Toward a Resilient and Sustainable Supply Chain: Operational Responses to Global Disruptions in the Post-COVID-19 Era

Abstract

1. Introduction

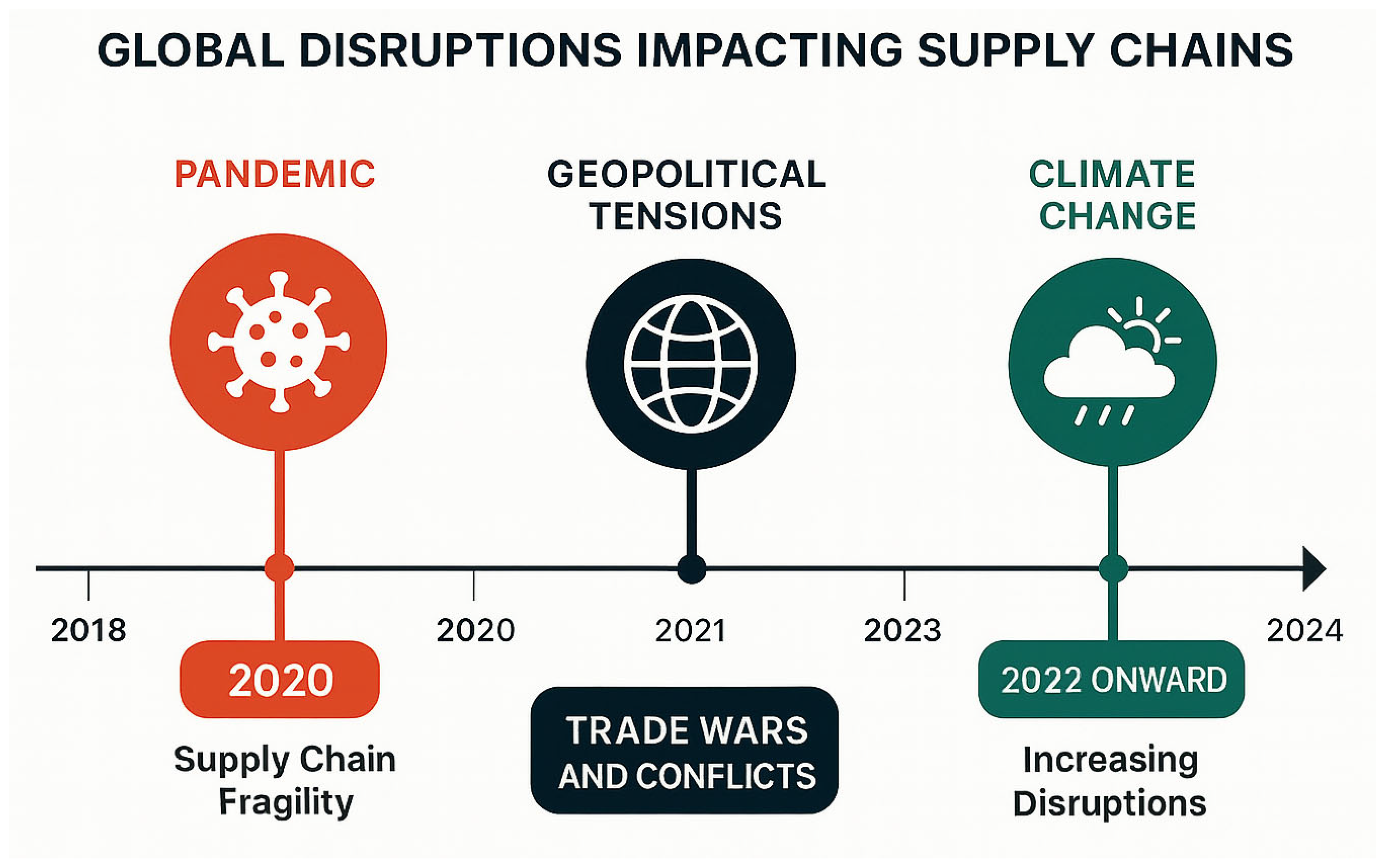

1.1. Background: Global Disruptions and Supply Chain Vulnerability

1.2. Post-COVID-19 Operational Challenges: The Sustainability Imperative

1.3. Research Gap and Conceptual Purpose

1.4. Contributions and Structure of the Paper

- (1)

- Theoretical integration: The framework draws upon two foundational theories—Dynamic Capabilities Theory, which explains how firms sense, seize, and reconfigure resources in response to disruptions, and the Triple Bottom Line (TBL), which frames sustainability outcomes across economic, environmental, and social dimensions. These theories serve to interlink resilience, operational transformation, and sustainability into a coherent foundation.

- (2)

- Synthesis across domains: The paper integrates the literature from operations management, sustainability science, disaster resilience, and global development to establish a transdisciplinary platform for future research and policy dialogue.

- (3)

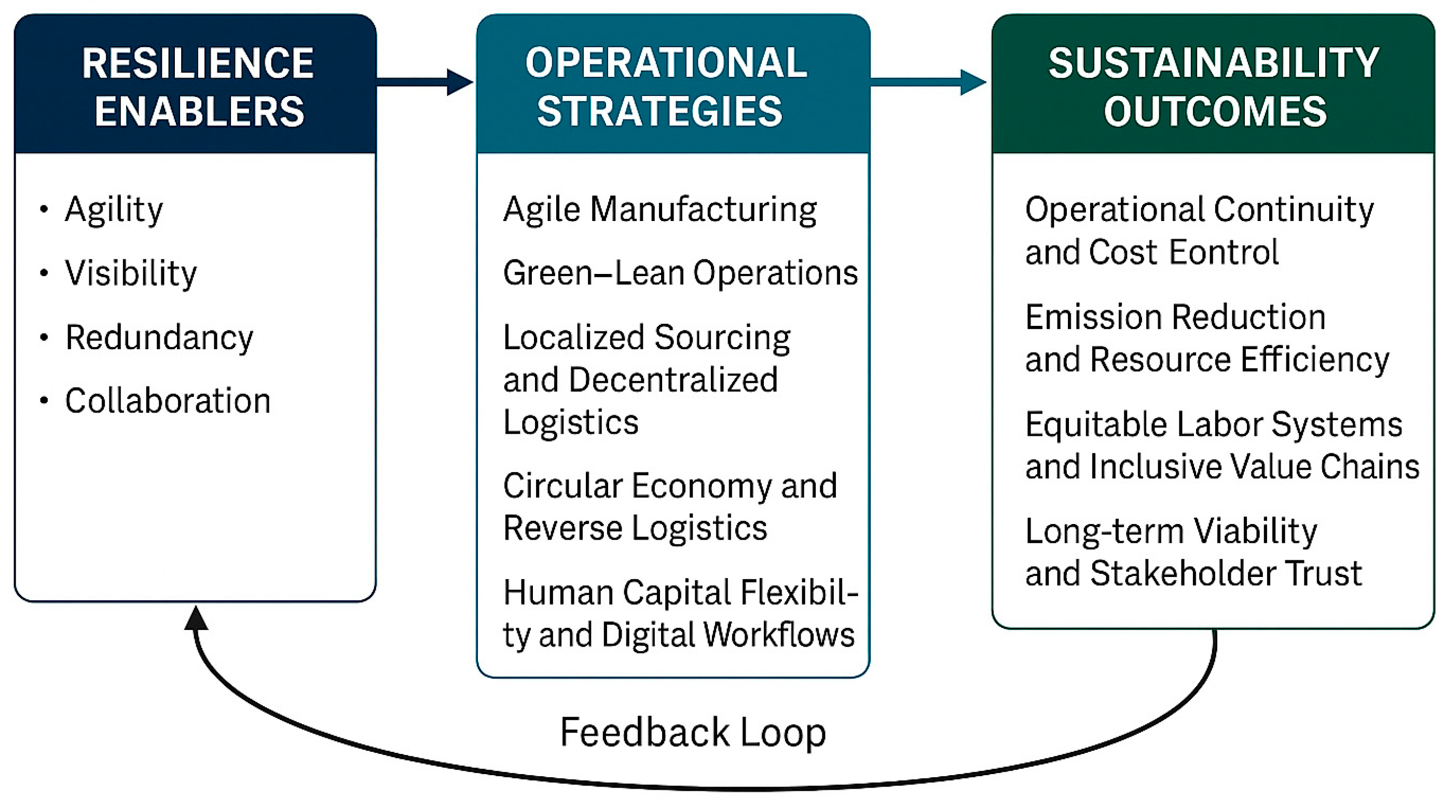

- Framework development: It introduces a conceptual model linking resilience drivers (e.g., agility, redundancy, visibility) with sustainability outcomes (e.g., emission reduction, social equity, resource efficiency), mediated by strategic operational responses.

- (4)

- Strategic typology: It proposes a typology of post-COVID-19 operational responses and classifies them based on their capacity to achieve dual resilience–sustainability goals.

- (5)

- Policy relevance: The framework provides insights for managers and policymakers seeking to future-proof supply chains against systemic risks while advancing sustainability targets.

- ▪

- Section 2 reviews theoretical foundations including Dynamic Capabilities Theory and TBL as core lenses to understand resilience–sustainability linkages.

- ▪

- Section 3 explores post-COVID-19 operational responses and classifies them through a new typology.

- ▪

- Section 4 presents the proposed conceptual framework.

- ▪

- Section 5 discusses implications for practice and policy.

- ▪

- Section 6 outlines a research agenda and interdisciplinary pathways for future work in sustainable operations.

2. Theoretical Foundations

2.1. Sustainability in Supply Chain Management (SCM)

2.2. Concept of Resilience: Definitions and Dimensions

- ▪

- Redundancy: This involves maintaining excess capacity or inventory to buffer against uncertainty.

- ▪

- Agility: This is the speed and flexibility of a system in responding to changes in demand or supply conditions.

- ▪

- Visibility: This is the degree to which a firm can monitor and interpret real-time data across the supply network.

- ▪

- Collaboration: This includes strategic partnerships that enable joint problem-solving and shared risk management [36].

2.3. Linking Operational Management with Sustainability Transitions

- ▪

- Decarbonization of supply chains, through process innovation and energy efficiency;

- ▪

- Localization and relocalization, which reduce dependency on high-emission global transportation;

- ▪

- Circular process design, where by-products are reintegrated into the value stream;

- ▪

2.4. Triple Bottom Line and UN SGD Framework in Operations

- ▪

- Economic dimension → operational efficiency, cost management, and productivity;

- ▪

- Environmental dimension → resource use optimization, waste minimization, and carbon emission reduction;

- ▪

- ▪

- Resilience offers adaptability, redundancy, and robustness;

- ▪

- Efficiency ensures productivity, cost reduction, and process optimization;

- ▪

- Sustainability anchors these efforts in long-term environmental and social responsibility.

