An Integrated Life Cycle Assessment of a Hemp-Based Craft Beer: A Case Study from Italy

Abstract

1. Introduction

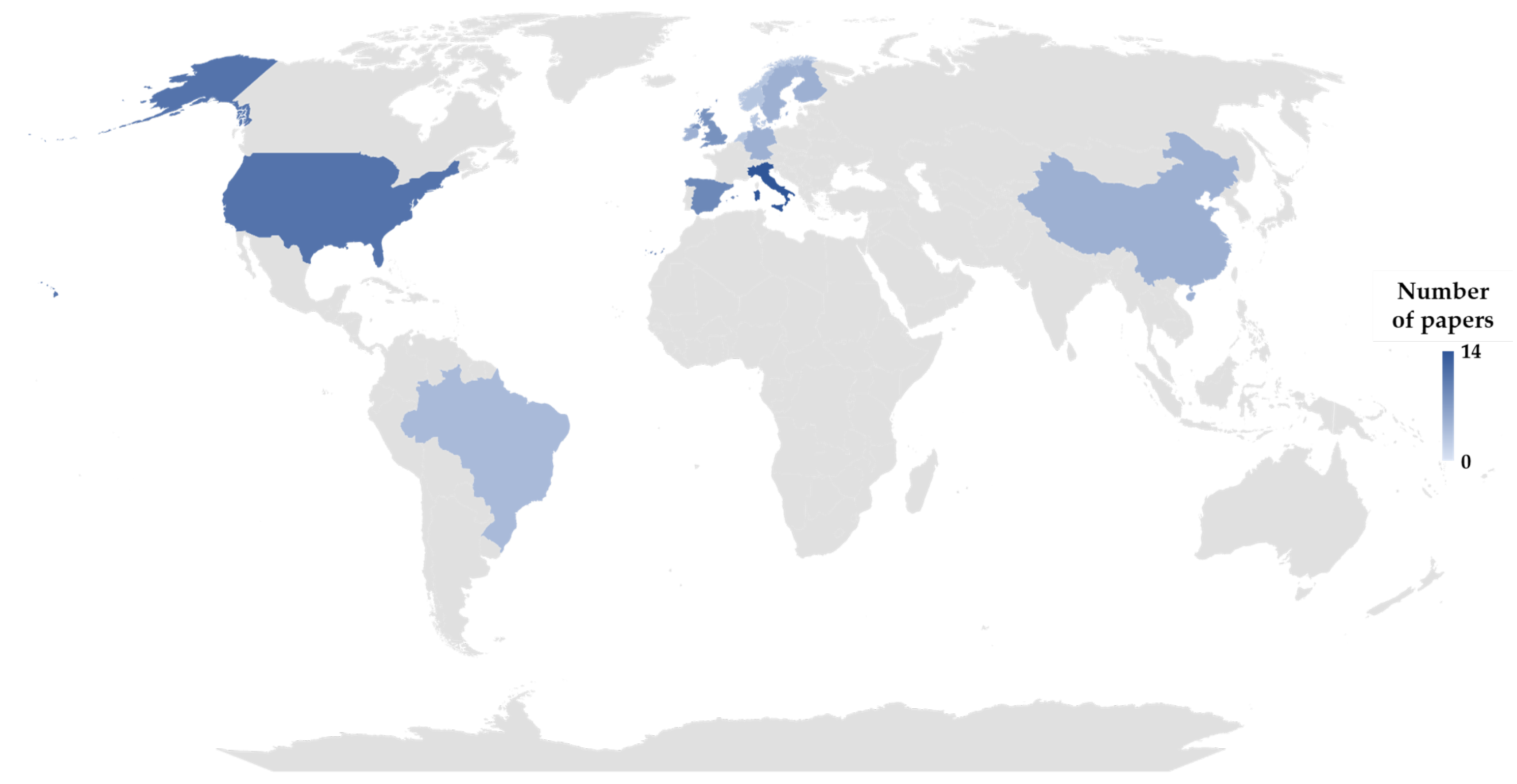

2. Literature Review

- Cluster 1 (red—6 items): beer, brewing industry, chemistry, environmental sustainability, food industry, packaging;

- Cluster 2 (green—6 items): carbon emission, circular economy, controlled study, sensitivity analysis, human, sustainable development;

- Cluster 3 (blue—6 items): environmental footprint, environmental impact, life cycle assessment, recycling, sustainability.

3. Materials and Methods

3.1. Case Study Description

- First, craft breweries represent a rapidly expanding production reality in Italy, but often under-studied in environmental impact studies. Focusing on small-scale local production allows to highlight specific criticalities and opportunities related to the small scale;

- Hemp pale ale was selected as the object of research because it represents an innovative product, combining the classic characteristics of a top-fermented beer with the addition of an unconventional ingredient, hemp, which is increasingly used in the agri-food sector for its aromatic properties and sustainability [32,33]. This allows not only to assess the environmental impact of the brewing process itself, but also to reflect on the role of alternative ingredients and their potential in differentiating the flavor profile of the final product;

- In addition, collaboration with the brewery made it possible to collect data on the individual stages of the production process, giving the possibility to conduct the study within a reasonable time frame.

