Innovative Wastewater Treatment Using 3D-Printed Clay Bricks Enhanced with Oyster Shell Powder: A Life Cycle Assessment

Abstract

1. Introduction

2. Materials and Methods

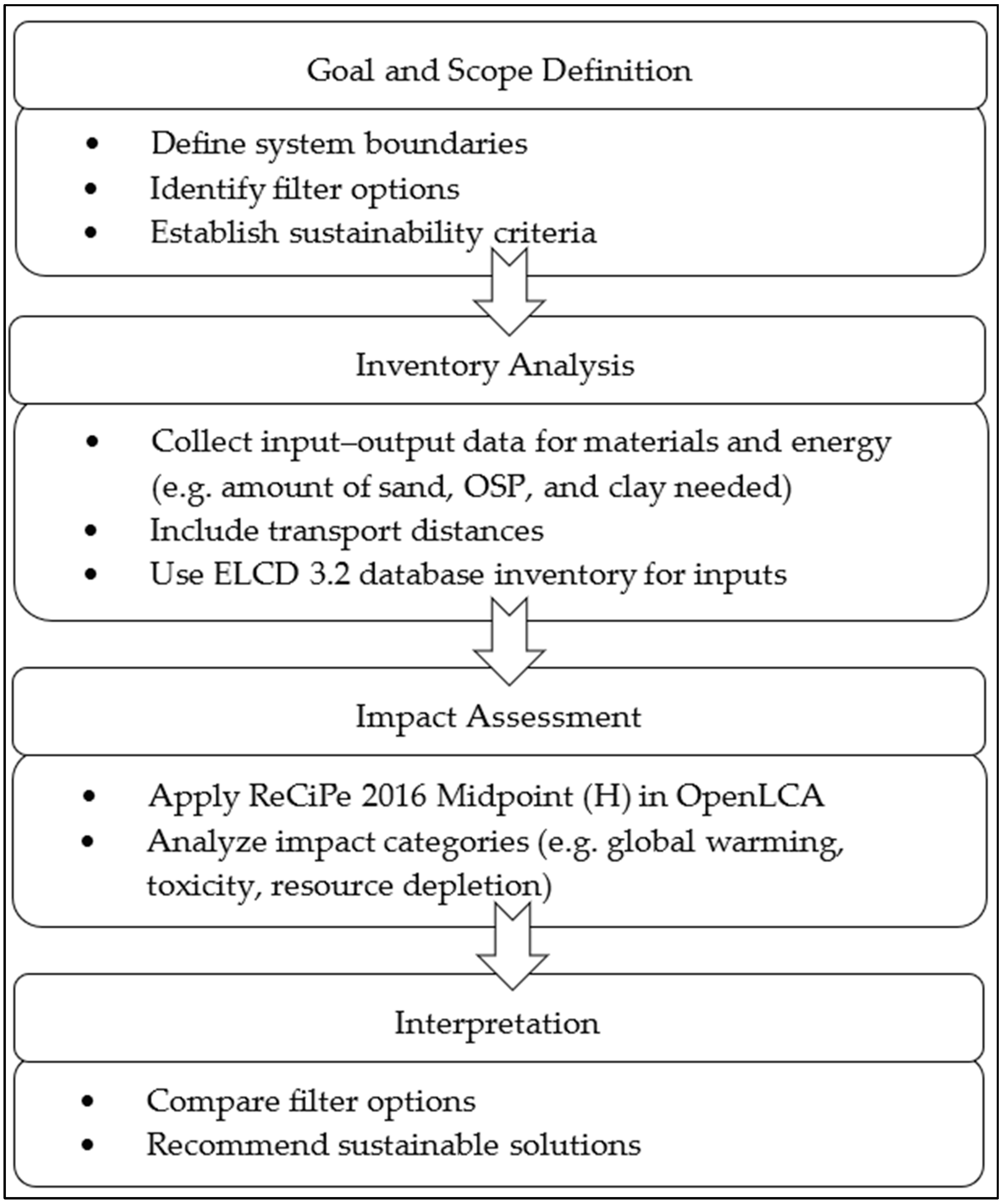

2.1. Life Cycle Assessment in Wastewater Treatment

2.2. Goal and Scope of the LCA

2.3. Functional Unit

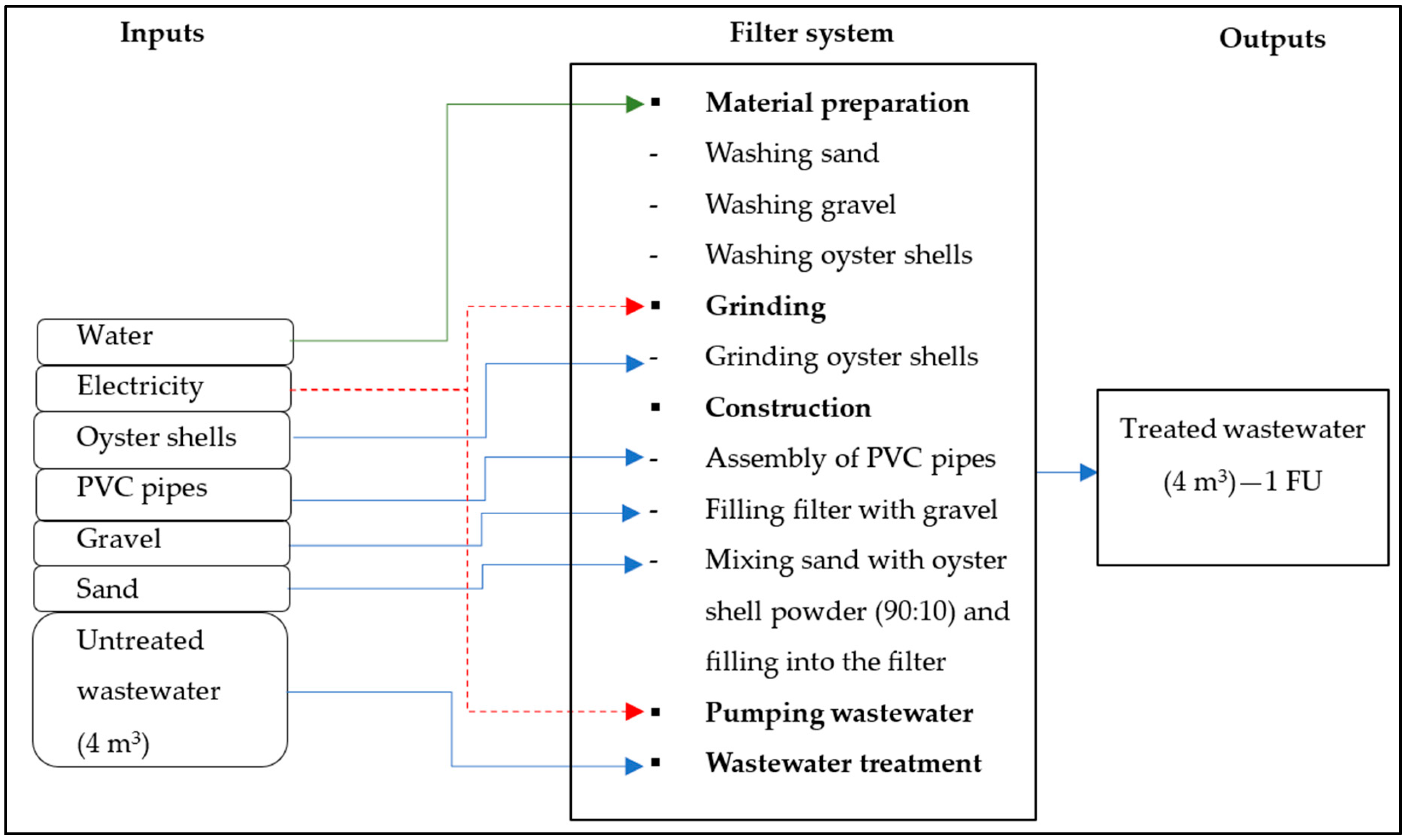

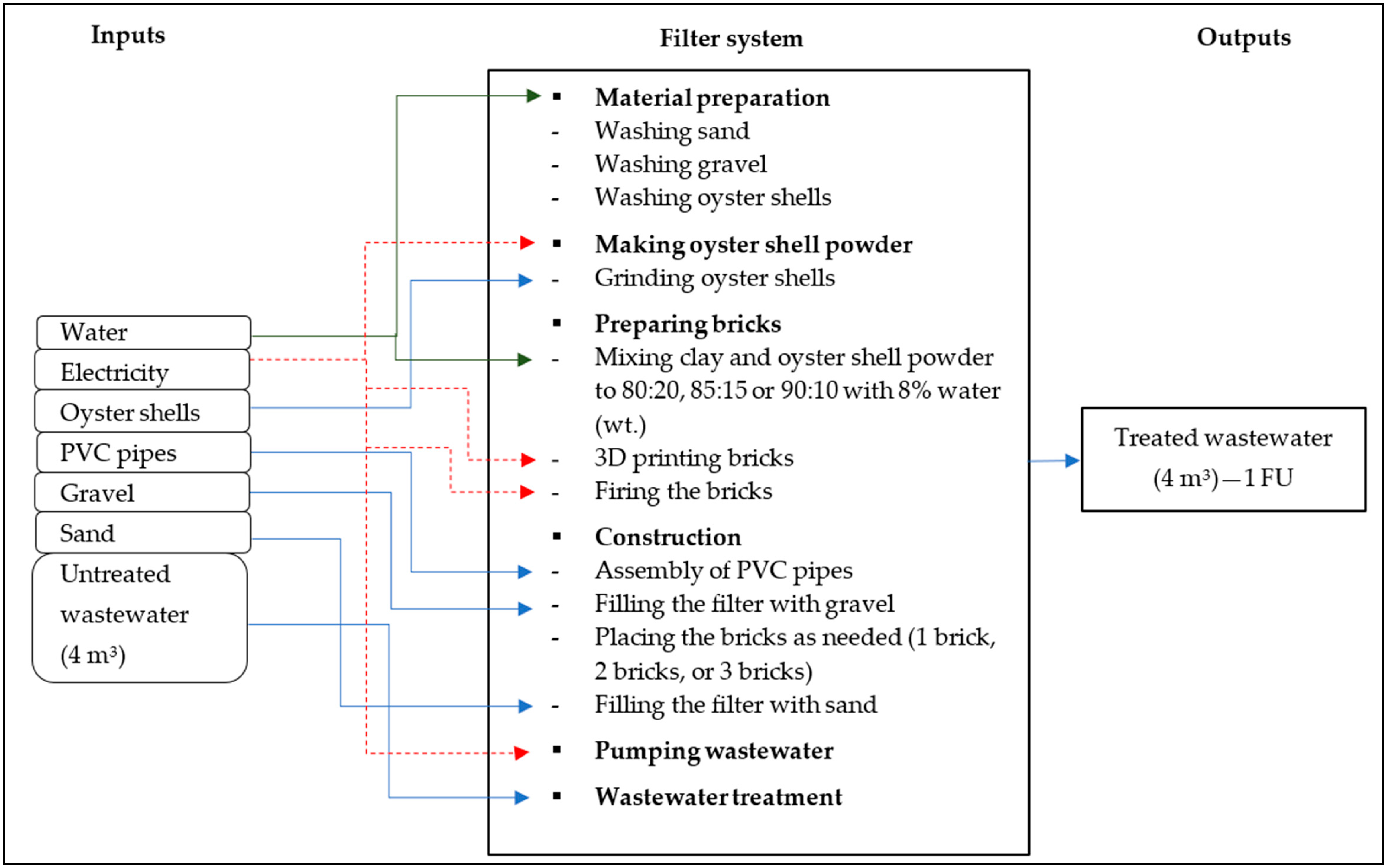

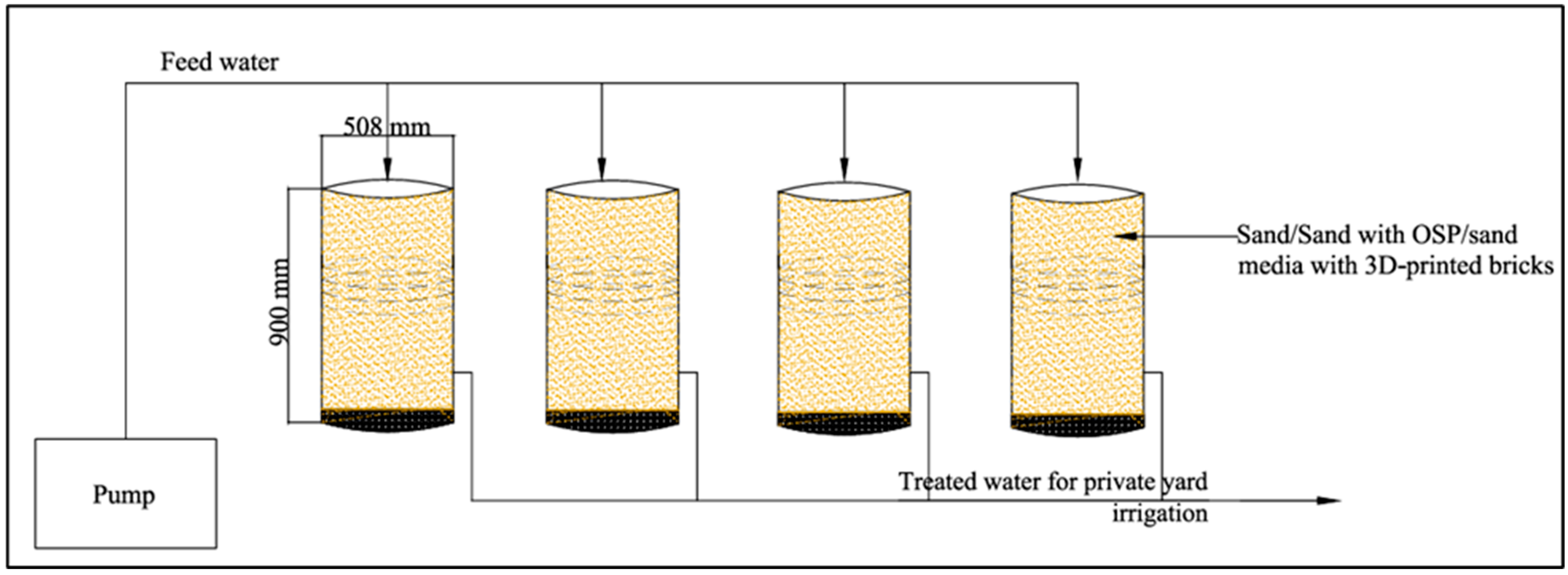

2.4. Product Systems and Its Components

2.4.1. System Boundaries

2.4.2. Calculation Procedure and Assumptions

