Research Progress on Castor Harvesting Technology and Equipment

Abstract

1. Introduction

2. Current Status and Harvesting Operation Modes of the Castor Industry

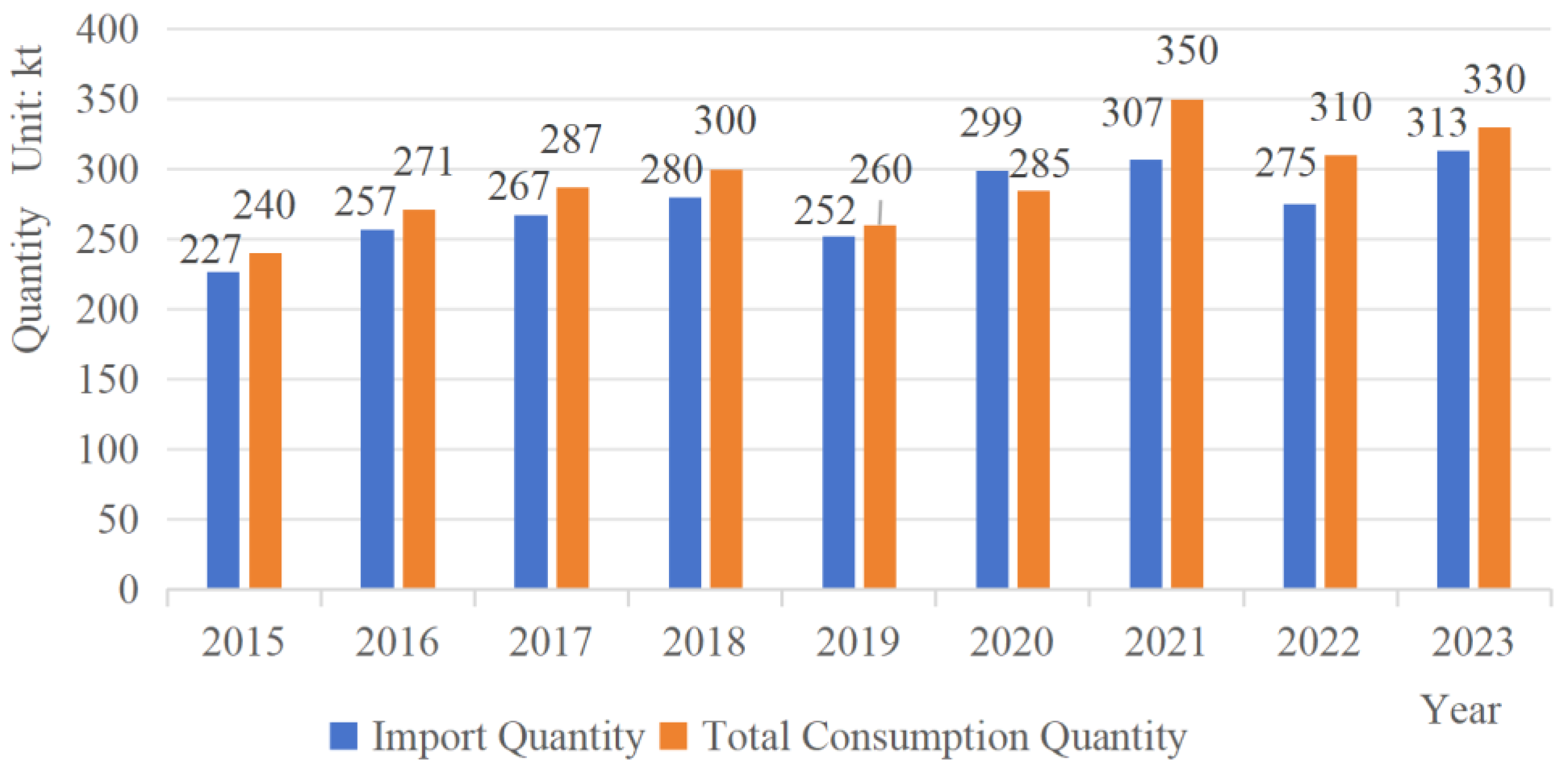

2.1. Castor Cultivation Area and Output Value

2.2. Castor Harvesting Methods

2.2.1. Combined Harvesting

2.2.2. Segmented Harvesting

3. Current Research Status of Castor Harvesting Technology

3.1. Current Research Status of Castor Harvesting Technology Abroad

3.2. Current Research Status of Castor Harvesting Machinery in China

3.3. Comparison and Analysis of Domestic and Foreign Equipment

4. Current Research Status of Cleaning Technology for Harvesters

5. Current Research Status of Castor Fruit Dehulling Technology

6. Problems and Development Suggestions for the Mechanized Harvesting of Castor

6.1. The Problems Faced by Mechanized Harvesting of Castor

6.2. Recommendations for the Mechanized Harvesting Development of Castor

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Merkouropoulos, G.; Kapazoglou, A.; Drosou, V. Dwarf hybrids of the bioenergy crop Ricinus communis, suitable for mechanized harvesting reveal differences in morphophysiological characteristics and seed metabolic profiles. Euphytica 2016, 210, 207–219. [Google Scholar] [CrossRef]

- Zhai, M.J.; Shi, L.; Zhang, Y.H. Research progress of castor oil in the preparation of polymer materials. J. Shaanxi Univ. Sci. Technol. 2022, 40, 106–114. [Google Scholar] [CrossRef]

- Sun, Z.J.; LV, L.Y.; Wu, Y.P. Castor industry development: From cultivation to product exploitation. J. China Agric. Univ. 2012, 17, 204–214. [Google Scholar] [CrossRef]

- Yu, A.; Li, F.; Xu, W. Application of a high-resolution genetic map for chromosome-scale genome assembly and fine QTLs mapping of seed size and weight traits in castor bean. Sci. Rep. 2019, 9, 11950. [Google Scholar] [CrossRef]