2.5. Methodology for Conceptual Framework Development

3. Post-COVID-19 Operational Responses: Typologies and Approaches

3.1. Agile Manufacturing and Digitalization

- ▪

- Internet of Things (IoT) for real-time asset visibility, enabling the continuous monitoring of production lines, inventory, and logistics flows to enhance responsiveness;

- ▪

- Additive manufacturing for customized, small-batch production, allowing rapid prototyping and decentralized manufacturing closer to demand points;

- ▪

- AI and predictive analytics for demand sensing, supporting proactive decision-making through real-time data analysis and forecasting models;

- ▪

- Cloud platforms for integrated supply chain communication [64,65]. This view aligns with Ivanov’s conceptualization of ripple effects and supply chain adaptation under VUCA (Volatility, Uncertainty, Complexity, Ambiguity) conditions, where agile digital strategies play a central role in mitigating disruption propagation and enhancing operational resilience [66]

- ▪

- Degree of system adaptability (from rigid to reconfigurable);

- ▪

- Level of digital integration (from analog to fully connected systems);

- ▪

- Sustainability alignment (from efficiency-driven to purpose-driven agility).

3.2. Lean and Green Operations

- ▪

- Carbon emissions;

- ▪

- Energy overuse;

- ▪

- Water inefficiencies;

- ▪

- Excess packaging or non-recyclable materials.

- ▪

- Process alignment: This is the extent to which lean workflows are redesigned for environmental impact.

- ▪

- Resource intelligence: This is the use of data and the IoT to track energy, emissions, and material usage in real time.

- ▪

- ▪

- Traditional lean systems that prioritize throughput and cost;

- ▪

- Green-only systems focused narrowly on compliance or CSR metrics;

- ▪

- Green–lean hybrids, which embed sustainability metrics into core operational KPIs and governance structures.

3.3. Local Sourcing and Decentralized Logistics

- ▪

- Proximity advantage: This is the degree to which geographic closeness reduces logistical complexity and exposure to disruption.

- ▪

- Resilience alignment: This is the extent to which localized systems can absorb, adapt to, and recover from external shocks.

- ▪

- ▪

- Centralized-global models: These are optimized for scale but fragile under shock.

- ▪

- Hybrid regional models: These balance efficiency with resilience, increasingly enabled by digital logistics.

- ▪

- Fully localized models: These are high in adaptability and sustainability but often constrained by scale and cost [90].

3.4. Circular Economy and Reverse Logistics

- ▪

- Design for return: This includes embedding recyclability, modularity, and disassembly into product and process design.

- ▪

- Flow inversion: This includes integrating reverse logistics infrastructure into supply chain networks, including collection, sorting, and redistribution.

- ▪

- ▪

- Linear operations, which treat post-consumption materials as externalities;

- ▪

- Partially circular systems, which adopt basic recycling or take-back schemes;

- ▪

3.5. Human Capital and Workforce Flexibility

- ▪

- Functional flexibility: This is the employees’ ability to switch tasks and roles as operational needs shift.

- ▪

- Numerical flexibility: This includes adjusting workforce size or schedules in response to demand volatility.

- ▪

- Cognitive and behavioral flexibility: This is the cultural and psychological capacity to adapt, learn, and lead under uncertainty [112].

4. Toward a Resilient and Sustainable Supply Chain Model

4.1. Systems Thinking and Life Cycle Perspective

- ▪

- ▪

- From optimization to optimization over time: Decisions are evaluated not only based on immediate outputs but also on long-term externalities and systemic implications.

- ▪

- From firm-centric to network-centric governance: Responsibility for resilience and sustainability is distributed across the supply network, involving suppliers, partners, communities, and consumers [124].

- ▪

- Resilience drivers (e.g., agility, visibility, collaboration);

- ▪

- Operational responses (e.g., digitalization, localization, circularity);

- ▪

- Sustainability outcomes (e.g., emission reduction, social equity, long-term viability).

4.2. Integrated Risk Management in Global Supply Network

- ▪

- ▪

- Distributed governance and decision-making: This involves empowering regional and local nodes to respond autonomously while aligning with global strategy, thus enhancing responsiveness without compromising coordination [132].

- ▪

- Scenario planning and adaptive capabilities: This involves moving beyond probabilistic assessments to include what-if simulations, stress testing, and system learning, enabling organizations to prepare for high-impact, low-probability events [133].

4.3. Role of Data Analytics and Real-Time Monitoring

- ▪

- Descriptive analytics: This includes providing retrospective insight (e.g., KPI dashboards, carbon footprint reporting).

- ▪

- Diagnostic analytics: This includes identifying root causes and performance gaps.

- ▪

- Predictive analytics: This includes using AI/ML to anticipate disruptions, demand fluctuations, or sustainability risks.

- ▪

- ▪

- Detect deviations or disruptions early (e.g., delayed shipments, quality failures);

- ▪

- Reconfigure production plans or sourcing routes in response;

- ▪

- ▪

- The continuous tracking of energy and resource usage;

- ▪

- The monitoring of supplier compliance with ESG standards;

- ▪

4.4. Conceptual Framework: Operational Drivers of Sustainable Resilience

- ▪

- Resilience and sustainability are mutually reinforcing, not mutually exclusive. Resilient operations that can withstand disruptions are more likely to maintain progress in long-term sustainability goals, while sustainability-oriented practices (e.g., localization, circularity) inherently reduce exposure to systemic risks.

- ▪

- Operational decisions are the bridge between organizational capabilities and sustainability performance. These decisions are not neutral—they reflect embedded values, risk tolerance, and strategic priorities.

- ▪

- External disruptions act as catalysts, not constraints, for transformation. They reveal system fragilities and create momentum for redesigning supply chains toward adaptive, ethical, and regenerative logics.

- (1)

- Resilience Enablers:

- ▪

- Agility: This is the ability to respond rapidly and reconfigure resources.

- ▪

- Visibility: This involves transparency across supply chain tiers enabled by data and digital tools.

- ▪

- Redundancy: This is the strategic buffering of capacity, inventory, or supplier options.

- ▪

- (2)

- Operational Strategies:

- ▪

- Agile manufacturing;

- ▪

- Green–lean operations;

- ▪

- Localized sourcing and decentralized logistics;

- ▪

- Circular economy and reverse logistics;

- ▪

- Human capital flexibility and digital workflows (see Section 3.1, Section 3.2, Section 3.3, Section 3.4 and Section 3.5).

- (3)

- Sustainability Outcomes:

- ▪

- Operational continuity and cost control;

- ▪

- Emission reduction and resource efficiency;

- ▪

- Equitable labor systems and inclusive value chains;

- ▪

5. Implications and Policy Perspectives

5.1. Managerial Implications for Operations Leaders

- ▪

- Operational resilience must be designed, not improvised.Leaders must proactively build agility, visibility, and collaboration into systems architecture, treating resilience enablers as core capabilities—rather than reactive add-ons after disruptions have occurred.

- ▪

- Efficiency can no longer be decoupled from sustainability.

- ▪

- Technology must serve system-level goals, not just automation.

- ▪

- Human capital must be managed as an adaptive system.

- ▪

- Localization and decentralization are strategic, not merely logistical.Regional sourcing and distributed logistics are not only tools for reducing lead times—they are key mechanisms for strengthening resilience and enabling place-based sustainability initiatives.

- ▪

- In Southeast Asia, operations leaders should engage with frameworks such as the ASEAN Green Logistics Vision and Regional Action Plan on Sustainable Transport, ensuring that their logistics strategies align with cross-border climate adaptation goals and regional sustainability pathways.

- ▪

5.2. Public Policy and Institutional Support

- ▪

- National sustainability strategies (e.g., low-carbon logistics roadmaps);

- ▪

- Regional integration frameworks (e.g., ASEAN Sustainable Connectivity Plan);

- ▪

- International regulatory regimes (e.g., WTO green trade principles, ISO standards);

- ▪

- (1)

- Infrastructure and Innovation Support:

- ▪

- Funding for renewable energy integration into industrial zones;

- ▪

- Public–private partnerships for circular economy innovation;

- ▪

- (2)

- Regulatory Harmonization and Incentive Alignment:

- (3)

- Institutional Learning and Adaptive Governance:

5.3. Link to UN SGDs and Global Development Goals

- SDG 9—Industry, Innovation, and Infrastructure:

- SDG 12—Responsible Consumption and Production:

- SDG 13—Climate Action:

- SDG 8—Decent Work and Economic Growth:

- SDG 17—Partnerships for the Goals:

- ▪

- SDG 3 (Good Health and Well-being) through safe working conditions and the supply of essential goods;

- ▪

- SDG 11 (Sustainable Cities and Communities) through localized logistics and reduced environmental pressures;

- ▪

- SDG 16 (Peace, Justice, and Strong Institutions) via transparent and accountable operations.

- ▪

- The ASEAN Sustainable Urbanization Strategy;

- ▪

- The African Continental Free Trade Area (AfCFTA) and its green industrialization agenda;

- ▪

- The G20 Action Plan for Resilient Supply Chains;

- ▪

- The UN Global Compact’s CEO Water Mandate and Climate Ambition Accelerator.

5.4. Future Directions for Practice

- (1)

- Operationalization through Capability Maturity Models (CMMs):

- (2)

- Embedding SDG Alignment into Procurement and Supplier Criteria:

- (3)

- Investment in Cross-Functional Training and Learning Systems:

- (4)

- Piloting Localized, Low-Carbon Logistics Models:

- (5)

- Partnership with Public and Civic Institutions:

- (6)

- Governance Innovation for Internal Alignment:

6. Research Agenda and Future Directions

6.1. Emerging Research Question on Sustainable Operations

- A.

- Theoretical Expansion and Critical Interrogation:

- ▪

- How do firms navigate trade-offs between operational resilience and sustainability in resource-constrained environments?Are these trade-offs real or constructed? How do they differ by sector or region?

- ▪

- What are the temporal dynamics between resilience investments and sustainability outcomes?Do certain resilience capabilities (e.g., redundancy) provide short-term security but undermine long-term sustainability?

- ▪

- How do institutional logics (e.g., compliance, competitiveness, climate responsibility) shape the configuration of operational strategies?Can these logics be harmonized through managerial sensemaking or do they produce fragmentation?

- ▪

- What are the epistemic risks of overly technocratic approaches to resilience and sustainability?How might datafication, automation, or over-standardization limit systemic learning or exclude vulnerable actors?

- B.

- Empirical Validation and Model Testing:

- ▪

- Quantitative hypothesis testing:

- ✓

- Use Structural Equation Modeling (SEM) or Partial Least Squares (PLS) to test the causal pathways among resilience enablers, operational strategies, and sustainability outcomes.

- ✓

- Example hypotheses:

- H1: Visibility positively moderates the relationship between agility and operational continuity.

