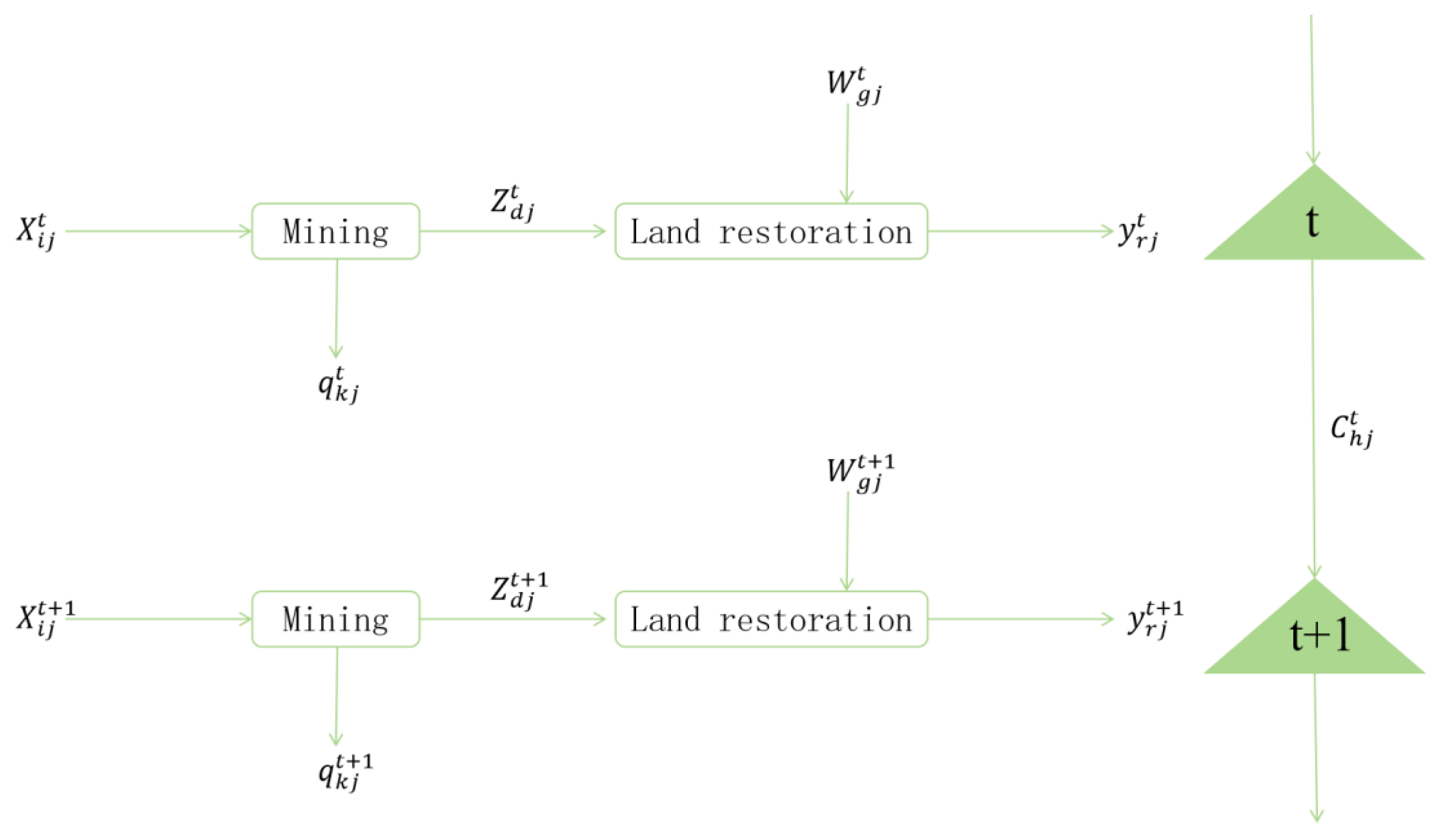

Using MaxDEA Ultra 9.1, the overall efficiency of 29 provinces from 2017 to 2021, as well as the efficiency of the mining production stage, land restoration stage, and overall efficiency for each individual year during this period, were obtained.

3.1. Efficiency and Dynamic Changes

According to the results, the overall efficiency of 29 provinces from 2017 to 2021 and the efficiency of each individual year were obtained.

Table 3 presents the overall efficiency and annual efficiency of the 29 provinces during the 2017–2021 period.