2.5. Inventory Analysis and Data Collection

2.6. Environmental Metrics and Impact Assessment

2.7. Evaluating Economic Sustainability

3. Results and Discussion

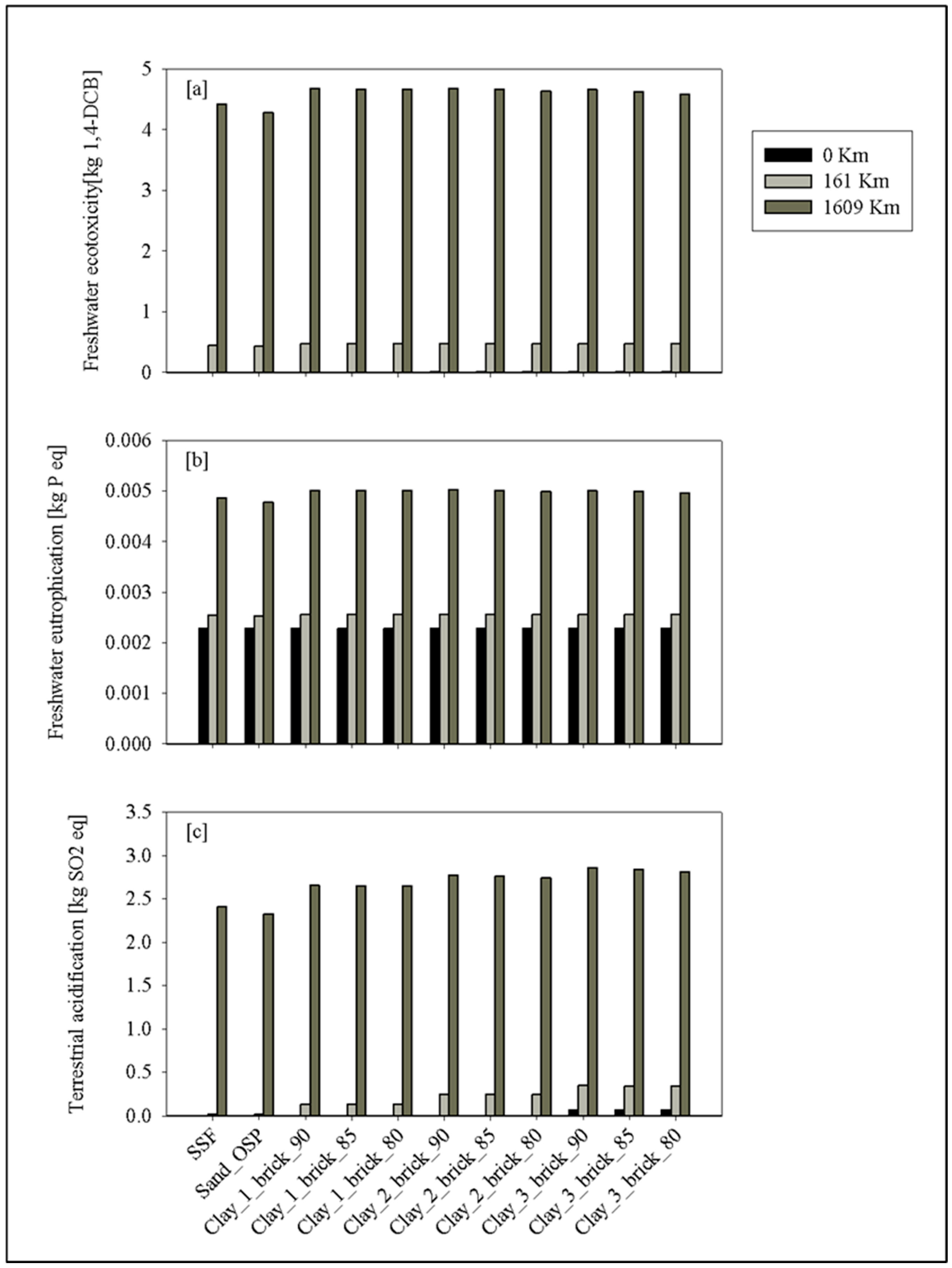

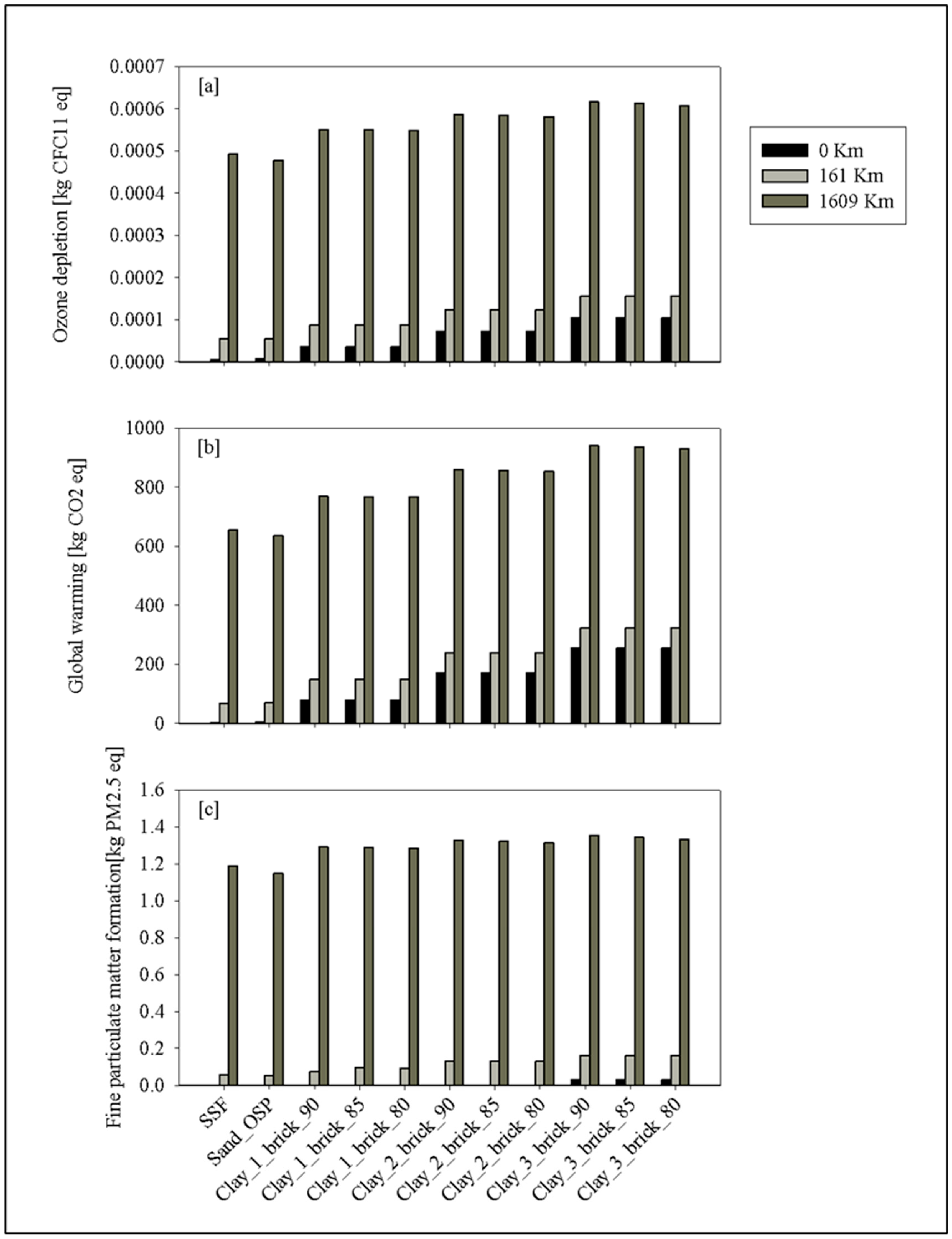

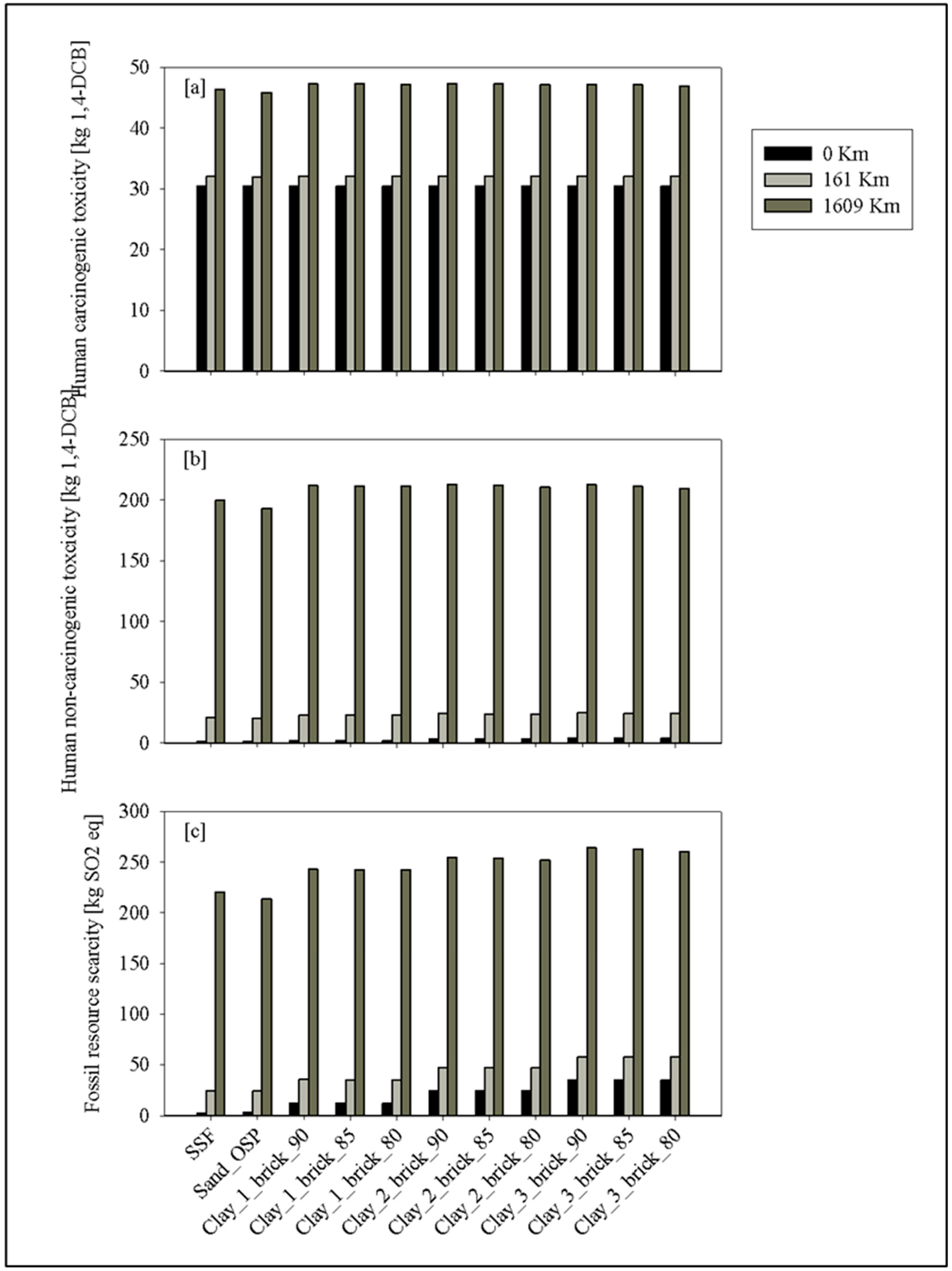

3.1. Environmental Impacts of the Selected Filtration Units

3.1.1. SSF

3.1.2. SSF with OSP

3.1.3. SSF with Bricks

3.2. Economic Sustainability

3.3. Filtration Performance: Basis for LCA