- H2: The integration of green–lean operations mediates the relationship between collaboration and emission reduction.

- ▪

- Longitudinal case studies:This involves tracking how operational configurations evolve over time under different types of disruptions (e.g., health, geopolitical, environmental). The focus is on learning dynamics, capability adaptation, and strategic reintegration post shock.

- ▪

- Comparative analysis across institutional contexts:This involves investigating how public policy environments, industry norms, or national sustainability agendas shape adoption of operational strategies. This approach is particularly relevant in comparing developed vs. emerging economies or regulated vs. loosely governed sectors.

- ▪

- Network-based analysis:This involves using social network analysis or System Dynamics Modeling to study the interdependencies and diffusion of resilient–sustainable practices across supply networks.

- C.

- Methodological Innovation and Integration:

- ▪

- Designing hybrid methods that combine survey data with digital trace data (e.g., sensor data, ESG ratings, emission dashboards);

- ▪

- Developing resilience–sustainability scoring tools or Capability Maturity Models (CMMs) for firm benchmarking and policy evaluation;

- ▪

- Leveraging AI-driven literature mapping or bibliometric analysis to detect emerging themes, clusters, and theoretical blind spots in the sustainable operations literature.

- D.

- Theoretical Invitation to Expand the Debate:

- ▪

- Integrate feminist perspectives on care, interdependence, and vulnerability in resilience design;

- ▪

- Apply critical theory to challenge assumptions about efficiency, growth, and managerialism;

- ▪

- Explore indigenous and vernacular knowledge systems in conceptualizing circularity or community-based resilience.

6.2. Methodological Suggestions for Empirical Validation

- A.

- Quantitative Approaches for Hypothesis Testing:

- ▪

- Structural Equation Modeling (SEM) or Partial Least Squares (PLS):These techniques allow for the simultaneous analysis of latent variables and multi-path relationships, enabling researchers to examine how resilience enablers (e.g., agility, collaboration) impact sustainability outcomes through mediating operational strategies.

- ▪

- Survey-based Measurement Models:This includes developing and validating measurement instruments for constructs such as

- ▪

- Multi-group SEM or Multi-level Modeling:This includes exploring differences across sectors, regions, firm sizes, or governance types—identifying boundary conditions and context-specific dynamics.

- B.

- Qualitative and Mixed Methods for Theory Building:

- ▪

- Longitudinal Case Studies:

- ▪

- Process Tracing:This includes analyzing causal mechanisms and temporal sequences in the adoption of resilience or sustainability practices—useful for identifying tipping points, tensions, and unintended consequences.

- ▪

- Grounded Theory:Applied in settings where empirical knowledge is scarce (e.g., Global South supply chains, informal economies), grounded theory allows for conceptual emergence from lived experiences rather than imposing predefined models.

- ▪

- Embedded Ethnography or Participatory Action Research (PAR):This is particularly relevant in sustainability-focused operations involving local communities, labor groups, or multi-stakeholder governance—where values, power, and narrative matter as much as processes.

- C.

- Systems-Based and Computational Modeling:

- ▪

- System Dynamics Modeling (SDM):This involves simulating feedback loops, delays, and trade-offs between resilience and sustainability over time.

- ▪

- Agent-Based Modeling (ABM):This is useful for modeling heterogeneity across supply chain actors and exploring emergent behaviors from decentralized decision-making.

- ▪

- Bayesian Networks:

- D.

- Data Integration and Digital Trace Analysis:

- ▪

- IoT-generated operational data (e.g., energy use, production flow);

- ▪

- ESG disclosures and sustainability ratings;

- ▪

- Social media or platform-based data from supply chain participants.

6.3. Interdisciplinary Integration Opportunities

- A.

- Sustainability Science and Environmental Economics:

- B.

- Organizational Behavior and Human Resource Development:

- C.

- Political Science and Institutional Theory:

- D.

- Ethics, Philosophy, and Critical Theory:

- E.

- Information Systems and Data Science:

Closing Reflection

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SCM | Supply Chain Management |

| TBL | Triple Bottom Line |

| SDGs | Sustainable Development Goals |

| VUCA | Volatility, Uncertainty, Complexity, and Ambiguity |

| CE | Circular Economy |

| RL | Reverse Logistics |

| IRM | Integrated Risk Management |

| ICT | Information and Communication Technology |

| IoT | Internet of Things |

| ESG | Environmental, Social, and Governance |

| ASEAN | Association of Southeast Asian Nations |

| EU | European Union |

| HRM | Human Resource Management |

| LCA | Life Cycle Assessment |

Appendix A. Definitions of Key Concepts

| Term | Definition |

| Resilience | The capability of a supply chain or operational system to anticipate, prepare for, respond to, and recover from disruptions while maintaining functionality. |

| Sustainability | The pursuit of environmental, social, and economic goals in operations and supply chains, aligned with long-term planetary and societal well-being. |

| Agile Manufacturing | A production strategy focused on flexibility, responsiveness, and quick adaptation to changes in demand or supply, often enabled by digital technologies. |

| Green Operations | Operational practices aimed at reducing environmental impact through eco-efficiency, circularity, and resource optimization. |

| Lean Operations | A management philosophy centered on waste elimination, continuous improvement, and process efficiency. |

| Green–Lean Operations | An integrated approach combining lean efficiency with environmental goals to achieve both economic and ecological performance. |

| Operational Efficiency | The ability of a system to deliver products or services using minimal resources while maximizing performance and output. |

| VUCA | An acronym describing environments characterized by Volatility, Uncertainty, Complexity, and Ambiguity. |

Appendix B. Theoretical and Analytical Frameworks Referenced

| Framework/Theory | Description and Relevance to Study |

| Triple Bottom Line (TBL) | A sustainability framework emphasizing the balance of environmental, social, and economic performance in operations and supply chain strategies. |

| VUCA Framework | Describes the volatile, uncertain, complex, and ambiguous conditions affecting global operations—used to frame resilience and agility needs. |

| Lean Thinking | A systematic method for waste reduction without sacrificing productivity—applied in discussions on efficiency and green–lean integration. |

| Circular Economy (CE) | An economic model focused on resource loops and minimizing waste, closely linked to green operations and reverse logistics practices. |

| Integrated Risk Management (IRM) | A holistic approach to identifying, assessing, and mitigating risks across supply chain tiers—relevant in discussions of operational resilience. |

| Agile Supply Chain Framework | A framework highlighting responsiveness, modularity, and rapid reconfiguration capabilities in dynamic environments. |

| Dynamic Capabilities Theory | The capacity of an organization to purposefully adapt and reconfigure internal and external competencies—supports sustainability and resilience transitions. |

| Industry 4.0 Paradigm | Emphasizes digital transformation through the IoT, AI, robotics, and cloud platforms—used to frame the digital enablement of agile and resilient operations. |

| Green–Lean Framework | The integration of lean practices and environmental considerations to simultaneously achieve operational efficiency and ecological sustainability. |

| SDG Alignment Framework | Operational goals and outcomes are mapped to Sustainable Development Goals (SDGs), particularly SDG 9, 12, and 13, to evaluate sustainability performance. |

References

- Wu, Z.; Oger, R.; Lauras, M.; Faugère, L.; Montreuil, B. A guiding framework for hyperconnected circular supply chain implementation. J. Clean. Prod. 2025, 501, 145229. [Google Scholar] [CrossRef]

- Parkouhi, S.V.; Lajimi, H.F.; Arab, A.; Vandchali, H.R. A hybrid BWM-DGRA approach for enhancing the resilience and sustainability of the ports. J. Clean. Prod. 2025, 509, 145588. [Google Scholar] [CrossRef]

- Reuters, T. 2025’s Supply Chain Challenge: Confronting Complexity and Disruption in Global Trade. Available online: https://tax.thomsonreuters.com/blog/2025s-supply-chain-challenge-confronting-complexity-and-disruption-in-global-trade-tri/?utm_source=chatgpt.com (accessed on 15 May 2025).

- Shi, J.; Sun, M.; Yang, X.; Jing, K.; Lai, K.K. Evaluating supply chain finance risks in a cross-border e-commerce context: An improved TOPSIS approach with loss penalty. Inf. Sci. 2025, 717, 122301. [Google Scholar] [CrossRef]

- Mukuruva, B. Precarity and essential work: Exploring the vulnerabilities of cross-border truck drivers during the COVID-19 pandemic through the lens of biopolitics. Discov. Glob. Soc. 2025, 3, 34. [Google Scholar] [CrossRef]

- Baertlein, L.-R. Ocean Cargo Rates Climb After New Red Sea Ship Attacks. Available online: https://www.reuters.com/markets/commodities/ocean-cargo-rates-climb-after-new-red-sea-ship-attacks-2024-01-03/?utm_source=chatgpt.com (accessed on 26 June 2025).

- Qu, C.; Zeng, Q.; Wang, G.W.Y. Modelling the procurement process and production disruption of a multilayer cruise supply chain. Marit. Policy Manag. 2020, 47, 435–455. [Google Scholar] [CrossRef]

- Liu, N.; Ren, S. Production disruption in supply chain systems: Impacts on consumers, supply chain agents and the society. Ann. Oper. Res. 2025, 344, 965–988. [Google Scholar] [CrossRef]

- Iccwbo. The Economic Cost of Extreme Weather Events. Available online: https://iccwbo.org/wp-content/uploads/sites/3/2024/11/2024-ICC-Oxera-The-economic-cost-of-extreme-weather-events.pdf?utm_source=chatgpt.com (accessed on 26 June 2025).

- World Bank Group. Climate Change. Available online: https://www.worldbank.org/en/topic/climatechange/overview?utm_source=chatgpt.com (accessed on 26 June 2025).

