The Circular Economy Approach to Dealing with Burdensome Waste from Poultry Industry

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- White poultry feathers after physical and mechanical treatment (Poultry Slaughterhouse—CEDROB S.A., Poland);

- Wool—length 50 mm (Poltops Sp. z o.o., Poland);

- PESco/polyethylene bicomponent fiber—length 50 mm.

2.1.1. Feathers Pre-Treatment

2.1.2. Nonwoven Manufacturing

2.2. Analytical Methods

2.2.1. Mechanical Properties

2.2.2. Biodegradation Tests

2.2.3. Microbiological Tests—Ecotoxicity

2.2.4. Phytotoxicity

2.2.5. Air Permeability Test

2.2.6. Determination of the Carbon and Nitrogen Content in Soil

2.2.7. Determination of Potassium and Nitrogen Content in Nonwoven

2.2.8. Determination of Water Retention Value (WRV)

- m1—weight of sample after centrifuging;

- m2—weight of sample after drying.

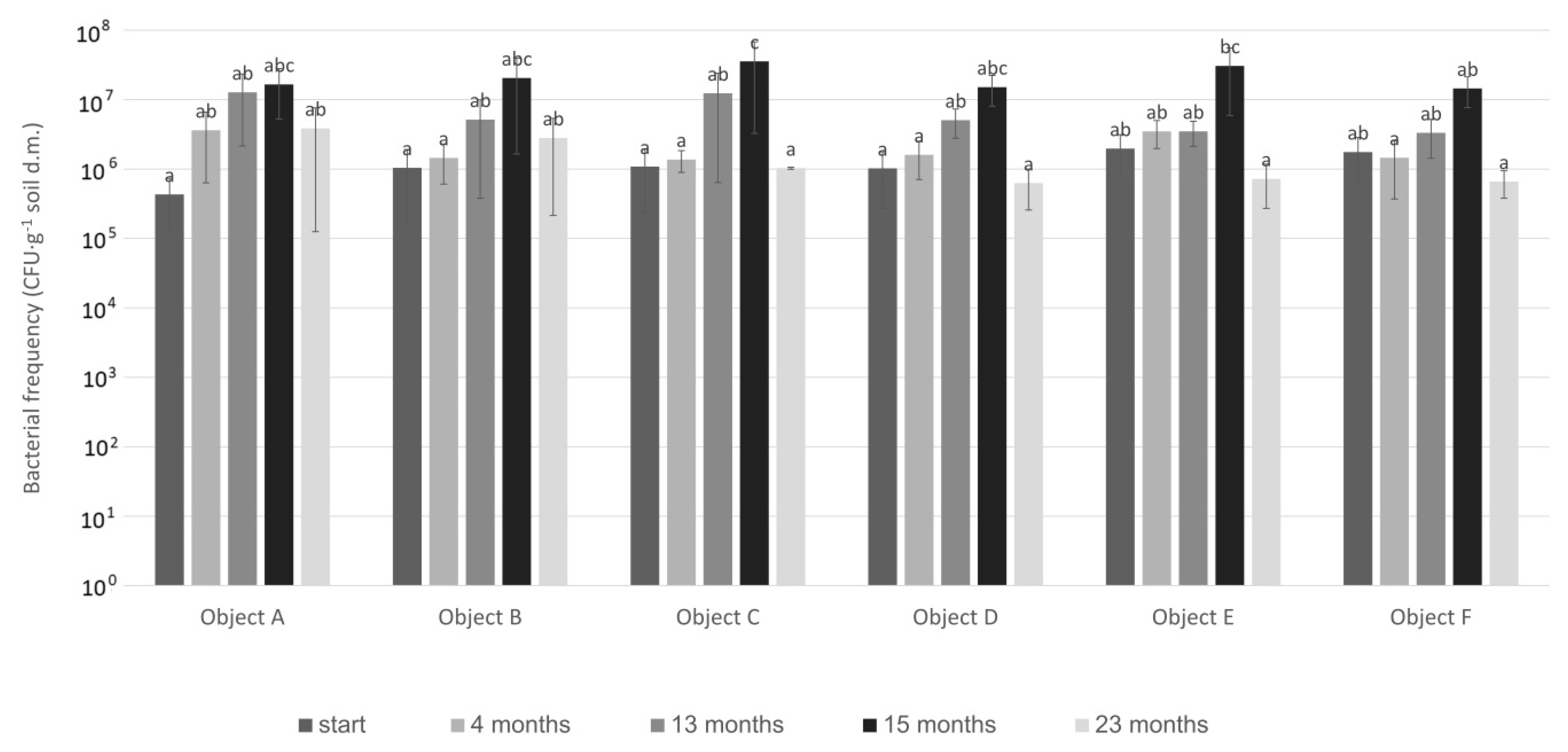

2.2.9. Analyses of Soil Microbiota Frequency Changes

2.3. Experimental Design

2.3.1. Experiment Plan

- With a grammage of 100 g·m−2, feather content of 18.7%, and needling speed—45 Hz;

- With a grammage of 200 g·m−2, feather content of 41.1%, and needling speed—30 Hz;

- With a grammage of 300 g·m−2, feather content of 19%, and needling speed—45 Hz;

- With a grammage of 17 g·m−2, commercial nonwoven called Pegas Agro.

