Abstract

In alignment with the United Nations’ Sustainable Development Goals (SDGs) 12 (Responsible Consumption and Production) and 13 (Climate Action), this research explores the sustainable valorization of mangosteen peels into mangosteen peel powder (MPP), a value-added product with pharmaceutical properties. Mangosteen peels are an abundant agricultural waste in Thailand. This study evaluates six MPP production schemes, each employing different drying methods. Life Cycle Assessment (LCA) is utilized to assess the global warming potential (GWP) of these schemes, and the quality of the MPP produced is also compared. The results show that a combination of frozen storage and freeze-drying (scheme 4) has the highest GWP (1091.897 kgCO2eq) due to substantial electricity usage, whereas a combination of frozen storage and sun-drying (scheme 5) has the lowest GWP (0.031 kgCO2eq) but is prone to microbial contamination. Frozen storage without coarse grinding, combined with hot-air drying (scheme 6), is identified as the optimal scheme in terms of GWP (11.236 kgCO2eq) and product quality. Due to the lack of an onsite hot-air-drying facility, two transportation strategies are integrated into scheme 6 for scenarios A and B. These transportation strategies include transporting mangosteen peels from orchards to a facility in another province or transporting a mobile hot-air-drying unit to the orchards. The analysis indicates that scenario B is more favorable both operationally and environmentally, due to its lower emissions. This research is the first to comparatively assess the GWP of different MPP production schemes using LCA. Furthermore, it aligns with the growing trend in international trade which places greater emphasis on environmentally friendly production processes.

1. Introduction

Mangosteen (Garcinia mangostana L.) is renowned for its unique flavor and health benefits, including anti-inflammatory, antioxidant, and antimicrobial properties [1,2,3,4,5]. Global mangosteen production stood at approximately 700,000 metric tons in 2023, with more than one third (240,000 metric tons) originating from Thailand’s southern province of Chumphon [6]. The perishability of mangosteen presents post-harvest challenges for mangosteen growers, thereby necessitating efficient post-harvest management to reduce waste and enhance resource use.

Mangosteen pericarp accounts for 70% of the fruit’s total weight and is normally discarded as agricultural waste in landfills [7]. The practice is harmful to the environment as improperly treated agricultural waste emits greenhouse gases (GHGs) into the atmosphere. Research has shown that the landfill treatment of solid waste is the largest contributor to GHG emissions [8]. The environmental impacts of GHG emissions have sparked interest in environmentally friendly solutions to valorizing agricultural waste [9]. Fruit waste, which is a type of agricultural waste, can be converted into high-value bioproducts such as bioactive compounds, organic acids, and biofertilizers [10,11].

Mangosteen peels are rich in bioactive compounds, including α-mangostin, catechins, polyphenols, and xanthones [12,13,14,15]. These bioactive compounds are active ingredients in cosmetic and pharmaceutical products [16,17]. Unlike fresh mangosteen pericarp which has a low economic value (USD 0.2 per 1 kg), the market price of pure xanthones extracted from mangosteen pericarp is significantly higher (USD 0.55 per 1 kg), and 1 kg of fresh mangosteen pericarp contains 2 g of pure xanthones [18,19]. However, fresh mangosteen peels have a high moisture content (65–70%), making them susceptible to spoilage [20]. As a result, drying mangosteen peels before processing reduces their moisture content and extends their shelf life while preserving essential bioactive compounds.

Life Cycle Assessment (LCA) is a process of compiling and evaluating the inputs, outputs, and potential environmental impacts of a product system throughout its life cycle (ISO 14040, 2006a). LCA has been applied to analyze the environmental impacts of food production and consumption, including GHG emissions [21].

Existing LCA research focused on the environmental impacts of valorizing fruit waste using different processing processes, such as hydrolysis, extraction, extrusion, distillation, digestion, and drying [22,23,24,25,26,27,28,29]. Joglekar et al. [22] evaluated the environmental impacts of hydrolysis, distillation, and anaerobic digestion processes from citrus peels using LCA. Silva da Costa et al. [23] applied LCA to assess the environmental impacts of hydrolysis and extraction processes from orange peels. Khanpit et al. [24] used LCA to evaluate the environmental impacts of the extrusion process of orange peels for soluble dietary fiber. The environmental impacts of orange peels thermally treated with an autoclave machine were evaluated using LCA, and the physicochemical properties of the processed product (i.e., soluble dietary fiber) were determined [25].

Midolo et al. [26] applied LCA to assess the environmental impacts of distillation and extraction processes from orange peels. Manakas et al. [27] evaluated the environmental impacts of different extraction methods from orange peels and compared the results. The LCA environmental impacts of dried pomegranate peels subjected to digestion, hydrolysis, and extraction processes were evaluated, and the bioactive compounds of the processed products were analyzed [28]. Pereira da Silva et al. [29] utilized LCA to assess the environmental impacts of extraction processes from mango kernel. Table 1 summarizes research studies on the valorization of food waste or agricultural waste.

Table 1.

Comparison between existing research on valorization of food or agricultural waste and this study.

In Thailand, LCA has been used to evaluate the environmental impacts (from cultivation to retailers) of mango and mangosteen [30]. The GHG emissions of one kilogram of mangosteen have been reported as 1.71 kgCO2eq [31], whereas the Thailand Greenhouse Gas Management Organization reported a lower value of 0.89 kgCO2eq [32]. This discrepancy (1.71 vs. 0.89 kgCO2eq) could be attributed to electricity required to pump water to irrigate mangosteen trees. By standardizing the functional unit (1 kg of dried MPP) and incorporating data on transportation and processing, the findings of this study help clarify the inconsistencies in previous estimates and offer a robust reference for future Life Cycle Assessments of mangosteen processing.

No research studies have specifically assessed the global warming potential (GWP) of the production of dried mangosteen peel powder (MPP) from fresh mangosteen peels. Existing research on MPP production has primarily focused on product quality, including the physical, chemical, and biological properties, while overlooking the environmental implications of valorizing mangosteen peels. To address this gap, this study is the first to apply Life Cycle Assessment (LCA) to evaluate the environmental impact of MPP production across various processing methods.

The aim of this research is to investigate the GWP of six MPP production schemes from fresh mangosteen peels. LCA is employed to assess the GWP associated with each processing step of different MPP production schemes, such as coarse grinding, quick freezing, and frozen storage. Additionally, the physical, chemical, and biological properties of MPP from different schemes are compared. The optimal MPP production scheme in terms of GWP and product quality is subsequently identified.

However, due to the lack of an onsite hot-air-drying facility, two transportation strategies are integrated into the optimal MPP production scheme (i.e., frozen storage without coarse grinding combined with hot-air drying; scheme 6). The two transportation strategies are as follows: (i) transporting frozen mangosteen peels by refrigerated trucks from Chumphon province to a hot-air-drying facility in Bangkok (scenario A); (ii) hauling a mobile hot-air-drying unit using a semi-trailer truck to Chumphon province (scenario B).

Specifically, this study aims to assess the environmental impacts of various MPP production schemes by identifying the schemes with the lowest and highest GWP. It further examines which production scheme achieves an optimal balance between acceptable product quality and low GWP. Additionally, the study evaluates two transportation strategies to determine which strategy is more environmentally friendly in terms of GWP.

