1. Introduction

The increasing global reliance on fossil fuels has resulted in serious environmental challenges, including greenhouse gas (GHG) emissions, climate change, and air pollution [

1]. Diesel engines, widely used for transportation, power generation, and industrial applications, contribute significantly to the release of harmful pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO) [

2,

3]. The combustion of high-speed diesel (HSD) in particular releases substantial amounts of these pollutants, leading to deteriorating air quality and various health-related issues. Pakistan, as a developing nation, heavily depends on the import of HSD to meet its energy needs, with annual imports reaching approximately 294.46 million tons, costing around USD 140.237 million. According to the Alternative Energy Development Board of Pakistan, replacing 10% of the imported HSD with biodiesel could potentially save 29.446 million tons of diesel, resulting in a considerable economic benefit of approximately USD 14.023 million per year [

4].

The quest for renewable and sustainable energy sources has gained global attention in response to climate change and energy security challenges [

5]. Biodiesel has emerged as one of the most promising alternatives to conventional fossil fuels due to its renewability, biodegradability, and favorable emission characteristics [

6,

7]. Derived from organic feedstocks such as vegetable oils, animal fats, and waste oils, biodiesel offers a cleaner burning alternative, significantly reducing net GHG emissions and contributing to improved air quality [

8,

9]. However, the selection of suitable feedstocks remains a critical factor in determining biodiesel’s feasibility and environmental impact. While plant-based oils are commonly used, their utilization poses ethical concerns related to food security and land use. Therefore, attention has increasingly shifted towards non-edible feedstocks and waste materials as more sustainable options [

10].

Fish waste, a byproduct of the fishing and seafood processing industries, has recently garnered attention as a viable biodiesel feedstock [

11]. According to the Marine Fisheries Department of Pakistan (2021), the total annual fish production is approximately 655,245 metric tons, of which 35–40% typically becomes waste, translating to nearly 163,811 metric tons of fish waste. This aligns with recent estimates in literature that highlight the substantial waste generated by the seafood processing industry in the region [

12,

13]. Improper disposal of fish waste not only contributes to environmental pollution but also results in lost economic potential. Valorizing this waste stream for biodiesel production not only addresses waste management issues but also provides an eco-friendly and economically viable alternative fuel source.

The process of converting fish waste into biodiesel primarily involves transesterification, where fish oil is reacted with alcohol (commonly methanol) in the presence of a catalyst to produce fatty acid methyl esters (FAME) and glycerol as a byproduct [

14,

15]. Previous studies have demonstrated that fish waste-derived biodiesel exhibits physicochemical properties comparable to conventional diesel, making it a feasible option for diesel engines without significant modifications [

16,

17]. Furthermore, fish waste biodiesel is characterized by its high cetane number and reduced emissions of CO, PM, and unburnt hydrocarbons, which are desirable traits for cleaner combustion.

Fish waste biodiesel offers a sustainable alternative to fossil fuels, having its potential to mitigate environmental pollution from waste and contribute to energy security [

18]. This abundant byproduct from the aquaculture and fishing industries, rich in lipids and beneficial fatty acids like EPA and DHA, serves as an excellent feedstock in producing biodiesel [

19]. Significant progress has been made in its production using different methods including transesterification being optimized through various catalytic approaches. Homogeneous and heterogeneous catalysts like sodium hydroxide (NaOH) and β-tri-calcium phosphate derived from fish waste itself offer improved reusability and high yields of ~92.1% and >95%, respectively, [

20,

21]. Nano-magnetic catalysts accelerate reactions and are easily recoverable, while supercritical methanol transesterification achieves very high yields of ~94.6% and purity without catalysts, addressing impurity issues [

22]. These production advancements consistently yield biodiesel that meets international fuel standards like ASTM D6751 and EN 14214 for properties such as flashpoint, calorific value, kinematic viscosity, and density [

23,

24].

However, challenges persist in its application. A significant hurdle lies in emission profiles. Fish waste biodiesel generally reduces carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM). For instance, the B50 ESBD blend achieved a substantial 69.23% reduction in CO and a 27.35% reduction in HC emissions [

25]. A B30 blend was also shown to lower CO2 emissions by 4% and HC emissions by 5% [

26]. However, it consistently increases nitrogen oxide (NOx) emissions due to higher combustion temperatures and increased oxygen content [

27]. Mitigation strategies, such as Exhaust Gas Recirculation (EGR) and the use of nano-metal oxide particles, are being explored. Studies have demonstrated significant NOx reductions with increasing EGR rates, e.g., 35.13% reduction at 5% EGR and up to 85.21% reduction at 15% EGR) though EGR can lead to increased soot [

28]. Long-term durability and material compatibility also pose concerns, as the oxygenated and acidic nature of biodiesel can cause corrosion in metallic fuel system components (e.g., copper and brass) potentially leading to premature component failure [

29].

Beyond technical aspects, economic viability and scalability are critical. Studies indicate that only large-scale production plants are economically viable with factory location and raw material transportation costs [

29]. Additionally, there is a significant gap in comprehensive life cycle assessment (LCA) studies specifically for fish waste biodiesel, which is vital for a full understanding of its environmental sustainability. Current research is actively addressing these deficiencies by developing more stable and reusable catalysts such as optimized β-tri-calcium phosphate [

30], integrating advanced process modeling with experimental validation for energy efficiency, systematically investigating material compatibility for anti-corrosion solutions [

29], and exploring approaches to simultaneously reduce NOx and optimize combustion [

26]. These efforts aim to overcome existing barriers, paving the way for fish waste biodiesel to become a truly sustainable and commercially viable energy source.

