Abstract

Addressing the challenges of Industry 4.0 in Thailand’s agri-food logistics (AFL), this study develops a structural logistics management model grounded in the Technology–Organization–Environment (TOE) framework, Resource-Based View (RBV), and Dynamic Capabilities (DC) theory. The model integrates four key constructs: standardization, operations management, smart technology, and wastage management targeting cold chain logistics (CCL) systems. Using a mixed-methods design, the study combines in-depth expert interviews with a quantitative survey of 300 logistics firms certified under the Q Cold Chain standard. Structural equation modeling (SEM) analysis confirms the robustness of the model (CMIN/DF = 1.151; GFI = 0.928; RMSEA = 0.022), supporting all five hypotheses. The findings show that standardization significantly enhances both operational performance and the adoption of digital technology, while waste reduction acts as a key mediator linking organizational processes to technological transformation. By highlighting institutional certification as a policy instrument, this research addresses existing gaps in logistics innovation literature. The results inform both theory and practice, supporting Thailand’s strategic transition toward sustainable, digitally enabled agri-logistics ecosystems.

1. Introduction

The transformation of Thailand’s economic structure toward the “Thailand 4.0” model represents a critical national agenda aimed at enhancing the country’s global competitiveness. This strategic shift moves beyond Thailand’s comparative advantages—namely, its biodiversity and rich cultural heritage—toward developing competitive advantages through technological innovation and industrial restructuring. In line with the 20-Year National Strategy (2018–2037) and the 13th National Economic and Social Development Plan (2023–2027), the focus is on fostering a high-value-added economy, promoting eco-friendly living, advancing an equitable society, and strengthening key national enablers. Agriculture remains a vital sector within Thailand’s economy, employing over 56.4% of the national workforce. However, despite its socio-economic significance, inefficiencies persist within the food value chain, particularly concerning food loss and food waste throughout production, transportation, storage, and distribution stages. National statistics reveal a growing volume of municipal solid waste, underscoring the magnitude of these inefficiencies, especially in highly urbanized areas such as Bangkok and its surrounding provinces. Compounding these challenges, the advent of the COVID-19 pandemic highlighted vulnerabilities within agricultural supply chains (ASCs), particularly concerning the distribution of perishable goods. Moreover, the global acceleration of e-commerce has significantly altered consumer behavior, with Thailand leading the region in the growth of business-to-consumer (B2C) e-commerce, especially in the frozen and ready-to-eat food sectors.

Nevertheless, Thailand’s agricultural sector faces a persistent gap, the lack of integrated cold chain management (CCM) across all stages of the supply chain, limiting the ability to meet modern consumer expectations for quality, safety, and convenience. Existing studies, e.g., Refs. [1,2,3], have examined aspects of cold chain logistics (CCL) and food supply chain (FSC) efficiency. However, research remains fragmented, often focusing on isolated stages of the supply chain rather than a holistic, systemic approach. Furthermore, practical models for the systematic implementation of CCM that are evidence-based, scalable, and tailored to the Thai agricultural industry remain underdeveloped. Despite the critical importance of agriculture to Thailand’s economy, there is still a lack of comprehensive frameworks that address the specific logistical, technological, and environmental challenges faced by this sector. This gap is further underscored by the work of [4], who emphasize the need for evaluation frameworks specific to regional agricultural products (AP), and [5], who advocate for the integration of context-aware smart technologies in agriculture.

This study thus attempts to bridge the theoretical and contextual gap by integrating three core perspectives—a Technology–Organization–Environment (TOE) framework, Resource-Based View (RBV), and Dynamic Capabilities (DC)—into a comprehensive structural model tailored to Thailand’s AFL context. The model aims to systematically address how standardization (STD) and smart technologies (STs) interact under institutional pressures to reduce food loss and enhance service quality in CCL. Building on the identified theoretical and contextual gaps, this study aims to develop a theory-informed structural model for improving service quality and sustainability outcomes in AFL, with a particular focus on refrigerated transportation in Thailand’s Industry 4.0 era. Grounded in the TOE framework and enriched by the RBV, this model hypothesizes that ST and organizational standardization, when effectively aligned, can enhance CCM, reduce food wastage, and improve service reliability. Institutional pressures such as the Q Cold Chain certification are also incorporated to reflect regulatory influences on adoption and compliance behaviors. Thailand’s agri-logistics sector is characterized by fragmented supply chain networks, a high reliance on informal markets, and an uneven adoption of standardized practices. These contextual specificities shape the practical implementation of cold chain innovations and require localized strategic models. This study reflects such conditions by sampling from Q Cold Chain-certified firms and embedding Thai policy drivers into the structural model. In sum, this research is positioned at the intersection of logistics innovation, AFL modernization, and institutional transformation. It seeks to offer both theoretical and practical contributions by providing an empirically tested framework that supports the development of efficient, compliant, and digitally enabled cold chain systems. Ultimately, the findings aim to inform policymakers, logistics providers, and agribusiness stakeholders in advancing Thailand’s transition toward a high-value, resilient, and sustainable food logistics ecosystem.

2. Theoretical Foundation

This research is based on an integrated conceptual framework that primarily utilizes the TOE framework and the RBV for analysis, incorporating selected concepts from the DC theory to deepen our understanding of organizational strategy and adaptability. The TOE framework [6] serves as a contextual structure that categorizes the factors influencing innovation’s adoption into three dimensions:

- Technological Dimension: Represented by “STs” such as IoT, real-time monitoring systems, and intelligent cold chain management technologies.

- Organizational Dimension: Illustrated through “STD”, including standardized operating procedures, internal quality control systems, and “Operations management (OM)”.

- Environmental Dimension: Reflected in market conditions, customer expectations, and industry standards such as the Q Cold Chain.

Within this conceptual framework, the RBV [7] is employed to elucidate how STs, STD, and OM function as strategic resources that are valuable, rare, and embedded within organizational structures. These resources are pivotal in enhancing operational efficiency, minimizing waste, and securing a sustainable competitive advantage. In this study, OM is defined as the organizational capability to plan, control, and manage temperature-controlled transportation (TCT) in compliance with established standards. This reflects the strategic deployment of resources as posited by the RBV, alongside systemic adaptation as conceptualized within the DC framework.

Simultaneously, “Wastage management (WM)” is conceptualized as a strategic outcome derived from the integration of technological advancements, standardized practices, and effective management systems. A reduction in product loss within the cold chain serves as evidence of an organization’s capacity to deploy resources efficiently while maintaining quality standards. To further enrich this strategic perspective, this study incorporates DC theory [8], which emphasizes that organizations must not only possess appropriate resources but also develop the ability to sense, seize, and reconfigure those resources and internal processes in response to evolving technological and regulatory environments. In summary, the TOE and RBV frameworks constitute the foundational analytical models for exploring innovation systems and organizational resources, whereas the DC perspective offers critical insights into adaptability and resource flexibility within the context of Thailand’s CCL sector.

Building on this integrated conceptual framework, this study proceeds to define the key constructs derived from the TOE, RBV, and DC theories. These constructs (OM, STD, WM, and ST) are operationalized to reflect the essential capabilities required for CCL performance in the agri-food sector. Drawing from both theoretical underpinnings and empirical studies, Table 1 outlines the definitions used for each construct, serving as the basis for subsequent model development and hypothesis testing.

Table 1.

Construct definitions for cold chain logistics capabilities.