From the perspective of overall efficiency of each province, Zhejiang, Ningxia, and Xinjiang have the highest overall efficiency, all of which are above 0.5. However, Guizhou, Heilongjiang, and Beijing have relatively low overall efficiency, with fluctuations around 0.12. The comprehensive efficiency of Anhui, Chongqing, Fujian, Henan, Hubei, Liaoning, Tianjin, Shandong, and Jiangsu has not reached 0.2 and needs further improvement.

Figure 3 shows the national overall efficiency through a national distribution map.

According to the China Statistical Yearbook, China is divided into four major regions: the Eastern Region, Central Region, Western Region, and Northeastern Region. Specifically, the Eastern Region includes 10 provinces/municipalities: Beijing, Tianjin, Hebei, Shanghai, Jiangsu, Zhejiang, Fujian, Shandong, Guangdong, and Hainan; the Central Region consists of 6 provinces: Shanxi, Anhui, Jiangxi, Henan, Hubei, and Hunan; the Western Region comprises 12 provinces/autonomous regions/municipalities: Inner Mongolia, Guangxi, Chongqing, Sichuan, Guizhou, Yunnan, Tibet, Shaanxi, Gansu, Qinghai, Ningxia, and Xinjiang; and the Northeastern Region is composed of three provinces: Liaoning, Jilin, and Heilongjiang.

From a regional perspective, the overall efficiency of the eastern region is highly differentiated. Zhejiang (0.547) leads in overall efficiency. Although Guangdong (0.217) and Jiangsu (0.144) have large economic aggregates, their overall efficiency fails to meet expectations, mainly due to differences in input-output mechanisms and industrial structures. Relying on the digital economy, high-end manufacturing, and modern service industries, Zhejiang has formed a “low input, high output” model: in the mining stage in 2021, it only invested 0.4 million employees but produced 446,697,200 tons of non-oil minerals, with only 5561 hectares of land damaged and a restoration investment of 1,293,950,000 yuan. The output efficiency per unit input and environmental cost control are significantly better than those of Guangdong and Jiangsu. In 2021, Guangdong invested 14,000 employees but only produced 420,329,000 tons of non-oil minerals, with 20,817 hectares of land damaged and a restoration investment of 914,290,000 yuan, resulting in a high restoration cost per unit area. Jiangsu invested 54,000 employees to produce only 118,883,500 tons, with 14,224 hectares of land damaged and a restoration investment of 1,529,060,000 yuan. Its labor input is 13.5 times that of Zhejiang, but its output is only 26.6% of Zhejiang’s, indicating that scale expansion has not brought about efficiency improvement. In terms of industrial structure, Zhejiang has a high proportion of high-end industries, strong resource utilization efficiency, and environmental friendliness, while Guangdong and Jiangsu have a large proportion of traditional manufacturing industries. Mining activities rely more on extensive input, leading to resource waste and high restoration costs. Although the scale of fixed asset investment is huge, resource allocation has not been effectively transformed into production efficiency, ultimately forming an efficiency differentiation between Zhejiang and Guangdong/Jiangsu. Cities such as Beijing (0.104) and Tianjin (0.156) are facing problems such as resource and environmental pressure and industrial relocation, which affect the overall efficiency. Hebei (0.250), Fujian (0.194), Shandong (0.145), and Hainan (0.250) all face challenges in industrial development and resource allocation.

The overall efficiency of the central region is mostly at a medium level, and the internal differences are small. Among them, Jiangxi (0.424) has relatively high efficiency because it is rich in mineral resources such as copper, tungsten, and rare earths. In recent years, it has actively undertaken industrial transfers from the eastern region. The revenue of the electronic information industry broke through one trillion yuan in 2022. Relying on the resource advantages of the “Asian Lithium Capital” and other areas, the new energy vehicle industry has attracted the gathering of leading enterprises, formed an industrial cluster effect, and promoted the improvement of input-output efficiency. However, the efficiencies of Shanxi (0.215), Anhui (0.199), Henan (0.181), Hubei (0.178), and Hunan (0.206) are close. As important agricultural and industrial bases, their resource endowments and industrial structures have obvious constraints: Shanxi has long relied on coal resources, with extensive mining methods and a single industrial structure. With an investment of 846,000 employees (2021), these resource advantages have not been transformed into diversified economic drivers. Traditional manufacturing industries account for a high proportion in Henan, Anhui, and other provinces. For example, in 2021, Henan invested 2.747 billion yuan in restoration, but the industrial transformation lagged behind. Although the non-oil output of Anhui was 60,100 tons (2021), it faced the problem of insufficient development of high-tech industries. Although the industrial systems of Hubei and Hunan are complete, the upgrading of traditional industries is slow. For example, in 2021, Hubei’s restoration area was 3253 hectares, but it was still restricted by the pressure of overcapacity. It generally presents the common characteristic of “resource endowment relying on traditional industries and insufficient conversion efficiency of emerging industries”.

