Abstract

Telemetry systems are increasingly finding applications in agriculture for a variety of tasks. These systems assist farmers in optimizing farm processes. By leveraging these technologies, energy resources can be used more efficiently, leading to reduced environmental pollution. The primary objective of this research is to analyze telemetry data and explore ways to enhance the efficiency of combine harvesters (CHs). For this study, data from the Lexion 750 TT CH equipped with a crawler chassis was selected. Harvesting operations were conducted across fields growing popular plant types in Lithuania, including wheat, barley, rapeseed, oats, corn, and beans. The selected CH was also equipped with a remote monitoring system for tracking machine parameters. During the research, the structure of the time distribution of the work and the consumed fuel was analyzed. The highest operational efficiency—defined as the proportion of time spent on productive harvesting tasks—was 78%, observed during the oat harvest, when the unloading while harvesting, unloading while idle, harvesting, and headland turns were 3%, 2%, 64%, and 9%, respectively. The lowest efficiency, 56%, occurred during wheat harvesting. It was found that harvesting 899.32 ha of six different plant species with the tested CH produces 46.11 t of GHG emissions in CO2eq. The largest part of the emission in CO2eq was released during direct harvesting, with the engine operating at 1800–1900 min−1. However, as much as 30% of the time and 11.2% of fuel was consumed by the CH for non-harvesting activities. In conclusion, attention should be paid to reducing the inefficient use of CH time. In this way, technological operations would not only be carried out more rationally, but also environmental pollution would be reduced, and in the case of this study, we could potentially reduce CO2eq emissions by more than 10%.

1. Introduction

Life on Earth is under severe threat from environmental degradation [1]. One of the most pressing problems is global warming, which is mainly caused by decades of intensive fossil fuel use [2,3]. Greenhouse gas (GHG) emissions have become a major environmental problem, with carbon dioxide emissions and pollution being the main drivers of climate change [4,5]. While technological advances over the centuries have improved the quality of life, they have also exacerbated environmental problems, particularly GHG emissions [6]. Carbon dioxide (CO2), the main GHG associated with human activities, has increased globally by 47.7% since the end of the 20th century [7]. In 2019, CO2 emissions from fossil fuels, deforestation, and other anthropogenic sources amounted to approximately 43 billion metric tons [8,9].

GHG emissions occur in five main sectors: energy systems, transport, buildings, industry, and agriculture [10]. While agriculture provides essential food resources, it is a significant source of GHG and air pollutants, mainly due to emissions from machinery and the management of biodegradable waste [11,12,13]. These practices contribute to water quality degradation, water wastage, and biodiversity loss [14,15]. Agriculture is the second largest source of GHGs, accounting for 24–30% of total emissions [6,16], with CO2, methane (CH4), and nitrous oxide (N2O) being the main sources [17]. The Global Warming Potential (GWP) metric, which is a common basis for emission reduction strategies, is relatively widely used to assess the long-term impacts of these gases [18,19].

Internal combustion engines (ICEs) play a dominant role in agriculture, transport, and industry, contributing significantly to air pollution and GHG emissions [20,21]. Agricultural machinery, mainly diesel-powered, consumes large amounts of fuel, ranging from 50 to 150 L per hectare for grain production [22]. This fuel consumption not only increases GHG emissions, but also has a significant impact on global public health, with around 4.2 million people dying each year due to air pollution [23]. Diesel combustion in agricultural machinery contributes to respiratory diseases and is classified as a carcinogen by the World Health Organization [24]. Addressing this problem requires advanced technologies to reduce fuel consumption and emissions [25,26].

CHs, which are indispensable for large-scale agriculture, contribute significantly to emissions. Harvesting operations are energy-intensive and fuel consumption is directly linked to CO2 emissions [27,28]. CH emissions range from 8.5 to 11.5 kg carbon equivalent per hectare [29]. Optimizing CH operations through technological and organizational improvements—such as adjusting speeds, operating modes, grain unloading methods, and operator training—can lead to significant reductions in emissions [30,31,32]. Skilled operators, with the help of advanced tools, can adapt machine settings to changing crop conditions and achieve near-optimal performance [33,34]. Drivers who are aware that they are being monitored by telematics systems may change their behavior, become more disciplined, and pay more attention [35]. However, modern technology can also place excessive demands on drivers, highlighting the need for a balanced implementation between human capacity and optimal technology application [36].