Macro Logistics Planning and Cold Chain Integration

Macro logistics literature focuses on theoretical development, national-level analytical tools, and policy decision-making models, such as freight flow models and national logistics cost assessments [16]. However, practical applications in developing countries remain underexplored. Conversely, cold chain research, particularly in the agriculture and food sectors, has advanced operationally, including smart temperature monitoring, optimized transport routing, and low-emission vehicles [17]. These innovations reduce food losses and improve cost efficiency and service quality. Furthermore, SME clustering and collaborative networks are key to resource enhancement and government support, especially for developing cold chain infrastructure in remote areas—crucial for minimizing food losses and enhancing supply chain resilience [18,19]. Taken together, while macro logistics remains theory-driven, its principles can inform cold chain innovations at the organizational level. This study employs Thailand’s policy framework and the Q Cold Chain standard to link national strategies with business-level implementation.

While prior studies have made important contributions to the field of CCL, most have treated key dimensions—such as standardization, waste reduction, and smart technologies—in isolation. Table 2 presents a comparative overview of representative studies, highlighting the conceptual fragmentation and the gap that this research aims to address.

Table 2.

Comparative analysis of existing models and the proposed framework.

Based on the construct definitions established above, this section presents the development of the research hypotheses and the conceptual framework. The hypotheses are formulated to reflect the theoretically driven interrelationships among the constructs, as informed by the TOE, RBV, and DC perspectives. The proposed structural model aims to empirically investigate the causal linkages that influence the effectiveness and sustainability of CCL operations within Thailand’s agri-food sector. To reinforce the theoretical foundation of this study, Table 3 presents a systematic mapping between the key research elements—including research questions (RQs), objectives (ROs), related theories, and hypotheses (H1–H5). This structure ensures logical coherence between the conceptual framework (TOE, RBV, and DC) and the empirical model. Each research question is explicitly linked to its theoretical underpinning and corresponding hypothesis, thereby aligning the study’s design with its theoretical foundations.

Table 3.

Theoretical mapping of research questions, objectives, and hypotheses.

3. Hypotheses Development and Theoretical Framework

3.1. Standardization

Ref. [3] points out that the sustainability of fresh FSC logistics relies heavily on the rigorous STD of storage and transportation processes. Ref. [1] supports the notion that temperature control standards within the cold chain significantly affect product quality and consumer trust. In the context of China, Ref. [4] demonstrates that standard-related factors have a substantial influence on performance evaluation systems for agricultural logistics services. However, Ref. [30] reveals that in many countries, the complexity and cost of agricultural product certification remain significant barriers for small-scale producers. Ref. [11] highlights the challenges of certification systems in the meat industry, which require compliance with both hygiene and environmental standards. In Thailand, although relevant regulations exist, enforcement remains inconsistent—particularly among SMEs, which often lack the necessary resources. Ref. [25] emphasizes that supply chain resilience must be grounded in a robust STD framework, while [31] identifies institutional enforcement as a continuing weakness in developing countries. A critical research gap yet to be addressed is the role of institutional pressure in the implementation of standards within Thailand’s CCL sector.

3.2. Wastage Management

Ref. [10] highlights that the majority of food losses within the supply chain stems from inadequate temperature control during transportation. Ref. [12] further explains that the assessment and recovery of waste in the food industry remain major challenges. Ref. [12] reviews advancements in waste reduction within the cold chain, particularly in the meat industry. Ref. [3] supports the view that well-designed standards can reduce waste at every level of the supply chain, while [11] emphasizes that perishable products such as meat exhibit high loss rates in the absence of robust control systems. Ref. [4] proposes cold chain management approaches that focus on efficient resource utilization. [32] link the concept of a circular economy to the reuse of food waste, while [1] underscores the role of the traceability systems in waste control. In the Thai context, traditional markets and small-scale logistics systems still lack the technology and expertise required for effective waste management. A key gap in the literature is the absence of empirical models measuring the impact of waste management strategies on FSCs’ performance, particularly among SMEs and smallholder farmers.

3.3. Operations Management

Ref. [4] proposes that cold chain process control must account for both cost and delivery efficiency. Ref. [33] supports the view that logistics service factors—such as routing and delivery timing—affect product quality. Ref. [3] argues that integrated logistics management, including inventory control and cross-organizational collaboration, is key to enhancing efficiency. Ref. [9] analyzes the role of inter-organizational coordination in the supply chain and emphasizes the importance of system-level cost management. Ref. [8] reviews research trends in resilience, focusing on a system’s ability to adapt to changes. Ref. [25] asserts that operational flexibility is a crucial component of supply chain resiliency. Ref. [1] highlights the importance of designing transport systems that ensure consistent temperature control. Similarly, Ref. [12] points out that efficiency in waste management depends on precise operations and the availability of supporting data. According to ref. [18] in Thailand, small-scale operators still lack decision-support systems such as ERP or KPI frameworks. An important gap lies in identifying suitable methods for applying operations management principles within Thailand’s resource-constrained environment.

3.4. Smart Technology

Ref. [34] reviews the role of smart technologies, such as IoT and AI, in enhancing efficiency within the agricultural sector. Ref. [4] reports that logistics service evaluation systems in China have begun integrating digital monitoring technologies to assess transport quality. Ref. [1] notes that smart cold chain systems, such as real-time temperature tracking, contribute to loss reductions. Ref. [35] emphasizes that blockchain and IoT can enhance transparency and traceability within supply chains. Ref. [4] points out that automation systems influence resource control in the cold chain, while [12] supports the use of technology to analyze waste data for more precise planning. Ref. [25] indicates that digital transformation improves supply chain resilience during crises such as COVID-19. Meanwhile, Ref. [34] also stresses the role of smart technologies in promoting agricultural sustainability. In Thailand, SMEs face limitations in accessing and adopting smart technologies due to cost constraints, limited skilled personnel, and a lack of understanding. A critical research gap lies in the investigation of the technological readiness and external pressures that influence technology adoption within Thailand’s cold chain sector.

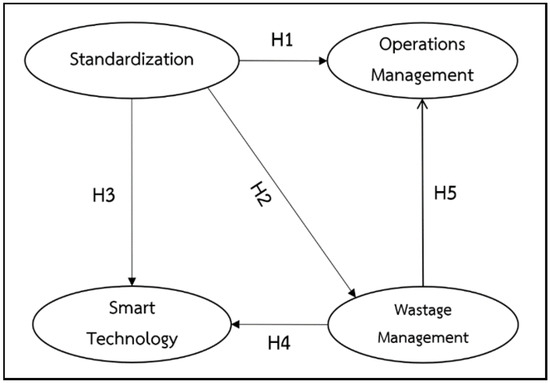

In response to the aforementioned theoretical considerations, this study integrates the TOE framework, the RBV, and DC theory to construct a comprehensive conceptual model. This model is structured around four key constructs and the interrelationships between them, articulated through five core hypotheses (H1–H5). This study contributes a novel structure by integrating institutional pressure (i.e., Q Cold Chain certification) as an enabling environmental context, which is rarely incorporated in prior models of smart cold chain logistics. While most frameworks stop at technical innovation, our model uniquely emphasizes how Thailand’s regulatory mechanisms and national logistics policy (e.g., SL vision) directly affect standardization and digital adoption at the firm level. This model aims to empirically examine the determinants of loss reductions and service quality enhancement in temperature-controlled logistics (TCL). within Thailand’s agricultural sector, as illustrated in Figure 1.

Figure 1.

Conceptual framework.

3.5. Relation Between “STS” and “OM”

The application of standards in the logistics sector plays a vital role in enhancing the quality of agricultural and food transportation services. Ref. [22] highlights that ISO standards help mitigate food safety risks in international logistics operations. Meanwhile, Ref. [23] suggests that the standardization of customer service improves responsiveness and increases customer satisfaction. Ref. [36] finds that the development of regional standards fosters collaboration among producers and enhances stability. In addition, Ref. [25] confirms a positive correlation between operational quality standards and customer satisfaction. Furthermore, Ref. [37] notes that comprehensive production standards contribute to improving the quality of AP, and quality control through internal transport organization standards enhances the credibility of sustainable logistics services.

