Characterisation of Waste Textiles from Mixed MSW and Separate Collection—A Case Study from Vienna, Austria

Abstract

1. Introduction

- (1)

- What are the amounts of waste textiles in mixed MSW (WT-MW) and in separate collection (WT-SC) in Vienna?

- (2)

- What are the properties of those textiles, particularly in regard to material composition and textile type?

- (3)

- How do the material flows of WT-MW and WT-SC relate to the analysed properties?

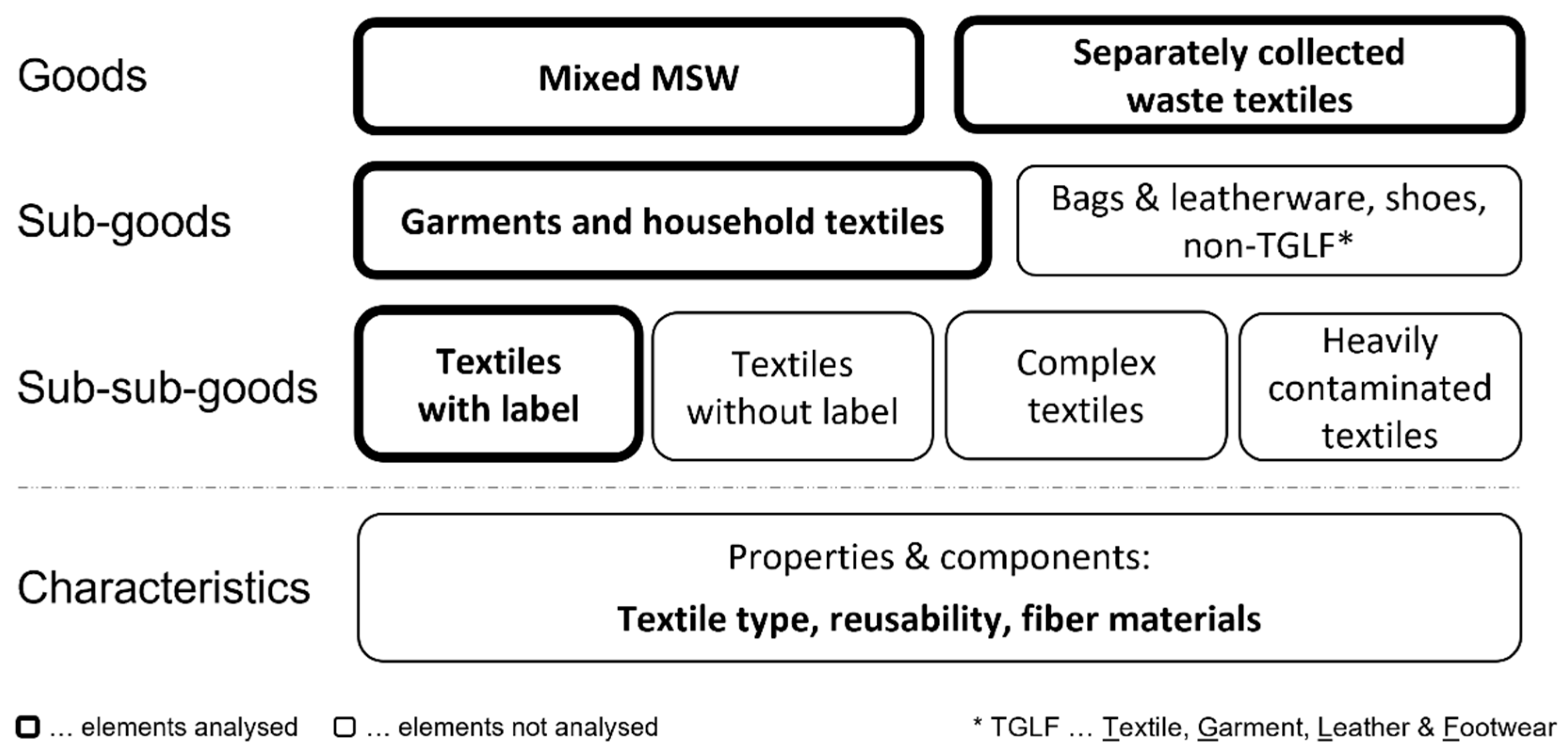

2. Materials and Methods

2.1. MFA of Waste Textiles in Vienna

2.1.1. Methodological Background

2.1.2. Textile Waste Management in Vienna

2.1.3. Material Flows of Goods and Transfer Coefficients

2.2. Sampling and Characterisation

2.2.1. Sampling of Mixed MSW and Separate Collection

2.2.2. Characterisation and Fraction Descriptions

3. Results and Discussion

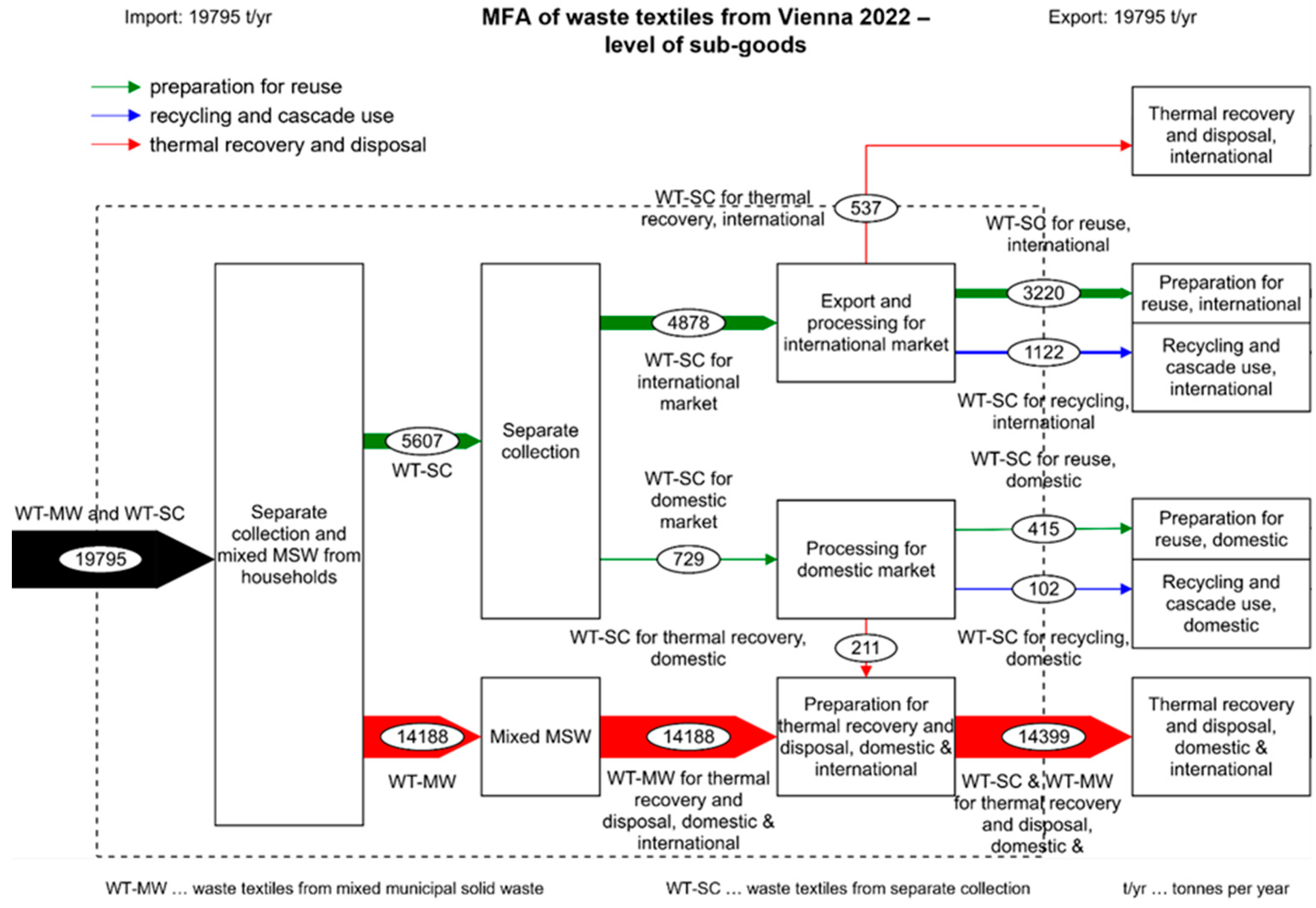

3.1. Material Flows of Waste Textiles in Vienna

3.2. Composition of Waste Textiles in Vienna

