Certification for Solar Panel Reuse: A Systematic Review of Cross-Sector Practices and Gaps

Abstract

1. Introduction

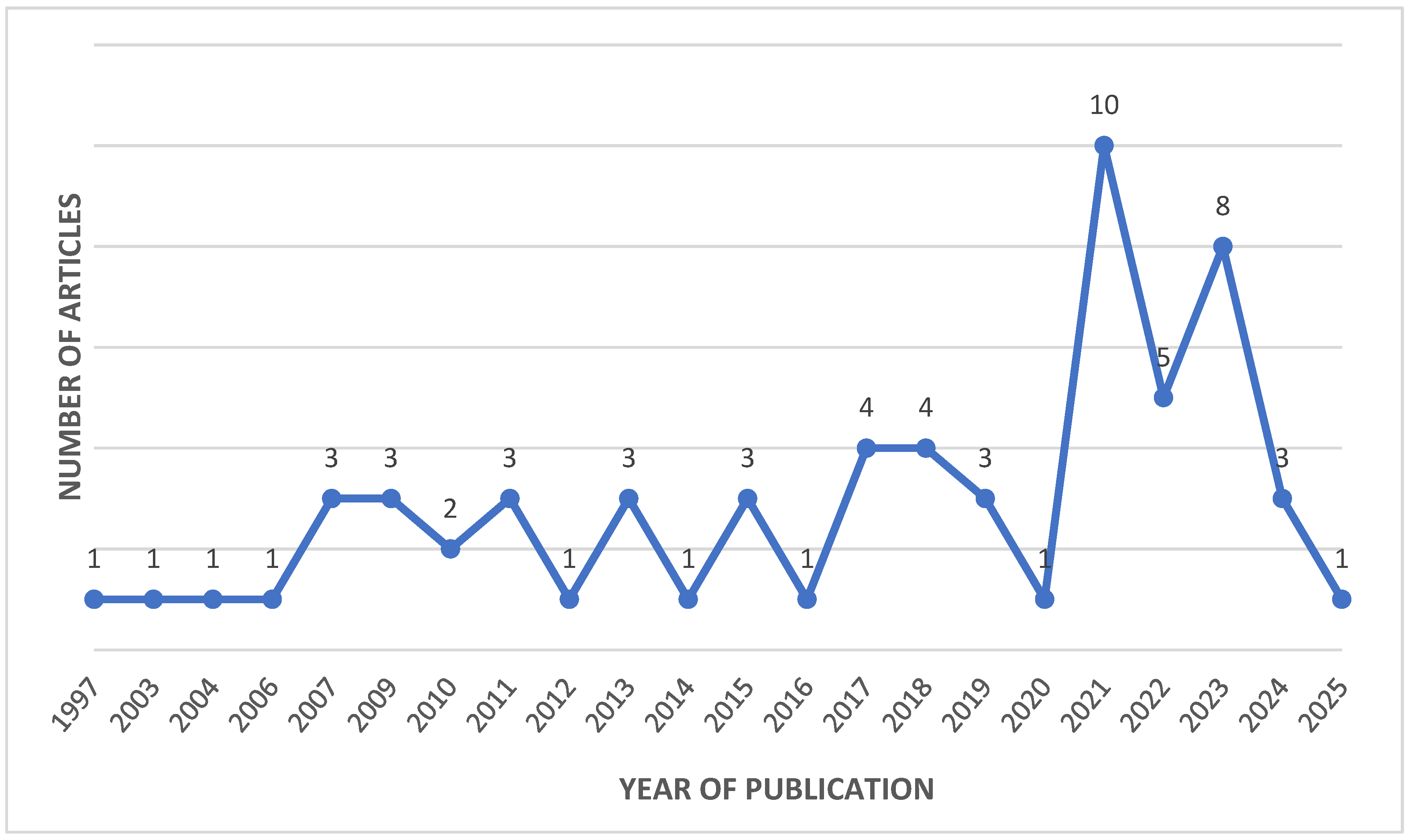

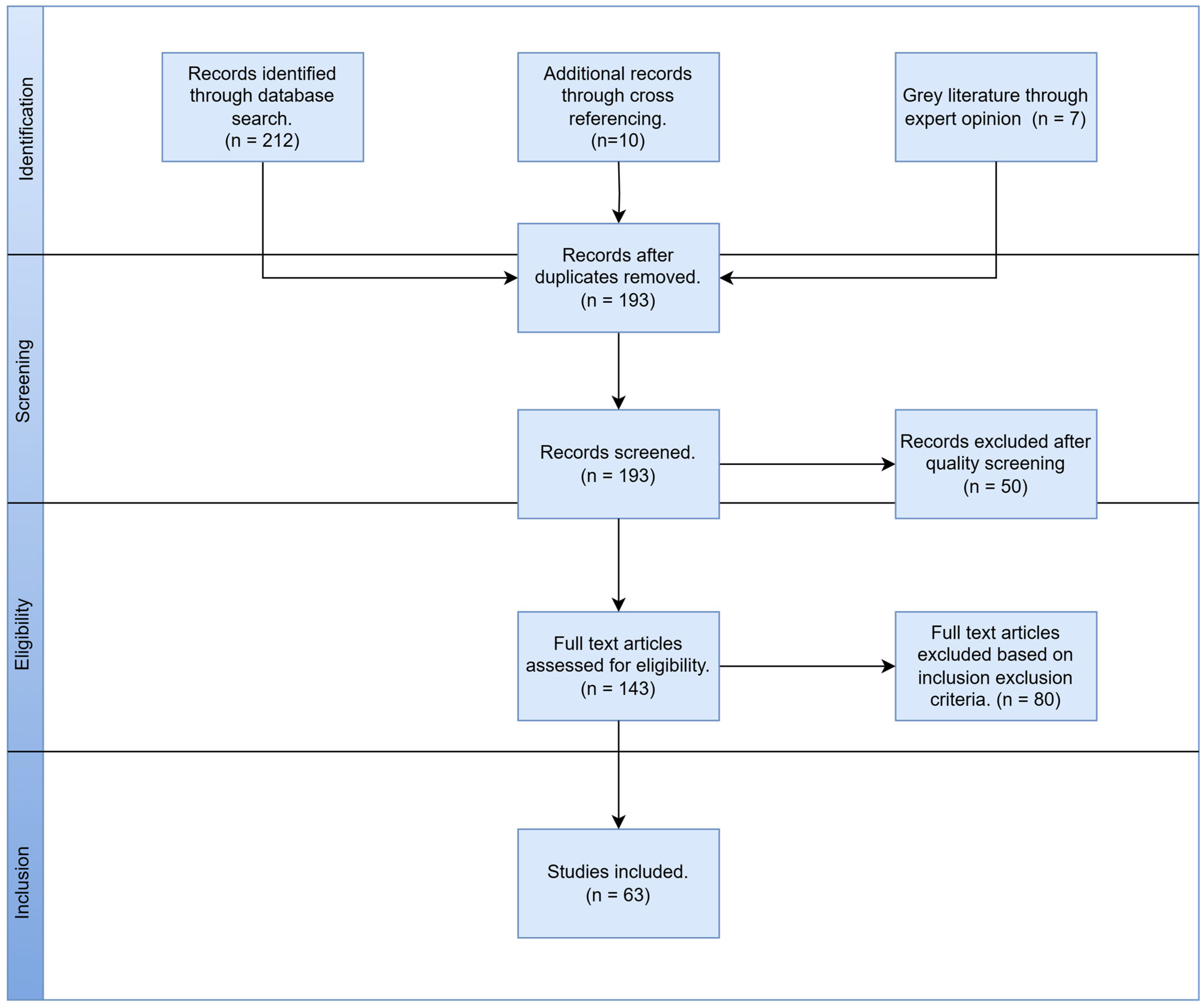

2. Methodology

2.1. Search String Development

2.2. Inclusion and Exclusion Criteria

2.3. Study Selection Strategy

3. Findings

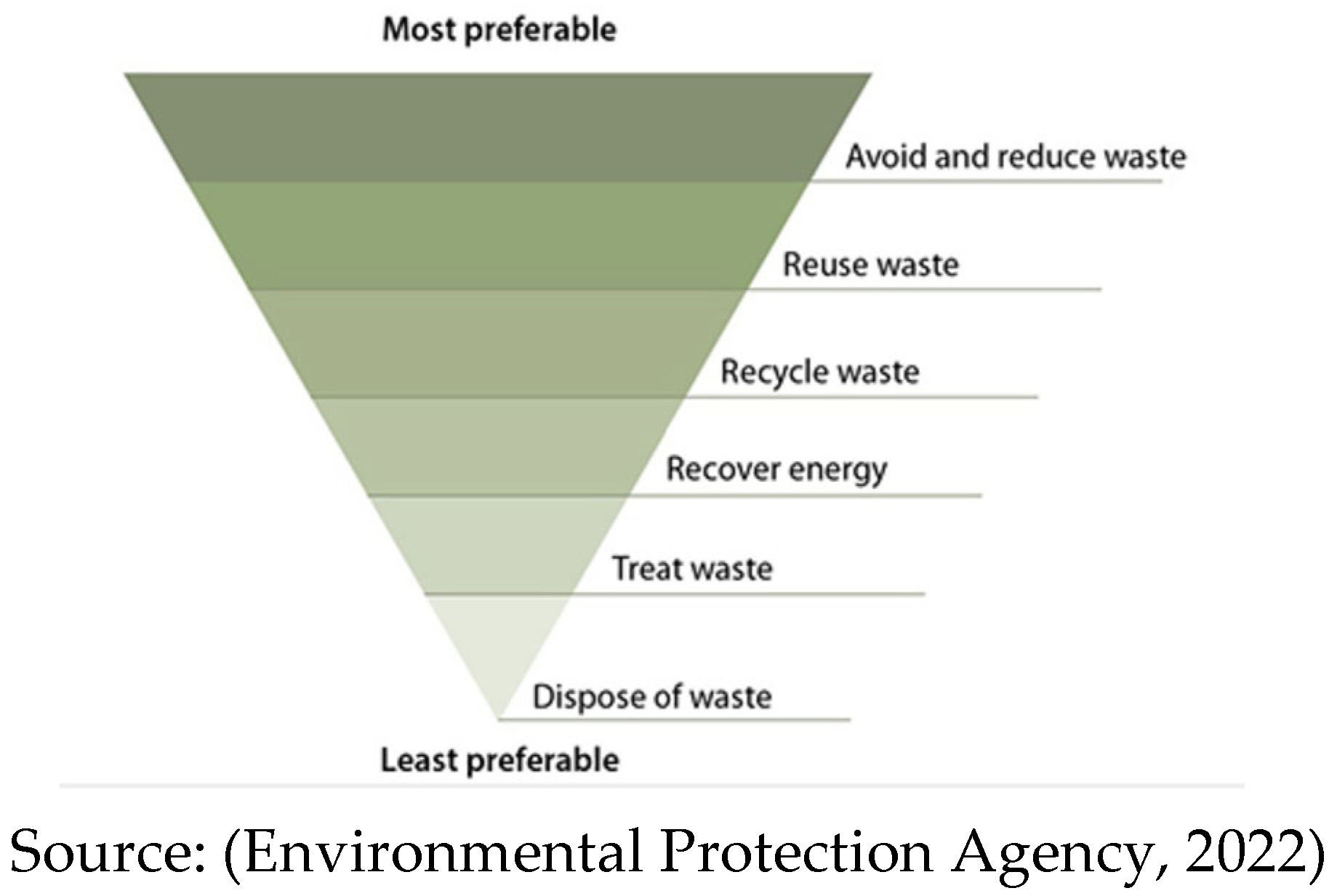

3.1. Key Components and Criteria for Product Reuse

3.2. Certification for Refurbished Electronics

3.3. Proposing a Reuse Framework for Solar Panels

4. Discussion

4.1. Challenges and Best Practices Associated with Product Reuse Certification

4.2. Implications

4.3. Limitations

5. Conclusions

Supplementary Materials

Funding

Conflicts of Interest

Appendix A. List of Relevant Papers for Systematic Literature Review

| Theme | Authors | Year | Description and Focus of Paper | Quality Measure (Scimago/ABDC List) |