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EPA U.S. Basic Information about Water Reuse. 2023. Available online: https://www.epa.gov/waterreuse/basic-information-about-water-reuse#basics (accessed on 9 July 2023).

- Gebreeyesus, M.; Gwenzi, W.; Mwamila, T.B.; Noubactep, C. Mitigating freshwater supply shortages in regions of high demand in Ethiopia: Integrated water resources management approach. Environ. Earth Sci. 2025, 84, 99. [Google Scholar] [CrossRef]

- Gude, V.G. Desalination and water reuse to address global water scarcity. Rev. Environ. Sci. Bio/Technol. 2017, 16, 591–609. [Google Scholar] [CrossRef]

- Florides, F.; Giannakoudi, M.; Ioannou, G.; Lazaridou, D.; Lamprinidou, E.; Loukoutos, N.; Spyridou, M.; Tosounidis, E.; Xanthopoulou, M.; Katsoyiannis, I.A. Water Reuse: A Comprehensive Review. Environments 2024, 11, 81. [Google Scholar] [CrossRef]

- Pathiranage, W.B.; Bray, L.; Jones, K.; Redwine, N.; Saralvarez, J.; D’Alessio, M. Perception and acceptance towards water reuse in the Southeast United States: A public survey. Sci. Total Environ. 2024, 908, 168224. [Google Scholar] [CrossRef]

- Barman, S.; Gavit, P.; Chowdhury, S.; Chatterjee, K.; Nain, A. 3D-Printed Materials for Wastewater Treatment. JACS Au 2023, 3, 2930–2947. [Google Scholar] [CrossRef]

- Fijoł, N.; Aguilar-Sánchez, A.; Mathew, A.P. 3D-printable biopolymer-based materials for water treatment: A review. Chem. Eng. J. 2022, 430, 132964. [Google Scholar] [CrossRef]

- Pathiranage, W.B.; Sharp, C.; Hong, Y.; Williams, C.; Algharibeh, O.; McKnight, A.; Williams, C.; Alkhateb, H.; D’Alessio, M. Enhancing slow sand filtration with 3D-printed eco-friendly bricks. Clean. Water 2025, 3, 100061. [Google Scholar] [CrossRef]