- Fan, W.; Anser, M.K.; Nasir, M.H.; Nazar, R. Uncertainty in firm innovation scheme and impact of green fiscal policy; Economic recovery of Chinese firms in the post-Covid-19 era. Econ. Anal. Policy 2023, 78, 1424–1439. [Google Scholar] [CrossRef]

- Badar, M.A.; Gupta, R.; Srivastava, P.; Ali, I.; Cudney, E.A. Handbook of Digital Innovation, Transformation, and Sustainable Development in a Post-Pandemic Era; Taylor & Francis Group: Abingdon, UK, 2024. [Google Scholar] [CrossRef]

- Sharma, M.; Kaushal, D.; Joshi, S.; Luthra, S. Resilience Through Low-Carbon Supply Chain Integration in Industry 4.0-Led Firms: A Moderated-Mediation Effect of Supplier Environmental Commitment. Bus. Strategy Environ. 2025, 34, 4679–4694. [Google Scholar] [CrossRef]

- Duong, L.; Sanderson, H.S.; Phillips, W.; Uwalaka, V.; Roehrich, J.K. Achieving resilient supply chains: Managing temporary healthcare supply chains during a geopolitical disruption. Int. J. Oper. Prod. Manag. 2025, 45, 1090–1118. [Google Scholar] [CrossRef]

- Shekarabi, S.A.H.; Mavi, R.K.; Macau, F.R. An extended robust optimisation approach for sustainable and resilient supply chain network design: A case of perishable products. Eng. Appl. Artif. Intell. 2025, 152, 110846. [Google Scholar] [CrossRef]

- Babu, K.V.S.M.; Dwivedi, D.; Pal, M.; Chakraborty, P.; Yemula, P.K. A comprehensive review on resilience definitions, frameworks, metrics, and enhancement strategies in electrical distribution systems. Appl. Energy 2025, 394, 126141. [Google Scholar] [CrossRef]

- Alquraish, M. Digital Transformation, Supply Chain Resilience, and Sustainability: A Comprehensive Review with Implications for Saudi Arabian Manufacturing. Sustainability 2025, 17, 4495. [Google Scholar] [CrossRef]

- Akash, M.H.; Aziz, R.A.; Karmaker, C.L.; Bari, A.B.M.M.; Kabir, K.M.A.; Islam, A.R.M. Investigating the attributes for implementing circular economy in the textile manufacturing supply chain: Implications for the triple bottom line of sustainability. Sustain. Horiz. 2025, 14, 100129. [Google Scholar] [CrossRef]

- Sithi, S.S.; Dhrubo, A.T.; Rony, A.H.; Ara, M.A.; Shabur, M.A. Sustainable supplier selection in the textile industry using triple bottom line and SWARA-TOPSIS approaches. Discov. Sustain. 2025, 6, 344. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Chen, C.-C.; Wu, K.-J.; Tan, R. Eco-efficient sustainable service supply chain management hierarchical model based on qualitative information and quantitative data. Manag. Environ. Qual. Int. J. 2020, 31, 961–984. [Google Scholar] [CrossRef]

- Nasrollah, S.; Najafi, S.E.; Bagherzadeh, H.; Rostamy-Malkhalifeh, M. An enhanced PSO algorithm to configure a responsive-resilient supply chain network considering environmental issues: A case study of the oxygen concentrator device. Neural. Comput. Appl. 2023, 35, 2647–2678. [Google Scholar] [CrossRef]

- Abuzawida, S.S.; Alzubi, A.B.; Iyiola, K. Sustainable Supply Chain Practices: An Empirical Investigation from the Manufacturing Industry. Sustainability 2023, 15, 14395. [Google Scholar] [CrossRef]

- Saha, K.; Farhanj, Z.; Kumar, V. A systematic review of circular economy literature in healthcare: Transitioning from a ‘post-waste’ approach to sustainability. J. Clean. Prod. 2025, 505, 145427. [Google Scholar] [CrossRef]

- Jayalath, M.M.; Ratnayake, R.M.C.; Perera, H.N.; Thibbotuwawa, A. Harvesting sustainability: Transforming traditional agri-food supply chains with circular economy in developing economies. Clean. Waste Syst. 2025, 11, 100264. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Bai, T. International digital trade and synergetic control of pollution and carbon emissions: Theory and evidence based on a nonlinear framework. J. Environ. Manag. 2025, 376, 124450. [Google Scholar] [CrossRef]

- Chen, F.; Zhu, L.; Li, Y.; Zhang, H. Innovation-driven cities: Reconciling economic growth and ecological sustainability. Sustain. Cities Soc. 2025, 121, 106230. [Google Scholar] [CrossRef]

- Silva, S.; Sá, J.C.; Silva, F.J.G.; Ferreira, L.P.; Santos, G. Lean Green—The Importance of Integrating Environment into Lean Philosophy—A Case Study; Springer: Berlin/Heidelberg, Germany, 2020; Volume 122. [Google Scholar] [CrossRef]

- Cao, R.Q.; Trimi, S.; Schniederjans, D.G. Ambidextrous supply chain strategy: Roles and consequences with agile manufacturing and resilience. Int. J. Logist. Manag. 2024, 35, 1981–2011. [Google Scholar] [CrossRef]

- Mishra, N.K.; Sharma, P.P.; Chaudhary, S.K. Redefining agile supply chain practices in the disruptive era: A case study identifying vital dimensions and factors. J. Glob. Oper. Strateg. Sourc. 2025, 18, 64–90. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhu, L.; Tu, M.; Shi, Y.; Venkatesh, V.G. Exploring the impact of building an agile automotive supply chain ecosystem on business performance: A social media perspective. Int. J. Logist. Manag. 2025, 36, 322–345. [Google Scholar] [CrossRef]

- Helmrich, A.; Kuhn, A.; Roque, A.; Santibanez, A.; Kim, Y.; Grimm, N.B.; Chester, M. Interdependence of social-ecological-technological systems in Phoenix, Arizona: Consequences of an extreme precipitation event. J. Infrastruct. Preserv. Resil. 2023, 4, 19. [Google Scholar] [CrossRef]

- Wachter, C.; Beckschulte, S.; Hinrichs, M.P.; Sohnius, F.; Schmitt, R.H. Strategies for Resilient Manufacturing: A Systematic Literature Review of Failure Management in Production. Procedia CIRP 2024, 130, 1393–1402. [Google Scholar] [CrossRef]

- Arias-Vargas, M.; Sanchis, R.; Poler, R. Capitalising Artificial Intelligence Capabilities to Foster Disruptive Events Anticipation and Proactive Resilience. Decis. Sci. 2025, 14778, 306–319. [Google Scholar] [CrossRef]

- Kang, P.S.; Bhawna, B. Enhancing supply chain resilience through supervised machine learning: Supplier performance analysis and risk profiling for a multi-class classification problem. Bus. Process Manag. J. 2025, in press. [CrossRef]

- Chan, T.H.Y. How does bike-sharing enable (or not) resilient cities, communities, and individuals? Conceptualising transport resilience from the socio-ecological and multi-level perspective. Transp. Policy 2025, 163, 247–261. [Google Scholar] [CrossRef]

- Izdori, F.J.; Mkwambisi, D.; Karuaihe, S.T.; Papargyropoulou, E. Multi-stakeholder collaboration framework for post-harvest loss reduction: The case of tomato value chain in Iringa and Morogoro regional in Tanzania. Agric. Food Econ. 2025, 13, 6. [Google Scholar] [CrossRef]

- Shafiabady, N.; MohammadiSavadkoohi, E.; Vakilian, J.; Hadjinicolaou, N.; Hettikankanamage, N.; Wu, R.M.X. eXplainable Artificial Intelligence (XAI) for improving organisational regility. PLoS ONE 2024, 19, e0301429. [Google Scholar] [CrossRef]

- Rivero-Villar, A.; Vieyra, A. Traditional Governance in the Coproduction of Urban Resilience: Institutional Enablers and Political Constraints. Int. J. Urban. Reg. Res. 2025, 49, 632–659. [Google Scholar] [CrossRef]

- Alamoodi, A.H.; Albahri, O.S.; Albahri, A.S.; Sharaf, I.M. Sustainability Transitions and Their Relationship to Digital Technology; Academic Press: Cambridge, MA, USA, 2024. [Google Scholar] [CrossRef]

- Derwort, P.; Jager, N.; Newig, J. How to Explain Major Policy Change Towards Sustainability? Bringing Together the Multiple Streams Framework and the Multilevel Perspective on Socio-Technical Transitions to Explore the German ‘Energiewende’. Policy Stud. J. 2022, 50, 671–699. [Google Scholar] [CrossRef]

- Radke, A.M.; Wuest, T.; Romero, D. Business Processes Digitalization as a Resolution Direction for Digital Operations Challenges in Digital Supply Networks. In Proceedings of the Conference on Production Systems and Logistics; University of Hanover: Hanover, Germany, 2022; pp. 693–702. [Google Scholar] [CrossRef]

- Kang, Y.; Dong, P.; Ju, Y.; Zhang, T. Differential game theoretic analysis of the blockchain technology investment and carbon reduction strategy in digital supply chain with government intervention. Comput. Ind. Eng. 2024, 189, 109953. [Google Scholar] [CrossRef]

- Schandl, H.; Boxall, N.J.; MacMillan, C.; Porter, N.; Terhorst, A.; Kong, T.; Walton, A.; Skidmore, M.; Muhlhausler, B.; Hodgkinson, J.; et al. Mission-Oriented Research and Theory of Change: Driving Australia’s Transition to a Circular Economy. Circ. Econ. Sustain. 2025, 5, 837–850. [Google Scholar] [CrossRef]

- Alqassimi, O. Innovative Pathways to Net-Zero: The Role of Startups in Accelerating Circular Economy Transitions. Int. Rev. Manag. Mark. 2025, 15, 266–274. [Google Scholar] [CrossRef]

- Aransyah, M.F.; Hermanto, B.; Muftiadi, A.; Oktadiana, H. Exploring sustainability oriented innovations in tourism: Insights from ecological modernization, diffusion of innovations, and the triple bottom line. Cogent. Soc. Sci. 2025, 11, 2447396. [Google Scholar] [CrossRef]

- Rasheed, U.; Ordaz, C.; Xu, X.; Hu, Y.; Li, S.; Sutton, T.; Cai, J. Understanding the Impact of Teleoperation Technology on the Construction Industry: Adoption Dynamics, Workforce Perception, and the Role of Broader Workforce Participation. J. Constr. Eng. Manag. 2025, 151, 16433. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. Industry 5.0 and Triple Bottom Line Approach in Supply Chain Management: The State-of-the-Art. Sustainability 2023, 15, 5712. [Google Scholar] [CrossRef]

- Machado, E.A.; Scavarda, L.F.; Caiado, R.G.G.; Santos, R.S. Industry 4.0 and Sustainability Integration in the Supply Chains of Micro, Small, and Medium Enterprises through People, Process, and Technology within the Triple Bottom Line Perspective. Sustainability 2024, 16, 1141. [Google Scholar] [CrossRef]

- Awan, U.; Kraslawski, A.; Huiskonen, J. Governing interfirm relationships for social sustainability: The relationship between governance mechanisms, sustainable collaboration, and cultural intelligence. Sustainability 2018, 10, 4473. [Google Scholar] [CrossRef]

- Hąbek, P.; Lavios, J.J. Striving for enterprise sustainability through supplier development process. Energies 2021, 14, 6256. [Google Scholar] [CrossRef]

- Hoang, D. Labour standards in the global supply chain: Workers’ agency and reciprocal exchange perspective. Societies 2019, 9, 38. [Google Scholar] [CrossRef]

- Hughes, A.; Morrison, E.; Ruwanpura, K.N. Public sector procurement and ethical trade: Governance and social responsibility in some hidden global supply chains. Trans. Inst. Br. Geogr. 2019, 44, 242–255. [Google Scholar] [CrossRef]