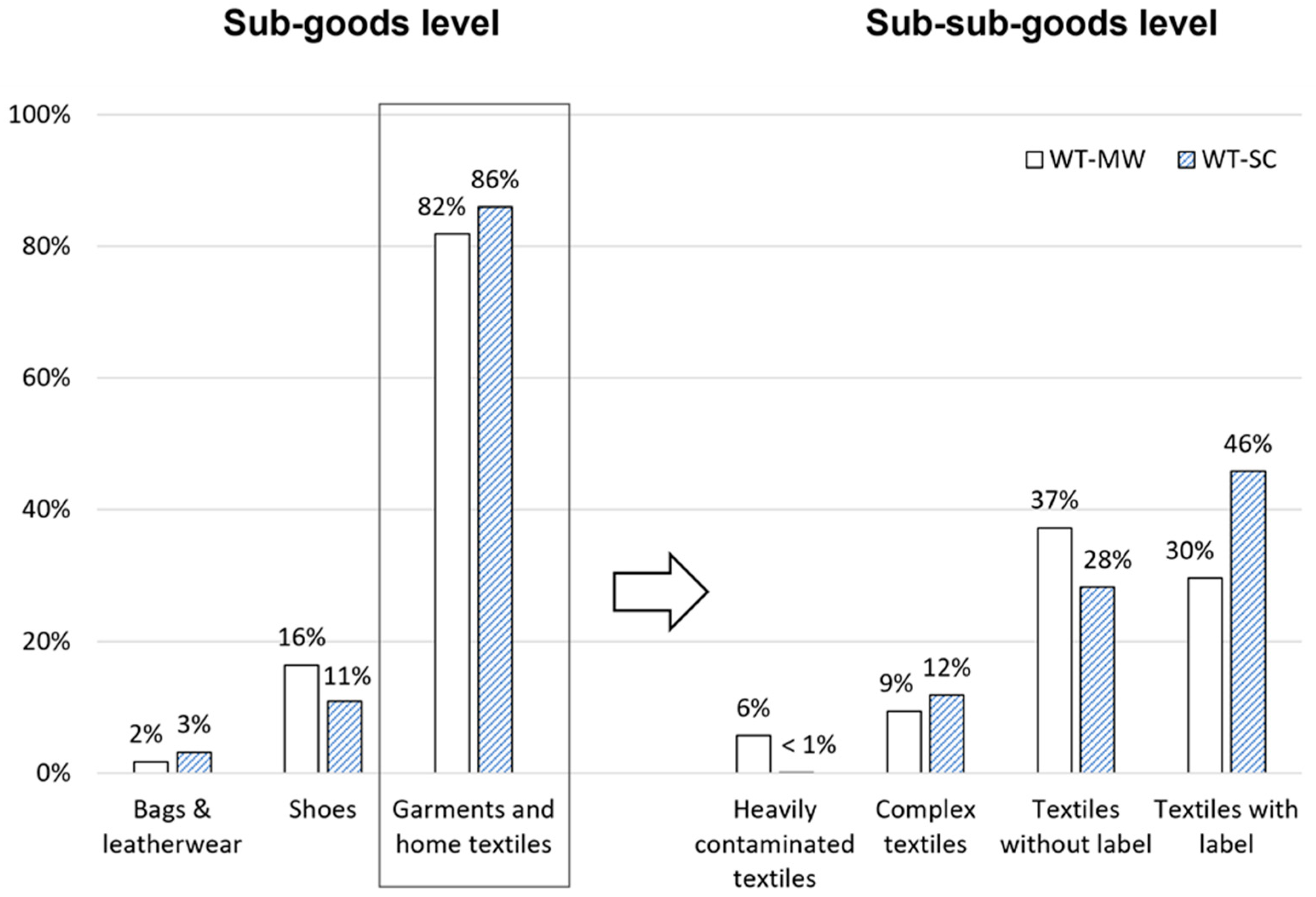

3.2.1. Sub-Goods and Sub-Sub-Goods

3.2.2. Characteristics

Textile Types

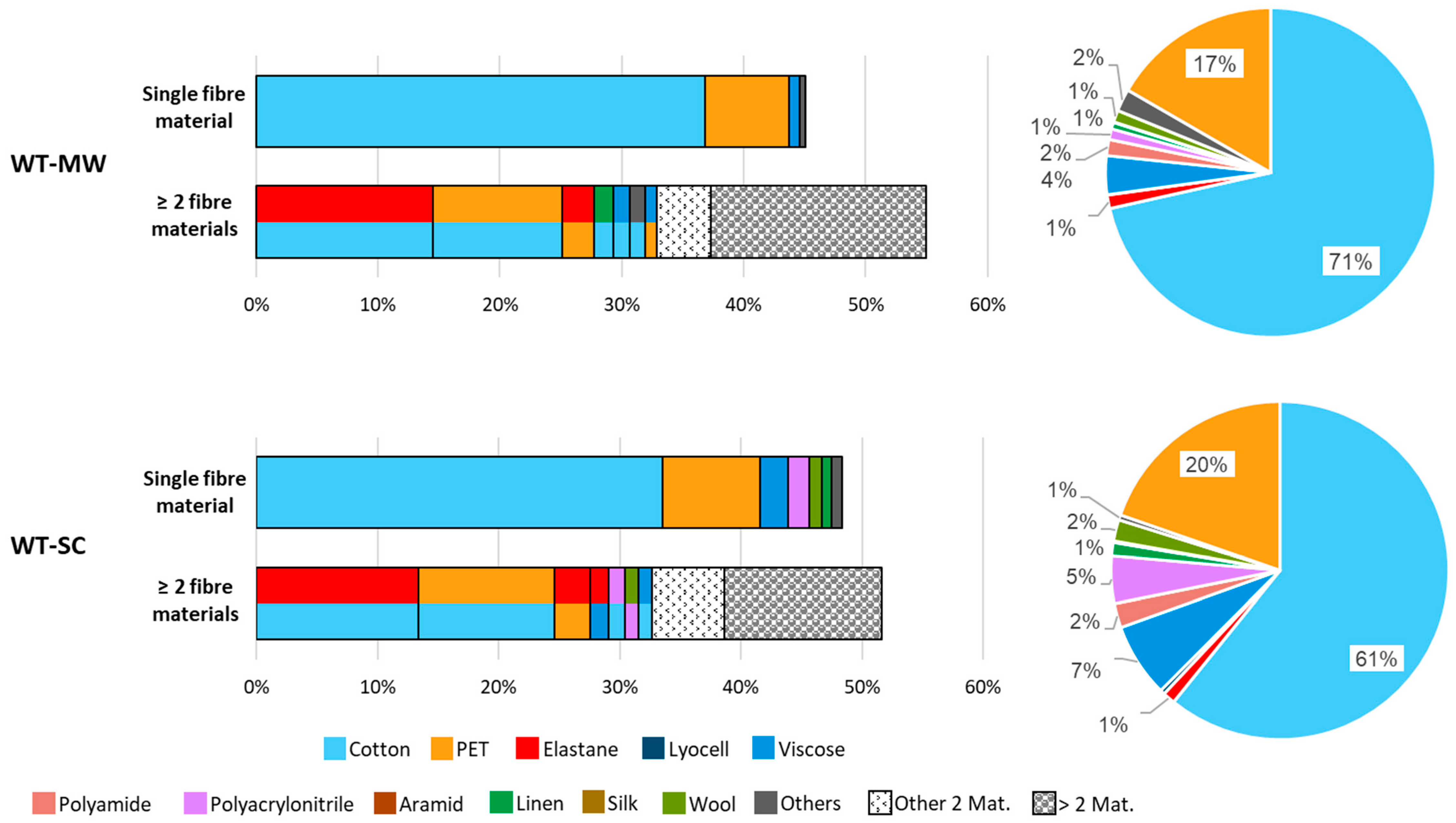

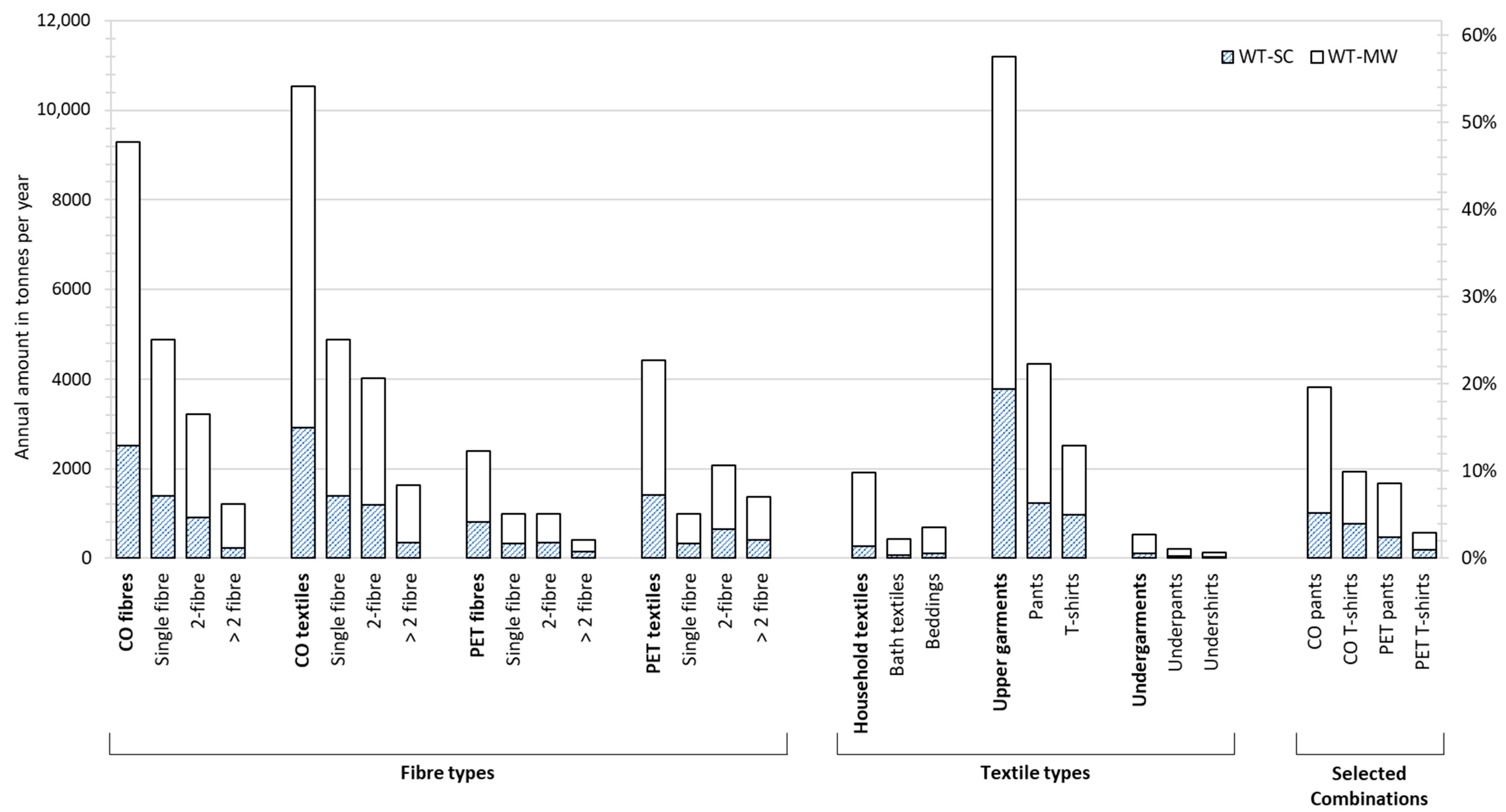

Fibre Types

3.3. MFA Based on Defined Textile Characteristics

3.4. Methodical Limits of the Study and Further Research

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AR | Aramid (short for aromatic polyamide) |

| CE | Circular Economy |

| CLY | Lyocell |

| CO | Cotton |

| CV | Viscose |

| EL | Elastane (elastic fibres made from polyurethanes, also known as Spandex) |

| LI | Linen |

| MA48 | Magistratsabteilung 48 (Vienna’s Municipal Department for Waste Management, Street Cleaning, and Vehicle Fleet) |

| MFA | Material flow analysis |

| MSW | Municipal solid waste |

| PA | Polyamide |

| PAN | Polyacrylonitrile |

| PET | Polyester (mostly polyethylene terephthalate) |

| SC | Separate collection |

| SE | Silk |

| TC | Transfer coefficients |

| TGLF | Textile, garment, leather, footwear |

