Circular Economy Development in the Shipping Sector in Finland

Abstract

1. Introduction

1.1. The Finnish Maritime Cluster

1.2. Previous Studies

1.3. Circular Economy

1.3.1. Theoretical Background

1.3.2. Global and Regional Outlook

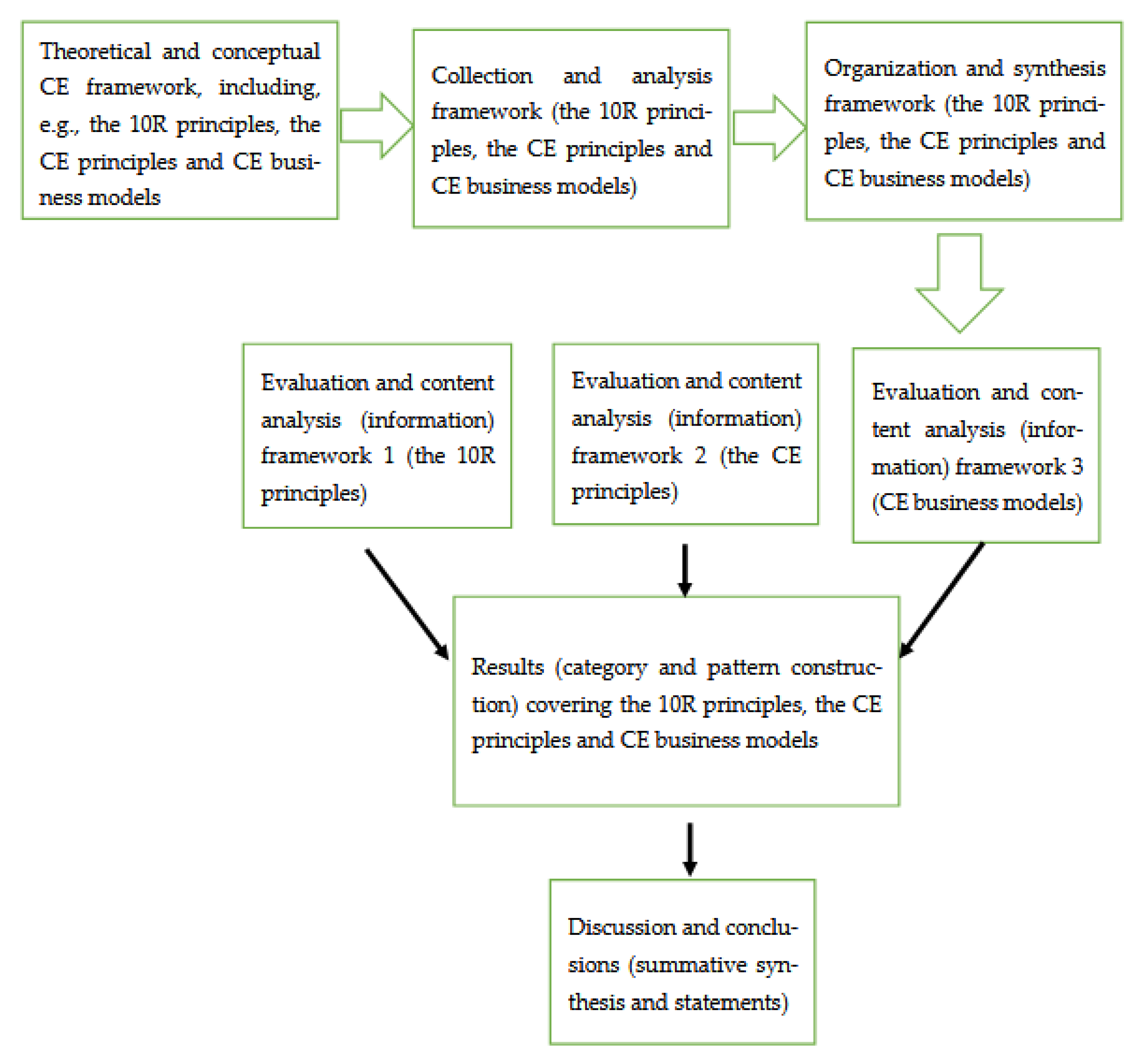

2. Materials and Methods

3. Results

3.1. Viking Line

3.2. Tallink Silja

3.3. Eckerö Goup

3.4. Finnlines

3.5. Wasaline

3.6. Arctia

3.7. Bore

3.8. ESL Shipping

3.9. Meriaura Group

3.10. Alfons Håkans

3.11. Rederi AB Nathalie

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maritime Cluster Is Multisectoral. Available online: https://www.marinefinland.fi/en-US/Humans_and_the_Baltic_Sea/Maritime_business/Finnish_Maritime_Cluster (accessed on 2 May 2025).

- Karvonen, T.; Grönlund, M.; Jokinen, L.; Mäkeläinen, K.; Oinas, P.; Pönni, V.; Ranti, T.; Saarni, J.; Saurama, A. Suomen Meriklusteri Kohti 2020-Lukua. Työ- ja Elinkeinoministeriön Julkaisuja 32/2016. Available online: https://julkaisut.valtioneuvosto.fi/handle/10024/75499 (accessed on 2 May 2025).

- Valtioneuvoston Periaatepäätös Meripolitiikan Toimenpideohjelmasta. Available online: https://valtioneuvosto.fi/delegate/file/103108 (accessed on 2 May 2025).

- Government Resolution on Finland’s Maritime Policy Guidelines: From the Baltic Sea to the Oceans. Available online: https://julkaisut.valtioneuvosto.fi/handle/10024/161376 (accessed on 2 May 2025).

- Maritime Spatial Plan for Finland 2030. Available online: https://meriskenaariot.info/merialuesuunnitelma/en/legislation-and-guidance/ (accessed on 2 May 2025).

- Sustainable Wellbeing from the Sea. Available online: https://meriskenaariot.info/merialuesuunnitelma/en/vision-2/ (accessed on 2 May 2025).

- Maritime Logistics. Available online: https://meriskenaariot.info/merialuesuunnitelma/en/maritime-logistics/ (accessed on 2 May 2025).

- Maritime Industry. Available online: https://meriskenaariot.info/merialuesuunnitelma/en/maritime-industry-2/ (accessed on 2 May 2025).

- Hakamo, H.; Majanen, K.; Varjoranta, R. State of Finnish Marine Industry 2023. Survey & Financial Analysis. Tesi. Available online: https://tesi.fi/wp-content/uploads/2023/07/20230705_meriteollisuuusselvitys_tesi.pdf (accessed on 2 May 2025).

- Finland Is a Member of the International Maritime Organization’s Council. Finnish Transport and Communications Agency. Available online: https://traficom.fi/en/finlandinimo (accessed on 2 May 2025).

- Ministry of Economic Affairs and Employment of Finland. Smart Maritime Technology Solutions. An Update: A Strategic Research Agenda for the Finnish Maritime Cluster 2017–2025. Finnish Maritime Industries. Available online: https://www.finnishmaritimecluster.fi/wp-content/uploads/2018/05/SRA2016_raportti_final_pages_0.pdf (accessed on 2 May 2025).

- Okumus, D.; Gunbeyaz, S.A.; Kurt, R.E.; Turan, O. Towards a Circular Maritime Industry: Identifying Strategy and Technology Solutions. J. Clean. Prod. 2023, 382, 134935. [Google Scholar] [CrossRef]

- Agarwala, N. Promoting Circular Economy in the shipping industry. J. Int. Marit. Saf. Environ. Aff. Shipp. 2023, 7, 2276984. [Google Scholar] [CrossRef]

- Husgafvel, R.; Linkosalmi, L.; Dahl, O. Company perspectives on the development of the circular economy in the seafaring sector and the Kainuu region in Finland. J. Clean. Prod. 2018, 186, 673–681. [Google Scholar] [CrossRef]

- de Andres Gonzalez, O.; Koivisto, H.; Mustonen, J.M.; Keinänen-Toivola, M.M. Digitalization in Just-In-Time Approach as a Sustainable Solution for Maritime Logistics in the Baltic Sea Region. Sustainability 2021, 13, 1173. [Google Scholar] [CrossRef]

- Lam, J.S.L. Designing a sustainable maritime supply chain: A hybrid QFD–ANP approach. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 70–81. [Google Scholar] [CrossRef]

- Santos, S.; Rodrigues, L.L.; Branco, M.C. Online sustainability communication practices of European seaports. J. Clean. Prod. 2016, 112, 2935–2942. [Google Scholar] [CrossRef]

- Lozano, R.; Fobbe, L.; Carpenter, A.; Sammalisto, K. Analysing sustainability changes in seaports: Experiences from the Gävle Port Authority. Sustain. Dev. 2019, 27, 409–418. [Google Scholar] [CrossRef]

- Asgari, N.; Hassani, A.; Jones, D.; Nguye, H.H. Sustainability ranking of the UK major ports: Methodology and case study. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 19–39. [Google Scholar] [CrossRef]

- Cheng, C.E.; Farahani, R.Z.; Lai, K.-H.; Sarkis, J. Sustainability in maritime supply chains: Challenges and opportunities for theory and practice. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 1–2. [Google Scholar] [CrossRef]

- Yang, Z.; Lun, V.; Lagoudis, I.N.; Lee, P.T.-W. Container transportation: Resilience and sustainability. Transp. Res. Part D Transp. Environ. 2018, 61, 420–422. [Google Scholar] [CrossRef]