- Qiu, L.J.; Liu, A.Z. The germplam exploration of castor bean and its utilization perspective for biodiesel production in China. Chin. Bull. Life Sci. 2014, 26, 503–508. [Google Scholar] [CrossRef]

- Lv, Y.P. Preparation of Castor Oil-Based Surfactant. Master’s Thesis, Henan University of Technology, Zhengzhou, China, 2021. [Google Scholar] [CrossRef]

- Lorestani, A.N.; Jaliliantabar, F.; Gholami, R. Preparation and properties of castor oil-based polyurethane modified polyacrylate pressure sensitive adhesive. Qual. Assur. Saf. Crops Foods 2012, 4, 29–32. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, B.L.; Liu, Y.Z. Determination of some mechanical properties of castor seed to design and fabricate an oil extraction machine. China Adhes. 2024, 33, 37–42. [Google Scholar] [CrossRef]

- Wei, H.L.; Li, X.M.; Li, M. Leaf shape simulation of castor bean and its application in nondestructive leaf area estimation. Int. J. Agric. Biol. Eng. 2019, 12, 135–140. [Google Scholar] [CrossRef]

- Ugwu, K.C.; Egwuagu, O.M.; Omoruyi, A. Determination of some mechanical and aerodynamic properties of castor fruits and seeds. Int. J. Sci. Eng. Res. 2015, 6, 659–666. [Google Scholar]

- Franco, J.M.; García-Zapateiro, L.A.; Valencia, C. Viscous, thermal and tribological characterization of oleic and ricinoleic acids-derived estolides and their blends with vegetable oils. J. Ind. Eng. Chem. 2013, 19, 1289–1298. [Google Scholar] [CrossRef]

- Qiu, Y.L.; Liu, Z.W.; Ma, N. Research Progress on Detection and Analysis Methods of Ricin. J. Toxicol. 2022, 36, 521–527. [Google Scholar] [CrossRef]

- Ren, C.H.; Huang, Y.F.; Guo, X.F. Detoxification of Castor Pomace and Its Application in Animal Production. China Feed 2014, 36–38+41. [Google Scholar] [CrossRef]

- Yang, J.; Zheng, J.B.; Zeng, X.F. Intratumoral injection of ricin-loaded thermosensitive hydrogel for the treatment of paclitaxel resistant ovarian cancer xenograft. Biomed. Eng. Clin. Med. 2011, 15, 308–311+399. [Google Scholar] [CrossRef]

- Yao, Y.; Li, F.S.; Chen, Y.S. Research Progress on Castor. J. Inn. Mong. Univ. Natl. Nat. Sci. 2009, 24, 172–175. [Google Scholar] [CrossRef]

- Ramprasad, R.; Bandopadhyay, R. Future of Ricinus communis after completion of the draft genome sequence. Curr. Sci. 2010, 99, 1316–1318. [Google Scholar]

- Severino, L.S.; Auld, D.L.; Baldanzi, M. A review on the challenges for increased production of castor. Agron. J. 2012, 104, 853–880. [Google Scholar] [CrossRef]

- Ji, Q.L. The Construction of Multi-Functional Microbiota and Its Application of Castor in Phytoremediation of Lead and Zinc Soil Contamination. Master’s Thesis, Central South University of Forestry & Technology, Changsha, China, 2021. [Google Scholar] [CrossRef]

- Wang, X.X.; Zhu, G.L.; He, Z.B. Effects of film mulching methods and planting densities on yield of dwarf castor. J. Inn. Mong. Univ. Natl. Nat. Sci. 2017, 32, 220–225. [Google Scholar] [CrossRef]

- Yan, X.C.; Wang, L.J. The states in quo and foreground of exploiting castor-oil plant as energy sources. J. Anhui Agric. Sci. 2007, 35, 11165. [Google Scholar] [CrossRef]

- Wu, Z.F.; Chen, W.C.; Sheng, Z.D. Study on the harvester development of ricinus communis. J. Agric. For. 2013, 62, 33–44. [Google Scholar]