This research is the first to comparatively assess the GWP of different MPP production schemes using LCA. Additionally, it aligns with the growing trend in international trade which places increasing emphasis on environmentally friendly products and production processes. Furthermore, the findings of this study are expected to contribute toward achieving the United Nations’ Sustainable Development Goals 12 (Responsible Consumption and Production) and 13 (Climate Action).

2. Materials and Methods

2.1. Experimental Materials

Mature mangosteen fruits with dark purple–black peels were sourced from a mangosteen orchard in Lang Suan district in Thailand’s southern province of Chumphon (latitude 9°56′42″ N and longitude 99°4′42″ E). The orchard has earned a Good Agricultural Practices certification. Folin–Ciocalteu reagent, sodium carbonate, and gallic acid of analytical grade were acquired from Sigma-Aldrich Chemicals. Ethanol (95% v/v) for α-mangostin extraction and methanol (98% v/v) for α-mangostin content analysis were purchased from RCI Labscan Limited, Bangkok, Thailand.

2.2. Life Cycle Assessment (LCA)

LCA is a multi-step process that assesses the environmental impacts of a product or service over its entire life cycle, including raw material extraction, manufacturing, distribution, use, and disposal. The LCA consists of four phrases: (i) Goal and Scope Definition, (ii) Life Cycle Inventory (LCI) analysis, (iii) Life Cycle Impact Assessment (LCIA), and (iv) interpretation [33].

The rationales for using LCA to assess the GWP of MPP production schemes are as follows: (i) LCA identifies which stages of the life cycle contribute most to environmental impacts; (ii) LCA provides quantitative data on various environmental impact categories, including GWP; (iii) LCA allows for the comparison of different processes or scenarios, facilitating decision making on the most environmentally viable option; (iv) LCA helps in formulating intervention strategies to lower emissions and improve energy efficiency.

2.2.1. Goal and Scope Definition

The goal of the LCA performed here is to assess the GWP associated with converting mangosteen peels into dried mangosteen peel powder. The scope of the LCA follows a gate-to-gate system boundary, starting from the point where raw materials (mangosteen peels) enter the conversion process and ending when the finished product (MPP) leaves the processing facility. Impacts from raw material extraction, product use, and disposal are excluded. Primary data were collected through on-site operations, including direct measurements, process monitoring, and process log reviews. Meanwhile, secondary data were sourced from the EcoInvent 3.6 database via the GaBi software version 9.

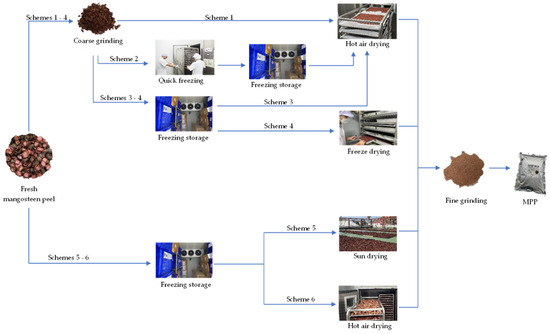

The aim of this study is to identify the MPP production scheme that yields high-quality MPP with low GWP. Six MPP production schemes (schemes 1–6) are evaluated, as illustrated in Figure 1. The functional unit is defined as the processing of 1 kg of MPP. This functional unit reflects a standard commercial unit commonly used in the market, thereby facilitating meaningful comparison and ensuring consistency across MPP production schemes and associated transportation scenarios [34].

Figure 1.

The process flows of MPP production schemes 1–6.

Currently, there is no permanent hot-air-drying facility in Chumphon province to convert fresh mangosteen peels into MPP. Therefore, frozen mangosteen peels are transported by refrigerated trucks to a hot-air-drying facility in the capital city, Bangkok. As a result, the scope of the study is extended to encompass transportation of mangosteen peels. There are two transportation strategies: (i) transporting mangosteen peels by refrigerated trucks from Chumphon province to a hot-air-drying facility in Bangkok (i.e., the current practice); and (ii) hauling a mobile hot-air-drying unit using a semi-trailer truck to Chumphon province for onsite processing. Both transportation strategies are separately incorporated into MPP production scheme 6 (i.e., frozen storage and hot-air drying) for scenarios A and B. (Note: scheme 6 was found to be the optimal MPP production scheme in terms of GWP and product quality.)

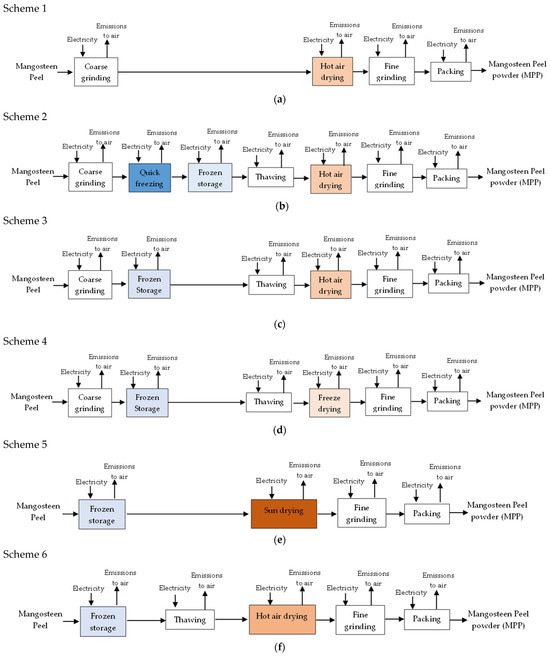

Figure 2 illustrates the system boundaries and the processing steps of schemes 1–6. Scheme 1 involves coarse grinding of fresh mangosteen peel (without frozen storage) and hot-air drying. Scheme 2 entails coarse grinding, quick freezing, frozen storage, and hot-air drying, while scheme 3 involves coarse grinding without quick freezing, frozen storage, and hot-air drying. Scheme 4 encompasses coarse grinding, frozen storage, and freeze-drying. Scheme 5 entails frozen storage (without coarse grinding) and sun drying; and scheme 6 encompasses frozen storage (without coarse grinding) and hot-air drying. Since coarse grinding of mangosteen peels is time-consuming and requires additional human labor, the coarse grinding process is deliberately excluded from schemes 5 and 6.

Figure 2.

The system boundaries of MPP production: (a) scheme 1, (b) scheme 2, (c) scheme 3, (d) scheme 4, (e) scheme 5, and (f) scheme 6.

Figure 3 depicts scenarios A and B of MPP production. Scenario A involves frozen storage (without coarse grinding) and hot-air drying (i.e., scheme 6), with frozen mangosteen peels transported from Chumphon province by refrigerated trucks to a hot-air-drying facility in Bangkok to process into MPP. Scenario B is similar to scenario A except that a mobile hot-air-drying unit is transported by a semi-trailer truck from Bangkok to Chumphon province for onsite MPP processing.

Figure 3.

MPP production scenarios under different transportation strategies: (a) scenario A and (b) scenario B.

2.2.2. Life Cycle Inventory

Table 2 tabulates the electricity consumption and yield (%) of MPP production schemes 1–6. Primary data were collected through direct measurements from experiments conducted at the KMITL Food Laboratory (King Mongkut’s Institute of Technology Ladkrabang, Lat Krabang, Thailand) between May and July 2023.

Table 2.