3.2. Life Cycle Assessment

3.2.1. Goal and Scope Definition

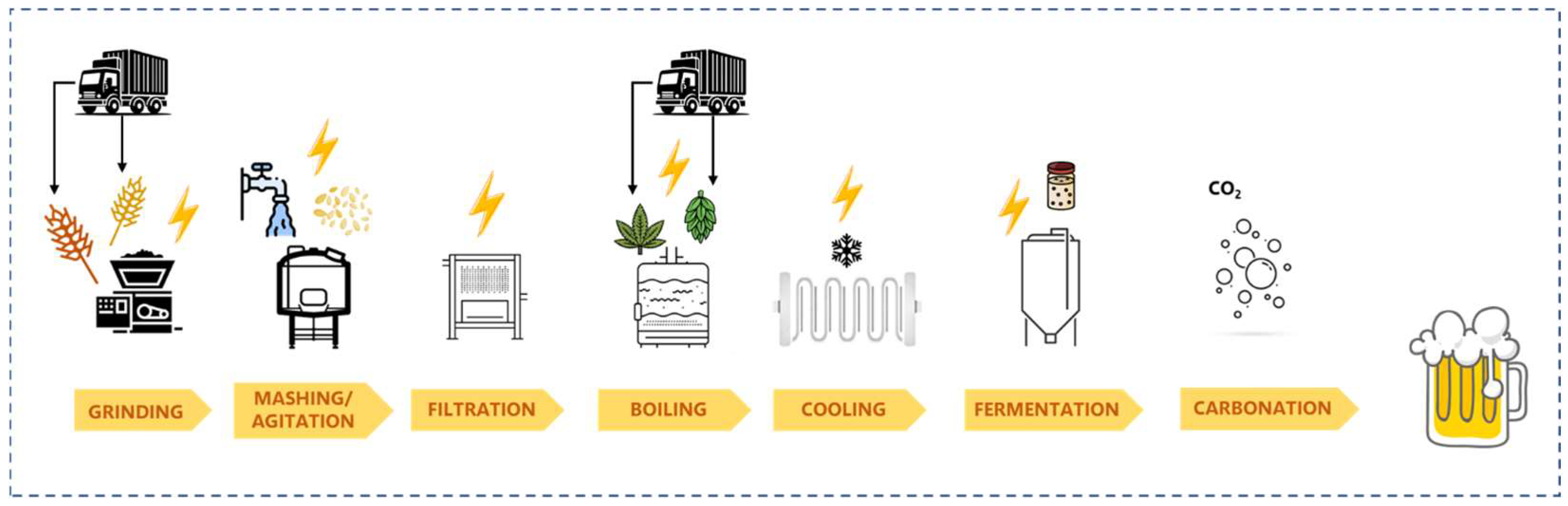

3.2.2. Life Cycle Inventory

- TKM is the transport of 1 ton of goods for 1 km of distance;

- ∅i is the distance in km as the crow flies of commodity i from a place x to a place;

- δ is the weight in kg of the material being transported.

| Input | Unit | Wort Preparation | Wort Boiling | Cooling | Fermentation | Carbonation | Tot. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grinding | Mashing/Agitation | Filtration/Sparging | |||||||||||||||

| ×1 L | ×Batch (100 L) | ×1 L | ×Batch (100 L) | ×1 L | ×Batch (100 L) | ×1 L | ×Batch (100 L) | ×1 L | ×Batch (100 L) | ×1 L | ×Batch (100 L) | ×1 L | ×Batch (100 L) | ×1 L | ×Batch (100 L) | ||

| Malt Barley | kg | 0.2 | 20 | - | - | - | - | - | - | - | - | - | - | - | - | 0.2 | 20 |

| Corn | kg | 0.05 | 5 | - | - | - | - | - | - | - | - | - | - | - | - | 0.05 | 5 |

| Hemp | kg | - | - | - | - | - | - | 0.005 | 0.5 | - | - | - | - | - | - | 0.005 | 0.5 |

| Water | L | - | - | 3.5 | 350 | - | - | - | - | - | - | - | - | - | - | 3.5 | 350 |

| Hops | g | - | - | - | - | - | - | 1.5 | 150 | - | - | - | - | - | - | 1.5 | 150 |

| Yeasts | g | - | - | - | - | - | - | - | - | - | - | 0.7 | 70 | - | - | 0.7 | 70 |

| Electricity | kWh | 0.005 | 0.5 | 0.35 | 35 | 0.02 | 2 | 0.25 | 25 | 0.07 | 7 | 0.06 | 6 | 0.004 | 0.4 | 0.76 | 76 |

| Liquid food CO2 (E290) | g | - | - | - | - | - | - | - | - | - | - | - | - | 8 | 800 | 8 | 800 |

| Time | 20 min | 60–90 min | 30–45 min | 60–90 min | 20–30 min | 5–7 days | 2–4 h | 7 days | |||||||||

| Temperature | °C | Room | 52–72 | 65–75 | 100 | from 100 to 20 | 18–24 | 4 | |||||||||

| Output | |||||||||||||||||

| Wort | L | 3.5 | 350 | 3.2 | 320 | 3.1 | 310 | 2.9 | 290 | 2.85 | 285 | 2.75 | 275 | - | - | - | - |