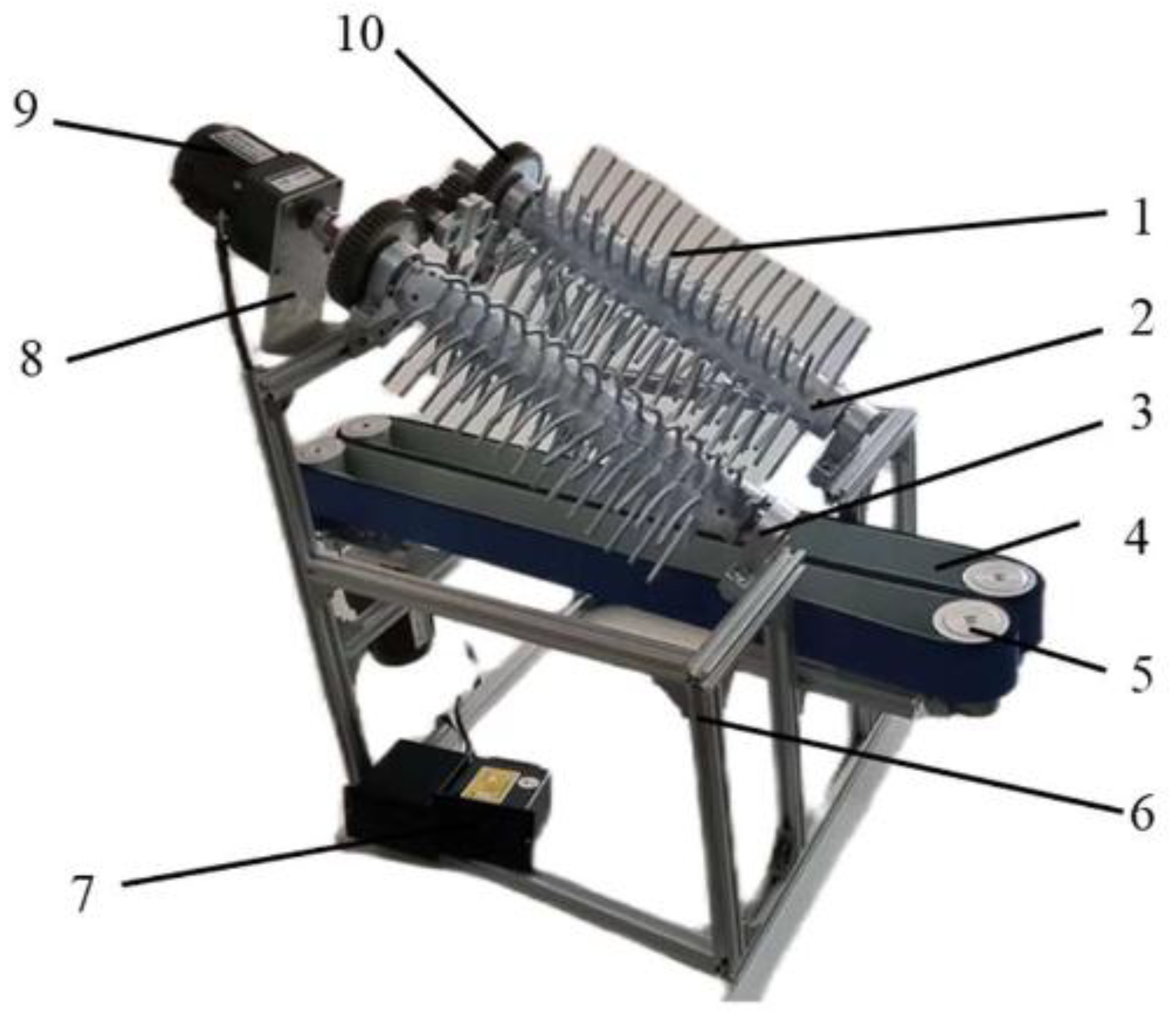

- Liu, L. Design and Optimization of Picking Mechanism for Brush-Roller Castor Capsule Harvester. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2022. [Google Scholar] [CrossRef]

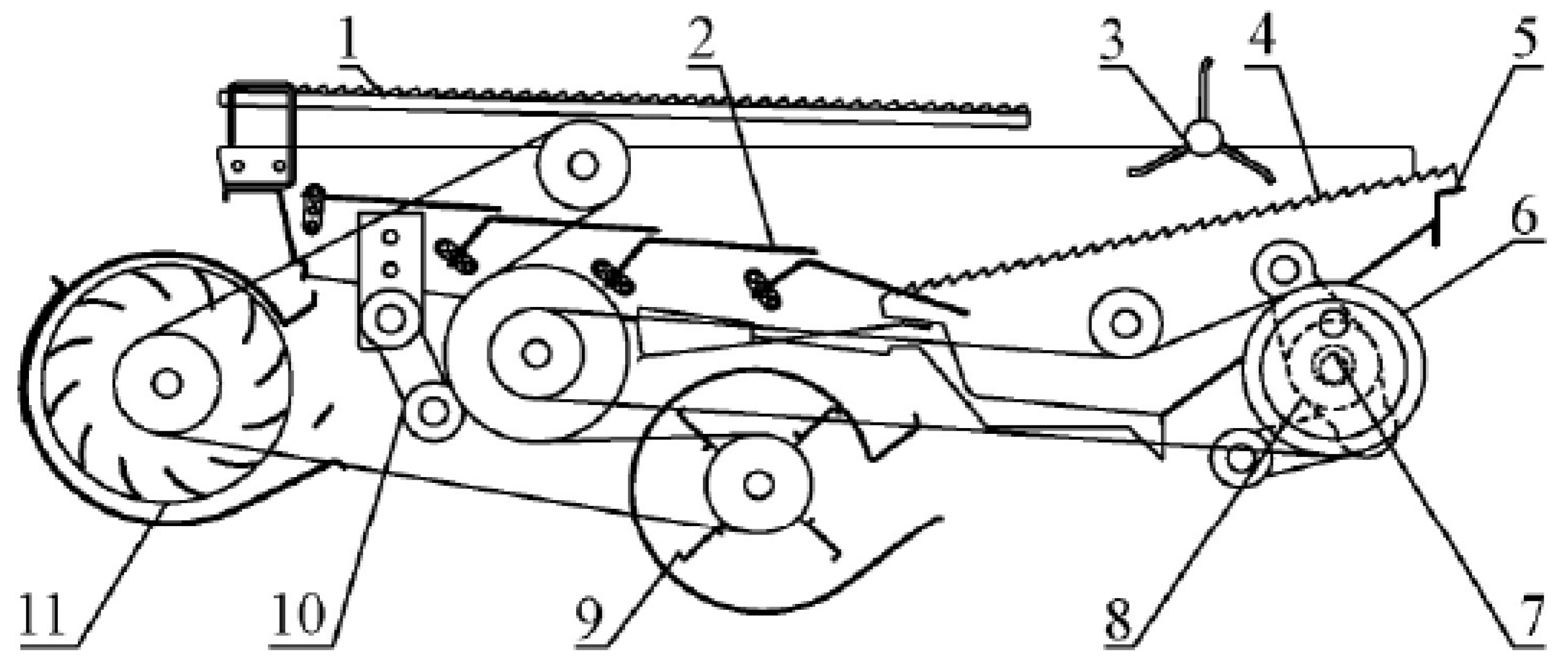

- Wu, T.; Kong, F.T.; Shi, L. Power consumption influence test of castor disc-cutting device. Agriculture 2022, 12, 1535. [Google Scholar] [CrossRef]

- Pari, L.; Suardi, A.; Stefanoni, W.; Latterini, F.; Palmieri, N. Environmental and economic assessment of castor oil supply chain: A case study. Sustainability 2020, 12, 6339. [Google Scholar] [CrossRef]

- Li, Z.C. Design and Simulation of a Deflection Roller Brush Type Castor Harvesting Device. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2024. [Google Scholar] [CrossRef]

- Lin, Y.; Lu, J.; Zhou, G. Analysis of castor industry in China based on industrial chain perspective. Chin. Agric. Sci. Bull. 2011, 27, 124–127. [Google Scholar]

- Import and Export Data Statistics of Chinese Castor Oil and Its Derivatives (HS15153000). Available online: http://stats.customs.gov.cn/ (accessed on 13 February 2025).