The present study aims to evaluate the performance and environmental impact of biodiesel produced from fish waste through an integrated approach involving experimental testing and simulation analysis. The LOMBARDINI 15LD225 diesel engine was employed to assess biodiesel blends’ efficiency, power output, and emissions under various operating conditions. Furthermore, a simulation model developed using Ricardo Wave software 2019.1 was validated against experimental results to assess its reliability. The findings from this study contribute to the broader effort of promoting sustainable energy solutions through effective waste valorization and achieving environmental sustainability by reducing reliance on fossil fuels.

3. Results and Discussion

3.1. Biodiesel Yield and Conversion Efficiency

The wet rendering method achieves a 35% fat-to-oil conversion, extracting 350 mL of oil from 1 kg of fish fat. During transesterification, 40 g of oil results in a 65% oil-to-biodiesel conversion, yielding 25 mL of biodiesel.

3.2. Physicochemical and Structural Characterization of Fish Waste Biodiesel

3.2.1. Physicochemical Properties Comparison with ASTM D6751 Standards

The physicochemical properties of biodiesel and its blends, i.e., B10, B20, B10W10 were found to be within the standard values of ASTM D6751 and presented in

Table 4. The calorific value of fish biodiesel was 40.47 MJ/Kg while B10, B20 and B10W10 were found to be 45 to 48 MJ/Kg. The lowest kinematic viscosity was recorded by B20 which was 2.53 mm

2/s. However, flash point was 10 °C higher than the standard of biodiesel and for other blends this property was comparable with mineral diesel. The cetane number of blends was slightly lowered, having the lowest cetane number found in B20 and B10W10 blends. The combustion behavior and performance of biodiesel blends are directly influenced by their physicochemical properties. The fish waste biodiesel used in this study exhibited a cetane number of 55.92, which exceeds the ASTM D6751 minimum of 47. This promotes shorter ignition delay and more stable combustion. The kinematic viscosity of the B20 blend (2.53 mm

2/s) lies well within the optimal range for diesel injectors, supporting fine atomization and efficient air–fuel mixing. The higher flash point (140 °C) indicates safer handling and storage, although it has limited impact on engine combustion under standard conditions. The calorific value of fish waste biodiesel (40.47 MJ/kg) is lower than that of mineral diesel, which results in slightly reduced brake power output, particularly at higher engine speeds. Additionally, the presence of oxygen in biodiesel molecules contributes to more complete combustion, thereby reducing CO emissions, as observed experimentally. These properties collectively support the feasibility of using fish waste biodiesel blends in existing diesel engines without modification, while also revealing minor performance trade-offs associated with lower energy density.