H1:

Latent variables: the “STD” element directly influences the “OM” element.

3.6. Relation Between “STD” and “WM”

Logistics standards play a critical role in enhancing the quality of transportation services for agricultural and food products, particularly in managing waste during transit. Ref. [22] demonstrates that the adoption of ISO standards in international logistics effectively ensures food quality and safety. Ref. [26] proposes a well-defined process standardization framework for managing raw materials and warehouses to minimize losses. Ref. [3] emphasizes the importance of closed-loop transport process control in CCL to reduce the spoilage of fresh AP. Ref. [36] highlights how Lean and Six Sigma methodologies enhance service quality while reducing waste. Finally, Ref. [32] illustrates that clear standards contribute to strengthening the capabilities and financial outcomes of logistics service providers.

H2:

Latent variables: the “STD” element directly influences the “WM” element.

3.7. Relation Between “STD” and “ST”

STD plays a pivotal role in driving the effective implementation of ST in agriculture and food transportation. Refs. [5,38] highlight that standardized infrastructures—such as sensor precision and IoT networks—enhance the efficiency of both agricultural production and logistics operations. Ref. [34] emphasizes that ICT standards in smart farming enhance the interoperability of automated systems. Ref. [36] affirms that standards serve as the backbone of quality management systems, reducing variability and improving the reliability of transport services. Additionally, Ref. [39] points out that standardization contributes to greater competitiveness by elevating the quality of AP. Ref. [40] further argues that standards facilitate service innovation and cross-organizational collaboration to develop smart solutions within the FSC.

H3:

Latent variables: the “STD” element directly influences the “ST” element.

3.8. Relation Between “WM” and “ST”

WM in agriculture and logistics has a direct impact on the development of smart technologies, which in turn enhance the efficiency of agricultural and food transportation services. Ref. [41] shows that smart sensors reduce waste in precision farming systems. Ref. [42] proposes the use of fuzzy logic-based irrigation systems to minimize excessive water usage. Ref. [43] emphasizes the role of IoT in forecasting and reducing post-harvest losses. Ref. [44] supports the use of AI to reduce pollution and promote sustainable water management. Ref. [45] develops the Internet of Everything (IoE) to enable precise logistics networking. Finally, Ref. [46] reports that smart water management systems can reduce wastage by up to 92%.

H4:

Latent variables: the “WM” element directly influences the “ST” element.

3.9. Relation Between “WM” and “OM”

WM plays a crucial role in enhancing operational efficiency. Ref. [40] demonstrates that quality management in logistics can significantly reduce systemic losses and improve organizational performance. Ref. [47] asserts that timely delivery and attentiveness in fresh food services can minimize losses during the delivery phase. Ref. [4] finds that the quality of CCL has a direct impact on reducing waste and increasing the efficiency of agricultural transportation. Ref. [48] emphasizes that effective WM in fresh FSCs contributes both to sustainability and financial performance Ref. [35] proposes the use of blockchain technology for data management to minimize losses in high-value food logistics systems. Finally, Ref. [49] highlights that waste control in halal food systems enhances the overall product quality and operational performance.

H5:

Latent variables: the “WM” element directly influences the “OM” element.

4. Materials and Methods

This study employed mixed methods, integrating both qualitative and quantitative research phases, to develop a logistics management model for agricultural and food products utilizing cold chain trucks in Thailand.

4.1. Qualitative

Qualitative, in-depth interviews were conducted with three logistics experts selected through purposive sampling to ensure a comprehensive representation across sectors. The expert panel consisted of

- A senior executive from a Temperature-Controlled Transport Company;

- A government official from a relevant regulatory agency;

- An academic specializing in logistics and supply chain management.

Integration of qualitative and quantitative phases: The expert interviews conducted in the qualitative phase were not merely descriptive but served as a critical foundation for the development of the quantitative research instrument. Insights obtained from logistics executives, government regulators, and academic specialists were thematically analyzed and mapped into observable indicators for each latent construct (OM, STD, WM, and ST). These indicators were operationalized into a structured questionnaire comprising 50 Likert-scale items—14 for OM, 13 for STD, 10 for WM, and 13 for ST—ensuring empirical coherence with the conceptual framework. This mixed-methods integration strengthens the validity of the findings and aligns with best practices in logistics and supply chain research methodology.

4.2. Quantitative

The quantitative research targeted logistics companies certified under the Q Cold Chain Standard 2023 by the Department of Land Transport of Thailand. The study population consisted of 1099 companies, with a sample size of 300 companies, determined according to the guidelines of [50]. This study selected Q Cold Chain-certified companies in Thailand as the research population for several key reasons. First, transportation directly affects food loss rates [51]. Second, the absence of standards and planning impacts the quality of APs [3]. Third, food losses result from the lack of standardized systems and closed-loop control throughout the transportation chain [3]. Therefore, the Q Cold Chain Standard plays a crucial role in domestic goods transportation, as it helps preserve product quality, control losses, and effectively enhance consumer confidence. For SEM, the sample size is considered adequate for robust multivariate analysis. A multi-stage sampling method was employed as follows:

- Stratified probability sampling was employed in the first stage to categorize companies into two groups: medium-sized TCL providers (150 companies) and large-sized TCL providers (150 companies).

- In the second stage, quota sampling was used to ensure balanced representation.

- The third stage applied simple random sampling (lottery method) to select companies within each group. The respondents were business owners or senior executives (e.g., managers, directors) responsible for logistics operations strategy.

However, it is important to acknowledge that the selected sample may have certain limitations specific to the Thai context, as the Q Cold Chain Standard is not yet widely adopted or internationally recognized. It is currently a standard utilized and accepted within Thailand.

4.3. Research Instruments

4.3.1. Qualitative Instrument

Qualitative data collection was conducted through an extensive review of relevant theories and prior studies, forming the basis for a structured interview guide. A set of structured, open-ended questions—specifically developed for this study—was employed to explore all four predefined dimensions.

4.3.2. Quantitative Instrument

Quantitative data were collected using a structured questionnaire comprising four sections. The instrument was developed and validated by three experts in the relevant field using the Index of Item-Objective Congruence (IOC), with all items exceeding the threshold of 0.50. A pilot test (try-out) was subsequently conducted with a sample of 30 participants possessing characteristics similar to those of the main study population. Discrimination analysis revealed standard deviations (S.D.s) greater than 0.30 for checklist items, while internal consistency reliability for scaled items yielded Cronbach’s alpha coefficients exceeding 0.90. These results indicated that the questionnaire was ready for full deployment.

- Section 1: General Organizational Information—Consisted of 2 checklist items and 3 open-ended questions.

- Section 2: Organizational Structure and Operations—Included 10 checklist items.

- Section 3: Enhancing Service Quality in Cold Chain Transportation for AFL in the Industry 4.0 Era—Comprised 50 items measured using a five-point Likert scale, based on the model proposed by Likert.

4.4. Data Analysis

4.4.1. Qualitative Analysis

Interview data were analyzed using content analysis. Responses were categorized and interpreted into themes aligned with the four dimensions to form a conceptual framework for enhancing service quality in the CCL sector.

4.4.2. Quantitative Analysis

The statistical analysis was conducted using Statistical Software and AMOS. The following methods were applied:

- Descriptive statistics: Frequency distributions, percentages, means (), and S.D.s were computed for checklist and Likert-scale items.

- Content analysis: Applied to open-ended responses in the quantitative section, with results expressed as frequencies.