|---|---|---|---|---|

| Safety and Certification in Critical Systems | D. Falessi et al. | 2011 | Planning for safety evidence collection. | Q1 |

| SM Lee, et al. | 2009 | Safety certification argument. | Q1 | |

| Bayrak, et al. | 2021 | Safety cases for medical devices. | Q1 | |

| Feiler | 2010 | Model-based validation of safety-critical systems. | Conference Paper | |

| Weaver, et al. | 2003 | Assurance of safety arguments. | Conference Paper | |

| W. Ridderhof, et al. | 2007 | Safety cases in automotive systems. | Conference Paper | |

| TW Sloan | 2007 | Safety reasoning. | Q1 | |

| Denney, et al. | 2011 | Measurement of confidence in safety cases. | Conference Paper | |

| E. Schoitsch, et al. | 2006 | Validation and certification of safety-critical systems. | Conference Paper | |

| Kotonya and Sommerville | 1997 | Integrating safety analysis in requirements engineering. | Conference Paper | |

| S. Linling, T. Kelly | 2009 | Safety arguments in aircraft certification. | Conference Paper | |

| S. Wagner, et al. | 2010 | Safety cases in the automotive domain. | Conference Paper | |

| Nair et al. | 2014 | Provision for safety certification. | Q1/A | |

| Wiengarten, et al. | 2017 | Certification standards and performance implications. | Q1/A | |

| Circular Economy and Sustainability | Bressanelli, G., et al. | 2022 | Business potential in circular economy. | Q1 |

| European Parliament and The Council of European Union | 2012 | Directive on waste electrical and electronic equipment. | EU Directive | |

| Friant, et al. | 2020 | Circular economy discourses. | Q1 | |

| Milios | 2018 | Policy mix for a circular economy. | Q1 | |

| Mc Kenna, et al. | 2013 | Energy savings in secondary reuse. | Q1/A | |

| Harms and Linton | 2015 | Eco-certified refurbished products. | Q1 | |

| Rajaeifar, et al. | 2022 | Electric vehicle battery supply chain. | Q1 | |

| Reuse and Recycling Strategies | Alqahtani, Ammar Y | 2017 | Warranty in reuse strategy. | Q1 |

| BSI | 2011 | Reuse of electrical and electronic equipment. | Industry report | |

| Chen, et al. | 2019 | Two modes of product recovery. | Q1/A* | |

| Santana et al. | 2021 | Cell phones recycling in Brazil. | Q1/A | |

| Chung, H.-C. | 2021 | LiFePO4 batteries repurposing. | Q1 | |

| Martinez-Laserna, et al. | 2018 | Viability of battery second life. | Q1 | |

| Pagliaro, et al. | 2019 | Battery reusing and recycling. | Q1 | |

| Gur k, et al. | 2018 | Battery second life in energy grid integration. | Q1 | |

| Saez-de-Ibarra, et al. | 2015 | Second-life battery for energy storage. | Q1 | |

| Shahjalal, et al. | 2022 | Second life of Li-ion batteries | Q1 | |

| Sathre, R., et al. | 2015 | EV batteries’ second life use in California. | Q1 | |

| Salim, et al. | 2023 | Second-hand market for solar panels. | Report | |

| Marinna, et al. | 2025 | PV modules decision-making framework for reuse. | Q1/A | |

| Stromberg | 2021 | Reuse of solar photovoltaic systems. | Report | |

| Skoczek et al. | 2009 | Performance measurements of photovoltaic modules. | Q1 | |

| Rabanal-Arabac | 2023 | Proposal to determine PV module status for its second life. | Report | |

| Test and Tag | 2024 | Testing second-hand equipment . | Report | |

| PV Lab | 2024 | PV panel re-use around the world. | Report | |

| James McGregor | 2023 | Solar panel reuse. | Report | |

| UNSW | 2023 | Repair, reuse and recycle solar panels. | Report | |

| Consumer Behavior and Market Dynamics | Weelden, E., et al. | 2016 | Refurbished mobile phones acceptance. | Q1 |

| Wang, Y., et al. | 2018 | Perceptions of remanufactured auto parts. | Q1 | |

| Pretner, et al. | 2021 | Consumers and third-party certifications. | Q1 | |

| Technological Aspects of Product Life Extension | Chen, X, et al. | 2022 | Electroluminescence images of solar modules. | Q1 |

| Hazelwood and Pecht | 2021 | Smartphone life extension. | Q1 | |

| Casals, et al. | 2017 | Second life of electric vehicle batteries. | Q1 | |

| Cheng et al. | 2023 | State-of-charge estimation for batteries. | Q1 | |

| Song, et al. | 2024 | Second-life battery utilization. | Q1 | |

| Elmahallawy, M, et al. | 2022 | State of health estimation. | Q1 | |

| Policy and Regulation | Hoglund, et al. | 2021 | Consumer electronics repair policy. | Q1 |