The overall efficiency of the Western Region varies significantly. Ningxia (0.534), Xinjiang (0.501), and Inner Mongolia (0.473) exhibit higher efficiency. Ningxia has developed well in the energy chemical industry and characteristic agriculture; Xinjiang has gained advantages in oil and natural gas mining/processing as well as planting and trade of characteristic agricultural products by virtue of abundant energy resources and unique geographical location; and Inner Mongolia has achieved high efficiency through the energy industry and animal husbandry. In contrast, Guizhou (0.139), Chongqing (0.197), and others show lower efficiency. Guizhou’s relatively weak economic foundation, complex geographical environment, and difficult infrastructure construction (e.g., transportation) have restricted industrial development and resource utilization efficiency; Chongqing faces challenges such as traditional industry transformation and emerging industry cultivation during industrial upgrading, affecting the improvement of overall efficiency.

The overall efficiency of Liaoning (0.163), Jilin (0.234), and Heilongjiang (0.120) in the northeastern region is relatively low, which is directly related to the long-term reliance on traditional resource development models in the region. As an energy base, Heilongjiang has experienced severe land damage caused by mineral extraction activities such as the Daqing Oilfield due to lagging technology. The damaged area from 2017 to 2021 has always been higher than 50,000 hectares, while the restoration area is less than 5000 hectares. Relying on traditional industries such as steel and equipment manufacturing, Liaoning had a non-oil mineral output of 29,100 tons in 2021, but the damaged land reached 57,400 hectares. The slow industrial transformation has resulted in high resource consumption and ecological costs. Although Jilin’s efficiency temporarily rose to 0.540 in 2020 due to a surge in restoration investment (225.78 million yuan), the traditional automobile industry was impacted by new energy, and the cultivation of emerging industries was insufficient. In 2021, the efficiency quickly fell back to 0.155, reflecting the deep-seated contradiction of a single industrial structure. Overall, due to the resource-based industries accounting for more than 60% and insufficient investment in restoration technology (the restoration investment of the three provinces was all less than 700 million yuan in 2021), the three provinces have formed a vicious cycle of “mining-damage-inefficient restoration”, leading to low overall efficiency.

The Hu Line (Heihe-Tengchong Line) was proposed by geographer Hu Huanyong in 1935, initially used to depict the spatial differentiation of population density in China—the southeast side of the line carries 96% of the population with 36% of the national territory, while the northwest side shows the characteristic of “vast land with sparse population”. This line is not only a boundary line of population density but also implies the spatial differentiation of resource endowment, ecological carrying capacity, and economic structure. Therefore, in this paper, according to the Hu Line, among the 29 provinces, Inner Mongolia, Sichuan, Shaanxi, Gansu, Qinghai, Ningxia and Xinjiang are classified as the northwest side, while the rest of the provinces are classified as the southeast side of the Hu Line. For provinces crossing the Hu Line, they are usually classified according to the side where the main body of the province is located. The average values of overall efficiency of the provinces on both sides are calculated, respectively, and it is found that the efficiency of the northwest side is 0.365 while that of the southeast side is 0.226.

The average overall efficiency of the 7 provinces on the northwest side of the Hu Line is higher than that of the 22 provinces on the southeast side, and this difference stems from multiple factors.

In terms of resource endowment, provinces on the northwest side, such as Inner Mongolia and Xinjiang, are rich in non-petroleum mineral resources. In 2021, Inner Mongolia’s non-petroleum output reached 125,966.61 ten thousand tons, and Shaanxi’s fixed asset investment amounted to 108,792.3008 million yuan. Large-scale mining has promoted input-output efficiency. In contrast, the southeast side (e.g., Zhejiang) has only 0.4 ten thousand mining employees and a non-petroleum output of 44,669.72 ten thousand tons. The diversified industrial structure results in a low proportion of mining, making it difficult to form economies of scale.

In terms of land destruction and restoration, take Inner Mongolia as an example. It damaged 143,000 hectares of land in 2021, with a restoration investment of 7168.47 million yuan. Concentrated damage and restoration reduced unit costs. Qinghai’s restored area in 2021 was 5556 hectares, even exceeding the damaged area. On the southeast side, however, Beijing only had 1267 hectares of damaged land, with scattered restoration investment. Provinces such as Tianjin have extremely little mining activity, leading to low restoration efficiency.