- Nizar, I.; Lalanie, P.P.; Amarasena, S.M. Steering towards carbon neutral transportation practices: A comprehensive analysis of the challenges confronting the shipping industry in Sri Lanka. Renew. Sustain. Energy Rev. 2025, 215, 115576. [Google Scholar] [CrossRef]

- Becha, H.; Kalai, M.; Houidi, S.; Helali, K. Digital financial inclusion, environmental sustainability and regional economic growth in China: Insights from a panel threshold model. J. Econ. Struct. 2025, 14, 4. [Google Scholar] [CrossRef]

- Florez-Jimenez, M.P.; Lleo, A.; Ruiz-Palomino, P.; Muñoz-Villamizar, A.F. Corporate sustainability, organizational resilience, and corporate purpose: A review of the academic traditions connecting them. Rev. Manag. Sci. 2025, 19, 67–104. [Google Scholar] [CrossRef]

- Nogueira, E.; Gomes, S.; Lopes, J.M. Unveiling triple bottom line’s influence on business performance. Discov. Sustain. 2025, 6, 43. [Google Scholar] [CrossRef]

- Felicioni, L.; Lupíšek, A.; Gaspari, J. Exploring the Common Ground of Sustainability and Resilience in the Building Sector: A Systematic Literature Review and Analysis of Building Rating Systems. Sustainability 2023, 15, 884. [Google Scholar] [CrossRef]

- Javed, S.; Paniagua, C.; Deventer, J.V.; Delsing, J.; Javed, I. Run-Time Value Chain Analysis and Cost Accounting via Microservices in Agile Manufacturing. IEEE Open J. Ind. Electron. Soc. 2025, 6, 181–201. [Google Scholar] [CrossRef]

- Pant, R.; Singh, R.; Gehlot, A.; Thakur, A.K. A Systematic Review of Emerging Industry 5.0 Technologies: Enhancing Agile Manufacturing for Sustainability. Oper. Res. Forum 2025, 6, 29. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, K.; Yan, T.; Cao, X. The impact of digital infrastructure on regional green innovation efficiency through industrial agglomeration and diversification. Humanit. Soc. Sci. Commun. 2025, 12, 220. [Google Scholar] [CrossRef]

- Liu, F.H.M.; Lai, K.P.Y.; Seah, B.; Chow, W.T.L. Decarbonising digital infrastructure and urban sustainability in the case of data centres. Npj Urban Sustain. 2025, 5, 15. [Google Scholar] [CrossRef]

- Lotfi, M.; Saghiri, S. Disentangling resilience, agility and leanness Conceptual development and empirical analysis. J. Manuf. Technol. Manag. 2018, 29, 168–197. [Google Scholar] [CrossRef]

- Vlachos, I.P.; Pascazzi, R.M.; Zobolas, G.; Repoussis, P.; Giannakis, M. Lean manufacturing systems in the area of Industry 4.0: A lean automation plan of AGVs/IoT integration. Prod. Plan. Control. 2023, 34, 345–358. [Google Scholar] [CrossRef]

- Zissis, D. Information sharing through digitalisation in decentralised supply chains. Ann. Oper. Res. 2023, 327, 763–778. [Google Scholar] [CrossRef]

- Chen, X.; Zong, X.; Yue, H. Construction of e-commerce cloud-based logistics service platform by communication technology. J. Comput. Methods Sci. Eng. 2024, 24, 3015–3030. [Google Scholar] [CrossRef]

- Ivanov, D.; Sokolov, B.; Dolgui, A. The Ripple effect in supply chains: Trade-off ‘efficiency-flexibility-resilience’ in disruption management. Int. J. Prod. Res. 2014, 52, 2154–2172. [Google Scholar] [CrossRef]

- Tian, G.; Yang, Y.; Zhao, M.; Tian, Y.; Zhang, X. From defensive reasoning to innovation: How digital tools foster positive emotions in organizations. BMC Psychol. 2025, 13, 146. [Google Scholar] [CrossRef]

- Kristoffersen, E.; Mikalef, P.; Li, J.; Blomsma, F. The smart circular economy: A digital-enabled circular strategies framework for manufacturing companies. J. Bus. Res. 2020, 120, 241–261. [Google Scholar] [CrossRef]

- Beier, G.; Matthess, M.; Guan, T.; Grudzien, D.I.d.O.P.; Xue, B.; de Lima, E.P.; Chen, L. Impact of Industry 4.0 on corporate environmental sustainability: Comparing practitioners’ perceptions from China, Brazil and Germany. Sustain. Prod. Consum. 2022, 31, 287–300. [Google Scholar] [CrossRef]

- Verma, N.; Sidhu, S.S.; Chatha, J.S.; Bali, S. To Study the Implementation of Kaizen in Northern Indian Manufacturing Industries; Springer: Singapore, 2023. [Google Scholar] [CrossRef]

- Womack, S.K. Toyota’s Improvement Thinking from the Inside: From Personal Transformation to Organizational Transformation; Productivity Press: New York, NY, USA, 2025. [Google Scholar] [CrossRef]

- Liu, T.; Guo, W.; Yang, S. Coupling Dynamics of Resilience and Efficiency in Sustainable Tourism Economies: A Case Study of the Beijing–Tianjin–Hebei Urban Agglomeration. Sustainability 2025, 17, 2860. [Google Scholar] [CrossRef]

- Liao, M.; Zhang, Y.; Cheung, T. Airline network response to government policies: COVID-19 and Russian airspace closure. Transp. Policy 2025, 169, 74–89. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Akubia, G.K.; Gaffar, V.; Sultan, M.A.; Andriana, D. The Impact of Green Logistics Management Practices on Manufacturing Firms’ Sustainability Performance in Ghana and Indonesia. Int. J. Supply Oper. Manag. 2025, 12, 215–235. [Google Scholar] [CrossRef]

- Halim-Lim, S.A.; Jamaludin, A.A.; Islam, A.S.M.T.; Weerabahu, S.; Priyono, A. Unlocking potential for a circular bioeconomy transition through digital innovation, lean manufacturing and green practices: A review. Manag. Environ. Qual. 2025, 36, 130–154. [Google Scholar] [CrossRef]

- Kamdar, M.; Desai, K.; Loonkar, S. Thematic Review of Green Lean Manufacturing and Process Optimization in the IT Industry. In Proceedings of the 2024 International Conference on Artificial Intelligence and Quantum Computation Based Sensor Applications Icaiqsa 2024 Proceedings, Nagpur, India, 20–21 December 2024. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Y.; Dan, B.; Zhang, X.; Sui, R. Simulation Modeling and Analysis on the Value-Added Service of the Third-Party E-Commerce Platform Supporting Multi-Value Chain Collaboration. J. Theor. Appl. Electron. Commer. Res. 2024, 19, 846–862. [Google Scholar] [CrossRef]

- Zhang, S.; Gu, F.; Gu, X.; Ji, Y.; Li, L.; Zheng, F. Blockchain-based data sharing method for multi-value chain collaboration. Jisuanji Jicheng Zhizao Xitong Comput. Integr. Manuf. Syst. C. 2024, 30, 3643–3657. [Google Scholar] [CrossRef]

- de Medeiros, N.C.; Filho, M.G.; Ganga, G.M.D.; Callefi, M.H.B.M. Employee involvement practices in lean manufacturing: A multimethod approach. Int. J. Serv. Oper. Manag. 2025, 50, 330–351. [Google Scholar] [CrossRef]

- Frank, A.G.; Benitez, G.B.; Sturgeon, T.J.; Marodin, G.A.; Cunha, S.F.E. How lean and industry 4.0 affect worker outcomes and operational performance: A quantitative assessment of competing models. Int. J. Prod. Econ. 2025, 279, 109475. [Google Scholar] [CrossRef]

- Mamoojee-Khatib, H.; Antony, J.; Teeroovengadum, V.; Garza-Reyes, J.A.; Tortorella, G.L.; Foster, M.; Cudney, E.A. A systematic review of lean implementation frameworks and roadmaps: Lessons learned and the way forward. TQM J. 2025, 37, 264–287. [Google Scholar] [CrossRef]

- Dorneanu, B.; Keykha, M.; Arellano-Garcia, H.; Masham, E.; Mechleri, E.; Cole, R. Assessment of centralised and localised ice cream supply chains using neighbourhood flow configuration models. Supply Chain. Anal. 2023, 4, 100043. [Google Scholar] [CrossRef]

- Kamble, S.; Belhadi, A.; Gupta, S.; Islam, N.; Verma, V.K.; Solima, L. Analyzing the Barriers to Building a 3-D Printing Enabled Local Medical Supply Chain Ecosystem. IEEE Trans. Eng. Manag. 2024, 71, 12974–12991. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, H.; Wang, J.; Jiang, C.; He, H.; Ding, Y. Forecasting time to risk based on multi-party data: An explainable privacy-preserving decentralized survival analysis method. Inf. Process. Manag. 2025, 62, 103881. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, B.; Yuan, D. Gossip-based asynchronous algorithms for distributed composite optimization. Neurocomputing 2025, 616, 128952. [Google Scholar] [CrossRef]

- Setyawan, E.B.; Novitasari, N. Indonesian High-Speed Railway Optimization Planning for Better Decentralized Supply Chain Implementation to Support e-Logistic Last Miles Distribution. J. Phys. Conf. Ser. 2019, 1381, 012020. [Google Scholar] [CrossRef]

- Shaviv, E.; Teschner, N.; Zemah-Shamir, S.; Parag, Y. A delicate dance: Value-added services and electricity security in decentralized systems. Energy Policy 2025, 200, 114550. [Google Scholar] [CrossRef]

- Ochoa-Barragán, R.; Ponce-Ortega, J.M.; Ramírez-Márquez, C.; Martín-Hernández, E.; Omelon, S. Strategies for phosphorus recovery in livestock operations: Assessing decentralized and distributed recovery systems. Waste Manag. 2025, 202, 114837. [Google Scholar] [CrossRef] [PubMed]

- Gimenez-Escalante, P.; Garcia-Garcia, G.; Rahimifard, S. A method to assess the feasibility of implementing distributed Localised Manufacturing strategies in the food sector. J. Clean. Prod. 2020, 266, 121934. [Google Scholar] [CrossRef]

- Li, Z.Z.; Zhao, J.; Cui, H.; Zheng, E.X.; Ma, X.; Liu, D.Y.W.; Au, M.H. Blockchain for Smart Logistics: Enhancing Identity Security, Bidding Transparency and Goods Tracking. In Proceedings of the 6th ACM International Symposium on Blockchain and Secure Critical Infrastructure—BSCI 2024, Singapore, 2 July 2024. [Google Scholar] [CrossRef]

