HVO Adoption in Brazil: Challenges and Environmental Implications

Abstract

1. Introduction

2. Literature Review

2.1. Production and Properties of HVO

2.2. Emissions in Internal Combustion Engines

2.3. Life Cycle Analysis (LCA) with HVO

2.4. HVO Cost and Future Trends

3. Methodology

- D + B13 (13% biodiesel in fossil diesel (D))

- D + B13 + HVO10 (13% biodiesel + 10% HVO in fossil diesel)

- D + B20 + HVO30 (20% biodiesel + 30% HVO in fossil diesel)

- D + B20 + HVO50 (20% biodiesel + 50% HVO in fossil diesel)

4. Results

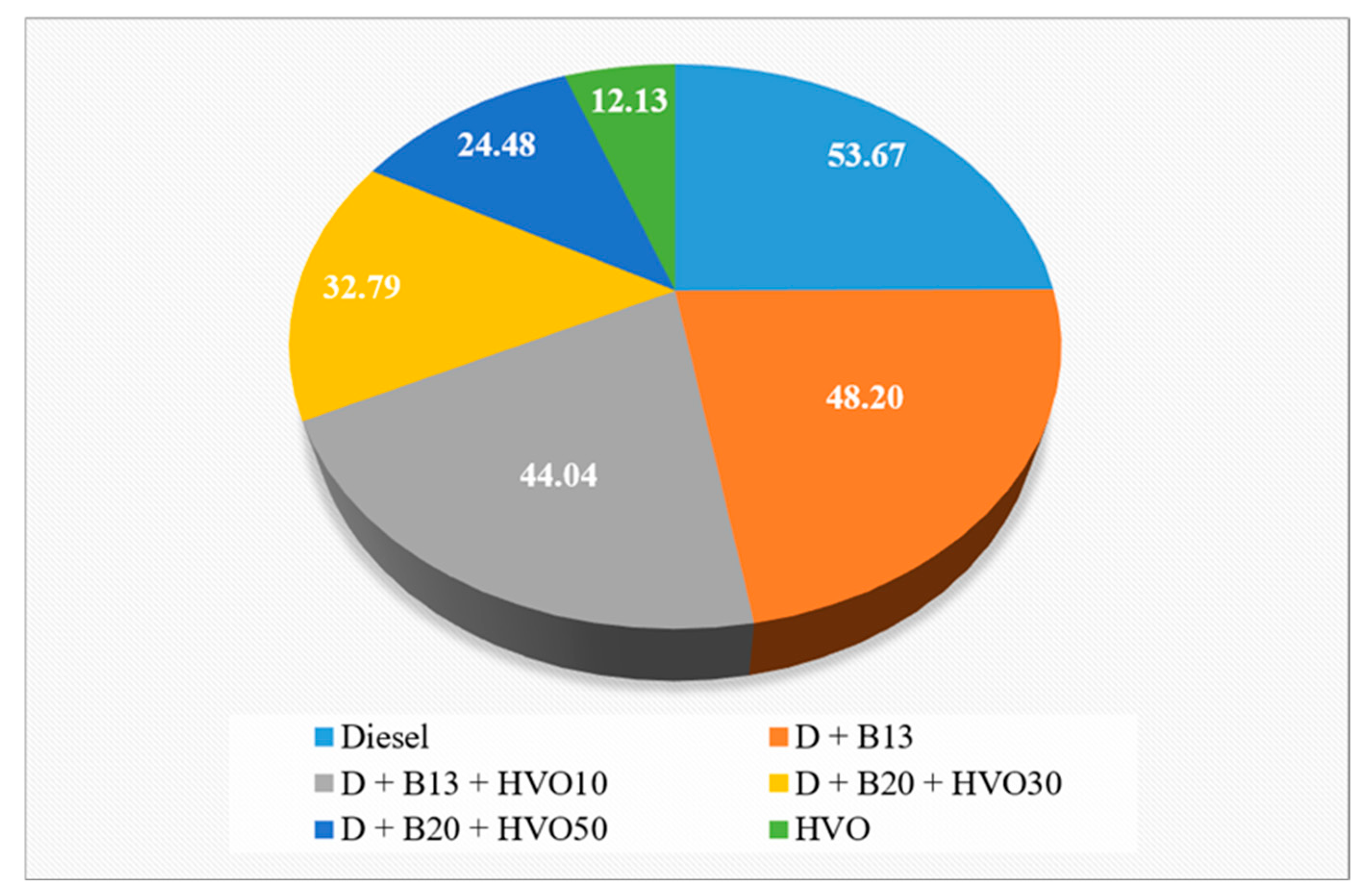

4.1. Life Cycle CO2 Emissions

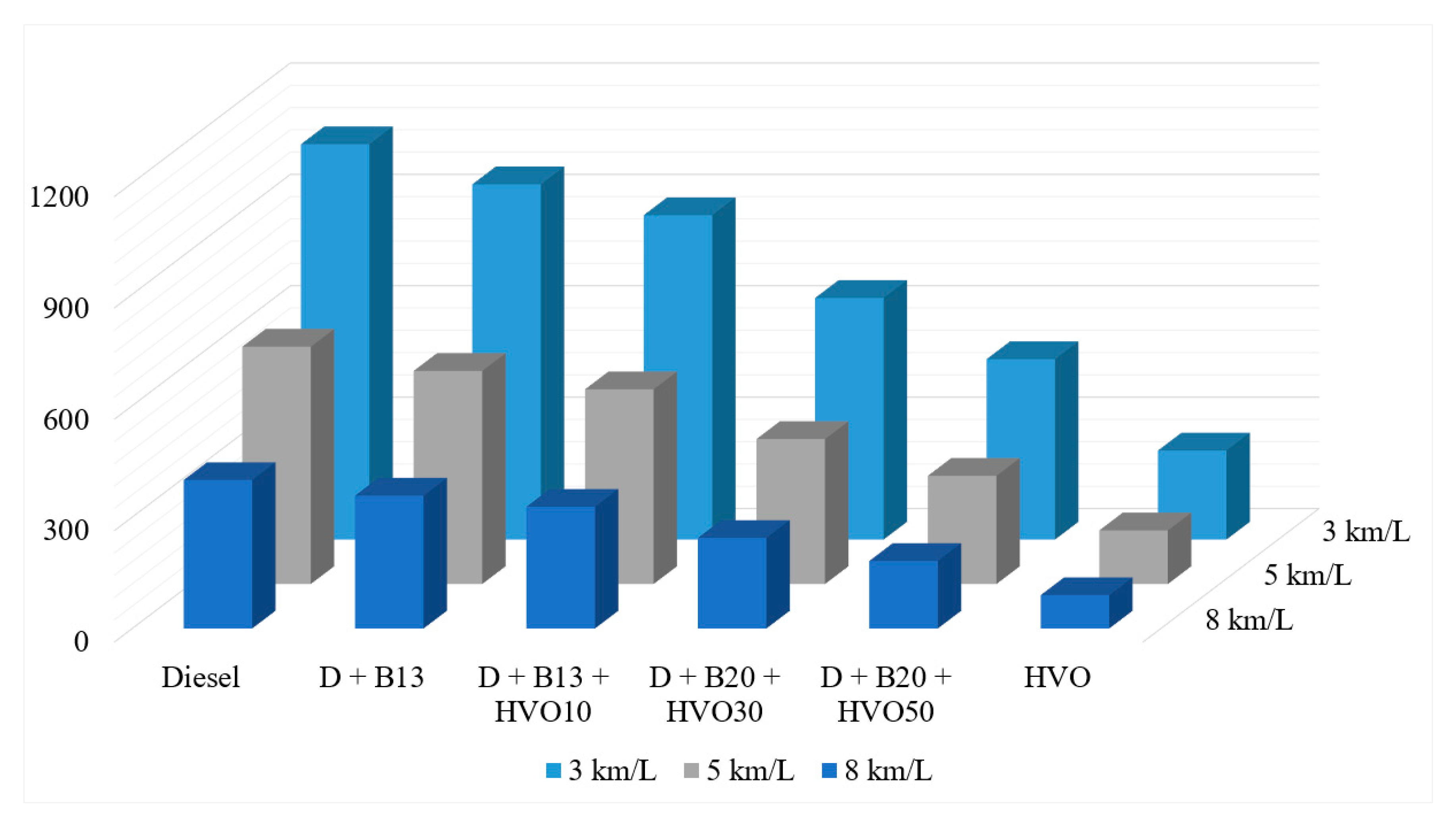

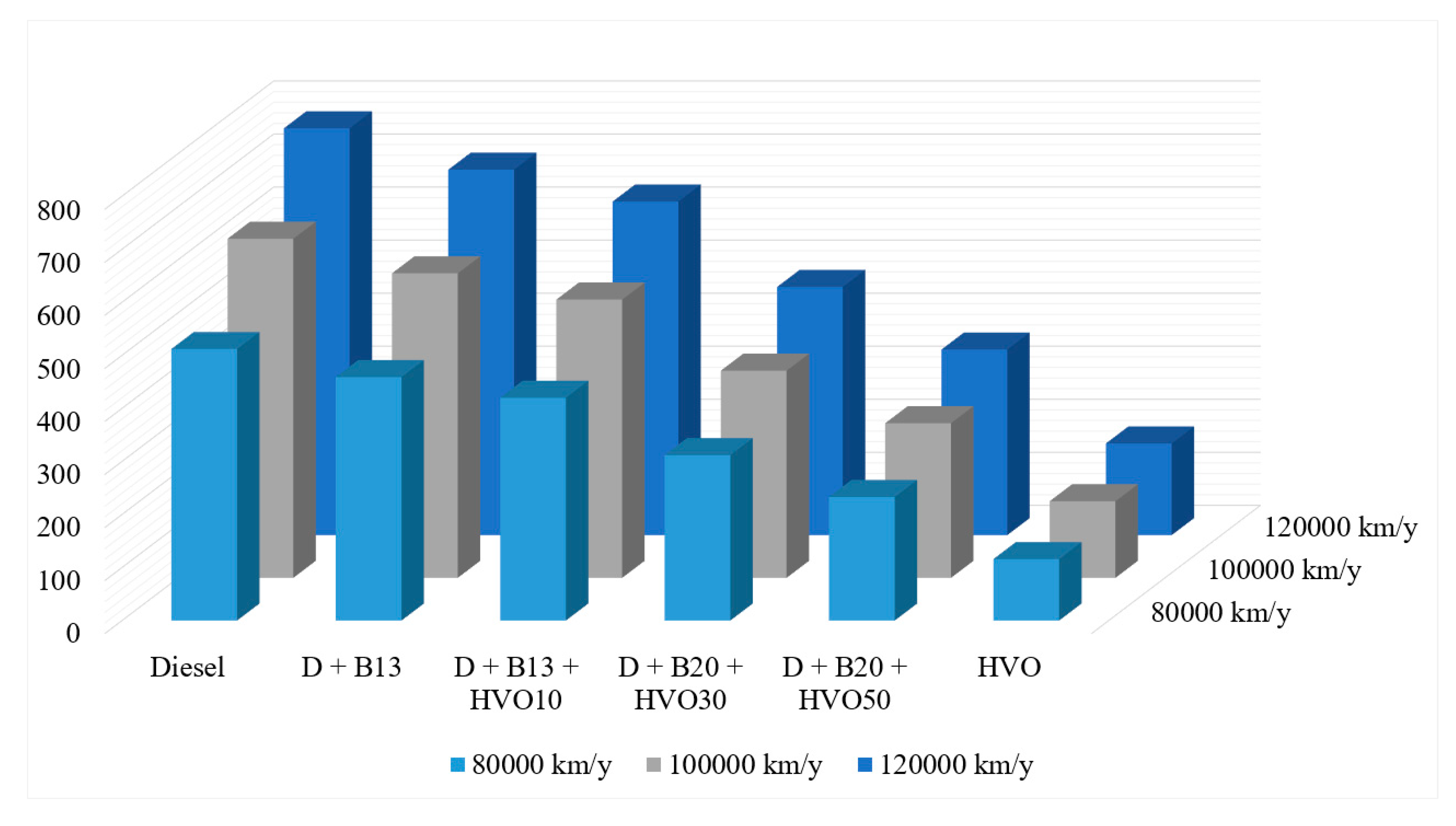

4.2. Net CO2 Emissions from Brazilian Diesel Fleets

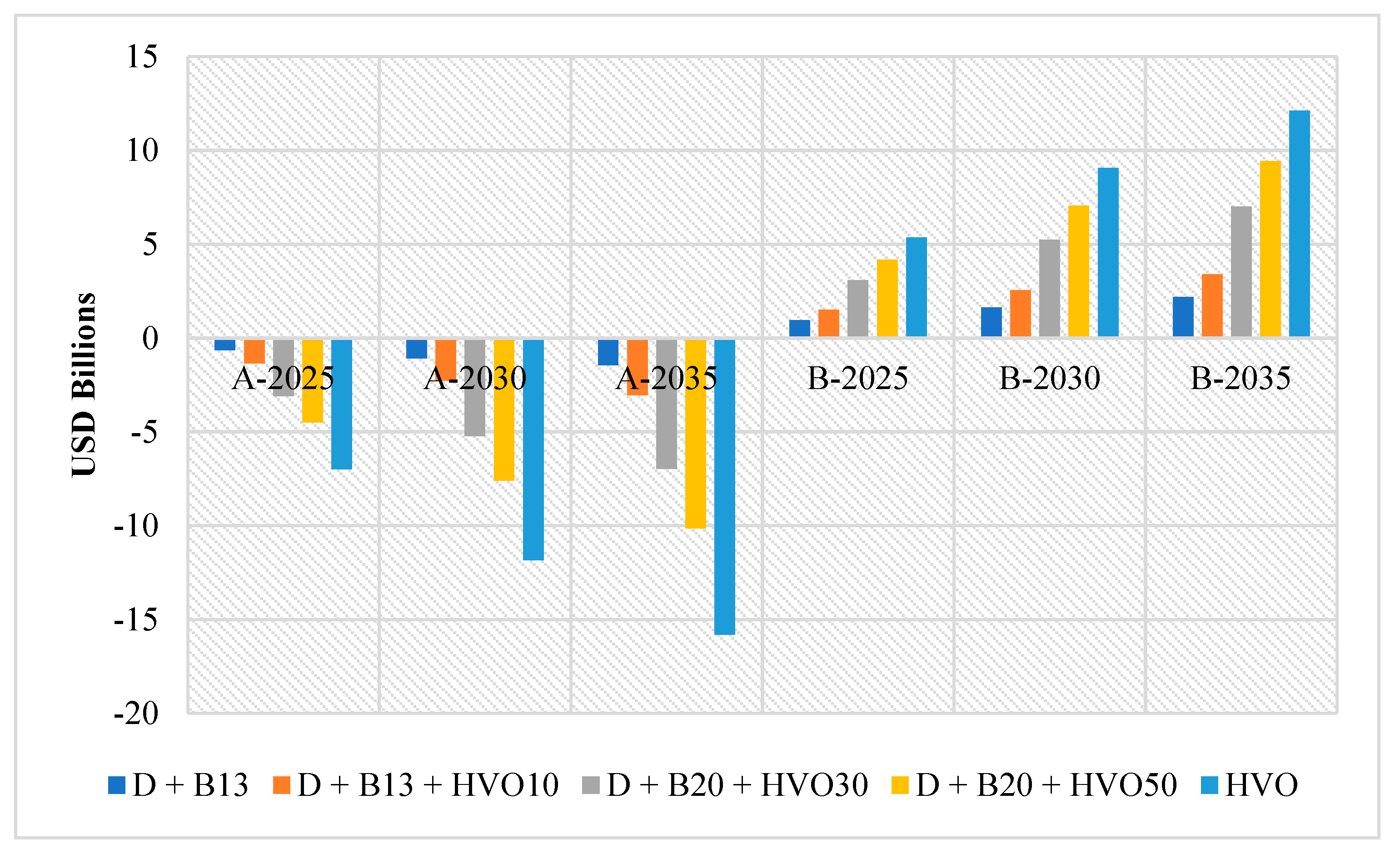

4.3. Future Projections

- Scenario A. The HVO price of 1.11 USD/L was considered for scenario calculations, based on medium retail prices data from California state U.S since January 2017. Additionally, the influence of marketing prices in other tree states, where HVO is also commercialized, was accounted for $0.011 USD/L reduction [60]. For the value of biodiesel and fossil diesel, the average commercialization values in the United States were considered, in the same period as HVO.