| Gerrard and Kandlikar | 2007 | European EoL Vehicle legislation. | Q1/A | |

| Wu, J., et al. | 2019 | Photovoltaic modules recycling models. | Q1 | |

| Shukla et al. | 2023 | Regulatory practices for refurbished medical devices. | Q1 | |

| Heide, et al. | 2023 | Re-use of PV modules: progress in standardization. | Report | |

| Svensson, et al. | 2021 | Policy landscape for repair of consumer electronics. | Q1/A | |

| GCC | 2021 | AS/NZS 5377 certification. | Certification standard | |

| Quality and Safety Management in Reused Products | Lo and Yu | 2013 | Quality management for reused products. | Q1/A |

| Shafiee, M., Animah, I. | 2017 | Decision-making in safety-critical systems life extension. | Q1 | |

| Miscellaneous | Franco, et al. | 2021 | Value chain for circular economy. | Q1 |

| Boukhatmi, et al. | 2023 | data-enhanced circular practices in solar industry. | Q1/A | |

| McKenna, et al. | 2013 | Automative sector—secondary reuse savings. | Q1/A | |

| Murthy, et al. | 2004 | Product warranty logistics. | Q1/A* |

References

- World Bank. World Development Report 2020: Trading for Development in the Age of Global Value Chains. 2020. Available online: https://www.worldbank.org/en/publication/wdr2020 (accessed on 23 August 2023).

- Toprak, T.; Anis, P. Textile industry’s environmental effects and approaching cleaner production and sustainability, an overview. J. Text. Eng. Fash. Technol. 2017, 2, 429–442. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- das Virgens, N.; Silva, S.; Laranjeira, E. Applications of the circular economy to the second-hand textile and clothing market: The case of Humana in Portugal. Int. J. Fash. Des. Technol. Educ. 2022, 16, 214–223. [Google Scholar] [CrossRef]

- Laitala, K.; Klepp, I. Clothing disposal habits and consequences for life cycle assessment (LCA). In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2015; pp. 345–365. [Google Scholar]

- Sandin, G.; Peters, G.M. Environmental impact of textile reuse and recycling–A review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

- Friant, M.C.; Vermeulen, W.J.; Salomone, R. A typology of circular economy discourses: Navigating the diverse visions of a contested paradigm. Resour. Conserv. Recycl. 2020, 161, 104917. [Google Scholar] [CrossRef]

- Milios, L. Advancing to a Circular Economy: Three essential ingredients for a comprehensive policy mix. Sustain. Sci. 2018, 13, 861–878. [Google Scholar] [CrossRef]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Russell, J.D. Market Transformation for Value-Retention Processes as a Strategy for Circular Economy; Rochester Institute of Technology: New York, NY, USA, 2018. [Google Scholar]

- Sundin, E.; Lee, H.M. In what way is remanufacturing good for the environment? In Proceedings of the Design for Innovative Value Towards a Sustainable Society: Proceedings of EcoDesign 2011: 7th International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Kyoto, Japan, 30 November–2 December 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 552–557. [Google Scholar]

- Ma, J.; Kremer, G.E.O.; Ray, C.D. A comprehensive end-of-life strategy decision making approach to handle uncertainty in the product design stage. Res. Eng. Des. 2018, 29, 469–487. [Google Scholar] [CrossRef]

- Fleischmann, M.; Bloemhof-Ruwaard, J.M.; Dekker, R.; Van der Laan, E.; Van Nunen, J.A.; Van Wassenhove, L.N. Quantitative models for reverse logistics: A review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef]

- den Hollander, M.C.; Bakker, C.A. A Business Model Framework for Product Life Extension. In Proceedings of the Sustainable Innovation 2012 Resource Efficiency, Innovation and Lifestyles, Bonn, Germany, 29–30 October 2012; p. 110. [Google Scholar]

- Maani, T.; Celik, I.; Heben, M.J.; Ellingson, R.J.; Apul, D. Environmental impacts of recycling crystalline silicon (c-SI) and cadmium telluride (CDTE) solar panels. Sci. Total Environ. 2020, 735, 138827. [Google Scholar] [CrossRef]

- Tsanakas, J.A.; van der Heide, A.; Radavičius, T.; Denafas, J.; Lemaire, E.; Wang, K.; Poortmans, J.; Voroshazi, E. Towards a circular supply chain for PV modules: Review of today’s challenges in PV recycling, refurbishment and re-certification. Prog. Photovolt. 2019, 28, 454–464. [Google Scholar] [CrossRef]

- Walzberg, J.; Carpenter, A.; Heath, G.A. Role of the social factors in success of solar photovoltaic reuse and recycle programmes. Nat. Energy 2021, 6, 913–924. [Google Scholar] [CrossRef]

- Preet, S.; Smith, S.T. A comprehensive review on the recycling technology of silicon based photovoltaic solar panels: Challenges and future outlook. J. Clean. Prod. 2024, 448, 141661. [Google Scholar] [CrossRef]

- Oteng, D.; Zuo, J.; Sharifi, E. A scientometric review of trends in solar photovoltaic waste management research. Sol. Energy 2021, 224, 545–562. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Huda, N.; Alavi, Z.; Islam, M.T.; Behnia, M. End-of-life photovoltaic modules: A systematic quantitative literature review. Resour. Conserv. Recycl. 2019, 146, 1–16. [Google Scholar] [CrossRef]

- Franco, M.A.; Groesser, S.N. A systematic literature review of the solar photovoltaic value chain for a circular economy. Sustainability 2021, 13, 9615. [Google Scholar] [CrossRef]

- Borenstein, M.; Hedges, L.V.; Higgins, J.P.; Rothstein, H.R. Introduction to Meta-Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate health care interventions: Explanation and elaboration. Ann. Intern. Med. 2009, 151, W-65–W-94. [Google Scholar] [CrossRef]

