1. Introduction

The agro-industrial sector represents a cornerstone of Peru’s national economy, acting as a fundamental driver of economic growth and national development [

1]. This sector demonstrates strong capabilities in both the production and commercialization of agricultural goods, effectively serving domestic demand while maintaining a robust presence in international markets [

2]. It accounts for a substantial share of the country’s Gross Domestic Product, underscoring its strategic economic importance. In 2022, Peru’s agricultural exports reached a total of USD 6.113 billion, reflecting a 23.5% increase compared to the previous year and highlighting the sector’s dynamic export performance [

3]. Despite these achievements, operational inefficiencies remain a challenge in certain areas. Specifically, the spinach production line of a Peruvian agro-industrial enterprise engaged in vegetable cultivation and distribution is experiencing excessive levels of waste. This issue adversely affects both productivity and profitability, indicating a critical need for process optimization and waste reduction strategies [

4].

Several studies have examined the impact of operational inefficiencies across various agro-industrial enterprises, identifying excessive waste generation as a recurring and critical issue. This challenge is particularly evident in the current technical gap of 21.07% reported in the spinach production line [

5]. This figure becomes especially significant when contrasted with the regional agro-industrial sector’s acceptable annual loss threshold of 5%, revealing a substantial deviation that culminates in a recorded loss rate of 26.07%. As a result, the company has incurred an estimated economic loss of USD 39,992 due to order rejections directly attributable to waste-related inefficiencies [

6]. In light of these findings, the present study aims to demonstrate that the persistent errors and operational challenges within the existing spinach production line significantly hinder process optimization and overall efficiency. This research builds upon a preliminary investigation previously conducted within the same company, which initially identified the scope and severity of the problem.

To address the company’s most pressing operational challenges, a set of targeted interventions was proposed. Total Productive Maintenance (TPM), with an emphasis on the preventive maintenance pillar, was implemented to minimize equipment failures and enhance both machinery availability and production efficiency [

7]. In parallel, a First-In–First-Out (FIFO) inventory system was introduced to mitigate spoilage caused by disorganized and prolonged storage practices [

8]. To further capitalize on the high volume of waste generated, circular economy principles were adopted. These aimed to reduce excessive waste accumulation, prevent product loss, and promote the reuse of organic materials through sustainable practices, thereby generating both environmental and organizational benefits [

9]. Additionally, process standardization was applied to establish a structured and consistent operational framework, ensuring clarity and uniformity across all stages of spinach production.

In addition to the aforementioned methodologies, digital transformation plays a critical role in enhancing the efficiency and responsiveness of the spinach production line. The integration of advanced digital technologies—such as Internet of Things (IoT) sensors, data analytics platforms, and automated control systems—enables improved traceability, real-time process monitoring, and data-driven decision-making. These tools facilitate the proactive management of production variables, reduce operational uncertainties, and support continuous improvement initiatives by providing actionable insights derived from real-time data streams [

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20].

To what extent can the integrated application of Total Productive Maintenance (TPM), First-In–First-Out (FIFO), process standardization, and circular economy principles—augmented by digital transformation—contribute to waste reduction and operational efficiency in the spinach production line of a Peruvian agro-industrial enterprise?

This study addresses a critical gap in the existing literature concerning the integrated application of TPM, FIFO, process standardization, and circular economy principles in conjunction with digital transformation within the agro-industrial sector. While prior research has examined these methodologies in isolation, there remains a lack of empirical evidence regarding their combined implementation and the synergistic role of digital technologies in enhancing their effectiveness. By offering empirical insights and proposing a structured, integrative framework, this research contributes to the advancement of the operations management literature. Furthermore, it provides actionable guidance for agro-industrial firms seeking to improve sustainability performance and operational efficiency through the strategic alignment of lean, circular, and digital practices.

This article is structured into five main sections. The first section presents a comprehensive literature review, examining the theoretical foundations and successful case applications of TPM, FIFO, process standardization, and circular economy principles. It also outlines the relevant regulatory framework applicable within the company. The second section introduces the proposed model, detailing its conceptual development and the performance indicators established for evaluation. The third section describes the implementation strategy, including the operational steps taken to apply the model in the production environment. The fourth section focuses on the validation process, presenting the empirical results and methodological rigor used to assess the model’s effectiveness. Finally, the fifth section offers a critical discussion, analyzing and comparing the findings in relation to the existing literature and practical implications.

2. Literature Background on Lean Tools

The literature review critically examines key methodologies, including TPM, preventive maintenance strategies, the FIFO system, process standardization, circular economy principles, and the PDCA cycle. It emphasizes their practical implementation and systematically evaluates their impact on process optimization and the enhancement of operational efficiency across various industrial contexts.

Total Productive Maintenance (TPM) was conceptualized as a comprehensive organizational strategy in which all levels of personnel—from executive management to frontline operators—were engaged within a unified maintenance framework centered on production equipment. This approach was recognized as a paradigm shift in maintenance management, as responsibilities for equipment care were distributed across the entire workforce [

21]. The primary objective was defined as the early identification and resolution of potential issues, in accordance with the principles of zero accidents and zero losses. Through its implementation, a culture of ownership and continuous improvement was fostered, leading to reductions in equipment failures, enhancements in operational efficiency, and the facilitation of cost-effective, high-impact interventions. Moreover, significant contributions were reported in the literature regarding improvements in Overall Equipment Effectiveness (OEE), product quality, and workplace safety [

22].