- Scenario B represents a more favorable projection regarding the reduction in HVO prices. A minimum HVO sales price of 0.92 USD/L was considered, based on the calculations by [56]. The fossil diesel price was set at 1.15 USD/L, reflecting the average price in California [60], the state with the most stringent atmospheric emissions policies, whose regulations often influence national environmental policies. The biodiesel price was set at 0.83 USD/L, the projected minimum future value according to [58].

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lima, A.V.; Queiroga Neto, A.D.; Schaedler, J.V.; Santos, L.S.; Eder, L.B. Produção de HVO a Partir do Hidrotratamento Catalítico do óleo de Farelo de Arroz. 2021. Available online: https://repositorio.ufsm.br/handle/1/22666%0Ahttps://repositorio.ufsm.br/bitstream/handle/1/22666/Lima_Anderson_Queiroga_Antonio_Schaedler_Joao_Santos_Lucas_Eder_Luisa_2021_TCC.pdf?sequence=1&isAllowed=y (accessed on 15 June 2025).

- Müller-langer, F.; Majer, S.; Keeffe, S.O. Benchmarking biofuels—A comparison of technical, economic and environmental indicators. Energy Sustain. Soc. 2014, 4, 20. [Google Scholar] [CrossRef]

- Nylund, N.O.; Erkkilä, K.; Ahtiainen, M.; Murtonen, T.; Saikkonen, P.; Amberla, A.; Aatola, H. Optimized Usage of NExBTL Renewable Diesel Fuel OPTIBIO; VTT Technical Research Centre of Finland: Espoo, Finland, 2011. [Google Scholar]

- International Energy Agency. CO2 Emissions in 2022; IEA: Paris, France, 2023. [Google Scholar] [CrossRef]

- Austin, K.; Jones, J.; Clark, C. A review of domestic land use change attributable to U.S. biofuel policy. Renew. Sustain. Energy Rev. 2022, 159, 112181. [Google Scholar] [CrossRef] [PubMed]

- SENATRAN. Secretaria Nacional de Transito, Estatísticas—Frota de Veículos—Brazilian Transit Secretariat. Brazil’s Vehicle fleet. 2025. Available online: https://www.gov.br/transportes/pt-br/assuntos/transito/conteudo-Senatran/estatisticas-frota-de-veiculos-senatran (accessed on 15 June 2025).

- Branco, J.E.H.; Prates, R.C.; Oliveira, A.L.D.N.; de Carvalho, A.K.F. Evaluation of the greenhouse gas emissions of the Brazilian biodiesel and the impact of the mandatory blending of the biofuel into commercial diesel fuel. Chemosphere 2025, 376, 144268. [Google Scholar] [CrossRef]