- Kitchenham, B. Procedures for Performing Systematic Reviews; Keele University: Keele, UK, 2004; Volume 33, pp. 1–26. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Petticrew, M.; Roberts, H. Systematic Reviews in the Social Sciences: A Practical Guide; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Ann. Intern. Med. 2009, 151, 264–269. [Google Scholar] [CrossRef]

- Seuring, S.; Gold, S. Conducting content-analysis based literature reviews in supply chain management. Supply Chain Manag. Int. J. 2012, 17, 544–555. [Google Scholar] [CrossRef]

- Duong, C. Repair, Reuse and Recycle: Dealing with Solar Panels at the End of Their Useful Life; UNSW Sydney: Sydney, Australia, 2023. [Google Scholar]

- Lo, H.-C.; Yu, R.-Y. A study of quality management strategy for reused products. Reliab. Eng. Syst. Saf. 2013, 119, 172–177. [Google Scholar] [CrossRef]

- Anityasari, M.; Kaebernick, H.; Kara, S. The role of warranty in the reuse strategy. In Proceedings of the Advances in Life Cycle Engineering for Sustainable Manufacturing Businesses: Proceedings of the 14th CIRP Conference on Life Cycle Engineering, Waseda University, Tokyo, Japan, 11–13 June 2007; Springer: Berlin/Heidelberg, Germany, 2007; pp. 335–340. [Google Scholar]

- Murthy, D.; Solem, O.; Roren, T. Product warranty logistics: Issues and challenges. Eur. J. Oper. Res. 2004, 156, 110–126. [Google Scholar] [CrossRef]

- Alqahtani, A.Y.; Gupta, S.M. Warranty as a marketing strategy for remanufactured products. J. Clean. Prod. 2017, 161, 1294–1307. [Google Scholar] [CrossRef]

- Papadopoulos, Y.; McDermid, J.A. The potential for a generic approach to certification of safety critical systems in the transportation sector. Reliab. Eng. Syst. Saf. 1999, 63, 47–66. [Google Scholar] [CrossRef]

- Wagner, S.; Schätz, B.; Puchner, S.; Kock, P. A case study on safety cases in the automotive domain: Modules, patterns, and models. In Proceedings of the 2010 IEEE 21st International Symposium on Software Reliability Engineering, San Jose, CA, USA, 1–4 November 2010; pp. 269–278. [Google Scholar]

- National Electrical Code (NEC). U. Solutions. 2020. Available online: https://link.nfpa.org/publications/70/2020 (accessed on 10 September 2023).

- ISO 9001; Quality management systems—Requirements. ISO: Geneva, Switzerland, 2015.

- Chen, Y.S.; Chang, C.H. Enhance green purchase intentions. Manag. Decis. 2012, 50, 502–520. [Google Scholar] [CrossRef]

- Wang, Y.; Huscroft, J.R.; Hazen, B.T.; Zhang, M. Green information, green certification and consumer perceptions of remanufctured automobile parts. Resour. Conserv. Recycl. 2018, 128, 187–196. [Google Scholar] [CrossRef]

- IEC 61508; Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems—Part 1: General Requirements. IEC: Geneva, Switzerland, 2010.

- ISO 26262-1:2018; Road Vehicles — Functional Safety. Part 1: Vocabulary. ISO: Geneva, Switzerland, 2018.

- EN 50126; Railway Applications. The Specification and Demonstration of Reliability, Availability, Maintainability and Safety (RAMS) Generic RAMS Process. British Standards Institution: London, UK, 2017.

- Wiengarten, F.; Humphreys, P.; Onofrei, G.; Fynes, B. The adoption of multiple certification standards: Perceived performance implications of quality, environmental and health & safety certifications. Prod. Plan. Control 2017, 28, 131–141. [Google Scholar]

- AS/NZS 5377; Certification—E-Waste Management Systems Certification. Global Compliance Certification: Petaling Jaya, Malaysia, 2011.

- Van Der Heide, A.; Godinho, D.; Hernandez, G.; Noels, S.; Clyncke, J. Re-Use of PV modules: Progress in Standardisation and Learnings from a Real Case Study. EU PVSEC. 2023. Available online: https://trust-pv.eu/wp-content/uploads/2024/04/EUPVSEC_2023_5DO.15.6_final.pdf (accessed on 10 September 2023).

- Boukhatmi, Ä.; Nyffenegger, R.; Grösser, S.N. Designing a digital platform to foster data-enhanced circular practices in the European solar industry. J. Clean. Prod. 2023, 418, 137992. [Google Scholar] [CrossRef]

- IEC 62933-5-3; Electrical Energy Storage (EES) Systems—Part 5-3: Safety Requirements for Grid-Integrated EES Systems—Performing Unplanned Modification of Electrochemical Based System. IEC: Geneva, Switzerland, 2023.

- Shrestha, N.; Zaman, A. Decommissioning and Recycling of End-of-Life Photovoltaic Solar Panels in Western Australia. Sustainability 2024, 16, 526. [Google Scholar] [CrossRef]

- Svensson-Hoglund, S.; Richter, J.L.; Maitre-Ekern, E.; Russell, J.D.; Pihlajarinne, T.; Dalhammar, C. Barriers, enablers and market governance: A review of the policy landscape for repair of consumer electronics in the EU and the U.S. J. Clean. Prod. 2021, 288, 125488. [Google Scholar] [CrossRef]

- UL 110; Standard for Sustainability for Mobile Phones. UL Standard: Northbrook, IL, USA, 2024.