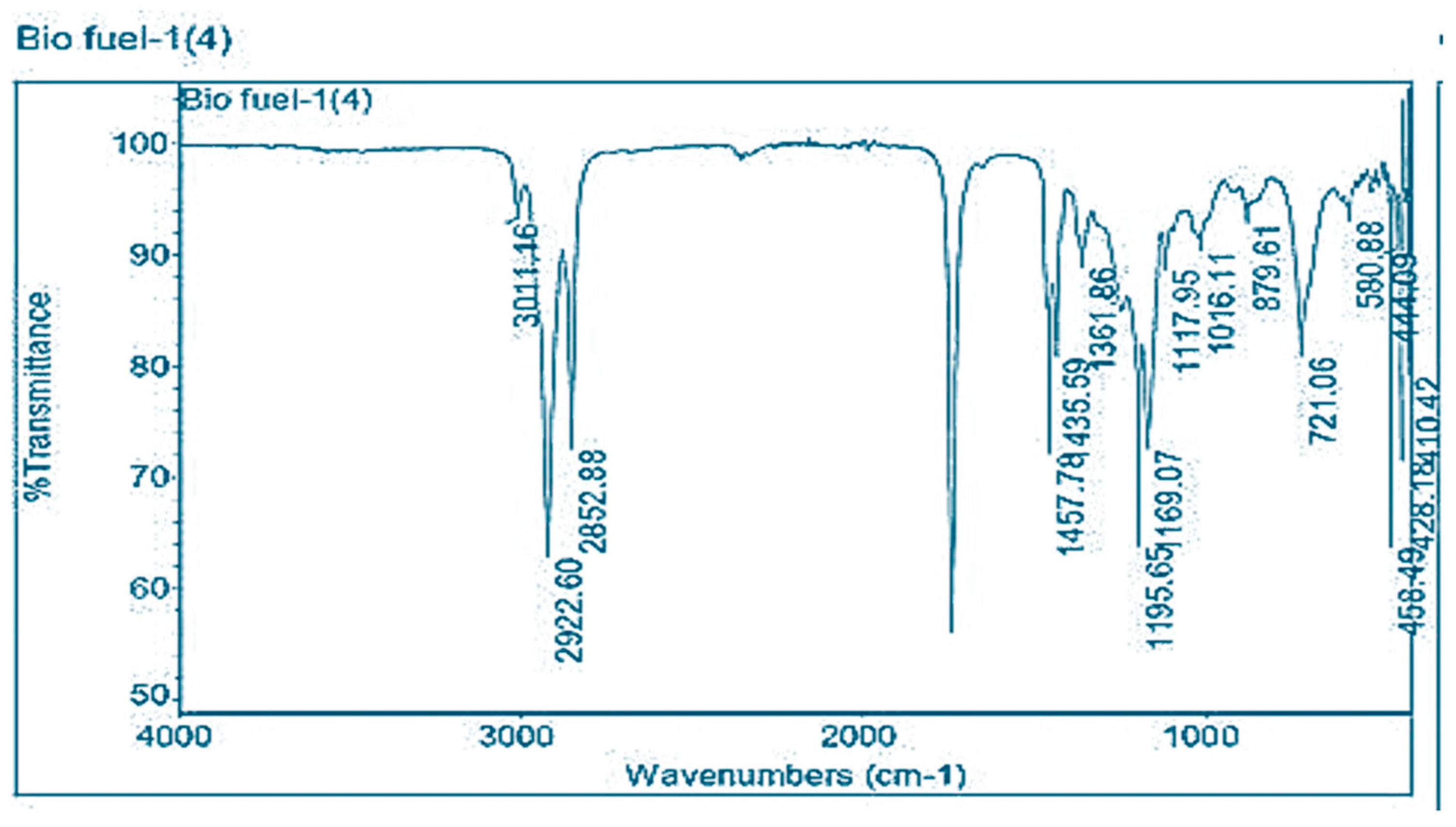

3.2.2. Functional Group Analysis by FTIR Spectroscopy

Fourier Transform Infrared Spectroscopy (FTIR) was used to distinguish and evaluate chemical substances by measuring a sample’s infrared light absorption. To identify specific functional groups, the resulting absorption spectra is subjected to Fourier transform analysis. The FTIR spectrum of fish waste biodiesel (

Figure 2) showed unique peaks associated with different functional groups. The broad feature at 3346–2816 cm

1 represents the carboxylic acid O-H stretch, whereas the acute peaks at 2922.60 and 2852.88 cm

1 indicate the asymmetric and symmetric CH

2 stretches, respectively. The C=O stretch was indicated by the sharp peak at 1558.82 cm

1, and the C-O stretch was indicated by the peak at 1020.69 cm

1. O-H bonds appeared in-plane and out-of-plane at 1457.82 and 1195 cm

1, respectively.

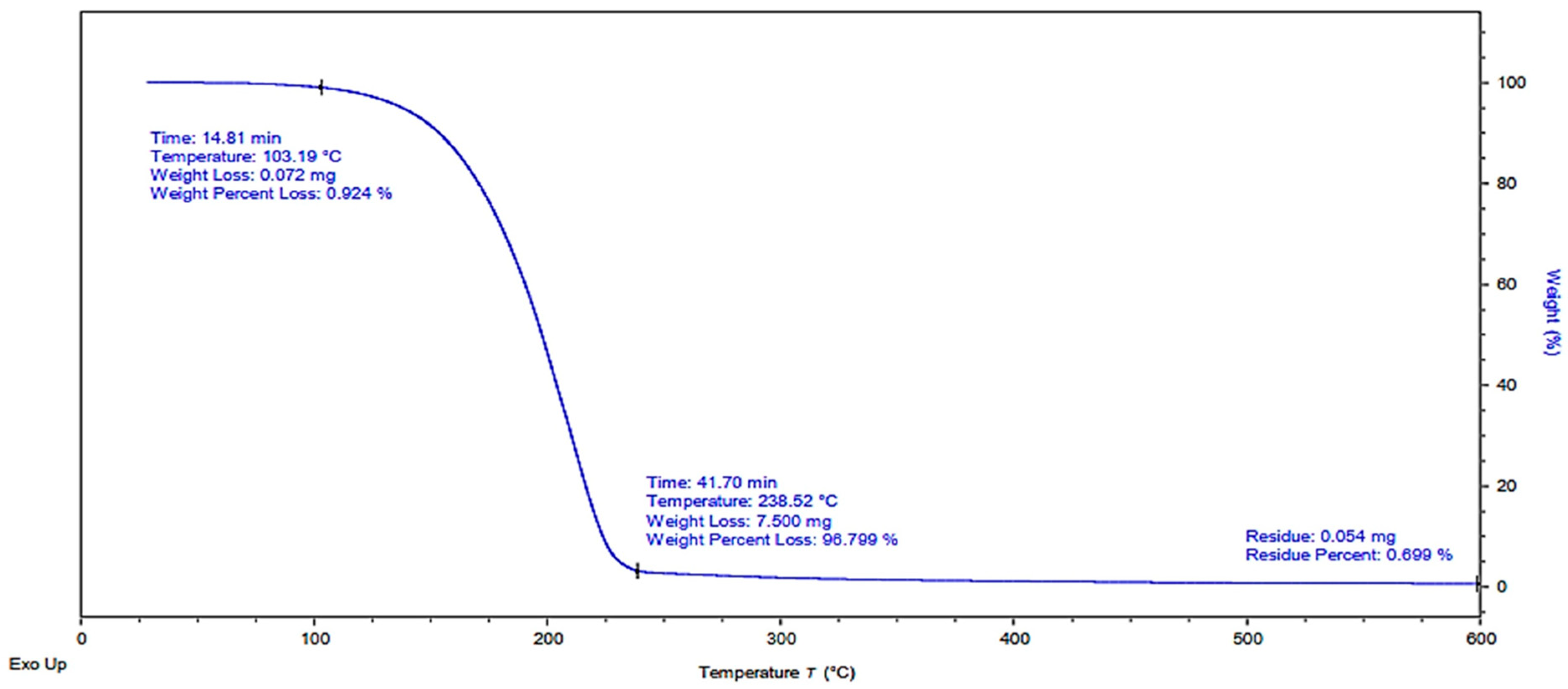

3.2.3. Thermal Degradation Characteristics via Thermogravimetric Analysis (TGA)

TGA test was conducted for examining the thermal stability and composition of materials using controlled heating or cooling. TGA as shown in

Figure 3 demonstrated considerable weight loss during thermal degradation of fish waste biodiesel as temperature increased. The observed weight loss curve shows fast breakdown, with the percentage of weight falling dramatically as the temperature was raised to 100 °C and eventually reached zero at 238.52 °C.

