The Quality of Lip Balm Produced with Grape Pomace Addition

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Measurement of the Mechanical Properties of the Lip Balms

2.2.1. Measurement of the Kinetic Friction Force

2.2.2. Measurement of the Maximum Shear Force

2.2.3. Measurement of Resistance During Sample Penetration

2.3. Antiradical Activity Against DPPH·

2.4. Determination of the Total Phenolic Content (TPC)

2.5. Analysis of Colour Parameters

2.6. Statistical Analysis

3. Results

4. Conclusions

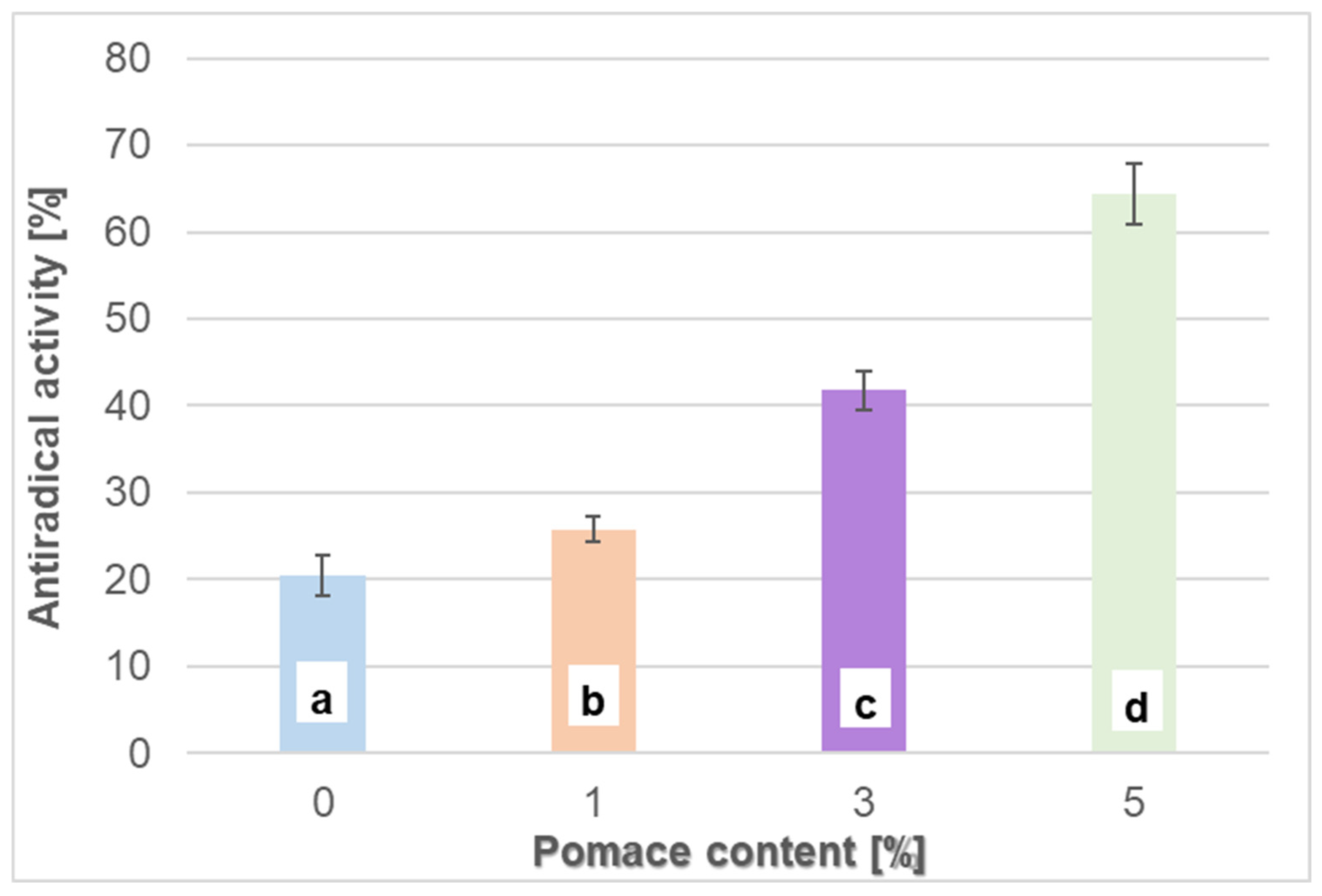

- Anthocyanin-containing formulations demonstrated the ability to act as antioxidants by scavenging free radicals in the lip balm matrix. The highest antiradical activity against the DPPH radical (64.44%) was noted for the lip balm with 5% pomace addition. However, as the additive proportion decreased, the antiradical activity of the lip balms also decreased.

