Evaluating the Use of Alternative Fuels in Cement Production for Environmental Sustainability

Abstract

1. Introduction

1.1. Problem Statement

1.2. Objectives of This Study

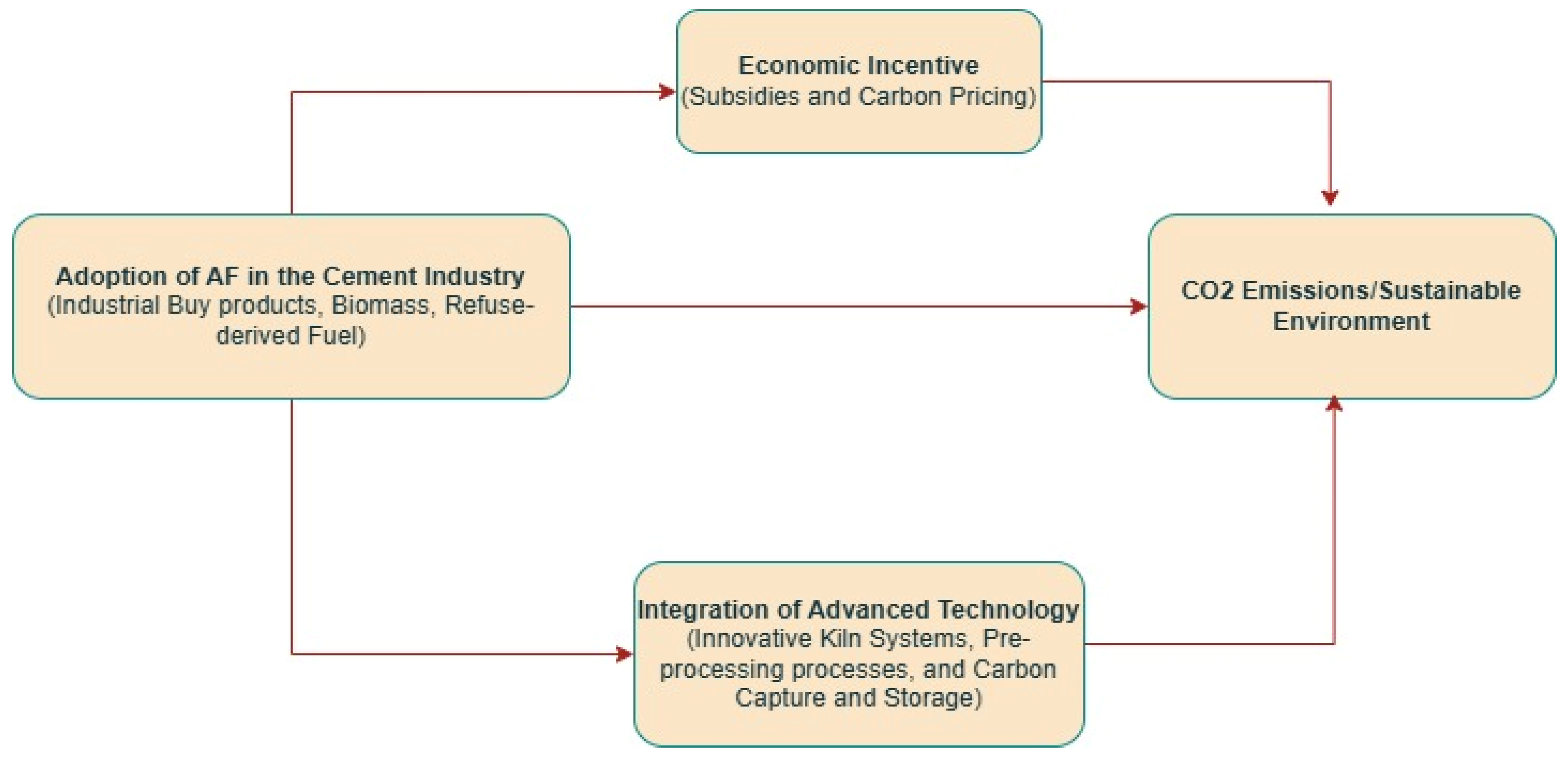

- To investigate the strength and direction of the relationship between the AFs and CO2 emissions;

- To identify the influence of economic incentives and integration of advanced technology on AF adoption;

- To examine the mediating effect of two variables such as economic incentives and advanced technology on CO2 emissions.