- Inferential statistics: (1) Bivariate correlation analysis was used to examine inter-variable relationships (significance thresholds at p < 0.001, 0.01, and 0.05). (2) Chi-square tests (Pearson’s χ2) were used to assess associations between firm characteristics and logistics performance. (3) Independent sample t-tests assessed performance differences across firm types (p < 0.05).

- SEM: (1) A multivariate SEM approach was applied using AMOS, following model development protocols [52]. The model’s latent constructs were assessed through latent variable adjustment procedures. (2) Model refinement was conducted using Modification Indices (M.I.s), guided by both theoretical reasoning and empirical indicators, until the model fit indices met recommended thresholds.

4.4.3. Measurement Model Development and Instrument Validation

To enhance its internal validity and minimize researcher bias, this study systematically designed its data collection procedures, employing standardized protocols for all respondents in both qualitative and quantitative phases. Interviewers were trained to apply a consistent interview approach across all cases to ensure comparability of data and reduce inter-individual variability.

To control for confounding variables, the structure of the questionnaire and the sampling strategies were tailored to align with the research objectives. The distribution and collection of the questionnaires were conducted within a short and consistent timeframe across all sample groups to mitigate the influence of external temporal factors.

Regarding the reliability and validity of the research instrument, internal consistency was assessed using Cronbach’s alpha, with all latent variables scoring above 0.80, indicating excellent reliability. Furthermore, both first-order (CFA) and second-order (S-CFA) confirmatory factor analyses were employed to verify the internal structure of the questionnaire. The model demonstrated good fit indices (GFI = 0.930, RMSEA = 0.020), supporting the adequacy of the measurement structure.

Finally, the issue of multicollinearity was evaluated by examining the Variance Inflation Factor (VIF). All VIF values were found to be below 3.30, as recommended [53], indicating no latent correlations that could compromise the accuracy of the model.

4.4.4. Assessment of Non-Response Bias and Procedural Remedies for Common Method Variance

To evaluate the potential for non-response bias, this study employed the extrapolation method as proposed [54]. This involved comparing data from early respondents and late respondents using an independent samples t-test. The analysis revealed no statistically significant differences at the p < 0.05 level, indicating the absence of non-response bias.

Furthermore, to control for common method variance (CMV), procedural remedies were applied, including the use of standardized measurement instruments, consistent instructions for all respondents, assurances of anonymity, and clearly separated items according to constructs. All questionnaires were distributed and collected within a narrow and consistent timeframe to minimize the influence of external factors. This design aligns with the widely accepted recommendations [55] for reducing CMV.

5. Results

5.1. Qualitative Insights

OM: In the domain of OM, the study reveals that the effectiveness of TCL in Thailand hinges on systematic planning and proactive operational strategies. Respondents emphasized the importance of real-time temperature monitoring, pre-planned routing, and consistent personnel training. For example, a business executive stated, “We have a 24 h temperature control center. If there is any temperature deviation, the system immediately sends an alert to mobile devices.” This reflects the integration of technology to enhance the responsiveness of logistics systems. Simultaneously, standard operating procedures (SOPs) and the promotion of green logistics were also found to play crucial roles. Government officials and academics noted, “We are piloting the use of electric vehicles for short-distance routes to conserve energy and reduce carbon emissions.” This trend signifies a systemic development that incorporates flexibility, precision, and environmental consciousness.

STD: Standards serve as a fundamental component in ensuring safety and consistency in temperature-controlled transportation. Informants across all sectors emphasized adherence to Good Manufacturing Practice (GMP) guidelines, the use of checklists for inspections, and documentation such as cold chain forms for temperature control. Government officials and academics noted, “Every inspection must be recorded—for example, vehicle cleanliness and driver health—to allow for traceability.” The private sector also highlighted the importance of personnel knowledge and selecting appropriate packaging based on product type, along with the certification of refrigerated containers to meet international standards. As stated by both executives and scholars, “Every vehicle must use a refrigerated unit certified by food safety authorities.” Collectively, these practices reflect a management approach centered on transparency, reliability, and traceability.

WM: Minimizing losses in TCL requires a comprehensive preventive approach, incorporating both technical and managerial strategies. The findings indicate that organizations employ suitable packaging materials, contingency planning for overflow situations, and continuous personnel training. For instance, an executive stated, “EPS boxes can retain cold temperatures even if the vehicle breaks down enroute. This is critically important during long transport times.” Meanwhile, scholars and government officials highlighted, “Leaving a refrigerated container door open for just a few minutes can spoil the entire shipment.” These insights underscore the importance of preventive system design aimed at risk reduction and enhanced flexibility in managing highly perishable goods.

ST: Modern technology plays a pivotal role in enhancing the capabilities of TCL systems, particularly in improving accuracy, enabling real-time monitoring, and facilitating stakeholder communication. Respondents widely cited the use of data loggers, GPS tracking systems, and transportation management systems (TMSs). For example, one executive, academic, and government official commented, “Temperature data from the past six months can be retrieved instantly for troubleshooting or audit purposes.” Government officials and academics also mentioned the pilot testing of Vehicle-to-Infrastructure (V2I) systems to improve fleet efficiency. Additionally, academics referred to the application of big data analytics to optimize truck utilization planning. This study also found that online platforms are increasingly used to allow customers to access real-time data, thereby enhancing trust and transparency in service delivery.

5.2. Industrial Business Factors

The respondents were 300 logistics companies in Thailand certified under the Q Cold Chain standard, including 150 medium-sized and 150 large-sized enterprises. The majority of the organizations were Partnership Registration as Company limited (52.30%) and had been in operation for more than 5 to 10 years (53.0%) (Table 4).

Table 4.

Industrial business factors.

The importance of cold chain trucks in improving the transportation service quality for agricultural and food products was assessed as high across both medium and large-sized enterprises. The overall mean score was 3.91 (S.D. = 0.45), indicating a consistently high perception of their contribution. When analyzing specific dimensions, all factors were rated at a high level of importance, as shown in Table 5. In particular, OM received the highest overall mean score of 3.97 (S.D. = 0.46), followed closely by ST ( = 3.96, S.D. = 0.50), STD ( = 3.90, S.D. = 0.57), and WM ( = 3.83, S.D. = 0.57). These findings suggest that logistics service providers across enterprise sizes recognize the critical role of CCL in maintaining quality, reducing waste, and ensuring operational efficiency within the agricultural and food sectors. Notably, large enterprises consistently reported slightly higher mean scores across all dimensions, particularly in ST ( = 3.99) and WM ( = 3.90), indicating their greater emphasis on leveraging CCL systems to enhance service quality and operational effectiveness.

Table 5.

Importance level CCL in Thailand’s agri-food sector.