In terms of policies and investment, the northwest side (e.g., Inner Mongolia) had a fixed asset investment of 109,182.0403 million yuan in 2021. National resource development and ecological compensation policy preferences provided financial support. The southeast side (e.g., Jiangsu) had a restoration investment of 1529.06 million yuan in 2021, which was lower than that of the northwest side.

At the technical management level, Gansu and Qinghai on the northwest side applied specialized restoration technologies for special landforms. For example, in the restoration of mines in the Loess Plateau region, the “terracing renovation + soil conditioner” technology was adopted. Shaanxi’s restoration investment of 3650.78 million yuan in 2021 corresponded to a restored area of 11,275 hectares, showing high efficiency. The southeast side (e.g., Anhui) invested 1328.29 million yuan in 2021 but only restored 2945 hectares, suffering from insufficient technical investment and decentralized management.

This difference is essentially the result of two models: the northwest side’s “resource development-concentrated restoration-policy support” and the southeast side’s “industrial transformation-decentralized restoration-insufficient investment”, reflecting the periodic characteristics of resource utilization and ecological protection in regional development.

As shown in

Figure 4, to visualize the overall efficiency and its changing trends of 29 provinces each year, we adopted a heat map visualization method. In the figure, the color ranging from light to dark represents the overall efficiency from low to high.

According to the results, overall, Ningxia Hui Autonomous Region, Xinjiang Uygur Autonomous Region, and Zhejiang Province are relatively efficient, and the values are at the forefront in most years from 2017 to 2021. The overall efficiency of Beijing, Anhui Province, Fujian Province, Gansu Province, Guizhou Province, Hainan Province, Hebei Province, Henan Province, Heilongjiang Province, Hubei Province, Hunan Province, Jilin Province, Jiangsu Province, Jiangxi Province, Liaoning Province, Shanxi Province, Shaanxi Province, Sichuan Province, Tianjin City, Chongqing City, and other provinces is relatively low, with most of them at the midstream and downstream levels.

Judging from the efficiency changes in each province, Anhui Province, Guangdong Province, Heilongjiang Province, Hubei Province, Hunan Province, Qinghai Province, Shandong Province, Xinjiang Uygur Autonomous Region, Yunnan Province, and Chongqing City showed an overall upward trend from 2017 to 2021. For example, after Anhui Province fell from 0.276 in 2017 to 0.107 in 2020, it rebounded to 0.128 in 2021; Guangdong Province rose from 0.194 in 2017 to 0.280 in 2021. The efficiency fluctuations in Beijing, Fujian Province, Gansu Province, Guangxi Zhuang Autonomous Region, Guizhou Province, Hainan Province, Hebei Province, Henan Province, Jilin Province, Jiangsu Province, Jiangxi Province, Liaoning Province, Inner Mongolia Autonomous Region, Ningxia Hui Autonomous Region, Shanxi Province, Shaanxi Province, Sichuan Province, and Tianjin City are significantly fluctuating. For example, Beijing was 0.103 in 2017, fell to 0.041 in 2020, and rose sharply to 0.181 in 2021; Fujian Province rose first, then fell, and then rose again from 2017 to 2021, starting at 0.160 in 2017, rose to 0.185 in 2019, fell to 0.129 in 2020, and rose to 0.315 in 2021. Although Zhejiang Province has fluctuations, it is on an upward trend, reaching 0.537 in 2017 and rising to 0.561 in 2021.

3.2. Efficiency and Decomposition

According to the results, the annual efficiency of the mining stage and land restoration stage for 29 provinces from 2017 to 2021 was obtained, respectively.