- Coronado, C.R.; de Carvalho, J.A.; Silveira, J.L. Biodiesel CO2 emissions: A comparison with the main fuels in the Brazilian market. Fuel Process. Technol. 2009, 90, 204–211. [Google Scholar] [CrossRef]

- EPE. Combustíveis renováveis para uso em motores do ciclo Diesel. Empresa de Pesquisa Energética—Nota Técnica DPG-SDB No. 01/2020, 1–18. 2020. Available online: https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-467/NT_Combustiveis_renovaveis_em_%20motores_ciclo_Diesel.pdf (accessed on 1 July 2025).

- ETIP BIOENERGY. Hydrogenated Vegetable Oil (HVO). Bioenergy Fact Sheet. 2020. Available online: https://old.etipbioenergy.eu/fact-sheets (accessed on 15 June 2025).

- Neste Corporation. Neste Renewable Diesel Handbook; Neste: Espoo, Finland, 2020; pp. 1–33. [Google Scholar]

- Millo, F.; Jafari, M.J.; Piano, A.; Postrioti, L.; Brizi, G.; Vassallo, A.; Pesce, F.; Fittavolini, C. A fundamental study of injection and combustion characteristics of neat Hydrotreated Vegetable Oil (HVO) as a fuel for light-duty diesel engines. Fuel 2025, 379, 132951. [Google Scholar] [CrossRef]

- NTU. A Revolução do HVO. Revista NTUrbano Ed. 42. 2019. Available online: https://ntu.org.br/novo/NoticiaCompleta.aspx?idArea=10&idNoticia=1279 (accessed on 15 June 2025).