- Davarzani, H.; Fahimnia, B.; Bell, M.; Sarkis, J. Greening ports and maritime logistics: A review. Transp. Res. Part D: Transp. Environ. 2016, 48, 473–487. [Google Scholar] [CrossRef]

- Karimpour, R.; Ballini, F.; Ölcer, A.I. Circular economy approach to facilitate the transition of the port cities into self-sustainable energy ports—A case study in Copenhagen-Malmö Port (CMP). WMU J. Marit. Aff. 2019, 18, 225–247. [Google Scholar] [CrossRef]

- Cerceau, J.; Mat, N.; Junqua, G.; Lin, L.; Laforest, V.; Gonzalez, C. Implementing industrial ecology in port cities: International overview of case studies and cross-case analysis. J. Clean. Prod. 2014, 74, 1–16. [Google Scholar] [CrossRef]

- Haezendonck, E.; Van den Berghe, K. Patterns of Circular Transition: What Is the Circular Economy Maturity of Belgian Ports? Sustainability 2020, 12, 9269. [Google Scholar] [CrossRef]

- Barreiro-Gen, M.; Lozano, R.; Temel, M.; Carpenter, A. Gender equality for sustainability in ports: Developing a framework. Mar. Policy 2021, 131, 104593. [Google Scholar] [CrossRef]

- Cheon, S.; Deakin, E. Supply Chain Coordination for Port Sustainability: Lessons for New Institutional Designs. Transp. Res. Rec. 2010, 2166, 10–19. [Google Scholar] [CrossRef]

- Kovačič Lukman, R.; Brglez, K.; Krajnc, D. A Conceptual Model for Measuring a Circular Economy of Seaports: A Case Study on Antwerp and Koper Ports. Sustainability 2022, 14, 3467. [Google Scholar] [CrossRef]

- Carpenter, A.; Lozano, R.; Sammalisto, K.; Astner, L. Securing a Port’s Future Through Circular Economy: Experiences from the Port of Gävle in Contributing to Sustainability. Mar. Pollut. Bull. 2018, 128, 539–547. [Google Scholar] [CrossRef]

- Kuznetsov, A.; Dinwoodie, J.; Gibbs, D.; Sansom, M.; Knowles, H. Towards a sustainability management system for smaller ports. Mar. Policy 2015, 54, 59–68. [Google Scholar] [CrossRef]

- Cerreta, M.; Giovene di Girasole, E.; Poli, G.; Regalbuto, S. Operationalizing the Circular City Model for Naples’ City-Port: A Hybrid Development Strategy. Sustainability 2020, 12, 2927. [Google Scholar] [CrossRef]

- Bonamigo, A.; Arcanjo, P.O.; Goncalves, M.J.; Pereira, N.N.; da Silveira, D.M.C. Lean 4.0 in port management: An alternative to support the development of the circular economy in the sector. Acta Logist. 2023, 10, 291–304. [Google Scholar] [CrossRef]

- Ellen McArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition. Available online: https://ellenmacarthurfoundation.org/towards-a-circular-economy-business-rationale-for-an-accelerated-transition (accessed on 7 May 2025).

- Rodríguez, J.; Rubio, L.; Celemín-Pedroche, M.; Alonso-Almeida, M. Analysis of the relations between circular economy and sustainable development goals. Int. J. Sustain. Dev. World Ecol. 2019, 26, 1–13. [Google Scholar] [CrossRef]

- Devlin, J.; Hopeward, K.; Hopeward, J.; Saint, C. Leading the Circular Future: South Australia’s Potential Influence on Circular Economy Development in Asia-Pacific Region. Sustainability 2023, 15, 13756. [Google Scholar] [CrossRef]

- Herrador, M.; Van, M.L. Circular economy strategies in the ASEAN region: A comparative study. Sci. Total Environ. 2024, 908, 168280. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Beamer, K.; Tuma, A.; Thorenz, A.; Boldoczki, S.; Kotubetey, K.; Kukea-Shultz, K.; Elkington, K. Reflections on Sustainability Concepts: Aloha ‘Āina and the Circular Economy. Sustainability 2021, 13, 2984. [Google Scholar] [CrossRef]

- Ibáñez- Forés, V.; Martínez-Sánchez, V.; Valls-Val, K.; Bovea, M.D. Sustainability reports as a tool for measuring and monitoring the transition towards the circular economy of organisations: Proposal of indicators and metrics. J. Environ. Manag. 2022, 320, 115784. [Google Scholar] [CrossRef]

- Herrador, M.; de Jong, W.; Nasu, K.; Granrath, L. Circular economy and zero-carbon strategies between Japan and South Korea: A comparative study. Sci. Total Environ. 2022, 820, 153274. [Google Scholar] [CrossRef]

- Circular Economy Principles. Available online: https://www.ellenmacarthurfoundation.org/circular-economy-principles (accessed on 7 May 2025).

- Circulate Products and Materials. Available online: https://www.ellenmacarthurfoundation.org/circulate-products-and-materials (accessed on 7 May 2025).

- Eliminate Waste and Pollution. Available online: https://www.ellenmacarthurfoundation.org/eliminate-waste-and-pollution (accessed on 7 May 2025).

- Regenerate Nature. Available online: https://www.ellenmacarthurfoundation.org/regenerate-nature (accessed on 7 May 2025).

- Hermann, R.R.; Pansera, M.; Nogueira, L.A.; Monteiro, M. Socio-technical imaginaries of a circular economy in governmental discourse and among science, technology, and innovation actors: A Norwegian case study. Technol. Forecast. Soc. Change 2022, 183, 121903. [Google Scholar] [CrossRef]

- Fornasari, T.; Neri, P. A Model for the Transition to the Circular Economy: The “R” Framework. Symphonya. Emerg. Issues Manag. 2022, 8, 78–91. [Google Scholar] [CrossRef]

- Herrador, M.; Dat, T.T.; Truong, D.D.; Hoa, L.T.; Łobacz, K. The Unique Case Study of Circular Economy in Vietnam Remarking Recycling Craft Villages. SAGE Open 2023, 13. [Google Scholar] [CrossRef]

- Herrador, M. Assessment of the first-ever circular economy framework of Cambodia: Barriers, international opportunities and recommendations. J. Clean. Prod. 2024, 438, 140778. [Google Scholar] [CrossRef]

- Borrello, M.; Pascucci, S.; Cembalo, L. Three Propositions to Unify Circular Economy Research: A Review. Sustainability 2020, 12, 4069. [Google Scholar] [CrossRef]

- Santa-Maria, T.; Vermeulen, W.J.V.; Baumgartner, R.J. How do incumbent firms innovate their business models for the circular economy? Identifying micro-foundations of dynamic capabilities. Bus. Strategy Environ. 2022, 31, 1308–1333. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Friant, M.C.; Vermeulen, W.J.V.; Salomone, R. Analysing European Union circular economy policies: Words versus actions. Sustain. Prod. Consum. 2021, 27, 337–353. [Google Scholar] [CrossRef]

- Friant, M.C.; Vermeulen, W.J.V.; Salomone, R. A typology of circular economy discourses: Navigating the diverse visions of a contested paradigm, Resources. Conserv. Recycl. 2020, 161, 104917. [Google Scholar] [CrossRef]

- Papamichael, I.; Voukkali, I.; Loizia, P.; Stylianou, M.; Economou, F.; Vardopoulos, I.; Klontza, E.E.; Lekkas, D.F.; Zorpas, A.A. Measuring Circularity: Tools for monitoring a smooth transition to Circular Economy. Sustain. Chem. Pharm. 2023, 36, 101330. [Google Scholar] [CrossRef]

- Superti, V.; Houmani, C.; Binder, C.R. A systemic framework to categorize Circular Economy interventions: An application to the construction and demolition sector. Resour. Conserv. Recycl. 2021, 173, 105711. [Google Scholar] [CrossRef]

- Borms, L.; Opstal, W.V.; Brusselaers, J.; Passel, S.V. The working future: An analysis of skills needed by circular startups. J. Clean. Prod. 2023, 409, 137261. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, H. Circular Economy: Measuring Innovation in the Product Chain. 2017. Available online: https://www.pbl.nl/en/publications/circular-economy-measuring-innovation-in-product-chains (accessed on 7 May 2025).

- Kirchherr, J.; Yang, N.-N.-H.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the circular economy (revisited): An analysis of 221 definitions, Resources. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Con-Servation Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Muñoz, S.; Reza Hosseini, M.; Crawford, R.H. Towards a holistic assessment of circular economy strategies: The 9R circularity index. Sustain. Prod. Consum. 2024, 47, 400–412. [Google Scholar] [CrossRef]

- Husgafvel, R. Company Perspectives on Circular Economy Management, Assessment and Reporting in the Kymenlaakso Region in Finland. Sustainability 2024, 16, 20. [Google Scholar] [CrossRef]

- OECD. Business Models for the Circular Economy: Opportunities and Challenges for Policy; OECD Publishing: Paris, France, 2019. [Google Scholar] [CrossRef]

- Lacy, P.; Long, J.; Spindler, W. The Circular Economy Handbook. Realizing the Circular Advantage; Palgrave Macmillan: London, UK, 2020. [Google Scholar]

- Antikainen, R.; Baudry, R.; Gössnitzer, A.; Karppinen, T.K.M.; Kishna, M.; Montevecchi, F.; Müller, F.; Pinet, C.; Uggla, R. Circular Business Models: Product-Service Systems on the way to Circular Economy. European Network of the Heads of Environment Protection Agencies (EPA Network)—Interest Group on Green and Circular Economy. 2021. Available online: https://epanet.eea.europa.eu/reports-letters/reports-and-letters/circular_business_models_interest-group-green-and-circular-economy.pdf (accessed on 7 May 2025).