| Beer | L | - | - | - | - | - | - | - | - | - | - | - | - | 1 | 100 | 1 | 100 |

3.2.3. Life Cycle Impact Assessment

3.3. Scenario Analysis

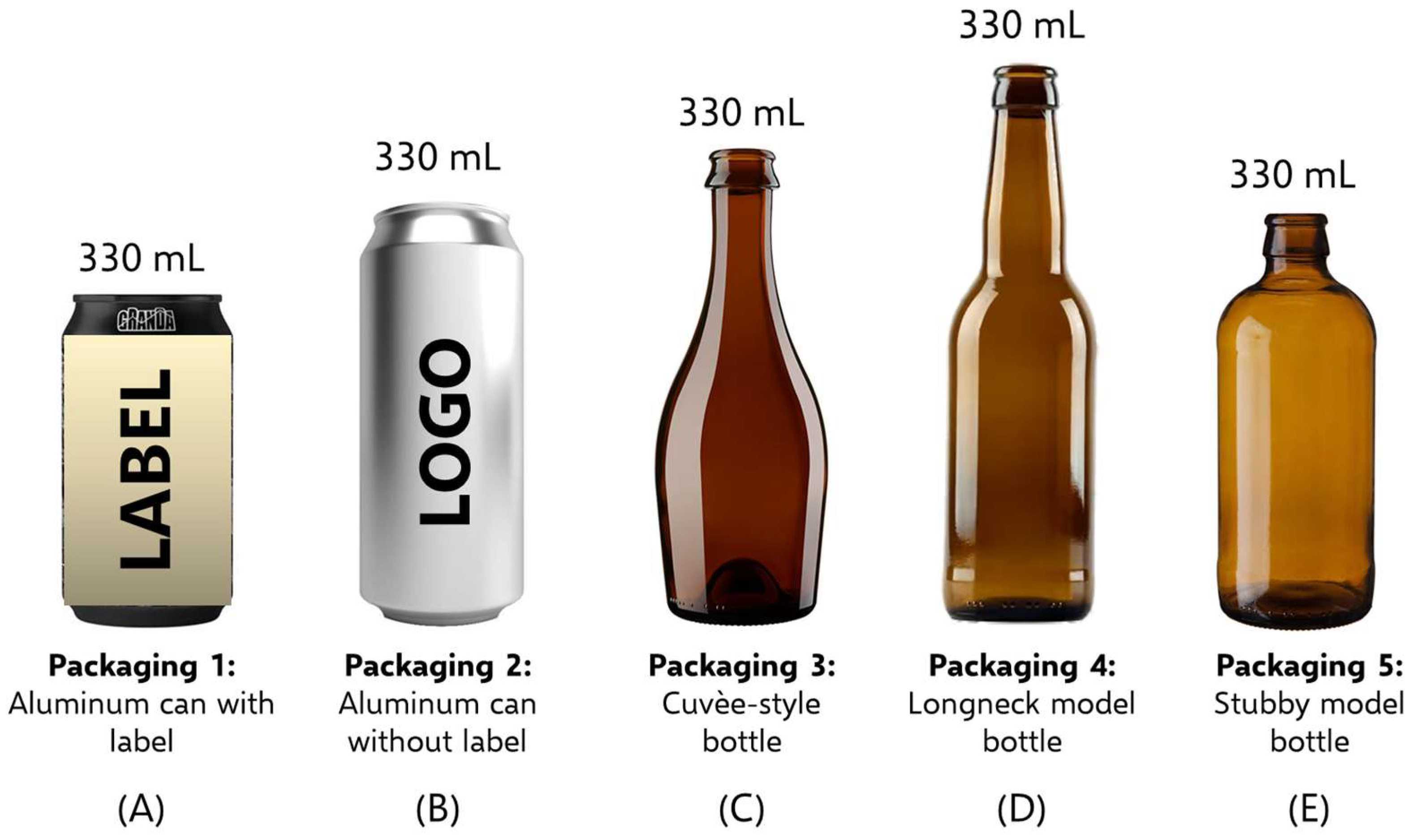

- Packaging 1: A single-color black aluminum can with a label printed and pasted by the manufacturer itself was considered (Figure 5A), with a total weight of ~15.7 g;

- Packaging 2: An aluminum can was considered without a label, but with the manufacturer’s logo printed on it, which was blacked out for reasons of commercial confidentiality and brand protection (Figure 5B). The total weight is ~13.3 g;

- Packaging 3: A dark blue “Cuvèe-style” bottle was considered, i.e., a thick glass bottle with a long neck and convex body, an example prototype of which is shown in Figure 5C, weighing ~253.4 g, commonly used in the craft beer industry;

- Packaging 4: A traditional “longneck” bottle, i.e., a disposable amber glass bottle, characterized by a long neck and sleek silhouette (an example prototype of which is shown in Figure 5D), weighing ~196.0 g, was considered;

- Packaging 5: A “stubby” bottle was considered, i.e., an amber glass bottle with a compact shape, wide body, and short neck (of which an example prototype is shown in Figure 5E), weighing ~221.3 g.

| Material | Body (g) | Label (g) | Cap (g) | Total Weight | Description | |

|---|---|---|---|---|---|---|

| Packaging 1 | Aluminium | 14.434 | 1.257 | Not present | 15.691 | Single-color aluminum can, label pasted on |

| Packaging 2 | Aluminium | 13.281 | Not present | Not present | 13.281 | Patterned aluminum can, no label |

| Packaging 3 | Glass | 250.18 | 1.07 | 2.18 | 253.430 | “Cuvèe-style” bottle, 0.33 L, in disposable dark glass |

| Packaging 4 | Glass | 192.63 | 1.01 | 2.29 | 195.930 | “Longneck” model bottle, 0.33 L, in disposable amber glass |

| Packaging 5 | Glass | 218.67 | 0.88 | 1.78 | 221.330 | “Stubby” model bottle, 0.33 L, in disposable amber glass |