| WO | Wool |

| WT-MW | Waste textiles from mixed municipal solid waste |

| WT-SC | Waste textiles from separate collection |

References

- Bartl, A.; Ipsmiller, W. Fast fashion and the Circular Economy: Symbiosis or antibiosis? Waste Manag. Res. J. A Sustain. Circ. Economy 2023, 41, 497–498. [Google Scholar] [CrossRef] [PubMed]

- Niinimäki, K. From Disposable to Sustainable—The Complex Interplay between Design and Consumption of Textiles and Clothing. Ph.D. Thesis, Aalto University, Espoo, Finland, 2011. [Google Scholar]

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The environmental price of fast fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Fonseca, A.; Ramalho, E.; Gouveia, A.; Henriques, R.; Figueiredo, F.; Nunes, J. Systematic Insights into a Textile Industry: Reviewing Life Cycle Assessment and Eco-Design. Sustainability 2023, 15, 15267. [Google Scholar] [CrossRef]

- Ipsmiller, W.; Bartl, A. Sourcing and re-sourcing end-of-use textiles. In Polluting Textiles: The Problem with Microfibres; Taylor and Francis: Abingdon, UK, 2022; pp. 214–244. [Google Scholar] [CrossRef]

- Fellner, J.; Lederer, J. Recycling rate—The only practical metric for a circular economy? Waste Manag. 2020, 113, 319–320. [Google Scholar] [CrossRef]

- Chen, X.; Memon, H.A.; Wang, Y.; Marriam, I.; Tebyetekerwa, M. Circular Economy and Sustainability of the Clothing and Textile Industry. Mater. Circ. Econ. 2021, 3, 12. [Google Scholar] [CrossRef]

- EC. DIRECTIVE (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on waste (Text with EEA Relevance). Off. J. Eur. Union2018, 61, 109–140. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32018L0851 (accessed on 30 June 2023).

- EC. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. EU Strategy for Sustainable and Circular Textiles. 2022. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52022DC0141 (accessed on 30 June 2023).