- Global Resources Outlook. UNEP, Bend the Trend. Pathways to a Livable Planet as Resource Use Spikes. International Resource Panel. 2024. Available online: https://www.unep.org/resources/Global-Resource-Outlook-2024 (accessed on 7 May 2025).

- The Circularity Gap Report 2024. Available online: https://www.circularity-gap.world/2024 (accessed on 7 May 2025).

- The EU Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 7 May 2025).

- European Commission, European Climate, Infrastructure and Environment Executive Agency, Sustainability Criteria for the Blue Economy—Main Report, Publications Office, 2021. Available online: https://data.europa.eu/doi/10.2826/399476 (accessed on 7 May 2025).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on a New Approach for a Sustainable Blue Economy in the EU Transforming the EU’s Blue Economy for a Sustainable Future. COM/2021/240 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52021DC0240 (accessed on 7 May 2025).

- European Commission: Directorate-General for Maritime Affairs and Fisheries, The EU Blue Economy Report 2020, Publications Office of the European Union, 2020. Available online: https://commission.europa.eu/about/departments-and-executive-agencies/maritime-affairs-and-fisheries_en#related-links (accessed on 9 May 2025).

- Circular Economy. Available online: https://environment.ec.europa.eu/topics/circular-economy_en (accessed on 9 May 2025).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions A New Circular Economy Action Plan For a Cleaner and More Competitive Europe. COM/2020/98 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2020:98:FIN (accessed on 9 May 2025).

- Ecodesign for Sustainable Products Regulation. Making Sustainable Products in the EU the Norm. Available online: https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/ecodesign-sustainable-products-regulation_en (accessed on 9 May 2025).

- Regulation (EU) 2024/1781 of the European Parliament and of the Council of 13 June 2024 Establishing a Framework for the Setting of Ecodesign Requirements for Sustainable Products, Amending Directive (EU) 2020/1828 and Regulation (EU) 2023/1542 and Repealing Directive 2009/125/EC (Text with EEA relevance). PE/106/2023/REV/1. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32024R1781 (accessed on 9 May 2025).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on Making Sustainable Products the Norm. COM/2022/140 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52022DC0140 (accessed on 9 May 2025).

- Member Companies and Ships. Available online: https://shipowners.fi/en/finnish-shipowners-association/member-companies-and-ships/ (accessed on 12 May 2025).

- Saldana, J. Fundamentals of Qualitative Research; Oxford University Press: Oxford, UK, 2011; pp. 3–30. ISBN 10:0199737959. [Google Scholar]

- Di Vaio, A.; Varriale, L.; Lekakou, M.; Stefanidaki, E. Cruise and container shipping companies: A comparative analysis of sustainable development goals through environmental sustainability disclosure. Marit. Policy Manag. 2021, 48, 184–212. [Google Scholar] [CrossRef]

- Husgafvel, R. Exploring Social Sustainability Handprint—Part 1: Handprint and Life Cycle Thinking and Approaches. Sustainability 2021, 13, 11286. [Google Scholar] [CrossRef]

- Husgafvel, R. Exploring Social Sustainability Handprint—Part 2: Sustainable Development and Sustainability. Sustainability 2021, 13, 11051. [Google Scholar] [CrossRef]

- Husgafvel, R. Exploring sustainability science, Agenda 2030 and the UN SDGs from the social sustainability handprint perspective. In Handbook of Sustainability Science in the Future; Leal Filho, W., Azul, A.M., Doni, F., Salvia, A.L., Eds.; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Sustainability Report 2023. Available online: https://www.vikingline.com/globalassets/documents/market_specific/corporate/environment/hbr2023-vikingline-en.pdf (accessed on 15 May 2025).

- No Hazardous Bottom Paint. Available online: https://www.vikingline.com/sustainable-travel/emissions-and-waste/no-hazardous-bottom-paint/ (accessed on 15 May 2025).

- Sustainable Travel. Available online: https://www.vikingline.com/sustainable-travel/ (accessed on 15 May 2025).

- Ship Innovations. Available online: https://www.vikingline.com/sustainable-travel/innovations/ (accessed on 15 May 2025).

- Viking Glory. Available online: https://www.vikingline.com/sustainable-travel/innovations/viking-glory/ (accessed on 15 May 2025).

- Viking Grace. Available online: https://www.vikingline.com/sustainable-travel/innovations/viking-grace/ (accessed on 15 May 2025).

- Environment. Available online: https://www.vikingline.com/sustainable-travel/environment/ (accessed on 15 May 2025).

- Waste Management. Available online: https://www.vikingline.com/sustainable-travel/emissions-and-waste/waste-management/ (accessed on 15 May 2025).

- Emissions and Waste. Available online: https://www.vikingline.com/sustainable-travel/emissions-and-waste/ (accessed on 15 May 2025).

- Sustainability Report 2023. Tallink. Available online: https://image.tallink.com/image/upload/grupp/documents/sustainability-reports/Tallink-Grupp-Sustainability-Report-2023.pdf (accessed on 15 May 2025).

- Annual Report 2023. AS Tallink Grupp. Available online: https://image.tallink.com/image/upload/grupp/documents/annual-reports/2023/AGM-2024-Tallink_Grupp-AR-2023-ENG-copy.pdf (accessed on 15 May 2025).

- Consolidated Sustainability Report 2024. AS TALLINK GRUPP. Available online: https://res.cloudinary.com/as-tallink-grupp/image/upload/grupp/documents/sustainability-reports/Tallink-Grupp-Sustainability-Report-2024-ENG-updated.pdf (accessed on 15 May 2025).

- Sustainability. Environment. Available online: https://www.tallink.com/sustainability/environment (accessed on 15 May 2025).

- Sustainability and Environment. Available online: https://en.tallink.com/sustainability-and-environment (accessed on 15 May 2025).

- Sustainability. Available online: https://company.tallink.com/esg/sustainability (accessed on 15 May 2025).

- Sustainability. Our Strategy. Available online: https://company.tallink.com/esg/strategy-and-goals (accessed on 15 May 2025).

- Environment and Responsibility. Available online: https://www.eckeroline.com/environment-and-responsibility (accessed on 19 May 2025).

- Sustainability Report. Eckerö Group 2023. Available online: https://rederiabeckero.ax/wp-content/uploads/2024/04/sustainability_report_2023.pdf (accessed on 19 May 2025).

- Sustainable Travel and Cargo Shipment. Available online: https://www.finnlines.com/company/environment/ (accessed on 19 May 2025).

- Sustainable Development Goals. Available online: https://www.finnlines.com/company/environment/un-goals/ (accessed on 19 May 2025).

- Sustainability. Available online: https://www.finnlines.com/wp-content/uploads/2022/05/2021-Finnlines-Environment.pdf (accessed on 19 May 2025).

- Climate Actions. Available online: https://www.finnlines.com/company/environment/climate-actions/ (accessed on 19 May 2025).

- Annual Report 2023. Available online: https://www.finnlines.com/wp-content/uploads/2024/03/finnlines-annual-report-2023.pdf (accessed on 19 May 2025).

- Commitments. Available online: https://www.finnlines.com/company/environment/commitments/ (accessed on 19 May 2025).

- Ecological Footprint in Detail. Available online: https://www.finnlines.com/company/environment/caring-for-the-environment-2/ecological-footprint/ (accessed on 19 May 2025).

- Environmental Policy and Principles. Available online: https://www.finnlines.com/company/environment/caring-for-the-environment-2/environmental-policy-and-principles/ (accessed on 19 May 2025).

- Rules and Regulations. Available online: https://www.finnlines.com/company/environment/rules-and-regulations/ (accessed on 19 May 2025).

- Sustainability Report 2023. Wasaline. Available online: https://indd.adobe.com/view/b81b1fa0-01df-4ced-bca5-faf533547940 (accessed on 19 May 2025).

- ETS at Wasaline. Available online: https://www.wasaline.com/en/ets/ (accessed on 19 May 2025).

- Sustainability at Wasaline. Available online: https://www.wasaline.com/en/sustainability/ (accessed on 19 May 2025).

- Climate Compensation Popular at Wasaline. Available online: https://www.wasaline.com/en/portfolio-item/climate-compensation/ (accessed on 19 May 2025).

- Wasaline Introduces Voluntary Climate Compensation also for Passengers. Available online: https://www.wasaline.com/en/portfolio-item/voluntary-climate-compensation/ (accessed on 19 May 2025).

- Annual and Corporate Sustainability Report 2023. Available online: https://www.arctia.fi/media/annual-reports/annual-reports-2023/annual_and_corporate_sustainability_report_2023.pdf (accessed on 19 May 2025).

- Code of Conduct. Available online: https://www.arctia.fi/media/dokumentit/arctias-code-of-conduct.pdf (accessed on 19 May 2025).