- Hazelwood, D.A.; Pecht, M.G. Life Extension of Electronic Products: A Case Study of Smartphones. IEEE Access 2021, 9, 144726–144739. [Google Scholar] [CrossRef]

- SERI. The Responsible Recycling (R2): 2013 Standard; SERI: Singapore, 2013. [Google Scholar]

- European Parliament and The Council of European Union. Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on waste electrical and electronic equipment, WEEE. Off. J. Eur. Union L 2012, 197, 38–71. [Google Scholar]

- BSI. PAS 141—Reuse of Used and Waste Electrical and Electronic Equipment (UEEE and WEEE); BSI: London, UK, 2011. [Google Scholar]

- Shafiee, M.; Animah, I. Life extension decision making of safety critical systems: An overview. J. Loss Prev. Process Ind. 2017, 47, 174–188. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Q.; Xu, Z. Research on China’s photovoltaic modules recycling models under extended producer responsibility. Int. J. Sustain. Eng. 2019, 12, 423–432. [Google Scholar] [CrossRef]

- McKenna, R.; Reith, S.; Cail, S.; Kessler, A.; Fichtner, W. Energy savings through direct secondary reuse: An exemplary analysis of the German automotive sector. J. Clean. Prod. 2013, 52, 103–112. [Google Scholar] [CrossRef]

- Song, H.; Chen, H.; Wang, Y.; Sun, X.-E. An Overview About Second-Life Battery Utilization for Energy Storage: Key Challenges and Solutions. Energies 2024, 17, 6163. [Google Scholar] [CrossRef]

- Chung, H.-C. Charge and discharge profiles of repurposed LiFePO4 batteries based on the UL 1974 standard. Sci. Data 2021, 8, 165. [Google Scholar] [CrossRef]

- Martinez-Laserna, E.; Sarasketa-Zabala, E.; Sarria, I.V.; Stroe, D.-I.; Swierczynski, M.; Warnecke, A.; Timmermans, J.-M.; Goutam, S.; Omar, N.; Rodriguez, P. Technical viability of battery second life: A study from the ageing perspective. IEEE Trans. Ind. Appl. 2018, 54, 2703–2713. [Google Scholar] [CrossRef]

- Gur, K.; Chatzikyriakou, D.; Baschet, C.; Salomon, M. The reuse of electrified vehicle batteries as a means of integrating renewable energy into the European electricity grid: A policy and market analysis. Energy Policy 2018, 113, 535–545. [Google Scholar] [CrossRef]

- Saez-de-Ibarra, A.; Martinez-Laserna, E.; Stroe, D.-I.; Swierczynski, M.; Rodriguez, P. Sizing study of second life Li-ion batteries for enhancing renewable energy grid integration. IEEE Trans. Ind. Appl. 2016, 52, 4999–5008. [Google Scholar] [CrossRef]

- Cheng, M.; Zhang, X.; Ran, A.; Wei, G.; Sun, H. Optimal dispatch approach for second-life batteries considering degradation with online SoH estimation. Renew. Sustain. Energy Rev. 2023, 173, 113053. [Google Scholar] [CrossRef]

- Basia, A.; Simeu-Abazi, Z.; Gascard, E.; Zwolinski, P. Review on State of Health estimation methodologies for lithium-ion batteries in the context of circular economy. CIRP J. Manuf. Sci. Technol. 2021, 32, 517–528. [Google Scholar] [CrossRef]

- Pagliaro, M.; Meneguzzo, F. Lithium Battery Reusing and Recycling: A Circular Economy Insight. Heliyon 2019, 5, e01866. [Google Scholar] [CrossRef]

- Sathre, R.; Scown, C.D.; Kavvada, O.; Hendrickson, T.P. Energy and climate effects of second-life use of electric vehicle batteries in California through 2050. J. Power Sources 2015, 288, 82–91. [Google Scholar] [CrossRef]

- Oteng, D.; Zuo, J.; Sharifi, E. An evaluation of the impact framework for product stewardship on end-of-life solar photovoltaic modules: An environmental lifecycle assessment. J. Clean. Prod. 2023, 411, 137357. [Google Scholar] [CrossRef]

- Casals, L.C.; García, B.A.; Aguesse, F.; Iturrondobeitia, A. Second life of electric vehicle batteries: Relation between materials degradation and environmental impact. Int. J. Life Cycle Assess. 2017, 22, 82–93. [Google Scholar] [CrossRef]

- Braco, E.; San Martín, I.; Sanchis, P.; Ursúa, A.; Stroe, D.-I. State of health estimation of second-life lithium-ion batteries under real profile operation. Appl. Energy 2022, 326, 119992. [Google Scholar] [CrossRef]

- Shahjalal, M.; Roy, P.K.; Shams, T.; Fly, A.; Chowdhury, J.I.; Ahmed, M.R.; Liu, K. A review on second-life of Li-ion batteries: Prospects, challenges, and issues. Energy 2022, 241, 122881. [Google Scholar] [CrossRef]

- Tsanakas, I.A.; Oreski, G.; Eder, G.; Gassner, A.; van der Heide, A.; Ariolli, D.M.G.; Hernandez, G.O.; Moser, D.; Wambach, K. Toward Reuse-Ready PV: A Perspective on Recent Advances, Practices, and Future Challenges. Adv. Energy Sustain. Res. 2024, 2400237. [Google Scholar] [CrossRef]

- Training, T.T. Testing Second-Hand Equipment for Safe Resale; Test & Tag Training: Auckland, New Zealand.