- No, S.-Y. Application of hydrotreated vegetable oil from triglyceride based biomass to CI engines—A review. Fuel 2014, 115, 88–96. [Google Scholar] [CrossRef]

- Vignesh, P.; Kumar, A.P.; Ganesh, N.S.; Jayaseelan, V.; Sudhakar, K. A review of conventional and renewable biodiesel production. Chin. J. Chem. Eng. 2021, 40, 1–17. [Google Scholar] [CrossRef]

- Pinto, G.; de Souza, T.; da Costa, R.; Roque, L.; Frez, G.; Coronado, C. Combustion, performance and emission analyses of a CI engine operating with renewable diesel fuels (HVO/FARNESANE) under dual-fuel mode through hydrogen port injection. Int. J. Hydrogen Energy 2023, 48, 19713–19732. [Google Scholar] [CrossRef]

- Rangel, N.V.; da Silva, L.P.; Pinheiro, V.S.; Figueredo, I.M.; Campos, O.S.; Costa, S.N.; Luna, F.M.T.; Cavalcante, C.L.; Marinho, E.S.; de Lima-Neto, P.; et al. Effect of additives on the oxidative stability and corrosivity of biodiesel samples derived from babassu oil and residual frying oil: An experimental and theoretical assessment. Fuel 2021, 289, 119939. [Google Scholar] [CrossRef]

- Singh, D.; Subramanian, K.; Singal, S. Emissions and fuel consumption characteristics of a heavy duty diesel engine fueled with Hydroprocessed Renewable Diesel and Biodiesel. Appl. Energy 2015, 155, 440–446. [Google Scholar] [CrossRef]

- Douvartzides, S.L.; Charisiou, N.D.; Papageridis, K.N.; Goula, M.A. Green Diesel: Biomass Feedstocks, Production Technologies, Catalytic Research, Fuel Properties and Performance in Compression Ignition Internal Combustion Engines. Energies 2019, 12, 809. [Google Scholar] [CrossRef]

- Soam, S.; Hillman, K. Factors influencing the environmental sustainability and growth of hydrotreated vegetable oil (HVO) in Sweden. Bioresour. Technol. Rep. 2019, 7, 100244. [Google Scholar] [CrossRef]

- Hilbers, T.J.; Sprakel, L.M.J.; Enk, L.B.J.v.D.; Zaalberg, B.; Berg, H.v.D.; van der Ham, L.G.J. Green Diesel from Hydrotreated Vegetable Oil Process Design Study. Chem. Eng. Technol. 2015, 38, 651–657. [Google Scholar] [CrossRef]

- Pérez-Rangel, N.; Coronado, C.; Ancheyta, J. Approaches to conditioning of vegetable oil feedstock for hydrotreating to produce renewable diesel. Fuel 2025, 383, 133897. [Google Scholar] [CrossRef]

- Julio, A.A.V.; Milessi, T.S.; Batlle, E.A.O.; Lora, E.E.S.; Maya, D.M.Y.; Palacio, J.C.E. Techno-economic and environmental potential of Renewable Diesel as complementation for diesel and biodiesel in Brazil: A comprehensive review and perspectives. J. Clean. Prod. 2022, 371, 133431. [Google Scholar] [CrossRef]

- Sonthalia, A.; Kumar, N. Hydroprocessed vegetable oil as a fuel for transportation sector: A review. J. Energy Inst. 2019, 92, 1–17. [Google Scholar] [CrossRef]

- IEA. Renewables 2019—Market Analysis and Forecast from 2019 to 2024. International Energy Agency, 204. 2019. Available online: https://www.iea.org/reports/renewables-2019 (accessed on 21 September 2022).

- Cárdenas-Guerra, C.; Alonso, F.; Ancheyta, J. Key Factors to Use Existing Commercial Hydrotreating Plants for the Co-Hydrotreating of Vegetable Oil and Gas Oil. Ind. Eng. Chem. Res. 2023, 62, 13235–13248. [Google Scholar] [CrossRef]

- Lorenzi, G.; Baptista, P.; Venezia, B.; Silva, C.; Santarelli, M. Use of waste vegetable oil for hydrotreated vegetable oil production with high-temperature electrolysis as hydrogen source. Fuel 2020, 278, 117991. [Google Scholar] [CrossRef]

- ANP. Resolução ANP No 842, de 14 de Maio de 2021 Brasil. 2021. Available online: https://www.in.gov.br/en/web/dou/-/resolucao-anp-n-842-de-14-de-maio-de-2021-320059616 (accessed on 15 June 2025).