- Zhao, H.Y.; Li, L.; Liu, G.Y. Comprehensive evaluation of castor harvester performance based on interval analytic hierarchy process and membership degree. J. Chin. Agric. Mech. 2018, 39, 107–111. [Google Scholar] [CrossRef]

- Kong, F.T.; Wang, D.F.; Shi, L. Dynamic analysis and parameter optimization of the cutting system for castor harvester picking devices. Appl. Sci. 2023, 13, 2116. [Google Scholar] [CrossRef]

- NY/T 4365-2023; National Agricultural Industry Standards, Operating Quality for Castor Harvester. China Agricultural Publishing House: Beijing, China, 2023.

- Liu, D.Y. Design of Comb-Brush Castor Capsule Picking Device and Its Damage Mechanism. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2024. [Google Scholar] [CrossRef]

- Kong, F.T.; Wu, T.; Shi, L. Research status and development prospect of Ricinus communis harvestor. J. Chin. Agric. Mech. 2019, 40, 32–36. [Google Scholar] [CrossRef]

- Wu, T.; Kong, F.T.; Shi, L. Analysis of the development status of Ricinus communis production technology. J. Chin. Agric. Mech. 2019, 40, 77–81. [Google Scholar] [CrossRef]

- Zhao, H.Y. Investigating the Mechanism of Vibration-Based Harvesting for Castor Bean Pods and Performance Optimization of Harvesting Devices. Doctoral Dissertation, Yanshan University, Qinhuangdao, China, 2023. Available online: https://kns.cnki.net/kcms2/article/abstract?v=i7m15r_oBqoQtTu-9K6E3XGdl6IgovMAqOMPBIgsvEOBY7x7cXSMjfD_oCGZg8iZG_7DvLg5oNf_a7ONusvAkQ0rGyLZFnJ6dkVduyAL4XuyQuJqLKW0cVYteM4saSM7ZBBmBj3Re1UQO2e5muMasg7qvpulpI7__28ghlg5L_aiGqj-68DSavZApTMhpnxC&uniplatform=NZKPT&language=CHS (accessed on 15 June 2025).

- Bai, J.B. The Design of Small-Sized Castor Harvester and Cutting Device. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2019. Available online: https://kns.cnki.net/kcms2/article/abstract?v=i7m15r_oBqqBUe2SQHjuRz-5fgptw-oJ3kdqzlpaYS3StXcUAGmhduQ4EnfuG7-QKZL0dZiS-snzu_gPKZ3z61hkka6a2k6iIcjoXU-7KrVjOS2ZoS4nVst3kkQcgydpaDPagbNUuagANvNhR-T4QR_GvAaOk01vFugfXWLc8Ykm_9vZ0m4Xz-UTLfVW1JI9&uniplatform=NZKPT&language=CHS (accessed on 15 June 2025). [CrossRef]

- Alexopoulou, E.; Papatheohari, Y.; Zanetti, F.; Tsiotas, K.; Papamichael, I.; Christou, M.; Namatov, I.; Monti, A. Comparative studies on several castor (Ricinus communis L.) hybrids: Growth, yields, seed oil and biomass characterization. Ind. Crop. Prod. 2015, 75, 8–13. [Google Scholar] [CrossRef]

- Stefanoni, W.; Latterini, F.; Malkogiannidis, V. Mechanical Harvesting of Castor Bean (Ricinus communis L.) with a Combine Harvester Equipped with Two Different Headers: A Comparison of Working Performance. Energies 2022, 15, 2999. [Google Scholar] [CrossRef]

- Latterini, F.; Stefanoni, W.; Cavalaris, C.; Karamoutis, C.; Pari, L.; Alexopoulou, E. Effectiveness of three terminating products on reducing the residual moisture in dwarf castor plants: A preliminary study of direct mechanical harvesting in central Greece. Agronomy 2022, 12, 146. [Google Scholar] [CrossRef]

- Liu, L.; Kong, F.T.; Shi, L. Experimental research on mechanical properties of castor plants. J. Chin. Agric. Mech. 2023, 44, 14–19. [Google Scholar] [CrossRef]

- Liu, L.; Wu, T.; Kong, F.T. Optimized design and experiment of the picking mechanism for brush-roller castor harvesters. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 19–29. [Google Scholar] [CrossRef]

- Ren, Z.T. Design of Comb-Brush Castor Picking Device and Study on Damage Mechanism of Capsule. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2023. [Google Scholar] [CrossRef]

- Kong, F.T.; Wang, D.F.; Shi, L. Design and experiment of disc-cutting picking device of castor. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 1–9. [Google Scholar] [CrossRef]

- Kong, F.T.; Wu, T.; Zhang, B. Edge curve fitting and optimization of the wave-type cutting disc for castor. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2024, 40, 66–75. [Google Scholar] [CrossRef]

- Zhao, H.Y.; Zhang, C.Y. Analysis on the research status and structure characteristics of castor harvester. In Proceedings of the 2019 IEEE International Conference on Mechatronics and Automation (ICMA), Tianjin, China, 4–7 August 2019. [Google Scholar] [CrossRef]

- Li, C.H.; Liu, C.C.; Zhuang, W.H. The structural design and motion simulation of the comb-type castor picking system. J. Mach. Des. Manuf. 2016, 5, 95–98. [Google Scholar] [CrossRef]