- Zamani, B.; Svanström, M.; Peters, G.; Rydberg, T. A Carbon Footprint of Textile Recycling: A Case Study in Sweden. J. Ind. Ecol. 2014, 19, 676–687. [Google Scholar] [CrossRef]

- McKinsey & Company. Scaling Textile Recycling in Europe-Turning Waste into Value; McKinsey & Company: New York, NY, USA, 2022. [Google Scholar]

- Solis, M.; Tonini, D.; Scheutz, C.; Napolano, L.; Biganzoli, F.; Huygens, D. Contribution of waste management to a sustainable textile sector. Waste Manag. 2024, 189, 389–400. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future; Ellen MacArthur Foundation: Isle of Wight, UK, 2017. [Google Scholar]

- Ko, Y.; Tamer, U.; Hinestroza, J.P. UiO-66 Inspired Superhydrophobic Coatings Fabricated from Discarded Polyester/Spandex Textiles. ACS Appl. Mater. Interfaces 2024, 16, 53163–53176. [Google Scholar] [CrossRef]

- Ko, Y.; Azbell, T.J.; Milner, P.; Hinestroza, J.P. Upcycling of Dyed Polyester Fabrics into Copper-1,4-Benzenedicarboxylate (CuBDC) Metal–Organic Frameworks. Ind. Eng. Chem. Res. 2023, 62, 5771–5781. [Google Scholar] [CrossRef]

