56.11 | 12.54 |

| Kg SO2 eq | 40.89 | 7.23 |

| kg P eq | 0.34 | 0.06 |

| kg N eq | 0.35 | 0.02 |

| kg 1,4-DCB | 49,371.20 | 5169.13 |

| kg 1,4-DCB | 63.45 | 2.61 |

| kg 1,4-DCB | 37.74 | 2.89 |

| kg 1,4-DCB | 13.00 | 2.60 |

| kg 1,4-DCB | 292.42 | 29.65 |

| m2a crop eq | 765.39 | 2109.05 |

| kg Cu eq | 91.52 | 4.40 |

| kg oil eq | 3926.70 | 445.41 |

| m3 | 87.80 | 11.93 |

| HAP, D | 2152 | 1647 |

| HAP, NWS | 51,664 | 49,811 |

| HSDP, D | 727 | 727 |

| HSDP, NSW | 28,632 | 28,632 |

| LCA of Concrete Floor (Darwin) | LCA of Concrete Floor (NSW) | LCA of Timber Floor (Darwin) | LCA of Timber Floor (NSW) | |

|---|---|---|---|---|

| Endpoint environmental impact excluding noise | 96.0 | 37.1 | 76.7 | 7.4 |

| Noise impact of transportation | 3.6 | 62.5 | 21.5 | 92.0 |

| Noise impact of machineries and equipment | 0.3 | 0.4 | 1.8 | 0.6 |

References

- Gámez-García, D.C.; Saldaña-Márquez, H.; Gómez-Soberón, J.M.; Arredondo-Rea, S.P.; Gómez-Soberón, M.C.; Corral-Higuera, R. Environmental challenges in the residential sector: Life cycle assessment of Mexican social housing. Energies 2019, 12, 2837. [Google Scholar] [CrossRef]

- Bin Marsono, A.K.; Balasbaneh, A.T. Combinations of building construction material for residential building for the global warming mitigation for Malaysia. Constr. Build. Mater. 2015, 85, 100–108. [Google Scholar] [CrossRef]

- Frenette, C.D.; Bulle, C.; Beauregard, R.; Salenikovich, A.; Derome, D. Using life cycle assessment to derive an environmental index for light-frame wood wall assemblies. Build. Environ. 2010, 45, 2111–2122. [Google Scholar] [CrossRef]

- Monteiro, H.; Freire, F. Life-cycle assessment of a house with alternative exterior walls: Comparison of three impact assessment methods. Energy Build. 2012, 47, 572–583. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Bin Marsono, A.K. Proposing of new building scheme and composite towards global warming mitigation for Malaysia. Int. J. Sustain. Eng. 2017, 10, 176–184. [Google Scholar] [CrossRef]

- Statistics. Available online: https://www.statista.com/statistics/1111178/australia-residential-construction-work-value/ (accessed on 11 August 2024).

- Bowlby, W.; Harris, R.A.; Cohn, L.F. Analyzing Construction Noise by a Level/Duration Weighted Population Technique. Transp. Res. Rec. 1986, 23–31. Available online: http://onlinepubs.trb.org/Onlinepubs/trr/1986/1058/1058-005.pdf (accessed on 11 August 2024).

- Wu, W. Introduction of effective analysis methods for construction noise assessment. Build. Acoust. 2010, 17, 339–357. [Google Scholar] [CrossRef]

- Eze, I.C.; Foraster, M.; Schaffner, E.; Vienneau, D.; Héritier, H.; Pieren, R.; Thiesse, L.; Rudzik, F.; Rothe, T.; Pons, M.; et al. Transportation noise exposure, noise annoyance and respiratory health in adults: A repeated-measures study. Environ. Int. 2018, 121, 741–750. [Google Scholar] [CrossRef]

- Cucurachi, S.; Heijungs, R. Characterisation factors for life cycle impact assessment of sound emissions. Sci. Total Environ. 2014, 468–469, 280–291. [Google Scholar] [CrossRef]

- Hansen, K.L.; Hansen, C.H.; Zajamšek, B. Outdoor to indoor reduction of wind farm noise for rural residences. Build. Environ. 2015, 94, 764–772. [Google Scholar] [CrossRef]