Furthermore, TPM was reported to have played a pivotal role in enhancing operational performance by enabling organizations to more effectively meet customer demands, thereby contributing to increased profitability and revenue generation within the industrial sector [

23]. Beyond its technical contributions, TPM was also found to promote employee engagement, fostering a more collaborative and motivating work environment. Its implementation was not limited to equipment optimization; rather, it was extended to emphasize continuous workforce development. Regular training in maintenance and operational best practices was provided to ensure that employees’ skills and knowledge remained current—an essential requirement in rapidly evolving industrial contexts.

For example, in a case study that addressed challenges related to operational efficiency and equipment maintenance, a TPM model was implemented based on core pillars and executed in three sequential phases: planning, improvement, and sustainability. Throughout the study, significant improvements in Overall Equipment Effectiveness (OEE) were observed, with average OEE reported to have increased from 54.23% in 2020 to 66.9% across five machines within the company [

7]. In addition to these quantitative gains, notable improvements in productivity were recorded, along with a reduction in unplanned downtime and heightened employee awareness of preventive maintenance practices. These findings were presented as evidence of TPM’s effectiveness as a strategic approach for enhancing performance in competitive manufacturing environments.

As a result, these findings were interpreted to illustrate that the adoption of TPM could be employed as an effective strategy for optimizing overall performance in competitive production environments. In conclusion, TPM was shown to provide a robust framework for enhancing both operational efficiency and equipment effectiveness. By involving the entire organization in a comprehensive maintenance program, a culture of continuous improvement and accountability was fostered, ultimately contributing to operational excellence and improved customer satisfaction.

Preventive maintenance was recognized as essential for ensuring the reliability and efficiency of equipment across various industrial sectors. Through the execution of scheduled inspections, adjustments, and component replacements, unexpected equipment failures were prevented, and operational availability was maximized. This proactive approach was shown to minimize unplanned downtime, extend equipment lifespan, and enhance workplace safety by reducing the risk of incidents associated with mechanical failures [

24]. When effectively implemented, preventive maintenance programs were found to yield measurable benefits, including optimized production processes, lower costs related to emergency repairs, and improved quality of final products.

Additionally, the early detection of potential issues was facilitated through preventive maintenance, allowing corrective actions to be taken before such issues escalated into major failures. By ensuring that equipment was maintained in optimal condition, companies were enabled to respond more effectively to market demands and sustain their competitive advantage [

25]. This approach also allowed for the more efficient planning of resources and personnel, as downtime was scheduled in a controlled and predictable manner. Furthermore, the reduction in unplanned interruptions was found to improve employee morale by alleviating the stress and pressure typically associated with unexpected breakdowns. Ultimately, the implementation of a well-structured preventive maintenance program was shown to strengthen a company’s reputation by ensuring timely deliveries and consistently high product quality.

In conclusion, by ensuring that equipment was maintained in optimal condition, companies were enabled to enhance their responsiveness to market demand and sustain competitiveness. This approach was found to streamline resources and personnel planning, as downtime was scheduled in a controlled and predictable manner. Moreover, the reduction in unplanned interruptions was reported to improve employee morale by alleviating the stress and pressure typically associated with equipment breakdowns. Ultimately, the implementation of an effective preventive maintenance program was shown to strengthen the company’s reputation by ensuring timely deliveries and consistently high product quality.

The FIFO system was defined as an inventory management methodology in which the earliest items received were the first to be dispatched. This approach was considered essential for preserving perishable goods or items with limited shelf life, such as vegetables, thereby preventing obsolescence and reducing waste. When effectively implemented, FIFO was found to improve inventory turnover, minimize losses, and optimize the utilization of storage space. Precise product control was facilitated through the use of color-coded labels assigned by the month of entry, allowing for the easy identification of older items. Additionally, strategic storage practices were promoted by positioning newly received materials behind older stock, ensuring that products were used in the correct chronological order.

A study based on the FIFO methodology was shown to yield significant improvements in warehouse efficiency, including reductions in inventory management costs, product waste, and storage expenses. For example, inventory-related costs were minimized to USD 193,317.76, and inventory turnover was improved, with available stock days ranging from 10.3 to 15.4—indicating the more efficient utilization of stored products [

26]. Beyond its operational advantages, FIFO was found to enhance product traceability, allowing companies to rapidly identify specific batches in the event of quality concerns or product recalls. The implementation of FIFO not only reduced waste-related costs but also contributed to increased customer satisfaction by ensuring the delivery of fresh, high-quality products. Furthermore, when combined with proper staff training and the application of the 5S methodology—comprising Seiri (Sort), Seiton (Set in order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain)—FIFO was reported to support more organized, accurate, and cost-effective inventory management. As a result, companies were better positioned to meet market demand efficiently and profitably.