- Hence, the following six objects were included in the study:

- A: Meadow grass–legume mixture;

- B: Meadow grass–legume mixture + fertilization;

- C: Meadow grass–legume mixture + fertilization + nonwoven 100;

- D: Meadow grass–legume mixture + fertilization + nonwoven 200;

- E: Meadow grass–legume mixture + fertilization + nonwoven 300;

- F: Meadow grass–legume mixture + fertilization + commercial nonwoven Pegas Agro.

- Biodegradable nonwovens were left on the objects, while the commercial nonwoven was removed from the experimental surface on 23 September 2019.

- I—Nonwoven: wool + feathers; basis weight approx. 100 g·m−2;

- II—Nonwoven: wool + feathers; basis weight approx. 200 g·m−2;

- III—Nonwoven: wool + feathers; basis weight approx. 300 g·m−2.

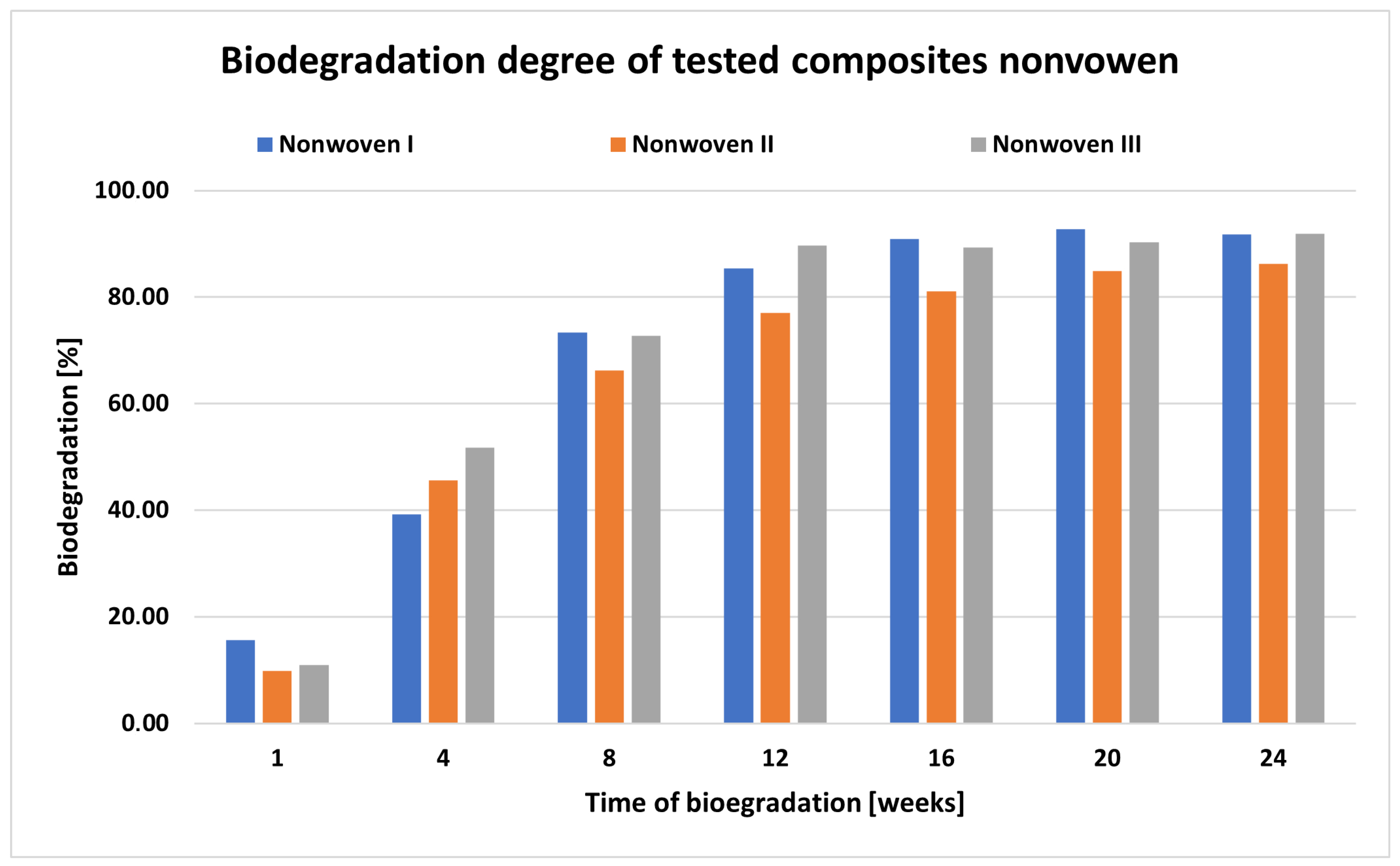

2.3.2. Nonwoven Fabrics Biodegradation Results

- Coefficient of variation of weight loss: 1.01%;

- Random error: ±2.29%;

- Weight loss confidence level: ±2.50%;

- Standard uncertainty of measurement (standard deviation): 0.92;

- Expanded measurement uncertainty: ± 4.30%;

- Additional information:

- Expanded uncertainty specified for a coverage factor k = 2 with a confidence level of 95%.