- Xu, L.Z.; Li, Y.; Li, Y.M. Research Progress on Cleaning Technology and Deviceof Grain Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2019, 50, 1–16. [Google Scholar] [CrossRef]

- Liu, D.W.; Lu, W.; Wang, X.S. Research Status and Development Trend of Cyclone Separating Cleaning Unit of Combine Harvesters. Agric. Equip. Veh. Eng. 2016, 54, 8–13. [Google Scholar] [CrossRef]

- Li, Y. Numerical Simulation and Experiment of Gas-Solid Two-Phase Flow in Multiple-Ducts Cleaning Device. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2017. [Google Scholar]

- Wang, L.J.; Liu, W.T.; Li, Y.H. Research of double-layer jitter plates with holes in large-feeding mass cleaning system of maize grain harvester. Trans. Chin. Soc. Agric. Mach. 2022, 53, 92–102. [Google Scholar] [CrossRef]

- Li, H. Research of Modern Design Method for Air-and-Screen Cleaning Device. Master’s Thesis, Nanjing Agricultural University, Nanjing, China, 2012. [Google Scholar]

- Li, Y.M.; Deng, L.L.; Ding, W.M. Analysis and Improvement Design on the Cleaning Mechanism of Small Grain Combine. J. Agric. Mech. Res. 2004, 3, 55–56. [Google Scholar] [CrossRef]

- Tang, L.; Guan, C.Y.; Wu, M.L. Distribution rules of airflow field in rape cleaning device. J. Hunan Agric. Univ. (Nat. Sci.) 2011, 37, 107–110. [Google Scholar] [CrossRef]

- Jiang, T. Research on Key Techniques of Loss Reduction for Rapeseed Pickup Combine Harvest. Doctoral Dissertation, Chinese Academy of Agricultural Sciences, Beijing, China, 2023. [Google Scholar] [CrossRef]

- Wu, J. Research on Key Technology of Threshing and Cleaning of Rape Combine Harvester on Sloping Land. Doctoral Dissertation, Chinese Academy of Agricultural Sciences, Beijing, China, 2023. [Google Scholar] [CrossRef]

- Gabi, M.; Klemm, T. Numerical and experimental investigations of cross-flow fan. J. Comput. Appl. Mech. 2004, 5, 251–261. [Google Scholar]

- Lu, R.; Liu, Z.X.; Gao, L.X. Development of air suction cleaning device of vertical conical peanut sheller for plot planting. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 23–30. [Google Scholar] [CrossRef]

- Lu, R. Research on Shelling Principle and Main Components of Vertical Peanut Sheller with Cone Roller. Doctoral Dissertation, Shenyang Agricultural University, Shenyang, China, 2020. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Hu, Z.Z.; Cao, M.Z. Design of cleaning device of tangential flow and whole-feed peanut combine harvester. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 29–37. [Google Scholar] [CrossRef]

- Liang, Z.W. Study on Designing Method of Multi-Duct Air-and-Screen Cleaning Unit and Grain Sieve Loss Monitoring and Controlling Technology. Doctoral Dissertation, Jiangsu University, Zhenjiang, China, 2018. [Google Scholar]

- Leng, J.; Su, X.Y.; Du, Y.F. Analysis and optimization of internal flow field of cleaning device of single longtitudinal axial flow grain combine harvester. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 39–48. [Google Scholar] [CrossRef]

- Dai, F.; Fu, Q.F.; Zhao, W.Y. Design and Test of Double Duct System of Air-screen Separating and Cleaning Machine for Flax Threshing Material. Trans. Chin. Soc. Agric. Mach. 2021, 52, 117–125+247. [Google Scholar] [CrossRef]

- Dai, F.; Zhao, W.Y.; Fu, Q.F. Parameter Optimization and Experiment on Double Duct System of Air-screen Separating and Cleaning Machine for Flax Threshing Material. Trans. Chin. Soc. Agric. Mach. 2021, 52, 83–92. [Google Scholar] [CrossRef]

- Wan, X.Y.; Yuan, J.C.; Liao, Q.X. Design and Experiment of Cyclone Separation Cleaning Device with Raised Cylinder Disturbing Airflow Field for Rapeseed Combine Harvest. Trans. Chin. Soc. Agric. Mach. 2023, 54, 159–172. [Google Scholar] [CrossRef]

- Wan, X.Y.; Liao, Q.X.; Xu, Y. Design and experiments on cyclone separation cleaning devices and a conical sieve for rape combine harvester. Appl. Eng. Agric. 2018, 34, 677–686. [Google Scholar] [CrossRef]

- Yuan, J.C.; Yang, J.; Wan, X.Y. Design and Experiment of Cylinder Sieve Type Re-cleaning Device for Rape Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2022, 53, 99–108. [Google Scholar] [CrossRef]

- Wang, H.H.; Li, Y.M.; Xu, L.Z. Simulation and experiment of air flow field in the cleaning device of ratooning rice combine harvesters. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 84–92. [Google Scholar] [CrossRef]

- Hou, J.M.; Li, J.P.; Yao, E.C. Calibration and Analysis of Discrete Element Parameters of Typical Castor. J. Shenyang Agric. Univ. 2019, 50, 565–575. [Google Scholar]

- Wang, L.J. Research on the Improvement of 6BBS-50 Type Castor Bean Shelling Machine. Agric. Dev. Equip. 2009, 22. [Google Scholar] [CrossRef]