Telematics is a promising solution offering remote monitoring and data recording of CH operations, allowing for optimized logistics and machine performance [37,38]. Modern CHs are equipped with sensors and control units that collect data such as fuel consumption, engine load, grain yield, moisture content, and GPS-based field position. This information is transmitted wirelessly via cellular networks, satellite links, or local Wi-Fi to cloud platforms or dedicated information systems. The data is then stored in structured databases for further analysis and decision-making on logistics, maintenance, and agronomic planning. The reliability of telemetry data has improved significantly with improvements in sensor accuracy, signal redundancy, and error-checking algorithms, although it can still be affected by network coverage and hardware calibration. Analysis of telematics data has shown that around 33% of CH time is spent moving from one field to another or standing with the engine running, rather than doing direct work. Analysis of individual machines showed that some of them spend 33% of their time in transport mode and about 37% in idle mode. The results of the field trials and the data stored in the telematics database showed that the selection of optimal technological operations and CH parameters in idle and transport mode can reduce the environmental impact by 1300 kg year−1 CO2 equivalent per machine [39]. Despite the potential, current telematics systems have shortcomings, including limited access to data and lack of transparency [40,41]. CH telematics data, which is often limited to time and fuel consumption indicators, cannot be analyzed over multiple machines or longer time periods, which is a barrier to wider environmental assessments [42]. Improved access to and use of telematics data could facilitate fuel efficiency and reduce GHG emissions. The development of IT tools for better analysis of telematics data would provide significant environmental and economic benefits, supporting sustainable agricultural practices.

This study is based on a detailed analysis of telematics data from a real-life case study of a CH working intensively in a variety of cereal crops and having a long and productive season. Such cases, however isolated, when analyzed in detail, make a significant contribution to the overall understanding and enrichment of knowledge in an area of importance to all. It highlights problem areas and suggests solutions.

The aim of this study is to assess the operational efficiency and environmental impact of a CH using telemetry data over a full harvest season. The specific objectives are: (I) To quantify time and fuel consumption across various operational modes (e.g., harvesting, idling, transport). (II) To analyze differences in efficiency and GHG emissions between six commonly cultivated cereal crops. (III) To identify inefficiencies in indirect activities and propose potential strategies to reduce fuel use and emissions.

2. Materials and Methods

The Lexion 750 TT (TerraTrac) CH (CLAAS, Harsewinkel, Germany) with a tracked chassis was chosen for the study. The six different cereal crops most commonly grown in Lithuania (and in the region) were studied: wheat (232.67 ha), barley (85.93 ha), oilseed rape (169.22 ha), oats (117.41 ha), maize (204.95 ha), and beans (89.14 ha). In total, 899.32 ha were harvested in the 2023 season. CH was equipped with an OM502 LA engine with a power of 436 kW and a V1050 cutter bar with an effective cutting width of 10.67 m. The CH was also equipped with a remote monitoring system for tracking the machine’s parameters—telematics. Harvest parameters such as area harvested, fuel consumption, and working hours in different operating modes were collected from a database stored in the telemetry system. The data was also recorded on electronic control units (ECUs) and subsequently uploaded to cloud storage. All data were obtained from the CH’s remote-control system and recorded by the CH’s microprocessors, thus ensuring a high degree of reliability, avoiding the human factor, and allowing for a comprehensive and multifaceted subsequent analysis. The principal data flow diagram is shown in Figure 1. Modern technology ensures the high quality and reliability of the recorded data.

Figure 1.

Telemetry data flow diagram.

Table 1 shows the standard frequencies for data transmission from the CH to remote databases. Manufacturers use their own standards and frequencies may vary. In many cases, the actual specifications are also protected by intellectual property rights.

Table 1.

Typical data transmission frequencies from CH via telematics system.

The amount of data collected by the telemetry system is extensive, but only the data that determines the efficiency of the CH was analyzed, which mainly relates to the time spent in the different states of the machine and the fuel consumed in them.

To calculate greenhouse gases (GHGs) and global warming potential (GWP) from data obtained from the telematics database, the fuel consumption data of the CH was converted from liters per year (L year−1) to kilograms per year (kg year−1), and from liters per hour (L h−1) to kilograms per hour (kg h−1). A diesel fuel volume-to-mass conversion factor (k) of 0.832 kg per liter was utilized for these calculations [43,44,45,46].

GHG emissions from telematics data analysis were estimated by using the methodology described in Chapter 1.A.4 of the EMEP/EEA’s Air Pollutant Emission Inventory Guidebook [47]:

where:

ECO2, CH4 or N2O is the emission of a specified GHG (CO2, CH4, or N2O), kg h−1;

FCdiesel fuel is the fuel consumption, L h−1;

EFCO2, CH4, or N2O is the pollutant emission factor, kg kg−1 of consumed fuel (Table 2).