3.2.1. Changes in Efficiency of the Mining Stage

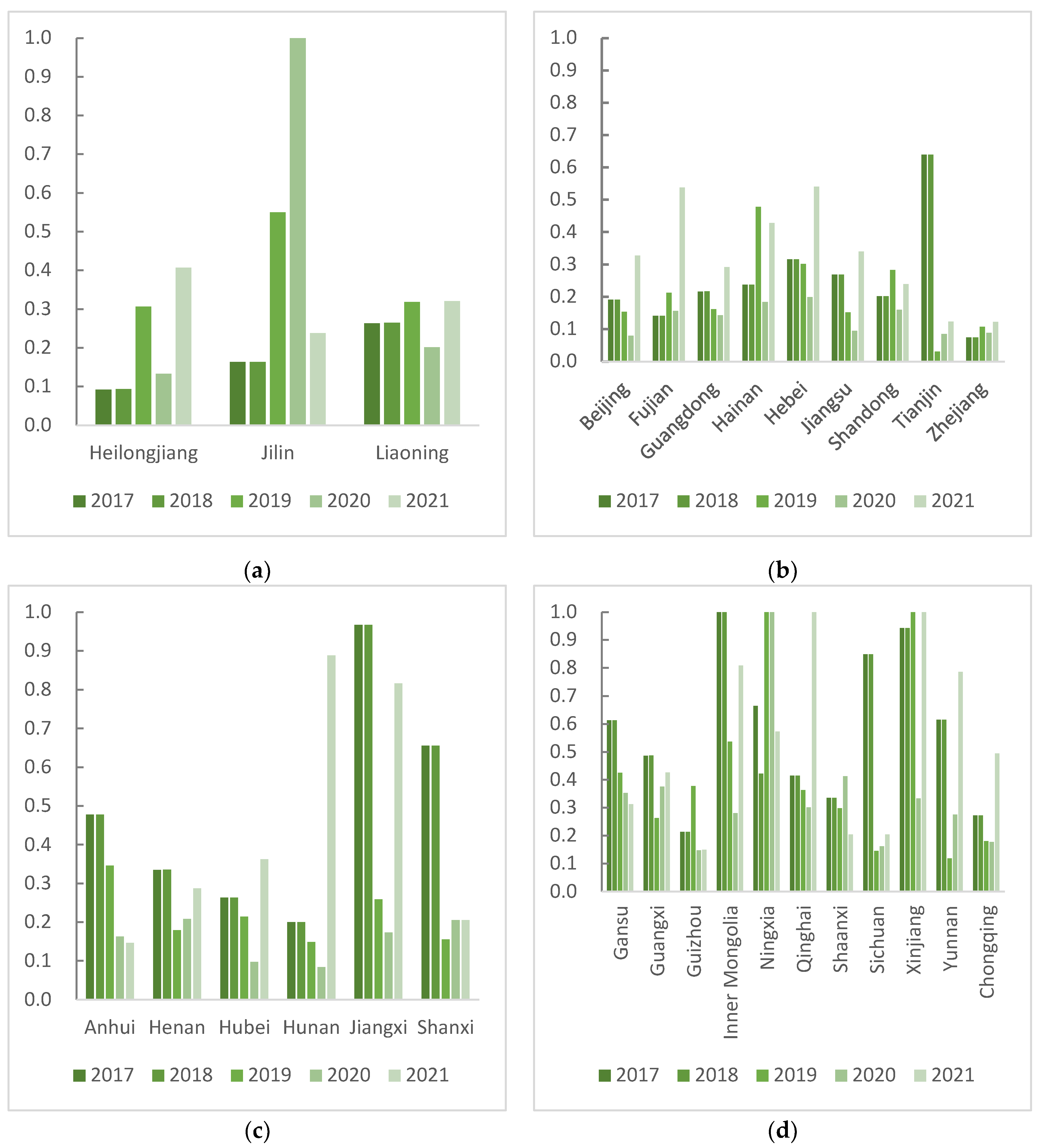

Figure 5 shows the efficiency of the mining stage in the four regions more intuitively through the bar chart. The specific efficiency values of the mining stage are shown in

Table 4. Based on input and output, the mining efficiency of each region is analyzed as follows.

As shown in

Figure 5a, the overall efficiency of the mining stage in the northeast region is low and showing an upward trend. From 2017 to 2021, Heilongjiang increased from 0.013 to 0.070, Jilin rose from 0.018 to 0.073, and Liaoning increased from 0.024 to 0.097.

In terms of input, the number of mining employees in the northeast region is generally declining. For example, Heilongjiang dropped from 256,000 in 2017 to 232,000 in 2021. In terms of output, production of non-petroleum mineral resources has increased and decreased, such as Heilongjiang, which rose from 156.2395 million tons in 2017 to 199.1649 million tons in 2021. This shows that to a certain extent, resource utilization efficiency has been improved, which has promoted the improvement of mining efficiency. At the same time, the area of destructed land is also showing a downward trend. The protection and utilization of land are gradually optimized during the mining process, reducing undesirable outputs and helping to improve mining efficiency.

