Evaluation of Low-Carbon Development in the Construction Industry and Forecast of Trends: A Case Study of the Yangtze River Delta Region

Abstract

1. Introduction

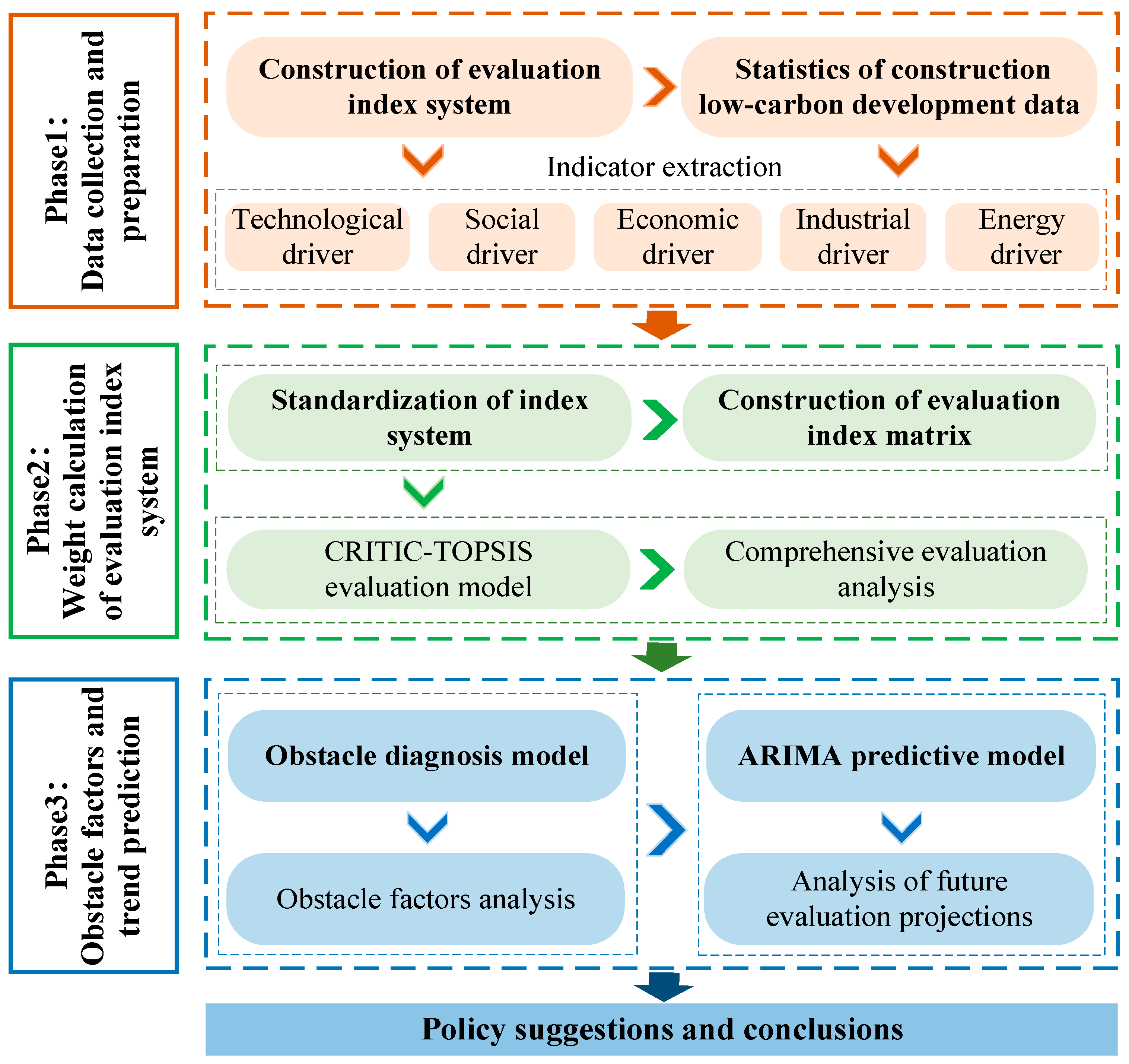

2. Materials and Methods

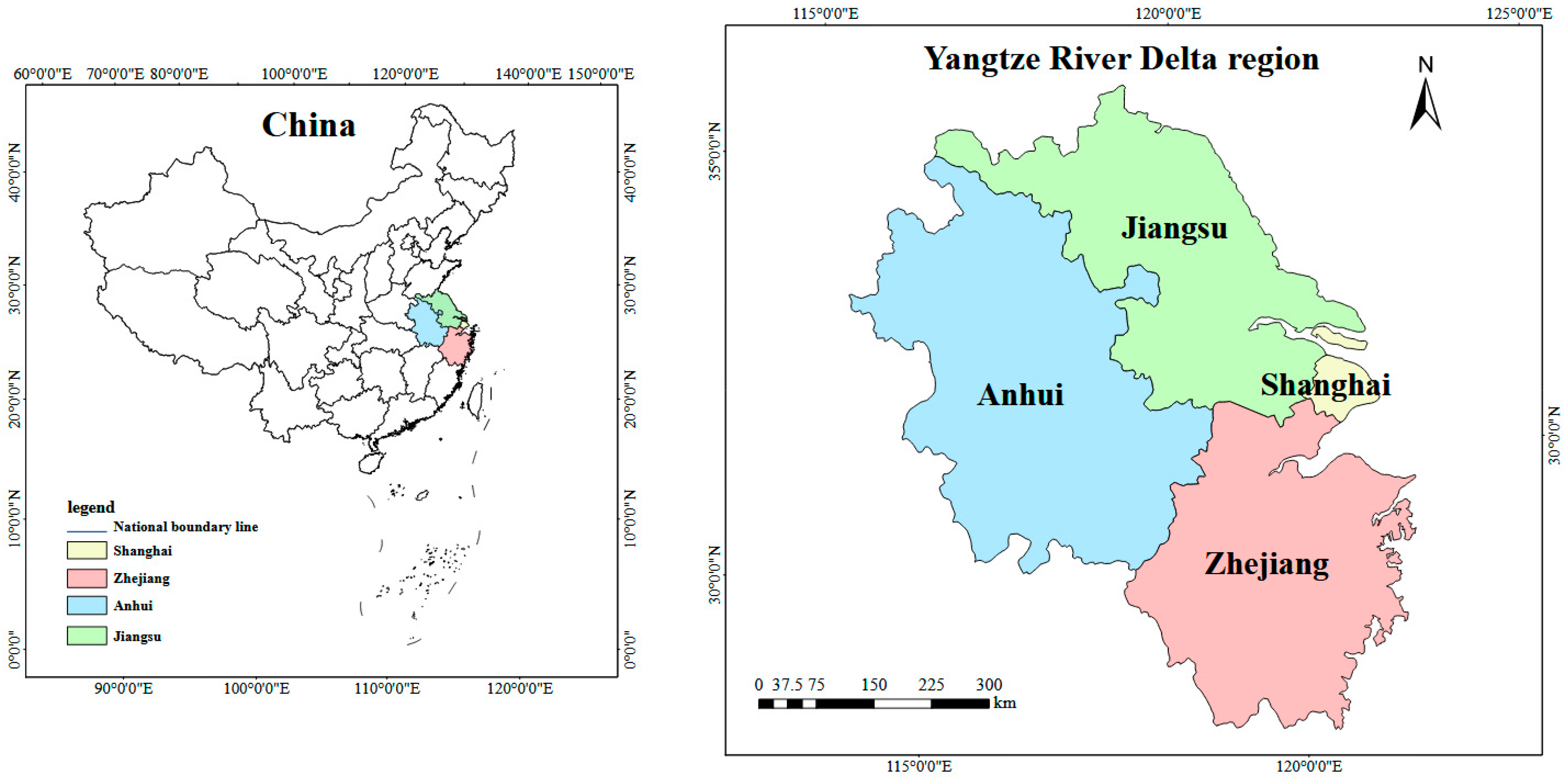

2.1. Study Area and Data Sources

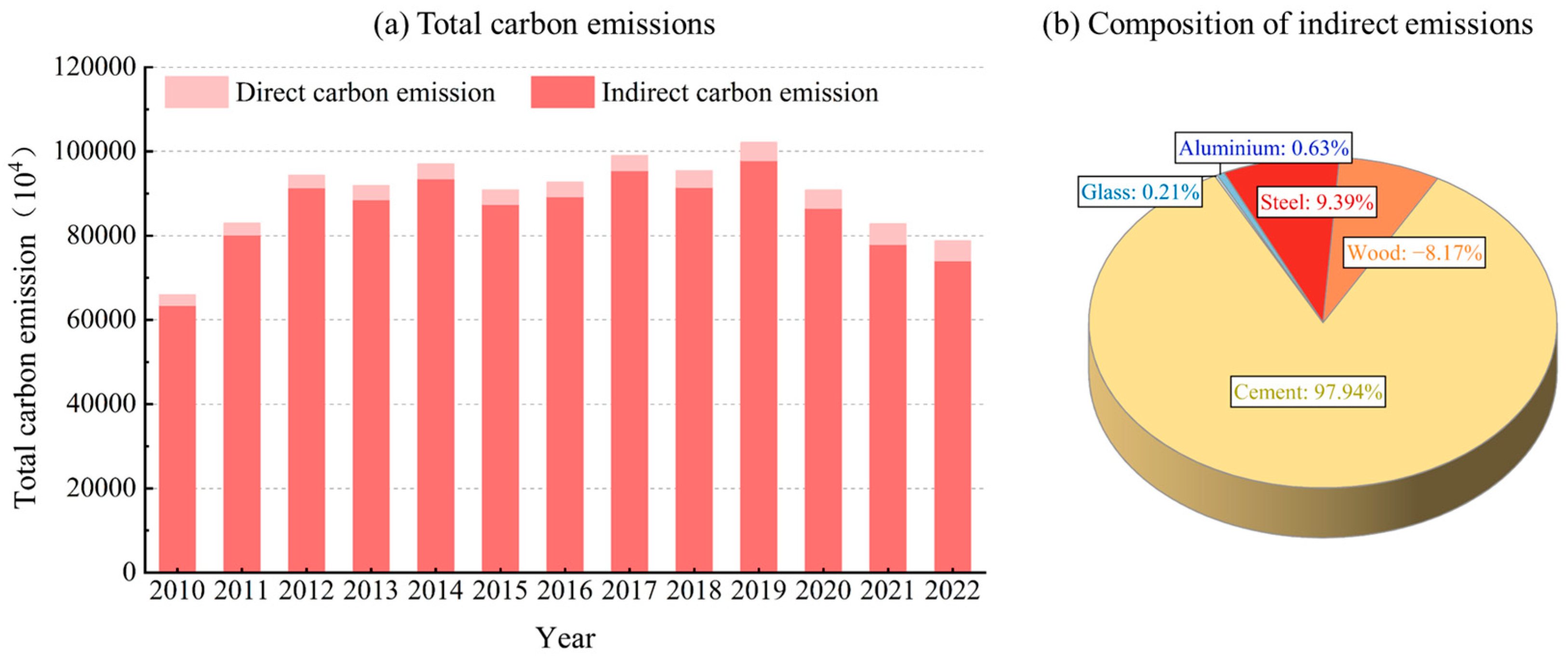

2.2. Carbon Emission Assessment in the Construction Industry

2.3. Evaluation Methodology for Low-Carbon Development in the Construction Industry

2.3.1. Construction of the Evaluation Indicator System

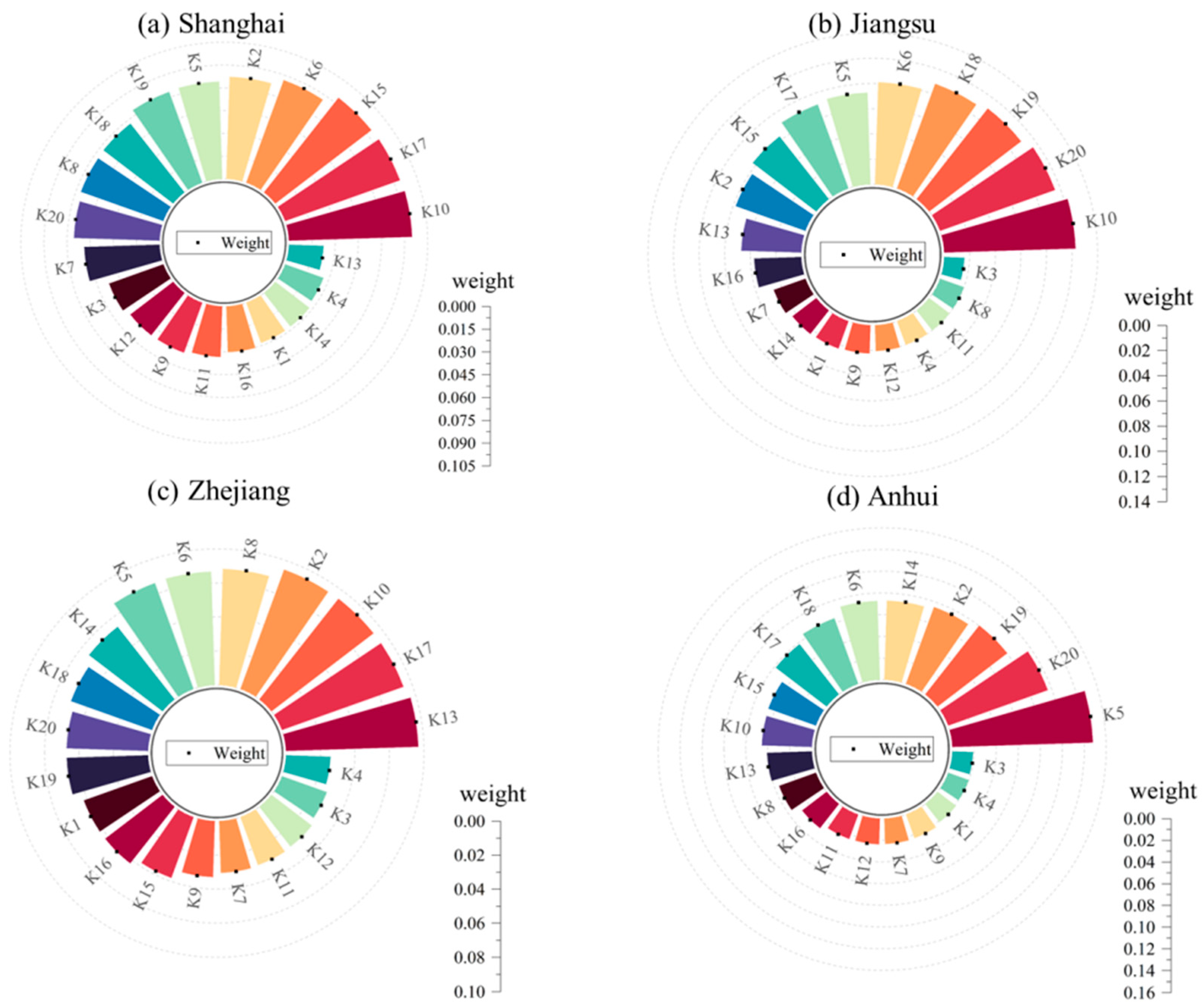

2.3.2. CRITIC-TOPSIS Evaluation Model

2.4. Diagnostic Model for Barriers to Low-Carbon Development

2.5. Low-Carbon Development Potential Forecasting Model

3. Results and Discussion