Table 2.

GHG emission factors (Tier 2) for agricultural transportation by combusting diesel fuel [47,48,49].

All GHG emissions have an impact on GWP (kg), which was calculated and expressed as CO2 equivalents as follows:

Each GHG, expressed as CO2 equivalents, is such that 1 kg of CO2 = 1 kg of CO2eq, 1 kg of CH4 = 25 kg of CO2eq; 1 kg of N2O = 298 kg of CO2eq [50,51,52,53].

3. Results and Discussion

The CH tested was above average in terms of time worked per season. As previous studies have shown, in the region, one CH averages about 246 h year−1 per season [39], while the CH in our study worked 492.8 h year−1 and harvested 899.32 ha year−1 in the 2023 season. This time includes all the time the engine is on—the effective and ineffective work of the CH. Much higher operating hours per season indicate that the CH belongs either to a large farm or to a rental company, as practice shows that such machines work longer. In principle, intensive use of a machine contributes to its more sustainable use, as an expensive and complex machine must be used to its maximum potential in order to maximize its economic and environmental impact [39]. During the study period (the 2023 season), the CH was operated by a total of two experienced male operators aged 47 and 49. Both had over five years of experience working with this type of machine. Each had a workload of approximately 250 h year−1. Since the harvest season is highly dependent on natural conditions (mainly precipitation), working hours were dependent on this. When possible, CH drivers work from early morning until late evening, when there is no dew or rain. The general structure of the work, with the area harvested, the average speed, and the fuel consumption per hectare, is presented in Table 3.

Table 3.

Operational parameters for harvesting different cereals.

From the data in Table 3, it can be highlighted that the harvested areas are broadly in line with the distribution of cereal crops grown in the region. Wheat, maize, and oilseed rape dominate the first positions. The other cereal crops are less popular and are used more for crop rotation purposes. Since the cultivated fields were scattered over a large area, the soil types were also varied, covering the predominant soil types in Lithuania— from light sandy loam to heavy clay loam. The highest average speed at harvest is recorded in maize and the lowest in wheat, 7.22 and 4.23 km h−1, respectively. Higher speeds are common in maize threshing, but there are some nuances involved, particularly the unloading of the grain during further threshing. The investigated CH in maize unloaded the grain by standing still for the greatest proportion of the time of any cereal crop harvested, which may be related to the high speed and the unfavorable waterlogged soil conditions, as the harvest is carried out in late autumn. In terms of fuel consumption per hectare, maize also had the highest consumption, while oats had the lowest consumption per hectare, at 19.53 and 10.71 L ha−1, respectively. Further analysis of the telematics data revealed the reasons for this fuel distribution.

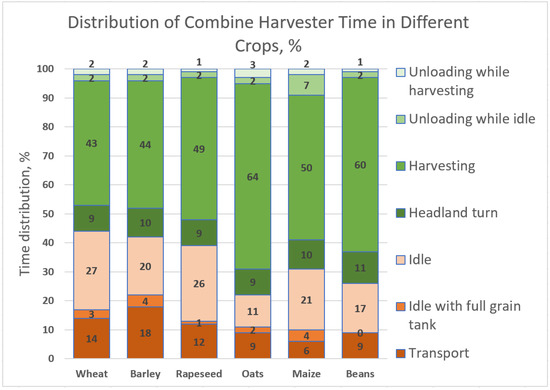

A detailed analysis of the timing in different cereal crops is presented in Figure 2. It can be noted that the proportion of useful work varies depending on the cereal harvested. The most efficient use of CH was in oats, while the lowest share of direct activity was in wheat which amounted to 78% and 56%, respectively. This was mainly due to the time spent idling and transport modes. As much as 30% of the time spent threshing wheat was spent idle while only 13% in oats. The analysis of telematics data allows us to see such differences, raise questions, and draw conclusions.

Figure 2.

Operational time distribution of CH in various crops.