3.2.4. Fatty Acid Profiling by Gas Chromatography (GC)

Gas chromatography (GC) was a technique used to separate and analyze the individual components of a mixture, such as oil. In the case of oil analysis, a sample of the oil is injected into the GC instrument and then separated as it passes through a stationary phase, typically a solid or a liquid, inside a column. The individual components of the oil are then detected and analyzed based on their chemical properties, such as boiling point, vapor pressure, and polarity. GC is commonly used to determine the composition of oils and to detect impurities or contaminants. The main component required for the production of biodiesel were present in fish waste oil samples as listed in

Table 5.

3.3. Engine Performance Evaluation and Emission Analysis

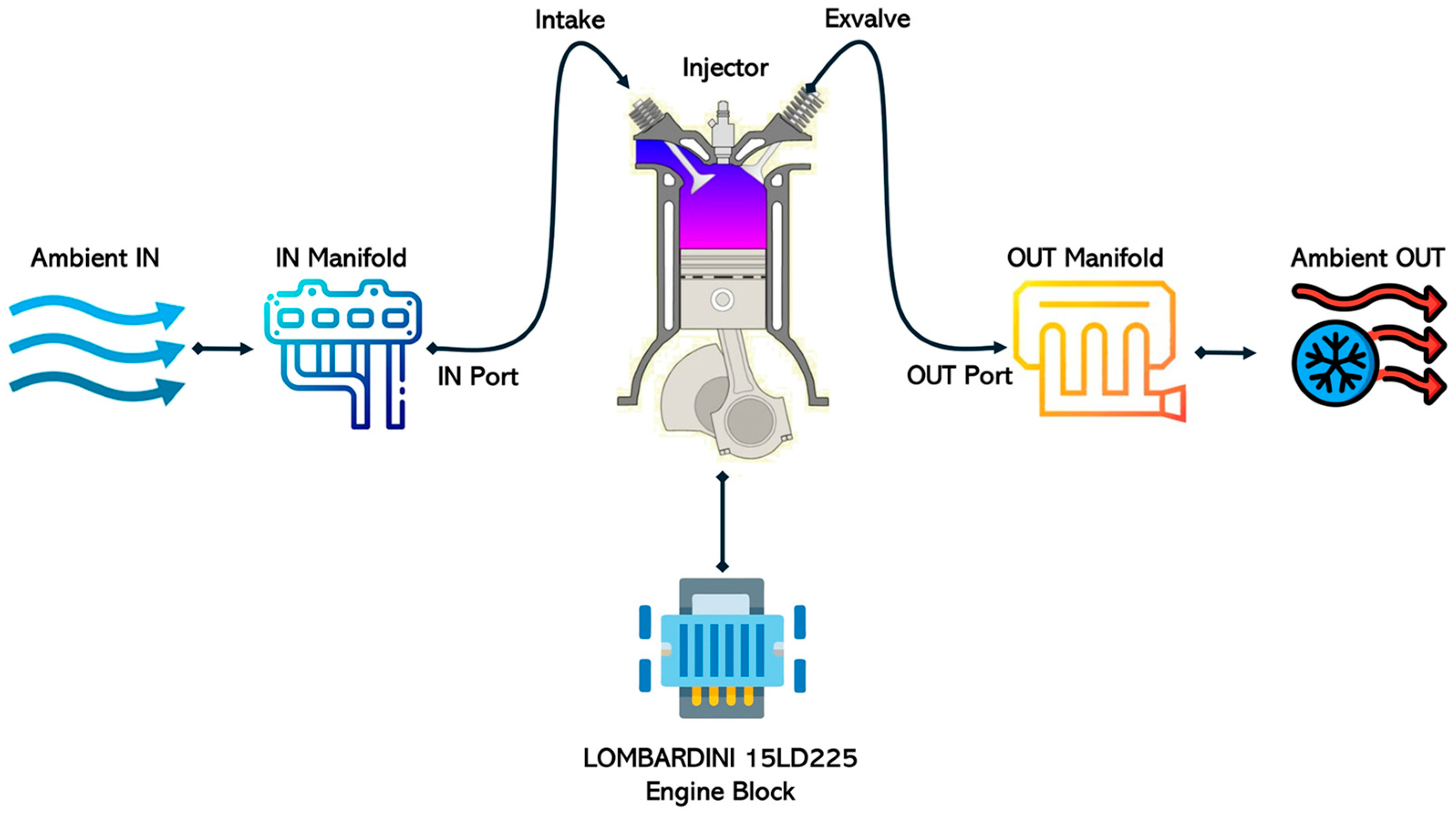

A LOMBARDINO 15LD225 diesel engine coupled with Cussons P8250 service module and KANE 905 emissions tester was used to measure important performance metrics such as power output, engine temperature, net temperature, CO emissions, and fuel efficiency were all part of the testing process. This study aims not only to evaluate the basic feasibility of using fish waste-derived biodiesel as an alternative to mineral diesel, but also to explore how such biodiesel blends can be utilized more effectively in existing diesel engine platforms. By integrating engine performance testing with high-fidelity simulation using Ricardo Wave, the research identifies optimal blend ratios, analyzes combustion behavior under variable load conditions, and validates emissions trends. This approach aligns with the evolving goals of biofuel research, which now emphasize operational optimization, fuel-engine compatibility, and pathway scalability, rather than mere substitution. The tests were carried out under controlled environment to select the suitable blend as a green-energy alternative to mineral diesel.