To sum up, beyond its operational advantages, FIFO was found to facilitate product traceability, enabling companies to quickly identify specific batches in the event of quality issues or product recalls. Its implementation was shown to reduce costs associated with waste while simultaneously enhancing customer satisfaction by ensuring the delivery of fresh, high-quality products. When combined with appropriate staff training and the structured application of the 5S methodology, FIFO was reported to contribute to more organized, accurate, and cost-effective inventory management. As a result, companies were better positioned to meet market demand both efficiently and profitably.

Process standardization was regarded as a critical instrument for ensuring consistency and quality in task execution across organizational operations. By establishing uniform methods and procedures, variability in outcomes was minimized, and staff training was conducted more efficiently [

26]. Furthermore, standardization provides a robust foundation for continuous improvement, facilitating the identification of opportunities and the implementation of corrective and preventive measures. This approach not only optimizes operational efficiency but also ensures that critical activities are performed in accordance with the best practices documented.

By establishing performance indicators and consistently monitoring processes, trends were able to be identified, and data-driven decisions were made to enhance operational efficiency and maintain market competitiveness. For instance, in a study conducted by a printing company, it was found that box packaging, printing, and manual publishing accounted for approximately 70% of its operations. Inadequate workstation design was identified as a significant risk factor for operators, resulting in inefficiencies, ergonomic challenges, and potential health hazards. After process standardization was implemented, the company reported a 20% increase in production levels, a 15% reduction in standard time, and a 40% decrease in unit costs [

27].

Moreover, previous analyses within the bakery industry suggested that process standardization substantially enhanced both product quality and operational efficiency. A multiple case study investigation reported that the adoption of uniform operational standards across various bakery settings contributed to a 12% reduction in cycle time and an 8% improvement in product weight consistency, thereby enabling more effective control over final product quality [

28]. These operational gains were further associated with a 15% increase in customer satisfaction scores and a 10% reduction in operational costs, largely attributed to a decrease in defective products and returns. This case illustrated the versatility of standardization as a core operational principle, emphasizing its critical role in fostering performance excellence across diverse industrial environments.

The studies reviewed demonstrate that process standardization can significantly enhance operational efficiency and product quality across various industries. Realyvásquez-Vargas et al. (2020) conducted research in the printing industry, revealing that deficiencies in workstation design posed risks to operators, resulting in inefficiencies, ergonomic issues, and health hazards [

27]. The implementation of process standardization led to a 20% increase in production levels, a 15% reduction in standard time, and a 40% decrease in unit costs. Similarly, Teixeira et al. (2014) analyzed the bakery industry, showing that process standardization resulted in substantial improvements in product quality and operational efficiency [

28]. Adopting uniform operational standards across multiple bakeries led to a 12% reduction in cycle time and an 8% improvement in product weight uniformity, ensuring better control over the final product quality. These enhancements translate into higher customer satisfaction, with a 15% increase in satisfaction scores and a 10% reduction in operational costs due to fewer defective products and returns. These examples underscore the versatility of standardization as a key pillar across various industries, highlighting its importance in the pursuit of operational excellence.

The circular economy represents a strategic framework aimed at minimizing waste and optimizing resource efficiency across the entire production lifecycle. Within the domain of vegetable handling, this approach emphasizes the reutilization of by-products that would otherwise be discarded, thereby fostering a more sustainable and efficient system. The integration of circular economic principles into the food industry has facilitated reductions in post-consumer waste through the selective collection and recycling of organic residues [

9]. Empirical studies have reported notable progress in urban food waste management, with pure organic waste collection rates (QCRs) ranging from 92% to 97%. However, these studies also highlighted substantial variability in the levels of impurities within the collected waste, suggesting that the selective collection infrastructure remains in a developmental phase.

Despite these challenges, the implementation of circular economic principles has contributed to a reduction in landfill waste by up to 30% compared to conventional waste management systems. Moreover, the minimization of by-products has enabled the generation of biogas and compost, leading to a 20% decrease in waste management costs for companies adopting this model. This approach not only improves operational efficiency but also fosters greater environmental stewardship within the food industry, aligning with broader global sustainability objectives. Additionally, research suggests that firms embracing circular economic strategies can enhance their market competitiveness by responding to the growing consumer demand for environmentally sustainable products.

In conclusion, the circular economy offers a flexible and impactful framework for advancing both operational efficiency and environmental sustainability within the food industry. Empirical findings underscore the value of integrating circular economic principles to achieve substantial improvements in waste management, cost efficiency, and competitive positioning. As selective collection systems continue to mature, further innovations are anticipated, reinforcing the circular economy’s pivotal role in driving operational excellence and supporting long-term sustainable development.

The PDCA cycle, also known in Spanish as the Planear–Hacer–Verificar–Actuar (PHVA) cycle, is a structured methodology for continuous improvement. This iterative approach emphasizes the systematic planning of objectives and strategies, the execution of corresponding actions, the assessment of outcomes, and the implementation of corrective measures to refine processes and products. Its significance lies in providing a disciplined and repeatable framework that enables organizations to effectively identify and resolve issues, foster a culture of learning and adaptability, and ensure sustained progress toward operational excellence and customer satisfaction.