1.3. Hypothesis

1.4. Importance of This Study

1.5. Research Gap

2. Method and Materials

2.1. Introduction

2.2. Secondary Data

2.3. Real-World Data

2.4. Data Description and Validation

2.5. Population for the Research

2.6. Sampling Technique

3. Results

3.1. Introduction

3.2. Descriptive Statistics

3.3. Correlation Analysis

3.4. Regression Analysis

3.5. Regression Analysis After the Addition of the Two Variables

4. Discussion

Practical Implications

5. Conclusions

5.1. Recommendations

5.2. Limitations of This Study

5.3. Research Value of This Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mishra, U.C.; Sarsaiya, S.; Gupta, A. A systematic review on the impact of cement industries on the natural environment. Environ. Sci. Pollut. Res. 2022, 29, 18440–18451. [Google Scholar] [CrossRef]

- IEA. Technology Roadmap Low-Carbon Transition in the Cement Industry; France/WBCSD: Geneva, Switzerland; IEA: Paris, France, 2018. [Google Scholar]

- Guo, Y.; Luo, L.; Liu, T.; Hao, L.; Li, Y.; Liu, P.; Zhu, T. A review of low-carbon technologies and projects for the global cement industry. J. Environ. Sci. 2024, 136, 682–697. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Manisalidis, I.; Stavropoulou, E.; Stavropoulos, A.; Bezirtzoglou, E. Environmental and health impacts of air pollution: A review. Front. Public Health 2020, 8, 14. [Google Scholar] [CrossRef]

- Etim, M.-A.; Babaremu, K.; Lazarus, J.; Omole, D. Health risk and environmental assessment of cement production in Nigeria. Atmosphere 2021, 12, 1111. [Google Scholar] [CrossRef]

- Ahmed, M.; Bashar, I.; Alam, S.T.; Wasi, A.I.; Jerin, I.; Khatun, S.; Rahman, M. An overview of Asian cement industry: Environmental impacts, research methodologies and mitigation measures. Sustain. Prod. Consum. 2021, 28, 1018–1039. [Google Scholar] [CrossRef]

- Jiang, P.; Chen, Y.; Wang, W.; Yang, J.; Wang, H.; Li, N.; Wang, W. Flexural behavior evaluation and energy dissipation mechanisms of modified iron tailings powder incorporating cement and fibers subjected to freeze-thaw cycles. J. Clean. Prod. 2022, 351, 131527. [Google Scholar] [CrossRef]

- Supriya; Chaudhury, R.; Sharma, U.; Thapliyal, P.; Singh, L. Low-CO2 emission strategies to achieve net zero target in cement sector. J. Clean. Prod. 2023, 417, 137466. [Google Scholar] [CrossRef]

- Marmier, A. Decarbonisation Options for the Cement Industry; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar]

- UN Environment; Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Subramanian, S.; Davis, R.; Thomas, B.S. Exploring the Potential of Geopolymer Binders: A Study on Basic Oxygen Furnace Slag and Fly Ash Mixes. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 48, 3135–3155. [Google Scholar] [CrossRef]

- Neale, R.E.; Barnes, P.W.; Robson, T.M.; Neale, P.J.; Williamson, C.E.; Zepp, R.G.; Wilson, S.R.; Madronich, S.; Andrady, A.L.; Heikkilä, A.M.; et al. Environmental effects of stratospheric ozone depletion, UV radiation, and interactions with climate change: UNEP Environmental Effects Assessment Panel, Update 2020. Photochem. Photobiol. Sci. 2021, 20, 1–67. [Google Scholar] [PubMed]

- Rathod, S.V.; Saras, P.; Gondaliya, S.M. Environmental pollution: Threats and challenges for management. In Eco-Restoration of Polluted Environment; CRC Press: Boca Raton, FL, USA, 2024; pp. 1–34. [Google Scholar]

- Alkhaldi, M.; Moonesar, I.A.; Issa, S.T.; Ghach, W.; Okasha, A.; Albada, M.; Chelli, S.; Takshe, A.A. Analysis of the United Arab Emirates’ contribution to the sustainable development goals with a focus on global health and climate change. Int. J. Health Gov. 2023, 28, 357–367. [Google Scholar] [CrossRef]

- Batikha, M.; McKenzie, W.; Ogwuda, O. Materials & Waste Management for Decarbonisation of the Cement Industry in the UAE; Heriot-Watt University’s Centre of Excellence: Dubai, United Arab Emirates, 2023. [Google Scholar]

- Berriel, S.S.; Favier, A.; Domínguez, E.R.; Machado, I.S.; Heierli, U.; Scrivener, K.; Hernández, F.M.; Habert, G. Assessing the environmental and economic potential of Limestone Calcined Clay Cement in Cuba. J. Clean. Prod. 2016, 124, 361–369. [Google Scholar] [CrossRef]