- This study suggests the potential for ACNs to be used as biologically active components in lip balm formulations. The highest phenolic content was noted for the sample with 5% addition of pomace (0.103 mg). The phenolic content decreased with decreasing pomace content.

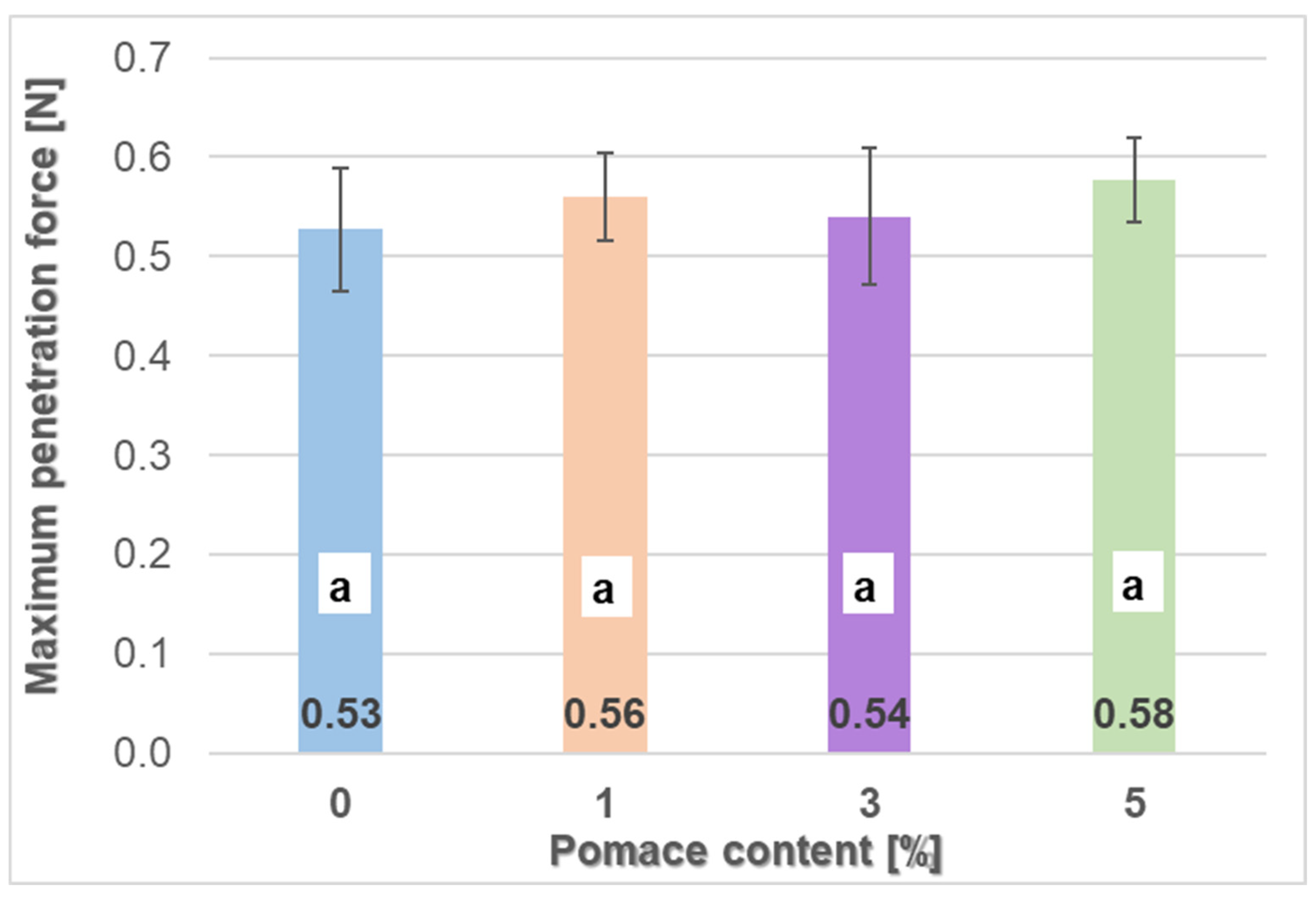

- Regarding the assessment of the physical property parameters, the addition of grape pomace to the lip balm formulation resulted in slight decreases in the values of kinetic friction, shear, and penetration forces. However, only in the case of maximum shear force and maximum friction force was the difference between the samples statistically significant, which indicates that the addition of grape pomace can result in lip balm brittleness.

- Based on the tests conducted, the use of grape pomace as an ingredient in peeling lip balms enables the development of cosmetic products with exfoliating and antioxidant properties while utilising waste products from the food industry, which contributes to reducing the environmental footprint of the cosmetics industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Łusiak, P.Ł.; Mazur, J.; Sobczak, P.; Zawiślak, K.; Panasiewicz, M. The use of carrot and apple pomace in the production of healthy snack bars. Agric. Eng. 2023, 1, 289–300. [Google Scholar] [CrossRef]

- Kawecka, L.; Galus, S. Fruit pomace—Characteristics and possibilities of recycling. Technol. Prog. Food Process. 2021, 1, 156–167. [Google Scholar]

- Wiza, P.L.; Czubak, W.; Kowalczewski, P. Grape marc as an addition to the production of homemade cider. Inżynieria Żywności 2018, 2, 9–14. [Google Scholar]