As shown in

Figure 5b, the efficiency differences in the mining stage in the eastern region are obvious. Zhejiang has always maintained a high efficiency of 1.000 from 2017 to 2021. The efficiency of Beijing and Tianjin has not reached 0.1 in five years. The efficiency of provinces such as Fujian and Guangdong fluctuated. For example, Fujian was 0.178 in 2017, and after rising to 0.220 in 2018, it fell year by year to 0.093 in 2021.

With only 4000 to 5000 employees in Zhejiang, with efficient production methods, production of non-petroleum mineral resources is stable and high, and destruction of land area is relatively small, and mining efficiency is always the highest. Although Fujian’s production of non-petroleum mineral resources has increased, the input reduction is limited, the destruction of land area has increased, and efficiency has decreased.

As shown in

Figure 5c, the efficiency of the mining stage in the central region is mostly at a moderate level, and the trend of change is different. Among them, Jiangxi was higher in 2017–2018, and then declined. Anhui, Henan, Hubei, Hunan, and other places have relatively low efficiency and fluctuations. For example, Anhui was 0.074 in 2017 and then rose to 0.083 in 2019 and then dropped to 0.052 in 2020.

The number of employees in the central region has generally declined, such as in Anhui, which dropped from 203,000 in 2017 to 130,000 in 2021. Production of non-petroleum mineral resources and destruction of land area vary. Taking Henan as an example, production of non-petroleum mineral resources rose from 265.4462 million tons in 2017 to 387.22 million tons in 2021. With the reduction of input, production of non-petroleum mineral resources increased significantly, while the destruction of land area fluctuated within a reasonable range, and mining efficiency was significantly improved.

As shown in

Figure 5d, the efficiency of the mining stage in the western region is extremely different. Ningxia, Guangxi, and Inner Mongolia performed outstandingly in some years, such as Ningxia 0.464 in 2017 and 0.658 in 2018. However, the efficiency of Guizhou, Sichuan, and other places is relatively low. For example, Guizhou fluctuated between 0.036 and 0.060 from 2017 to 2020 and was 0.083 in 2021.

The number of employees in the western region varies differently, and production of non-petroleum mineral resources and destruction of land area fluctuate greatly. Taking Guangxi as an example, from 2018 to 2020, production of non-petroleum mineral resources increased significantly from 439.3509 million tons to 617.5068 million tons, and the number of employees dropped from 30,000 to 8000. Although the area of destructed land has also changed, the significant increase in output and the significant reduction in input have greatly improved efficiency; from 2020 to 2021, production decreased and efficiency decreased.

3.2.2. Changes in Efficiency of the Land Restoration Stage

Figure 6 shows more intuitively the efficiency of the land restoration stage in the four regions from 2017 to 2021 through the bar chart. The specific efficiency values of land restoration stage are shown in

Table 5. Based on input and output, the mining efficiency of each region is analyzed as follows.

As shown in

Figure 6a, the overall efficiency in the Northeast region shows a trend of rising first and then falling, and there are large internal differences. Heilongjiang grew from 0.092 in 2017 to 0.407 in 2021, with a relatively obvious growth. Jilin reached a high efficiency of 1.000 in 2020 but dropped to 0.238 in 2021. Liaoning’s efficiency is relatively stable, maintaining between 0.2 and 0.32 from 2017 to 2021, but there is still a lot of room for improvement.

In terms of input, the changes in restoration investment vary from province to province. In terms of output, the restoration of land area has increased. For example, Heilongjiang invested 29.65 million yuan in 2017 and increased to 488.94 million yuan in 2021, and the restoration area increased from 32 hectares in 2017 to 3008 hectares in 2021. With the increase in investment in Heilongjiang, the restoration area has increased significantly, and its efficiency has increased from 0.092 in 2017 to 0.407 in 2021. Jilin’s input in 2020 has significantly decreased, and the restoration area has decreased significantly, but its efficiency has reached the highest level.

As shown in

Figure 6b, the regional efficiency differences in the eastern region are significant. Tianjin’s efficiency was relatively high from 2017 to 2018, but it declined significantly from 2019 to 2021. Zhejiang’s efficiency has always been low, ranging from 0.074 to 0.122 from 2017 to 2021. Fujian’s efficiency has improved significantly in 2021, from the previous 0.1–0.2 to 0.538.

From the perspective of input-output, taking Beijing as an example, the area of restoration grew slowly from 2017 to 2019 and grew rapidly from 2020 to 2021. At the same time, investment also increased significantly, and efficiency first decreased and then increased, indicating that the previous investment was not fully converted into the growth of the area of restoration, and the efficiency of investment utilization in the later stage has been improved. Fujian’s restoration investment decreased in 2021, but the increase in restoration area has greatly improved efficiency and more efficient resource utilization.