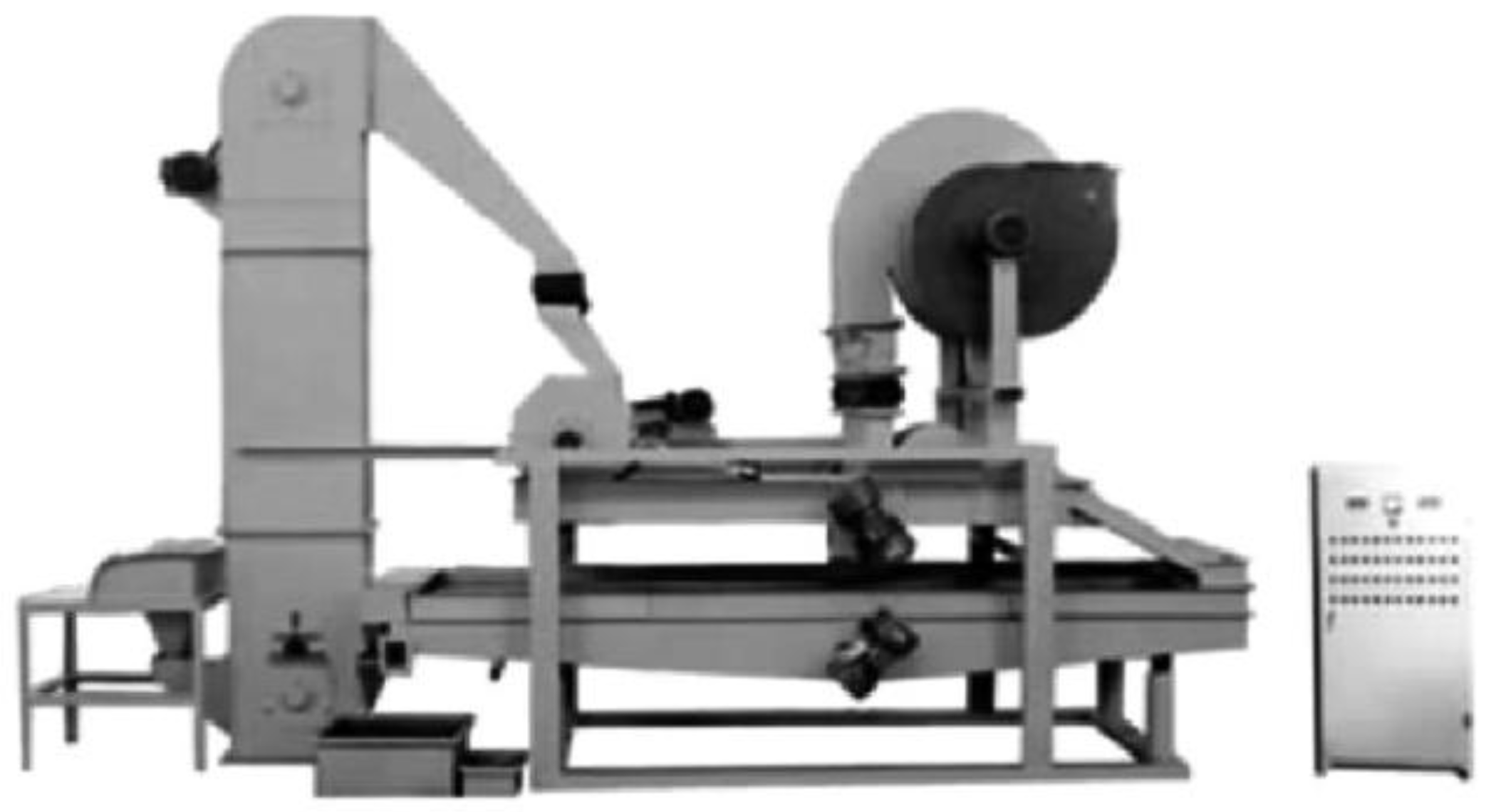

- Hou, J.M.; Bai, J.B.; He, T. Design and Experiment of Castor Dehulling and Cleaning Device with Double Curved Table. Trans. Chin. Soc. Agric. Mach. 2018, 49, 139–147. [Google Scholar] [CrossRef]

- Hou, J.M.; Li, J.P.; Bai, J.B. Experimental and Finite Element Analysis of Mechanical Properties of Castor Fruit. Agric. Dev. Equip. 2018, 49, 574–583. [Google Scholar]

- Yang, Y. Damage Law and Experimental on Shelling Collision of Castor Capsule Based on Finite Element Method. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2019. [Google Scholar] [CrossRef]

- Hou, J.M.; Bai, J.B.; Yang, Y. Study and simulation analysis on curling mechanical properties of castor stem. J. Northeast Agric. Univ. 2018, 49, 69–78. [Google Scholar] [CrossRef]

- He, T. Design and Experimental Study of Squeezing and Rubbing Castor Shelling and Cleaning Device. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2018. [Google Scholar]

- Hou, J.M.; Yao, E.C.; Li, J.P. Motion Analysis and Experiment on Shelling Process of Kneading and Pressing Castor Shelling Machine. Trans. Chin. Soc. Agric. Mach. 2020, 51, 220–232. [Google Scholar] [CrossRef]

- Cao, Y.H.; Li, C.Y.; Zhang, Z.X. Improvement design and test to key components of castor capsule hulling device. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2012, 28, 16–22. [Google Scholar] [CrossRef]

- Cao, Y.H.; Li, C.Y.; Qing, Y.M. Finite Element Analysis on Mechanical Properties of Castor- Capsule. J. Jiangsu Univ. (Nat. Sci. Ed.) 2010, 31, 383–387. [Google Scholar] [CrossRef]