Electricity usage and yields of schemes 1–6. (Source: KMITL’s Food Laboratory.)

The functional unit for evaluating all processes is defined as 1 kg of MPP output. The percentage yield of each process is calculated based on the product obtained after processing and expressed as a percentage of the input, using the following formula: Yield (%) = (Output/Input) × 100. Both input and output are measured in the same unit (kilograms). In cases involving packaging, the weight or volume of the raw material remains consistent.

Electricity consumption and processing durations are specific to the 2023 production year in Thailand. For energy consumption, only electricity was used for all laboratory-scale processes, with data obtained from standard laboratory equipment setups.

Coarse grinding

In schemes 1–4, mangosteen peels are first coarsely ground using a grinding machine (CAMP, SKU: C-BBD-50, Bangkok, Thailand). The capacity of the grinder is 2 kg per cycle with electricity consumption of 1.50 kW/h. One cycle of grinding takes approximately 5 min. The coarsely ground mangosteen peels are packed in plastic bags of 2 kg each prior to quick freezing or frozen storage.

Quick freezing

In scheme 2, coarsely ground mangosteen peels are quick-frozen at −38 °C using an air-blast freezer equipped with a semi-contact plate freezer (R404a: non-CFC, Compact freeze, PATKOL, Bangkok, Thailand), with a cool air velocity of 3 min/s for 2 h.

Frozen storage

For schemes 2–6, mangosteen peels are stored at −25 °C in a mobile cold room (Cool Innotech, Bangkok, Thailand) for subsequent processing.

Thawing

Frozen mangosteen peels (in schemes 2, 3, 4 and 6) are thawed at 4 °C for 12 h using a refrigerator (Panasonic Bangkok, Thailand, SBC-P2DBA) prior to drying.

Hot-air drying

Mangosteen peels (in schemes 1, 2, 3, and 6) are transferred to aluminum trays and hot-air dried at 60 °C with an air velocity of 1.3 m/s using an in-house hot air dryer [35]. The hot-air drying process is terminated once the moisture content is within the range of 2–10% [36,37].

Freeze-drying

In scheme 4, coarsely ground mangosteen peels are frozen and vacuumed-dried using a freezer (I.T.C., Bangkok, Thailand). The freeze-drying duration is 48 h.

Sun drying

In scheme 5, frozen mangosteen peels are laid out on PE plastic sheets and dried in the sun at 35–45 °C for 3 days.

Fine grinding

The dried mangosteen peels (in schemes 1–6) are finely ground by a hammer mill (HM-030C, Unique Tools, Chachoengsao, Thailand) and sieved through a 60 mesh (250 µm) sieve for mangosteen peel powder.

Packing

Mangosteen peel powder is packed in aluminum bags and sealed before storing at room temperature (25 °C) for subsequent analysis of product quality, including the moisture content, water activity, and α-mangostin and microbial count.

Table 3 presents the of six MPP production schemes, and Table 4 tabulates the LCI of scenarios A and B. The LCI data belong to the 2023 production year and are specific to Thailand. The data are based on 1 kg of MPP. Scenario A involves frozen storage and hot-air drying with frozen mangosteen peels transported from Chumphon province by refrigerated trucks to a hot-air-drying facility in Bangkok to process into MPP. Scenario B is similar to scenario A except that a mobile hot-air-drying unit is transported by a semi-trailer truck from Bangkok to Chumphon province for onsite MPP processing.

Table 3.

LCI of MPP production schemes 1–6.

Table 4.

LCI of scenarios A and B.

Transportation

Transportation is a significant contributor of GHG emissions [38]. In scenario A, frozen mangosteen peels are transported by refrigerated trucks from the southern province of Chumphon to a hot-air-drying facility in Bangkok. The outbound load capacity is 100% and 0% on the return trip. In scenario B, a mobile hot-air-drying unit is transported by a semi-trailer truck from Bangkok to Chumphon province for the onsite production of MPP.

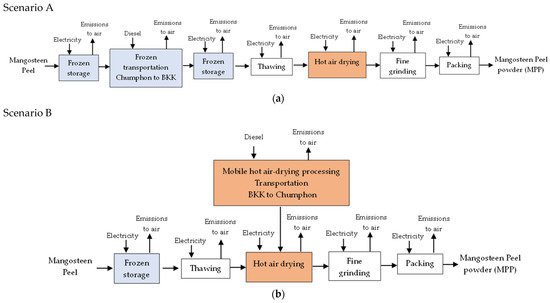

Figure 4 depicts the map of Thailand and the locations of Chumphon province in the South and the capital city, Bangkok, in the Central Plains. Table 5 tabulates the input parameters of the transportation stage from Chumphon province to Bangkok and return for scenario A; and from Bangkok to Chumphon province and return for scenario B.

Figure 4.

Map of Thailand and the locations of Chumphon province and the capital Bangkok.

Table 5.

The input parameters of the transportation stage of scenarios A and B.

2.2.3. Life Cycle Impact Assessment

The life cycle impact assessment (LCIA) is carried out based on the inventory data of MPP production schemes 1–6 (Table 2) and scenarios A and B (Table 3) using the Gabi9 software. Gabi is a software tool for LCA that evaluates the environmental impacts of a product or process from raw material acquisition to disposal. In this study, CML2001 is utilized to assess the environmental impact of MPP production, particularly global warming potential (GWP). The CML2001 method is an LCIA method that is recognized by the Thailand Environment Institute and many state agencies in Thailand [39,40].

The following are the assumptions and limitations of this study:

- Health impacts are excluded from the analysis, as the MPP production process involves only hot-air drying, which generates minimal vapor emissions. These vapors are not expected to pose any health risks.

- Transportation of the raw material (i.e., fresh mangosteen peels from mangosteen orchards) to the processing site and the frozen storage are not considered in the analysis.

- Wastewater treatment is excluded because the MPP production process generates minimal wastewater, which is free of chemical contaminants. Most of the moisture is removed through evaporation.

- The geographical location is Thailand, and the emissions and energy consumption are specific to Thailand.

- Emissions from post-processing of the MPP (i.e., product use and disposal) are not part of the analysis.

- The LCIA is limited to GWP.

2.2.4. Interpretation

In the interpretation phase, the LCA results are analyzed to identify the optimal MPP production scheme that achieves low GWP and high-quality product in terms of moisture content, water activity, α-mangostin, and microbial count. The interpretation of the results is detailed in the discussion section of the study findings.

2.3. Physical, Chemical and Biological Properties

2.3.1. Moisture Content

The determination of MPP moisture content follows AOAC [41], whereby 3 g of MPP is oven-dried using a hot-air-drying oven (UF55, Memmert GmbH, Schwabach, Germany) at 105 ± 5 °C until a constant weight is reached. The moisture content is expressed in percentage (wet basis) and calculated using Equation (1). Experiments are carried out in triplicate for each MPP sample.

where W1 is the initial weight of sample (g) and W2 is the sample weight after oven-drying (g).

Moisture content (%) = [(W1 − W2)/W1] × 100

2.3.2. Water Activity

The water activity of MPP (3 g) is determined using an electronic water activity meter (Decagon Model, AquaLab, Washington, DC, USA), following Zhang et al. [42]. Experiments are carried out in triplicate for each MPP sample.