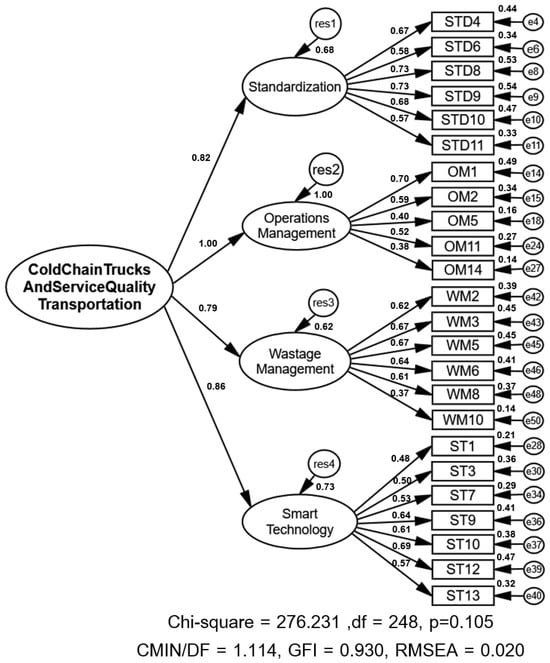

5.3. S-CFA: Second-Order Confirmatory Factor Analysis

The refinement of the S-CFA, based on a fully developed first-order CFA structure, resulted in a significantly improved model fit. This aligns with widely accepted criteria for evaluating model adequacy. The model fit indices fall within satisfactory ranges (CMIN-ρ = 0.105; CMIN/DF = 1.114; GFI = 0.930; RMSEA = 0.020), reflecting a strong congruence between the hypothesized model and the empirical data. The analysis of standardized regression weights and coefficients of determination (R2) enabled prioritization of the four latent constructs based on their relative influence: OM (β = 1.002, R2 = 1.004), ST (β = 0.857, R2 = 0.735), STD (β = 0.822, R2 = 0.675), and WM (β = 0.790, R2 = 0.625). These findings underscore the hierarchical structure of the model and provide empirical support for the theoretical foundations of the relationships among the constructs in the context of logistics (Figure 2).

Figure 2.

S-CFA model fit after modification.

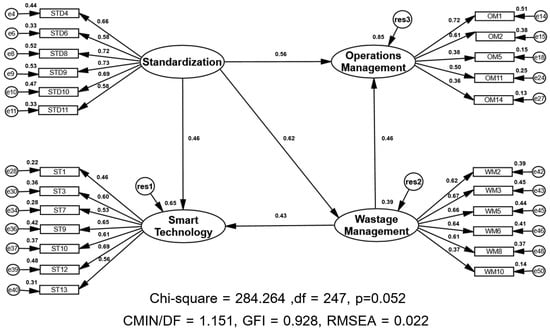

5.4. SEM Analysis

Trucks in Improving Transportation Service Quality for Agricultural and Food Products was evaluated in its standardized form, comprising 24 observed variables and five hypothesized. As a result, the SEM and model fit indices were a good fit, with values of CMIN-ρ = 0.052, CMIN/DF = 1.151, GFI = 0.928, and RMSEA = 0.022. These results confirm that the revised SEM model was statistically acceptable, in line with the criteria proposed [51]. Furthermore, all five hypotheses (H1–H5) were supported, with statistically significant path coefficients at the 0.001 level. The standardized regression weights for the respective hypotheses were 0.56, 0.62, 0.46, 0.43, and 0.46, as summarized in Figure 3 and Table 6 and Table 7.

Figure 3.

Structural equation model after modification.

Table 6.

Final SEM model fit indices and evaluation statistics.

Table 7.

The observed variable factors left after model modification.

For model modification, the observed variable factors were prioritized based on standardized regression weights. The highest-loading indicators for each latent construct were identified as follows: STD9 (0.73) for STD, OM1 (0.72) for OM, WM3 (0.67) for WM, and ST12 (0.69) for ST (Table 7).

Finally, the hypothesis testing results under the developed SEM confirmed that all five hypotheses were positively supported, with statistical significance at the p-value < 0.000 level (Table 8).

Table 8.

Hypotheses testing and SEM results.

The hypotheses testing results are summarized as follows:

H1 testing result: The “STD” element showed a variance = 0.30 and influenced the “OM” element with a standardized regression weight = 0.56 and squared multiple correlations = 0.85, with a variance = 0.06 at a statistically significant level of 0.001.

H2 testing result: The “STD” element showed a variance = 0.15 and influenced the “WM” element with a standardized regression weight = 0.62 and squared multiple correlations = 0.39, with a variance = 0.15 at a statistically significant level of 0.001.

H3 testing result: The “STD” element showed a variance = 0.05 and influenced the “ST” element with a standardized regression weight = 0.46 and squared multiple correlations = 0.65, with a variance = 0.05 at a statistically significant level of 0.001.

H4 testing result: The “WM” element showed a variance = 0.05 and influenced the “ST” element with a standardized regression weight = 0.43 and squared multiple correlations = 0.65, with a variance = 0.05 at a statistically significant level of 0.001.

H5 testing result: The “WM” element showed a variance = 0.06 and influenced the “OM” element with a standardized regression weight = 0.46 and squared multiple correlations = 0.85, with a variance = 0.06 at a statistically significant level of 0.001.

The total effects within the revised SEM were analyzed, taking into account both direct and indirect standardized path coefficients as shown in Table 9. Among all the structural relationships, the strongest total effect was observed from “STD” to “OM,” with a standardized total effect value of 0.85. This consisted of a direct effect of 0.56 and an indirect effect through “WM” (0.62 × 0.46 = 0.285). This finding underscores the critical role of implementing standardized procedures in promoting not only operational efficiency but also more effective waste control mechanisms.

Table 9.

Total effects between latent variables.

The second-highest direct effect was identified between “ST” and “WM,” with a standardized coefficient of 0.43. This indicates that the integration of digital technologies and technological readiness has a direct impact on the effectiveness of waste reduction strategies. Furthermore, “STD” also exhibited a secondary indirect effect on “WM” through “ST” (0.46 × 0.43 = 0.198), further highlighting the multi-level influence of structured practices on operational resilience.

These results validate the theoretical model by emphasizing the mediating roles of both “WM” and “ST.” They also provide valuable insights for stakeholders in logistics who aim to enhance performance through structured technology-driven CCL systems.

These analytical results reaffirm the critical role of “STD” as a key enabler within CCL systems. It not only exerts a direct influence on operations management but also enhances overall operational efficiency indirectly through its impact on waste management. The model further reveals that “ST” functions as an intermediary mechanism that enables standardization to effectively contribute to waste reduction. This finding provides empirical support for strategic investments in standardized operational processes, the adoption of digital technologies, and logistics planning aligned with sustainability goals.

6. Discussion

This research is particularly significant in the context of Thailand’s transition toward an Industry 4.0 economy, as it presents a comprehensive framework to enhance the operational performance of agricultural and FLPs through advanced CCM. Drawing upon core components—namely STD, WM, OM, and ST adoption—the proposed model systematically addresses long-standing inefficiencies in CCL. Although the model is developed within the Thai agricultural context, its theoretical foundation aligns with broader supply chain literature, thereby reinforcing its applicability and robustness. This framework not only contributes to the academic discourse on CCL but also responds to critical national policy objectives by offering an empirically grounded approach to elevating service quality, reducing food losses, and improving consumer satisfaction across the supply chain. Ultimately, it bridges the current research practice gap and serves as a strategic tool for enhancing sustainability and resilience in AFL systems under Thailand 4.0. The implications of these results are discussed below:

6.1. Theoretical Implications

This study presents a comprehensive structural model for enhancing CCL service quality in Thailand’s agricultural sector, grounded in the four interrelated constructs: standardization, operations management, wastage management, and smart technology. The results offer empirical support for all five hypotheses (H1–H5), confirming the multidimensional interplay among these factors. The following discussion synthesizes these relationships, contextualizes them within the current literature, and draws implications for future cold chain system development in emerging economies.

6.1.1. STD as a Systemic Enabler

Our analysis reveals that STD exerts a statistically significant and positive influence on both OM (H1) and WM (H2) and the deployment of ST (H3), underscoring its role as a foundational enabler within Thailand’s CCL ecosystem. Consistent with [22], standard operating procedures such as ISO standards, vehicle certification, and systematic training for personnel serve to minimize risks and ensure quality control in temperature-sensitive logistics. This study expands upon previous findings by incorporating a holistic set of practices: not only technical compliance (e.g., STD9, STD10) but also human factor integration such as health monitoring (STD6) and process management (STD11), which are often overlooked in earlier models. Moreover, echoing [40], we find that standardization catalyzes the operationalization of ST by aligning equipment, infrastructure, and data protocols. These results provide empirical validation for the conceptual framework proposed, wherein standardization operates as a latent construct with a central role in reducing inefficiencies and facilitating cross-process integration.