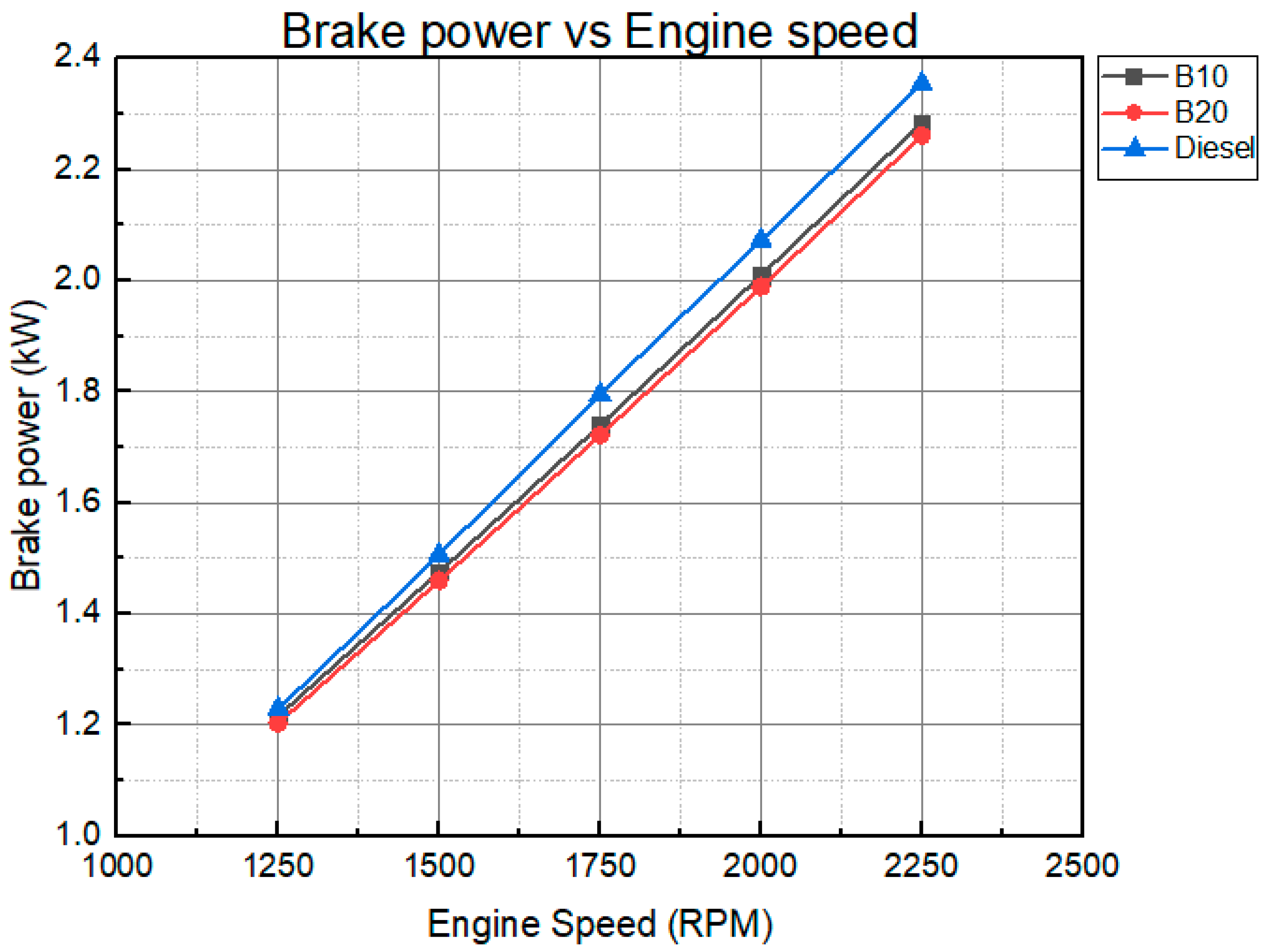

By examining engine power curves (

Figure 4) in comparison to conventional diesel fuel, this study explores the impact of fish waste biodiesel blends, specifically B10 and B20, on engine performance. The curves for B10 and B20 were found to be lower than those for diesel fuel, implying that these biodiesel mixes may reduce engine power. The B20 blend performed linearly throughout different engine speeds, but with less power at higher speeds as compared to other fuels. These findings help us understand the applicability of fish waste biodiesel blends for engine applications and emphasize the significance of additional research and optimization in biodiesel fuel formulations.

The observed trends in engine performance and emissions can be better understood by examining the physicochemical and structural properties of the biodiesel blends used in this study. The following analysis connects fuel characteristics to key combustion outcomes:

Combustion Performance: The slightly lower brake power of B20 at higher RPMs is explained by its reduced calorific value (47.57 MJ/kg) compared to mineral diesel (52.8 MJ/kg). The energy density deficit results in lower thermal energy release per unit mass, which becomes more pronounced at higher engine loads.

Ignition Quality and Combustion Stability: The high cetane number of the fish biodiesel (55.92) supports efficient ignition, reducing delay and improving combustion stability, especially under partial load conditions. This property compensates for the lower energy content to some extent and contributes to smoother operation with B10.

Emission Reduction Behavior: The substantial decrease in CO emissions in both B10 and B20 blends is directly tied to the inherent oxygen content in biodiesel molecules. This oxygen facilitates more complete combustion, reducing the formation of incomplete products like CO—even when engine parameters remain unchanged.

Viscosity and Atomization: The B20 blend had the lowest viscosity (2.53 mm2/s), supporting fine fuel atomization and uniform mixing, which enhances combustion quality and lowers unburned fuel emissions.