4. Results and Discussion

4.1. Life Cycle Assessment

4.2. Scenario Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GWP | Global Warming Potential |

| SOD | Stratospheric Ozone Depletion |

| IR | Ionizing Radiation |

| OFHH | Ozone Formation Human Health |

| FPMF | Fine Particulate Matter Formation |

| OFTE | Ozone Formation Terrestrial Ecotoxicity |

| TAP | Terrestrial Acidification |

| FEP | Freshwater Eutrophication |

| MEP | Marine Eutrophication |

| TEC | Terrestrial Ecotoxicity |

| FEC | Freshwater Ecotoxicity |

| MEC | Marine Ecotoxicity |

| HCT | Human Carcinogenic Toxicity |

| HNCT | Human Non-Carcinogenic Toxicity |

| LU | Land Use |

| MRS | Mineral Resource Scarcity |

| FRS | Fossil Resource Scarcity |

| WC | Water Consumption |

References

- Oliver, G. The Oxford Companion to Beer; Oxford University Press: New York, NY, USA, 2012; ISBN 978-0-19-536713-3. [Google Scholar] [CrossRef]

- World Population Review. Alcohol Consumption by Country 2025. 2025. Available online: https://worldpopulationreview.com/country-rankings/alcohol-consumption-by-country (accessed on 7 April 2025).

- Gobbi, L.; Stanković, M.; Ruggeri, M.; Savastano, M. Craft beer in food science: A review and conceptual framework. Beverages 2024, 10, 91. [Google Scholar] [CrossRef]

- Ramanan, M.; Fox, G.P.; Marco, M.L. Beer for live microbe delivery. J. Funct. Foods 2024, 113, 105987. [Google Scholar] [CrossRef]

- Romano, G.; Tufariello, M.; Calabriso, N.; del Coco, L.; Fanizzi, F.P.; Blanco, A.; Carluccio, M.A.; Grieco, F.; Laddomada, B. Pigmented cereals and legume grains as healthier alternatives for brewing beers. Food Biosci. 2023, 52, 102463. [Google Scholar] [CrossRef]

- Salanță, L.C.; Coldea, T.E.; Ignat, M.V.; Pop, C.R.; Tofană, M.; Mudura, E.; Borșa, A.; Pasqualone, A.; Zhao, H. Non-Alcoholic and Craft Beer Production and Challenges. Processes 2020, 8, 1382. [Google Scholar] [CrossRef]

- Bamforth, C.W.; Fox, G.P. Malting and brewing. In ICC Handbook of 21st Century Cereal Science and Technology; Elsevier Inc.: Amsterdam, The Netherlands, 2023; pp. 363–368. [Google Scholar] [CrossRef]

- World Population Review. Beer Consumption by Country 2025. 2025. Available online: https://worldpopulationreview.com/country-rankings/beer-consumption-by-country (accessed on 7 April 2025).

- Testa, B.; Coppola, F.; Letizia, F.; Albanese, G.; Karaulli, J.; Ruci, M.; Pistillo, M.; Germinara, G.S.; Messia, M.C.; Succi, M.; et al. Versatility of Saccharomyces cerevisiae 41CM in the Brewery Sector: Use as a Starter for “Ale” and “Lager” Craft Beer Production. Processes 2022, 10, 2495. [Google Scholar] [CrossRef]

- Monerawela, C.; Bond, U. Brewing up a storm: The genomes of lager yeasts and how they evolved. Biotechnol. Adv. 2017, 35, 512–519. [Google Scholar] [CrossRef]

- Anderson, H.E.; Liden, T.; Berger, B.K.; Zanella, D.; Manh, L.H.; Wang, S.; Schug, K.A. Profiling of contemporary beer styles using liquid chromatography quadrupole time-of-flight mass spectrometry, multivariate analysis, and machine learning techniques. Anal. Chim. Acta 2021, 1172, 338668. [Google Scholar] [CrossRef]

- Smithers, G.W. Alcoholic Beverages. In Encyclopedia of Food Safety, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2024; Volume 1-4, pp. 176–186. [Google Scholar] [CrossRef]

- Faganel, A.; Rižnar, I. The Growth in Demand for Craft Beer and the Proliferation of Microbreweries in Slovenia. Beverages 2023, 9, 86. [Google Scholar] [CrossRef]

- Brewers Association. Brewers Association Releases Annual Craft Brewing Industry Production Report and Top 50 Producing Craft Brewing Companies for 2023. 2024. Available online: https://www.brewersassociation.org/association-news/brewers-association-releases-annual-craft-brewing-industry-production-report-and-top-50-producing-craft-brewing-companies-for-2023/ (accessed on 7 April 2025).

- MASE. Strategia Nazionale per L’economia Circolare. 2022. Available online: https://www.mase.gov.it/sites/default/files/archivio/allegati/PNRR/SEC_21.06.22.pdf (accessed on 7 April 2025).

- Coldiretti. Consumi: Triplica la Birra Made in Italy, è il Record del Decennio. 2023. Available online: https://www.coldiretti.it/consumi/consumi-triplica-la-birra-made-in-italy-e-il-record-del-decennio (accessed on 7 April 2025).