2.3.3. α-Mangostin Assay

In the α-mangostin assay, 5 g of MPP is mixed with 50 mL of 60% (v/v) ethanol, vortexed for 1 min, and macerated for 24 h, following Yoswathana [43] with minor modifications. The mixture is centrifuged at 4000× g for 5 min (Mikro 220R, Hettich, Tuttlingen, Germany). The supernatant is collected and filtered through a 0.45 μm syringe filter nylon membrane (Cnw Technologies, Shanghai, China). The α-mangostin content (mg/g DW of mangosteen peel) is assayed by high-performance liquid chromatography (HPLC; Shimadzu, Kyoto, Japan) at 232 nm equipped with a column (Inertril ODS-3, 250 mm × 4.6 mm, 5 μm particle size, GL Science, Japan). The column temperature is 40 °C. The mobile phase is methanol at isocratic elution with a flow rate of 1 mL/min. The α-mangostin content of the MPP samples are compared with a control. In this research, α-mangostin of 97% purity (Toronto Research Chemicals, France) is used as the control.

2.3.4. Microbial Count

Prior to the microbial analysis, 0.85% (w/v) Butterfield’s phosphate buffer (225 mL) was added to stomacher bags containing 25 g of MPP and homogeneously mixed using a Stomacher (400 VW BagMixer, Interscience, Saint Nom la Bretêche, FRANCE). The mixture (1 mL) was pipetted and diluted in 9 mL of 0.85% (w/v) Butterfield’s phosphate buffer for 10−1, 10−2, and 10−3 dilutions.

Total bacteria count was determined using the aerobic plate count method [44]. Serial dilutions (10−1, 10−2, and 10−3) were prepared, and 1 mL of each was pipetted into sterile petri dishes. A measure of 15–20 mL of melted nutrient agar (NA) was poured into each dish, and the plates were gently rotated to ensure uniform mixing. As a control, 1 mL of 0.85% (w/v) Butterfield’s phosphate buffer (without MPP) was pipetted into a separate dish and left to solidify. All dishes were incubated at 35 °C for 48 h. Colonies in the range of 30–300 were counted and expressed as colony-forming units (CFUs)/g of MPP. Each dilution was tested in triplicate.

Yeast and mold counts were performed by using the aerobic plate count method, whereby 1 mL of 10−1, 10−2, and 10−3 dilutions were individually pipetted into sterile petri dishes before pouring 15–20 mL of melted potato dextrose agar (PDA). The petri dishes were rotated to evenly mix the sample with PDA and left to solidify before incubation at room temperature for 5 days. The yeast and mold counts in the range of 30–300 colonies were determined and calculated as CFU/g of MPP. Experiments were performed in triplicate for each dilution.

3. Results of Life Cycle Assessment (LCA)

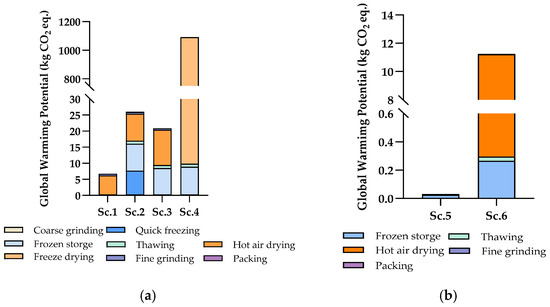

Figure 5a,b shows the GWPs of MPP production schemes 1–4 and 5–6, respectively. Coarse grinding generates low GHG emissions, as evidenced by low GWP in the range of 0.277–0.294 kgCO2eq. In this research, schemes 1–4 involve the coarse grinding of mangosteen peels, while schemes 5 and 6 require no coarse grinding.

Figure 5.

GWPs of six MPP production schemes: (a) schemes 1–4 and (b) schemes 5–6. (Note: Due to GWP scale differences, schemes 1–4 and schemes 5 and 6 are grouped separately.)

The freezing and drying processes have the most significant impact on GWP. In scheme 2, the GWPs of quick freezing and frozen storage are 7.377 kgCO2eq and 8.37 kgCO2eq, respectively. The GWPs of frozen storage are 8.213 kgCO2eq for scheme 3 and 8.583 kgCO2eq for scheme 4. For hot-air drying, the GWPs of schemes 1, 2, 3, and 6 are 5.935, 8.377, 10.940, and 10.922 kgCO2eq, given the drying durations of 4.50, 6.13, 8.16, and 48 h, respectively. Meanwhile, in scheme 4, freeze-drying contributes significantly to GHG emissions, as evidenced by the very high GWP of 1081.495 kgCO2eq. The excessively high GWP is attributable to the high electricity consumption of freeze-drying and the long freeze-drying time (48 h).

The sun-drying process of scheme 5 has the lowest GWP (0.031 kgCO2eq). The low GWP is attributable to the use of natural solar energy in drying mangosteen peels. Since no electrical energy is required in the drying process, the environmental impact in terms of GHG emissions is minimized. However, the sun-dried MPP has quality issues and suffers from microbial contamination. Meanwhile, fine grinding and packing contribute minimally to GHG emissions, as evidenced by the GWPs of 0.514–0.549 kgCO2eq for fine grinding and 0.001–0.107 kgCO2eq for packing.

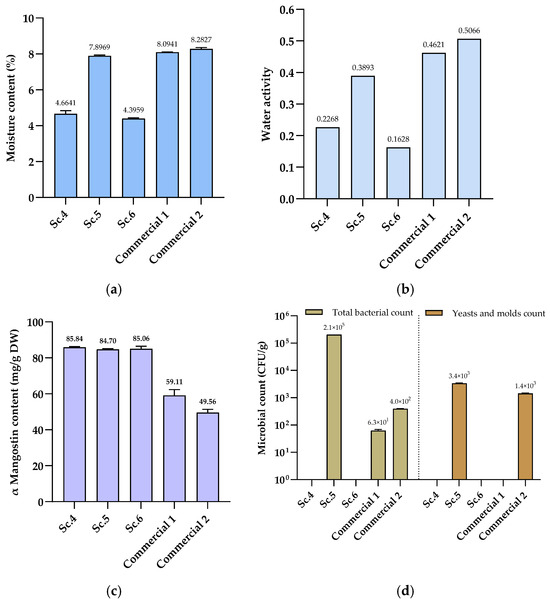

Figure 6 compares the physical, chemical and biological properties of the MPP produces in schemes 4–6 and commercially available MPP. By comparison, the moisture content (4.396%) and water activity (0.163) of MPP produced in scheme 6 are the lowest, with an α-mangostin content of 85.06 mg/g DW, as shown in Figure 6a–c, respectively.

Figure 6.

The physical, chemical, and biological properties of MPP produced in schemes 4–6 and commercial MPP: (a) moisture content; (b) water activity; (c) α-mangostin content; (d) microbial count.

In scheme 5 (sun drying), despite the lowest GWP, the sun-dried MPP has the highest moisture content (7.896%) and water activity (0.462), rendering it highly susceptible to contamination. In addition, sun drying exposes the mangosteen peels to the elements (i.e., atmospheric conditions), resulting in excessively high total bacterial count and yeasts and molds of 2.5 × 105 CFU g−1 and 3.4 × 103 CFU g−1, respectively. By contrast, no microbial count is detected in MPP produced in scheme 6 (Figure 6d). Essentially, scheme 6 (frozen storage and hot-air drying) is the optimal MPP production scheme in terms of GWP and product quality.