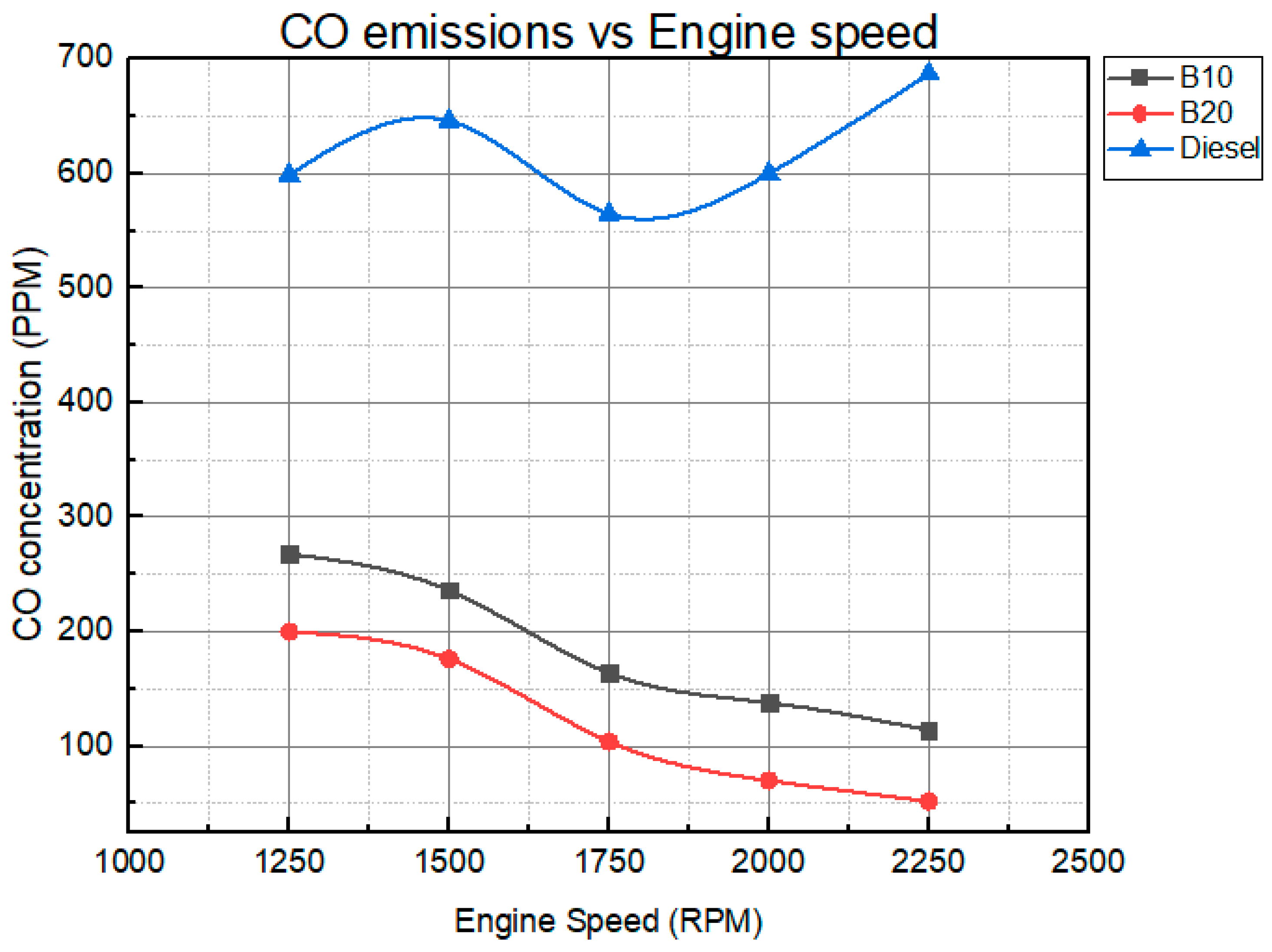

The graph plotted looks on the emissions from fish waste biodiesel mixes, with a particular emphasis on CO emissions, see

Figure 5. The maximum particle per minute of CO was found in mineral diesel fuel in the range of 600 to 700 ppm, while B10 and B20 blends had much lower CO levels [

35]. CO emissions fell as the blend ratio increased, with B20 blend showing an initial spike 200 ppm at 1250 RPMs followed by a decline reaching to 50ppm at 2250 RPM. Moreover, the B10 blend had the highest CO emissions among the blends which ranged from 300 ppm to 100 ppm. The observed CO emission spike at 1250 RPM for the B20 blend—reaching up to 200 ppm—can be attributed to suboptimal combustion conditions at low engine speeds. At reduced RPMs, the engine operates with lower in-cylinder turbulence, leading to weaker air–fuel mixing. The relatively higher viscosity and lower volatility of the B20 blend compared to diesel may result in delayed atomization and incomplete combustion during ignition. These factors contribute to an increase in CO formation due to inadequate oxygen-fuel interaction. As engine speed increases, the turbulence and mixing improve, leading to more complete combustion and a subsequent drop in CO levels.

CO emissions, a major contributor to air pollution, endanger both human health and the environment. The reduction in CO emissions reported with fish waste biodiesel blends, notably B10 and B20, is a viable technique for improving air quality, mitigating climate change, and promoting public health.

3.4. Simulation Analysis and Validation via Ricardo Wave Software

To provide a more comprehensive understanding of fish waste biodiesel performance, the Ricardo Wave simulation model was used to simulate engine operation under controlled conditions mirroring the experimental setup. The LOMBARDINI 15LD225 engine was digitally replicated with precise geometric and operational parameters, enabling simulation across various engine speeds (1250 to 2250 RPM) and using B10 and B20 blends. Key elements such as the Wiebe combustion model and Woschni heat transfer model allowed the simulation to account for realistic combustion dynamics and energy exchange, ensuring that the model reflected engine thermodynamics accurately.