- Sipperly, E.; Edinger, K.; Ziegler, N.; Roberts, E. Comparative Cradle to Gate Life Cycle Assessment of 100% Barley-based Singha Lager Beer in Thailand. King Mongkut’s University of Technology: Bangkok, Thailand, 2014. [Google Scholar]

- Cimini, A.; Moresi, M. Carbon footprint of a pale lager packed in different formats: Assessment and sensitivity analysis based on transparent data. J. Clean. Prod. 2016, 112, 4196–4213. [Google Scholar] [CrossRef]

- Morgan, D.R.; Styles, D.; Lane, E.T. Thirsty work: Assessing the environmental footprint of craft beer. Sustain. Prod. Consum. 2021, 27, 242–253. [Google Scholar] [CrossRef]

- Salazar Tijerino, M.B.; San Martín-González, M.F.; Velasquez Domingo, J.A.; Huang, J.-Y. Life Cycle Assessment of Craft Beer Brewing at Different Scales on a Unit Operation Basis. Sustainability 2023, 15, 11416. [Google Scholar] [CrossRef]

- McDonagh, K.; Zhang, R.; Merkouri, L.P.; Arnell, M.; Hepworth, A.; Duyar, M.; Short, M. Lowering the carbon footprint of beer through waste breadcrumb substitution for malted barley: Life cycle assessment and experimental study. Clean. Environ. Syst. 2024, 15, 100241. [Google Scholar] [CrossRef]

- Marrucci, L.; Daddi, T.; Iraldo, F. Identifying the most sustainable beer packaging through a Life Cycle Assessment. Sci. Total Environ. 2024, 948, 174941. [Google Scholar] [CrossRef]

- de Sadeleer, I.; Lyng, K.A. A Life Cycle Assessment on Single-Use and Reuse Beer Cups at Festivals. Circ. Econ. Sust. 2022, 2, 1517–1539. [Google Scholar] [CrossRef]

- Rajaniemi, M.; Mikkola, H.; Ahokas, J. Greenhouse Gas Emissions from Oats, Barley, Wheat and Rye Production. Agron. Res. 2011, 9, 189–195. [Google Scholar]

- D’Ascenzo, F.; Vinci, G.; Maddaloni, L.; Ruggeri, M.; Savastano, M. Application of Life Cycle Assessment in Beer Production: Systematic Review. Beverages 2024, 10, 86. [Google Scholar] [CrossRef]

- Lalonde, S.; Nicholson, A.; Schenck, R. Life Cycle Assessment of Beer in Support of an Environmental Product Declaration. Read. 2013. Available online: https://www.readkong.com/page/life-cycle-assessment-of-beer-in-support-of-an-2212961 (accessed on 4 April 2025).

- European Commission. Hemp Production in the EU. 2025. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 1 July 2025).

- Michels, M.; Brinkmann, A.; Mußhoff, O. Economic, Ecological and Social Perspectives of Industrial Hemp Cultivation in Germany: A Qualitative Analysis. J. Environ. Manag. 2025, 389, 126117. [Google Scholar] [CrossRef]

- Regulation (EU) No 1307/2013 of the European Parliament and of the Council of 17 December 2013 Establishing Rules for Direct Payments to Farmers Under Support Schemes Within the Framework of the Common Agricultural Policy and Repealing Council Regulation (EC) No 637/2008 and Council Regulation (EC) No 73/2009. Available online: https://eur-lex.europa.eu/eli/reg/2013/1307/oj/eng (accessed on 1 July 2025).

- LEGGE. Disposizioni per la Promozione Della Coltivazione e Della Filiera Agroindustriale Della Canapa. (16G00258) (GU Serie Generale n.304 del 30-12-2016). 2 Dicembre 2016, n. 242. Available online: https://www.gazzettaufficiale.it/eli/id/2016/12/30/16G00258/sg (accessed on 1 July 2025).

- U.S. Department of Agriculture (USDA). The American Relief Act. 2025. Available online: https://www.fsa.usda.gov/tools/informational/farm-bill (accessed on 1 July 2025).

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a potential raw material toward a sustainable world: A review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef]

- Nissen, L.; Casciano, F.; Gianotti, A.; Babini, E. Industrial hemp foods and beverages and product properties. In Industrial Hemp: Food and Nutraceutical Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2022; pp. 219–246. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principle and Framework. International Organisation for Standardisation (ISO): Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 9 April 2025).

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organisation for Standardisation (ISO): Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 9 April 2025).

- Wild, P. Recommendations for a Future Global CO2-Calculation Standard for Transport and Logistics. Transp. Res. Part D Transp. Environ. 2021, 100, 103024. [Google Scholar] [CrossRef]

- ISO 14083:2023; Greenhouse Gases—Quantification and Reporting of Greenhouse Gas Emissions Arising from Transport Chain Operations. International Organisation for Standardisation (ISO): Geneva, Switzerland, 2023. Available online: https://www.iso.org/standard/78864.html (accessed on 2 July 2025).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- de Vries, J.; de Bruyn, S.; Boerdijk, S.; Juijn, D.; Bijleveld, M.; van der Giesen, C.; Korteland, M.; Odenhoven, N.; van Santen, W.; Pápai, S. Environmental Prices Handbook 2024: EU Version. November 2024. Available online: https://cedelft.eu/publications/environmental-prices-handbook-2024-eu27-version/ (accessed on 9 April 2025).