- Chen, X.; Karin, T.; Jain, A. Automated defect identification in electroluminescence images of solar modules. Sol. Energy 2022, 242, 20–29. [Google Scholar] [CrossRef]

- Marinna, P.; Laís, V.; Fernando, O.R.P.; Ricardo, R. Circular solar economy: PV modules decision-making framework for reuse. J. Clean. Prod. 2025, 493, 144941. [Google Scholar] [CrossRef]

- Rabanal-Arbach, J.; Fuentealba-vidal, E. Procedure proposal to determine PV module status for its second life application. In Proceedings of the 40th European Photovoltaic Solar Energy Conference and Exhibition, Lisbon, Portugal, 18–22 September 2023. [Google Scholar]

- Stromberg, R. Reuse of Solar Photovoltaic Systems for Social and Economic Benefit. In Proceedings of the SOLAR 2021 Conference, Yokohama, Japan, 12–13 October 2021; International Solar Energy Society: Freiburg im Breisgau, Germany, 2021; pp. 1–12. [Google Scholar] [CrossRef]

- Skoczek, A.; Sample, T.; Dunlop, E.D. The results of performance measurements of field-aged crystalline silicon photovoltaic modules. Prog. Photovolt. Res. Appl. 2009, 17, 227–240. [Google Scholar] [CrossRef]

- Nair, S.; De La Vara, J.L.; Sabetzadeh, M.; Briand, L. An extended systematic literature review on provision of evidence for safety certification. Inf. Softw. Technol. 2014, 56, 689–717. [Google Scholar] [CrossRef]

- Bloch, M. General Solar & Storage News. In Towards Australian Standards for Second-Hand Solar Panels; Solarquotes: Adelaide, Australia, 2022. [Google Scholar]

- Bennett, A. Second Life Solar: Making the Most of Used Panels. In Solar Panels; Solarquotes: Adelaide, Australia, 2025. [Google Scholar]

- Gerrard, J.; Kandlikar, M. Is European end-of-life vehicle legislation living up to expectations? Assessing the impact of the ELV Directive on ‘green’ innovation and vehicle recovery. J. Clean. Prod. 2007, 15, 17–27. [Google Scholar] [CrossRef]

- EN 50614:2020; Requirements for the Preparing for Re-Use of Waste Electrical and Electronic Equipment. British Standards Institution: London, UK, 2020.

- PAS 777. Available online: https://knowledge.bsigroup.com/products/specification-for-the-qualification-and-labelling-of-used-automotive-engines-and-any-related-transmission-units (accessed on 10 September 2023).

- IEC 61215/61730. Available online: https://en.millennialsolar.com/application-1052.html?gad_source=1&gad_campaignid=22579070339&gbraid=0AAAAA_kvu82aW9D3GVi10oQy0bz-MuBQj&gclid=EAIaIQobChMI_4iD5MuQjgMV2qhmAh27wCuGEAAYASAAEgLcMfD_BwE (accessed on 10 September 2023).

- Granata, G.; Altimari, P.; Pagnanelli, F.; De Greef, J. Recycling of solar photovoltaic panels: Techno-economic assessment in waste management perspective. J. Clean. Prod. 2022, 363, 132384. [Google Scholar] [CrossRef]

- Tao, M.; Fthenakis, V.; Ebin, B.; Steenari, B.M.; Butler, E.; Sinha, P.; Corkish, R.; Wambach, K.; Simon, E.S. Major challenges and opportunities in silicon solar module recycling. Prog. Photovolt. Res. Appl. 2020, 28, 1077–1088. [Google Scholar] [CrossRef]

- Chen, P.-H.; Chen, W.-S.; Lee, C.-H.; Wu, J.-Y. Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques. Sustainability 2024, 16, 60. [Google Scholar] [CrossRef]

- Polzin, F.; von Flotow, P.; Klerkx, L. Addressing barriers to eco-innovation: Exploring the finance mobilisation functions of institutional innovation intermediaries. Technol. Forecast. Soc. Change 2016, 103, 34–46. [Google Scholar] [CrossRef]

- Van Weelden, E.; Mugge, R.; Bakker, C. Paving the way towards circular consumption: Exploring consumer acceptance of refurbished mobile phones in the Dutch market. J. Clean. Prod. 2016, 113, 743–754. [Google Scholar] [CrossRef]

- Shukla, S.; Kalaiselvan, V.; Raghuvanshi, R.S. How to improve regulatory practices for refurbished medical devices. Bull. World Health Organ. 2023, 101, 412. [Google Scholar] [CrossRef]

- Chiquillo Molano, J.; Xing, K.; Majewski, P.; Huang, B. A holistic reverse logistics planning framework for end-of-life PV panel collection system design. J. Environ. Manag. 2022, 317, 115331. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Chen, F. On the competition between two modes of product recovery: Remanufacturing and refurbishing. Prod. Oper. Manag. 2019, 28, 2983–3001. [Google Scholar] [CrossRef]

- Salim, H.; Florin, N.; Wakefield-Rann, R.; Madden, B. Enabling a Responsible Second-Hand Market for Photovoltaic Systems in Australia; The Institute for Sustainable Futures, University of Technology Sydney: Sydney, Australia, 2023. [Google Scholar]

- Rajaeifar, M.A.; Ghadimi, P.; Raugei, M.; Wu, Y.; Heidrich, O. Challenges and Recent Developments in Supply and Value Chains of Electric Vehicle Batteries: A Sustainability Perspective; Elsevier: Amsterdam, The Netherlands, 2022; Volume 180, p. 106144. [Google Scholar]

- Harms, R.; Linton, J.D. Willingness to pay for eco-certified refurbished products: The effects of environmental attitudes and knowledge. J. Ind. Ecol. 2016, 20, 893–904. [Google Scholar] [CrossRef]

- Pinçe, Ç.; Ferguson, M.; Toktay, B. Extracting maximum value from consumer returns: Allocating between remarketing and refurbishing for warranty claims. Manuf. Serv. Oper. Manag. 2016, 18, 475–492. [Google Scholar] [CrossRef]

- Bressanelli, G.; Visintin, F.; Saccani, N. Circular Economy and the evolution of industrial districts: A supply chain perspective. Int. J. Prod. Econ. 2022, 243, 108348. [Google Scholar] [CrossRef]