Meanwhile, commercial products 1 and 2 contain very high moisture content and water activity but substantially lower α-mangostin. The commercial products are commercially available dried mangosteen peel powder from two different manufacturers. (Note: The product quality of MPP produced in schemes 1–3 are unsatisfactorily low and thereby are excluded from Figure 5. Readers are advised to refer to the Thai agricultural standard [45] for the quality of MMP produced in schemes 1–3.)

As previously mentioned, at present frozen mangosteen peels have to be transported by refrigerated trucks from Chumphon province to a hot-air-drying facility in Bangkok due to a lack of onsite hot-air-drying facilities. As a result, the scope of the study is expanded to encompass transportation. There are two transportation strategies being studied: (i) transporting frozen mangosteen peels by refrigerated trucks from Chumphon province to the hot-air-drying facility in Bangkok (i.e., the current practice); and (ii) hauling a mobile hot-air-drying unit using a semi-trailer truck to Chumphon province. Both transportation strategies are incorporated into MPP production scheme 6 (i.e., the optimal scheme) for scenarios A and B.

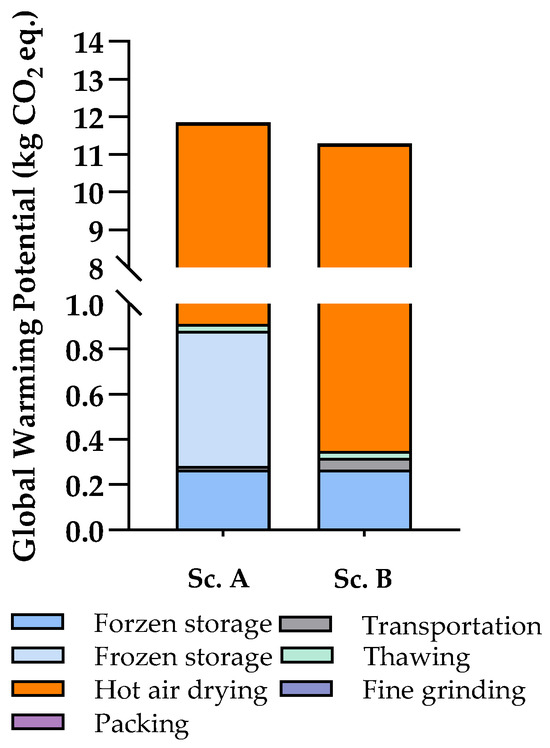

Figure 7 illustrates the GWP of MPP production under different transportation strategies: scenarios A and B. In both scenarios, hot-air drying contributes significantly to GHG emissions, with a GWP of 10.922 KgCO2 eq for both scenarios A and B. For the transportation, GWP are 0.016 KgCO2eq for scenario A and 0.053 KgCO2eq for scenario B. The higher GWP of scenario A is attributable to the need for refrigerated trucks to transport frozen mangosteen peels from Chumphon province to Bangkok; and for frozen storage to store the frozen mangosteen peels upon arrival in Bangkok.

Figure 7.

GWP of MPP production under different transportation strategies: (Sc. A) scenario A and (Sc. B) scenario B.

4. Discussion of Research Findings

The findings indicate that the drying process (i.e., hot-air drying and freeze-drying) has the most significant environmental impact, primarily due to high electricity consumption. In hot-air drying, the low enthalpy takes a long time to dehydrate mangosteen peels, resulting in a loss of energy through the dryer walls and outlet [46]. Insulating the dryer can improve the drying rate and reduce the drying time and energy consumption [47,48].

By comparison, freeze-drying takes considerably more time, resulting in higher electricity consumption and higher GHG emissions. Cooling and freezing vegetables and fruits is energy-intensive and is a major contributor to GHG emissions [49]. The energy consumption of the freeze-drying process is substantially higher than that of hot-air drying due to differences in drying durations and system complexity [50]. Specifically, freeze-drying involves two stages, including freezing and drying, while hot-air drying involves only one stage, i.e., hot-air drying to dehydrate the product. For example, freeze-drying 1000 kg of green onions requires 1080 kWh of electricity [51], significantly impacting the environment by contributing to greater GHG emissions. In addition to the long drying duration (24 h minimum) and high energy consumption, freeze-drying systems require large financial investments, thereby limiting their application. Essentially, the findings of this study align with previous research that has documented the high environmental impact of the energy-intensive freeze-drying process. Furthermore, the results highlight the potential of hot-air drying as an operationally and environmentally viable alternative to energy-intensive drying methods.

Despite having the lowest GWP, sun drying (scheme 5) suffers from product quality issues as the microbial counts in MPP exceed the safety limits for dried herbal products [45]. Sun-dried foods are prone to contamination as the sun-drying process exposes the food products to the elements (i.e., atmospheric conditions) [52,53]. Nevertheless, sun drying is commonly practiced in many tropical countries to preserve food products. For example, in Thailand, sun drying results in low-quality dried banana products as the bananas are directly exposed to the elements [54].

In addition, the study reveals that scheme 1 (coarse grinding without frozen storage and hot-air drying) is not practical because fresh mangosteen peels have a short shelf life and thus are highly perishable. As a result, effective management of fresh mangosteen peels (i.e., frozen storage) is essential to maintain their freshness.

The results also indicate that transportation choice (between scenarios A and B) plays a role in lowering the overall environmental impact. This is consistent with dravkovic, Snoeck [55], who reported that a mobile processing unit is more environmentally-friendly than transporting apples to a distant location for processing.

Table 6 presents the total GWP of MPP production scheme 1–6 and scenarios A and B. The total GWP of schemes 1, 2, and 3 are 6.738 kgCO2eq, 17.627 kgCO2eq, and 20.892 kgCO2eq, respectively. Scheme 4 (frozen storage and freeze-drying) exhibits the highest GWP at 1091.897 kgCO2eq, primarily due to the high energy demand of the freeze-drying process. In contrast, scheme 5 (frozen storage and sun drying) has the lowest GWP at 0.031 kgCO2eq, attributed to sun drying, which requires no electricity. However, the resulting MPP has a high microbial count. The total GWP of scheme 6 is 11.236 kgCO2eq. Combining frozen storage and hot-air drying, scheme 6 is identified as the optimal processing scheme due to its low GWP and ability to preserve the functional quality of MPP. This balance between environmental performance and product integrity highlights its potential as a scalable option for sustainable MPP production. Furthermore, percentage differences in total GWP among the six production schemes and between the two transportation scenarios are compared, using scheme 1 as the reference for production schemes and scheme 6 as reference for transportation.

Table 6.

Total GWP of MPP production schemes 1–6 and scenarios A and B.

Hot-air drying (i.e., schemes 1, 2, 3, and 6) has a lower GWP compared to freeze-drying (scheme 4) due to lower electricity consumption. Since the hot-air drying process relies primarily on heat energy, the heat can be sourced from liquified petroleum gas [56] or an energy mix [57], resulting in a lower GWP. Meanwhile, the total GWP of scenarios A and B are 11.834 kgCO2eq and 11.241 kgCO2eq, respectively. The higher total GWP of scenario A could be attributed to the need for refrigerated trucks to transport frozen mangosteen peels from Chumphon province to Bangkok; and for frozen storage to store the frozen mangosteen peels upon arrival in Bangkok.