- Sound Environment. Available online: https://bore.eu/approach-in-roro-shipping/sound-environment/ (accessed on 19 May 2025).

- Long Term Thinking for Sustainability. Available online: https://bore.eu/approach-in-roro-shipping/long-term-thinking/ (accessed on 19 May 2025).

- Our Environmental Policy. Available online: https://bore.eu/approach-in-roro-shipping/environmental-policy/ (accessed on 19 May 2025).

- Sustainability. Available online: https://www.eslshipping.com/en/sustainability (accessed on 19 May 2025).

- Environmental Responsibility. Available online: https://www.eslshipping.com/en/sustainability/environment (accessed on 19 May 2025).

- ESL Shipping Sustainability Report 2023. Available online: https://www.eslshipping.com/en/sustainability/2023 (accessed on 19 May 2025).

- Code of Conduct. Available online: https://www.eslshipping.com/en/company/code-of-conduct (accessed on 19 May 2025).

- Sustainable Development. Available online: https://meriaura.fi/en/sustainability/ (accessed on 22 May 2025).

- Meriaura Sustainability Report 2023. Available online: https://app.seidat.com/presentation/shared/Wx5rRpdicYtvPpzY8/0/0 (accessed on 22 May 2025).

- Environmental Policy. Available online: https://meriaura.fi/en/environmental-policy/ (accessed on 22 May 2025).

- Sustainability. Available online: https://alfonshakans.fi/sustainability/ (accessed on 22 May 2025).

- Fueled By Purpose. Available online: https://www.rabn.fi/about-us/ (accessed on 22 May 2025).

- Puig, M.; Pla, A.; Seguí, X.; Darbra, R.M. Tool for the identification and implementation of Environmental Indicators in Ports (TEIP). Ocean Coast. Manag. 2017, 140, 34–45. [Google Scholar] [CrossRef]

- Laxe, F.G.; Bermúdez, F.M.; Palmero, F.M.; Novo-Corti, I. Assessment of port sustainability through synthetic indexes. Application to the Spanish case. Mar. Pollut. Bull. 2017, 119, 220–225. [Google Scholar] [CrossRef]

- Mańkowska, M.; Kotowska, I.; Pluciński, M. Seaports as Nodal Points of Circular Supply Chains: Opportunities and Challenges for Secondary Ports. Sustainability 2020, 12, 3926. [Google Scholar] [CrossRef]

- Puig, M.; Wooldridge, C.; Casal, J.; Darbra, R.M. Tool for the identification and assessment of Environmental Aspects in Ports (TEAP). Ocean Coast. Manag. 2015, 113, 8–17. [Google Scholar] [CrossRef]

- Roberts, T.; Williams, I.; Preston, J.; Clarke, N.; Odum, M.; O’Gorman, S. A Virtuous Circle? Increasing Local Benefits from Ports by Adopting Circular Economy Principles. Sustainability 2021, 13, 7079. [Google Scholar] [CrossRef]

- Roh, S.; Thai, V.V.; Jang, H.; Yeo, G.T. The best practices of port sustainable development: A case study in Korea. Marit. Policy Manag. 2023, 50, 254–280. [Google Scholar] [CrossRef]

- Lu, C.S.; Shang, K.C.; Lin, C.C. Examining sustainability performance at ports: Port managers’ perspectives on developing sustainable supply chains. Marit. Policy Manag. 2016, 43, 909–927. [Google Scholar] [CrossRef]

- Shiau, T.-A.; Chuang, C.C. Social Construction of Port Sustainability Indicators: A Case Study of Keelung Port. Marit. Policy Manag. 2015, 42, 26–42. [Google Scholar] [CrossRef]

- Gravagnuolo, A.; Angrisano, M.; Fusco Girard, L. Circular Economy Strategies in Eight Historic Port Cities: Criteria and Indicators Towards a Circular City Assessment Framework. Sustainability 2019, 11, 3512. [Google Scholar] [CrossRef]

- Mansouri, S.A.; Lee, H.; Aluko, O. Multi-objective decision support to enhance environmental sustainability in maritime shipping: A review and future directions. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 3–18. [Google Scholar] [CrossRef]

- Del Giudice, M.; Di Vaio, A.; Hassan, R.; Palladino, R. Digitalization and new technologies for sustainable business models at the ship–port interface: A bibliometric analysis. Marit. Policy Manag. 2022, 49, 410–446. [Google Scholar] [CrossRef]

| 10Rs | Identified 10R Approaches |

|---|---|

| Replacement of products or making of products redundant (R0) | 1. The application of new climate-smart technology [82] 2. Testing of alternative technological solutions [82] 3. No use of environmentally hazardous paint on the bottoms of vessels [82,83] 4. Cooperation with local producers and use of locally produced food [82] 5. Use of digital information and reduction in paper consumption [82] 6. Investment in climate-smart vessels and updating of technologies throughout their life cycles [82] 7. Sustainable wines in onboard shops [82] 8. Use of LED lights, solar cells and geothermal heating [82] 9. Use of azipod rudder propeller system to reduce fuel consumption [84] 10. Offering of vegan and plant-based options in restaurants [84] |

| Rethinking of products (R1) | 1. The creation of circular material flows [82] 2. Gradual uptake of sustainable fuels (e.g., biogas and biodiesel) and phasing out of fossil fuels [82] 3. Participation in knowledge exchanges [82] 4. The integration of sustainability into value chains [82] 5. Sustainability as a basis of decisions (with ecological and economic consequences) [82] 6. No use of environmentally hazardous paint on the bottoms of vessels [82,83] 7. The development of a new carbon-neutral sea route [85] 8. Environmentally friendly cleaning routines [82] 9. Cooperation with local producers and use of locally produced food [82] 10. The use of digital information and reduction in paper consumption [82] 11. Sustainability as a criterion for products in all product categories [82] 12. Investment in climate-smart vessels and updating of technologies throughout their life cycles [82] 13. Sustainable wines in onboard shops [82] 14. Use of LED lights, solar cells and geothermal heating [82] 15. Dynamic control system for the automatization of lights, heating and ventilation in cabins [84] 16. Use of azipod rudder propeller system to reduce fuel consumption [84] 17. Investment in sustainable maritime transport and climate-smart innovations [84] 18. Offering of vegan and plant-based options in restaurants [84] 19. Use of sulfur-free liquefied natural gas as fuel [85,86,87] 20. Optimized hull design [86,87] |

| Reduction in the use of resources in the manufacturing and use of products (R2) | 1. Creation of circular material flows [82] 2. Reuse of materials [82] 3. Reduction of environmental impacts and minimization of emissions [82] 4. Reduction in the use of chemicals and water in operations [82] 5. Reduction in waste quantities [82] 6. Fuel saving using smart technologies [82] 7. Reduction of food waste in restaurants [82] 8. Use of digital information and reduction in paper consumption [82] 9. Sustainability as a criterion for products in all product categories [82] 10. Investment in climate-smart vessels and updating of technologies throughout their life cycles [82] 11. Sustainable wines in onboard shops [82] 12. Use of LED lights, solar cells and geothermal heating [82] 13. Continuous reduction of carbon footprint and work towards a climate-neutral future [84] 14. Use of shore power at ports [84] 15. Dynamic control system for the automatization of lights, heating and ventilation in cabins [84] 16. Utilization of waste cooling from liquefied natural gas [84] 17. Environmentally sound management of residual products from operations [88] 18. Energy recycling system (conversion of waste heat from the engines into electricity) [86,87] 19. Utilization of waste cold from liquefied natural gas for cold storage and cooling equipment [86] |

| Reuse of products (R3) | 1. Creation of circular material flows [82] 2. Reuse of materials [82,89] 3. Use of fibers from textiles as sustainable raw materials [82,89] 4. CE through processing of carpets into raw material for new carpets [82,89] |

| Repair of products (R4) | - |

| Refurbishment of products (R5) | - |

| Remanufacturing of products (R6) | 1. CE through processing of carpets into raw material for new carpets [82] 2. Use of fibers from textiles as sustainable raw materials [82] |

| Repurposing of products and their parts (R7) | - |

| Recycling of materials (R8) | 1. Creation of circular material flows [82] 2. Reuse of materials [82,89] 3. Sorting of waste and by-products generated by operations [82,89] 4. Maximization of recycling [82,89,90] 5. Use of fibers from textiles as sustainable raw materials [82,89] 6. CE through processing of carpets into raw material for new carpets [82,89] 7. Recycling of glass, scrap metal and paper [82,89,90] |

| Recovery of materials (R9) | 1. Creation of circular material flows [82] 2. CE through processing of carpets into raw material for new carpets [82,89] 3. Use of fibers from textiles as sustainable raw materials [82,89] 4. Recycling of glass, scrap metal and paper [82,89,90] 5. Recycling of biowaste to produce biogas [84,89] |

| CE Principles | Identified Approaches Related to the CE Principles |

|---|---|

| Circulation of products and materials | 1. The creation of circular material flows 2. The integration of sustainability into value chains and sustainability as a basis of decisions (with ecological and economic consequences) 3. Reuse of materials 4. Sustainability as a criterion for products in all product categories 5. Use of fibers from textiles as sustainable raw materials 6. CE through processing of carpets into raw material for new carpets 7. The maximization of recycling 8. Recycling of glass, scrap metal and paper 9. Recycling of biowaste to produce biogas |