- Razzak, S.A. Municipal Solid and Plastic Waste Co-pyrolysis Towards Sustainable Renewable Fuel and Carbon Materials: A Comprehensive Review. Chem. Asian J. 2024, 19, e202400307. [Google Scholar] [CrossRef]

- Poudyal, L.; Adhikari, K. Environmental sustainability in cement industry: An integrated approach for green and economical cement production. Resour. Environ. Sustain. 2021, 4, 100024. [Google Scholar] [CrossRef]

- Prasad, S.; Venkatramanan, V.; Singh, A. Renewable Energy for a Low-Carbon Future: Policy Perspectives. In Sustainable Bioeconomy: Pathways to Sustainable Development Goals; Venkatramanan, V., Shah, S., Prasad, R., Eds.; Springer: Singapore, 2021; pp. 267–284. [Google Scholar]

- Fulton, L.; Mejia, A.; Arioli, M.; Dematera, K.; Lah, O. Climate Change Mitigation Pathways for Southeast Asia: CO2 Emissions Reduction Policies for the Energy and Transport Sectors. Sustainability 2017, 9, 1160. [Google Scholar] [CrossRef]

- Liu, D. International energy agency (IEA). In The Palgrave Encyclopedia of Global Security Studies; Springer: Berlin/Heidelberg, Germany, 2023; pp. 830–836. [Google Scholar]

- Saunders, M.N.; Bezzina, F. Reflections on conceptions of research methodology among management academics. Eur. Manag. J. 2015, 33, 297–304. [Google Scholar] [CrossRef]

- Bell, E.; Harley, B.; Bryman, A. Business Research Methods; Oxford University Press: Oxford, UK, 2022. [Google Scholar]

- Creswell, J.W.; Creswell, J.D. Research Design: Qualitative, Quantitative, and Mixed Methods Approaches; Sage Publications: New York, NY, USA, 2017. [Google Scholar]

- Schneider, M.; Hoenig, V.; Ruppert, J.; Rickert, J. The cement plant of tomorrow. Cem. Concr. Res. 2023, 173, 107290. [Google Scholar] [CrossRef]

- Krzymowski, A. Sustainable Development Goals in Arab Region–United Arab Emirates’ Case Study. Probl. Ekorozwoju 2020, 15, 211–220. [Google Scholar] [CrossRef]

- Khalil, E.; AbouZeid, M. A Global Assessment Tool for Cement Plants Improvement Measures for the Reduction of CO2 Emissions. Results Eng. 2025, 26, 104767. [Google Scholar] [CrossRef]

- Klee, H.; Coles, E. The cement sustainability initiative–implementing change across a global industry. Corp. Soc. Responsib. Environ. Manag. 2022, 11, 114–120. [Google Scholar] [CrossRef]

- Board, A.; Gauthier, D. European Cement Research Academy GmbH. 2021. Available online: https://www.ecra-online.org/ (accessed on 10 January 2025).

- Saradara, S.M.; Khalfan, M.M.A.; Rauf, A.; Qureshi, R. On the path towards sustainable construction—The case of the United Arab Emirates: A review. Sustainability 2023, 15, 14652. [Google Scholar] [CrossRef]

- Quemin, S. Raising climate ambition in emissions trading systems: The case of the EU ETS and the 2021 review. Resour. Energy Econ. 2022, 68, 101300. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, C.; He, B.; Yi, S.; Tang, L. Recycling fine powder collected from construction and demolition wastes as partial alternatives to cement: A comprehensive analysis on effects, mechanism, cost and CO2 emission. J. Build. Eng. 2023, 71, 106507. [Google Scholar] [CrossRef]

- El-Hakim, Y.; AbouZeid, M.N. Towards mitigating climate change negative impact: The role of regulations and governance in the construction industry. Sustainability 2024, 16, 6822. [Google Scholar] [CrossRef]

- Locke, J.; Dsilva, J.; Zarmukhambetova, S. Decarbonization strategies in the UAE built environment: An evidence-based analysis using COP26 and COP27 recommendations. Sustainability 2023, 15, 11603. [Google Scholar] [CrossRef]

- Taherdoost, H. Data collection methods and tools for research; a step-by-step guide to choose data collection technique for academic and business research projects. Int. J. Acad. Res. Manag. (IJARM) 2021, 10, 10–38. [Google Scholar]

- Taherdoost, H. What are different research approaches? Comprehensive review of qualitative, quantitative, and mixed method research, their applications, types, and limitations. J. Manag. Sci. Eng. Res. 2022, 5, 53–63. [Google Scholar] [CrossRef]