- Coefficient of variation of weight loss: 1.63%;

- Random error: ± 3.49%;

- Weight loss confidence level: ±4.04%;

- Standard uncertainty of measurement (standard deviation): 1.40;

- Expanded measurement uncertainty: ± 6.97%.

- Additional information:

- Expanded uncertainty specified for a coverage factor k = 2 with a confidence level of 95%.

- Coefficient of variation of weight loss: 1.42%;

- Random error: ±3.25%;

- Weight loss confidence level: ± 3.53%;

- Standard uncertainty of measurement (standard deviation): 1.31;

- Expanded measurement uncertainty: ± 6.49%.

- Additional information:

- Expanded uncertainty specified for a coverage factor k = 2 with a confidence level of 95%.

3. The Scope of Research Conducted

3.1. Investigated Soil Properties

- The grain size distribution using the Cassagrande aerometric method, modified by Pruszyński;

- Total organic carbon (TOC) and total nitrogen (TN) content—using a LECO CNS analyzer;

- pH—measured potentiometrically in H2O KCl (soil–solution ratios of 1:2.5);

- The content of available phosphorus (Pav) and potassium (Kav) using the Egner–Riehm method;

- The content of magnesium (Mgav) using the Schachtschabel method;

- The hydrolytic acidity (HA) was measured in 1 M CH3COONa using the Kappen method, and the basic exchangeable cations (Ca2+, K+, Mg2+, and Na+) were measured in 1 M CH3COONH4 by ICP-OES (iCAP 6000 Series).