- Babbitt, C.W.; Althaf, S.; Graedel, T.E.; Rios, F.C.; Bilec, M.M. The role of design in circular economy solutions for critical materials. One Earth 2021, 4, 353–362. [Google Scholar] [CrossRef]

- Zhu, H.; Hu, J.; Yang, Y. Towards a circular supply chain for retired electric vehicle batteries: A systematic literature review. Int. J. Prod. Econ. 2025, 282, 109556. [Google Scholar] [CrossRef]

- Werner-Lewandowska, K.; Golinska-Dawson, P.; Mierzwiak, R. Enablers and barriers in building the circular supply chain through remanufacturing—Grey DEMATEL approach. Int. J. Prod. Econ. 2025, 284, 109617. [Google Scholar] [CrossRef]

- Yu, H. Modeling a remanufacturing reverse logistics planning problem: Some insights into disruptive technology adoption. Int. J. Adv. Manuf. Technol. 2022, 123, 4231–4249. [Google Scholar] [CrossRef]

- Li, Y.; Kannan, D.; Jha, P.C.; Garg, K.; Darbari, J.; Agarwal, N. Design of a multi echelon product recovery embeded reverse logistics network for multi products and multi periods. Ann. Oper. Res. 2023, 323, 131–152. [Google Scholar] [CrossRef]

- Vargas, D.B.; Campos, L.M.D.S.; Luna, M.M.M. Brazil’s Formal E-Waste Recycling System: From Disposal to Reverse Manufacturing. Sustainability 2024, 16, 66. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Chiaraluce, G.; Bentivoglio, D.; Finco, A. Circular Economy for a Sustainable Agri-Food Supply Chain: A Review for Current Trends and Future Pathways. Sustainability 2021, 13, 9294. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Mallick, P.K.; Pigosso, D.C.A.; McAloone, T.C.; Salling, K.B. Towards a circular economy: Development of a support tool for designing reverse logistics systems. J. Environ. Manag. 2024, 351, 119819. [Google Scholar] [CrossRef]

- Camilleri, M. Cocreating Value Through Open Circular Innovation Strategies: A Results-Driven Work Plan and Future Research Avenues. Bus. Strategy Environ. 2025, 34, 4561–4580. [Google Scholar] [CrossRef]

- Bag, S.; Routray, S.; Rahman, M.S.; Gupta, S. Digital innovation for circular supply chain sustainability and resilience for achieving carbon neutrality: An empirical study. J. Environ. Manag. 2025, 386, 125665. [Google Scholar] [CrossRef] [PubMed]

- Aishwarya, V.M.; Singh, V.; Ekren, B.Y.; Singh, T. Integrating sustainability across the lifecycle of electric vehicle batteries: Circular supply chain challenges, innovations, and global policy impacts. Renew. Sustain. Energy Rev. 2025, 216, 115671. [Google Scholar] [CrossRef]

- Zeng, B.; Chotia, V.; Ghosh, V.; Cheng, J. Digital antecedents and mechanisms towards sustainable digital innovation ecosystems: Examining the role of circular supply chain resilience. Technol. Forecast. Soc. Change 2025, 218, 124220. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, H.; Zheng, X. Impact of government fund policy and blockchain technology on closed-loop supply chains in textile and apparel industry. J. Clean. Prod. 2024, 434, 140037. [Google Scholar] [CrossRef]

- Schneikart, G.; Mayrhofer, W.; Löffler, C.; Frysak, J. A roadmap towards circular economies in pharma logistics based on returnable transport items enhanced with Industry 4.0 technologies. Resour. Conserv. Recycl. 2024, 206, 107615. [Google Scholar] [CrossRef]

- Abdelaziz, S.; Munawaroh, M. Mitigating Supply Chain Vulnerabilities: A Bibliometric Analysis of Sustainable Logistics for Resilience and Risk Management with Perspectives on the Automotive Industry. Int. J. Automot. Sci. Technol. 2024, 8, 544–588. [Google Scholar] [CrossRef]

- Gutu, I.; Medeleanu, C.N. Assessing Teleworkforce and Electronic Leadership Favorable for an Online Workforce Sustainability Framework by Using PLS SEM. Sustainability 2023, 15, 13615. [Google Scholar] [CrossRef]

- Przybyłek, A.; Belter, D.; Conboy, K. A study of Scrum @ S&P Global in the post-COVID-19 era: Unsuitable for remote work or just flawed implementation? Inf. Softw. Technol. 2025, 183, 107728. [Google Scholar] [CrossRef]

- Jahroh, S.; Indrawan, D.; Abdullah, A.; Fahmi, I.; Junaid, Z.B.; Siddique, M. The smart and healthy city business model Canvas—A post Covid-19 resilience for smart city business modeling framework. Clin. Ehealth 2025, 8, 78–93. [Google Scholar] [CrossRef]

- Antonova, E.; Kumari, V.; Schlosser, K.; Pandey, R. Coping With COVID-19: Mindfulness-Based Approaches for Mitigating Mental Health Crisis. Front. Psychiatry 2021, 12, 563417. [Google Scholar] [CrossRef]

- Lee, J.; Song, J.H. Developing a measurement of employee learning agility. Eur. J. Train. Dev. 2022, 46, 450–467. [Google Scholar] [CrossRef]

- Tripathi, A.; Dhir, S. HRD interventions, learning agility and organizational innovation: A PLS-SEM modelling approach. Int. J. Organ. Anal. 2023, 31, 2322–2336. [Google Scholar] [CrossRef]

- Jeong, J.U. Integrating disability policies in a post-unification Korea: Insights and strategies for social and health equity. Discov. Soc. Sci. Health 2025, 5, 28. [Google Scholar] [CrossRef]

- Zhu, Q.; Basar, T. Revisiting Game-Theoretic Control in Socio-Technical Networks: Emerging Design Frameworks and Contemporary Applications. IEEE Control Syst. Lett. 2025, 9, 74–89. [Google Scholar] [CrossRef]

- Akhavantaheri, H.; Sandborn, P.; Das, D. Using sociotechnical network modeling to analyze the impact of blockchain for supply chain on the risk of procuring counterfeit electronic parts. Adv. Eng. Inform. 2025, 65, 103272. [Google Scholar] [CrossRef]

- Wilden, D.; Hopkins, J.; Sadler, I. The Utility of Critical Systems Practice: A Supply Chain Practitioner Perspective. Syst. Res. Behav. Sci. 2025, 42, 206–218. [Google Scholar] [CrossRef]

- Chen, Q.; Chen, J.; Magnusson, M. Exploring Systems Approaches to Innovation Management From Second-Order Science in the West and China: System of Systems and TiXi. Syst. Res. Behav. Sci. 2025, 42, 964–979. [Google Scholar] [CrossRef]

- Kurrahman, T.; Tsai, F.M.; Sethanan, K.; Lim, M.K.; Tseng, M.-L. Data-driven life cycle assessment of the automobile industry in Indonesia: Identifying circular supply chain enablers. Resour. Conserv. Recycl. 2025, 220, 108338. [Google Scholar] [CrossRef]

- Zamani, S.M.; Pradhan, R.; Dutta, A.; Thimmanagari, M. Supply chain design of biocarbon production from Miscanthus through hydrothermal carbonization in southern Ontario: A life cycle assessment perspective. J. Clean. Prod. 2025, 513, 145758. [Google Scholar] [CrossRef]

- Feng, N.; Ran, C. Design and optimization of distributed energy management system based on edge computing and machine learning. Energy Inform. 2025, 8, 17. [Google Scholar] [CrossRef]

- Abujassar, R.S. Intelligent IoT-driven optimization of large-scale healthcare networks: The INRwLF algorithm for adaptive efficiency. Discov. Comput. 2025, 28, 93. [Google Scholar] [CrossRef]

- Hirth, S.; Morgan, E.; Kaptan, G.; Sourd, R.C.D.; Tallontire, A.; Young, W.; Winter, M. Restoring Food System Resilience in a Turbulent World: Supply Chain Actors’ Shared Responsibility. Bus. Strategy Environ. 2025, 34, 3387–3403. [Google Scholar] [CrossRef]

- Lu, H.; Falkenberg, L.; Liu, X. Investigating the Impact of Corporate Social Responsibility (CSR) on Risk Management Practices. Bus. Soc. 2022, 61, 496–534. [Google Scholar] [CrossRef]

- Klein, V.H., Jr.; Reilley, J.T. The temporal dynamics of enterprise risk management. Crit. Perspect. Account. 2024, 99, 102363. [Google Scholar] [CrossRef]

- Singh, K.; Senthilkumar, D.V.; Chandrasekar, V.K.; Zou, W.; Kurths, J. Graph coloring framework to mitigate cascading failure in complex networks. Commun. Phys. 2025, 8, 170. [Google Scholar] [CrossRef]

- Zheng, X.; Li, H.; Liu, X.; Wang, X.; Zhang, Y.; Tang, Q.; Ren, B. Supply risk propagation in international trade networks of the tungsten industry chain. Humanit. Soc. Sci. Commun. 2025, 12, 54. [Google Scholar] [CrossRef]

- Li, L.; Liu, Y.; Jin, Y.; Cheng, T.C.E.; Zhu, X. The Interplay Between Supply Chain Transparency and Visibility: Implications for Firm Performance in Manufacturing and Service Sectors. J. Bus. Logist. 2025, 46, e70016. [Google Scholar] [CrossRef]

- Fani, V.; Bandinelli, R.; Ciccullo, F.; Pero, M. Cultivating trust: An empirical exploration of blockchain’s adoption within the Italian wine supply chain. Electron. Mark. 2025, 35, 35. [Google Scholar] [CrossRef]

- Pongnumkul, S.; Ittipornpaisarn, P.; Pongnumkul, S. Comparison of blockchain vs. centralised IT infrastructure costs for food traceability: A Thai broiler supply chain case study. J. Innov. Entrep. 2025, 14, 13. [Google Scholar] [CrossRef]

- Chatfield, A.T.; Reddick, C.G. Collaborative Network Governance Framework for Aligning Open Justice and e-Justice Ecosystems for Greater Public Value. Soc. Sci. Comput. Rev. 2020, 38, 252–273. [Google Scholar] [CrossRef]

- Li, H.; Jiang, Y.; Mi, Y.; Liu, G.; Ye, X. Multi-scenario planning of pelagic island microgrid with generalized energy storage under the influence of typhoon. Electr. Power Syst. Res. 2023, 224, 109747. [Google Scholar] [CrossRef]

- Elhoushy, S.; Ribeiro, M.A. Socially responsible consumers and stockpiling during crises: The intersection of personal norms and fear. Soc. Responsib. J. 2024, 20, 180–203. [Google Scholar] [CrossRef]