- Sellappan, E.; Janakiraman, K. Environmental noise from construction site power systems and its mitigation. Noise Vib. Worldw. 2014, 45, 14–20. [Google Scholar] [CrossRef]

- Cucurachi, S.; Heijungs, R.; Ohlau, K. Towards a general framework for including noise impacts in LCA. Int. J. Life Cycle Assess. 2012, 17, 471–487. [Google Scholar] [CrossRef] [PubMed]

- Tokairin, T.; Kitada, T. Study on the effect of porous fence on air quality and traffic noise level around a double-decked road structure. Environ. Monit. Assess. 2005, 105, 121–143. [Google Scholar] [CrossRef] [PubMed]

- Nitschke, M.; Tucker, G.; Simon, D.; Hansen, A.; Pisaniello, D. The link between noise perception and quality of life in South Australia. Noise Health 2014, 16, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Miedema, H.M.E.; Vos, H. Noise annoyance from stationary sources: Relationships with exposure metric day–evening–night level (DENL) and their confidence intervals. J. Acoust. Soc. Am. 2004, 116, 334–343. [Google Scholar] [CrossRef]

- Miiller-Wenk, R. A Method to Include in LCA Road Traffic Noise and its Health Effects. Int. J. Life Cycle Assess. 2004, 9, 76–85. [Google Scholar] [CrossRef]

- Marcinkowski, A.; Kopania, J. Environmental performance of noise reduction system in cogeneration plants—A life cycle assessment study. Energies 2021, 14, 1324. [Google Scholar] [CrossRef]

- Perna, M.; Padois, T.; Trudeau, C.; Bild, E.; Laplace, J.; Dupont, T.; Guastavino, C. Comparison of road noise policies across Australia, Europe, and north America. Int. J. Environ. Res. Public Health 2022, 19, 173. [Google Scholar] [CrossRef]

- Rashedi, A.; Khanam, T. Life cycle assessment of most widely adopted solar photovoltaic energy technologies by mid-point and end-point indicators of ReCiPe method. Environ. Sci. Pollut. Res. 2020, 27, 29075–29090. [Google Scholar] [CrossRef]

- Bahman, N.; Naser, N.; Khan, E.; Mahmood, T. Environmental science, policy, and industry nexus: Integrating Frameworks for better transport sustainability. Glob. Transit. 2025, 7, 29–40. [Google Scholar] [CrossRef]

- Hadi, S.P. Creating Green Industries through Circular Economy. IOP Conf. Ser. Earth Environ. Sci. 2022, 1098, 012079. [Google Scholar] [CrossRef]

- Calão, J.; Marques, D.L.; Completo, A.G.; Coelho, M.C. Life Cycle Thinking Approach Applied to a Novel Micromobility Vehicle. Transp. Res. Rec. 2022, 2676, 514–529. [Google Scholar] [CrossRef]

- Sultana, R.; Rashedi, A.; Khanam, T.; Jeong, B.; Hosseinzadeh-Bandbafha, H.; Hussain, M. Life Cycle Environmental Sustainability and Energy Assessment of Timber Wall Construction: A Comprehensive Overview. Sustainability 2022, 14, 4161. [Google Scholar] [CrossRef]

- Cucurachi, S.; Hellweg, S.; Schiess, S.; Froemelt, A. Noise footprint from personal land-based mobility. J. Ind. Ecol. 2019, 23, 1028–1038. [Google Scholar] [CrossRef]

- Lafleche, V.; Sacchetto, F. Noise Assessment in LCA-A Methodology Attempt: A Case Study with Various Means of Transportation on a Set Trip. Int. J. Life Cycle Assess. 1997, 2, 111–115. [Google Scholar] [CrossRef]

- Meyer, R.; Benetto, E.; Igos, E.; Lavandier, C. Analysis of the different techniques to include noise damage in life cycle assessment. A case study for car tires. Int. J. Life Cycle Assess. 2017, 22, 744–757. [Google Scholar] [CrossRef]

- Bao, D.; Yan, Y.; Li, Y.; Chu, J. The Future of Last-Mile Delivery: Lifecycle Environmental and Economic Impacts of Drone-Truck Parallel Systems. Drones 2025, 9, 54. [Google Scholar] [CrossRef]