In a case study, the PDCA methodology was applied to reduce waste within an automotive manufacturing company, resulting in a marked decline in waste levels [

29]. The application of this methodology generated substantial economic benefits, with an annual cost reduction of approximately USD 135,000. Furthermore, the PDCA methodology enhanced production process efficiency by 18% through the identification and elimination of bottlenecks. This approach also contributed to a 12% increase in the plant’s overall productivity. Additionally, the implementation of PDCA facilitated staff involvement, fostering an organizational culture centered on continuous improvement. This not only positively impacted operational outcomes but also boosted employee morale by directly involving them in problem identification and resolution.

In conclusion, while previous research has explored the application of lean methodologies across various industrial sectors, this study distinguishes itself by holistically integrating these efficiency-oriented tools with the transformative capabilities of digital technologies and the sustainability-driven framework of the circular economy, specifically adapted to the distinctive characteristics of the agro-industrial sector.

Although previous studies have explored the individual benefits of lean tools and circular economy practices across various industries, limited research has examined their combined application in agro-industrial contexts, particularly when supported by digital technologies. This study addresses this gap by focusing on spinach production, where post-harvest waste is a major challenge.

Accordingly, this research is guided by the following questions:

How effective are lean tools such as TPM, FIFO, and process standardization in reducing waste and improving efficiency in agro-industrial production lines?

In what ways can digital technologies enhance the implementation of these tools to support sustainable production?

How does the integration of circular economy principles contribute to environmental sustainability and resource optimization in the agro-industrial sector?

3. Methodology

This research has a case study with a combined lean management approach, with a descriptive research philosophy. This study primarily aims to enhance sustainability in spinach production by systematically identifying operational inefficiencies and deploying targeted lean manufacturing methodologies to minimize waste throughout the production line. The methodological framework adopted in this study was deliberately structured to be data-driven, iterative, and digitally enabled, thereby ensuring both diagnostic precision and long-term operational enhancement.

The selection of lean tools was informed by three principal considerations:

The intrinsic characteristics of the production system—namely its agricultural nature, perishability, and batch-oriented structure;

The specific categories of waste identified, such as sealing defects and inventory obsolescence;

The necessity for predictive insights to assess the prospective impact of implemented interventions.

This integrative approach, which has demonstrated efficacy in prior scholarly investigations [

30,

31], serves as a guiding paradigm for the present study. This aligns with the findings of Jebbor et al. (2023a, 2023b) [

30,

31], who demonstrated that lean tools significantly reduce waste and cycle time in both automotive and shipbuilding industries. Their work supports the idea that context-specific lean tool selection is critical for operational success.