- Lim, C.H.; Bok, C.H.; Ngan, S.L.; How, B.S.; Ng, W.P.Q.; Lam, H.L. Evaluation of Sustainable Palm Oil Production Certification via LCA. In Encyclopedia of Sustainable Technologies, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2024; pp. 323–337. [Google Scholar] [CrossRef]

- Pal, P.; Gopal, P.R.C.; Ramkumar, M. Impact of transportation on climate change: An ecological modernization theoretical perspective. Transp. Policy 2023, 130, 167–183. [Google Scholar] [CrossRef]

- Borrion, A.L.; Khraisheh, M.; Benyahia, F. Environmental life cycle impact assessment of Gas-to-Liquid processes. In Proceedings of the 3rd Gas Processing Symposium, Doha, Qatar, 5–7 March 2012; Elsevier Inc.: Amsterdam, The Netherlands, 2012; pp. 71–77. [Google Scholar] [CrossRef]

- Jourdaine, M.; Loubet, P.; Trebucq, S.; Sonnemann, G. A detailed quantitative comparison of the life cycle assessment of bottled wines using an original harmonization procedure. J. Clean. Prod. 2020, 250, 119472. [Google Scholar] [CrossRef]

- Hawrot-Paw, M.; Koniuszy, A.; Zając, G.; Szyszlak-Bargłowicz, J. Ecotoxicity of soil contaminated with diesel fuel and biodiesel. Sci. Rep. 2020, 10, 16436. [Google Scholar] [CrossRef] [PubMed]

- Pongboriboon, N.; Mariyappan, V.; Wu, W.; Chandra-Ambhorn, W. Economic and environmental analyses for achieving net-zero CO2 emissions of a green diesel production process. J. Taiwan Inst. Chem. Eng. 2024, 165, 105781. [Google Scholar] [CrossRef]

- Liang, Z.; Deng, H.; Xie, H.; Chen, B.; Sun, M.; Wang, Y. Rethinking the paper product carbon footprint accounting standard from a life-cycle perspective. J. Clean. Prod. 2023, 393, 136352. [Google Scholar] [CrossRef]

- Al-Alimi, S.; Yusuf, N.K.; Ghaleb, A.M.; Lajis, M.A.; Shamsudin, S.; Zhou, W.; Altharan, Y.M.; Abdulwahab, H.S.; Saif, Y.; Didane, D.H.; et al. Recycling aluminium for sustainable development: A review of different processing technologies in green manufacturing. Results Eng. 2024, 23, 102566. [Google Scholar] [CrossRef]

- The Aluminium Association. Aluminum Container Design Guide Outlines Four Keys to Circular Recycling. 2020. Available online: https://www.aluminum.org/news/aluminum-container-design-guide-outlines-four-keys-circular-recycling (accessed on 16 April 2025).

- Nuss, P.; Eckelman, M.J. Life Cycle Assessment of Metals: A Scientific Synthesis. PLoS ONE 2014, 9, e101298. [Google Scholar] [CrossRef]

| Impact Categories | Unit | Water | Maize | Barley Malt | Hemp | Hop | Yeast | Carbon Dioxide, Liquid | Electricity | Input Transport | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Atmospherical effects | |||||||||||

| GWP | kg CO2 eq | 1.31 × 10−3 | 0.02 | 0.27 | 2.68 × 10−3 | 3.54 × 10−3 | 2.75 × 10−3 | 0.01 | 0.37 | 0.24 | 0.92 |

| SOD | kg CFC11 eq | 4.39 × 10−10 | 2.09 × 10−7 | 1.02 × 10−6 | 3.23 × 10−8 | 1.74 × 10−8 | 1.80 × 10−8 | 1.29 × 10−9 | 2.11 × 10−7 | 8.34 × 10−8 | 1.59 × 10−6 |

| IR | kBq Co-60 eq | 3.71 × 10−4 | 2.66 × 10−4 | 0.01 | 7.45 × 10−5 | 8.07 × 10−6 | 4.16 × 10−5 | 8.16 × 10−4 | 0.05 | 1.32 × 10−3 | 0.06 |

| OFHH | kg NOx eq | 2.75 × 10−6 | 1.05 × 10−4 | 6.14 × 10−4 | 1.65 × 10−5 | 1.45 × 10−5 | 3.05 × 10−6 | 6.12 × 10−6 | 6.03 × 10−4 | 2.80 × 10−3 | 4.16 × 10−3 |

| FPMF | kg PM2.5 eq | 7.18 × 10−7 | 2.54 × 10−6 | 1.32 × 10−4 | 1.31 × 10−6 | 1.67 × 10−6 | 4.17 × 10−7 | 1.32 × 10−6 | 8.29 × 10−5 | 1.30 × 10−5 | 2.35 × 10−4 |

| OFTE | kg NOx eq | 2.76 × 10−6 | 1.97 × 10−4 | 6.18 × 10−4 | 1.65 × 10−5 | 1.48 × 10−5 | 3.05 × 10−6 | 6.14 × 10−6 | 6.04 × 10−4 | 2.82 × 10−3 | 4.28 × 10−3 |

| TAP | kg SO2 eq | 4.50 × 10−6 | 6.80 × 10−4 | 1.13 × 10−3 | 6.64 × 10−5 | 5.91 × 10−5 | 3.57 × 10−5 | 1.43 × 10−5 | 2.38 × 10−3 | 1.22 × 10−3 | 0.01 |

| Eutrophication | |||||||||||

| FEP | kg P eq | 9.00 × 10−7 | 9.39 × 10−6 | 6.28 × 10−5 | 2.53 × 10−6 | 2.70 × 10−6 | 3.56 × 10−6 | 2.48 × 10−6 | 9.84 × 10−5 | 6.86 × 10−6 | 1.89 × 10−4 |