The results suggest that MPP production scheme 6 should be prioritized to achieve an optimal balance between product quality and sustainability (i.e., low GWP). Additionally, investing in a mobile hot-air-drying unit (scenario B) prevents significant capital from being tied up in fixed infrastructure while enhancing operational flexibility. Despite these environmental and operational benefits, implementing scheme 6 and scenario B in real-world settings may face practical challenges, including the high initial cost of the hot-air-drying unit [58], limited infrastructure, and technical constraints, particularly in rural areas. Overcoming these barriers is crucial for broader adoption and long-term sustainability.

In terms of environmental sustainability, converting mangosteen peels (i.e., agricultural waste) into value-added MPP promotes efficient resource use and improves the sustainability of mangosteen farming. This aligns with SDG 12 (Ensure Sustainable Consumption and Production Patterns), which is key to sustaining the livelihoods of current and future generations. Additionally, converting mangosteen peels into MPP decreases the amount of agricultural waste disposed of in landfills, thereby reducing GHG, one of the main drivers of climate change, and contributing to SDG 13: Take Urgent Action to Combat Climate Change and its Impacts.

5. Conclusions and Future Research

This research comparatively investigates six MPP production schemes from fresh mangosteen peels. Scheme 1 involves coarse the grinding of fresh mangosteen peel without frozen storage and hot-air drying. Scheme 2 entails coarse grinding, quick freezing, frozen storage, and hot-air drying, while scheme 3 involves coarse grinding without quick freezing, frozen storage, and hot-air drying. Scheme 4 combines coarse grinding, frozen storage, and freeze-drying. Scheme 5 entails frozen storage without coarse grinding and sun drying; and scheme 6 encompasses frozen storage without coarse grinding and hot-air drying.

LCA is utilized to assess the GWPs of different MPP production schemes. Additionally, the physical, chemical, and biological properties of MPP from various schemes are compared, including the moisture content, water activity, α-mangostin, and microbial count. The results show that scheme 4 has the highest GWP (1091.897 kgCO2eq) due to substantial electricity usage, while scheme 5 has the lowest GWP (0.031 kgCO2eq) but suffers from product quality issues. Scheme 6 is the optimal scheme in terms of both GWP (11.236 kgCO2eq) and product quality.

Due to the lack of an onsite hot-air-drying facility, frozen mangosteen peels need to be transported by refrigerated trucks from Chumphon province to a hot-air-drying facility in Bangkok. As a result, the scope of the study is extended to encompass transportation. There are two transportation strategies: (i) transporting by refrigerated trucks from Chumphon province to the hot-air-drying facility in Bangkok; (ii) hauling a mobile hot-air-drying unit using a semi-trailer truck to Chumphon province. Both transportation strategies are independently incorporated into MPP production scheme 6 (i.e., the optimal scheme) for scenarios A and B.

The total GWP of scenarios A and B are 11.834 kgCO2eq and 11.241 kgCO2eq, respectively. The higher total GWP of scenario A is attributable to the need for refrigerated trucks for transportation from Chumphon province to Bangkok, as well as frozen storage upon arrival at the hot-air-drying facility in Bangkok. Investing in a mobile hot-air-drying unit (scenario B) offers several practical benefits, including lower GHG emissions from transportation and minimal capital investment in fixed infrastructure. Additionally, this approach aligns with environmental sustainability goals. As a result, scenario B is both operationally and environmentally more favorable. These findings highlight the potential of optimized valorization pathways for mangosteen peel waste to reduce environmental impacts while generating value-added products. This supports the principles of sustainable agriculture and the circular economy by promoting waste reduction, resource efficiency, and environmentally responsible production practices.

This research encounters three limitations. First, the study focuses primarily on the GWP of different MPP production schemes, excluding other environmental impacts. Second, the production processes of MPP rely solely on electricity, excluding renewable energy alternatives. Additionally, the transportation strategies consider only diesel trucks, excluding EV trucks. Third, this study explores the applicability of processing methods for only one type of agricultural waste (i.e., mangosteen peels).

Subsequent research will assess other environmental impacts, such as acidification potential, human toxicity potential, and ozone depletion potential, to generate more comprehensive data for improving MPP production processes. Future studies will also examine the integration of EV trucks and renewable energy alternatives, such as solar-powered drying, to further reduce reliance on conventional energy sources and mitigate GHG emissions. In addition, to broaden the scope of sustainable waste valorization, future research will explore the applicability of this processing method to other types of agricultural waste, including mango peels and durian shells.

Author Contributions

Conceptualization, A.S., P.P. and J.K.; methodology, J.K. and T.H.; software, J.K. and T.H.; validation, J.K., P.P. and S.R.; formal analysis, A.S., P.P. and Z.S.; investigation, P.P.; resources, A.S. and J.K.; data curation, A.S. and J.K.; writing—original draft preparation, A.S., Z.S. and T.H.; writing—review and editing, A.S. and P.P.; visualization, A.S. and P.P.; supervision, P.P. and S.R.; project administration, P.P.; funding acquisition, A.S., S.R. and P.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the King Mongkut’s Institute of Technology Ladkrabang (KREF046509) research fund.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article.

Acknowledgments

We would like to thank the staff at KMITL: FACTory Classroom.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zadernowski, R.; Czaplicki, S.; Naczk, M. Phenolic acid profiles of mangosteen fruits (Garcinia mangostana). Food Chem. 2009, 112, 685–689. [Google Scholar] [CrossRef]

- Suksamrarn, S.; Suwannapoch, N.; Phakhodee, W. Anti-mycobacterial activity of prenylated xanthones from the fruits of Garcinia mangostana. Chem. Pharm. Bull. 2003, 51, 857–859. [Google Scholar] [CrossRef] [PubMed]

- Geetha, R.; Roy, A.; Lakshmi, T. Evaluation of antibacterial activity of fruit rind extract of Garcinia mangostana linn on enteric pathogens—An in vitro study. Asian J. Pharm. Clin. Res. 2011, 4, 115–118. [Google Scholar]

- Gutierrez-Orozco, F.; Failla, M.L. Biological activities and bioavailability of mangosteen xanthones: A critical review of the current evidence. Nutrients 2013, 5, 3163–3183. [Google Scholar] [CrossRef]

- Zarena, A.; Sankar, K.U. Phenolic acids, flavonoid profile and antioxidant activity in mangosteen (Garcinia mangostana L.) pericarp. J. Food Biochem. 2012, 36, 627–633. [Google Scholar] [CrossRef]

- Cheok, Y.C.; Adzahan, M.N.; Rahman, A.R.; Abedin, H.Z.N.; Hussain, N.; Sulaiman, R.; Chong, H.G. Current trends of tropical fruit waste utilization. Crit. Rev. Food Sci. Nutr. 2017, 58, 335–361. [Google Scholar] [CrossRef]

- Lee, K.T.; Chen, W.H.; Sarles, P.; Park, Y.K.; Ok, Y.S. Recover energy and materials from agricultural waste via thermochemical conversion. One Earth 2022, 5, 1200–1204. [Google Scholar] [CrossRef]