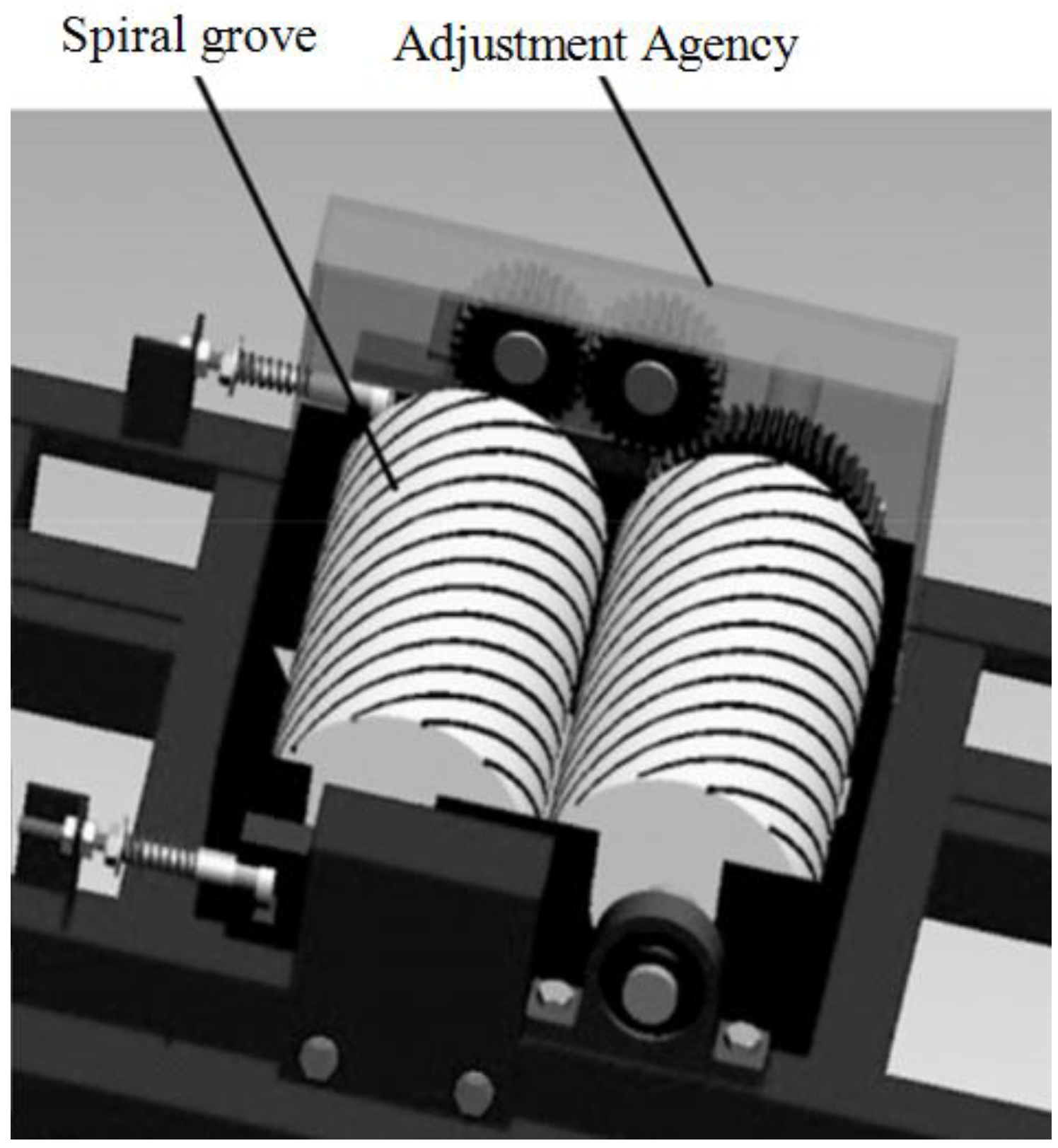

- Cheng, X.X. Study on Shelling Method of Castor Beans and Key Technology of Rolling-Rubbing Shelling Machine. Master’s Thesis, Central South University, Changsha, China, 2013. [Google Scholar]

- Li, C.Z.; Liu, R.K.; Cheng, X.X. Structure design and parameters optimization of the roll-rub shelling machine for castor capsule. J. Cent. South Univ. For. Technol. 2016, 36, 110–113+134. [Google Scholar] [CrossRef]

- Yao, L.L.; Cao, Y.H.; Li, C.Y. Dynamics property of Air-and-Screen cleaning mechanism of castor hulling. J. Agric. Mech. Res. 2014, 36, 70–73. [Google Scholar] [CrossRef]

- Yakubu, A.U.; Muhammad, U.S.; Ishiaka, M. Development and Performance Evaluation of a Castor Seed (Ricinus communis) Shelling Machine with a Winnowing System. FUOYE J. Eng. Technol. 2020, 5, 1–5. [Google Scholar] [CrossRef]

- Gbabo, A.; Lukman, A.; Kuku, A. Design and Performance Assessment of a Spike Toothed Drum Mechanism for Shelling of Castor. Int. J. Eng. Res. Manag. 2015, 2, 6–13. [Google Scholar]

- Gatmen, N.C.; Sicat, E.V.; Gavino, R. Design, Fabrication, and Performance Evaluation of Shelling Machine for Castor Bean (Ricinus communis L.). IAMURE Multidiscip. Res. 2016, 13, 113–128. [Google Scholar]

- Petrů, M.; Novák, O.; Herák, D.; Simanjuntak, S. Finite element method model of the mechanical behavior of Jatropha curcas, L. seed under compression loading. Biosyst. Eng. 2012, 111, 412–421. [Google Scholar] [CrossRef]