- Shanmugam, R. Understanding Research Methods: An Overview of the Essentials: By Mildred L. Patten and Michelle Newhart, New York, NY, Routledge Press, 2018, 338+ xiv pp., $17.99 (paperback); Taylor & Francis: Abingdon, UK, 2020; ISBN 978-0-41579052-9. [Google Scholar]

- Patten, M.L. Understanding Research Methods: An Overview of the Essentials; Routledge: New York, NY, USA, 2016. [Google Scholar]

- Barbhuiya, S.; Das, B.B.; Adak, D. Roadmap to a net-zero carbon cement sector: Strategies, innovations and policy imperatives. J. Environ. Manag. 2024, 359, 121052. [Google Scholar] [CrossRef]

- Kumar, M.; Karmakar, S.; Nimesh, V. Statistical investigation of combustion and emission characteristics of biofuels according to their physical properties: A way to explore suitable alternative fuels. Fuel 2024, 358, 130242. [Google Scholar] [CrossRef]

- Kusuma, R.T.; Hiremath, R.B.; Rajesh, P.; Kumar, B.; Renukappa, S. Sustainable transition towards biomass-based cement industry: A review. Renew. Sustain. Energy Rev. 2022, 163, 112503. [Google Scholar] [CrossRef]

- Tan, C.; Yu, X.; Guan, Y. A technology-driven pathway to net-zero carbon emissions for China’s cement industry. Appl. Energy 2022, 325, 119804. [Google Scholar] [CrossRef]

- Borghesi, S.; Montini, M. The Best (and Worst) of GHG Emission Trading Systems: Comparing the EU ETS with Its Followers. Front. Energy Res. 2016, 4, 27. [Google Scholar] [CrossRef]

- Meadows, D.; Vis, P.; Zapfel, P. The EU Emissions Trading System. Towards a Climate-Neutral Europe; European Commission: Brussels, Belgium, 2019; pp. 66–94. [Google Scholar]

- Teixidó, J.; Verde, S.F.; Nicolli, F. The impact of the EU Emissions Trading System on low-carbon technological change: The empirical evidence. Ecol. Econ. 2019, 164, 106347. [Google Scholar] [CrossRef]

- Li, T.; Liu, P.; Li, Z. Impacts of low-carbon targets and hydrogen production alternatives on energy supply system transition: An infrastructure-based optimization approach and a case study of China. Processes 2021, 9, 160. [Google Scholar] [CrossRef]

- MA, R.; Qian, H. Plant-Level Evaluation of China’s National Emissions Trading Scheme: Benchmark Matters. Clim. Change Econ. 2022, 13, 2240009. [Google Scholar] [CrossRef]

- Dsilva, J.; Shaikh, M.I.; Usmani, F.Z.A. Net Zero Policies and Climate Resilience: A Focus on Emerging Technologies and Implementation Strategies in the Middle East. In Transition Towards a Sustainable Future: Net Zero Policies and Environmental Sustainability; Singh, R., Crowther, D., Eds.; Springer: Singapore, 2024; pp. 119–138. [Google Scholar]

- Sharma, P.; Sheth, P.N.; Mohapatra, B. Recent progress in refuse derived fuel (RDF) co-processing in cement production: Direct firing in kiln/calciner vs process integration of RDF gasification. Waste Biomass Valorization 2022, 13, 4347–4374. [Google Scholar] [CrossRef]

- Elghamrawi, S. Greening the Cement Industry in Egypt: Exploring Decarbonisation Policies for the Cement Industry; The American University in Cairo (Egypt): New Cairo, Egypt, 2023. [Google Scholar]

- Darraj, N.; Abdelrahman, M.M.; Alklih, M.Y. Regional Review for Large-Scale Deployment of Carbon Capture and Storage (CCS) in the Middle East. In Proceedings of the Mediterranean Offshore Conference, Alexandria, Egypt, 20–22 October 2024. [Google Scholar]

- Raygoza-L, M.E.; Orduño-Osuna, J.H.; Herrera, A.M.; Murrieta-Rico, F.N. Energetic Efficiency and Sustainability: Artificial Intelligence in the Design of Public Policies. In Public Governance Practices in the Age of AI; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 355–376. [Google Scholar]