- Miiller-wenk, R. Life-Cycle Management: State-of-the-Art Theory and Practice. Int. J. Life Cycle Assess 2003, 7, 86899. [Google Scholar]

- Indacoechea-Vega, I.; Miera-Dominguez, H.; Lastra-González, P.; Castro-Fresno, D. Life cycle approach for evaluating the environmental and economic viability of low-noise asphalt pavements. J. Clean. Prod. 2024, 466, 142785. [Google Scholar] [CrossRef]

- Sultana, R.; Khanam, T.; Rashedi, A.; Rajabipour, A. Integrating Noise into Life Cycle Assessment for Sustainable High-Rise Construction: A Comparative Study of Concrete, Timber, and Steel Frames in Australia. Sustainability 2025, 17, 4040. [Google Scholar] [CrossRef]

- Hofstetter, P.; Mu, R. Monetization of health damages from road noise with implications for monetizing health impacts in life cycle assessment. J. Clean. Prod. 2005, 13, 1235–1245. [Google Scholar] [CrossRef]

- Piao, Z.; Waldner, U.; Heutschi, K.; Poulikakos, L.D.; Hellweg, S. Modified life cycle assessment for Low-Noise urban roads including acoustics and monetarization. Transp. Res. Part D Transp. Environ. 2022, 112, 103475. [Google Scholar] [CrossRef]

- Miedema, H.M.E.; Oudshoorn, C.G.M. Annoyance from Transportation Noise: Relationships with Exposure Metrics DNL and DENL and Their Confidence Intervals. Environ. Health Perspect. 2001, 109, 409–416. [Google Scholar] [CrossRef][Green Version]

- Ongel, A. Inclusion of Noise in Environmental Assessment of Road Transportation. Environ. Model. Assess. 2016, 21, 181–192. [Google Scholar] [CrossRef]

- Shi, J.; Hu, J.; Ma, M.; Wang, H. An environmental impact analysis method of machine-tool cutting units based on LCA. J. Eng. Des. Technol. 2021, 19, 1192–1206. [Google Scholar] [CrossRef]

- Kantová, R. Evaluation of construction site noise to allow the optimisation of construction processes and construction machinery selection. Appl. Sci. Appl. Sci. 2021, 11, 4389. [Google Scholar] [CrossRef]

- Li, C.; Nie, Z.; Cui, S.; Gong, X.; Wang, Z.; Meng, X. The life cycle inventory study of cement manufacture in China. J. Clean. Prod. 2014, 72, 204–211. [Google Scholar] [CrossRef]

- Fnais, A.; Rezgui, Y.; Petri, I.; Beach, T.; Yeung, J.; Ghoroghi, A.; Kubicki, S. The application of life cycle assessment in buildings: Challenges, and directions for future research. Int. J. Life Cycle Assess. 2022, 27, 627–654. [Google Scholar] [CrossRef]

- Ma, L.; Azari, R.; Elnimeiri, M. A Building Information Modeling-Based Life Cycle Assessment of the Embodied Carbon and Environmental Impacts of High-Rise Building Structures: A Case Study. Sustainability 2024, 16, 569. [Google Scholar] [CrossRef]

- Deng, Y.; Cheng, J.C.P.; Anumba, C. A framework for 3D traffic noise mapping using data from BIM and GIS integration. Struct. Infrastruct. Eng. 2016, 12, 1267–1280. [Google Scholar] [CrossRef]

- Eslami, H.; Yaghma, A.; Jayasinghe, L.B.; Waldmann, D. Comparative life cycle assessment of light frame timber and reinforced concrete masonry structural systems for single-family houses in Luxembourg. Heliyon 2024, 10, e26083. [Google Scholar] [CrossRef]

- Li, X.; Song, Z.; Wang, T.; Zheng, Y.; Ning, X. Health impacts of construction noise on workers: A quantitative assessment model based on exposure measurement. J. Clean. Prod. 2016, 135, 721–731. [Google Scholar] [CrossRef]