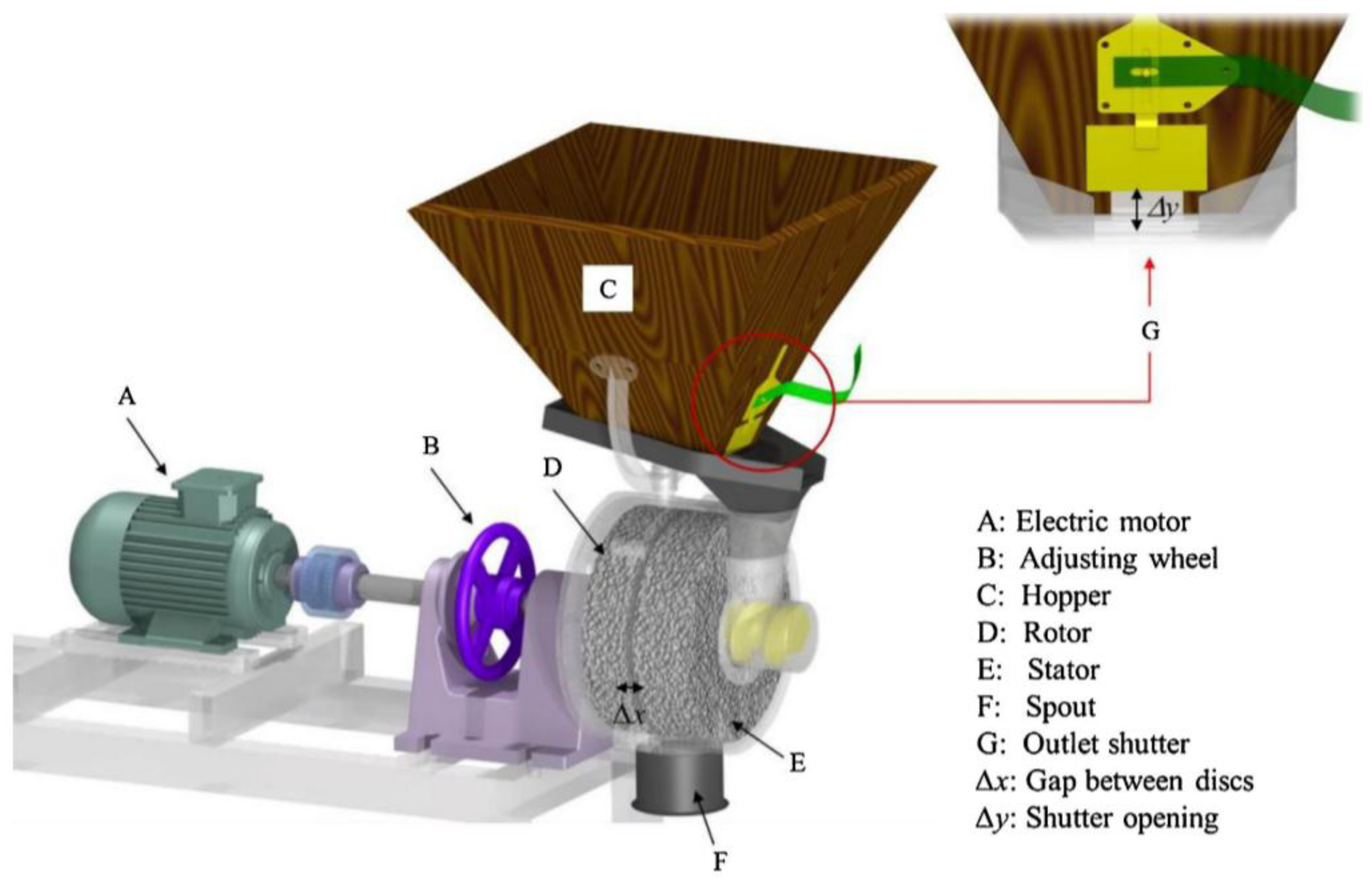

- Romuli, S.; Karaj, S.; Müller, J. Influence of physical properties of Jatropha curcas, L. seeds on shelling performance using a modified disc mill. Ind. Crops Prod. 2015, 77, 1053–1062. [Google Scholar] [CrossRef]

- Lim, B.Y.; Shamsudin, R.; Baharudin, B.H.T.; Yunus, R. Performance evaluation and cfd multiphase modeling for Multistage Jatropha Fruit Shelling Machine. Ind. Crop. Prod. 2016, 5, 125–138. [Google Scholar] [CrossRef]

| Equipment Name | Harvest Mode | Machine Maturity | Harvest Header Type | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Brazilian Roller Brush Type Castor Harvesting Machine [36] | Combined harvesting | Relatively mature | Roller brush type | Grain harvesting; high degree of mechanization; high operation efficiency. | Suitable for dwarf varieties; collision loss is significant. |

| 4BZ-4 Roller Brush Type Harvester of Castor Fruit [40] | Staggered harvesting | Sample trial production | Roller brush type | Variable row spacing harvesting; economic efficiency. | Low operation efficiency; high impurity rate. |

| Cutting-type castor harvester [34] | Staggered harvesting | Sample trial production | Cutting type | High operation efficiency; low impurity rate. | High loss rate; sowing time delayed. |

| Disc-cutting harvesting device of castor harvester [42] | Staggered harvesting | Experimental research phase | Cutting type | Low loss rate; the stubble is neat. | Low harvesting efficiency; suitable for dwarfs. |

| Impact-type castor harvester [44] | Staggered harvesting | Experimental research phase | Impact type | Achievable high-stakes harvest; the damage ratio is low. | Low operation efficiency; low research maturity. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, T.; Kong, F.; Zhang, B.; Xie, Q.; Sun, Y.; Zhao, H. Research Progress on Castor Harvesting Technology and Equipment. Sustainability 2025, 17, 5703. https://doi.org/10.3390/su17135703

Wu T, Kong F, Zhang B, Xie Q, Sun Y, Zhao H. Research Progress on Castor Harvesting Technology and Equipment. Sustainability. 2025; 17(13):5703. https://doi.org/10.3390/su17135703

Chicago/Turabian StyleWu, Teng, Fanting Kong, Bin Zhang, Qing Xie, Yongfei Sun, and Huayang Zhao. 2025. "Research Progress on Castor Harvesting Technology and Equipment" Sustainability 17, no. 13: 5703. https://doi.org/10.3390/su17135703

APA StyleWu, T., Kong, F., Zhang, B., Xie, Q., Sun, Y., & Zhao, H. (2025). Research Progress on Castor Harvesting Technology and Equipment. Sustainability, 17(13), 5703. https://doi.org/10.3390/su17135703