- Olawade, D.B.; Wada, O.Z.; David-Olawade, A.C.; Fapohunda, O.; Ige, A.O.; Ling, J. Artificial intelligence potential for net zero sustainability: Current evidence and prospects. Next Sustain. 2024, 4, 100041. [Google Scholar] [CrossRef]

| Variable | Mean | Median | Std. Deviation | Min. | Max. | IQR |

|---|---|---|---|---|---|---|

| AF Adoption Rate (%) | 45.2 | 47.5 | 12.3 | 15 | 78 | 18.5 |

| CO2 Reduction (%) | 22.4 | 21 | 6.8 | 8 | 40 | 9 |

| Subsidy (USD/ton AF) | 35 | 30 | 15.2 | 10 | 80 | 20 |

| Plants with CCS (%) | 18.5 | 15 | 10.1 | 5 | 50 | 12 |

| Correlated Variables | Pearson’s r | (p-Value) | Key Insights |

|---|---|---|---|

| Adoption of AF (%) against CO2 Emissions | −0.82 | p < 0.001 | A strong negative correlation confirms that AF use lowers emissions |

| Biomass versus CO2 Emissions | −0.91 | p < 0.001 | The strongest negative correlation; biomass is most effective in emission reduction |

| RDF (Refuse-derived Fuel) versus CO2 Emissions | −0.65 to −0.75 | p < 0.01 | Moderate correlation; effectiveness varies by composition |

| Sewage Sludge against CO2 Emissions | −0.45 | p < 0.05 | Weakest correlation; higher emissions from processing reduce benefits |

| Economic Incentives against AF Adoption | 0.78 | p < 0.001 | Strong positive correlation; incentives boost AF adoption |

| Innovative Technology Integration versus AF Adoption | 0.62 | p < 0.01 | Moderate positive correlation; advanced tech aids AF integration |

| Technology Advancement vs. CO2 Emissions | −0.69 | p < 0.01 | Moderate negative correlation; better tech lowers emissions |

| Model | Predictors | Key Coefficients | Interpretation | R2 Value |

|---|---|---|---|---|

| Model 1: The Impact of Basic AF Adoption | AF% | β1 = −0.0065 (p < 0.001) | An increase of 1% in AF adoption reduces CO2 by 0.0065 metric tons per metric ton of clinker; 30% AF leads to ~0.195 metric tons per metric ton of clinker reduction (~21.7%). | 0.67 |

| Model 2: The Impact of a Specific Fuel | Biomass%, Waste% | Biomass%: −0.0082 (p < 0.001) | Biomass has a double impact in reducing CO2 emissions. | 0.73 |

| Waste%: −0.0043 (p = 0.002) | ||||

| Model 3: The Impact of a Full Model with Mediators | AF%, Incentives, Technology | AF%: −0.0041 (p = 0.003) | The integration of technology and economic incentives improves the AF effect by ~37%. | 0.81 |

| Incentives: −0.032 (p = 0.008) | ||||

| Technology: −0.041 (p < 0.001) |

| Variable | Coefficient (β) | p-Value | Interpretation |

|---|---|---|---|

| AF Adoption (%) | −0.41 *** | <0.001 | The adoption of 30% AF could lead to a 15.3% CO2 reduction, provided other factors are kept constant. |

| Economic Incentives | −0.17 ** | 0.003 | Policies enhance AF’s impact but less than tech (β3 = −0.30 ***). |

| Advanced Technology | −0.30 *** | <0.001 | Upgrading with CCS and kiln technology leads to a CO2 emission reduction. |

| Production Volume | +0.58 *** | <0.001 | A 10% increase in the production of cement could increase CO2 emissions by 5.8%, confirming the scale effect. |

| Energy Efficiency | −0.22 *** | <0.001 | A 10% efficiency gain could lead to a 2.2% CO2 emission reduction. |

| R2 | 0.85 | After the addition of two variables, the percentage jumped to 85% from 83% with the other two variables. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wali, T.; Qayum, A.; Algarni, F.; Malik, F.; Jan, S.U. Evaluating the Use of Alternative Fuels in Cement Production for Environmental Sustainability. Sustainability 2025, 17, 5924. https://doi.org/10.3390/su17135924

Wali T, Qayum A, Algarni F, Malik F, Jan SU. Evaluating the Use of Alternative Fuels in Cement Production for Environmental Sustainability. Sustainability. 2025; 17(13):5924. https://doi.org/10.3390/su17135924

Chicago/Turabian StyleWali, Taj, Azmat Qayum, Fahad Algarni, Fazle Malik, and Saeed Ullah Jan. 2025. "Evaluating the Use of Alternative Fuels in Cement Production for Environmental Sustainability" Sustainability 17, no. 13: 5924. https://doi.org/10.3390/su17135924

APA StyleWali, T., Qayum, A., Algarni, F., Malik, F., & Jan, S. U. (2025). Evaluating the Use of Alternative Fuels in Cement Production for Environmental Sustainability. Sustainability, 17(13), 5924. https://doi.org/10.3390/su17135924