- Hägele, L.; Klier, M.; Moestue, L.; Obermeier, A. Aspect-based currency of customer reviews: A novel probability-based metric to pave the way for data quality-aware decision-making. Electron. Mark. 2025, 35, 10. [Google Scholar] [CrossRef]

- Yang, S.; Liao, H.; Wu, X. Prescriptive analytics for dynamic multi-criterion decision making considering learned knowledge of alternatives. Expert. Syst. Appl. 2025, 268, 126350. [Google Scholar] [CrossRef]

- Huang, D.; Zhang, J.; Liu, Z.; Liu, R. Prescriptive analytics for freeway traffic state estimation by multi-source data fusion. Transp. Res. E Logist. Transp. Rev. 2025, 198, 104105. [Google Scholar] [CrossRef]

- Kim, C.J.; Han, S.B.; Seo, B.W.; Bae, I.; Kim, D.; Kim, S.; Cho, Y.T. Architecture Development of Digital Twin-Based Wire Arc Directed Energy Deposition. Int. J. Precis. Eng. Manuf. Green Technol. 2025, 12, 885–904. [Google Scholar] [CrossRef]

- Tkalich, A.; Sporsem, T.; Stray, V.; Moe, N.B.; Barbala, A.; Klotins, E. User feedback in continuous software engineering: Revealing the state-of-practice. Empir. Softw. Eng. 2025, 30, 79. [Google Scholar] [CrossRef]

- Seifdar, M.H.; Amiri, B. Strategic adoption of generative AI in organizations: A game-theoretic and network-based approach. Int. J. Inf. Manag. 2025, 84, 102932. [Google Scholar] [CrossRef]

- Hartl, B.; Levin, M.; Zöttl, A. Neuroevolution of decentralized decision-making in N-bead swimmers leads to scalable and robust collective locomotion. Commun. Phys. 2025, 8, 194. [Google Scholar] [CrossRef]

- Strelets, K.; Zaborova, D.; Kokaya, D.; Petrochenko, M.; Melekhin, E. Building Information Modeling (BIM)-Based Building Life Cycle Assessment (LCA) Using Industry Foundation Classes (IFC) File Format. Sustainability 2025, 17, 2848. [Google Scholar] [CrossRef]

- Peng, X.; Zhong, W.; Zhang, T.; Shen, F.; Ding, J. Automated machine learning-assisted enhanced product carbon footprint tracking and analysis in refinery industry: A graph-based life cycle assessment framework. J. Clean. Prod. 2025, 514, 145613. [Google Scholar] [CrossRef]

- Tukiran, M.; Sofi, N.A.; Anas, W.P. A decision science approach to redesigning organizational structure: Empirical insights from business process mapping and strategy alignment. Decis. Sci. Lett. 2025, 14, 63–78. [Google Scholar] [CrossRef]

- Felipe, T.; de Oliveira, R.T.; Toth-Peter, A.; Mathews, S.; Dulleck, U. Digital transformation in commercial banks: Unraveling the flow of Industry 4.0. Digit. Bus. 2025, 5, 100129. [Google Scholar] [CrossRef]

- Lima, A.; Temby, O.; Kim, D.; Song, A.M.; Hickey, G.M. Trust and influence in the Gulf of Mexico’s fishery public management network. Sustainability 2019, 11, 6090. [Google Scholar] [CrossRef]

- Ghondaghsaz, N.; Engesser, S. Identification of factors and outcomes of trust in mobile supply chains. Eur. J. Manag. Bus. Econ. 2022, 31, 325–344. [Google Scholar] [CrossRef]

- Bühler, M.M.; Nübel, K.; Jelinek, T.; Riechert, D.; Bauer, T.; Schmid, T.; Schneider, M. Data Cooperatives as a Catalyst for Collaboration, Data Sharing and the Digital Transformation of the Construction Sector. Buildings 2023, 13, 442. [Google Scholar] [CrossRef]

- Meskarpour-Amiri, M.; Shokri, N.; Bahadori, M.; Hosseini-Shokouh, S.-M.; Aliyari, S. Strategies to reduce costs and increase revenue in hospitals: A mixed methods investigation in Iran. BMC Health Serv. Res. 2025, 25, 127. [Google Scholar] [CrossRef]

- Duan, L.; Carlino, A.; Caldeira, K. Near-term benefits from investment in climate adaptation complement long-term economic returns from emissions reduction. Commun. Earth Environ. 2025, 6, 14. [Google Scholar] [CrossRef]

- Wang, H.; Zeng, Y.; Zhang, J.; Wang, Z.; Yu, S.; Deng, Y. Sustainable performance analysis and environmental protection optimization of green entrepreneurship-driven energy enterprises. Humanit. Soc. Sci. Commun. 2025, 12, 104. [Google Scholar] [CrossRef]

- Khan, N.R.; Malik, F.; Khan, M.R.; Khan, I.; Ghouri, A.M. Organizational sustainability: The role of environmentally focused practices in enhancing environmental performance—An emerging market perspective. Discov. Sustain. 2025, 6, 73. [Google Scholar] [CrossRef]

- Junejo, I.; Sohu, J.M.; Alwadi, B.M.; Ejaz, F.; Nasir, A.; Hossain, M.B. Green supply chain management and SMEs sustainable performance in developing country: Role of green knowledge sharing, green innovation and big data-driven supply chain. Discov. Sustain. 2025, 6, 342. [Google Scholar] [CrossRef]

- Hleb, K.K.; Schara, T.; Mirvis, P.H. Responsible Leadership: Strategic Versus Integrative Practices in Complex System Transformation. Adm. Sci. 2025, 15, 145. [Google Scholar] [CrossRef]

- Jääskä, E.; Aaltonen, K.; Hellens, L.; Kujala, J. Bridging change and project management: A review and future research directions. Proj. Leadersh. Soc. 2025, 6, 100172. [Google Scholar] [CrossRef]

- Ferrazzi, M.; Costa, F.; Frecassetti, S.; Portioli-Staudacher, A. Unlocking synergies in lean manufacturing for enhanced environmental performance: A cross-sector investigation through fuzzy DEMATEL. Clean. Logist. Supply Chain. 2025, 15, 100219. [Google Scholar] [CrossRef]

- Rana, J.A.; Jani, S.Y. A Structural Framework to Achieve Operational Excellence by Adopting Sustainable Lean Six Sigma and Industry 4.0 Technologies. Int. J. Math. Eng. Manag. Sci. 2025, 10, 1080–1099. [Google Scholar] [CrossRef]

- Çömez-Dolgan, N.; Tanyeri-Günsür, B.; Mai, F.; Zhao, X.; Devaraj, S. Lean operations and firm resilience—Contrasting effects of COVID-19 and economic recession. Omega 2025, 135, 103308. [Google Scholar] [CrossRef]

- Anghel, I.; Cioara, T.; Bevilacqua, R.; Barbarossa, F.; Grimstad, T.; Hellman, R.; Solberg, A.; Boye, L.T.; Anchidin, O.; Nemes, A.; et al. New care pathways for supporting transitional care from hospitals to home using AI and personalized digital assistance. Sci. Rep. 2025, 15, 18247. [Google Scholar] [CrossRef]

- Shabur, M.A.; Ara, M.A.; Shahriar, A. From automation to collaboration: Exploring the impact of industry 5.0 on sustainable manufacturing. Discov. Sustain. 2025, 6, 341. [Google Scholar] [CrossRef]

- Basana, S.R.; Malelak, M.I.; Suprapto, W.; Tarigan, Z.J.H.; Tarigan, Z.V.B.; Doron, R.O. The influence of information technology integration on firm performance through supply chain quality and supply chain resilience. Decis. Sci. Lett. 2025, 14, 225–238. [Google Scholar] [CrossRef]

- Rapuano, V.; Valickas, A. A Model for an Organizational Career Development System Applying the Theoretical Principles of Complex Adaptive Systems|Organizacinės Karjeros Sistemos Vystymo Modelis Taikant Kompleksiškų Adaptyviųjų Sistemų Teorinius Principus. Public Policy Adm. 2023, 22, 393–404. [Google Scholar] [CrossRef]

- Janani, M.; Vijayalakshmi, V. Arts as a driver of agility: A mixed-method inquiry. Acta. Psychol. 2024, 251, 104640. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A review of bioplastics and their adoption in the circular economy. Polymers 2021, 13, 1229. [Google Scholar] [CrossRef]

- Barmparitsas, N.; Karellas, S.; Pallis, P.; Thanopoulos, S.; Kobelt, D. An Innovative Heating, Ventilation, Air Conditioning and Refrigeration Circular Economy System for Reducing Carbon Dioxide Emissions in Europe via Extensive Reuse of Existing Fluorinated Gases. Energies 2023, 16, 7705. [Google Scholar] [CrossRef]

- Berthet, E.; Lavalley, J.; Anquetil-Deck, C.; Ballesteros, F.; Stadler, K.; Soytas, U.; Hauschild, M.; Laurent, A. Assessing the social and environmental impacts of critical mineral supply chains for the energy transition in Europe. Glob. Environ. Change 2024, 86, 102841. [Google Scholar] [CrossRef]

- Gopinathan, U.; Elgersma, I.; Bjørbæk, M.; Fretheim, A.; Dalsbø, T. Strengthening research preparedness for crises: Lessons from Norwegian government agencies in using randomized trials and quasi-experimental methods to evaluate public policy interventions. Health Res. Policy Syst. 2025, 23, 8. [Google Scholar] [CrossRef]

- de Sousa, E.A.; Gonçalves, R.M.P.; de Oliveira, D.K.L.; Santana, J.S. The formulation of public policies for inclusive education in peripheral countries under the aegis of international organizations | A formulação das políticas públicas para a educação inclusiva nos países periféricos sob a égide dos organismos internacion. Acta Sci. Educ. 2025, 47, 63494. [Google Scholar] [CrossRef]

- Spatola, S. Financial Conditionality and Economic Policy Direction: The Means as a Coordinator End|Condizionalità finanziaria e indirizzo politico economico: I mezzi come fine coordinatore. Fed. It 2025, 2025, 138–167. [Google Scholar]

- Sreevidya, K.V.; Nagaraja, V. Navigating the landscape of health and hospital management in India: An analysis of hard and soft laws. Discov. Soc. Sci. Health 2025, 5, 16. [Google Scholar] [CrossRef]

- Kotukov, O.; Karamyshev, D.; Kotukova, T.; Chernoivanenko, A.; Serenok, A. Can Digital Transparency Tools Systematically Reduce Corruption in Government? Evidence from Estonia, Ukraine and Brazil. J. Theor. Appl. Inf. Technol. 2025, 103, 4256–4257. [Google Scholar]

- Jin, J.; Wang, Y. Can public data openness reduce carbon emissions of listed companies? Evidence from China. Energy Rep. 2025, 13, 5512–5524. [Google Scholar] [CrossRef]