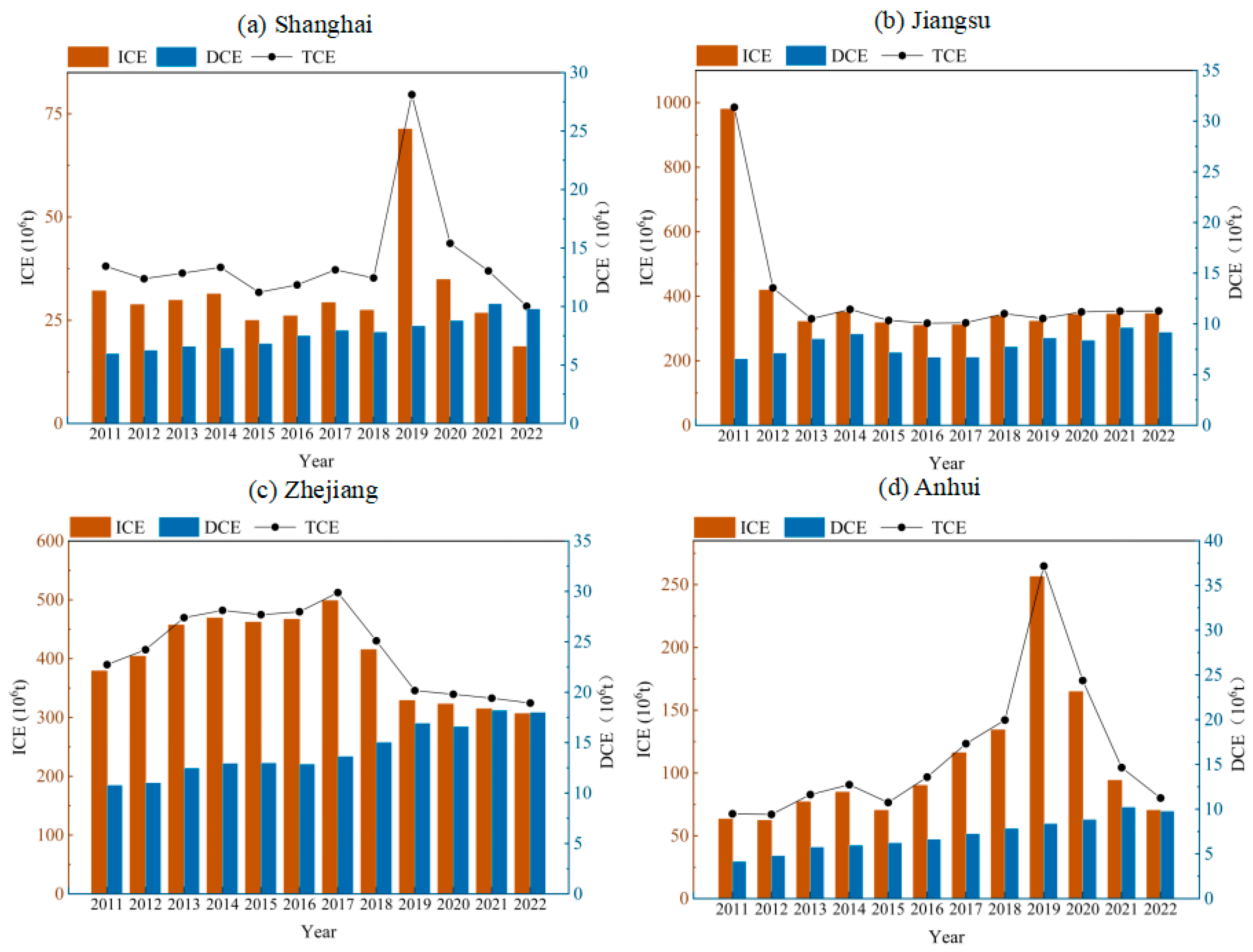

3.1. Characteristics of Carbon Emission Changes

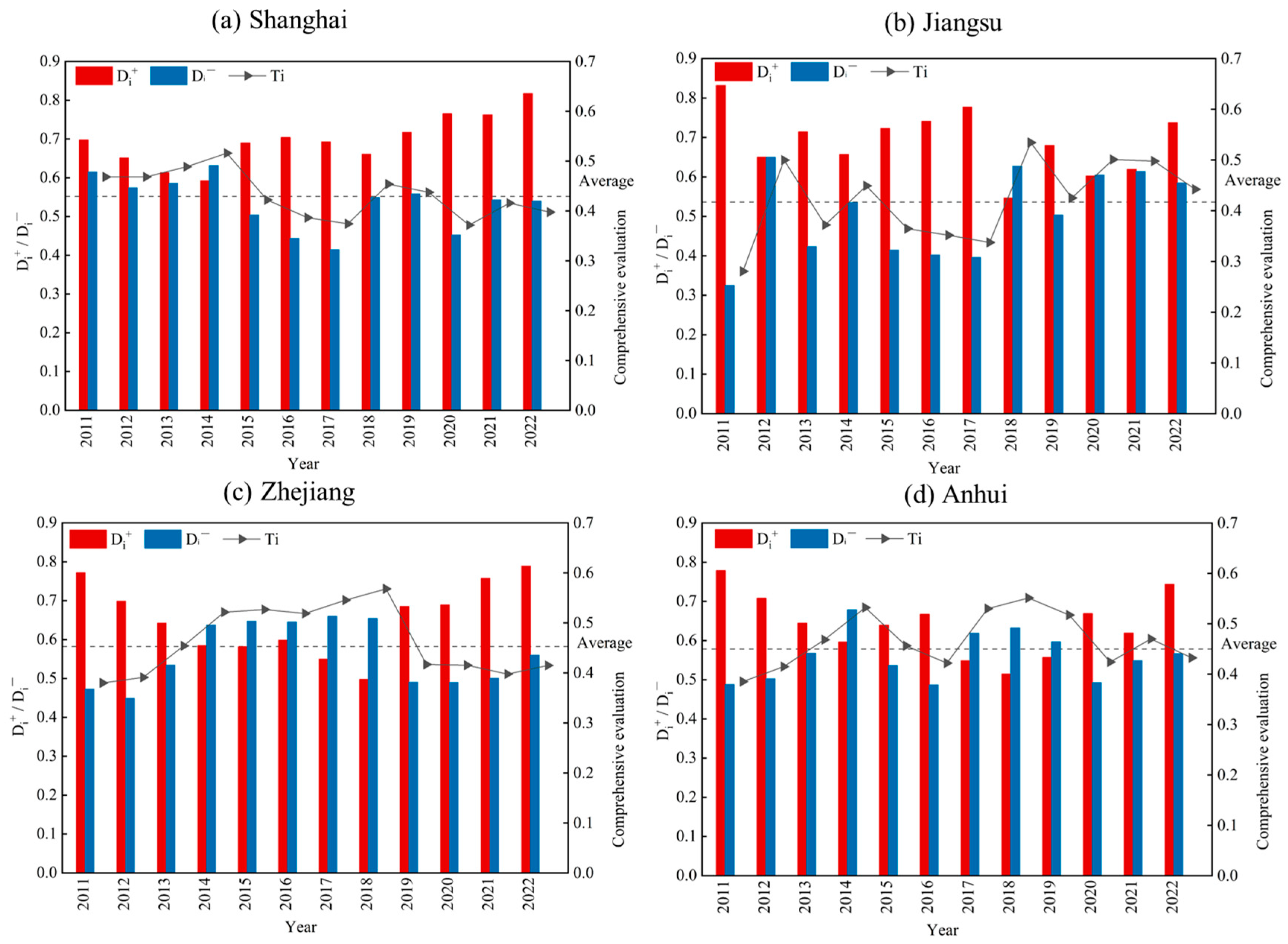

3.2. Low-Carbon Development Evaluation

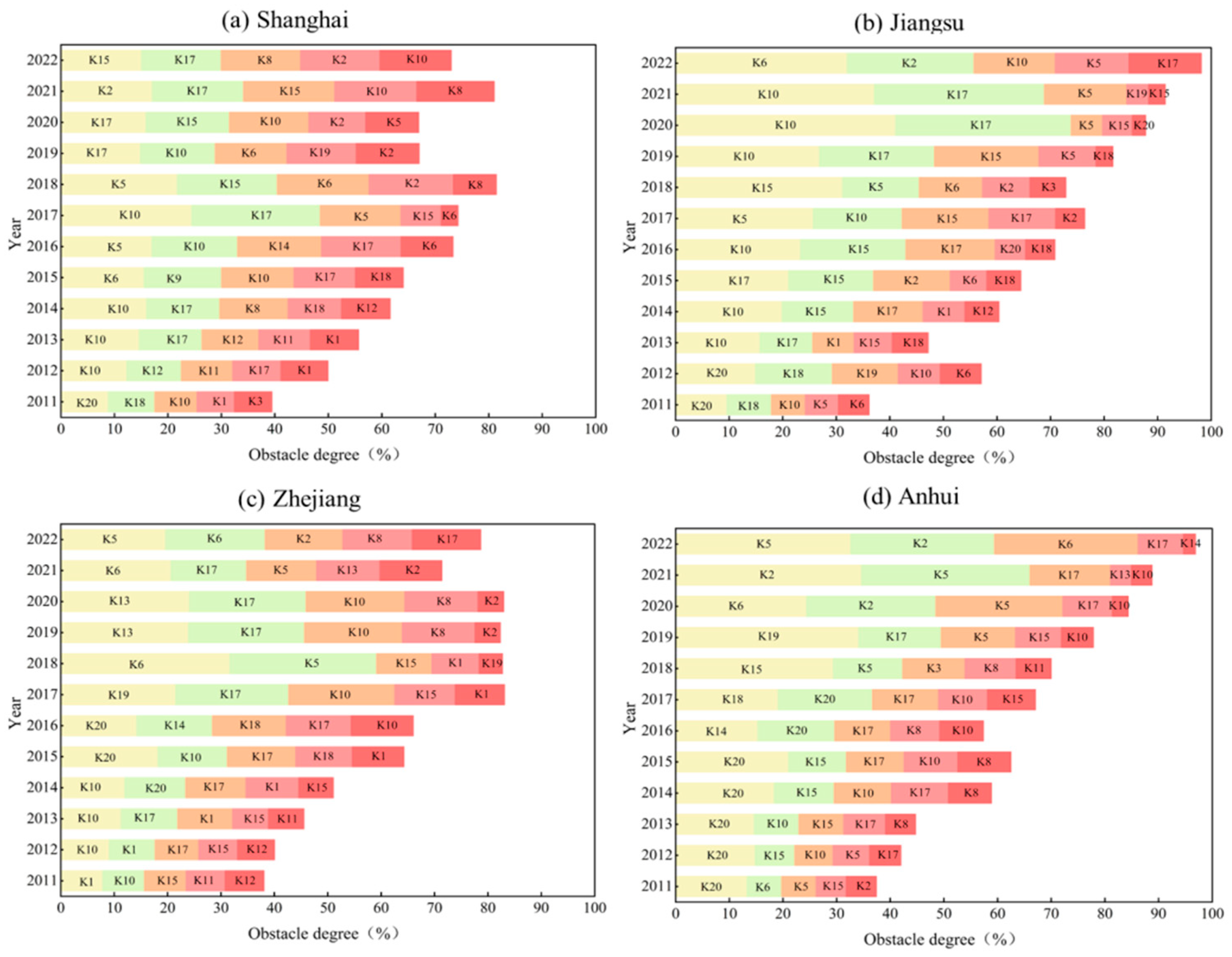

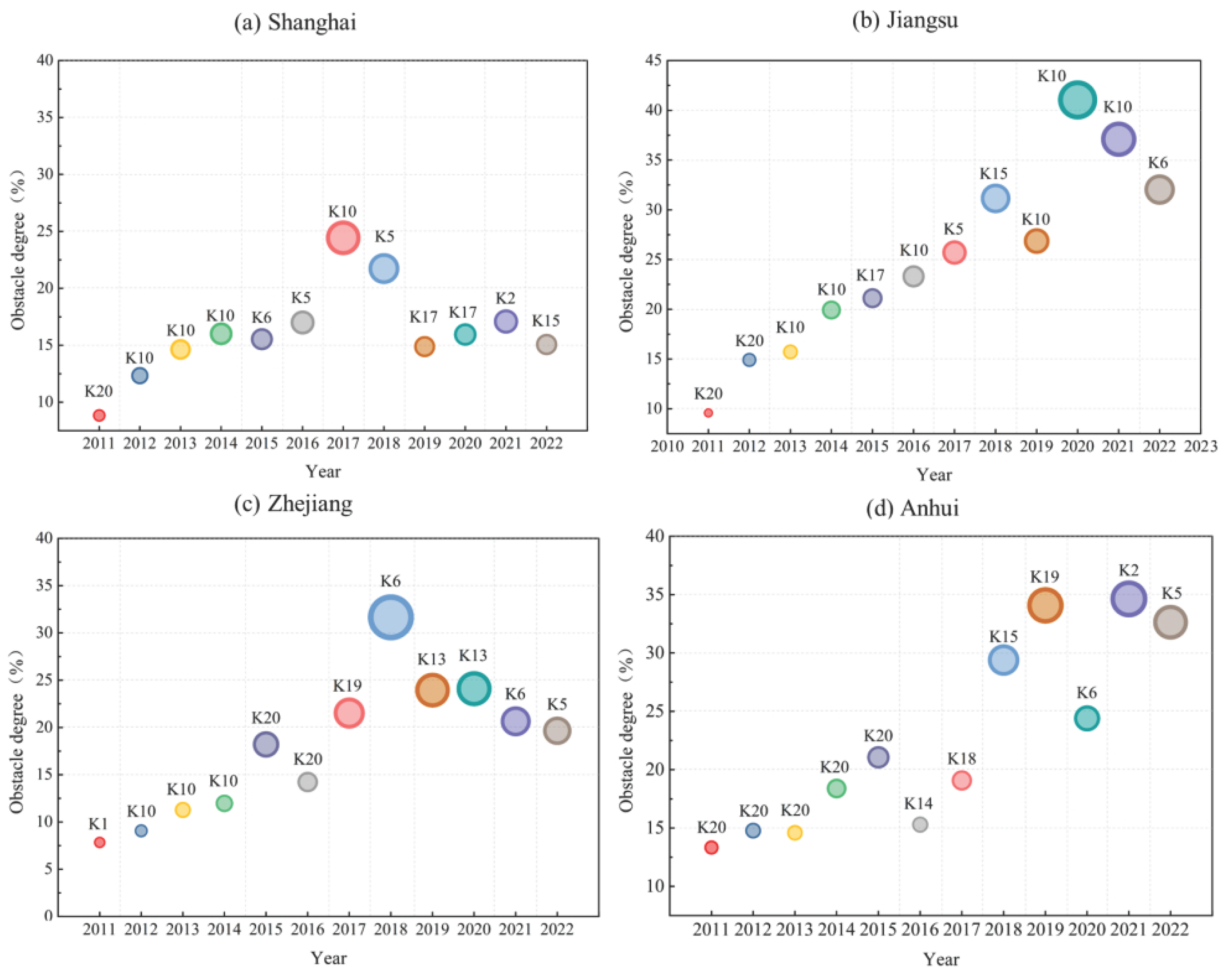

3.3. Analysis of Obstacle Factors in the Low-Carbon Development of the Construction Industry

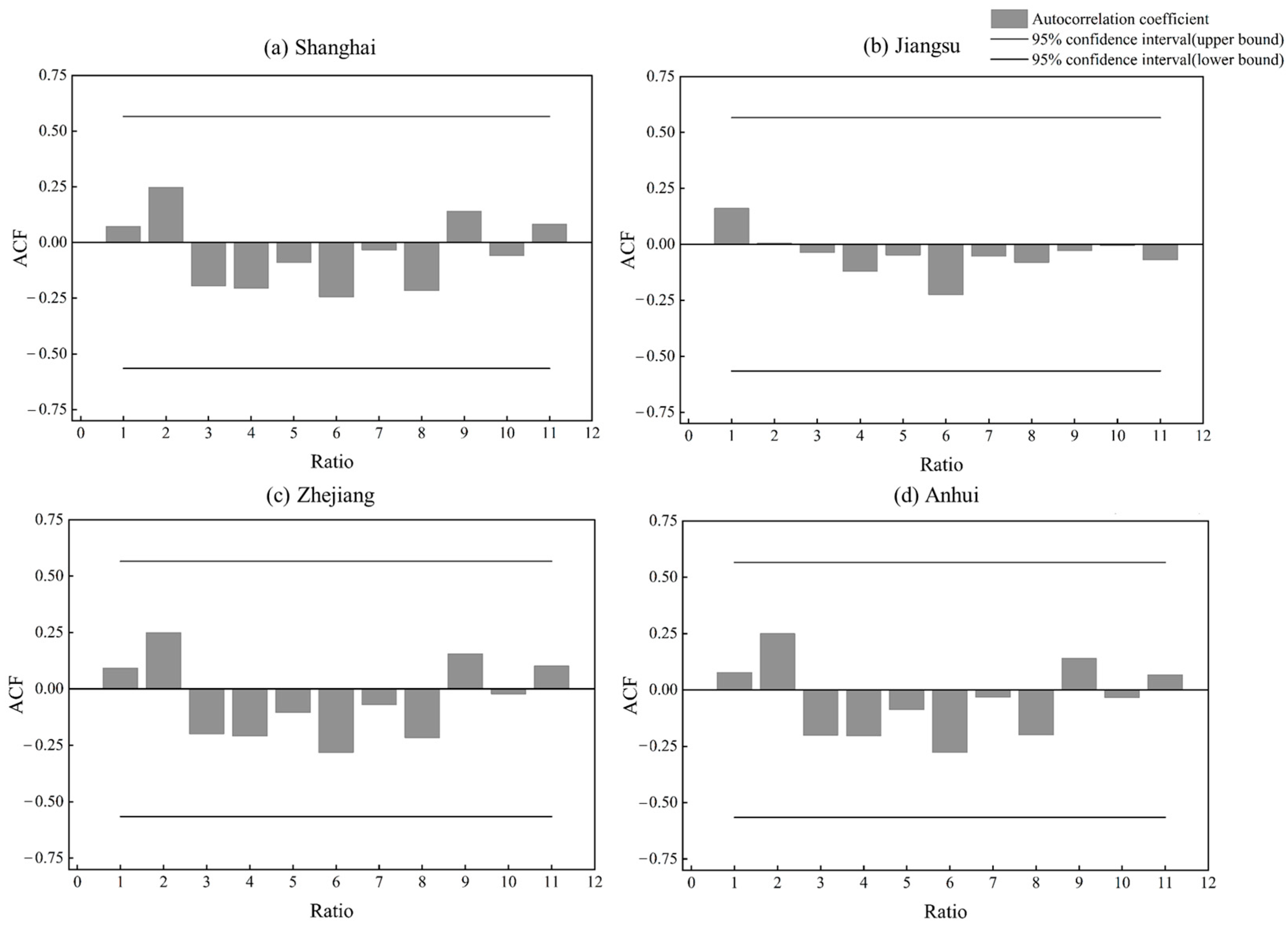

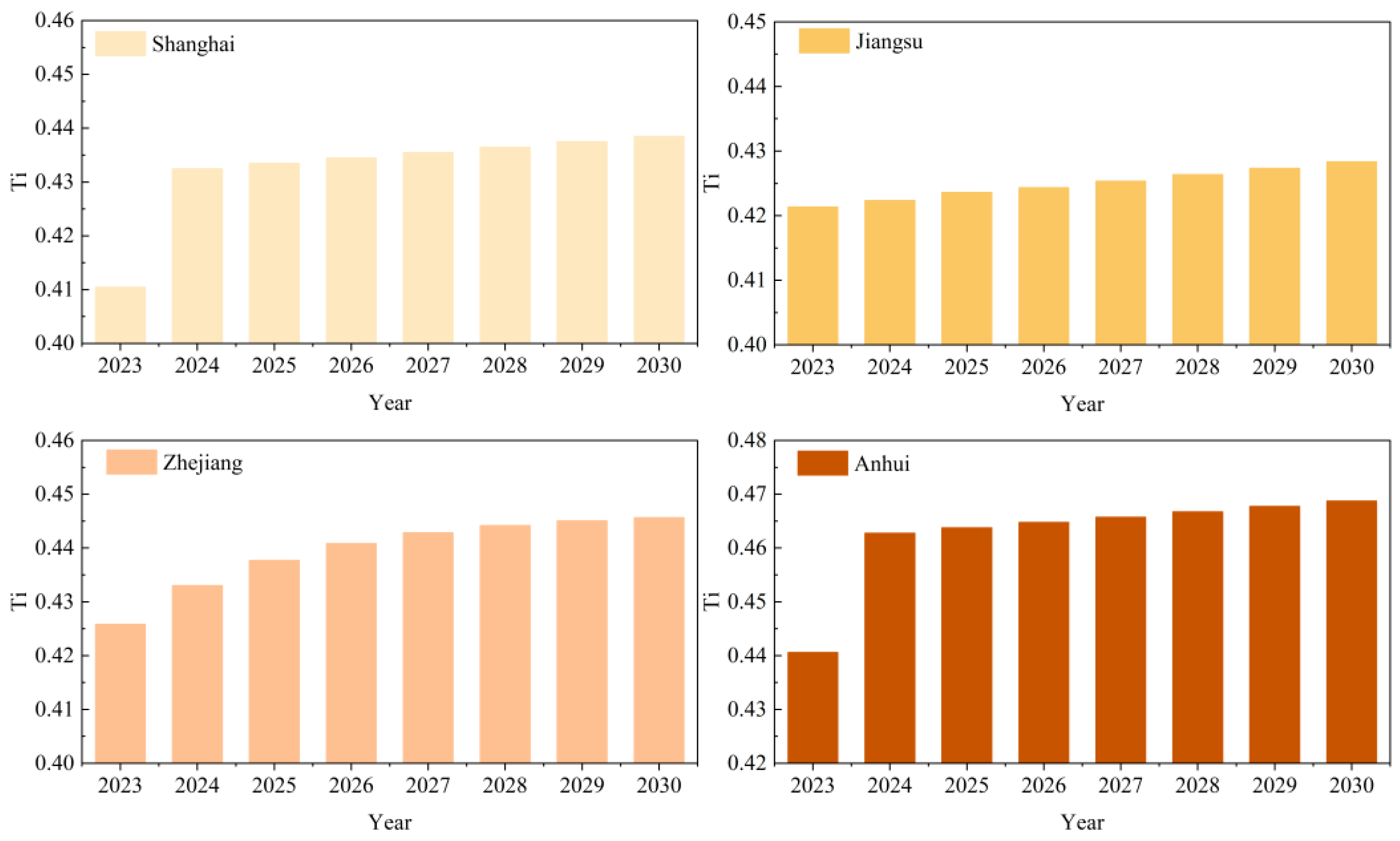

3.4. Trend Forecasting of Low-Carbon Evaluation Drivers in the Construction Industry

4. Conclusions

5. Policy Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lyu, L.; Fang, L. A study on EC translation of BP statistical review of world energy 2022 from the perspective of schema theory. J. Linguist. Commun. Stud. 2023, 2, 10–14. [Google Scholar] [CrossRef]