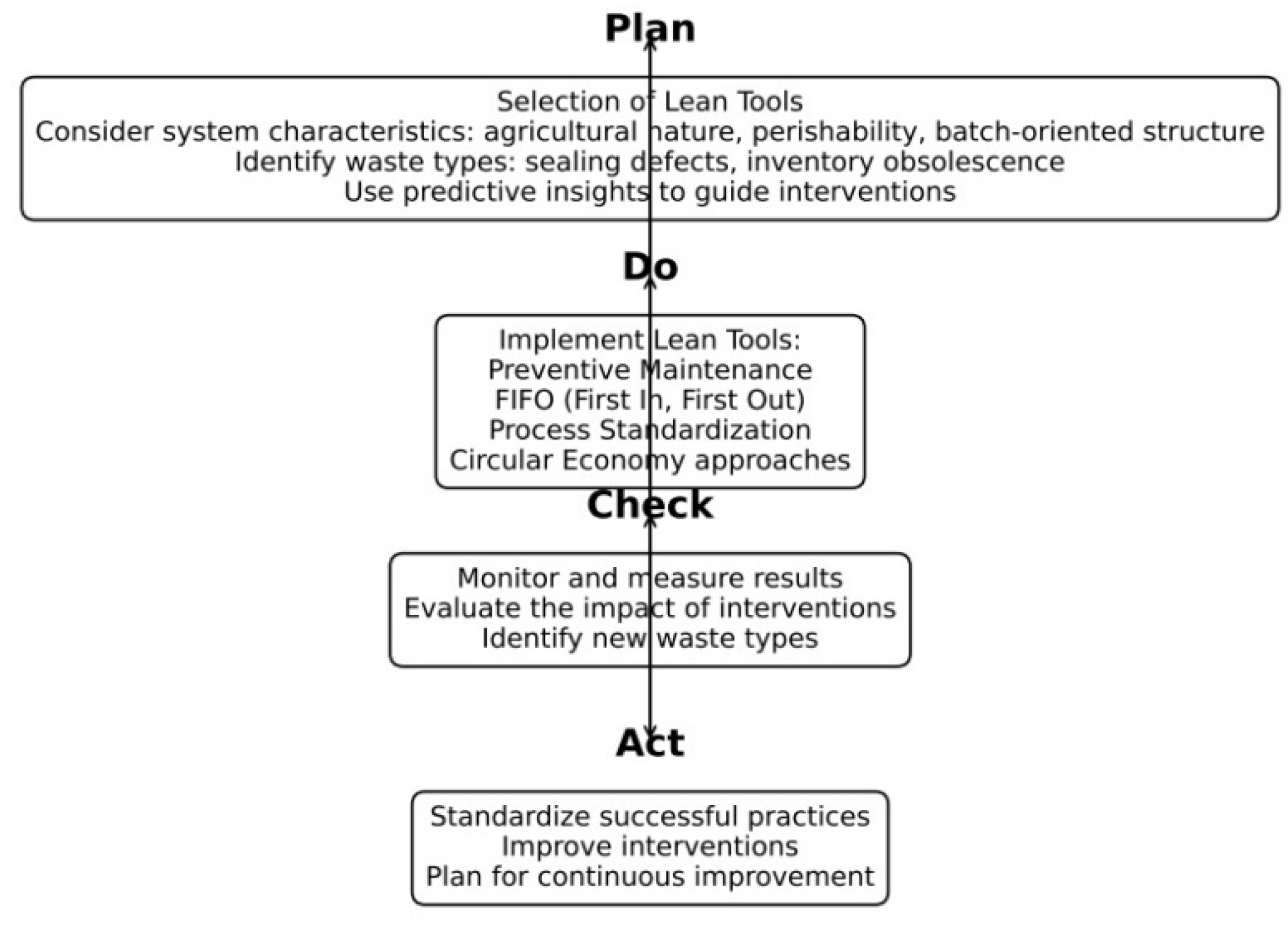

To address the efficiency challenges faced by the agro-industrial company, a solution model based on the PDCA methodology was proposed (

Figure 1). This methodology, recognized for its systematic and effective approach to problem-solving, was deemed suitable for the continuous improvement of operational processes. It served as the foundational framework for the implementation of engineering solution tools, whose effectiveness had been substantiated by prior studies and documented success cases across various industries [

6].

In this study, we applied the PDCA (Plan–Do–Check–Act) methodology to structure the implementation of lean practices within an agricultural production context. The cycle was adapted to reflect the specific characteristics of the system, including perishability, batch-oriented operations, and biological variability.

Plan: During the planning phase, we identified the most appropriate lean tools by considering the intrinsic features of the production system. We analyzed the types of waste most prevalent in the process—such as sealing defects and inventory obsolescence—and incorporated predictive insights to estimate the potential impact of the proposed interventions.

Do: In the implementation phase, we applied the selected lean tools. Preventive maintenance was introduced to reduce equipment-related failures, FIFO (First-In–First-Out) was used to manage perishable inventory, process standardization was established to ensure operational consistency, and circular economy principles were integrated to enhance resource efficiency.

Check: We then monitored the outcomes of the interventions. This involved collecting performance data, evaluating the effectiveness of each tool, and identifying any new or persistent sources of waste that emerged during the process.

Act: Based on the findings from the Check phase, we standardized the successful practices and revised the less effective ones. This allowed us to refine our approach and prepare for subsequent cycles of improvement, in line with the continuous improvement philosophy of lean methodology.

This structured methodology facilitated the systematic integration of lean principles into the agricultural production system, thereby ensuring that all interventions were both contextually appropriate and grounded in data-driven decision-making. Accordingly, this approach was adopted with the overarching objective of minimizing operational waste and enhancing process quality. Through the strategic deployment of lean tools—namely, preventive maintenance, FIFO, process standardization, and circular economy principles—the initiative substantially elevated the organization’s operational efficiency and service standards.

3.1. Lean Tools

3.1.1. Preventive Maintenance

The implementation of Total Productive Maintenance (TPM) was intended to ensure the optimal availability of critical equipment through structured preventive maintenance practices. This process involved securing management commitment to allocating the necessary resources and establishing a maintenance schedule, forming a TPM committee composed of key organizational stakeholders, and conducting a comprehensive evaluation of equipment based on criticality and frequency failure. The committee—comprising the General Manager, Production Manager, Production Supervisor, Production Operator, and Maintenance Technician—oversaw the execution of the program. The evaluation process identified the most critical machines, such as the sealing machine, which exhibited frequent failures and therefore required immediate maintenance interventions to minimize unplanned downtime and extend equipment lifespan [

32].

To identify the machines with the highest failure frequency, a Pareto diagram was employed, revealing that the sealing machine and the packing machine exhibited the most frequent failures [

33]. Based on these findings, the sealing machine was prioritized for the development of a targeted preventive maintenance plan. This plan was further informed by the equipment’s technical sheet to ensure a comprehensive understanding of its operational capabilities and potential failure points (see

Figure 2).

The implementation of TPM was aimed at ensuring optimal equipment availability through rigorous preventive maintenance practices. This process involved identifying potential failure modes and documenting them in a detailed preventive maintenance plan, with specific tasks—such as inspection, cleaning, component replacement, and repair—assigned to both operators and technicians. Staff training played a critical role, with scheduled sessions conducted for both management and operational personnel to ensure a thorough understanding of preventive maintenance procedures. Following the training, the preventive maintenance plan was executed and meticulously documented using appropriate tools. Key performance indicators, including the non-conforming product rate and machine availability, were established to evaluate the effectiveness of the initiative. In 2023, the non-conforming product rate in the sealing area stood at 4.45%, while machine availability was calculated at 78.13%. The established targets were to reduce the non-conforming product rate to below 3% and to increase machine availability to above 90% [

34].