| MEP | kg N eq | 8.55 × 10−8 | 4.76 × 10−5 | 8.85 × 10−4 | 1.90 × 10−5 | 1.02 × 10−5 | 8.51 × 10−6 | 4.49 × 10−7 | 7.19 × 10−6 | 2.49 × 10−7 | 9.78 × 10−4 |

| Toxicity | |||||||||||

| TEC | kg 1.4-DCB | 7.92 × 10−5 | 0.09 | 0.02 | 5.02 × 10−5 | 2.87 × 10−4 | 1.16 × 10−3 | 0.03 | 0.03 | 0.23 | 0.40 |

| FEC | 5.43 × 10−6 | 2.55 × 10−3 | 3.97 × 10−3 | 1.22 × 10−6 | 9.79 × 10−6 | 2.19 × 10−4 | 1.04 × 10−5 | 1.43 × 10−4 | 5.19 × 10−4 | 0.01 | |

| MEC | 2.39 × 10−6 | 9.19 × 10−4 | 7.10 × 10−4 | 3.17 × 10−7 | 3.37 × 10−6 | 5.48 × 10−5 | 3.26 × 10−6 | 7.84 × 10−5 | 2.47 × 10−4 | 2.02 × 10−3 | |

| HCT | 3.96 × 10−7 | 2.42 × 10−6 | 6.44 × 10−5 | 1.08 × 10−7 | 5.97 × 10−7 | 1.02 × 10−7 | 1.82 × 10−6 | 2.32 × 10−5 | 6.68 × 10−4 | 7.60 × 10−4 | |

| HNCT | 4.09 × 10−6 | 6.15 × 10−4 | 1.06 × 10−3 | 5.79 × 10−6 | 1.06 × 10−5 | 2.75 × 10−4 | 3.14 × 10−5 | 3.12 × 10−4 | 0.01 | 0.01 | |

| Abiotic resources | |||||||||||

| LU | m2a crop eq | 1.59 × 10−4 | 0.05 | 0.74 | 0.02 | 0.01 | 0.01 | 1.49 × 10−4 | 0.01 | 3.28 × 10−3 | 0.84 |

| MRS | kg Cu eq | 9.13 × 10−6 | 4.86 × 10−5 | 0.00 | 2.09 × 10−4 | 5.54 × 10−6 | 3.60 × 10−6 | 5.16 × 10−6 | 1.43 × 10−4 | 5.08 × 10−5 | 1.20 × 10−3 |

| FRS | kg oil eq | 3.16 × 10−4 | 2.77 × 10−3 | 0.04 | 4.67 × 10−4 | 9.06 × 10−4 | 3.01 × 10−4 | 1.20 × 10−3 | 0.09 | 0.08 | 0.21 |

| WC | m3 | 3.52 × 10−3 | 3.14 × 10−3 | 0.01 | 1.22 × 10−5 | 5.04 × 10−4 | 0.01 | 4.66 × 10−5 | 9.56 × 10−3 | 7.86 × 10−5 | 0.03 |

| Impact Categories | Unit | Water | Maize | Barley Malt | Hemp | Hop | Yeast | Carbon Dioxide, Liquid | Electricity | Input Transport | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Atmospherical effects | |||||||||||

| GWP | kg CO2 eq | 0.14% | 1.99% | 29.03% | 0.29% | 0.39% | 0.30% | 1.19% | 40.67% | 26.13% | 100.00% |

| SOD | kg CFC11 eq | 0.03% | 13.13% | 63.98% | 2.03% | 1.10% | 1.13% | 0.08% | 13.31% | 5.24% | 100.00% |

| IR | kBq Co-60 eq | 0.59% | 0.43% | 14.69% | 0.12% | 0.01% | 0.07% | 1.31% | 81.27% | 2.12% | 100.00% |

| OFHH | kg NOx eq | 0.07% | 2.53% | 14.75% | 0.40% | 0.35% | 0.07% | 0.15% | 14.49% | 67.27% | 100.00% |

| FPMF | kg PM2.5 eq | 0.31% | 1.08% | 56.16% | 0.56% | 0.71% | 0.18% | 0.56% | 35.23% | 5.52% | 100.00% |

| OFTE | kg NOx eq | 0.06% | 4.59% | 14.45% | 0.38% | 0.35% | 0.07% | 0.14% | 14.11% | 65.90% | 100.00% |

| TAP | kg SO2 eq | 0.08% | 12.18% | 20.19% | 1.19% | 1.06% | 0.64% | 0.26% | 42.69% | 21.79% | 100.00% |

| Eutrophication | |||||||||||

| FEP | kg P eq | 0.48% | 4.97% | 33.27% | 1.34% | 1.43% | 1.89% | 1.31% | 52.14% | 3.64% | 100.00% |

| MEP | kg N eq | 0.01% | 4.87% | 90.47% | 1.94% | 1.04% | 0.87% | 0.05% | 0.74% | 0.03% | 100.00% |

| Toxicity | |||||||||||

| TEC | kg 1.4-DCB | 0.02% | 22.71% | 3.73% | 0.01% | 0.07% | 0.29% | 7.70% | 7.69% | 57.80% | 100.00% |