3.2. Assessment of the Number of Germinated Seeds and the Number of Plants Surpassing the Nonwovens

4. Results and Discussion

4.1. Results

4.1.1. Soil Properties

4.1.2. Number of Seedlings

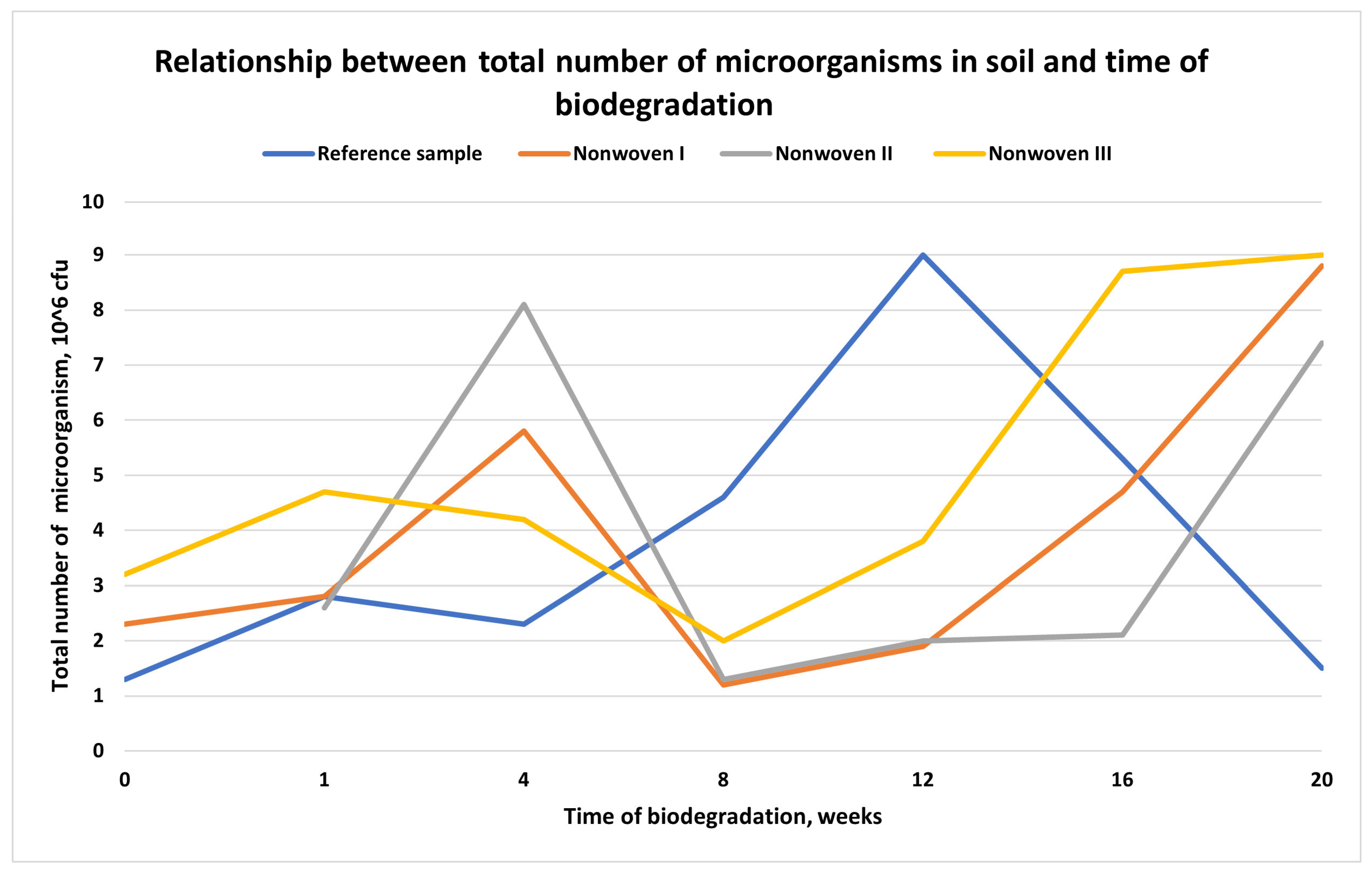

4.1.3. Microbiological Characteristics of the Soil

4.2. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Stefanakis, A.; Nikolaou, I. (Eds.) Circular Economy and Sustainability: Volume 1: Management and Policy; Elsevier: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Bonafe, S. The importance of the circular economy model. Accelerating the transition to a circular economy model is not an option, but a mandatory decision. Circ. Econ. Eur. Union Interim Rev. 2020, 6, 55–56. [Google Scholar] [CrossRef]

- Borys, M. Przepisy i wymogi oraz aktualny stan obwałowań przeciwpowodziowych w Polsce. Woda Sr. Obsz. Wiej. 2007, 7, 25–44. [Google Scholar]

- Pohl, M.; Graf, F.; Buttler, A.; Rixen, C. The relationship between plant species richness and soil aggregate stability can depend on disturbance. Plant Soil 2012, 355, 87–102. [Google Scholar] [CrossRef]

- Ibrahim, A.D.; Rabah, A.B.; Ibrahim, M.L.; Magami, I.M.; Isah, J.G.; Muzoh, O.I. Bacteriological and chemical properties of soil amended with fermented poultry bird feather. Int. J. Biol. Chem. Sci. 2014, 8, 1281–1289. [Google Scholar] [CrossRef][Green Version]

- Schmidt, W.F. Innovative feather utilization strategies. In Proceedings of the National Poultry Waste Management Symposium, Springdale, AR, USA, 19–21 October 1998; Auburn University Printing Services: Auburn, AL, USA, 1998; pp. 276–282. [Google Scholar]

- Hegedűs, M.; Schmidt, J.; Rafai, P. Állati Eredetű Melléktermékek Hasznosítása (Animal by-Product Recycle); Mezőgazda Publisher: Budapest, Hungary, 1998; pp. 15–29, 65–93. [Google Scholar]

- Joardar, J.C.; Rahman, M. Poultry feather waste management and effects on plant growth. Int. J. Recycl. Org. Waste Agric. 2018, 7, 183–188. [Google Scholar] [CrossRef]

- Lasekan, A.; Bakar, F.A.; Hashim, D. Potential of chicken by-products as sources of useful biological resources. Waste Manag. 2013, 33, 552–565. [Google Scholar] [CrossRef] [PubMed]

- Pal, A.; Adhikary, R.; Bera, M.; De, S.K.; Sardar, M. Application of different Geotextile in Soil to Improve the Soil health in humid and hot Sub humid region of West Bengal, India. Int. J. Curr. Microbiol. App. Sci. 2020, 9, 2812–2818. [Google Scholar] [CrossRef]

- Mitchell, D.J.; Barton, A.P.; Fullen, M.A.; Hocking, T.J.; Zhi, W.B.; Yi, Z. Field studies of the effects of jute geotextiles on runoff and erosion in Shropshire, UK. Soil Use Manag. 2003, 19, 182–184. [Google Scholar] [CrossRef]

- Kozlowski, R.M.; Mackiewicz-Talarczyk, M. (Eds.) Handbook of Natural Fibres: Volume 2–Processing and Applications, 2nd ed.; Woodhead Publishing: Sawston, UK, 2020. [Google Scholar]

- Prambauer, M.; Wendeler, C.; Weitzenböck, J.; Burgstaller, C. Biodegradable geotextiles–An overview of existing and potential materials. Geotext. Geomembr. 2019, 47, 48–59. [Google Scholar] [CrossRef]