- Yasmin, N.; Jamuda, M.; Panda, A.K.; Samal, K.; Nayak, J.K. Emission of greenhouse gases (GHGs) during composting and vermicomposting: Measurement, mitigation, and perspectives. Energy Nexus 2022, 7, 100092. [Google Scholar] [CrossRef]

- Ufitikirezi, J.d.D.M.; Filip, M.; Ghorbani, M.; Zoubek, T.; Olšan, P.; Bumbálek, R.; Strob, M.; Bartoš, P.; Umurungi, S.N.; Murindangabo, Y.T.; et al. Agricultural Waste Valorization: Exploring Environmentally Friendly Approaches to Bioenergy Conversion. Sustainability 2024, 16, 3617. [Google Scholar] [CrossRef]

- Gianico, A.; Gallipoli, A.; Gazzola, G.; Pastore, C.; Tonanzi, B.; Braguglia, C.M. A novel cascade biorefinery approach to transform food waste into valuable chemicals and biogas through thermal pretreatment integration. Bioresour. Technol. 2021, 338, 125517. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, A.K. Exploitation of Food Industry Waste for High-Value Products. Trends Biotechnol. 2016, 34, 58–69. [Google Scholar] [CrossRef] [PubMed]

- Hemshekhar, M.; Sunitha, K.; Santhosh, M.S.; Devaraja, S.; Kemparaju, K.; Vishwanath, B.; Niranjana, S.; Girish, K. An overview on genus garcinia: Phytochemical and therapeutical aspects. Phytochem. Rev. 2011, 10, 325–351. [Google Scholar] [CrossRef]

- Pinto, M.; Sousa, M.; Nascimento, M.S. Xanthone derivatives: New insights in biological activities. Curr. Med. Chem. 2005, 12, 2517–2538. [Google Scholar] [CrossRef] [PubMed]

- Pedraza-Chaverrí, J.; Reyes-Fermín, L.M.; Nolasco-Amaya, E.G.; Orozco-Ibarra, M.; Medina-Campos, O.N.; González-Cuahutencos, O.; Rivero-Cruz, I.; Mata, R. ROS scavenging capacity and neuroprotective effect of α-mangostin against 3-nitropropionic acid in cerebellar granule neurons. Exp. Toxicol. Pathol. 2009, 61, 491–501. [Google Scholar] [CrossRef]

- Ghasemzadeh, A.; Jaafar, Z.E.H.; Baghdadi, A.; Tayebi-Meigooni, A. Alpha-Mangostin-Rich Extracts from Mangosteen Pericarp: Optimization of Green Extraction Protocol and Evaluation of Biological Activity. Molecules 2018, 23, 1852. [Google Scholar] [CrossRef]

- Ibrahim, M.Y.; Hashim, N.M.; Mariod, A.A.; Mohan, S.; Abdulla, M.A.; Abdelwahab, S.I.; Arbab, I.A. α-Mangostin from Garcinia mangostana linn: An updated review of its pharmacological properties. Arab. J. Chem. 2016, 9, 317–329. [Google Scholar] [CrossRef]

- Liu, S.H.; Lee, L.T.; Hu, N.Y.; Huange, K.K.; Shih, Y.C.; Munekazu, I.; Li, J.M.; Chou, T.Y.; Wang, W.H.; Chen, T.S. Effects of α-mangostin on the expression of anti-inflammatory genes in U937 cells. Chin. Med. 2012, 7, 19. [Google Scholar] [CrossRef]

- Yuvanatemiya, V.; Srean, P.; Klangbud, W.K.; Venkatachalam, K.; Wongsa, J.; Parametthanuwat, T.; Charoenphun, N. A Review of the Influence of Various Extraction Techniques and the Biological Effects of the Xanthones from Mangosteen (Garcinia mangostana L.) pericarps. Molecules 2022, 27, 8775. [Google Scholar] [CrossRef]

- Sukatta, U. Xanthones from Mangosteen Peels in the Cosmetic Industry. Available online: https://www3.rdi.ku.ac.th/?p=62656 (accessed on 30 August 2022).

- García, M.L.; Carrión, M.H.; Escobar, S.; Rodríguez, A.; Cortina, J.R. Optimization of the antioxidant capacity of mangosteen peels (Garcinia mangostana L.) extracts: Management of the drying extraction processes. Food Sci. Technol. Int. 2021, 27, 404–412. [Google Scholar] [CrossRef]

- Sonesson, U.; Davis, J.; Ziegler, F. Food Production and Emissions of Greenhouse Gases: An Overview of the Climate Impact of Different Product Groups; The Swedish Institute for Food and Biotechnology: Gothenburg, Sweden, 2010. [Google Scholar]

- Joglekar, S.N.; Pathak, P.D.; Mandavgane, S.A.; Kulkarni, B.D. Process of fruit peel waste biorefinery: A case study of citrus waste biorefinery, its environmental impacts and recommendations. Environ. Sci. Pollut. Res. 2019, 26, 34713–34722. [Google Scholar] [CrossRef]

- da Costa, J.S.; Maranduba, H.L.; de Sousa Castro, S.; de Almeida Neto, J.A.; Rodrigues, L.B. Environmental performance of orange citrus waste as raw material for pectin and essential oil production. Food Bioprod. Process. 2022, 135, 165–177. [Google Scholar] [CrossRef]

- Khanpit, V.V.; Tajane, S.P.; Mandavgane, S.A. Orange waste peel to high value soluble dietary fiber concentrate: Comparison of conversion methods and their environmental impact. Biomass Convers. Biorefin. 2022, 13, 14413–14423. [Google Scholar] [CrossRef]

- Khanpit, V.V.; Tajane, S.P.; Mandavgane, S.A. Production of soluble dietary fiber concentrate from waste orange peels: Study of nutritional and physicochemical properties and life cycle assessment. Biomass Conv. Bioref. 2023, 13, 14615–14627. [Google Scholar] [CrossRef]

- Midolo, G.; Cutuli, G.; Porto, S.M.C.; Ottolina, G.; Paini, J.; Valenti, F. LCA analysis for assessing environmenstal sustainability of new biobased chemicals by valorising citrus waste. Sci. Rep. 2024, 14, 21418. [Google Scholar] [CrossRef] [PubMed]

- Manakas, P.; Balafoutis, A.T.; Kottaridi, C. Sustainability assessment of orange peel waste valorization pathways from juice industries. Biomass Convers. Biorefin. 2025, 15, 6525–6544. [Google Scholar] [CrossRef]

- Shinde, P.N.; Mandavgane, S.A.; Karadbhajane, V. Process development and life cycle assessment of pomegranate biorefinery. Environ. Sci. Pollut. Res. 2020, 27, 25785–25793. [Google Scholar] [CrossRef]

- da Silva, A.K.P.; Cardoso, A.; de Sá Filho, E.B.; de Azeredo, H.M.C.; Freire, F.; Casimiro Filho, F.; de Figueirêdo, M.C.B. Integrating life cycle assessment in early process development stage: The case of extracting starch from mango kernel. J. Clean. Prod. 2021, 321, 128981. [Google Scholar] [CrossRef]

- Phanchandee, W.; Sachakamol, P. Life cycle assessment of mango and mangosteen in Thailand. In Proceedings of the 51st Kasetsart University Annual Conference, Bangkok, Thailand, 5–7 February 2013. [Google Scholar]