As shown in

Figure 6c, the overall efficiency of the central region fluctuates greatly, and the development of each province is uneven. Jiangxi was extremely efficient from 2017 to 2018, and then it dropped significantly. Anhui, Henan, Hubei, and other places have relatively low efficiency and fluctuations. For example, Anhui has dropped from 0.478 in 2017 to 0.147 in 2021.

Taking Anhui as an example, from 2017 to 2019, the restored area increased from 3712 hectares to 4681 hectares, with a year-on-year growth of 26.10%. However, the investment increased more significantly, from 628.90 million yuan to 1291.14 million yuan, with a year-on-year growth of 105.30%, leading to a decline in efficiency. From 2020 to 2021, both the restored area and investment decreased, with the restored area showing a year-on-year growth of −0.27% and the investment a year-on-year growth of −14.60%, further reducing efficiency. In Hunan, from 2017 to 2019, the investment increased by 411.25% year-on-year, and the restored area increased by 176.79% year-on-year. The faster growth of investment led to a decline in efficiency. From 2020 to 2021, the investment decreased while the restored area increased, and the efficiency was significantly improved, which to a certain extent reflects the positive impact of the optimization of the input-output structure on efficiency.

As shown in

Figure 6d, the overall efficiency of the western region is relatively high, and some provinces have performed outstandingly. Inner Mongolia, Ningxia, and Xinjiang have achieved high efficiency of 1.000 in many years. Efficiency fluctuations in Gansu, Sichuan, and other places were obvious, such as Sichuan, which was 0.849 from 2017 to 2018 and fell to 0.146 from 2019.

Taking Inner Mongolia as an example, from 2017 to 2019, investment increased while the restored area fluctuated but showed an overall upward trend, maintaining a relatively high level of efficiency. From 2020 to 2021, investment continued to rise, and the restored area also increased. Although efficiency experienced some fluctuations, it remained at a high level, indicating that investment effectively promoted the growth of the restored area and sustained high efficiency. In Sichuan, investment increased from 2017 to 2019, but the investment failed to be effectively translated into stable growth of the restored area. The restored area first decreased and then increased, leading to a significant decline in efficiency.

3.2.3. Two-Stage Efficiency Matrix Analysis

Table 6 shows the mining efficiency and land restoration efficiency of 29 provinces from 2017 to 2021.

Figure 7 clearly shows the comprehensive performance of the average efficiency of each province in two stages through the form of a radar map. There are great differences in efficiency in different stages of China’s provinces. The fluctuations between provinces are also very large every year, which is closely related to the mineral resources and measures taken in each region. In five years, land restoration efficiency has generally been higher than mining efficiency. The average mining efficiency is 0.154, and the average land restoration efficiency is 0.365.

By region, the overall efficiency of the Northeast and the Central Region is in the middle range in the two stages. Jiangxi is relatively efficient in the mining stage (0.211) and land restoration stage (0.636), and the development of these two aspects is relatively balanced and has good results; Heilongjiang is relatively low in both stages, with the mining stage being 0.034 and the land restoration stage being 0.206, which faces great challenges in resource development and land restoration.

The eastern provinces are more scattered on the radar map. For example, Zhejiang is extremely efficient in the mining stage (1.000) but has low efficiency in the land restoration stage (0.093); Beijing and Tianjin are at a relatively low level in both stages.

The differences in provinces in the western region are obvious. Inner Mongolia (0.725), Ningxia (0.732), and Xinjiang (0.844) have outstanding efficiency in the land restoration stage, but in the mining stage, Ningxia (0.336) and Inner Mongolia (0.221) are relatively good, while Xinjiang (0.158) needs to be improved. Guizhou’s efficiency is relatively low in both stages, with the mining production stage being 0.057 and the land restoration stage being 0.220. Therefore, most provinces have an imbalance in efficiency during the mining stage and land restoration stage.

As shown in

Figure 8, we adopted a scatter plot to take the average values of mining efficiency and land restoration efficiency of 29 provinces from 2017 to 2021 as the horizontal and vertical axes, respectively. Each scatter point represents a province, intuitively reflecting the relationship and distribution characteristics between the efficiencies of the two stages in each province.