- Aatola, H.; Larmi, M.; Sarjovaara, T.; Mikkonen, S. Hydrotreated Vegetable Oil (HVO) as a Renewable Diesel Fuel: Trade-off between NOx, Particulate Emission, and Fuel Consumption of a Heavy Duty Engine. SAE Int. J. Engines 2008, 1, 1251–1262. [Google Scholar] [CrossRef]

- Pechout, M.; Kotek, M.; Jindra, P.; Macoun, D.; Hart, J.; Vojtisek-Lom, M. Comparison of hydrogenated vegetable oil and biodiesel effects on combustion, unregulated and regulated gaseous pollutants and DPF regeneration procedure in a Euro6 car. Sci. Total. Environ. 2019, 696, 133748. [Google Scholar] [CrossRef]

- Hartikka, T.; Kuronen, M.; Kiiski, U. Technical Performance of HVO (Hydrotreated Vegetable Oil) in Diesel Engines; SAE Technical Papers, 9; SAE Publication: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Boehman, A.L.; Morris, D.; Szybist, J.; Esen, E. The Impact of the Bulk Modulus of Diesel Fuels on Fuel Injection Timing. Energy Fuels 2004, 18, 1877–1882. [Google Scholar] [CrossRef]

- Tilli, A.; Kaario, O.; Imperato, M.; Larmi, M. Fuel Injection System Simulation with Renewable Diesel Fuels; SAE: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Arguelles-Arguelles, A.; Amezcua-Allieri, M.A.; Ramírez-Verduzco, L.F. Life Cycle Assessment of Green Diesel Production by Hydrodeoxygenation of Palm Oil. Front. Energy Res. 2021, 9, 690725. [Google Scholar] [CrossRef]

- Lapuerta, M.; Villajos, M.; Agudelo, J.R.; Boehman, A.L. Key properties and blending strategies of hydrotreated vegetable oil as biofuel for diesel engines. Fuel Process. Technol. 2011, 92, 2406–2411. [Google Scholar] [CrossRef]

- Puricelli, S.; Cardellini, G.; Casadei, S.; Faedo, D.; van den Oever, A.E.M.; Grosso, M. A review on biofuels for light-duty vehicles in Europe. Renew. Sustain. Energy Rev. 2021, 137, 110398. [Google Scholar] [CrossRef]

- Wahnfried, C.M. Green Diesel HVO. Effects on the Fuel System, Engine and Standardization Status; Paper/Conference Presentation; AEA—Brazilian Association of Automotive Engineering: São Paulo, Brazil, 2020. [Google Scholar]

- da Costa, R.B.R.; Roque, L.; de Souza, T.; Coronado, C.; Pinto, G.; Cintra, A.; Raats, O.; Oliveira, B.; Frez, G.; da Silva, M. Experimental assessment of renewable diesel fuels (HVO/Farnesane) and bioethanol on dual-fuel mode. Energy Convers. Manag. 2022, 258, 115554. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, J.; Hernández, J.J.; Sánchez-Valdepeñas, J. Effect of oxygenated and paraffinic alternative diesel fuels on soot reactivity and implications on DPF regeneration. Fuel 2016, 185, 460–467. [Google Scholar] [CrossRef]

- Garraín, D.; Herrera, I.; Lechón, Y.; Lago, C. Well-to-Tank environmental analysis of a renewable diesel fuel from vegetable oil through co-processing in a hydrotreatment unit. Biomass Bioenergy 2014, 63, 239–249. [Google Scholar] [CrossRef]

- Cremonez, P.A.; Teleken, J.G.; Meier, T.W. Potential of Green Diesel To Complement the Brazilian Energy Production: A Review. Energy Fuels 2021, 35, 176–186. [Google Scholar] [CrossRef]

- Bortel, I.; Vávra, J.; Takáts, M. Effect of HVO fuel mixtures on emissions and performance of a passenger car size diesel engine. Renew. Energy 2019, 140, 680–691. [Google Scholar] [CrossRef]

- McCaffery, C.; Zhu, H.; Ahmed, C.S.; Canchola, A.; Chen, J.Y.; Li, C.; Johnson, K.C.; Durbin, T.D.; Lin, Y.-H.; Karavalakis, G. Effects of hydrogenated vegetable oil (HVO) and HVO/biodiesel blends on the physicochemical and toxicological properties of emissions from an off-road heavy-duty diesel engine. Fuel 2022, 323, 124283. [Google Scholar] [CrossRef]

- Götz, K.; Fey, B.; Singer, A.; Krahl, J.; Bünger, J.; Knorr, M.; Schröder, O. Exhaust Gas Exhaust Gas Emissions and Engine Oil Interactions from a New Biobased Fuel Named Diesel R33; SAE Publication: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

- Kim, D.; Kim, S.; Oh, S.; No, S.-Y. Engine performance and emission characteristics of hydrotreated vegetable oil in light duty diesel engines. Fuel 2014, 125, 36–43. [Google Scholar] [CrossRef]

- Sheehan, J.; Camobreco, V.; Duffield, J.; Graboski, M.; Shapouri, H. An Overview of Biodiesel and Petroleum Diesel Life Cycles; U.S. Department of Agriculture and U.S Department of Energy: Washington, DC, USA, 1998; pp. 1–60. Available online: http://www.nrel.gov/docs/legosti/fy98/24772.pdf (accessed on 15 June 2025).