- Rasheed, F.; Kayani, W.K.; Asghar, M.U.; Farrukh, A.; Gul, S.; Khan, I.; Nazli, N. Unlocking the potential of biowaste: Sustainable strategies to produce valuable industrial products. J. Environ. Qual. 2025, 54, 319–329. [Google Scholar] [CrossRef] [PubMed]

- Desai, A.N.; Kant, R. Geotextiles made from natural fibres. In Geotextiles; Koerner, R.M., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 61–87. [Google Scholar] [CrossRef]

- Pritchard, M.; Sarsby, R.W.; Anand, S.C. Textiles in Civil Engineering. Part 2–Natural Fibre Geotextiles. In Handbook of Technical Textiles; Horrocks, A.R., Anand, S.C., Eds.; Woodhead Publishing: Sawston, UK, 2000; pp. 372–405. [Google Scholar] [CrossRef]

- Sarkar, T.; Perween, T.; Datta, P. Assessing the effect of geotextile mulch on yield and physico-chemical qualities of litchi–A new technical approach. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 1984–1989. [Google Scholar] [CrossRef]

- Mewoli, A.; Segovia, C.; Ebanda, F.B.; Ateba, A.; Girods, P.; Nicolas, B. Development of novel non-woven Triumfetta cordifolia bast fibers and polylactide fibers biocomposites. Waste Biomass Valorization 2024, 15, 3109–3121. [Google Scholar] [CrossRef]

- Shakoorjavan, S.; Eskafi, M.; Stawski, D.; Akbari, S. New effective ways of polypropylene and polylactide nonwovens functionalization. J. Text. Inst. 2024, 11, 1413–1425. [Google Scholar] [CrossRef]

- Gabryś, T.; Fryczkowska, B.; Grzybowska-Pietras, J.; Biniaś, D. Modification and properties of cellulose nonwoven fabric—multifunctional mulching material for agricultural applications. Materials 2021, 14, 4335. [Google Scholar] [CrossRef]

- Broda, J.; Gawłowski, A.; Przybyło, S.; Biniaś, D.; Rom, M.; Grzybowska-Pietras, J.; Laszczak, R. Innovative wool geotextiles designed for erosion protection. J. Ind. Text. 2018, 48, 599–611. [Google Scholar] [CrossRef]

- Wu, H.; Yao, C.; Li, C.; Miao, M.; Zhong, Y.; Lu, Y.; Liu, T. Review of application and innovation of geotextiles in geotechnical engineering. Materials 2020, 13, 1774. [Google Scholar] [CrossRef]

- Giménez-Morera, A.; Sinoga, J.R.; Cerdà, A. The impact of cotton geotextiles on soil and water losses from Mediterranean rainfed agricultural land. Land Degrad. Dev. 2010, 21, 210–217. [Google Scholar] [CrossRef]

- Choudary, R.B.; Burri, M.; Srinath, R.; Alex, R. Novel Use of Waste Chicken Feather Fiber for making Prototype Non-woven Mats and their Evaluation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 653, 012020. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Structure and properties of chicken feather barbs as natural protein fibers. J. Polym. Environ. 2007, 15, 81–87. [Google Scholar] [CrossRef]

- PN-EN 29073-1:1994; Textiles—Test Methods for Nonwo-ven—Determination of Surface Density. Polish Committee for Standardization: Warszawa, Poland, 1994.

- EN ISO 9073-2:2002; Textiles—Test Methods for Nonwovens—Part 2: Determination of Thickness. European Committee for Standardization: Brussels, Belgium, 2002.

- PN-EN 29073-3:1994; Textiles—Test Methods for Nonwo-ven—Determination of Tensile Strength and Elongation at Break. Polish Committee for Standardization: Warszawa, Poland, 1994.

- PN-EN ISO 9073-4:2002; Textiles—Methods for Testing Nonwovens—Part 4: Determination of Tear Strength. Polish Committee for Standardization: Warszawa, Poland, 2002.

- PN ISO 11266:2020-11; Soil quality—Principles of Laboratory Tests on the Biodegradation of Organic Compounds in Soil Under Aerobic Conditions. Polish Committee for Standardization: Warszawa, Poland, 2020.

- PN-EN ISO 11721-1:2002; Textiles—Determination of the Resistance of Cellulose-Containing Textiles to Microorganisms—Soil Burial Test—Part 1: Assessment of Rot-Retardant Finishing. Polish Committee for Standardization: Warszawa, Poland, 2002.

- PN-EN ISO 11721-2:2005; Textiles—Determination of the Resistance of Cellulose-Containing Textiles to Micro-Organisms—Soil Burial Test—Part 2: Identification of Long-Term Resistance of a Rot-Retardant Finish. Polish Committee for Standardization: Warszawa, Poland, 2005.

- PN-EN ISO 7218:2008; Microbiology of Food and Snimal Feeding Stuffs – General Requirements and Guidance for Microbiological Examinations. Polish Committee for Standardization: Warszawa, Poland, 2008.