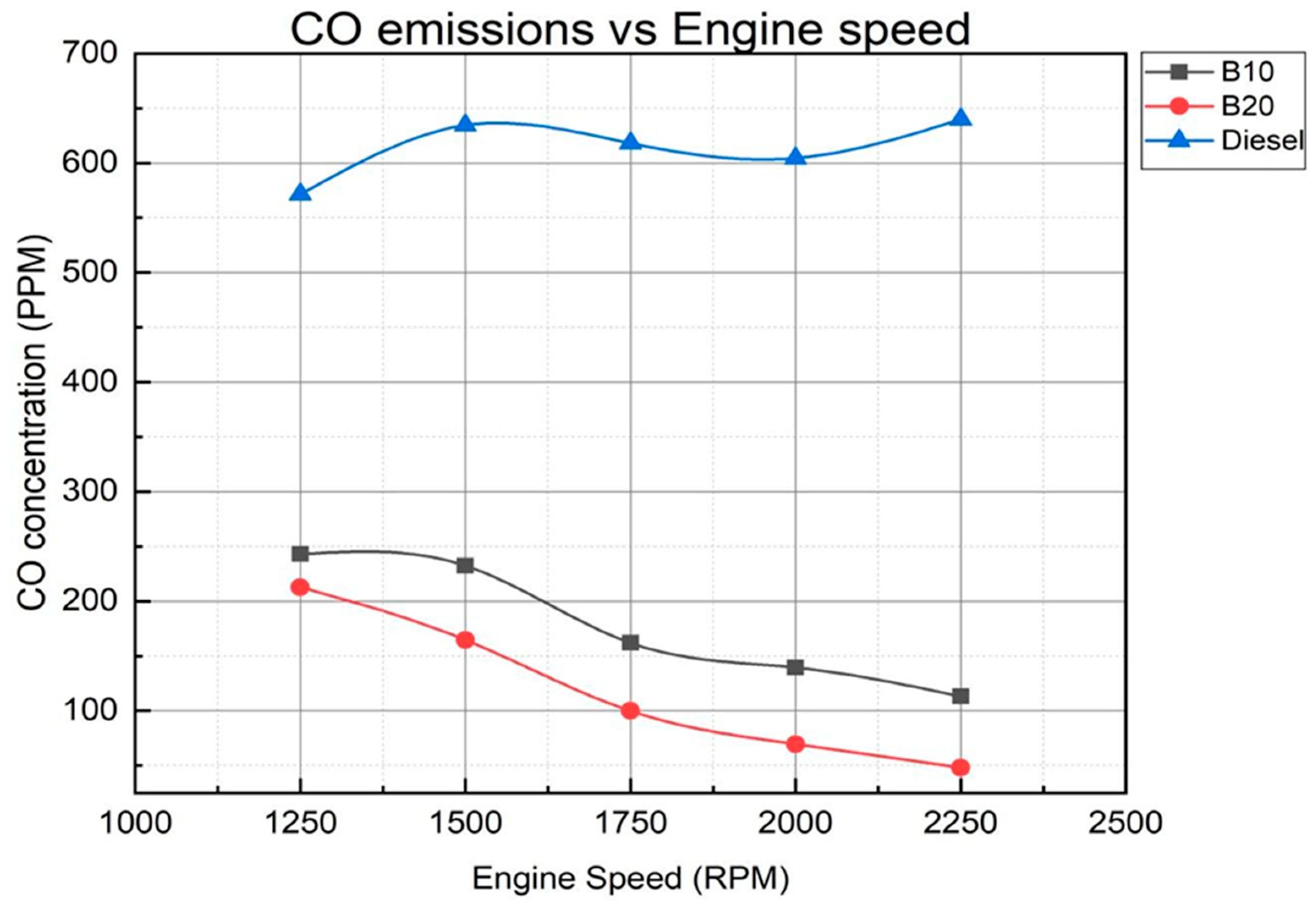

The simulation results as presented in

Figure 6 and

Figure 7 showed a consistent trend of reduced carbon monoxide (CO) emissions for biodiesel blends compared to conventional diesel, corroborating experimental observations. The CO reduction is attributed to the oxygen-rich nature of biodiesel, promoting more complete combustion. Notably, the B20 blend exhibited a smoother decline in CO emissions at higher RPMs, indicating enhanced combustion stability and reduced formation of incomplete combustion products.

Brake power outputs across different blends also aligned closely with experimental results, showing negligible discrepancies and reaffirming the engine’s ability to operate efficiently on biodiesel without performance loss. This suggests the simulation model can serve as a predictive tool in future engine calibration for biodiesel adoption.

Moreover, these simulations validate the accuracy of using prebuilt fuel libraries in Ricardo Wave for approximating biodiesel behavior, particularly when elemental composition is correctly modified to match ASTM PS121 standards. This step is essential, as biodiesel from fish waste may differ slightly in fatty acid content compared to standard FAME. The simulation also helps bridge the gap between lab-scale findings and large-scale implementation, by allowing the prediction of engine behavior under varying loads, fuel blends, and speeds before real-world deployment. Such models are invaluable for optimizing biodiesel blend ratios and guiding engine redesign for better performance and emissions control.

3.5. Experimental Validation of Simulation Results

The validation phase of the Ricardo Wave simulation model focused on aligning the predicted CO emissions with empirical data obtained from engine testing. The percentage error at each engine speed was calculated using the formula: Error (%) = |Simulated − Actual|/Actual × 100. The mean of the individual accuracies across all RPM points was used to estimate the model’s overall accuracy. The model achieved an overall accuracy of approximately 90%, which is highly commendable in computational modeling [

36]. This high correlation underscores the robustness of the thermodynamic assumptions and combustion models used, especially considering the inherent complexities of real-world engine behavior. The simulation’s ability to accurately predict CO emissions is strongly supported by the incorporation of realistic fuel properties—such as cetane number and elemental oxygen content—into the Ricardo Wave model. This alignment between biodiesel’s combustion characteristics and the simulation framework contributed to the model’s ∼90% accuracy, particularly under steady-state engine speeds.