- Tarko, T.; Duda-Chodak, A.; Bebak, A. Aktywność biologiczna wybranych wytłoków owocowych oraz warzywnych. Żywność Nauka Technol. Jakość 2012, 4, 55–65. [Google Scholar]

- Anderson, O.M.; Jordheim, M. Basic Anthocyanin Chemistry and Dietary Sources in Anthocyanins in Health and Disease, 1st ed.; CRC Press: Boca Raton, FL, USA, 2014; pp. 13–90. [Google Scholar]

- Giusti, M.M.; Wrolstad, R.E. Acylated anthocyanins from edible sources and their applications in food systems. Biochem. Eng. J. 2003, 14, 217–225. [Google Scholar] [CrossRef]

- Sigurdson, G.T.; Tang, P.; Giusti, M.M. Natural colorants: Food colorants from natural sources. Annu. Rev. Food Sci. Technol. 2017, 8, 261–280. [Google Scholar] [CrossRef]

- Mazza, G.; Kay, C.D.; Holub, B.J. Absorption of Anthocyanins from Blueberries and Serum Antioxidant Status in Human Subjects. J. Agric. Food Chem. 2002, 50, 7731–7737. [Google Scholar] [CrossRef]

- Sánchez-Ortiz, A.; Mateo-Sanz, J.M.; Mateos-Fernandez, M.A.; Figueras, M.L. New Labeling Rules for Wine: Wine Alcohol-Derived Calories and Polyphenol Consumption on Health. Foods 2024, 13, 295. [Google Scholar] [CrossRef]

- Shih, P.-H.; Yeh, C.-T.; Yen, G.-C. Anthocyanins Induce the Activation of Phase II Enzymes through the Antioxidant Response Element Pathway against Oxidative Stress-Induced Apoptosis. J. Agric. Food Chem. 2007, 55, 9427–9435. [Google Scholar] [CrossRef]

- You, J.L.; Yoon, K.Y.; You, Y.K.; Oran, K. Effects of an aqueous extract of purple sweet potato on nonalcoholic fatty liver in high fat/cholesterol-fed mice. J. Nutr. Health 2015, 48, 1–8. [Google Scholar][Green Version]

- Gee, J.M.; Johnson, I.T. Polyphenolic compounds: Interactions with the gut and implications for human health. Curr. Med. Chem. 2001, 8, 1245–1255. [Google Scholar] [CrossRef]