| Elimination of waste and pollution | 1. The reduction of environmental impacts and minimization of emissions 2. The reduction in the use of chemicals and water in operations 3. The reduction in waste quantities 4. The reduction of food waste in restaurants 5. Use of digital information and reduction in paper consumption 6. Continuous reduction of carbon footprint and work towards a climate-neutral future 7. Environmentally sound management of residual products from operations 8. Sorting of waste and by-products generated by operations |

| Regeneration of nature | 1. Sustainable wines and no use of environmentally hazardous paint 2. Offering of vegan and plant-based options in restaurants 3. Recycling of biowaste to produce biogas |

| CE Business Models | Identified Approaches Related to the CE Business Models |

|---|---|

| Circular supply models, supply chains and inputs | 1. The creation of circular material flows 2. The integration of sustainability into value chains and sustainability as a basis of decisions (with ecological and economic consequences) 3. Reuse of materials 4. Sustainability as a criterion for products in all product categories 5. Use of fibers from textiles as sustainable raw materials 6. CE through processing of carpets into raw material for new carpets 7. The maximization of recycling 8. Recycling of glass, scrap metal and paper 9. Recycling of biowaste to produce biogas |

| Resource recovery | 1. Energy recycling system (conversion of waste heat from the engines into electricity) 2. The utilization of waste cold from liquefied natural gas for cold storage and cooling equipment 3. Environmentally sound management of residual products from operations 4. The reduction in waste quantities 5. The reduction of food waste in restaurants 6. Use of fibers from textiles as sustainable raw materials 7. CE through processing of carpets into raw material for new carpets 8. The maximization of recycling 9. Recycling of glass, scrap metal and paper 10. Recycling of biowaste to produce biogas 11. Sorting of waste and by-products generated by operations |

| Product use/life extension | 1. Use of LED lights and solar cells |

| Sharing and sharing platforms | - |

| Product-as-a-service and product-service systems | - |

| 10Rs | Identified 10R Approaches |

|---|---|

| Replacement of products or making of products redundant (R0) | 1. The promotion of the circular economy [91,92] 2. The development of CE principles within the company [93] 3. Reduction and phasing out of single-use plastics [91,94] 4. Goal to become a paperless business, office and service [91,94] 5. Local sourcing of products and buying of local materials and supplies [91,92,93] 6. Sourcing of sustainable products, supplies and materials [91,92,93] 7. Installation of new and more efficient propellers for one route [91] 8. Use of only paper or reusable shopping bags [95] 8. The reduction in use of and the replacement of plastic straws with biodegradable straws [95] 9. Minimization of the use of single-use dishware and unnecessary plastic usage in restaurants and cafeterias [95] 10. The abandoning of single-use dishes and plastic Club One cards in stages [95] 11. Cooperation with suppliers to reduce plastic packaging [95] 12. The use of energy-efficient light bulbs and fluorescent lighting tubes, including gradual change towards LED technology [95] 13. Use of sustainable, certified and locally produced food and materials [95] 14. The development of vegetarian and vegan food selections and use of Nordic meat and materials produced in neighboring countries [95] 15. The provision of drinking water from a separate tank to fill water bottles [95] |

| Rethinking of products (R1) | 1. The promotion of the circular economy [91,92] 2. The development of CE principles within the company [93] 3. The promotion of sustainable environmental performance [91] 4. The development of the double materiality assessment process (e.g., circular economy, identification of sustainability areas, and wide value chain perspective and mapping) [91] 5. Vessel-level environmental data collection, verification and sharing with relevant authorities [91] 6. The reduction and phasing out of single-use plastics [91,94] 7. The implementation of efforts to become a paperless business, office and service [91,94] 8. Local sourcing of products and buying of local materials and supplies [91,92,93] 9. Sourcing of sustainable and local products, supplies and materials, including locally produced food [91,92,93,95] 10. Continuous increase in energy efficiency and saving of resources [91] 11. The installation of new and more efficient propellers for one route [91] 12. Partnering with organizations with similar goals and values [91,96] and the introduction of a new all-stakeholders-connecting-sustainability agenda [97] 13. Monthly monitoring and collection of environmental data from ships (under Significant Environmental Aspects) [91] 14. The engagement of stakeholders (investors, suppliers and partners) as part of the double materiality process [92] 15. Collaboration with research institutions to advance technological innovations (e.g., to enhance energy, fuel and water savings) and with partners to reduce greenhouse gas emissions [94] 16. Continuous monitoring of the impact of supply chains and logistics [94] 17. Consideration of the efficient use of materials and energy in the operation of ships and office [94] 18. The application of similar environmental standards by suppliers, contractors and all affiliated companies [91,94] 19. Use of only paper or reusable shopping bags [95] 20. The reduction in use of and the replacement of plastic straws with biodegradable straws [95] 21. The minimization of the use of single-use dishware and unnecessary plastic usage in restaurants and cafeterias [95] 22. The abandoning of single-use dishes and plastic Club One cards in stages [95] 23. Cooperation with suppliers to reduce plastic packaging [95] 24. The use of energy-efficient light bulbs and fluorescent lighting tubes, including gradual change towards LED technology [95] 25. The reduction of printing on board and in land operations [95] 26. The development of vegetarian and vegan food selections and use of Nordic meat and materials produced in neighboring countries [95] 27. The provision of drinking water from a separate tank to fill water bottles [95] 28. Offering of an emissions surcharge for travel bookings [91] 29. The calculation of emissions/footprints for passengers and cargo [95] 30. Use of detergents without phosphates [95] |

| Reduction in the use of resources in the manufacturing and use of products (R2) | 1. The promotion of the circular economy [91,92] 2. The development of CE principles within the company [93] 3. The simultaneous increase in CE practices and support of communities (e.g., reuse of items from ships, offices and hotels, such as furniture, technical equipment, textiles, soft furnishings, bedding, decorations, lamps and food outside the company) [91,96] 4. The reduction and phasing out of single-use plastics [91,94] 5. The implementation of efforts to become a paperless business, office and service [91,94] 6. Local sourcing of products and reduction of footprint through buying of local materials and supplies [91,92,93] 7. Sourcing of sustainable products, supplies and materials [91,92,93] 8. Group-level monitoring and analysis of fuel consumption and greenhouse gas emissions [91] 9. Continuous increase in energy efficiency and saving of resources [91] 10. Installation of shore power equipment on vessels and connection of vessels to shore power supply network [91,95] 11. Use of liquefied natural gas-fueled vessels on one route [91] 12. Installation of new and more efficient propellers for one route [91] 13. Monthly monitoring and collection of environmental data from ships (under Significant Environmental Aspects) [91] 14. Collaboration with research institutions to advance technological innovations (e.g., to enhance energy, fuel and water savings) and with partners to reduce greenhouse gas emissions [94] 15. Continuous monitoring of the impact of supply chains and logistics [94] 16. Consideration of the efficient use of materials and energy in the operation of ships and offices [94] 17. The use of low-sulfur fuel, economical navigation, and modern engines and catalyzers [95] 18. Saving of waste heat from engines and its reuse on board for, e.g., general heating [95] 19. Fuel monitoring system to optimize the operation of ships and to lower fuel consumption, emissions and use of energy [95] 20. Lower travel speed to reduce fuel consumption and emissions [95] 21. Regular cleaning of hulls by divers and use of non-toxic paints (no chemicals that are harmful to the environment) [95] 22. Use of only paper or reusable shopping bags [95] 23. The reduction in use of and the replacement of plastic straws with biodegradable straws [95] 24. The minimization of the use of single-use dishware and unnecessary plastic usage in restaurants and cafeterias [95] 25. The abandoning of single-use dishes and plastic Club One cards in stages [95] 26. Cooperation with suppliers to reduce plastic packaging [95] 27. Use of energy-efficient light bulbs and fluorescent lighting tubes, including gradual change towards LED technology [95] 28. The reduction in printing on board and in land operations [95] 29. The provision of drinking water from a separate tank to fill water bottles [95] |

| Reuse of products (R3) | 1. The adoption of the principle of reuse [94] 2. Sending of as many item for reuse as possible [93] 3. The simultaneous increase in CE practices and support of communities (e.g., reuse of items from ships, offices and hotels, such as furniture, technical equipment, textiles, soft furnishings, bedding, decorations, lamps and food outside the company) [91,96] |

| Repair of products (R4) | - |

| Refurbishment of products (R5) | - |

| Remanufacturing of products (R6) | - |

| Repurposing of products and their parts (R7) | - |

| Recycling of materials (R8) | 1. The promotion of the circular economy [91,92] 2. The development of CE principles within the company [93] 3. The adoption of the principle of recycling [94] 4. The simultaneous increase in CE practices and support of communities (e.g., reuse of items from ships, offices and hotels, such as furniture, technical equipment, textiles, soft furnishings, bedding, decorations, lamps and food outside the company) [91,96] 5. Monitoring and sorting of waste based on categories [91] 6. Recycling of metal, glass, plastic, cardboard, organic and special waste on board [95] |