- Vashishth, E.; Raulo, A.; Srivastava, R.K.; Nandan, B. Waste-cotton-cloth-derived sustainable and flexible high-performance supercapacitor. ACS Sustain. Resour. Manag. 2024, 1, 548–562. [Google Scholar] [CrossRef]

- Amini, S.; Ahmed, R.F.S.M.; Kumar, S.; Ankanathappa, S.M.; Sannathammegowda, K. Electrifying waste textiles: Transforming fabric scraps into high-performance triboelectric nanogenerators for biomechanical energy harvesting. Waste Manag. 2024, 190, 477–48524. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Fan, W.; Wang, H.; Shi, Y.; Wang, S.; Liew, R.K.; Ge, S. Recycling of bast textile wastes into high value-added products: A review. Environ. Chem. Lett. 2022, 20, 3747–3763. [Google Scholar] [CrossRef]

- Cho, E.J.; Lee, Y.G.; Song, Y.; Kim, H.Y.; Nguyen, D.-T.; Bae, H.-J. Converting textile waste into value-added chemicals: An integrated bio-refinery process. Environ. Sci. Ecotechnology 2023, 15, 100238. [Google Scholar] [CrossRef] [PubMed]

- Köhler, A.; Watson, D.; Trzepacz, S.; Löw, C.; Liu, R.; Danneck, J. Circular Economy Perspectives in the EU Textile Sector Final Report. Publications Office of the European Union: Luxembourg, 2021. [Google Scholar] [CrossRef]

- Terra for Eco TLC. Technical Monitoring on Optical Sorting and Textile Recognition Technologies at a European Level Summary. 2020. Available online: https://refashion.fr/pro/sites/default/files/fichiers/Terra_summary_study_on_textile_material_sorting_VUK300320.pdf (accessed on 30 June 2023).

- European Commission: Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs; Duhoux, T.; Maes, E.; Hirschnitz-Garbers, M.; Peeters, K.; Asscherickx, L.; Christis, M.; Stubbe, B.; Colignon, P.; Hinzmann, M.; et al. Study on the Technical, Regulatory, Economic and Environmental Effectiveness of Textile Fibres Recycling: Final Report; Publications Office of European Union: Brussels, Belgium, 2021. [Google Scholar]

- Refashion. Mechanical Recycling of Textiles. 2025. Available online: https://recycle.refashion.fr/wp-content/uploads/2025/04/REFASHION_Mechanical-recycling-of-textiles.pdf (accessed on 6 June 2025).

- Baloyi, R.B.; Gbadeyan, O.J.; Sithole, B.; Chunilall, V. Recent advances in recycling technologies for waste textile fabrics: A review. Text. Res. J. 2023, 94, 508–529. [Google Scholar] [CrossRef]

- Piribauer, B.; Bartl, A.; Ipsmiller, W. Enzymatic textile recycling–Best practices and outlook. Waste Manag. Res. 2021, 39, 1277–1290. [Google Scholar] [CrossRef]

- Palme, A.; Peterson, A.; de la Motte, H.; Theliander, H.; Brelid, H. Development of an efficient route for combined recycling of PET and cotton from mixed fabrics. Cloth. Sustain. 2017, 3, 4. [Google Scholar] [CrossRef]

- Boschmeier, E.; Archodoulaki, V.M.; Schwaighofer, A.; Lendl, B.; Ipsmiller, W.; Bartl, A. New separation process for elastane from polyester/elastane and polyamide/elastane textile waste. Resour. Conserv. Recycl. 2023, 198, 107215. [Google Scholar] [CrossRef]

- European Environment Agency. Management of Used and Waste Textiles in Europe’s Circular Economy (Briefing No. 03/2024); European Environment Agency: Copenhagen, Denmark, 2024. [Google Scholar] [CrossRef]

- Dahlbo, H.; Aalto, K.; Eskelinen, H.; Salmenperä, H. Increasing textile circulation—Consequences and requirements. Sustain. Prod. Consum. 2017, 9, 44–57. [Google Scholar] [CrossRef]

- Dahlbo, H.; Rautiainen, A.; Savolainen, H.; Oksanen, P.; Nurmi, P.; Virta, M. Textile Flows in Finland 2019. 2021. Available online: https://www.turkuamk.fi/en/publication/textile-flows-in-finland-2019/ (accessed on 10 June 2025).