- Chan, C.F.; Lien, C.Y.; Lai, Y.C.; Huang, C.L.; Liao, W.C. Influence of purple sweet potato extracts on the UV absorption properties of a cosmetic cream. J. Cosmet. Sci. 2010, 61, 333–341. [Google Scholar]

- Bae, J.Y.; Lim, S.S.; Kim, S.J.; Choi, S.-J.; Park, J.; Ju, S.M.; Han, S.J.; Kang, I.-J.; Kang, Y.-H. Bog blueberry anthocyanins alleviate photoaging in ultraviolet-B irradiation-induced human dermal fibroblasts. Mol. Nutr. Food Res. 2009, 53, 726–738. [Google Scholar] [CrossRef]

- Tsoyi, K.; Park, H.B.; Kim, Y.M.; Chung, J.I.; Shin, S.C.; Lee, W.S.; Seo, H.G.; Lee, J.H.; Chang, K.C.; Kim, H.J. Anthocyanins from Black Soybean Seed Coats Inhibit UVB-Induced Inflammatory Cylooxygenase-2 Gene Expression and PGE2 Production through Regulation of the Nuclear Factor-kappaB and Phosphatidylinositol 3-Kinase/Akt Pathway. J. Agric. Food Chem. 2008, 56, 8969–8974. [Google Scholar] [CrossRef]

- Hsu, C.K.; Chou, S.-T.; Huang, P.-J.; Mong, M.-C.; Wang, C.-K.; Hsueh, Y.-P.; Jhan, J.-K. Crude ethanol extracts from grape seeds and peels exhibit anti-tyrosinase activity. J. Cosmet. Sci. 2012, 63, 225–232. [Google Scholar]

- Gonzaga, E.R. Role of UV light in photodamage, skin aging, and skin cancer: Importance of photoprotection. Am. J. Clin. Dermatol. 2009, 20, 19–24. [Google Scholar] [CrossRef]

- Bojanowski, K. Hypodermal delivery of cosmetic actives for improved facial skin morphology and functionality. J. Cosmet. Sci. 2013, 35, 562–567. [Google Scholar] [CrossRef]

- Crisan, M.; Luminata, D.; Moldovan, B.; Vulcu, A.; Dreve, S.; Perde-Schlepler, M.; Tatomir, C.; Filip, A.G.; Bolfa, P.; Achim, M.; et al. New nanomaterials for the improvement of psoriatic lesions. J. Mater. Chem. 2013, 1, 3152–3158. [Google Scholar] [CrossRef]

- Kim, M.J.; Choung, S.Y. Mixture of polyphenols and anthocyanins from Vaccinium uliginosum L.alleviates DNCB-induced atopic dermatitis in NC/Nga mice. Evid.-Based Complement. Altern. Med. 2012, 2012, 461989. [Google Scholar] [CrossRef]

- Westfall, A.; Sigurdson, G.T.; Giusti, M.M. Antioxidant, UV Protection, and Antiphotoaging Properties of Anthocyanin-Pigmented Lipstick Formulations. J. Cosmet. Sci. 2019, 70, 63–76. [Google Scholar]

- Ugale, C. Metamorphosis of domestic waste to an active skincare product. Natl. Acad. Sci. Lett. 2022, 45, 331–333. [Google Scholar] [CrossRef]

- Guo, X.; He, L.; Sun, J.; Ye, H.; Yin, C.; Zhang, W.; Han, H.; Jin, W. Exploring the Potential of Anthocyanins for Repairing Photoaged Skin: A Comprehensive Review. Foods 2024, 13, 3506. [Google Scholar] [CrossRef]

- Richard, C. Lipstick Adhesion Measurement. In Surface Science and Adhesion in Cosmetics; Wiley-Scrivener: Centre Val de Loire, France, 2021; pp. 637–641. [Google Scholar]

- Tataruch, K.; Kucia, M. Eco-Friendly Waterless Cosmetics. Manag. Qual. 2022, 4, 204–218. [Google Scholar]

- Yu, J.; Ahmedna, M. Functional components of grape pomace: Their composition biological properties and potential applications. Int. J. Food Sci. Technol. 2013, 48, 221–237. [Google Scholar] [CrossRef]

- Mazur, J.; Różyło, R.; Wójcik, M.; Panasiewicz, M.; Zawiślak, K.; Sobczak, P. Development of an Innovative Attachment Determining Friction Parameters for Quality Assessment in Sustainable Processing. Sustainability 2022, 14, 12986. [Google Scholar] [CrossRef]

- ASTM D1894-1. Available online: https://www.astm.org/standards/d1894.htm (accessed on 23 April 2025).