| Recovery of materials (R9) | 1. The promotion of the circular economy [91,92] 2. The development of CE principles within the company [93] 3. The strict zero-spill-to-the-sea policy [91,94] 4. Monitoring and sorting of waste based on categories [91] 5. The adoption of the principle of recycling [94] 6. The recycling of metal, glass, plastic, cardboard, organic and special waste on board [95] 7. Treatment of all waste waters in waste-water treatment plants [95] 8. The investigation of the use of organic waste for composting [95] 9. The reduction of food waste through cooperation with a partner and passengers (e.g., focus on environmental impacts and creation of information and awareness) [95] |

| CE Principles | Identified Approaches Related to the CE Principles |

|---|---|

| Circulation of products and materials | 1. The promotion of the circular economy 2. The development of CE principles within the company 3. Sourcing of sustainable and local products, supplies and materials 4. The use of only paper or reusable shopping bags 5. The development of the double materiality assessment process (e.g., circular economy and identification of sustainability areas) 6. The engagement of stakeholders (investors, suppliers and partners) as part of the double materiality process 7. Consideration of the efficient use of materials and energy in the operation of ships and offices 8. Use of only paper or reusable shopping bags 9. The simultaneous increase in CE practices and support of communities (e.g., reuse of items from ships, offices and hotels, such as furniture, technical equipment, textiles, soft furnishings, bedding, decorations, lamps and food outside the company) 10. The adoption of the principle of reuse 11. Sending of as many items for reuse as possible 12. Recycling of metal, glass, plastic, cardboard, organic and special waste on board |

| Elimination of waste and pollution | 1. The reduction and phasing out of single-use plastics 2. The goal to become a paperless business, office and service 3. The use of only paper or reusable shopping bags 4. The reduction in use of and the replacement of plastic straws with biodegradable straws 5. The minimization of the use of single-use dishware and unnecessary plastic usage in restaurants and cafeterias 6. The abandoning of single-use dishes and plastic Club One cards in stages 7. Cooperation with suppliers to reduce plastic packaging 8. The provision of drinking water from a separate tank to fill water bottles 9. Continuous increase in energy efficiency and saving of resources 10. Collaboration with research institutions to advance technological innovations (e.g., to enhance energy, fuel and water savings) and with partners to reduce greenhouse gas emissions 11. Continuous monitoring of the impact of supply chains and logistics 12. Consideration of the efficient use of materials and energy in the operation of ships and offices 13. Use of only paper or reusable shopping bags 14. The reduction in printing on board and in land operations 15. Offering of an emissions surcharge for travel bookings 16. The calculation of emissions/footprints for passengers and cargo 17. The simultaneous increase in CE practices and support of communities (e.g., reuse of items from ships, offices and hotels, such as furniture, technical equipment, textiles, soft furnishings, bedding, decorations, lamps and food outside the company) 18. Group-level monitoring and analysis of fuel consumption and greenhouse gas emissions 19. Installation of shore power equipment on vessels and connection of vessels to shore power supply network 20. Use of liquefied natural gas-fueled vessels on one route 21. Monthly monitoring and collection of environmental data from ships 22. The use of low-sulfur fuel, economical navigation, and modern engines and catalyzers 23. Saving of waste heat from engines and its reuse on board for, e.g., general heating 24. Fuel monitoring system to optimize the operation of ships and to lower fuel consumption, emissions and use of energy 25. Lower travel speed to reduce fuel consumption and emissions 26. Regular cleaning of hulls by divers and use of non-toxic paints (no chemicals that are harmful to the environment) 27. The adoption of the principle of reuse 28. Sending of as many items for reuse as possible 29. Monitoring and sorting of waste based on categories 30. Recycling of metal, glass, plastic, cardboard, organic and special waste on board 31. The strict zero-spill-to-the-sea policy 32. Treatment of all waste waters in waste-water treatment plants 33. The investigation of the use of organic waste for composting 34. The reduction of food waste through cooperation with a partner and passengers (e.g., focus on environmental impacts) |

| Regeneration of nature | 1. Sourcing of sustainable products, supplies and materials 2. The reduction in use of and the replacement of plastic straws with biodegradable straws 3. The development of vegetarian and vegan food selections and use of Nordic meat and materials produced in neighboring countries 4. The promotion of sustainable environmental performance 5. Use of detergents without phosphates 6. Regular cleaning of hulls by divers and use of non-toxic paints (no chemicals that are harmful to the environment) 7. The investigation of the use of organic waste for composting 8. The reduction of food waste through cooperation with a partner and passengers (e.g., focus on environmental impacts) |

| CE Business Models | Identified Approaches Related to the CE Business Models |

|---|---|

| Circular supply models, supply chains and inputs | 1. The promotion of the circular economy 2. The development of CE principles within the company 3. Sourcing of sustainable and local products, supplies and materials 4. The use of only paper or reusable shopping bags 5. The development of the double materiality assessment process (e.g., circular economy, identification of sustainability areas, and wide value chain perspective and mapping) 6. The engagement of stakeholders (investors, suppliers and partners) as part of the double materiality process 7. Continuous monitoring of the impact of supply chains and logistics 8. The simultaneous increase in CE practices and support of communities (e.g., reuse of items from ships, offices and hotels, such as furniture, technical equipment, textiles, soft furnishings, bedding, decorations, lamps and food outside the company) 9. The adoption of the principle of reuse 10. Sending of as many items for reuse as possible 11. Recycling of metal, glass, plastic, cardboard, organic and special waste on board |

| Resource recovery | 1. The use of only paper or reusable shopping bags 2. The reduction in use of and the replacement of plastic straws with biodegradable straws 3. Continuous increase in energy efficiency and saving of resources 4. Collaboration with research institutions to advance technological innovations (e.g., to enhance energy, fuel and water savings) and with partners to reduce greenhouse gas emissions 5. Consideration of the efficient use of materials and energy in the operation of ships and offices 6. Use of only paper or reusable shopping bags 7. Saving of waste heat from engines and its reuse on board for, e.g., general heating 8. The adoption of the principle of reuse 9. Sending of as many items for reuse as possible 10. Monitoring and sorting of waste based on categories 11. Recycling of metal, glass, plastic, cardboard, organic and special waste on board 12. The strict zero-spill-to-the-sea policy 13. Treatment of all waste waters in waste-water treatment plants 14. The investigation of the use of organic waste for composting 15. The reduction of food waste through cooperation with a partner and passengers (e.g., focus on environmental impacts) |

| Product use/life extension | 1. The use of energy-efficient light bulbs and fluorescent lighting tubes, including gradual change towards LED technology 2. The provision of drinking water from a separate tank to fill water bottles 3. Use of only paper or reusable shopping bags |

| Sharing and sharing platforms | - |

| Product-as-a-service and product-service systems | - |

| 10Rs | Identified 10R Approaches |

|---|---|

| Replacement of products or making of products redundant (R0) | 1. Use of energy-efficient LED lamps, induction hobs, automatic water taps and vacuum flush toilets [98] 2. The replacement of necessary packaging and disposable materials with ecological alternatives based on renewable or recycled materials [98] |

| Rethinking of products (R1) | 1. Sustainable, local and high-quality food, including monitoring of food waste covering the whole supply chain [98] 2. Multiple measures to reduce food loss, encompassing procurement (e.g., optimized amounts, reliable suppliers and efficient storage cycles), preparation (e.g., careful planning of food quantities, monitoring of food consumption, use of high-quality kitchen tools and cooking methods, and optimized processing of raw materials), serving (e.g., food presentation, size of serving plates and cutlery, and size of pieces and portions), plate waste (e.g., self-service buffet restaurants and raising of customer awareness) and minimization of the loss of café products (e.g., 30% off products) [98] 3. The creation of ecosystems (e.g., collaboration with educational institutions, authorities, suppliers, partners and tour operators) [98] 4. Preference for domestic and locally produced products and application of seasonal thinking in procurement [98] 5. Buying of fish and seafood from responsible suppliers and sustainable and certified sources [98] 6. Focus on the origin of meat and dairy products (e.g., responsible domestic producers) and preference for organic products in procurement [98] 7. Preference for local partners (e.g., services and events) [98] 8. Provision of sustainable transportation for passengers and employees [99] |

| Reduction in the use of resources in the manufacturing and use of products (R2) | 1. The reduction in fuel consumption, energy optimization measures and transitioning to climate-neutral energy sources in the long term [98,99] 2. The limitation of water consumption; increase in energy efficiency through multiple technical solutions [98] 3. The reduction in waste generation [98] 4. The replacement of packaging and disposable materials with ecological alternatives made from renewable or recycled materials [98] 5. The minimization of the consumption of disposable packaging materials (e.g., use of reusable cutlery and utensils and biodegradable napkins) [98] 6. The application of life cycle thinking and focus on local suppliers and manufacturers in procurement [98] 7. The advancement of clean energy technology [99] |

| Reuse of products (R3) | 1. Use of reusable cutlery and utensils [98] 2. The minimization of the use of disposable items and the consumption of disposable packaging materials [98] |

| Repair of products (R4) | 1. The repair of old products instead of buying new products [98] |

| Refurbishment of products (R5) | 1. Keeping old products in use and collaboration with partner organizations [98] |

| Remanufacturing of products (R6) | 1. Collaboration with partner organizations to advance waste reduction and enhance recycling efficiency (e.g., textiles) [98] |

| Repurposing of products and their parts (R7) | - |

| Recycling of materials (R8) | 1. Recycling of discarded products and materials [98] 2. Sorting of all waste based on defined categories [98] 3. Raising awareness of the negative environmental impacts of plastic waste (e.g., cigarette stumps) [98] |