- ISO 11133:2014; Microbiology of Food, Animal Feed and Water — Preparation, Production, Storage and Performance Testing of Culture Media. International Organization for Standardization: Geneva, Switzerland, 2014.

- PN-EN ISO 11133:2014-07/A1; Microbiology of Food, Animal Feed and Water. Polish Committee for Standardization: Warszawa, Poland, 2014.

- PN-EN ISO 4833-1:2013-12; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms. Part 1: Colony Count at 30 °C by the Pour Plate Technique. Polish Committee for Standardization: Warszawa, Poland, 2013.

- EN ISO 19036:2020-04; Microbiology of the Food Chain—Estimation of Measurement Uncertainty for Quantitative Determinations. European Committee for Standardization: Brussels, Belgium, 2020.

- PN-EN ISO 9237:1998; Textiles—Determination of Permeability of Fabrics to Air. Polish Committee for Standardization: Warszawa, Poland, 1998.

- PN-84/P-04654; Test Methods for Textiles—Yarns—Determination of Static Tensile Indices. Polish Committee for Standardization: Warszawa, Poland, 1984.

- Kaszycki, P.; Supel, P.; Petryszak, P. Bacterial population dynamics in waste oily emulsions from the metal-processing industry. J. Ecol. Eng. 2014, 15, 14–22. [Google Scholar] [CrossRef]

- Supel, P.; Kaszycki, P.; Kasperczyk, M.; Kacorzyk, P. Dynamics of microbiota changes of silage environment resulting from the use of new generation films. Przem. Chem. 2018, 97, 1333–1339. [Google Scholar] [CrossRef]

- Golia, E.E.; Liava, V. The use of geotextiles in agricultural soils and their effects on soil properties and nutrients availability: Are waste plastics likely to become useful materials in agriculture? Sustain. Chem. Pharm. 2024, 29, 101544. [Google Scholar] [CrossRef]

- Golia, E.E.; Liava, V.; Bethanis, J.; Zorpas, A.; Tziourrou, P. Potential valorization and transformation of plastic biomass waste into useful fertilizers in agricultural Mediterranean soils under extreme climate conditions. Process Saf. Environ. Prot. 2024, 187, 73–82. [Google Scholar] [CrossRef]

- Malinconico, M. (Ed.) Soil Degradable Bioplastics for a Sustainable Modern Agriculture; Springer: Berlin/Heidelberg, Germany, 2017; Volume 185. [Google Scholar] [CrossRef]

- Domagała-Świątkiewicz, I.; Siwek, P. The effect of direct covering with biodegradable nonwoven film on the physical and chemical properties of soil. Pol. J. Environ. Stud. 2013, 22, 667–674. [Google Scholar]

- Bhattacharyya, R.; Fullen, M.A.; Booth, C.A.; Smets, T.; Poesen, J.; Black, A. Use of palm-mat geotextiles for soil conservation: I. Effects on soil properties. Catena 2011, 84, 99–107. [Google Scholar] [CrossRef]

- Onuegbu, G.; Okorie, C.C.; Anyiam, C.K.; Akanbi, M.N. Utilization of geotextiles for soil improvement. J. Inst. Polym. Eng. 2017, 1, 11–20. [Google Scholar]

- Vašák, F.; Černý, J.; Buráňová, Š; Kulhanek, M.; Balík, J. Soil pH changes in long-term field experiments with different fertilizing systems. Soil Water Res. 2015, 10, 19–23. [Google Scholar] [CrossRef]

- Barak, P.; Jobe, B.O.; Krueger, A.R.; Peterson, L.A.; Laird, D.A. Effects of long-term soil acidification due to nitrogen fertilizer inputs in Wisconsin. Plant Soil 1997, 197, 61–69. [Google Scholar] [CrossRef]

- Malhi, S.S.; Nyborg, M.; Harapiak, J.T. Effects of long-term N fertilizer-induced acidification and liming on micronutrients in soil and in bromegrass hay. Soil Tillage Res. 1998, 48, 91–101. [Google Scholar] [CrossRef]

- Zul, D.; Denzel, S.; Kotz, A.; Overmann, J. Effects of plant biomass, plant diversity, and water content on bacterial communities in soil lysimeters: Implications for the determinants of bacterial diversity. Appl. Environ. Microbiol. 2007, 73, 6916–6929. [Google Scholar] [CrossRef] [PubMed]

- Miransari, M. Soil microbes and plant fertilization. Appl. Microbiol. Biotechnol. 2011, 92, 875–885. [Google Scholar] [CrossRef] [PubMed]

- Luo, P.; Han, X.; Wang, Y.; Han, M.; Shi, H.; Liu, N.; Bai, H. Influence of long-term fertilization on soil microbial biomass, dehydrogenase activity, and bacterial and fungal community structure in a brown soil of Northeast China. Ann. Microbiol. 2015, 65, 533–542. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Qi, Y.; Dong, Y.; Xiao, S.; Peng, Q.; Liu, X.; Sun, L. Effect of nitrogen fertilization on soil microbial biomass and community functional diversity in temperate grassland in Inner Mongolia, China. Clean Soil Air Water 2013, 41, 1216–1221. [Google Scholar] [CrossRef]