6.1.2. OM as a Critical Interface

As proposed in H1 and H5, OM emerges as both a recipient of upstream enablers (STD and WM) and a critical determinant of service quality. The statistical significance of the path coefficients—e.g., STD → OM (β = 0.56) and WM → OM (β = 0.46) confirms that both technical and procedural readiness directly influence cold chain performance. Prior works [56] and [12] support this finding, emphasizing that operational governance and sustainable transport practices enhance freshness and responsiveness [2]. In our context, high-loading observed variables such as OM1 (vehicle readiness) and OM2 (manual adherence) further reinforce this view. Notably, this study bridges the existing research gap by situating OM not as an isolated function but as an outcome of systematic alignment between organizational standards and real-time logistics execution. Such an integration aligns with Thailand’s broader Industry 4.0 policy trajectory toward high-value and efficient agri-logistics systems.

6.1.3. WM as a Performance Mediator

The results reinforce the notion that WM plays a dual role: not only minimizing loss but also strengthening downstream operational performance and enabling technological adoption. Prior studies (e.g., [11,57]) primarily addressed waste reduction as a sustainability issue. Our study, however, shows that waste control is also a strategic enabler for efficiency and digital readiness. Practices such as employee reskilling (WM3), equipment specialization (WM6), and the selection of sustainable materials (WM8) demonstrate how integrated waste strategies can yield both environmental and economic benefits. These insights extend the literature by positioning wastage management as a link—not an end—in the logistics quality chain.

6.1.4. ST as an Integrative Accelerator

Consistent with H3 and H4, ST’s adoption is shown to be significantly influenced by both STD and WM, with standardized regression weights of 0.45 and 0.43, respectively. These results confirm the enabling role of organizational readiness in supporting digital transformation within AFL. Drawing from the frameworks of [34,58,59], we observe that tools like GPS tracking, V2I communication (ST3), and data loggers (ST7) are not only effective in real-time monitoring but also instrumental in maintaining service quality. Moreover, the integration of big data platforms (ST12) and mobile-enabled dashboards (ST10) promotes operational agility and decision-making accuracy. These findings are particularly relevant in the Thai context, where fragmented infrastructure often hampers the real-time utilization of data. The role of standardization (e.g., through equipment interoperability and procedural alignment) is thus reinforced as a key precursor to effective SL implementation.

6.1.5. Author’s Theoretical Propositions

- This research contributes to the theoretical discourse on CCL and Industry 4.0 in several ways:

- It proposes and validates a holistic structural equation model integrating operational, technical, and sustainability dimensions—an advancement over prior single-dimensional studies.

- It introduces wastage management as a mediating construct, thereby reframing it from a cost-control issue to a strategic enabler of technology and service performance.

- It positions wastage management not as a passive outcome but as an active strategic enabler of logistics excellence.

- The findings reinforce and extend the TOE framework, suggesting that standardization represents a critical “organizational readiness” factor influencing both operational outcomes and SL enablement.

- Empirical validation in an emerging market context like Thailand enhances the external validity of global supply chain theories, providing culturally and structurally relevant insights.

- This study advances theory by positioning wastage management as a strategic mediating capability that links standardization and smart technology—moving beyond its conventional treatment as a static outcome. Through the integrated application of TOE, RBV, and DC frameworks, this model captures the institutional and operational dynamics of cold chain systems in emerging markets. As summarized in Table 2, this structure addresses prior gaps in the empirical testing, theoretical integration, and strategic framing of digital logistics innovation.

6.2. Practical Implications in the Thai Agri-Food Cold Chain Context

Our research underscores the critical role of standardization as a key mechanism for enhancing the quality of cold chain logistics management in Thailand’s agricultural sector. This is particularly evident among medium and large-scale enterprises certified under the Q Cold Chain—a Thai-specific standard with tangible policy implications. Field operations revealed that temperature monitoring before and during transportation, the systematic management of transport documentation, and the use of real-time tracking technologies are crucial factors directly influencing logistics efficiency in a tropical climate with diverse transportation infrastructures, such as those found in Bangkok, its surrounding metropolitan areas, and agricultural zones in the North. In practice, wastage management is not only a matter of cost and environmental concern but also a vital enabler for the effective adoption of smart technologies. This includes training staff to analyze product loss data and selecting insulation materials tailored to Thai agricultural products—such as durian, mangosteen, or temperature-sensitive leafy greens.

Moreover, the deployment of smart technologies does not solely depend on infrastructure readiness but hinges on organizational understanding and acceptance. The co-development of platforms between transport providers and service recipients enhances reliability and generates added value through transparency and real-time data accessibility.

Policy recommendations: The government should promote and expand Q Cold Chain certification to include small-scale operators by emphasizing hands-on training, equipment support, and tax incentives to ensure the practical and sustained implementation of standards. In addition, evaluation tools should be developed that are responsive to the specific characteristics of different agricultural products across Thailand’s regions.

6.3. Limitations and Future Research

- This study is subject to several limitations:

- Contextual limitation: The findings are based on Thai logistics firms and may not directly generalize to other ASEAN countries.

- Model scope: Additional constructs such as regulatory pressure, investment capacity, and digital literacy may further enrich the model.

- Technological granularity: The smart technology construct primarily measured surface-level adoption; future studies may investigate AI and blockchain integration more deeply.

- While the sample selection focused on Q Cold Chain-certified companies to ensure consistency and industry relevance, this certification is uniquely applied within Thailand and not yet recognized internationally. Therefore, the findings may not be fully generalizable to other emerging markets or ASEAN member countries.

- Additionally, the purposive sampling in the qualitative phase—limited to three experts—provides depth but may lack broad sectoral representation. The quantitative phase used a stratified random sampling of medium and large enterprises, which may overlook the perspectives of smaller operators that represent a significant portion of Thailand’s AFL landscape.

- Furthermore, a theoretical limitation should be noted. Although this model integrates TOE, RBV, and DC theories, certain potentially relevant constructs—such as organizational culture, regulatory intensity, and stakeholder pressure—were not included. Future studies could explore these dimensions to further enrich the explanatory power of the framework.

Author Contributions

Conceptualization, T.K. and S.T.; methodology, T.K.; software, T.K.; validation, T.K.; formal analysis, T.K.; investigation, T.K.; resources, T.K.; data curation, T.K.; writing—original draft preparation, T.K.; writing—review and editing, T.K. and S.T.; visualization, T.K.; supervision, T.K.; project administration, T.K.; funding acquisition, T.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Faculty of Business Administration, Ramkhamhaeng University, under the research grant contract No. 194/2566. and the APC was funded by Ramkhamhaeng University.

Institutional Review Board Statement

This study was conducted in accordance with the principles of the Declaration of Helsinki and was approved by the Research Ethics and Integrity Committee of Ramkhamhaeng University, Thailand (Approval No. RU-HRE 67/0044, dated 17 May 2024).

Informed Consent Statement

Informed consent was obtained from all participants involved in the study prior to their participation.