| Recovery of materials (R9) | 1. Recycling of discarded products and materials [98] 2. Sorting of all waste based on defined categories [98] 3. Closed waste-water system and treatment of waste water ashore [98] 4. The reduction in and monitoring of food loss covering the whole supply chain and including the application of the main waste categories [98] |

| CE Principles | Identified Approaches Related to the CE Principles |

|---|---|

| Circulation of products and materials | 1. The replacement of necessary packaging and disposable materials by ecological alternatives based on renewable or recycled materials 2. The creation of ecosystems (e.g., collaboration with educational institutions, authorities, suppliers, partners and tour operators) 3. The minimization of the consumption of disposable packaging materials 4. Use of reusable cutlery and utensils 5. The minimization of the use of disposable items and the consumption of disposable packaging materials 6. The repair of old products instead of buying new products 7. Keeping old products in use and collaboration with partner organizations 8. Collaboration with partner organizations to advance waste reduction and enhance recycling efficiency (e.g., textiles) 9. Recycling of discarded products and materials |

| Elimination of waste and pollution | 1. Use of energy-efficient LED lamps, induction hobs, automatic water taps and vacuum flush toilets 2. The replacement of necessary packaging and disposable materials by ecological alternatives based on renewable or recycled materials 3. Monitoring of food waste covering the whole supply chain 4. Multiple measures to reduce food loss, encompassing procurement (e.g., optimized amounts, reliable suppliers and efficient storage cycle), preparation (e.g., careful planning of food quantities, monitoring of food consumption, use of high-quality kitchen tools and cooking methods, and optimized processing of raw materials), serving (e.g., food presentation, size of serving plates and cutlery, and size of pieces and portions), plate waste (e.g., self-service buffet restaurants and raising of customer awareness) and minimization of the loss of café products (e.g., 30% off products) 5. Provision of sustainable transportation for passengers and employees 6. The reduction in fuel consumption, energy optimization measures and transitioning to climate-neutral energy sources in the long term 7. The limitation of water consumption; increase in energy efficiency through multiple technical solutions 8. The reduction in waste generation 9. The minimization of the consumption of disposable packaging materials (e.g., use of reusable cutlery and utensils and of biodegradable napkins) 10. The advancement of clean energy technology 11. Use of reusable cutlery and utensils 12. The minimization of the use of disposable items and the consumption of disposable packaging materials 13. The repair of old products instead of buying new products 14. Keeping old products in use and collaboration with partner organizations 15. Collaboration with partner organizations to advance waste reduction and enhance recycling efficiency (e.g., textiles) 16. Recycling of discarded products and materials 17. Sorting of all waste based on defined categories 18. Closed waste-water system and treatment of waste water ashore |

| Regeneration of nature | 1. The replacement of necessary packaging and disposable materials by ecological alternatives based on renewable or recycled materials 2. Sustainable, local and high-quality food 3. Preference for domestic and locally produced products and application of seasonal thinking in procurement 4. Buying of fish and seafood from responsible suppliers and sustainable and certified sources 5. Focus on the origin of meat and dairy products (e.g., responsible domestic producers) and preference for organic products in procurement 6. The minimization of the consumption of disposable packaging materials (e.g., use of biodegradable napkins) 7. The advancement of clean energy technology |

| CE Business Models | Identified Approaches Related to the CE Business Models |

|---|---|

| Circular supply models, supply chains and inputs | 1. The replacement of necessary packaging and disposable materials with ecological alternatives based on renewable or recycled materials 2. The creation of ecosystems (e.g., collaboration with educational institutions, authorities, suppliers, partners and tour operators) 3. Use of reusable cutlery and utensils 4. The minimization of the use of disposable items and the consumption of disposable packaging materials 5. The repair of old products instead of buying new products 6. Keeping old products in use and collaboration with partner organizations 7. Collaboration with partner organizations to advance waste reduction and enhance recycling efficiency (e.g., textiles) 8. Recycling of discarded products and materials |

| Resource recovery | 1. The replacement of necessary packaging and disposable materials by ecological alternatives based on renewable or recycled materials 2. Monitoring of food waste covering the whole supply chain 3. Multiple measures to reduce food loss, encompassing procurement (e.g., optimized amounts, reliable suppliers and efficient storage cycle), preparation (e.g., careful planning of food quantities, monitoring of food consumption, use of high-quality kitchen tools and cooking methods, and optimized processing of raw materials), serving (e.g., food presentation, size of serving plates and cutlery, and size of pieces and portions), plate waste (e.g., self-service buffet restaurants and raising of customer awareness) and minimization of the loss of café products (e.g., 30% off products) 4. The reduction in fuel consumption; energy optimization measures; and transitioning to climate-neutral energy sources in the long term 5. The limitation of water consumption; increase in energy efficiency through multiple technical solutions 6. The reduction in waste generation 7. Collaboration with partner organizations to advance waste reduction and enhance recycling efficiency (e.g., textiles) 8. Recycling of discarded products and materials 9. Sorting of all waste based on defined categories 10. Closed waste-water system and treatment of waste water ashore |

| Product use/life extension | 1. Use of energy-efficient LED lamps 2. The application of life cycle thinking 3. Use of reusable cutlery and utensils 4. The minimization of the use of disposable items and the consumption of disposable packaging materials 5. The repair of old products instead of buying new products 6. Keeping old products in use and collaboration with partner organizations |

| Sharing and sharing platforms | - |

| Product-as-a-service and product-service systems | - |

| 10Rs | Identified 10R Approaches |

|---|---|

| Replacement of products or making of products redundant (R0) | 1. Gradual development of new technologies and alternative fuels [100] 2. Ecological choice of commodities (e.g., materials used in the design of ship interiors, chemicals and food assortments) [101] 3. Investment in clean technologies and emission-free port calls to combat climate change and its impacts [101,102] 4. Investment in fleet renewal [103] 5. Change of propeller blades and installation of bulb rudders (reduction in water resistance and energy savings) [103] 6. Use of new hybrid vessels with technology to save energy and minimize emissions, such as high-powered battery banks, an air lubrication system under the keel, solar panels and connection to on-shore power [103] 7. Investment in modern vehicles and equipment [104] |

| Rethinking of products (R1) | 1. Support of the transition towards greener shipping and participation in the development of low-emission maritime transport [100] 2. Gradual development of new technologies and alternative fuels [100] 3. Taking part in societal activities (e.g., decision-making and research) and collaboration with stakeholders [100] 4. The reduction of material footprint through digitalization and automation [101] 5. Ecological choice of commodities (e.g., materials used in the design of ship interiors, chemicals and food assortments) [101] 6. Investment in clean technologies and emission-free port calls to combat climate change and its impacts [101,102] 7. Life cycle approach to the environmental effects of the whole transport chain [101] 8. Continuous investigation and testing of energy-saving innovations [101] 9. Verified passenger-specific carbon dioxide emission figures [105] 10. Preference for environmentally friendly products [106] 11. Auditing of suppliers and assessment of their sustainability [106] 12. Investment in modern technologies and vehicles as a part of port and stevedoring operations [102] 13. Collaboration with flag and port state administration, customers, personnel, owners, port operators, classification society, contractors and inhabitants of harbor and fairway areas in environmental matters [102] 14. Overall development of a sustainable transport system with emphasis on adaptability, flexibility and smart approaches considering continuously changing needs and trends [102] 15. Continuous renewal and development of fleet based on latest technologies and innovations [104] 16. Continuous dialogue with customers, stakeholders and employees [104] 17. Installation of exhaust gas cleaning systems [102,103] |

| Reduction in the use of resources in the manufacturing and use of products (R2) | 1. Use of eco/energy-efficient vessels [100,102] 2. High utilization rates on routes and in vessels (ro-pax concept) [100] 3. Gradual development of alternative fuels [100] 4. Smart use of resources as part of operations [100] 5. The reduction in energy use and environmental effects of cargo and passenger operations [101,102] 6. The reduction of material footprint through digitalization and automation [101] 7. Ecological choice of commodities (e.g., materials used in the design of ship interiors, chemicals and food assortments) [101] 8. Investment in clean technologies and emission-free port calls to combat climate change and its impacts [101] 9. Life cycle approach to the environmental effects of the whole transport chain [101,102] 10. Continuous investigation and testing of energy-saving innovations [101] 11. Route optimization [103] 12. Regular cleaning of the underwater hull of all ships to reduce friction and fuel consumption [103] 13. Responsible use of natural resources [107] 14. Investigation of methods to reduce consumption and waste [106] |

| Reuse of products (R3) | 1. Reuse as part of operations [100] 2. Reuse of waste and processing of waste into material [104] |

| Repair of products (R4) | 1. Retrofitting of existing vessels [103] |

| Refurbishment of products (R5) | 1. Retrofitting of existing vessels [103] 2. Lengthening of ro-ro vessels (reduction in emissions per cargo unit) [103] |

| Remanufacturing of products (R6) | 1. Retrofitting of existing vessels [103] 2. Lengthening of ro-ro vessels (reduction in emissions per cargo unit) [103] |

| Repurposing of products and their parts (R7) | - |

| Recycling of materials (R8) | 1. Recycling as part of operations [100] 2. The maximization of waste recycling [106] 3. The recycling of metal, glass, paper and cardboard as raw material for industry [100,106] 4. Ship recycling, including inventory of hazardous materials [108] |