- Faissal, A.; Ouazzani, N.; Parrado, J.R.; Dary, M.; Manyani, H.; Morgado, B.R.; Barragán, M.D.; Mandi, L. Impact of fertilization by natural manure on the microbial quality of soil: Molecular approach. Saudi J. Biol. Sci. 2017, 24, 1437–1443. [Google Scholar] [CrossRef]

- Nakhro, N.; Dkhar, M.S. Impact of Organic and Inorganic Fertilizers on Microbial Populations and Biomass Carbon in Paddy Field Soil. J. Agron. 2010, 9, 102–110. [Google Scholar] [CrossRef]

- Kacorzyk, P.; Strojny, J.; Białczyk, B. The impact of biodegradable geotextiles on the effect of sodding of difficult terrain. Sustainability 2021, 13, 5828. [Google Scholar] [CrossRef]

| Parameter | Commercial Spring Nonwoven | Nonwoven I | Nonwoven II | Nonwoven III | ||||

|---|---|---|---|---|---|---|---|---|

| Thickness [mm] | - | 1.33 | 2.04 | 2.83 | ||||

| Basic weight [g/m2] | - | 78.2 | 158 | 284 | ||||

| Tensile strength in the longitudinal direction [N] | - | 1.11 | 3.91 | 21.2 | ||||

| Tensile strength in the vertical direction [N] | - | 2.02 | 10.2 | 27.2 | ||||

| Tear resistance in the longitudinal direction [N] | - | 1.80 | 5.18 | 31.2 | ||||

| Tear resistance in the vertical direction [N] | - | 1.22 | 4.94 | 15.4 | ||||

| Feathers content [%] | - | 38.5 | 34.8 | 44.4 | ||||

| Air permeability l/m2s | - | 2960 | 1946 | 1176 | ||||

| Field tests | ||||||||

| For | After | For | After | For | After | For | After | |

| WRV [%] | 7.050 | 13.030 | 42.840 | 69.330 | 45.090 | 66.370 | 47.270 | 57.640 |

| Nitrogen content N [%] | 0.061 | 0.301 | 16.690 | 8.460 | 16.190 | 13.020 | 16.380 | 13.600 |

| Potassium content K [%] | - | 0.018 | 0.129 | 0.402 | 0.124 | 0.146 | 0.136 | 0.198 |