- Pathiranage, W.B.; Sharp, C.; Williams, C.; McKnight, A.; Algharibeh, O.; Hong, Y.; Williams, C.; Rushing, G.; Alkhateb, H.; D’Alessio, M. Enhanced ability of 3D-printed bricks to treat wastewater under variable conditions. J. Environ. Manag. 2025, 386, 125690. [Google Scholar] [CrossRef]

- Ramjeawon, T. Introduction to Sustainability for Engineers; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Manda, B.K.; Worrell, E.; Patel, M.K. Innovative membrane filtration system for micropollutant removal from drinking water–prospective environmental LCA and its integration in business decisions. J. Clean. Prod. 2014, 72, 153–166. [Google Scholar] [CrossRef]

- Walsh, T.; Mellor, J. Comparative life cycle assessment of four commonly used point-of-use water treatment technologies. J. Water Sanit. Hyg. Dev. 2020, 10, 862–873. [Google Scholar] [CrossRef]

- Bové, J.; Pujol, J.; Arbat, G.; Duran-Ros, M.; de Cartagena, F.R.; Puig-Bargués, J. Environmental assessment of underdrain designs for a sand media filter. Biosyst. Eng. 2018, 167, 126–136. [Google Scholar] [CrossRef]

- Bhakar, V.; Kumar, D.H.; Sai, N.K.; Sangwan, K.S.; Raghuvanshi, S. Life cycle assessment of filtration systems of reverse osmosis units: A case study of a university campus. Procedia CIRP 2016, 40, 268–273. [Google Scholar] [CrossRef]

- Ortiz, M.; Raluy, R.; Serra, L. Life cycle assessment of water treatment technologies: Wastewater and water-reuse in a small town. Desalination 2007, 204, 121–131. [Google Scholar] [CrossRef]

- Yang, X.; Huang, G.; Zhang, P.; An, C.; Yao, Y.; Li, Y.; Zhou, S. Life cycle-based water footprint analysis of ceramic filter for point-of-use water purification in remote areas. Sci. Total Environ. 2021, 786, 147424. [Google Scholar] [CrossRef]

- Behjat, M.; Svanström, M.; Peters, G.; Wennberg, N. Life Cycle Assessment of recirculating aquaculture systems with innovative biochar filter for enhanced nutrient recirculation. Resour. Environ. Sustain. 2025, 21, 100233. [Google Scholar] [CrossRef]

- OpenLCA. 2007. Available online: https://www.openlca.org/ (accessed on 15 May 2025).

- Anang, S.; Nasr, M.; Fujii, M.; Ibrahim, M.G. Synergism of life cycle assessment and sustainable development goals techniques to evaluate downflow hanging sponge system treating low-carbon wastewater. Sustainability 2024, 16, 2035. [Google Scholar] [CrossRef]

- Allami, D.M.; Sorour, M.T.; Moustafa, M.; Elreedy, A.; Fayed, M. Life cycle assessment of a domestic wastewater treatment plant simulated with alternative operational designs. Sustainability 2023, 15, 9033. [Google Scholar] [CrossRef]

- Longo, S.; d’Antoni, B.M.; Bongards, M.; Chaparro, A.; Cronrath, A.; Fatone, F.; Lema, J.M.; Mauricio-Iglesias, M.; Soares, A.; Hospido, A. Monitoring and diagnosis of energy consumption in wastewater treatment plants. A state of the art and proposals for improvement. Appl. Energy 2016, 179, 1251–1268. [Google Scholar] [CrossRef]

- Sabeen, A.H.; Noor, Z.Z.; Ngadi, N.; Almuraisy, S.; Raheem, A.B. Quantification of environmental impacts of domestic wastewater treatment using life cycle assessment: A review. J. Clean. Prod. 2018, 190, 221–233. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Y.; Zhang, Z. An LCA-based environmental impact assessment model for construction processes. Build. Environ. 2010, 45, 766–775. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Rose Law Group Reporter. Stacking up Yard Sizes by State. 2018. Available online: https://roselawgroupreporter.com/2018/10/stacking-up-yard-sizes-by-state/#:~:text=The%20average%20residential%20lawn%20in,Share%20this! (accessed on 2 February 2025).

- Lipford, D.; Perry, C. How To Calculate Lawn Irrigation Water Usage and Costs. 2024. Available online: https://todayshomeowner.com/lawn-garden/guides/calculating-lawn-irrigation-costs/ (accessed on 1 March 2024).

- Partinoudi, V.; Collins, M.R.; Unger, M.; Dwyer, P. Integrating Biological Filtration Treatment Systems. 2006. Available online: https://www.unh.edu/wttac/Presentations/partinoudi_biological_filtration_treatment.pdf (accessed on 15 May 2025).

- The Engineering Tool Box. Densities of Common Products. 2010. Available online: https://www.engineeringtoolbox.com/density-materials-d_1652.html (accessed on 25 February 2025).

- The Engineering Tool Box. Dirt and Mud—Densities. 2010. Available online: https://www.engineeringtoolbox.com/dirt-mud-densities-d_1727.html (accessed on 1 June 2025).

- Shao, W.-C.; Lu, C.-L.; Dong, Y.-W.; Chen, J.-W.; Chiang, Y.-T. Research on Innovative Green Building Materials from Waste Oyster Shells into Foamed Heat-Insulating Bricks. Clean. Mater. 2024, 11, 100222. [Google Scholar] [CrossRef]

- WASP. 60100 HDP Large Scale Printing with Granular Materials. 2024. Available online: https://www.3dwasp.com/wp-content/uploads/dlm_uploads/2023/09/60100-HDP-Technical-Sheet.pdf (accessed on 15 May 2025).