- Kalnes, T.N.; Koers, K.P.; Marker, T.; Shonnard, D.R. A technoeconomic and environmental life cycle comparison of green diesel to biodiesel and syndiesel. Environ. Prog. Sustain. Energy 2009, 28, 111–120. [Google Scholar] [CrossRef]

- Permpool, N.; Gheewala, S.H. Environmental and energy assessment of alternative fuels for diesel in Thailand. J. Clean. Prod. 2017, 142, 1176–1182. [Google Scholar] [CrossRef]

- Xu, H.; Lee, U.; Wang, M. Life-cycle energy use and greenhouse gas emissions of palm fatty acid distillate derived renewable diesel. Renew. Sustain. Energy Rev. 2020, 134, 110144. [Google Scholar] [CrossRef]

- Xu, H.; Ou, L.; Li, Y.; Hawkins, T.R.; Wang, M. Life Cycle Greenhouse Gas Emissions of Biodiesel and Renewable Diesel Production in the United States. Environ. Sci. Technol. 2022, 56, 7512–7521. [Google Scholar] [CrossRef]

- JRC. JEC Well-To-Wheels Report v5. Report JCR, EUCAR and Concawe. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC121213 (accessed on 15 June 2025).

- Volonterio, E.; Vieitez, I.; Grassi, J.; Suescun, L.; Amaya, A.; Bussi, J.; Castiglioni, J.; Jachmanián, I. Catalytic hydrotreatment of vegetable oils: Effect of oil quality on hydrocarbon yield. Fuel 2024, 371, 131885. [Google Scholar] [CrossRef]

- Torres-Mancera, P.; Ancheyta, J.; Martínez, J. Deactivation of a hydrotreating catalyst in a bench-scale continuous stirred tank reactor at different operating conditions. Fuel 2018, 234, 326–334. [Google Scholar] [CrossRef]

- Choe, C.; Lee, B.; Lim, H. Sustainable and carbon-neutral green diesel synthesis with thermochemical and electrochemical approach: Techno-economic and environmental assessments. Energy Convers. Manag. 2022, 254, 115242. [Google Scholar] [CrossRef]

- Julio, A.A. Avaliação Exergoeconômica e Exergoambiental de Biorrefinarias de Óleo de Palma. Dissertação, UNIFEI, Itajubá, Brazil, 2020. Issue 16. [Google Scholar]

- Martinez-Hernandez, E.; Ramírez-Verduzco, L.F.; Amezcua-Allieri, M.A.; Aburto, J. Process simulation and techno-economic analysis of bio-jet fuel and green diesel production—Minimum selling prices. Chem. Eng. Res. Des. 2019, 146, 60–70. [Google Scholar] [CrossRef]

- Glisic, S.B.; Pajnik, J.M.; Orlović, A.M. Process and techno-economic analysis of green diesel production from waste vegetable oil and the comparison with ester type biodiesel production. Appl. Energy 2016, 170, 176–185. [Google Scholar] [CrossRef]

- Brown, A.; Waldheim, L.; Landälv, I.; Saddler, J.; Mahmood, E.; McMillan, J.D.; Bonomi, A.; Klein, B. Advanced Biofuels—Potential for Cost Reduction. IEA Bioenergy 2020, 1–88. Available online: https://task39.sites.olt.ubc.ca/files/2020/02/Advanced-Biofuels-Potential-for-Cost-Reduction-Final-Draft.pdf (accessed on 15 June 2025).

- Neste. Renewable Products. 2025. Available online: https://www.neste.com/investors/market-data/renewable-products (accessed on 15 June 2025).

- U.S. Department of Energy. Alternative Fuel Price Report. 2024. Available online: https://afdc.energy.gov/fuels/prices.html (accessed on 15 June 2025).

- Fortune. Hydrotreated Vegetable Oil Market Size [2023–2030] Exhibits 12.95 % CAGR to Reach USD 35.19 Billion in 2030. 2023. Available online: https://www.globenewswire.com/news-release/2023/12/06/2791605/0/en/Hydrotreated-Vegetable-Oil-Market-Size-2023-2030-Exhibits-12-95-CAGR-to-Reach-USD-35-19-billion-in-2030.html (accessed on 15 June 2025).

- Market Research Future. Global Hydrotreated Vegetable Oil (HVO) Market Overview. 2025. Available online: https://www.marketresearchfuture.com/reports/hydrotreated-vegetable-oil-hvo-market-24009 (accessed on 15 June 2025).

- NMSC. Hydrotreated Vegetable Oil (HVO) Market. 2025. Available online: https://www.nextmsc.com/report/hydrotreated-vegetable-oil-market (accessed on 15 June 2025).

- Shay, T. Viewpoint: European HVO Demand to Rise in Argus Media. 2025. Available online: https://www.argusmedia.com/en/news-and-insights/latest-market-news/2641460-viewpoint-european-hvo-demand-to-rise-in-2025 (accessed on 15 June 2025).

- CARB. Low Carbon Fuel Standard. 2024. Available online: https://ww2.arb.ca.gov/our-work/programs/low-carbon-fuel-standard (accessed on 25 May 2025).

- LII. Cal. Code Regs. Tit. 13, § 2281—Sulfur Content of Diesel Fuel. 2006. Available online: https://www.law.cornell.edu/regulations/california/13-CCR-2281 (accessed on 15 June 2025).

- ANP. Mistura de Biodiesel ao Diesel Passa a ser de 13% a Partir de Hoje. 2022. Available online: https://www.gov.br/anp/pt-br/canais_atendimento/imprensa/noticias-comunicados/mistura-de-biodiesel-ao-diesel-passa-a-ser-de-13-a-partir-de-hoje-1-3 (accessed on 15 June 2025).