3.1.2. FIFO

The implementation of the FIFO (First-In–First-Out) system was intended to improve inventory management by ensuring that older products were utilized first, thereby minimizing waste and enhancing operational efficiency. This approach was particularly critical for preventing the obsolescence of perishable goods such as spinach and for maintaining the freshness of the final product. Key steps included securing management’s commitment to allocating the necessary resources and establish clear objectives, analyzing the existing inventory system to identify vulnerabilities and risks, and designing the FIFO system with features such as color-coded labels and optimized storage configurations. Staff were trained in the new procedures, after which the system was implemented through the reorganization of storage areas and the labeling of products. Performance was continuously monitored using key indicators, including the obsolescence rate. For example, the current obsolescence rate in spinach storage was recorded at 1.52%, underscoring the need for improvement, given that the optimal rate in the food sector is typically 1% or lower [

35].

3.1.3. Process Standardization

Standardizing the washing process was essential for ensuring the quality and freshness of spinach, as well as for maintaining compliance with food safety regulations. The initiative began with securing management’s commitment to allocating the necessary resources and supporting the standardization effort. A multidisciplinary team was assembled to lead the process. The existing washing procedure was documented and analyzed to identify inefficiencies, revealing that 3317 out of 180,819 spinach units were improperly washed in 2023. Based on this assessment, new standards and best practices were established, including adjusting the chlorine concentration to 100 ppm and implementing a two-stage washing protocol. Staff training was conducted to ensure proper adherence to the updated procedures. The standardized process was then implemented and continuously monitored using a Process Activity Diagram (PAD) to ensure consistency and to identify opportunities for further refinement. Key performance indicators, such as the quality indicator, were used to assess the effectiveness of the standardization. The current quality indicator stood at 98.17%, falling short of the 99% target, thereby indicating the need for continued improvement to meet industry standards [

34,

36].

3.1.4. Circular Economy

The circular economy approach aims to maximize resource utilization within production processes by promoting waste reduction, reuse, and recycling. In the context of spinach processing, the initiative focused on minimizing waste through sustainable practices that leveraged by-products and optimized resource use. The process began with securing management’s commitment, followed by an evaluation of waste generation, which revealed that 17,527 units were discarded in 2023—primarily from sealing, washing, and storage operations. Based on this assessment, a composting system was designed using containers compliant with Servicio Nacional de Sanidad y Calidad Agroalimentaria (SENASA) standards and protocols for enriched compost production. Staff were trained in waste collection and composting procedures, after which the proposal was implemented in designated pilot areas. The system’s performance was continuously monitored and evaluated using the waste collection rate as a key indicator. At the time of implementation, the collection rate stood at 0%, with a target of 97%, a benchmark expected to significantly enhance the company’s sustainability efforts and align its operations with global environmental trends—potentially opening new market opportunities for eco-friendly products [

9].

4. Findings

The pilot plan was selected as a validation method to assess the feasibility and effectiveness of the proposed improvements prior to large-scale implementation. This controlled approach enabled the identification of potential issues, the refinement of strategies, and the alignment of solutions—such as circular economy practices, process standardization, FIFO, and preventive maintenance—with broader sustainability and efficiency objectives [

29]. To ensure statistical validity in data collection, a sample size of 375 was calculated based on a population of 15,068 spinach units, assuming a standard deviation of 0.5, a 95% confidence level, and a 5% margin of error [

37]. Samples were collected in intervals of 25 every 15 days, completing the total within 50 days. This approach provided descriptive data to evaluate the impact of the improvements without requiring exhaustive statistical comparisons. Additionally, the Holt–Winters forecasting model was employed to compare the results of the two-week pilot plan with annual performance indicators, accounting for both trends and seasonality in the time series. This method allowed the 25-sample dataset to be scaled to an annual projection, facilitating accurate comparisons with predefined benchmarks. As a result, the improvements introduced in the production process were evaluated in a representative and statistically grounded manner [

37].