- TEquipment. Thermo Scientific LBM Moldatherm. Available online: https://www.tequipment.net/Thermo-Scientific/LBM-Moldatherm-1.99L/Laboratory-Oven/ (accessed on 26 July 2024).

- Nelson, D. How Much Does It Cost to Operate my Submersible Well Pump? 2018. Available online: https://www.rcworst.com/blog/How-Much-does-it-Cost-to-Operate-my-Submersible-Well-Pump#:~:text=The%20power%20consumption%20of%20the,is%20$0.15%20per%20kilowatt%20hour (accessed on 1 January 2025).

- European Commission Joint Research Centre. European Reference Life Cycle Database (ELCD) III; The Joint Research Centre: Brussels, Belgium, 2013. [Google Scholar]

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; Van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Jaganmohan, M.; Average U.S. Price of Construction Sand and Gravel 2010–2023. 2024. Available online: https://www.statista.com/statistics/219381/sand-and-gravel-prices-in-the-us/#:~:text=In%20the%20United%20States%2C%20the,per%20metric%20ton%20in%202023 (accessed on 26 July 2024).

- Business Analytiq. PVC Price Index. 2025. Available online: https://businessanalytiq.com/procurementanalytics/index/pvc-price-index/ (accessed on 25 January 2025).

- Choose Energy. Electricity Rates by State. 2024. Available online: https://www.chooseenergy.com/electricity-rates-by-state/ (accessed on 26 July 2024).

- U.S. Department of Energy. Average On-Road Fuel Economy for Medium/Heavy Trucks Ranged from 4.0 mpg to 10.1 mpg in 2021. 2024. Available online: https://www.energy.gov/eere/vehicles/articles/fotw-1342-may-13-2024-average-road-fuel-economy-mediumheavy-trucks-ranged-40#:~:text=The%20average%20fuel%20economy%20of,electrification%20or%20other%20alternative%20fuels (accessed on 20 February 2025).

- U.S. Energy Information Administration. Gasoline and Diesel Fuel Update. 2025. Available online: https://www.eia.gov/petroleum/gasdiesel/ (accessed on 20 February 2025).

- Jeon, J.; Son, Y.; Kim, D.; Kim, T. Estimation of Life Cycle CO2 emissions using oyster shells and bottom ash as materials for soil-mixing and a drainage layer. J. Clean. Prod. 2020, 270, 122477. [Google Scholar] [CrossRef]

- Nayak, P.S.; Singh, B.K. Removal of phenol from aqueous solutions by sorption on low cost clay. Desalination 2007, 207, 71–79. [Google Scholar] [CrossRef]

- De Gisi, S.; Lofrano, G.; Grassi, M.; Notarnicola, M. Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: A review. Sustain. Mater. Technol. 2016, 9, 10–40. [Google Scholar] [CrossRef]

- ElSayed, E.; Ibrahim, L.A.; Ghandour, A.; Zelenakova, M.; Vranayova, Z.; Abu-Hashim, M. Efficiency of natural clay mineral adsorbent filtration systems in wastewater treatment for potential irrigation purposes. Sustainability 2021, 13, 5738. [Google Scholar] [CrossRef]

- Gopal, G.; Mukherjee, A. Removal of emerging pollutants by clay and clay-nZVI nanocomposites-A review. Environ. Technol. Rev. 2023, 12, 476–492. [Google Scholar] [CrossRef]

- Akowanou, A.V.O.; Deguenon, H.E.J.; Groendijk, L.; Aina, M.P.; Yao, B.K.; Drogui, P. 3D-printed clay-based ceramic water filters for point-of-use water treatment applications. Prog. Addit. Manuf. 2019, 4, 315–321. [Google Scholar] [CrossRef]

- He, Z.; Shanmugasundaram, T.; Singh, G. Inkjet 3D printing of clay ceramics for water treatment. Prog. Addit. Manuf. 2018, 3, 215–219. [Google Scholar] [CrossRef]

- Biswas, P.; Mamatha, S.; Varghese, K.; Johnson, R.; Vijay, R.; Kumar, R. 3D printing of high surface area ceramic honeycombs substrates and comparative evaluation for treatment of sewage in Phytorid application. J. Water Process Eng. 2020, 37, 101503. [Google Scholar] [CrossRef]

- Khalil, A.; Hashaikeh, R.; Hilal, N. 3D printed zeolite-Y for removing heavy metals from water. J. Water Process Eng. 2021, 42, 102187. [Google Scholar] [CrossRef]

- Xu, X.; Liu, X.; Oh, M.; Park, J. Oyster shell as a low-cost adsorbent for removing heavy metal ions from wastewater. Pol. J. Environ. Stud 2019, 28, 2949–2959. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.-G.; Fu, X.; Cui, Y. Removal of tetracycline from wastewater by Fe-modified oyster shell. Ferroelectrics 2021, 581, 73–81. [Google Scholar] [CrossRef]

- Xu, C.; Liu, R.; Chen, L. Removal of phosphorus from domestic sewage in rural areas using oyster shell-modified agricultural waste–rice husk biochar. Processes 2023, 11, 2577. [Google Scholar] [CrossRef]

- Yamashiro, K.; Ikemoto, R.; Ogata, F.; Tanei, S.; Kawasaki, N. Evaluation of the Mechanism of Phosphate Removal Using Oyster Shell Powder in Aqueous Environments. Chem. Pharm. Bull. 2023, 71, 655–660. [Google Scholar] [CrossRef]

- Lin, H.; Hou, Q.; Luo, Y.; Hu, G.; Yu, J.; Yu, R. Reutilization of waste oyster shell as filler for filter for drinking water pretreatment: Feasibility and implication. J. Environ. Manag. 2022, 315, 115142. [Google Scholar] [CrossRef]