- Koligkioni, A.; Parajuly, K.; Sørensen, B.L.; Cimpan, C. Environmental Assessment of End-of-Life Textiles in Denmark. Procedia CIRP 2018, 69, 962–967. [Google Scholar] [CrossRef]

- Malinverno, N.; Schmutz, M.; Nowack, B.; Som, C. Identifying the needs for a circular workwear textile management—A material flow analysis of workwear textile waste within Swiss Companies. Resour. Conserv. Recycl. 2022, 189, 106728. [Google Scholar] [CrossRef]

- Amicarelli, V.; Bux, C. Quantifying textile streams and recycling prospects in Europe by material flow analysis. Environ. Impact Assess. Rev. 2022, 97, 106878. [Google Scholar] [CrossRef]

- Napolano, L.; Foschi, J.; Caldeira, C.; Huygens, D.; Sala, S. Understanding textile value chains: Dynamic Probabilistic Material Flow Analysis of textile in the European Union. Resour. Conserv. Recycl. 2024, 212, 107888. [Google Scholar] [CrossRef]

- Nørup, N.; Pihl, K.; Damgaard, A.; Scheutz, C. Development and testing of a sorting and quality assessment method for textile waste. Waste Manag. 2018, 79, 8–21. [Google Scholar] [CrossRef] [PubMed]

- Nørup, N.; Pihl, K.; Damgaard, A.; Scheutz, C. Quantity and quality of clothing and household textiles in the Danish household waste. Waste Manag. 2019, 87, 454–463. [Google Scholar] [CrossRef]

- Refashion. Characterisation Study of the Incoming and Outgoing Streams from Sorting Facilities. April 2023. Available online: https://pro.refashion.fr/sites/default/files/rapport-etude/Overview_Characterisation_study_Refashion_2023_EN.pdf (accessed on 13 December 2023).

- Weber, S.; Weber, O.; Habib, K.; Dias, G.M. Textile waste in Ontario, Canada: Opportunities for reuse and recycling. Resour. Conserv. Recycl. 2022, 190, 106835. [Google Scholar] [CrossRef]

- Bernhardt, A.; Brandstätter, C.; Broneder, C.; Gold, C.; Neubauer, C.; Oliva, J.; Roll, M.; Schaffernak, A.; Stoifl, B.; Tesar, M.; et al. Die Bestandsaufnahme der Abfallwirtschaft in Österreich—Statusbericht 2024 für das Referenzjahr 2022. 2024. Available online: https://www.bmluk.gv.at/service/publikationen/klima-und-umwelt/die-bestandsaufnahme-der-abfallwirtschaft-in-oesterreich-statusbericht-2024-fuer-das-referenzjahr-2022.html (accessed on 10 June 2025).

- MA 48-Magistratsabteilung MA 48 City of Vienna. Wiener Restmüll- und Altstoffanalysen 2022/23. Available online: https://www.pulswerk.at/projekte/restmuell-und-altstoffanalyse-wien-2022-23/ (accessed on 10 June 2025).

- Brunner, P.H.; Rechberger, H. Handbook of Material Flow Analysis: For Environmental, Resource and Waste Engineers; GRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Bernhardt, A.; Brandstätter, C.; Karigl, B.; Neubauer, C.; Stoifl, B.; Van Eygen, E. Aufkommen Und Behandlung Von Textilabfällen in Österreich-Materialien zum Bundes-Abfallwirtschaftsplan. 2022. Available online: https://www.umweltbundesamt.at/fileadmin/site/publikationen/rep0788.pdf (accessed on 21 June 2023).

- Stadt Wien. Das Mist-ABC–Müll Richtig Entsorgen. Available online: https://www.wien.gv.at/umwelt/ma48/beratung/muelltrennung/mistabc.html (accessed on 18 July 2024).

- Humana People to People. Deine Kleiderspende. Available online: https://humana.at/deine-kleiderspende/ (accessed on 24 July 2024).

- Caritas der Erzdiözese Wien. Kleidung und Textilien. Available online: https://www.caritas-wien.at/spenden-helfen/sachspenden/kleidung (accessed on 24 July 2024).

- Öpula Rohstoff-Recycling Ges.m.b.H. Neues Leben für alte Kleider. Available online: https://www.oepula.at/containersammlung (accessed on 24 July 2024).

- Stadt Wien. Wohin Mit Gebrauchten Textilien? Available online: https://www.wenigermist.at/wohin-mit-gebrauchten-textilien (accessed on 18 July 2024).

- Gritsch, L.; Lederer, J. A historical-technical analysis of packaging waste flows in Vienna. Resour. Conserv. Recycl. 2023, 194, 106975. [Google Scholar] [CrossRef]

- BMK. Verordnung der Bundesministerien für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie über ein Abfallverzeichnis (Abfallverzeichnisverordnung 2020). BGBl. II Nr. 409/2020, Anhang 1 Abfallverzeichnis. 2020. Available online: https://www.ris.bka.gv.at/eli/bgbl/II/2020/409 (accessed on 27 August 2024).

- Huber, F. Strategische Umweltprüfung zum Wiener Abfallwirtschaftsplan (Wr. AWP) 2025–2030 und zum Wiener Abfallvermeidungsprogramm (Wr. AVP) 2025–2030 Anhang I Ist-Zustand der Wiener Abfallwirtschaft 2023. Available online: https://www.wien.gv.at/umwelt/ma48/service/pdf/awp-avp-25-30-anhang1.pdf (accessed on 24 January 2025).