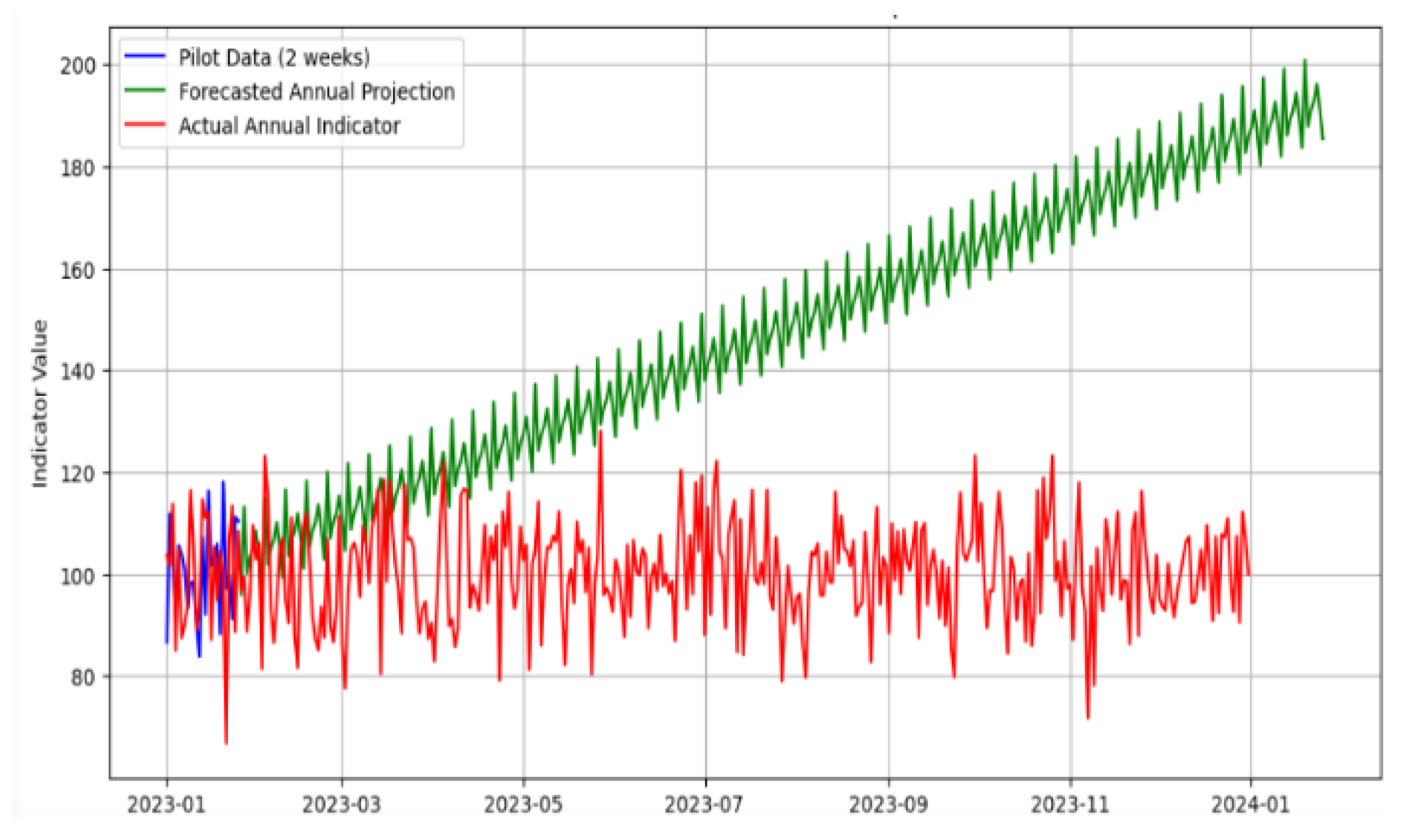

The validation results for each tool are presented below. Furthermore, a Holt–Winters forecast was conducted for all collected samples. The TPM pilot plan was implemented on the sealing machine, which had been identified as exhibiting the highest frequency of failures (see

Figure 3).

Below is the Holt–Winters forecast model visualization comparing the two-week pilot plan data with the forecasted annual projection and the actual annual indicator:

Figure 3.

Holt–Winters forecast model comparison.

Figure 3.

Holt–Winters forecast model comparison.

This chart illustrates how the pilot data (blue) was extrapolated using the Holt–Winters method (green) to estimate annual performance and how it compares to the actual annual indicator (red). This approach accounts for both trends and seasonality, providing a statistically grounded basis for evaluating the representativeness and potential impact of the pilot implementation.

This plan, approved by senior management, assigned key roles to the plant manager, who coordinated training and supervised the execution of maintenance tasks. The strategy aimed to standardize cleaning and maintenance procedures to reduce failures and enhance operational efficiency (see

Figure 4).

The maintenance plan encompassed a structured set of activities, including daily cleaning, biweekly lubrication, and quarterly as well as semiannual mechanical and electrical inspections. These procedures were systematically supported by a checklist to ensure adherence at each stage, a work order form to document every intervention, and a roadmap outlining the intended objectives and corresponding timelines. The overarching aim was to cultivate a culture of preventive maintenance, thereby enhancing both the availability and reliability of the equipment.

Over the course of the 15-day pilot implementation, a total of 375 samples were collected, of which 370 were properly sealed, resulting in a success rate of 98.67%. To project these findings on an annual scale, the Holt–Winters forecasting model was employed, calibrated to a 95% confidence interval. The model estimates that approximately 122 defective units would occur over the span of one year, which represents a substantial improvement relative to historical data (see

Table 1).

Additionally, a detailed record of repair time and failure frequency was maintained to calculate key indicators such as the availability percentage. The final forecast projected 144 failures over a full year, based on trends observed in the initial sampling.

The project began with a thorough analysis of the current warehouse situation, identifying weaknesses in the organization of the flow of materials, which generated risks of obsolescence and loss of products. This diagnosis showed that the current system lacked adequate order and control (see

Figure 4).

Based on the findings, a FIFO system was designed that was adapted to the specific needs of the warehouse. This system allows spinach batches to be identified and organized according to their production date and batch number. For its implementation, specific racks and a tempered glass board were purchased, on which the day of the week, batch number and production date are visibly recorded. This reorganization guarantees greater efficiency in inventory rotation and significantly reduces the risk of obsolescence (see

Figure 5).