However, a detailed analysis reveals that prediction errors, though minor, tend to vary across engine speeds. For instance, discrepancies were slightly higher at lower speeds (1250 RPM) and in the B10 blend, where combustion dynamics are more sensitive to minor variations in air–fuel ratios and cylinder temperature gradients. This indicates that simulation precision is highly dependent on the granularity of engine input parameters such as injector timing, spray characteristics, and local turbulence effects.

The findings in

Table 6 demonstrate that prediction errors for CO emissions remained within an acceptable range (typically below 10%), validating the model’s applicability for simulating emissions behavior. These results also highlight areas where further refinement—such as incorporating real-time heat transfer coefficients or adapting the Wiebe function for different biodiesel compositions—could reduce the margin of error.

Additionally, while the model focused primarily on CO emissions, its framework can be extended to estimate other pollutants such as nitrogen oxides (NOx), particulate matter (PM), and unburnt hydrocarbons. Future iterations of the model should include subroutines for NOx formation kinetics and soot modeling, particularly as these emissions play a crucial role in regulatory compliance and environmental sustainability.

Experimental validation not only confirms the simulation’s credibility but also enhances confidence in using such digital tools for pre-implementation assessments of biodiesel fuels. The integration of simulation and experimental methods promotes a more efficient research approach, minimizing resource use and reducing the trial-and-error associated with biodiesel engine testing.

4. Discussion

The findings of this study provide significant insights into the potential of fish waste-derived biodiesel as a sustainable and environmentally friendly alternative to conventional fossil fuels. By effectively utilizing fish waste, a major byproduct of the fishing industry, this study demonstrates a promising approach to waste valorization that aligns with the principles of the circular economy. The production of biodiesel from fish waste not only offers a solution for reducing environmental pollution associated with improper disposal but also contributes to the generation of renewable energy. Considering the large quantities of fish waste generated annually, particularly in developing countries like Pakistan, this approach presents a viable opportunity to enhance energy security and reduce dependency on imported diesel.

From an environmental perspective, the reduction in carbon monoxide (CO) emissions achieved through the use of fish waste biodiesel is particularly significant. The lower CO emissions observed with B10 and B20 biodiesel blends compared to conventional diesel can be attributed to the higher oxygen content of biodiesel, which facilitates complete combustion. This finding has substantial implications for improving air quality and mitigating the harmful health effects associated with diesel engine exhaust. Furthermore, the utilization of waste materials such as fish waste for biodiesel production can contribute to reducing overall greenhouse gas (GHG) emissions, thereby supporting global efforts to combat climate change.

The economic implications of fish waste biodiesel production are also noteworthy. The integration of biodiesel production within existing fish processing industries could provide additional revenue streams while simultaneously addressing waste disposal challenges. This dual benefit could enhance the economic feasibility of biodiesel production and encourage investment in related technologies. Moreover, the successful demonstration of fish waste biodiesel’s compatibility with existing diesel engines provides a practical pathway for integrating biodiesel into the current energy infrastructure without requiring significant engine modifications or costly technological changes.

In addition to the economic and environmental benefits, the findings of this study have important implications for policy development and regulatory frameworks. Governments and regulatory bodies seeking to promote sustainable energy solutions may consider encouraging the use of biodiesel produced from waste materials through incentives, subsidies, and supportive policies. Establishing standards for biodiesel production from unconventional feedstocks such as fish waste could further enhance the credibility and acceptability of this approach. Furthermore, the successful implementation of fish waste biodiesel production could serve as a model for other countries seeking to reduce their carbon footprint and enhance energy resilience.

The technological implications of this study are equally important. The successful application of Ricardo Wave software for simulation and validation of engine performance indicates the potential of computational modeling as a valuable tool for optimizing biodiesel production and engine compatibility. The 90% accuracy achieved in predicting CO emissions demonstrates the reliability of the simulation approach, suggesting that future research could expand this method to include other pollutants such as nitrogen oxides (NOx) and particulate matter (PM). Additionally, refining simulation models to account for heat transfer and combustion characteristics more accurately could enhance predictive accuracy and reduce the experimental burden associated with biodiesel testing.

Overall, the implications of this study extend beyond the laboratory setting to practical applications in industrial processes, environmental management, and policymaking. By providing a comprehensive evaluation of fish waste biodiesel in terms of yield, characterization, engine performance, emissions, and simulation accuracy, this study contributes valuable knowledge to the field of renewable energy. The successful utilization of fish waste as a biodiesel feedstock could inspire further research on other types of organic waste, contributing to a broader effort to achieve sustainability and reduce environmental impacts associated with conventional diesel usage. A limitation of this study is the absence of NOx and particulate number (PN) emission measurements, which are essential for a comprehensive assessment of diesel engine emissions; future work will address this by incorporating advanced exhaust gas analyzers to evaluate the full spectrum of combustion byproducts from fish waste biodiesel blends.

5. Conclusions

This study demonstrated the viability of fish waste-derived biodiesel as a sustainable and environmentally friendly alternative to conventional diesel fuel. Through a two-step transesterification process, high-FFA fish oil was successfully converted into biodiesel with fuel properties that met ASTM D6751 standards. The key innovation lies in the integrated assessment of this biodiesel through both experimental engine testing and simulation modeling using Ricardo Wave.

The research showed that B10 and B20 blends provided substantial reductions in CO emissions while maintaining acceptable engine performance, especially under moderate load conditions. The simulation model achieved ~90% accuracy in predicting emission behavior, validating its use as a digital tool for optimizing biodiesel application.

By valorizing fish industry waste and applying it in real-world engine scenarios without requiring injector modification, the study contributes to circular economy strategies and offers a pathway for low-cost, low-emission fuel deployment. Future work will address the current limitation of NOx and particulate emission analysis to further enhance the environmental assessment of biodiesel blends.