- Bayrak, T.; Soylu, S.I. Reprocessing of single use medical devices: A new proposal for a regulation. Health Policy Technol. 2021, 10, 100553. [Google Scholar] [CrossRef]

- Pretner, G.; Darnall, N.; Testa, F.; Iraldo, F. Are consumers willing to pay for circular products? The role of recycled and second-hand attributes, messaging, and third-party certification. Resour. Conserv. Recycl. 2021, 175, 105888. [Google Scholar] [CrossRef]

- Liu, G.; Tan, Y.; Li, X. China’s policies of building green retrofit: A state-of-the-art overview. Build. Environ. 2020, 169, 106554. [Google Scholar] [CrossRef]

- Kim, B.; Azzaro-Pantel, C.; Pietrzak-David, M.; Maussion, P. Life cycle assessment for a solar energy system based on reuse components for developing countries. J. Clean. Prod. 2019, 208, 1459–1468. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

| Criteria Type | Criteria Description |

|---|---|

| Inclusion | |

| Focus | Peer-reviewed studies related to reuse, recycling, refurbishment, or certification of second-hand electronic products. |

| Content | Studies offering valuable information, artifacts, or techniques essential for certification. |

| Publication Type | To ensure rigor, peer-reviewed articles and conference papers were selected. In addition to peer-reviewed articles, a limited number of gray literature sources from credible sources (such as government reports) were included based on their relevance and credibility. |

| Language | Publications in English. |

| Time Frame | No restriction on publication date to ensure comprehensive coverage. |

| Exclusion | |

| Relevance | Studies not directly related to the reuse and certification of second-hand electronic products. |

| Publication Type | Working papers, PhD theses, non-peer-reviewed materials like books, tutorials, and poster publications. |

| Reference | Number of Panels Tested | Panel Age (Years) | Tests Conducted | Reusability Percentage |

|---|---|---|---|---|

| Marinna et al., 2025 [74] | 76 | 22 | Visual inspection, Insulation testing, IV tests, EL imaging | 68% |

| Rabanal-Arabac, 2023 [75] | 1000 | - | Visual inspection, IV tests, EL, IR imaging | 30–34% |

| Stromberg, 2021 [76] | 221 | 2–20 | Visual inspection, IV tests, Thermal imaging | 64% |

| Skoczek et al., 2009 [77] | 204 | 19–23 | Visual inspection, IV tests, Thermal imaging | 65% |

| Certification Element | Electronics (Smartphones) | Batteries | Automotive (EoL Vehicles/Parts) | Solar Panels (Proposed) |

|---|---|---|---|---|

| Physical Inspection | Visual, cosmetic, and damage inspection (e.g., EN 50614:2020) [82] | External/internal inspection for damage, corrosion, leakage (UL 1974) | Mechanical and structural checks during dismantling (ARA guidelines) | Cracks, delamination, and discoloration checks |

| State of Health (SoH) | Limited device-level testing; ~80% battery health threshold common | Capacity, internal resistance, performance metrics (≥70–80% threshold in UL 1974) | Functional testing of major components (e.g., engines, pressure, emissions) | Power output retention; typically, ≥70–90% of original efficiency |

| Performance Testing | Electrical safety, functionality and system integrity testing (EN 50614, PAT+) | Load, insulation resistance and dielectric withstand testing (UL 1974) | Functional safety and system-level performance verification (ARA, PAS 777) [83] | Flash test (IV curve), electroluminescence imaging, insulation checks (per IEC 61215/61730) [84] |

| Traceability Systems | Unique identifiers, refurbishment logs, and serial tracking (EN 50614 compliance) | Full lifecycle records; upcoming EU Digital Battery Passport | VIN-based tracking and dismantler records (e.g., IDIS/IMDS in EU) | QR-code/blockchain based history logs proposed (e.g., EU Digital Product Passport pilot) |

| Warranty and Consumer Assurance | Typically 90-day to 1-year warranty; 90-day minimum recommended (EN 50614) | Limited warranty (~1–5 years); based on risk assessments | 30–90 day parts warranty; longer for critical components (ARA Gold Seal) | Proposed class-based assurance |

| Classification Framework | Functional and cosmetic grading (e.g., “full function” vs. “key functions” per R2) | Class A/B based on capacity and degradation metrics (UL 1974) | Typically tagged as remanufactured or refurbished (ARA Damage Codes) | Proposed: Gold, Silver, Bronze based on SOH |

| Certification Standards | EN 50614:2020, R2 Standard, ANSI/NRTL certifications | ANSI/CAN UL 1974, EU Battery Regulation (2023/1542) | ARA Gold Seal certification | No unified standard |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chhillar, I.; Sandhu, S.; Parida, S.; Majewski, P. Certification for Solar Panel Reuse: A Systematic Review of Cross-Sector Practices and Gaps. Sustainability 2025, 17, 5995. https://doi.org/10.3390/su17135995

Chhillar I, Sandhu S, Parida S, Majewski P. Certification for Solar Panel Reuse: A Systematic Review of Cross-Sector Practices and Gaps. Sustainability. 2025; 17(13):5995. https://doi.org/10.3390/su17135995

Chicago/Turabian StyleChhillar, Ishika, Sukhbir Sandhu, Subhadarsini Parida, and Peter Majewski. 2025. "Certification for Solar Panel Reuse: A Systematic Review of Cross-Sector Practices and Gaps" Sustainability 17, no. 13: 5995. https://doi.org/10.3390/su17135995

APA StyleChhillar, I., Sandhu, S., Parida, S., & Majewski, P. (2025). Certification for Solar Panel Reuse: A Systematic Review of Cross-Sector Practices and Gaps. Sustainability, 17(13), 5995. https://doi.org/10.3390/su17135995