- Franco, V.; Garraín, D.; Vidal, R. Methodological proposals for improved assessments of the impact of traffic noise upon human health. Int. J. Life Cycle Assess. 2010, 15, 869–882. [Google Scholar] [CrossRef]

- Lavandier, C.; Meyer, R.; Benetto, E. Characterization of damages from road traffic noise in life cycle impact assessment: A method based on emission and propagation models. J. Clean. Prod. 2019, 231, 121–131. [Google Scholar] [CrossRef]

- Lee, S.C.; Kim, J.H.; Hong, J.Y. Characterizing perceived aspects of adverse impact of noise on construction managers on construction sites. Build. Environ. 2019, 152, 17–27. [Google Scholar] [CrossRef]

- Edwards, M.; Chevillotte, F.; Bécot, F.X.; Jaouen, L.; Totaro, N. Polynomial relations for cylindrical wheel stiffness characterization for use in a rolling noise prediction model. Acta Acust. 2020, 4, 4. [Google Scholar] [CrossRef]

- Anderson, D.; Sburlati, D. Monitoring ground-borne and structure-borne noise for management of construction impacts. In Proceedings of the 2nd Australasian Acoustical Societies’ Conference (Acoustics 2016), Brisbane, Australia, 9–11 November 2016; Volume 2, pp. 808–815. [Google Scholar]

- Caniato, M.; Bettarello, F.; Schmid, C.; Fausti, P. The use of numerical models on service equipment noise prediction in heavyweight and lightweight timber buildings. Build. Acoust. 2019, 26, 35–55. [Google Scholar] [CrossRef]

- Sahin, Y.; Serin, H.; Demir, S. Research on Noise Level of Wood Processing Machine Groups. Kastamonu Univ. J. For. Fac. 2017, 17, 450–457. [Google Scholar] [CrossRef]

- Choi, J.; Kang, H.; Hong, T.; Baek, H.; Lee, D.-E. Automated noise exposure assessment model for the health of construction workers. Autom. Constr. 2021, 126, 103657. [Google Scholar] [CrossRef]

- Kwon, N.; Song, K.; Lee, H.-S.; Kim, J.; Park, M. Construction Noise Risk Assessment Model Focusing on Construction Equipment. J. Constr. Eng. Manag. 2018, 144, 04018034. [Google Scholar] [CrossRef]

- Gilchrist, A.; Allouche, E.N.; Cowan, D. Prediction and mitigation of construction noise in an urban environment. Can. J. Civ. Eng. 2003, 30, 659–672. [Google Scholar] [CrossRef]

- Horn, V.V.; Dudas, A. Acoustical aspects of the reconstruction of a historical building with closed courtyard. Pollack Period. 2020, 15, 197–208. [Google Scholar] [CrossRef]

- Guarnaccia, C.; Quartieri, J.; Ruggiero, A. Acoustical noise study of a factory: Indoor and outdoor simulations integration procedure. Int. J. Mech. 2014, 8, 298–306. [Google Scholar]

- Kisku, G.C.; Sharma, K.; Kidwai, M.M.; Barman, S.C.; Khan, A.H.; Singh, R.; Mishra, D.; Bhargava, S.K. Profile of noise pollution in Lucknow city and its impact on environment. J. Environ. Biol. 2006, 27, 409–412. [Google Scholar]

- Lee, S.W.; Chang, S.I.; Park, Y.M. Utilizing noise mapping for environmental impact assessment in a downtown redevelopment area of Seoul, Korea. Appl. Acoust. 2008, 69, 704–714. [Google Scholar] [CrossRef]

- Piao, Z.; Heutschi, K.; Pieren, R.; Mikhailenko, P.; Poulikakos, L.D.; Hellweg, S. Environmental trade-offs for using low-noise pavements: Life cycle assessment with noise considerations. Sci. Total Environ. 2022, 842, 156846. [Google Scholar] [CrossRef]

- Radun, J.; Hongisto, V.; Suokas, M. Variables associated with wind turbine noise annoyance and sleep disturbance. Build. Environ. 2019, 150, 339–348. [Google Scholar] [CrossRef]

- Salomons, E.M.; Polinder, H.; Lohman, W.J.A.; Zhou, H.; Borst, H.C.; Miedema, H.M.E. Engineering modeling of traffic noise in shielded areas in cities. J. Acoust. Soc. Am. 2009, 126, 2340–2349. [Google Scholar] [CrossRef]