- Sun, G.; Liu, Y.; Li, B.; Guo, L. Road to sustainable development of China: The pursuit of coordinated development between carbon emissions and the green economy. J. Clean. Prod. 2024, 434, 139833. [Google Scholar] [CrossRef]

- Liu, J.B.; Yuan, X.Y.; Lee, C.C. Prediction of carbon emissions in China’s construction industry using an improved grey prediction model. Sci. Total Environ. 2024, 938, 173351. [Google Scholar] [CrossRef]

- Song, M.; Wang, Y.; Wang, C.; Musakwa, W.; Ji, Y. Spatial and Temporal Characteristics of Carbon Emissions from Construction Industry in China from 2010 to 2019. Sustainability 2024, 16, 5927. [Google Scholar] [CrossRef]

- Liu, Y.; Gan, L.; Cai, W.; Li, R. Decomposition and decoupling analysis of carbon emissions in China’s construction industry using the generalized Divisia index method. Environ. Impact Assess. Rev. 2024, 104, 107321. [Google Scholar] [CrossRef]

- He, J.; Qiao, L. Low Carbon Innovation: The Construction of Green Patent Pools in Guangdong-Hong Kong-Macao Greater Bay Area. IOP Conf. Ser. Earth Environ. Sci. 2020, 529, 012015. [Google Scholar] [CrossRef]

- Chen, L.; Huang, L.; Hua, J.; Chen, Z.; Wei, L.; Osman, A.I.; Yap, P.S. Green construction for low-carbon cities: A review. Environ. Chem. Lett. 2023, 21, 1627–1657. [Google Scholar] [CrossRef]

- Wang, W.Z.; Shang, X.Y.; Guo, J.; Skibniewski, M.J.; Chen, Z.S. Unveiling the impact of digital transformation on carbon emissions: Evidence from China’s construction enterprises. Enterp. Inf. Syst. 2024, 18, 2437660. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Gao, P.; Li, C. Construction and Application of Carbon Performance Evaluation Index System for Chinese Industrial Enterprises From the Perspective of Low-Carbon Transition. J. Int. Dev. 2025, 37, 736–757. [Google Scholar] [CrossRef]

- Wei, H.; Jiao, Y.; Wang, Z.; Wang, W.; Zhang, T. Optimal retrofitting scenarios of multi-objective energy-efficient historic building under different national goals integrating energy simulation, reduced order modelling and NSGA-II algorithm. Build. Simul. 2024, 17, 933–954. [Google Scholar] [CrossRef]

- Oke, A.E.; Oyediran, A.O.; Koriko, G.; Tang, L.M. Carbon trading practices adoption for sustainable construction: A study of the barriers in a developing country. Sustain. Dev. 2024, 32, 1120–1136. [Google Scholar] [CrossRef]

- Shen, Z.; Min, H.; Wang, L.; Zhang, Y. Evaluation of Carbon Neutrality Capacity of Regional Construction Industry Based on the Entropy Weight TOPSIS Model. Buildings 2024, 14, 2363. [Google Scholar] [CrossRef]

- Kong, X.; Feng, Z. Evaluation Study on the Level of High-Quality Development of the Construction Industry in Henan Province of China. Open J. Appl. Sci. 2023, 13, 366–382. [Google Scholar] [CrossRef]

- Naik, M.G.; Kishore, R.; Dehmourdi, S.A.M. Modeling a multi-criteria decision support system for prequalification assessment of construction contractors using CRITIC and EDAS models. Oper. Res. Eng. Sci. Theory Appl. 2021, 4, 79–101. [Google Scholar] [CrossRef]