During the execution of the pilot plan, constant monitoring of the performance of the new system was carried out, evaluating key indicators such as inventory turnover and loss reduction.

A total of 375 samples were collected over 15 days, with a success rate of 99.73% in the timely recall of products. These results were projected annually using the Holt–Winters forecasting model, which estimated a drop of 71 units for the full year, showing a notable improvement compared to previous figures.

The implementation of process standardization focused on improving the critical stages of washing and rinsing spinach, where significant deficiencies were identified. Initial analysis revealed that the chlorine concentration used in the process was 80 ppm, lower than the 100 ppm recommended by regulations. This underlined the need to adjust operating parameters to meet established standards and improve the quality of the final product.

The pilot plan included the adoption of a washing system based on the best practices in the industry. Clear procedures were established, such as the use of three tanks for the washing, disinfection, and rinsing stages, as well as the constant monitoring of chlorine concentration, pH, and water temperature. In addition, specific practices were defined, such as gentle agitation and final rinsing with potable water, to ensure the effective removal of contaminants and chemical residues.

Staff training was an essential component of the pilot plan. Training sessions were held to ensure that workers understood the importance of each stage of the process and properly handled the chemicals used.

During the pilot plan, 375 samples were collected and analyzed over a 15-day period. Initial results showed that only two units had deficiencies in the washing process, an indication of the positive impact of the improvements implemented. From this data, the Holt–Winters forecasting model was used to project an annual estimate, resulting in a total of 48 units with problems, significantly lower than the historical average.

Circular Economy

A composting system designed to transform organic waste into useful resources, such as soil fertilizer, was implemented.

First, the personnel responsible for waste management received extensive training on best practices in separation and composting. This process included rigorous quality controls and compliance with SENASA regulations, reflecting a commitment to sustainability and continuous improvement. The training ranged from correct waste segregation to the application of advanced composting techniques.

The composting system was implemented with 120 L containers, strategically located in the quality, planting, harvesting, and distribution areas. These containers were visually differentiated to facilitate the efficient collection and separation of organic waste. During the pilot plan, the containers were emptied daily to evaluate the efficiency of the system, but the collection frequency was adjusted to every three days, thus optimizing resources (see

Figure 6).

The composting process was carried out in a 20-square-meter area, roofed and ventilated to maintain ideal conditions. The compost piles were enriched weekly with minerals such as natural phosphate and wood ash, following a standardized protocol that included weekly turning and temperature and humidity controls. This ensured that the compost reached maturity in approximately one week, producing a high-quality compost (see

Figure 7).

Finally, as part of the pilot plan, 375 samples were collected and analyzed over a 15-day period. These data were used to project annual results using the Holt–Winters method, ensuring an accurate assessment of the implemented system. The forecast projected a significant reduction in the volume of waste sent to landfills, highlighting the positive impact of the composting system on waste management and operational sustainability.

6. Conclusions and Future Works

This research aims to reduce the waste rate in the spinach production line by diagnosing and addressing the underlying causes. The analysis identifies post-harvest processes as the primary source of waste, accounting for 86% of the total, with significant contributions from washing (19%), quality control (8%), sealing (45%), and storage (15%). To tackle these issues, tools such as TPM preventive maintenance, process standardization, circular economic practices, and the FIFO method were implemented due to their relevance to the identified challenges.

The preventive maintenance program in the sealing area, supported by a criticality matrix, Pareto chart, FMEA, and staff training, enhanced equipment reliability. Process standardization in the washing area, including a revised chlorinated solution procedure, reduced waste and improves product quality. The FIFO method optimized storage organization, reducing obsolescence by ensuring older products are used first. The circular economy model repurposed unused spinach waste as fertilizer, promoting sustainability and reducing the environmental impact.

The effectiveness of these interventions was evaluated through a pilot plan involving 325 production samples. Forecasts of annual waste generation revealed positive outcomes: a 3% reduction in non-conforming products, a 15% increase in equipment availability, a 1% improvement in product quality, a 1% decrease in obsolescence, and a WCR of 98%. Economically, the reduction of 12,765 units of waste resulted in significant savings, optimizing resources and enhancing operational efficiency, with an expected economic benefit of USD 4439.

Future efforts should focus on providing regular training programs for preventive maintenance, emphasizing the importance of employee involvement in equipment care. This approach can help ensure operational efficiency and workplace safety while also reducing unexpected repair costs and fostering a collaborative work environment.

The development of Standard Operating Procedures (SOPs) is recommended to ensure consistency and quality across the production process. SOPs can facilitate the onboarding of new employees and minimize operational errors. Creating a work culture that encourages employees to identify problems and propose solutions should be prioritized, using suggestion systems and regular team meetings to drive continuous improvement.

Efforts to recycle and reuse materials within the production process should also be implemented. These initiatives may contribute to waste reduction and long-term sustainability, aligning operations with environmentally responsible practices. Such a sustainable approach can enhance both operational efficiency and the company’s environmental stewardship while also strengthening brand perception as a socially responsible organization.