From the quadrant, the first quadrant is high mining efficiency-high land restoration efficiency, the second quadrant is low mining efficiency-high land restoration efficiency, the third quadrant is low mining efficiency-low land restoration efficiency, and the fourth quadrant is high mining efficiency-low land restoration efficiency.

There is no distribution of provinces in the first quadrant, which means there is no province that can achieve high efficiency in both stages at the same time. There is an imbalance in the development process of 29 provinces. The provinces distributed in the second quadrant have invested more resources in the land restoration stage and achieved good results, but the mining link is relatively weak, and there are more provinces in the western region. These areas pay more attention to ecological restoration or have shortcomings in mining technology and industrial planning, resulting in low mining efficiency.

The provinces distributed in the third quadrant performed poorly in both stages, with more provinces in the eastern region, and these provinces may face major challenges in resource development and ecological protection. Provinces distributed in the fourth quadrant have high efficiency in the mining stage and may have advantages in resource mining technology and management models. However, insufficient investment or backward technology in land restoration leads to low land restoration efficiency. This situation may cause long-term ecological problems, and development strategies need to be adjusted in a timely manner, and land restoration work needs to be strengthened.

Overall, the distribution of scatter points in the graph is mostly concentrated in the second and third quadrants, namely low mining efficiency—high land restoration efficiency and low mining efficiency—low land restoration efficiency. Most provinces have low mining efficiency and are very different from the efficiency combination of the land restoration stage. The development levels of different provinces in the two links of mineral resource development and land restoration are uneven.

Judging from the distribution trend of scatter points, there is no obvious linear correlation between the efficiency of the mining stage and the efficiency of the land restoration stage. This shows that the level of mining efficiency in a province cannot directly determine its land restoration efficiency. The development of the two stages is affected by different factors. For example, the degree and method of impact of factors such as resource endowment, industrial policies, technical level, and capital investment on mining and land restoration are different, resulting in no simple correlation between the two.

3.2.4. Influencing Factors of Mining-Land Restoration Efficiency

In order to explore the relationship between exogenous factors and mining efficiency, land restoration efficiency, and overall efficiency, this study analyzes the PLS-SEM multivariate statistical analysis method (partial least squares structural equation modeling, a structural equation model based on the partial least squares method). Due to the large difference in variable units, IBM SPSS Statistics 27.0.1 was used for standardization. The selected data are the overall efficiency, mining efficiency, and land restoration efficiency of the 29 provinces from 2017 to 2021 and the average of the temperature, annual precipitation, sunshine duration, regional GDP, ECEP, R&D institutions, R&D personnel, and patents.

The results shown in

Table 7 indicate that in terms of the measurement model’s convergent validity, except for the climate-related factor “sunshine duration”, the factor loadings of observed variables for each latent factor are all greater than 0.7, and the average variance extracted (AVE) values of all latent factors exceed 0.5, suggesting that the measurement model has good convergent validity. Regarding the discriminant validity of the measurement model, according to the criteria of the Fornell–Larcker Criterion, since the square root of the AVE value of each latent factor is greater than its correlation coefficient with any other latent factor, the measurement model is determined to have good discriminant validity; additionally, the confidence intervals of the HTMT (heterotrait-monotrait ratio) estimates between all latent factors do not include 1, further verifying that the measurement model has good discriminant validity [

64].

As shown in

Figure 9, land restoration efficiency has a significant positive impact on overall efficiency (0.707). Improving land restoration efficiency can directly enhance overall efficiency, and the impact is substantial. Mining efficiency also has a significant positive effect on overall efficiency (0.733), slightly higher than that of land restoration efficiency, indicating that improving mining efficiency plays a more critical role in contributing to overall efficiency. Policy and economic factors have a significant negative impact on land restoration efficiency (−0.522), suggesting that current policies or economic measures inhibit the improvement of land restoration efficiency. These factors exhibit a highly significant negative effect on mining efficiency (coefficient = −0.802), implying that existing policy or economic conditions may impose substantial constraints on mining efficiency. Climatic factors have a weak negative impact on land restoration efficiency, possibly because extreme weather conditions (such as droughts and floods) increase the difficulty of restoration. Conversely, climatic factors have a slight positive impact on mining efficiency—for example, moderate temperature and other favorable climatic conditions facilitate mining operations. Technological innovation has a weak positive effect on land restoration efficiency, indicating that the application of current technological innovations has not yet fully unleashed its potential in the field of land restoration. In contrast, technological innovation has an extremely strong positive impact on mining efficiency (coefficient = 0.910), demonstrating that technological innovation serves as the core driving force for improving mining efficiency.