- Beigl, P.; Happenhofer, A.; Salhofer, S. Technische Anleitung für die Durchführung von Restmüll-Sortieranalysen (Technical Instructions for the Performance of Residual Waste Sorting Analysis); BIMI: Vienna, Austria, 2017. [Google Scholar]

- Gritsch, L.; Breslmayer, G.; Rainer, R.; Stipanovic, H.; Tischberger-Aldrian, A.; Lederer, J. Critical properties of plastic packaging waste for recycling: A case study on non-beverage plastic bottles in an urban MSW system in Austria. Waste Manag. 2024, 185, 10–24. [Google Scholar] [CrossRef]

- Caritas der Erzdiözese Wien. Kleidercontainer der Caritas Erzdiözese Wien-Stand 06.02.2024. Available online: https://www.carla-wien.at/fileadmin/storage/wien/shops-services/carla/aktuell/20240206_Containerliste_kompakt.pdf (accessed on 27 February 2025).

- Team Demographie. Demographisches Jahrbuch 2022; Team Demographie: Vienna, Austria, 2023. [Google Scholar]

- Textile Exchange. Preferred Fiber & Materials Market Report; Textile Exchange: Lamesa, TX, USA, 2023. [Google Scholar]

- Matsuo, T. Fibre materials for advanced technical textiles. Text. Prog. 2008, 40, 87–121. [Google Scholar] [CrossRef]

- Euratex. Facts & Key Figures 2024 of the European Textile and Clothing Industry. 2024. Available online: www.euratex.eu (accessed on 28 February 2024).

- EC. Directive 2008/98/EC of The European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance). 2008. Available online: http://data.europa.eu/eli/dir/2008/98/oj (accessed on 13 December 2024).

- Bäck, T. Sensorgestützte Sortierung von Alttextilien Mittels NIR. [Masterarbeit, Montanuniversität Leoben (000)]. Master’s Thesis, Montanuniversität, Leoben, Austria, 2023. [Google Scholar] [CrossRef]

- Refashion. Technical Monitoring of Optical Sorting, Recognition and Disassembly Technologies for Textiles at European Scale. 2023. Available online: https://refashion.fr/pro/sites/default/files/rapport-etude/240428_Synth%C3%A8se_Veille-technos-tri-d%C3%A9lissage_VF-EN.pdf (accessed on 8 January 2024).

- Tischberger-Aldrian, A.; Stipanovic, H.; Kuhn, N.; Bäck, T.; Schwartz, D.; Koinig, G. Automatisierte Textilsortierung–Status quo, Herausforderungen und Perspektiven. Österr Wasser-Abfallw 2024, 76, 63–79. [Google Scholar] [CrossRef]

| WT-MW | WT-SC | |

|---|---|---|

| Household Textiles | ||

| Single-fibre materials | 71.3% (12.4%) | 90.7% (5.6%) |

| CO | 67.1% (11.7%) | 75.6% (4.7%) |

| PET | 3.1% (<1%) | 15.1% (<1%) |

| Others | 1.1% (<1%) | <1% (<1%) |

| Upper garments | ||

| Single-fibre materials | 40.0% (31.3%) | 45.7% (41.6%) |

| CO | 30.4% (23.8%) | 30.7% (27.9%) |

| PET | 8.1% (6.3%) | 7.6% (6.9%) |

| CV | 1.1% (<1%) | 2.5% (2.3%) |

| Others | <1% (<1%) | 4.9% (4.4%) |

| Undergarments | ||

| Single-fibre materials | 31.7 (1.4%) | 41.2% (1.1%) |

| CO | 31.7 (1.4%) | 31.6% (<1%) |

| PET | - | 8.0% (<1%) |

| PA | - | 1.6% (<1%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kählig, P.; Ipsmiller, W.; Bartl, A.; Lederer, J. Characterisation of Waste Textiles from Mixed MSW and Separate Collection—A Case Study from Vienna, Austria. Sustainability 2025, 17, 5484. https://doi.org/10.3390/su17125484

Kählig P, Ipsmiller W, Bartl A, Lederer J. Characterisation of Waste Textiles from Mixed MSW and Separate Collection—A Case Study from Vienna, Austria. Sustainability. 2025; 17(12):5484. https://doi.org/10.3390/su17125484

Chicago/Turabian StyleKählig, Pablo, Wolfgang Ipsmiller, Andreas Bartl, and Jakob Lederer. 2025. "Characterisation of Waste Textiles from Mixed MSW and Separate Collection—A Case Study from Vienna, Austria" Sustainability 17, no. 12: 5484. https://doi.org/10.3390/su17125484

APA StyleKählig, P., Ipsmiller, W., Bartl, A., & Lederer, J. (2025). Characterisation of Waste Textiles from Mixed MSW and Separate Collection—A Case Study from Vienna, Austria. Sustainability, 17(12), 5484. https://doi.org/10.3390/su17125484