- Fernández-Ríos, A.; Laso, J.; Hoehn, D.; Amo-Setién, F.J.; Abajas-Bustillo, R.; Ortego, C.; Fullana-I-Palmer, P.; Bala, A.; Batlle-Bayer, L.; Balcells, M.; et al. A critical review of superfoods from a holistic nutritional and environmental approach. J. Clean. Prod. 2022, 379, 134491. [Google Scholar] [CrossRef]

- Pleerux, N.; Aimkuy, N. Carbon footprint of mangosteen farm level evaluation in eastern Thailand. Curr. J. Appl. Sci. Technol. 2021, 21, 419–430. [Google Scholar]

- Bisinella, V.; Schmidt, S.; Varling, A.S.; Laner, D.; Christensen, T.H. Waste LCA and the future. Waste Manag. 2024, 174, 53–75. [Google Scholar] [CrossRef]

- Koiwanit, J.; Riensuwarn, F.; Palungpaiboon, P.; Pornchaloempong, P. Business viability and carbon footprint of Thai-grown Nam Dok Mai mango powdered drink mix. J. Clean. Prod. 2020, 254, 119991. [Google Scholar] [CrossRef]

- Pongsuttiyakorn, T.; Sooraksa, P.; Pornchalermpong, P. Simple Effective and Robust Weight Sensor for Measuring Moisture Content in Food Drying Process. Sens. Mater. 2019, 31, 2393–2404. [Google Scholar] [CrossRef]

- TAS 2-2013; National Bureau of Agricultural Commodity and Food Standards, Mangosteen Thai Agricultural Standard. Thai Agricultural Standard: Bangkok, Thailand, 2014.

- Saohin, W.; Boonchoong, P.; Iamlikitkuakoon, S.; Jamnoiprom, I.; Mungdee, W. Effects of drying temperature and residual moisture content of Fa-Tha-Li (Andrographis paniculata (Burm. f.) Nees) crude powder for capsule preparation. Thai J. Pharm. Sci. 2007, 31, 28–35. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.R.; Bosch, P.R.; Dave, R.; Meyer, L.A. Climate Change 2007 Mitigation. Contribution of Working Group III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2007. [Google Scholar]

- Lohsomboon, P.; Jirajariyavech, A. Life Cycle Inventory for Cement Product and Steel Making towards Sustainable Development; Thailand Environment Institute (TEI): Nonthaburi, Thailand, 2004. [Google Scholar]

- Wankanapon, P.; Chindapol, S.; Tantasavasdi, C. Environmental impact assessment for typical and innovative housing construction materials in Thailand. Int. J. Build. Urban Inter. Landsc. Technol. 2013, 2, 43–53. [Google Scholar]

- Association of Official Analytical Chemists. Official Methods of Analysis; AOAC International: Washington, DC, USA, 2005. [Google Scholar]

- Zhang, Y.; Jiao, S.; Lian, Z.; Deng, Y.; Zhao, Y. Effect of single- and two-cycle high hydrostatic pressure treatments on water properties, physicochemical and microbial qualities of minimally processed squids (Todarodes pacificus). J. Food Sci. 2015, 80, 1012–1020. [Google Scholar] [CrossRef]

- Yoswathana, N. Accelerated extraction of Xanthone from Mangosteen pericarp using ultrasonic technique. Afr. J. Pharm. Pharmacol. 2012, 7, 302–330. [Google Scholar] [CrossRef]

- Maturin, L.; James, T.P. Bacteriological Analytical Manual Chapter 3: Aerobic Plate Count Edition 8, Revision A. 2001. Available online: https://www.fda.gov/food/science-research-food/laboratory-methods-food (accessed on 20 June 2010).

- National Bureau of Agricultural Commodity and Food Standards; Part4: Fruit and Seeds; Thai Agricultural Standard: Bangkok, Thailand, 2020; Available online: https://tas2go.acfs.go.th/upload_standard/45_en.pdf (accessed on 30 August 2022).

- Maysami, M.A.; Sedighi, R.; Ghaffari, H. Evaluation of different drying processes by energy consumption in an insulated and not insulated laboratory convection dryer. Food Res. 2020, 4, 107–111. [Google Scholar] [CrossRef]

- Akpinar, E.K.; Midilli, A.; Bicer, Y. Single layer drying behaviour of potato slices in a convective cyclone dryer and mathematical modeling. Energy Convers. Manag. 2003, 44, 1689–1705. [Google Scholar] [CrossRef]

- Esmaeili Adabi, M.; Mousavi Seyedi, S.R.; Kalantari, D.; Ghavami Adl, B. Mathematical modelling, kinetics and energy consumption for drying Aloe vera gel in hot air dryer with exhaust air recycle. J. Food Sci. Technol. 2016, 13, 73–83. [Google Scholar]

- Wróbel-Jędrzejewska, M.; Polak, E. Determination of carbon footprint in the processing of frozen vegetables using an online energy measurement system. J. Food Eng. 2022, 322, 110974. [Google Scholar] [CrossRef]

- Yao, J.; Chen, W.; Fan, K. Novel Efficient Physical Technologies for Enhancing Freeze Drying of Fruits and Vegetables: A Review. Foods 2023, 12, 4321. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, M.J.; Perez-Palacios, T.; Ruiz-Carrascal, J. Physico-chemical and sensory characteristics of freeze-dried and airdehydrated yogurt foam. LWT 2017, 80, 328–334. [Google Scholar] [CrossRef]

- El Hage, H.; Herez, A.; Ramadan, M.; Brazzi, H.; Khaled, M. An investigation on solar drying: A review with economic and environmental assessment. Energy 2018, 157, 815–829. [Google Scholar] [CrossRef]

- Singh, P.; Shrivastava, V.; Kumar, A. Recent developments in greenhouse solar drying: A review. Renew. Sustain. Energy Rev. 2018, 82, 3250–3262. [Google Scholar] [CrossRef]

- Udomkun, P.; Romuli, S.; Schock, S.; Mahayothee, B.; Sartas, M.; Wossen, T.; Njukwe, E.; Vanlauwe, B.; Müller, J. Review of solar dryers for agricultural products in Asia and Africa: An innovation landscape approach. J. Environ. Manag. 2020, 268, 110730. [Google Scholar] [CrossRef] [PubMed]

- Zdravkovic, M.; Snoeck, R.E.; Zicari, A.; Vranken, L.; Heinz, V.; Smetana, S.; Aganovic, K. Sustainability assessment of mobile juice processing unit: Farmers perspective. Future Foods 2021, 4, 100064. [Google Scholar] [CrossRef]

- Sirimark, P.; Yotmanee, S.; Pradubsri, W.; Somsila, P. Comparison of efficiency between liquefied petroleum gas (LPG) and electric hot air dryer: Case study of dried pork slice. J. Food 2023, 21, 181–188. [Google Scholar] [CrossRef]

- Castagnoli, A.; Salem, A.M.; Desideri, U.; Pecorini, I. Environmental assessment of gasification and green hydrogen potential role in waste management decarbonization. J. Clean. Prod. 2024, 482, 144174. [Google Scholar] [CrossRef]

- Martynenko, A.A.; Vieira, G.N.A. Sustainability of drying technologies: System analysis. Sustain. Food Technol. 2023, 1, 629–640. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).