- Cifuentes-Faura, J. Building an index based on key SDG 12 indicators to promote the transition to a circular economy. Financ. Res. Lett. 2025, 82, 107610. [Google Scholar] [CrossRef]

- Dreifke, T.; Lysychkina, I. Reference Curricula: An Impactful Tool for Institutional Capacity Building? Connections 2025, 24, 113–127. [Google Scholar] [CrossRef]

- Macedo, M.I.V.Q.; Ferreira, F.A.F.; Dabić, M.; Ferreira, N.C.M.Q.F. Structuring and analyzing initiatives that facilitate organizational transformation processes: A sociotechnical approach. Technol. Forecast. Soc. Change 2024, 209, 123739. [Google Scholar] [CrossRef]

- Perumal, E.; Krishnan, R.; Kandasamy, L.; Elaiyaraja, A.; Abirami, A. Sustainable Leadership, Employee Engagement, and Organizational Resilience: A Holistic Approach to Green Management; IGI Global: Hershey, PA, USA, 2025. [Google Scholar] [CrossRef]

- Ma, A. Relationship between carbon disclosure quality, green innovation and organizational performance under the background of carbon neutrality. Financ. Res. Lett. 2025, 82, 107524. [Google Scholar] [CrossRef]

- Huang, S.; Hu, M.; He, L.; Ren, S.; Wu, X.; Cui, S. Construction of manganese ferrite/zinc ferrite anchored graphene-based hierarchical aerogel photocatalysts following Z-scheme electron transfer for visible-light-driven carbon dioxide reduction. J. Colloid. Interface. Sci. 2025, 694, 137678. [Google Scholar] [CrossRef] [PubMed]

- Rückert, A.; Dornack, C.; Balkute, G. Calculating the Environmental Benefit of Reuse Platforms. Circ. Econ. Sustain. 2024, 4, 1913–1936. [Google Scholar] [CrossRef]

- Çetin, E.; Yıldız, İ.A.E.; Yaşar, Ç.Ö.; Yulistyorini, A. Life Cycle Assessment of Medical Waste Management: Case Study for Istanbul. Appl. Sci. 2025, 15, 4439. [Google Scholar] [CrossRef]

- Iyer, G.; Zhao, A.; Bryant, A.; Bistline, J.; Blanford, G.; Cui, R.; Fawcett, A.A.; Goldstein, R.; Levin, A.; Mahajan, M.; et al. A multi-model study to inform the United States’ 2035 NDC. Nat. Commun. 2025, 16, 643. [Google Scholar] [CrossRef]

- Das, P.; Chaturvedi, V.; Rajbanshi, J.; Khan, Z.A.; Kumar, S.; Goenka, A. A new scenario set for informing pathways to India’s next nationally determined contribution and 2070 net-zero target: Structural reforms, LIFE, and sectoral pathways. Energy Clim. Change 2025, 6, 100192. [Google Scholar] [CrossRef]

- Obergassel, W.; Beuermann, C.; Elsner, C.; de Coninck, H. The potential of international institutions to foster transitions. The example of the Global Stocktake under the Paris Agreement. Environ. Innov. Soc. Transit. 2025, 57, 101005. [Google Scholar] [CrossRef]

- Sotnyk, I.; Sasse, J.-P.; Trutnevyte, E. Decarbonizing Ukraine’s electricity sector in 2035: Scenario analysis. Energy Clim. Change 2025, 6, 100170. [Google Scholar] [CrossRef]

- Sellami, I.; Amin, H.; Ozturk, O.; Zaman, A.; Tok, E.; Sever, S.D. Digital, localised and human-centred design makerspaces: Nurturing skills, values and global citizenship for sustainability. Discov. Educ. 2025, 4, 28. [Google Scholar] [CrossRef]

- Ezenwaka, U.; Mbachu, C.; Onwujekwe, O. A scoping review of the roles of stakeholders and coordination mechanisms for enhanced multi-sectoral and multi-level interventions in COVID-19 response in Nigeria. Health Res. Policy Syst. 2025, 23, 18. [Google Scholar] [CrossRef]

- Hui, W. Research on cross-organizational integration and sharing strategies of digital health resources in the context of cloud platforms. Sci. Rep. 2025, 15, 17296. [Google Scholar] [CrossRef] [PubMed]

- Šimić, D.; Ređep, N.B.; Rako, S.; Kadoić, N.; Van Petegem, W.; Rienties, B.; Lanzo, N.C.; Eichhorn, M.; Guàrdia, L.; Softić, S.K.; et al. HELA-CMM: Capability maturity model for adoption of learning analytics in higher education. Int. J. Educ. Technol. High. Educ. 2025, 22, 25. [Google Scholar] [CrossRef]

- Wu, X.-Y.; Pu, X.; Chi, X. Blockchain Adoption and Collaborative Emission Reduction in Vertical-Shareholding Supply Chain. Manag. Decis. Econ. 2025, 46, 1012–1028. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, S.; Xu, H.; Wu, Z. Advancing urban hub planning: A bibliometric analysis of concepts, effects evaluation, and spatial design. Land Use Policy 2025, 152, 107507. [Google Scholar] [CrossRef]

- Ahmed, R.O.; Al-Mohannadi, D.M.; Linke, P. Multi-objective resource integration for sustainable industrial clusters. J. Clean. Prod. 2021, 316, 128237. [Google Scholar] [CrossRef]

- Alhazemi, A. Integrating ESG Framework with Social Sustainability Metrics: A Dual SEM-PLS Formative–Reflective Model Perspective. Sustainability 2025, 17, 2566. [Google Scholar] [CrossRef]

- Uwuigbe, U.; Issah, O.; Zubeiru, M.; Anaba, S.; Seidu, A.-A.J.; Ranti, U.O. Circular Economy: A Bibliometric Review of Research in Emerging Economies (2010–2024). Int. J. Energy Econ. Policy 2025, 15, 77–89. [Google Scholar] [CrossRef]

- Houaneb, A.; Khan, U.; Khan, A.M. Greening the Cityscape: Strategies for Sustainable Urbanization, Low Carbon Emissions, and Robust Economic Growth. Int. J. Energy Econ. Policy 2025, 15, 292–300. [Google Scholar] [CrossRef]

- Liu, L.; Xin, Y.; Kong, W.; Liu, B.; Pang, Y. The panel threshold analysis of digitalization on manufacturing industry’s green total factor productivity. Sci. Rep. 2025, 15, 4336. [Google Scholar] [CrossRef]

- Lee, C.; Lin, L.-S.; Martínez-Huitle, C.A.; Pensini, E. Towards decentralized and sustainable water and wastewater treatment systems. Sci. Rep. 2025, 15, 14331. [Google Scholar] [CrossRef]

- Lee, E.J.; Tahmoush, D. Auditors’ decision-making aid for going concern audit opinions through machine learning analysis. Int. J. Account. Inf. Syst. 2025, 56, 100732. [Google Scholar] [CrossRef]

- Sahu, D.; Nidhi; Chaturvedi, R.; Prakash, S.; Yang, T.; Rathore, R.S.; Wang, L.; Tahir, S.; Bakhsh, S.T. Revolutionizing load harmony in edge computing networks with probabilistic cellular automata and Markov decision processes. Sci. Rep. 2025, 15, 3730. [Google Scholar] [CrossRef] [PubMed]

- Gartler, S.; Scheer, J.; Meyer, A.; Abass, K.; Bartsch, A.; Doloisio, N.; Falardeau, J.; Hugelius, G.; Irrgang, A.; Ingimundarson, J.H.; et al. A transdisciplinary, comparative analysis reveals key risks from Arctic permafrost thaw. Commun. Earth Environ. 2025, 6, 21. [Google Scholar] [CrossRef]

- Ni, H.; Zeng, H.; Liu, Z.; Li, W.; Miao, S.; Yang, A.; Wang, Y. Towards decarbonizing the supply chain of dairy industry: Current practice and emerging strategies. Carbon Neutrality 2025, 4, 8. [Google Scholar] [CrossRef]

- Mengesha, I.; Roy, D. Carbon pricing drives critical transition to green growth. Nat. Commun. 2025, 16, 1321. [Google Scholar] [CrossRef]

- Lynch, T.N.K.; Lovett, S.; Jung, J. An examination of the relationship between Grey Swan disruptions, job attitudes, organization identification and employee productivity. Manag. Res. Rev. 2025, 48, 1086–1104. [Google Scholar] [CrossRef]

- Wu, H.; Liu, J.; Liang, B. AI-Driven Supply Chain Transformation in Industry 5.0: Enhancing Resilience and Sustainability. J. Knowl. Econ. 2024, 16, 3826–3868. [Google Scholar] [CrossRef]

- Volkov, M. The Root of Algocratic Illegitimacy. Philos. Technol. 2025, 38, 48. [Google Scholar] [CrossRef]

- Niraula, D.; Cuneo, K.C.; Dinov, I.D.; Gonzalez, B.D.; Jamaluddin, J.B.; Jin, J.J.; Luo, Y.; Matuszak, M.M.; Haken, R.K.T.; Bryant, A.K.; et al. Intricacies of human–AI interaction in dynamic decision-making for precision oncology. Nat. Commun. 2025, 16, 1138. [Google Scholar] [CrossRef] [PubMed]

| Dimension | Pre-COVID-19 | Post-COVID-19 |

|---|---|---|

| Sourcing Model | Global, centralized supply chains | Local, regional sourcing |

| Decision-Making | Cost minimization | Resilience and flexibility |

| Technology Integration | Limited digitalization | Embraces digitalization |

| Labor System | Specialized roles, static | Flexible, adaptive workforce |

| Sustainability Focus | Focused on efficiency | Aligned with sustainability objectives |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Setyadi, A.; Pawirosumarto, S.; Damaris, A. Toward a Resilient and Sustainable Supply Chain: Operational Responses to Global Disruptions in the Post-COVID-19 Era. Sustainability 2025, 17, 6167. https://doi.org/10.3390/su17136167

Setyadi A, Pawirosumarto S, Damaris A. Toward a Resilient and Sustainable Supply Chain: Operational Responses to Global Disruptions in the Post-COVID-19 Era. Sustainability. 2025; 17(13):6167. https://doi.org/10.3390/su17136167

Chicago/Turabian StyleSetyadi, Antonius, Suharno Pawirosumarto, and Alana Damaris. 2025. "Toward a Resilient and Sustainable Supply Chain: Operational Responses to Global Disruptions in the Post-COVID-19 Era" Sustainability 17, no. 13: 6167. https://doi.org/10.3390/su17136167

APA StyleSetyadi, A., Pawirosumarto, S., & Damaris, A. (2025). Toward a Resilient and Sustainable Supply Chain: Operational Responses to Global Disruptions in the Post-COVID-19 Era. Sustainability, 17(13), 6167. https://doi.org/10.3390/su17136167