- Trojanek, R.; Huderek-glapska, S. Measuring the noise cost of aviation–The association between the Limited Use Area around Warsaw Chopin Airport and property values. J. Air Transp. Manag. 2018, 67, 103–114. [Google Scholar] [CrossRef]

- Baptista, J.F.; Kokare, S.; Francisco, A.V.; Godina, R.; Aelenei, D. A comparative life cycle assessment of ETICS and ventilated façade systems with timber cladding. Energy Build. 2023, 304, 113842. [Google Scholar] [CrossRef]

- Barry, G.; Jurevicius, D.; Stead, M. Case Study of the Sound Reduction of Various Residential Glazing Treatments. Available online: http://www.magnetite.com.au/Fits-Existing-Window.aspx (accessed on 15 February 2025).

- Yüksel DİCle, S.; Zoroğlu, F.; Atmaca, A.B.; Yüğrük Akdağ, N.; Gülay, Z.G. Evaluation of energy consumption and noise reduction change of a strengthened building: An educational building case. Sigma J. Eng. Nat. Sci. 2024, 42, 1276–1291. [Google Scholar] [CrossRef]

- Sporchia, F.; Bruno, M.; Neri, E.; Pulselli, F.M.; Patrizi, N.; Bastianoni, S. Complementing emergy evaluation and life cycle assessment for enlightening the environmental benefits of using engineered timber in the building sector. Sci. Total Environ. 2025, 970, 1790300. [Google Scholar] [CrossRef]

- Eslami, H.; Yaghma, A.; Jayasinghe, L.B.; Waldmann, D. Influence of Different End-of-Life Cycle Scenarios on the Environmental Impacts of Timber-Concrete Composite Floor Systems. In Proceedings of the 13th World Conference on Timber Engineering (WCTE 2023), Oslo, Norway, 19–22 June 2023; Volume 2, pp. 982–988. [Google Scholar] [CrossRef]

- Sun, Q.; Huang, Q.; Duan, Z.; Zhang, A. Recycling Potential Comparison of Mass Timber Constructions and Concrete Buildings: A Case Study in China. Sustainability 2022, 14, 6174. [Google Scholar] [CrossRef]

- Tae, S.; Baek, C.; Shin, S. Life cycle CO2 evaluation on reinforced concrete structures with high-strength concrete. Environ. Impact Assess. Rev. 2011, 31, 253–260. [Google Scholar] [CrossRef]

- Jung, S.; Kang, H.; Choi, J.; Hong, T.; Park, H.S.; Lee, D.E. Quantitative health impact assessment of construction noise exposure on the nearby region for noise barrier optimization. Build. Environ. 2020, 176, 106869. [Google Scholar] [CrossRef]

- ISO 1996-2:1987; Acoustics—Description and Measurement of Environmental Noise—Part 2: Acquisition of Data Pertinent to Land Use. International Organization for Standardization: Geneva, Switzerland, 1987.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sultana, R.; Khanam, T.; Rashedi, A. Integrating Noise Pollution into Life Cycle Assessment: A Comparative Framework for Concrete and Timber Floor Construction. Sustainability 2025, 17, 6514. https://doi.org/10.3390/su17146514

Sultana R, Khanam T, Rashedi A. Integrating Noise Pollution into Life Cycle Assessment: A Comparative Framework for Concrete and Timber Floor Construction. Sustainability. 2025; 17(14):6514. https://doi.org/10.3390/su17146514

Chicago/Turabian StyleSultana, Rabaka, Taslima Khanam, and Ahmad Rashedi. 2025. "Integrating Noise Pollution into Life Cycle Assessment: A Comparative Framework for Concrete and Timber Floor Construction" Sustainability 17, no. 14: 6514. https://doi.org/10.3390/su17146514

APA StyleSultana, R., Khanam, T., & Rashedi, A. (2025). Integrating Noise Pollution into Life Cycle Assessment: A Comparative Framework for Concrete and Timber Floor Construction. Sustainability, 17(14), 6514. https://doi.org/10.3390/su17146514