- Lin, H.; Hou, Q.; Sun, X.; Hu, G.; Yu, R. Oyster shell for drinking water filtration compared with granular activated carbon: Advantages and limitations. Environ. Sci. Pollut. Res. 2023, 30, 121475–121486. [Google Scholar] [CrossRef]

- Hao, L.; Gao, W.; Yan, S.; Niu, M.; Liu, G.; Hao, H. Preparation and characterization of porous ceramics with low-grade diatomite and oyster shell. Mater. Chem. Phys. 2019, 235, 121741. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, M.; Luo, Z.; Wang, Y.; Wen, X.; Wang, Z. Effects of calcined oyster shell powder composited with iron salt on the simultaneous removal of phosphorus and arsenic during algal bloom control process. Algal Res. 2024, 80, 103546. [Google Scholar] [CrossRef]

| Impact Indicator | Unit | Meaning in the Context of the LCA |

|---|---|---|

| Freshwater ecotoxicity | kg 1,4-DCB eq | Indicates the rise in environmental risks associated with freshwater contamination and is expressed in kg of 1,4-dichlorobenzene equivalent (kg 1,4-DCB eq) [36] |

| Freshwater eutrophication | kg P eq | Indicates the phosphorus (P) increase in freshwater and is expressed in kg phosphorus equivalent (kg P eq) [36] |

| Global warming potential | kg CO2 eq | Measures the overall increase in infrared radiative forcing caused by a greenhouse gas and is expressed in kg carbon dioxide equivalent (kg CO2 eq) [36] |

| Terrestrial acidification | kg SO2 eq | Quantifies the acidifying pollutants in the soil and atmosphere and is expressed in kg sulfur dioxide equivalent (kg SO2 eq) [36] |

| Fine particulate matter formation | kg PM2.5 eq | Quantifies the human population intake of particulate matter with a diameter of 2.5 mm or less (PM2.5) and is expressed in Kg PM2.5 eq [36] |

| Human carcinogenic toxicity | kg 1,4-DCB eq | Indicates the increased risk of developing cancer and is expressed in kg of 1,4-dichlorobenzene equivalent (kg 1,4-DCB eq) [36] |

| Human non-carcinogenic toxicity | kg 1,4-DCB eq | Indicates the increased risk of developing non-cancer diseases and is expressed in kg of 1,4-dichlorobenzene equivalent (kg 1,4-DCB eq) [36] |

| Ozone depletion potential | kg CFC11 eq | Indicates the long-term cumulative decline in stratospheric ozone concentration and is expressed in Kg of trichlorofluoromethane (CFC11) equivalent [36] |

| Fossil resource scarcity | kg oil eq | Defined as the ratio of a fossil resource’s higher heating value to the energy content of crude oil (fossil fuel potential) and it expressed in Kg of oil equivalent [36] |

| Scenario | Clay/OSP | Sand Cost | PVC Cost | Gravel Cost | Electricity Cost | Labor Cost | Total Cost |

|---|---|---|---|---|---|---|---|

| Single-brick columns | 90:10 | USD 11.22 | USD 105.67 | USD 0.74 | USD 24.38 | USD 200 | USD 342.01 |

| Single-brick columns | 85:15 | USD 11.22 | USD 105.67 | USD 0.74 | USD 24.41 | USD 200 | USD 342.04 |

| Single-brick columns | 80:10 | USD 11.22 | USD 105.67 | USD 0.74 | USD 24.44 | USD 200 | USD 342.07 |

| Two-brick columns | 90:10 | USD 10.54 | USD 105.67 | USD 0.74 | USD 48.92 | USD 200 | USD 366.87 |

| Two-brick columns | 85:15 | USD 10.54 | USD 105.67 | USD 0.74 | USD 48.97 | USD 200 | USD 366.92 |

| Two-brick columns | 80:10 | USD 10.54 | USD 105.67 | USD 0.74 | USD 49.01 | USD 200 | USD 366.96 |

| Three-brick columns | 90:10 | USD 9.76 | USD 105.67 | USD 0.74 | USD 71.41 | USD 200 | USD 387.58 |

| Three-brick columns | 85:15 | USD 9.76 | USD 105.67 | USD 0.74 | USD 71.48 | USD 200 | USD 387.65 |

| Three-brick columns | 80:10 | USD 9.76 | USD 105.67 | USD 0.74 | USD 71.55 | USD 200 | USD 387.72 |

| SSF with OSP | - | USD 10.74 | USD 105.67 | USD 0.74 | USD 4.65 | USD 200 | USD 321.80 |

| SSF | - | USD 11.93 | USD 105.67 | USD 0.74 | USD 3.92 | USD 200 | USD 322.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benthota Pathiranage, W.; Alkhateb, H.; D’Alessio, M. Innovative Wastewater Treatment Using 3D-Printed Clay Bricks Enhanced with Oyster Shell Powder: A Life Cycle Assessment. Sustainability 2025, 17, 5428. https://doi.org/10.3390/su17125428

Benthota Pathiranage W, Alkhateb H, D’Alessio M. Innovative Wastewater Treatment Using 3D-Printed Clay Bricks Enhanced with Oyster Shell Powder: A Life Cycle Assessment. Sustainability. 2025; 17(12):5428. https://doi.org/10.3390/su17125428

Chicago/Turabian StyleBenthota Pathiranage, Wathsala, Hunain Alkhateb, and Matteo D’Alessio. 2025. "Innovative Wastewater Treatment Using 3D-Printed Clay Bricks Enhanced with Oyster Shell Powder: A Life Cycle Assessment" Sustainability 17, no. 12: 5428. https://doi.org/10.3390/su17125428

APA StyleBenthota Pathiranage, W., Alkhateb, H., & D’Alessio, M. (2025). Innovative Wastewater Treatment Using 3D-Printed Clay Bricks Enhanced with Oyster Shell Powder: A Life Cycle Assessment. Sustainability, 17(12), 5428. https://doi.org/10.3390/su17125428