| Soil Property | Mean Value | SD | |

|---|---|---|---|

| TN | % | 0.14 | 0.03 |

| SOC | 1.69 | 0.44 | |

| pH H2O | 6.8 | 0.3 | |

| pH KCl | 6.0 | 0.3 | |

| Ca++ | mg/100 g | 12.1 | 1.2 |

| K+ | 0.3 | 0.1 | |

| Mg++ | 2.1 | 0.1 | |

| Na+ | 1.3 | 0.3 | |

| HA | 0.0 | 0.0 | |

| CEC | 15.8 | 1.0 | |

| BS | % | 91.5 | 2.4 |

| Mgav | mg/100 g | 35.7 | 2.6 |

| Kav | 11.0 | 4.2 | |

| Pav | 0.3 | 0.1 | |

| RLD | cm/cm3 | no plants and roots | |

| Bacteria | CFU/ g d.m. × 10−3 | 980.9 | 780.9 |

| Yeast | 0.4 | 0.2 | |

| Week | Number of Colonies [Colony Forming Unit. CFU/g] | |||

|---|---|---|---|---|

| Reference Sample | Nonwoven I | Nonwoven II | Nonwoven III | |

| 1 | 1.3 × 106 | 2.3 × 106 | Uncountable * | 3.2 × 107 |

| 4 | 2.8 × 105 | 2.8 × 106 | 1.6 × 106 | 4.7 × 106 |

| 8 | 2.3 × 106 | 5.8 × 106 | 8.1 × 106 | 4.2 × 107 |

| 12 | 4.6 × 105 | 1.2 × 106 | 1.3 × 107 | 2.0 × 106 |

| 16 | 9.0 × 105 | 1.9 × 106 | 2.0 × 107 | 3.8 × 106 |

| 20 | 5.3 × 105 | 4.7 × 105 | 2.1 × 106 | 8.7 × 106 |

| 24 | 1.5 × 106 | 8.8 × 105 | 7.4 × 106 | 9.0 × 106 |

| Sprouted Seeds Index [%] | ||||

|---|---|---|---|---|

| Parameter | Reference Sample | Nonwoven I | Nonwoven II | Nonwoven III |

| Mustard | 70 | - | - | - |

| Wheat | 90 | - | - | - |

| Cress | 50 | - | - | - |

| Mustard 25% | - | 100 | 100 | 80 |

| Mustard 50% | - | 100 | 90 | 90 |

| Wheat 25% | - | 100 | 90 | 100 |

| Wheat 50% | - | 90 | 100 | 100 |

| Cress 25% | - | 60 | 50 | 70 |

| Cress 50% | - | 50 | 50 | 60 |

| Sample Code | Repetition Number | Biodegradation Time—Week (day) | ||||||

|---|---|---|---|---|---|---|---|---|

| 1(7) | 4(28) | 8(56) | 12(84) | 16(112) | 20(140) | 24(168) | ||

| Weight Loss % | ||||||||

| Nonwoven I | 1 | 15.3 | 39.7 | 75.6 | 83.4 | 92.7 | 93.9 | 92.3 |

| 2 | 16.6 | 28.4 | 75.7 | 87.2 | 88.5 | 91.6 | 90.7 | |

| 3 | 14.8 | 49.4 | 68.8 | 85.5 | 91.4 | 92.7 | 92.3 | |

| Sample Code | Repetition Number | Biodegradation Time—Week (days) | ||||||

|---|---|---|---|---|---|---|---|---|

| 1(7) | 4(28) | 8(56) | 12(84) | 16(112) | 20(140) | 24(168) | ||

| Weight Loss [%] | ||||||||

| Nonwoven II | 1 | 9.57 | 43.5 | 65.5 | 77.8 | 77.8 | 86.3 | 86.1 |

| 2 | 9.38 | 44.9 | 62.9 | 72.6 | 83.4 | 82.2 | 84.9 | |

| 3 | 10.5 | 48.5 | 70.4 | 80.6 | 82.2 | 86.2 | 87.7 | |

| Sample Code | Repetition Number | Biodegradation Time—Week (days) | ||||||

|---|---|---|---|---|---|---|---|---|

| 1(7) | 4(28) | 8(56) | 12(84) | 16(112) | 20(140) | 24(168) | ||

| Weight Loos [%] | ||||||||

| Nonwoven III | 1 | 11.2 | 53.9 | 79.0 | 91.5 | 86.4 | 91.0 | 92.8 |

| 2 | 11.1 | 54.8 | 74.0 | 90.3 | 89.6 | 90.0 | 92.5 | |

| 3 | 10.4 | 46.5 | 65.1 | 87.2 | 92.1 | 90.0 | 90.4 | |

| Sample Code | C:N Ratio—Week (days) | ||||||

|---|---|---|---|---|---|---|---|

| 1(7) | 4(28) | 8(56) | 12(84) | 16(112) | 20(140) | 24(168) | |

| Reference sample | 14.4 | 14.8 | 14.4 | 14.8 | 14.5 | 14.2 | 14.3 |

| Nonwoven I | 14.8 | 14.9 | 14.0 | 14.3 | 14.5 | 13.5 | 14.0 |

| Nonwoven II | 20.8 | 19.3 | 17.4 | 20.1 | 18.9 | 18.3 | 18.7 |

| Nonwoven III | 14.3 | 14.6 | 12.2 | 12.7 | 12.8 | 12.8 | 12.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kacorzyk, P.; Strojny, J.; Niewiadomski, M.; Supel, P.; Kaszycki, P.; Brishty, I.-E.-A.; Józefowska, A.; Wrześniewska-Tosik, K.; Kowalewski, T.; Pałczyńska, M.; et al. The Circular Economy Approach to Dealing with Burdensome Waste from Poultry Industry. Sustainability 2025, 17, 5997. https://doi.org/10.3390/su17135997

Kacorzyk P, Strojny J, Niewiadomski M, Supel P, Kaszycki P, Brishty I-E-A, Józefowska A, Wrześniewska-Tosik K, Kowalewski T, Pałczyńska M, et al. The Circular Economy Approach to Dealing with Burdensome Waste from Poultry Industry. Sustainability. 2025; 17(13):5997. https://doi.org/10.3390/su17135997

Chicago/Turabian StyleKacorzyk, Piotr, Jacek Strojny, Michał Niewiadomski, Paulina Supel, Paweł Kaszycki, Ishrat-E-Anwar Brishty, Agnieszka Józefowska, Krystyna Wrześniewska-Tosik, Tomasz Kowalewski, Michalina Pałczyńska, and et al. 2025. "The Circular Economy Approach to Dealing with Burdensome Waste from Poultry Industry" Sustainability 17, no. 13: 5997. https://doi.org/10.3390/su17135997

APA StyleKacorzyk, P., Strojny, J., Niewiadomski, M., Supel, P., Kaszycki, P., Brishty, I.-E.-A., Józefowska, A., Wrześniewska-Tosik, K., Kowalewski, T., Pałczyńska, M., & Walisiak, D. (2025). The Circular Economy Approach to Dealing with Burdensome Waste from Poultry Industry. Sustainability, 17(13), 5997. https://doi.org/10.3390/su17135997