| Recovery of materials (R9) | 1. Recycling as part of operations [100] 2. The maximization of waste recycling [106] 3. The utilization of biowaste in nutrient production [100,106] 4. The recycling of metal, glass, paper and cardboard as raw material for industry [100,106] 5. Ship recycling, including inventory of hazardous materials [108] 6. Waste recovery and processing of waste into materials [104] 7. The separation of hazardous waste and its delivery to a designated container in the port [104] |

| CE Principles | Identified Approaches Related to the CE Principles |

|---|---|

| Circulation of products and materials | 1. Smart use of resources as part of operations 2. Reuse as part of operations 3. Reuse of waste and processing of waste into material 4. Retrofitting of existing vessels 5. Recycling as part of operations and the maximization of waste recycling 6. The recycling of metal, glass, paper and cardboard as raw material for industry 7. Ship recycling, including inventory of hazardous materials |

| Elimination of waste and pollution | 1. Gradual development of new technologies and alternative fuels 2. Investment in clean technologies and emission-free port calls to combat climate change and its impacts 3. Change of propeller blades and installation of bulb rudders (reduction in water resistance and energy savings) 4. Use of new hybrid vessels with technology to save energy and minimize emissions, such as high-powered battery banks, an air lubrication system under the keel, solar panels and connection to on-shore power 5. Investment in modern vehicles and equipment 6. Support of the transition towards greener shipping and participation in the development of low-emission maritime transport 7. The reduction of material footprint through digitalization and automation 8. Life cycle approach to the environmental effects of the whole transport chain 9. Continuous investigation and testing of energy-saving innovations 10. Verified passenger-specific carbon dioxide emission figures 11. Collaboration with flag and port state administration, customers, personnel, owners, port operators, classification society, contractors and inhabitants of harbor and fairway areas in environmental matters 12. Installation of exhaust gas cleaning systems 13. Use of eco/energy-efficient vessels 14. The reduction in energy use and environmental effects of cargo and passenger operations 15. Route optimization 16. Regular cleaning of the underwater hulls of all ships to reduce friction and fuel consumption 17. Investigation of methods to reduce consumption and waste 18. Reuse as part of operations 19. Reuse of waste and processing of waste into material 20. Lengthening of ro-ro vessels (reduction in emissions per cargo unit) 21. Recycling as part of operations and the maximization of waste recycling 22. The recycling of metal, glass, paper and cardboard as raw material for industry 23. Ship recycling, including inventory of hazardous materials 24. The separation of hazardous waste and its delivery to a designated container in the port |

| Regeneration of nature | 1. Ecological choice of commodities (e.g., materials used in the design of ship interiors, chemicals and food assortments) 2. The utilization of biowaste in nutrient production |

| CE Business Models | Identified Approaches Related to the CE Business Models |

|---|---|

| Circular supply models, supply chains and inputs | 1. Smart use of resources as part of operations 2. Reuse as part of operations 3. Reuse of waste and processing of waste into material 4. Retrofitting of existing vessels 5. Recycling as part of operations and the maximization of waste recycling 6. The recycling of metal, glass, paper and cardboard as raw material for industry 7. Ship recycling, including inventory of hazardous materials |

| Resource recovery | 1. Use of new hybrid vessels with technology to save energy and minimize emissions, such as high-powered battery banks, an air lubrication system under the keel, solar panels and connection to on-shore power 2. The reduction of material footprint through digitalization and automation 3. Life cycle approach to the environmental effects of the whole transport chain 4. Continuous investigation and testing of energy-saving innovations 5. Collaboration with flag and port state administration, customers, personnel, owners, port operators, classification society, contractors and inhabitants of harbor and fairway areas in environmental matters 6. Use of eco/energy-efficient vessels 7. The reduction in energy use and environmental effects of cargo and passenger operations 8. Route optimization 9. Regular cleaning of the underwater hulls of all ships to reduce friction and fuel consumption 10. Investigation of methods to reduce consumption and waste 11. Reuse of waste and processing of waste into material 12. Lengthening of ro-ro vessels (reduction in emissions per cargo unit) 13. The utilization of biowaste in nutrient production 14. Recycling as part of operations and the maximization of waste recycling 15. The recycling of metal, glass, paper and cardboard as raw material for industry 16. Ship recycling, including inventory of hazardous materials 17. The separation of hazardous waste and its delivery to a designated container in the port |

| Product use/life extension | 1. Reuse as part of operations |

| Sharing and sharing platforms | - |

| Product-as-a-service and product-service systems | - |

| 10Rs | Identified 10R Approaches |

|---|---|

| Replacement of products or making of products redundant (R0) | 1. Investments in sustainability (e.g., engines with lower emissions) [109] 2. Pilot project (Green Corridor Fridays), including the use of certified biogas and additional payments by customers [109] 3. Use of intelligent heating, ventilation and lighting on board [109] 4. Vessel machinery that runs on a dual fuel and battery solution [109] 5. Use of sustainable materials (e.g., recyclable tabletops and carpets) [109] 6. Cooperation with local companies and use of local raw materials [109] 7. The reduction of garbage at the source (e.g., minimization of packaging on board) and recycling, including the use of recyclable packaging as needed [109] 8. Investments in sustainability initiatives (e.g., technical vessel modifications, shore power and efficient terminal operations) [110] 9. Working towards fuel diversity (e.g., renewable, future and alternative fuels and e-fuel) [111] 10. Local suppliers of food [111] |

| Rethinking of products (R1) | 1. Investments in sustainability (e.g., engines with lower emissions) [109] 2. Cooperation with sustainability networks and suppliers [109] 3. Allocation of more resources to sustainability projects [109] 4. Pilot project (Green Corridor Fridays), including the use of certified biogas and additional payments by customers [109] 5. Use of intelligent heating, ventilation and lighting on board [109] 6. Intelligent use of water [109] 7. Vessel machinery that runs on a dual fuel and battery solution [109] 8. Use of sustainable materials (e.g., recyclable tabletops and carpets) [109] 9. Enhanced focus on resource- and energy-efficient operations [109] 10. Cooperation with local companies and use of local raw materials [109] 11. Striving towards zero emissions and continuous optimization of crossings, arrivals, loading and departures to save fuel and reduce emissions [109] 12. Use of recyclable packaging as needed [109] 13. Working with multiple partners to achieve climate neutrality and green shipping corridors (zero-emission routes) [109,111] 14. Investments in sustainability initiatives (e.g., technical vessel modifications, shore power and efficient terminal operations) [111] 15. Working towards fuel diversity (e.g., renewable, future and alternative fuels and e-fuel) [111] 16. Local suppliers of food [111] 17. Climate compensation fee as an option to offset the carbon footprint of journeys (operating with biogas and batteries) [112,113] |

| Reduction in the use of resources in the manufacturing and use of products (R2) | 1. Investments in sustainability (e.g., engines with lower emissions) [109] 2. Pilot project (Green Corridor Fridays), including the use of certified biogas and additional payments by customers [109] 3. Use of intelligent heating, ventilation and lighting on board [109] 4. Intelligent use of water [109] 5. Optimized energy consumption [109] 6. Vessel machinery that runs on a dual fuel and battery solution [109] 7. Use of sustainable materials (e.g., recyclable tabletops and carpets) [109] 8. Use of shore power in ports [109] 9. Continuous reduction of environmental footprint [109] 10. Enhanced focus on resource- and energy-efficient operations [109] 11. Cooperation with local companies and use of local raw materials [109] 12. Striving towards zero emissions and continuous optimization of crossings, arrivals, loading and departures to save fuel and reduce emissions [109] 13. Use of recyclable packaging as needed [109] 14. Working with multiple partners to achieve climate neutrality and green shipping corridors (zero-emission routes) [109,111] 15. Investments in sustainability initiatives (e.g., technical vessel modifications, shore power and efficient terminal operations) [110] 16. Working towards fuel diversity (e.g., renewable, future and alternative fuels and e-fuel) [111] 17. Local suppliers of food [111] 18. Garbage management, including reduction at the source (e.g., minimization of packaging on board) [109] |

| Reuse of products (R3) | 1. Use of sustainable materials (e.g., recyclable tabletops and carpets) [109] 2. Use of recyclable packaging as needed [109] |

| Repair of products (R4) | - |

| Refurbishment of products (R5) | - |

| Remanufacturing of products (R6) | 1. Use of sustainable materials (e.g., recyclable tabletops and carpets) [109] |

| Repurposing of products and their parts (R7) | - |

| Recycling of materials (R8) | 1. Use of sustainable materials (e.g., recyclable tabletops and carpets) [109] 2. Onboard waste management by the crew [109] 3. Waste sorting according to multiple categories [109] 4. Recycling and use of recyclable packaging as needed [109] |

| Recovery of materials (R9) | 1. Use of sustainable materials (e.g., recyclable tabletops and carpets) [109] 2. Onboard waste management by the crew [109] 3. Waste sorting according to multiple categories [109] 4. Recycling and use of recyclable packaging as needed [109] |

| CE Principles | Identified Approaches Related to the CE Principles |

|---|---|

| Circulation of products and materials | 1. Use of sustainable materials (e.g., recyclable tabletops and carpets) 2. Enhanced focus on resource- and energy-efficient operations 3. Recycling and use of recyclable packaging as needed |