Data Availability Statement

The data presented in this study are available upon request to the corresponding author, because the managers interviewed and surveyed agreed to respond under the confidentiality of the information.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CCM | Cold Chain Management |

| CCL | Cold Chain Logistics |

| ASC | Agricultural Supply Chains |

| AFL | Agri-Food Logistics |

| FSC | Food Supply Chain |

| FLP | Food Logistics Providers |

| TCL | Temperature-Controlled Logistics |

| AP | Agricultural Products |

References

- Mustafa, M.F.M.S.; Navaranjan, N.; Demirovic, A. Food Cold Chain Logistics and Management: A Review of Current Development and Emerging Trends. J. Agric. Food Res. 2024, 18, 101343. [Google Scholar] [CrossRef]

- Zhang, B.; Mohammad, J. Sustainability of Perishable Food Cold Chain Logistics: A Systematic Literature Review. SAGE Open 2024, 14, 21582440241280455. [Google Scholar]

- Ye, J.; Liu, S.-C. Resarch on the Whole Process Control of Cold Chain Transportation under the Background of Resource Saving. IOP Conf. Ser. Earth Environ. Sci. 2021, 791, 012116. [Google Scholar] [CrossRef]

- Jian, X.; Tonesakulrungruang, L.; Sajjanand, S.; Chantanasiri, S. Factors Influencing on the Evaluation System of Cold Chain Logistics Services for Agricultural Products in Guangxi, China. Int. J. Innov. Sci. Res. Technol. 2024, 9, 1150–1161. [Google Scholar] [CrossRef]

- Assimakopoulos, F.; Vassilakis, C.; Margaris, D.; Kotis, K.; Spiliotopoulos, D. The Implementation of “Smart” Technologies in the Agricultural Sector: A Review. Information 2024, 15, 466. [Google Scholar] [CrossRef]

- Wernerfelt, B. A resource-based view of the firm. Strateg. Manag. J. 1984, 5, 171–180. [Google Scholar] [CrossRef]

- Barney, J.B. Firm Resources and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Chen, Y.-H. Intelligent algorithms for cold chain logistics distribution optimization based on big data cloud computing analysis. J. Cloud Comput. 2020, 9, 37. [Google Scholar] [CrossRef]

- Echo Global Logistics. Temperature-controlled freight: The unsung hero of the supply chain. Food Logistics. 2023. Available online: https://www.foodlogistics.com/ (accessed on 19 March 2025).

- Caccialanza, A.; Cerrato, D.; Galli, D. Sustainability practices and challenges in the meat supply chain: A systematic literature review. Br. Food J. 2023, 125, 4470–4497. [Google Scholar] [CrossRef]

- Davoudi, S.; Stasinopoulos, P.; Shiwakoti, N. Two Decades of Advancements in Cold Supply Chain Logistics for Reducing Food Waste: A Review with Focus on the Meat Industry. Sustainability 2024, 16, 6986. [Google Scholar] [CrossRef]

- Ivanov, D. Transformation of supply chain resilience research through the COVID-19 pandemic. Int. J. Prod. Res. 2024, 62, 8217–8238. [Google Scholar] [CrossRef]

- Aloini, D.; Fronzetti Colladon, A.; Gloor, P.; Marzi, G. Enhancing Operations Management through Smart Sensors: Measuring and Improving Well-Being and Productivity in Organizations. arXiv 2021, arXiv:2112.08213. [Google Scholar] [CrossRef]

- Pajić, V.; Andrejić, M.; Chatterjee, P. Enhancing Cold Chain Logistics: A Framework for Advanced Temperature Monitoring in Transportation and Storage. Mechatron. Intell. Transp. Syst. 2024, 3, 16–30. [Google Scholar] [CrossRef]

- Hu, B.; Huang, B.; Liu, Z.; Guo, H.; Chen, Z.; Shi, L.; Qu, X. Optimization Model of Carbon Footprint of Fresh Products in Cold Chain from the Energy Conservation and Emission Reduction Perspective. Math. Probl. Eng. 2021, 2021, 5559021. [Google Scholar] [CrossRef]

- Shashi; Ertz, M.; Centobelli, P.; Cerchione, R. Shaping the Future of Cold Chain 4.0 Through the Lenses of Digital Transition and Sustainability. IEEE Trans. Eng. Manag. 2022, 71, 2812–2828. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, Y.; Liang, Z.; Liu, Y. Cluster social capital’s influence on regional public brands in specialty agriculture: A value co-creation perspective. Asia Pac. J. Mark. Logist. 2024, 36, 3213–3235. [Google Scholar] [CrossRef]

- Banomyong, R.; Supatn, N.; Potter, A. Developing a supply chain performance tool for SMEs in Thailand. Supply Chain Manag. Int. J. 2011, 16, 20–31. [Google Scholar] [CrossRef]

- Sasaki, Y.; Orikasa, T.; Nakamura, N.; Hayashi, K.; Yasaka, Y.; Makino, N.; Shobatake, K.; Koide, S.; Shiina, T. Optimal packaging for strawberry transportation: Evaluation and modeling of the relationship between food loss reduction and environmental impact. J. Food Eng. 2022, 314, 110767. [Google Scholar] [CrossRef]

- Ivanov, D.; Tsipoulanidis, A.; Schönberger, J. Digital Supply Chain, Smart Operations and Industry 4.0. In Global Supply Chain and Operations Management; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Chermala, A.; Acharya, P.; Singh, R.K. Cold chain logistics performance: A framework. Meas. Bus. Excel. 2024, 29, 55–75. [Google Scholar] [CrossRef]

- Aditjandra, P.; Hussain, I.; Utomo, D.; Gripton, A.; Greening, P. Cold chain for sustainable infrastructure planning. Transp. Res. Procedia 2025, 82, 481–494. [Google Scholar] [CrossRef]

- Joshi, R.; Banwet, D.; Shankar, R.; Gandhi, J. Performance improvement of cold chain in an emerging economy. Prod. Plan. Control 2012, 23, 817–836. [Google Scholar] [CrossRef]

- Shao, X.; Liu, Y.; Tian, J.; Cheng, T. A Cold Chain Logistics Traceability System Framework Based on the Identification and Resolution System for Industrial Internet. In Proceedings of the 2022 10th International Conference on Information Technology: IoT and Smart City (ICIT ’22), Guangzhou, China, 16–18 December 2022; pp. 242–250. [Google Scholar] [CrossRef]

- Zhang, J.; Trautman, D.; Liu, Y.; Bi, C.; Chen, W.; Ou, L.; Goebel, R. Achieving the Rewards of Smart Agriculture. Agronomy 2024, 14, 452. [Google Scholar] [CrossRef]

- Khan, A.U.; Ali, Y. Enhancement of resilience and quality of cold supply chain under the disruptions caused by COVID-19: A case of a developing country. Aust. J. Manag. 2022, 48, 341–365. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, S. Research on Application of WSN in Cold Chain Logistics’ Warehousing and Transportation. In Advanced Graphic Communications and Media Technologies; Zhao, P., Ouyang, Y., Xu, M., Yang, L., Ouyang, Y., Eds.; Lecture Notes in Electrical Engineering; Springer: Singapore, 2017; Volume 417. [Google Scholar]

- Yin, X.; Gu, C.; Fan, Z.; Huang, H. Routing Optimization in Distribution of Cold Chain Logistics. In Proceedings of the 2017 10th International Symposium on Computational Intelligence and Design (ISCID), Hangzhou, China, 7–8 October 2017; Volume 2, pp. 171–176. [Google Scholar] [CrossRef]

- Guan, K.; Lin, W.; Zhou, X. A Case Study on How to Improve Cold Chain Logistics for Specialty Food and Agricultural Products. Adv. Econ. Manag. Politi-Sci. 2024, 143, 136–141. [Google Scholar] [CrossRef]

- Gupta, A.; Singh, R.K.; Mathiyazhagan, K.; Suri, P.K.; Dwivedi, Y.K. Exploring relationships between service quality dimensions and customers satisfaction: Empirical study in context to Indian logistics service providers. Int. J. Logist. Manag. 2022, 34, 1858–1889. [Google Scholar] [CrossRef]

- Huang, Q.; Yan, X. On the Application of Internet of Things (IoT) in Cold Chain Logistics Management. In Proceedings of the 2018 International Symposium on Communication Engineering & Computer Science (CECS 2018), Shanghai, China, 28–30 September 2018; Volume 86, pp. 470–473. [Google Scholar] [CrossRef]

- Arbuckle, J.L. IBM SPSS Amos 26 User’s Guide; IBM: New York, NY, USA, 2019; Available online: https://shorturl.asia/IjkJ0 (accessed on 19 April 2025).