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of Free Radical Method to Evaluate Antioxidant Activity. Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventos, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzymol. 1974, 299, 152–178. [Google Scholar]

- Rafferty, D.W.; Dupin, L.; Zellia, J.; Giovannitti-Jensen, A. Predicting lipstick sensory properties with laboratory tests. Int. J. Cosmet. Sci. 2018, 40, 451–460. [Google Scholar] [CrossRef]

- Łusiak, P.; Różyło, R.; Mazur, J.; Sobczak, P.; Matwijczuk, A. Evaluation of physical parameters and spectral characterization of the quality of soaps containing by-products from the food industry. Sci. Rep. 2024, 14, 4687. [Google Scholar]

- Esposito, C.L.; Kirilov, P. Preparation, Characterization and Evaluation of Organogel-Based Lipstick Formulations: Application in Cosmetics. Gels 2021, 7, 97. [Google Scholar] [CrossRef]

- Soto, M.L.; Falque, E.; Dominguez, H. Relevance of Natural Phenolics from Grape and Derivative Products in the Formulation of Cosmetics. Cosmetics 2015, 2, 259–276. [Google Scholar] [CrossRef]

- Azwanida, N.N.; Normasarah, A.A. Utilization and Evaluation of Betalain Pigment from Red Dragon Fruit (Hylocereus Polyrhizus) as a Natural Colorant for Lipstick. J. Teknol. (Sci. Eng.) 2014, 69, 139–142. [Google Scholar] [CrossRef]

- Oborska, A. Kosmetyczne zastosowanie winorośli. Chem. Rev. 2015, 9–10, 18–20. [Google Scholar]

| Ingredients [g] | Control Sample [S0] |

|---|---|

| Shea butter [g] | 20 |

| Cocoa butter [g] | 20 |

| Beeswax [g] | 18 |

| Sesame oil [g] | 18 |

| Coconut oil [g] | 10 |

| Bee honey [g] | 8 |

| Apricot kernel oil [g] | 6 |

| Addition of PG (%) | L* | a* | b* | ΔE |

|---|---|---|---|---|

| 0 | 7575.6 ± 1.00 a | −1.2 ± 0.17 a | 12.9 ± 0.15 a | — |

| 1 | 7878.3 ± 0.77 b | −1.4 ± 0.14 b | 13.4 ± 0.15 a | 1.6 ± 0.05 a |

| 3 | 6666.8 ± 0.87 c | 0.2 ± 0.05 b | 9.1 ± 0.09 b | 13.5 ± 0.81 a |

| 5 | 5353.3 ± 1.01 c | 1.7 ± 0.02 b | 4.4 ± 0.14 b | 25.5 ± 0.34 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łusiak, P.; Kęska, P.; Mazur, J.; Wójcik, M.; Sobczak, P. The Quality of Lip Balm Produced with Grape Pomace Addition. Sustainability 2025, 17, 6146. https://doi.org/10.3390/su17136146

Łusiak P, Kęska P, Mazur J, Wójcik M, Sobczak P. The Quality of Lip Balm Produced with Grape Pomace Addition. Sustainability. 2025; 17(13):6146. https://doi.org/10.3390/su17136146

Chicago/Turabian StyleŁusiak, Patrycja, Paulina Kęska, Jacek Mazur, Monika Wójcik, and Paweł Sobczak. 2025. "The Quality of Lip Balm Produced with Grape Pomace Addition" Sustainability 17, no. 13: 6146. https://doi.org/10.3390/su17136146

APA StyleŁusiak, P., Kęska, P., Mazur, J., Wójcik, M., & Sobczak, P. (2025). The Quality of Lip Balm Produced with Grape Pomace Addition. Sustainability, 17(13), 6146. https://doi.org/10.3390/su17136146