| FEC | 0.07% | 34.35% | 53.49% | 0.02% | 0.13% | 2.95% | 0.14% | 1.93% | 7.00% | 100.00% | |

| MEC | 0.12% | 45.60% | 35.21% | 0.02% | 0.17% | 2.72% | 0.16% | 3.89% | 12.24% | 100.00% | |

| HCT | 0.05% | 0.32% | 8.47% | 0.01% | 0.08% | 0.01% | 0.24% | 3.06% | 87.81% | 100.00% | |

| HNCT | 0.03% | 5.06% | 8.74% | 0.05% | 0.09% | 2.26% | 0.26% | 2.56% | 80.98% | 100.00% | |

| Abiotic resources | |||||||||||

| LU | m2a crop eq | 0.02% | 5.49% | 88.46% | 2.86% | 0.81% | 0.69% | 0.02% | 1.27% | 0.39% | 100.00% |

| MRS | kg Cu eq | 0.76% | 4.04% | 61.33% | 17.33% | 0.46% | 0.30% | 0.43% | 11.89% | 4.22% | 100.00% |

| FRS | kg oil eq | 0.15% | 1.31% | 18.13% | 0.22% | 0.43% | 0.14% | 0.57% | 43.57% | 35.63% | 100.00% |

| WC | m3 | 14.07% | 12.54% | 23.28% | 0.05% | 2.01% | 23.40% | 0.19% | 38.21% | 0.31% | 100.00% |

| Impact Categories | Unit | Packaging 1— Aluminium Can with Label | Packaging 2—Aluminium Can Without Laber | Packaging 3—Cuvèe-Style Bottle | Packaging 4—Longneck Bottle | Packaging 5—Stubby |

|---|---|---|---|---|---|---|

| Atmospherical effects | ||||||

| GWP | kg CO2 eq | 0.465 | 0.449 | 0.717 | 0.625 | 0.664 |

| SOD | kg CFC11 eq | 5.62 × 10−7 | 5.57 × 10−7 | 6.28 × 10−7 | 6.04 × 10−7 | 6.15 × 10−7 |

| IR | kBq Co-60 eq | 2.27 × 10−2 | 2.24 × 10−2 | 1.93 × 10−2 | 1.97 × 10−2 | 1.95 × 10−2 |

| OFHH | kg NOx eq | 1.67 × 10−3 | 1.64 × 10−3 | 2.50 × 10−3 | 2.25 × 10−3 | 2.36 × 10−3 |

| FPMF | kg PM2.5 eq | 9.23 × 10−5 | 8.91 × 10−5 | 5.54 × 10−4 | 4.45 × 10−4 | 4.94 × 10−4 |

| OFTE | kg NOx eq | 1.72 × 10−3 | 1.69 × 10−3 | 2.54 × 10−3 | 2.29 × 10−3 | 2.40 × 10−3 |

| TAP | kg SO2 eq | 2.35 × 10−3 | 2.30 × 10−3 | 3.90 × 10−3 | 3.43 × 10−3 | 3.64 × 10−3 |

| Eutrophication | ||||||

| FEP | kg P eq | 6.36 × 10−5 | 6.28 × 10−5 | 2.44 × 10−4 | 2.02 × 10−4 | 2.21 × 10−4 |

| MEP | kg N eq | 3.25 × 10−4 | 3.24 × 10−4 | 3.35 × 10−4 | 3.32 × 10−4 | 3.33 × 10−4 |

| Toxicity | ||||||

| TEC | kg 1.4-DCB | 0.149 | 0.147 | 0.207 | 0.194 | 0.197 |

| FEC | 2.47 × 10−3 | 2.46 × 10−3 | 2.98 × 10−3 | 2.86 × 10−3 | 2.91 × 10−3 | |

| MEC | 6.88 × 10−4 | 6.82 × 10−4 | 9.19 × 10−4 | 8.62 × 10−4 | 8.86 × 10−4 | |

| HCT | 3.16 × 10−4 | 3.09 × 10−4 | 3.95 × 10−4 | 3.64 × 10−4 | 3.77 × 10−4 | |

| HNCT | 4.36 × 10−3 | 4.30 × 10−3 | 7.43 × 10−3 | 6.75 × 10−3 | 6.98 × 10−3 | |

| Abiotic resources | ||||||

| LU | m2a crop eq | 0.279 | 0.278 | 0.329 | 0.318 | 0.323 |

| MRS | kg Cu eq | 6.17 × 10−4 | 5.92 × 10−4 | 1.08 × 10−3 | 1.01 × 10−3 | 9.80 × 10−4 |

| FRS | kg oil eq | 0.109 | 0.105 | 0.172 | 0.149 | 0.159 |

| WC | m3 | 1.474 | 1.358 | 0.017 | 0.016 | 0.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruggeri, M.; Vinci, G.; Savastano, M.; Maddaloni, L. An Integrated Life Cycle Assessment of a Hemp-Based Craft Beer: A Case Study from Italy. Sustainability 2025, 17, 6232. https://doi.org/10.3390/su17136232

Ruggeri M, Vinci G, Savastano M, Maddaloni L. An Integrated Life Cycle Assessment of a Hemp-Based Craft Beer: A Case Study from Italy. Sustainability. 2025; 17(13):6232. https://doi.org/10.3390/su17136232

Chicago/Turabian StyleRuggeri, Marco, Giuliana Vinci, Marco Savastano, and Lucia Maddaloni. 2025. "An Integrated Life Cycle Assessment of a Hemp-Based Craft Beer: A Case Study from Italy" Sustainability 17, no. 13: 6232. https://doi.org/10.3390/su17136232

APA StyleRuggeri, M., Vinci, G., Savastano, M., & Maddaloni, L. (2025). An Integrated Life Cycle Assessment of a Hemp-Based Craft Beer: A Case Study from Italy. Sustainability, 17(13), 6232. https://doi.org/10.3390/su17136232