- Dieguez-Santana, K.; Sarduy-Pereira, L.; Ruiz-Reyes, E.; Cossío, N.S. Application of the Circular Economy in Research in the Agri-Food Supply Chain: Bibliometric, Network, and Content Analysis. Sustainability 2025, 17, 1899. [Google Scholar] [CrossRef]

- Rejeb, A.; Abdollahi, A.; Rejeb, K.; Keogh, G.J. Smart Logistics for Sustainable Food Industries. In Smart Logistics for Sustainable Food Industries; CRC Press: Boca Raton, FL, USA, 2020; pp. 292–306. [Google Scholar] [CrossRef]

- Bhardwaj, M.; Venaik, A.; Garg, P. Visualizing Perishable Product Supply Chain Using Petri Net Modeling. In Digitalization and Analytics for Smart Plant Performance; Springer: Cham, Switzerland, 2022; pp. 252–262. [Google Scholar] [CrossRef]

- Ababou, M.; Chelh, S.; Elhiri, M. A Bibliometric Analysis of the Literature on Food Industry Supply Chain Resilience: Investigating Key Contributors and Global Trends. Sustainability 2023, 15, 8812. [Google Scholar] [CrossRef]

- Xu, X.; Yuen, C.W.; Koting, S.B.; Musa, S.N.B. Construction of a blockchain based cold chain logistics information platform for Gannan navel oranges to enhance transparency and efficiency. Front. Sustain. Food Syst. 2024, 8, 1464918. [Google Scholar] [CrossRef]

- Cao, H. The Role of Standardization in the Operation of Enterprise Quality Management Systems. Mod. Econ. Manag. Forum 2023, 4, 21. [Google Scholar] [CrossRef]

- Sun, H.-B.; Li, P.; Ouyang, Y. Standardization and international competitiveness: Evidence from China’s agricultural products. Appl. Econ. Lett. 2022, 30, 1090–1096. [Google Scholar] [CrossRef]

- Ahmad, A.N.; Rahman, R.A.; Othman, M.; Ishak, F.A.C.; Mohamad, S.F.; Abidin, U.F.U.Z. The Relationship between Halal Food Management System Critical Constructs Implementation, Operational Performance and Product Quality. Int. J. Acad. Res. Bus. Soc. Sci. 2020, 10. [Google Scholar] [CrossRef] [PubMed]

- Paul, K.; Chatterjee, S.S.; Pai, P.; Varshney, A.; Juikar, S.; Prasad, V.; Bhadra, B.; Dasgupta, S. Viable smart sensors and their application in data driven agriculture. Comput. Electron. Agric. 2022, 198, 107096. [Google Scholar] [CrossRef]

- Bin, L.; Shahzad, M.; Khan, H.; Bashir, M.M.; Ullah, A.; Siddique, M. Sustainable Smart Agriculture Farming for Cotton Crop: A Fuzzy Logic Rule Based Methodology. Sustainability 2023, 15, 13874. [Google Scholar] [CrossRef]

- Olayinka, A.; Adetunji, C.; Nwankwo, W.; Olugbemi, O.T.; Olayinka, T.C. A Study on the Application of Bayesian Learning and Decision Trees IoT-Enabled System in Postharvest Storage. In Artificial Intelligence-Based Internet of Things Systems; Springer: Cham, Switzerland, 2022; pp. 467–491. [Google Scholar] [CrossRef]

- Parra-López, C.; Ben Abdallah, S.; Garcia-Garcia, G.; Hassoun, A.; Trollman, H.; Jagtap, S.; Gupta, S.; Aït-Kaddour, A.; Makmuang, S.; Carmona-Torres, C. Digital technologies for water use and management in agriculture: Recent applications and future outlook. Agric. Water Manag. 2025, 309. [Google Scholar] [CrossRef]

- Zhan, J.; Dong, S.; Hu, W. IoE-supported smart logistics network communication with optimization and security. Sustain. Energy Technol. Assessments 2022, 52, 102052. [Google Scholar] [CrossRef]

- Marx, E.; Daudrich, R.; Pauli, T.; Matzner, M.; Beverungen, D. Standardization as a Catalyst for Extending Resources and Capabilities in Service Systems Engineering: Findings from the omlox case. J. Serv. Manag. Res. 2023, 7, 213–231. [Google Scholar] [CrossRef]

- Jiang, Y.; Lai, P.; Chang, C.-H.; Yuen, K.; Li, S.; Wang, X. Sustainable Management for Fresh Food E-Commerce Logistics Services. Sustainability 2021, 13, 3456. [Google Scholar] [CrossRef]

- Muthukumar, R.; Poojitha, G.; Chatterjee, M. Impact of Agri-Fresh Food Supply Chain and Quality Practices on Environmental Sustainability. Int. J. Sci. Dev. Res. 2023, 8, 506–512. Available online: https://ijsdr.org/papers/IJSDR2301084.pdf (accessed on 19 March 2025).

- Touil, S.; Richa, A.; Fizir, M.; García, J.E.A.; Gómez, A.F.S. A review on smart irrigation management strategies and their effect on water savings and crop yield. Irrig. Drain. 2022, 71, 1396–1416. [Google Scholar] [CrossRef]

- Comrey, A.L.; Lee, H.B. A First Course in Factor Analysis, 2nd ed.; Psychology Press: New York, NY, USA, 1992; pp. 325–350. [Google Scholar]

- Tavakkoli-Moghaddam, R.; Ghahremani-Nahr, J.; Samadi Parviznejad, P.; Nozari, H.; Najafi, E. Application of Internet of Things in the Food Supply Chain: A Literature Review. J. Appl. Res. Ind. Eng. 2022, 9, 475–492. [Google Scholar] [CrossRef]

- Kononets, Y.; Konvalina, P.; Bartos, P.; Smetana, P. The Evolution of Organic Food Certification: Challenges and Opportunities. Front. Sustain. Food Syst. 2023, 7, 1167017. [Google Scholar] [CrossRef]

- Kock, N. Common Method Bias in PLS-SEM. Int. J. e-Collaboration 2015, 11, 1–10. [Google Scholar] [CrossRef]

- Armstrong, J.S.; Overton, T.S. Estimating Nonresponse Bias in Mail Surveys. J. Mark. Res. 1977, 14, 396–402. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef]

- Ndraha, N.; Vlajic, J.; Chang, C.-C.; Hsiao, H.-I. Food Industry Wastes: Assessment and Recuperation of Commodities, 2nd ed; Kosseva, M.R., Webb, C., Eds.; Elsevier: Amsterdam, The Netherlands; Academic Press: Cambridge, MA, USA, 2020; pp. 467–484. [Google Scholar]

- Luo, N.; Olsen, T.; Liu, Y.; Zhang, A. Reducing Food Loss and Waste in Supply Chain Operations. Transp. Res. Part E Logist. Transp. Rev. 2022, 162, 102730. [Google Scholar] [CrossRef]

- Kamilaris, A.; Fonts, A.; Prenafeta-Boldύ, F.X. The rise of blockchain technology in agriculture and food supply chains. Trends Food Sci. Technol. 2019, 91, 640–652. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).