- Tiburcio, R.S.; de Macêdo, T.R.; Neto, A.M.P. Brazilian Biofuels Policy (RenovaBio): Overview and generation of decarbonization credits by biodiesel production facilities. Energy Sustain. Dev. 2023, 77, 101334. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Average Annual Vehicle Miles Traveled by Major Vehicle Category. 2021. Available online: https://afdc.energy.gov/data/10309 (accessed on 15 June 2025).

- Hernández, J.J.; Rodríguez-Fernández, J.; Calle-Asensio, A. Performance and regulated gaseous emissions of a Euro 6 diesel vehicle with Lean NOx Trap at different ambient conditions: Sensitivity to the type of fuel. Energy Convers. Manag. 2020, 219, 113023. [Google Scholar] [CrossRef]

- ILOS. Transporte Rodoviário: Perspectivas Para 2023. 2023. Available online: https://ilos.com.br/transporte-rodoviario-perspectivas-para-2023/ (accessed on 15 June 2025).

- Victor, L. Composição de Custos no Transporte Rodoviário. 2022. Available online: https://blendtransportes.com.br/composicao-do-custo-do-transporte-rodoviario/ (accessed on 15 June 2025).

| Property | DIESEL | BIODIESEL | HVO | Reference |

|---|---|---|---|---|

| Appearance at 25 °C | Yellowish transparent | Light yellow to orange | Clear and transparent | - |

| C (wt.%) | 85.33 | 76.88 | 84.60 | (da Costa et al. 2022) [38] |

| H (wt.%) | 13.12 | 11.46 | 15.39 | |

| O (wt.%) | 1.55 | 11.64 | 0.00 | |

| S (wt.%) | 0.001 | 0.00 | 0.00 | |

| H/C ratio | 1.84 | 1.77 | 2.14 | - |

| Stoichiometric air fuel ratio | 14.92 | 12.19 | 14.89 | - |

| LHV (MJ/kg) | 43.04 | 37.26 | 43.96 | (Rodríguez-Fernández et al. 2016) [39] |

| Density at 15 °C (kg/m3) | 811 | 874 | 780 | |

| Kinematic viscosity at 40 °C (cSt) | 2.02 | 4.50 | 2.99 | |

| Cetane number | 67 | 69 | 95 | |

| Lubricity WS1.4 (μm) | 226 | 187 | 334 | |

| Total aromatics (wt.%) | 30 | 0 | 0 | (Garraín et al. 2014) [40] |

| Stability storage | Good | Challenging | Good |

| Study (Source) | Feedstock | Price (USD/L) | Country/Region | Capacity (kt/y) | Economic Considerations |

|---|---|---|---|---|---|

| Julio (2020) [55] | Palm oil | 0.2 | Brazil | - | HVO produced as a byproduct, 4× cheaper than biodiesel in Brazil. |

| Martinez-Hernandez et al. (2019) [56] | Palm oil | 0.92 | Mexico | ≥7.8 * | Stand-alone with MSP to mitigate financial risks: 1 USD/L. |

| Glisic et al. (2016) [57] | Waste vegetable oil | 0.631 | - | ≥200 | Economic viability improves with co-processing in refineries. |

| Lorenzi et al. (2020) [27] | UCO | 0.79 | Sweden and Norway | 100 | Tax incentives enhance HVO competitiveness. |

| Brown et al. (2020) [58] | - | 0.55–0.97 | Global | - | Costs largely influenced by raw material prices and feedstock availability. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez-Rangel, N.V.; Ancheyta, J.; de Souza, T.A.Z.; da Costa, R.B.R.; Sousa, D.J.; Cardinali, V.B.A.; Frez, G.V.; Vidigal, L.P.V.; Pinto, G.M.; Roque, L.F.A.; et al. HVO Adoption in Brazil: Challenges and Environmental Implications. Sustainability 2025, 17, 6128. https://doi.org/10.3390/su17136128

Pérez-Rangel NV, Ancheyta J, de Souza TAZ, da Costa RBR, Sousa DJ, Cardinali VBA, Frez GV, Vidigal LPV, Pinto GM, Roque LFA, et al. HVO Adoption in Brazil: Challenges and Environmental Implications. Sustainability. 2025; 17(13):6128. https://doi.org/10.3390/su17136128

Chicago/Turabian StylePérez-Rangel, N. V., J. Ancheyta, T. A. Z. de Souza, R. B. R. da Costa, D. J. Sousa, V. B. A. Cardinali, G. V. Frez, L. P. V. Vidigal, G. M. Pinto, L. F. A. Roque, and et al. 2025. "HVO Adoption in Brazil: Challenges and Environmental Implications" Sustainability 17, no. 13: 6128. https://doi.org/10.3390/su17136128

APA StylePérez-Rangel, N. V., Ancheyta, J., de Souza, T. A. Z., da Costa, R. B. R., Sousa, D. J., Cardinali, V. B. A., Frez, G. V., Vidigal, L. P. V., Pinto, G. M., Roque, L. F. A., Mattos, A. P., Coronado, C. J. R., & Hernández, J. J. (2025). HVO Adoption in Brazil: Challenges and Environmental Implications. Sustainability, 17(13), 6128. https://doi.org/10.3390/su17136128