- Lederer, L.; Ellingerová, H.; Ďubek, S.; Bočkaj, J.; Ďubek, M. Construction Price Forecasting Models in the Construction Industry: A Comparative Analysis. Buildings 2024, 14, 1325. [Google Scholar] [CrossRef]

- Pourrahimian, E.; Al Hattab, M.; Khalife, S.; ElMenshawy, M.; AbouRizk, S. Using Simulation-Based Forecasting to Project Singapore’s Future Residential Construction Demand and Impacts on Sustainability. In Proceedings of the 2022 Winter Simulation Conference (WSC), Singapore, 11–14 December 2022; pp. 843–854. [Google Scholar]

- Yang, J.; Li, G.; Zhong, Z.; Li, Q.; Du, G.; Guo, J. Current situation, bottlenecks, and path options for the development of capital flows and integration in the Yangtze River Delta region. Front. Sustain. Cities 2023, 5, 1100685. [Google Scholar] [CrossRef]

- Oh, H.; Yoon, H.; Park, S.; Kim, Y.; Choi, B.; Sun, W.; Jeong, H. Estimation of CO2 storage capacities in saline aquifers using material balance. Fuel 2024, 374, 132411. [Google Scholar] [CrossRef]

- Osei-Yeboah, M.; Grabovsky, V.I.; Agam, N.; Gelfand, I. Water and nitrogen availability define emissions of carbon dioxide and nitrogen oxides from desert soil differently. Soil Biol. Biochem. 2024, 195, 109460. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, D. A prediction method of regional carbon emission peak based on energy consumption elasticity coefficient. Int. J. Glob. Energy Issues 2024, 46, 678–692. [Google Scholar] [CrossRef]

- Cheng, M.; Lu, Y.; Zhu, H.; Xiao, J. Measuring CO2 emissions performance of China’s construction industry: A global Malmquist index analysis. Environ. Impact Assess. Rev. 2022, 92, 106673. [Google Scholar] [CrossRef]

- Xian, Y.; Wang, H.; Zhang, Z.; Yang, Y.; Zhong, Y. Driving factors and reduction paths dynamic simulation optimization of carbon dioxide emissions in China’s construction industry under the perspective of dual carbon targets. Environ. Impact Assess. Rev. 2025, 112, 107789. [Google Scholar] [CrossRef]

- Paschalidis, I.C.; Li, K.; Estanjini, R.M. An actor-critic method using least squares temporal difference learning. In Proceedings of the 48h IEEE Conference on Decision and Control (CDC) held jointly with 2009 28th Chinese Control Conference, Shanghai, China, 15–18 December 2009; pp. 2564–2569. [Google Scholar]

- Fojtíková, L.; Vavrek, R.; Doleželová, P. Road of the least developed countries to sustainable development: Assessing trade participation in the context of the sustainable development goals. Sustain. Dev. 2023, 31, 2492–2506. [Google Scholar] [CrossRef]

- Yu, H.; Gao, Y.; Yang, L.; Liu, F.; Gao, X.; Tan, Q. Knowledge reasoning of transmission line component detection using CRITIC and TOPSIS approaches. Soft Comput. 2023, 27, 991–1004. [Google Scholar] [CrossRef]

- LLiu, W.; Li, L.; He, X.; Lv, G. Evaluation of soil quality and analysis of barriers of protection forests along Tarim Desert highway based on a minimum data set. Land 2024, 13, 498. [Google Scholar] [CrossRef]

- Duran, H.E. The future of regional inequalities: An ARIMA forecast. Lett. Spat. Resour. Sci. 2024, 17, 16. [Google Scholar] [CrossRef]

- Kimura, T.; Goto, T.; Shintani, H.; Ishizaka, K.; Arima, T.H.; Tokura, Y. Magnetic control of ferroelectric polarization. Nature 2003, 426, 55–58. [Google Scholar] [CrossRef]

- Opoku, A. Construction industry and the sustainable development goals (SDGs). In Research Companion to Construction Economics; Edward Elgar Publishing: Northampton, MA, USA, 2022; pp. 199–214. [Google Scholar]

- Miao, H.; Quan, Q.; Yang, M. Study on the Regional Carbon Emissions Reduction Effect of Green Manufacturing—A Policy Experiment Based on the Construction of Green Parks in China. Sustainability 2025, 17, 1527. [Google Scholar] [CrossRef]

- Mu, J.; Wang, J.; Liu, B.; Yang, M. Spatiotemporal dynamics and influencing factors of CO2 emissions under regional collaboration: Evidence from the Beijing-Tianjin-Hebei region in China. Environ. Pollut. 2024, 357, 124403. [Google Scholar] [CrossRef]

- Li, Z.; Tang, D. Pathways of the Digital Economy’s Impact on Green Total Factor Productivity in the Construction Industry. Sustainability 2024, 16, 11283. [Google Scholar] [CrossRef]

- Ni, G.; Fang, Y.; Niu, M.; Lv, L.; Song, C.; Wang, W. Spatial differences, dynamic evolution and influencing factors of China’s construction industry carbon emission efficiency. J. Clean. Prod. 2024, 448, 141593. [Google Scholar] [CrossRef]

- Chen, L.; Hu, Y.; Wang, R.; Li, X.; Chen, Z.; Hua, J.; Yap, P.S. Green building practices to integrate renewable energy in the construction sector: A review. Environ. Chem. Lett. 2024, 22, 751–784. [Google Scholar] [CrossRef]

- Li, H.; Sun, Y.; Zhang, J.; Liu, D.; Han, Z.; Li, Y. Critical uncertainty analysis of the application of new-generation digital technology in China’s construction industry—A study based on the LDA-DEMATEL-ISM improvement model. Appl. Sci. 2023, 14, 57. [Google Scholar] [CrossRef]

- Xue, L.; Li, C.R.; Jin, Y.M. An improved carbon emission calculation framework of precast concrete column in construction stage based on LCA. J. Chin. Inst. Eng. 2023, 46, 220–228. [Google Scholar] [CrossRef]

- Li, Q.; Chen, H.; Sharma, S.; Singh, R.; Abbas, M. Optimization countermeasures for high-quality development of green economy driven by environmental regulations, carbon emission reductions, and efficiency enhancements. Stoch. Environ. Res. Risk Assess. 2024, 38, 4169–4191. [Google Scholar] [CrossRef]

- Lan, X. Evaluation method for sustainable development of urban carbon ecological cobstruction based on super-efficiency data envelopment analysis (SE-DEA) model. Environ. Eng. Manag. J. (EEMJ) 2024, 23, 2455–2466. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, B.; Yang, Y.; Qin, B.; Wang, Z. Interprovincial inequality between economic benefit and carbon footprint: Perspective from China’s Construction industry. Environ. Impact Assess. Rev. 2024, 104, 107293. [Google Scholar] [CrossRef]

- Dong, H.; Liu, S.; Pang, L.; Liu, D.; Deng, L.; Fang, L.; Zhang, Z. A debris-flow forecasting method with infrasound-based variational mode decomposition and ARIMA. J. Mt. Sci. 2024, 21, 4019–4032. [Google Scholar] [CrossRef]

- Zhang, C.; Lian, J.; Min, H.; Li, M. Shanghai as a Model: Research on the Journey of Transportation Electrification and Charging Infrastructure Development. Sustainability 2024, 17, 91. [Google Scholar] [CrossRef]

| Type of Energy | Conversion Factor for Standard Coal (kgce/kg) | Carbon Emission Factor (kgCO2/kgce) |

|---|---|---|

| Raw coal | 0.7143 | 0.7559 |

| Petrol | 1.4714 | 0.5538 |

| Paraffin | 1.4714 | 0.5714 |

| Diesel oil | 1.4571 | 0.5921 |

| Fuel oil | 1.4286 | 0.6185 |

| Liquefied petroleum gas | 1.7143 | 0.5042 |

| Natural gas | 1.3300 | 0.4483 |

| Electricity | 0.1229 | 0.2900 |

| Building Material | Cement | Glass | Steel | Aluminum | Wood |

|---|---|---|---|---|---|

| Carbon emission factor | 0.815 kg/kg | 0.9655 kg/kg | 1.789 kg/kg | 2.6 kg/kg | −842.8 kg/m3 |

| Recovery factor | - | 0.7 | 0.8 | 0.85 | 0.2 |

| Target Layer | First Indicators | Secondary Indicators | Indicator Characterization | Indicator Properties | Indicator |

|---|---|---|---|---|---|

| Evaluation of low-carbon development in the construction industry | Technological driver | Patents for inventions | Measuring regional innovation capacity in science and technology | Positive | K1 |

| Total power of construction machinery and equipment owned by the end of the year | Measuring mechanical construction production capacity in the building industry | Positive | K2 | ||

| Research and Experimental Development (R&D) institution personnel | Measuring the ability to transform regional scientific research results | Positive | K3 | ||

| R&D expenditure | Measuring the strength of regional investment in science and technology innovation | Positive | K4 | ||

| Technical equipment rate | Measuring the technological level and productivity of the construction industry in the region | Positive | K5 | ||

| Power equipment rate | Measuring the ability to provide construction machinery in the construction industry | Positive | K6 | ||

| Social driver | Year-end resident population | Regional population distribution | Positive | K7 | |

| Employment in construction enterprises | People working in the construction industry in the region | Positive | K8 | ||

| Urbanization rate | Rural and urban distribution of the resident population in the region | Positive | K9 | ||

| Economic driver | Gross output value of the construction industry | Regional economic income capacity of the construction industry | Positive | K10 | |

| Gross regional product | Regional economic situation and development level | Positive | K11 | ||

| GDP per capita | Living standard of people in the region | Positive | K12 | ||

| Industrial driver | Completed floor space of residential buildings | Measurement of physical output capacity of the construction industry | Positive | K13 | |

| Industrial scale | Measures the ratio of gross output value to the number of enterprises in the construction industry | Positive | K14 | ||

| Number of construction enterprises | Measures the construction industry’s level of development over a period of time | Positive | K15 | ||

| Labor productivity in the construction industry | Measuring the production efficiency of enterprises in the construction industry | Positive | K16 | ||

| Industrial structure | Measuring the ratio of the gross output value of the construction industry to the gross regional product | Positive | K17 | ||

| Energy driver | Energy consumption in the construction industry | Regional energy consumption in the construction sector | Negative | K18 | |

| Carbon dioxide emissions | Carbon intensity of an industry in the region | Negative | K19 | ||

| Energy intensity | Ratio of energy consumption to economic output in the regional construction industry | Negative | K20 |

| Target Layer | First Indicators | Indicator Weights Under the System | Secondary Indicators | Indicator | Combined Weights |

|---|---|---|---|---|---|

| Evaluation of low-carbon development in the construction industry | Technological driver | 0.0951 | Patents for inventions | K1 | 0.0287 |

| 0.2282 | Total power of construction machinery and equipment owned by the end of the year | K2 | 0.0688 | ||

| 0.0831 | Research and Experimental Development (R&D) institution personnel | K3 | 0.0251 | ||

| 0.0768 | R&D expenditure | K4 | 0.0232 | ||

| 0.2745 | Technical equipment rate | K5 | 0.0828 | ||

| 0.2423 | Power equipment rate | K6 | 0.0731 | ||

| Social driver | 0.3047 | Year-end resident population | K7 | 0.0323 | |

| 0.4269 | Employment in construction enterprises | K8 | 0.0452 | ||

| 0.2684 | Urbanization rate | K9 | 0.0284 | ||

| Economic driver | 0.5831 | Gross output value of the construction industry | K10 | 0.0758 | |

| 0.2069 | Gross regional product | K11 | 0.0269 | ||

| 0.2101 | GDP per capita | K12 | 0.0273 | ||

| Industrial driver | 0.1848 | Completed floor space of residential buildings | K13 | 0.0468 | |

| 0.1764 | Industrial scale | K14 | 0.0447 | ||

| 0.2231 | Number of construction enterprises | K15 | 0.0565 | ||

| 0.1357 | Labor productivity in the construction industry | K16 | 0.0344 | ||

| 0.2800 | Industrial structure | K17 | 0.0709 | ||

| Energy driver | 0.3106 | Energy consumption in the construction industry | K18 | 0.0650 | |

| 0.3370 | Carbon dioxide emissions | K19 | 0.0705 | ||

| 0.3524 | Energy intensity | K20 | 0.0737 |

| Region | Information Guidelines | Goodness of Fit | |

|---|---|---|---|

| AIC | BIC | R2 | |

| Shanghai | −56.800 | −54.861 | 0.796 |

| Jiangsu | −54.728 | −52.789 | 0.805 |

| Zhejiang | −56.903 | −54.963 | 0.800 |

| Anhui | −57.323 | −55.383 | 0.798 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Zhang, Y.; Yu, G.; Sun, J.; Liu, J.; Wang, Y.; Yu, Y. Evaluation of Low-Carbon Development in the Construction Industry and Forecast of Trends: A Case Study of the Yangtze River Delta Region. Sustainability 2025, 17, 5435. https://doi.org/10.3390/su17125435

Li M, Zhang Y, Yu G, Sun J, Liu J, Wang Y, Yu Y. Evaluation of Low-Carbon Development in the Construction Industry and Forecast of Trends: A Case Study of the Yangtze River Delta Region. Sustainability. 2025; 17(12):5435. https://doi.org/10.3390/su17125435

Chicago/Turabian StyleLi, Min, Yue Zhang, Gui Yu, Jiazhen Sun, Jie Liu, Yinsheng Wang, and Yang Yu. 2025. "Evaluation of Low-Carbon Development in the Construction Industry and Forecast of Trends: A Case Study of the Yangtze River Delta Region" Sustainability 17, no. 12: 5435. https://doi.org/10.3390/su17125435

APA StyleLi, M., Zhang, Y., Yu, G., Sun, J., Liu, J., Wang, Y., & Yu, Y. (2025). Evaluation of Low-Carbon Development in the Construction Industry and Forecast of Trends: A Case Study of the Yangtze River Delta Region. Sustainability, 17(12), 5435. https://doi.org/10.3390/su17125435