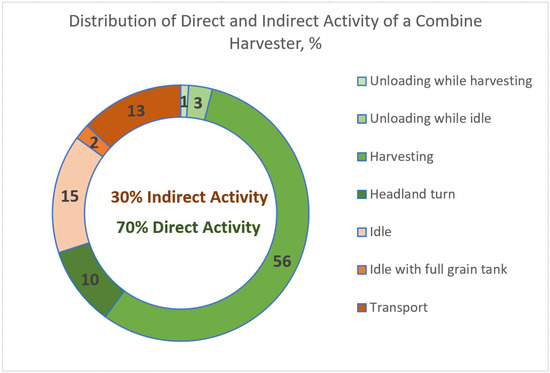

As regards the efficiency of the machine, it is first necessary to analyze the structure of its working time. A summary of the data is given in Figure 3. The total time spent with the engine running can be divided into Direct Activity (unloading while harvesting, unloading while idle, harvesting, and headland turns) and Indirect Activity (idle, idle with full grain tank, and transport). It can be seen that as much as 30% of the time CH spent in indirect activity and most of it in idling. Other authors report that agricultural machinery can idle for 10 to 43% [54] of their total operating time. Studies show that in some cases, machines powered by an internal combustion engine (ICE) can idle as much as >70% of their total life cycle [55]. There are several reasons why the machine idles for a long time, one of which is operator discomfort and air conditioning in the cab of the machine [56]. The need for convenience and comfort is understandable, but future engineers will have to look for other ways to ensure comfort in the relatively small space of the machine cab, avoiding a fuel-intensive, powerful ICE. Spending 2% of the time idle with a full grain tank can be an indication that the support transport was not provided on time, which is a problem for work organization. This is a known problem, especially on smaller farms where the lack of auxiliary transport can be acute. Conversely, large and well-organized farms can ensure a smooth organization of operations, with uninterrupted threshing and transport of grain.

Figure 3.

Share of CH fuel consumption in direct and indirect activities.

The transport mode accounted for a significant 13% of the total time. Driving CH from one field to another or moving to another location in the same field has a negative impact on fuel consumption and the environment. There is no way to avoid such crossings, but their number and duration must be reduced. In order to reduce the use of the transport mode, it may be necessary to evaluate the possibility of transporting CH by auxiliary transport and to better plan the route in the harvest fields [57]. Other authors also argue that a good road transport system is essential for the overall improvement of the transport situation in rural areas. The transport infrastructure sector is a key force for sustainable development, intertwined with many other sectors [58].

Direct activity is mostly harvesting (56%), but some time is also spent on headland turns (10%) and grain unloading (both while harvesting (1%) and idle (3%)). The overall working principle to reduce fuel consumption and environmental impact should be to focus on the largest possible portion of grain unloading during harvesting, to minimize headland turns, and to maximize engine load during the harvesting. This achieves the best economic and environmental results.

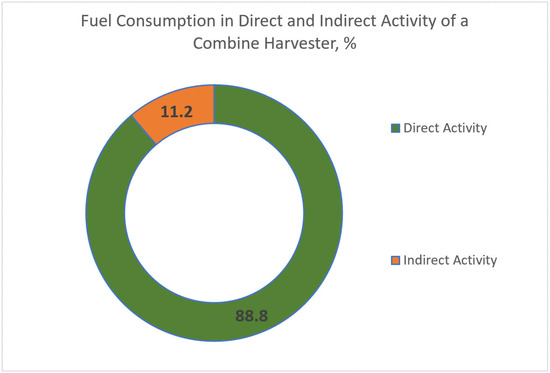

The study showed that CH consumed 17,499 L of fuel during a season, representing 46.11 t of GHG emissions in CO2eq. Although the time consumption of CH for direct and indirect activity is distributed at 70 and 30%, respectively, the fuel consumption structure is different. As can be seen in Figure 4, the share of fuel consumption in direct and indirect activity is 88.8 and 11.2%, respectively. This unequal distribution is due to the lower hourly fuel consumption in idle and transport modes. Meanwhile, the highest fuel consumption per hour is during harvesting. It is worth noting separately that the fuel consumption in transport and idle modes was 1265 and 702 L year−1 equivalent to 5.18 t year−1 of CO2 in total. This >5 t year−1 figure must be the main target, to see it and to try to keep it as close to 0 as possible.

Figure 4.

Fuel consumption split into CH activities.

A detailed analysis of the CH distribution for the engine load and speed range is given in Table 4. The distribution of the timing in harvesting mode 1800–1900 min−1, in idle 1100–1200 min−1, and transport 1300–1400 min−1 mode is clearly visible. As far as CH efficiency is concerned, the engine should be loaded to its maximum during harvesting. Studies by other scientists have shown that a heavy-duty diesel engine needs to be loaded with 80 to 94% load [59,60]. In this load range, the ICE performs the most work in terms of fuel consumption and also has the least negative impact on the environment, through emissions of air pollutants and GHGs.

Table 4.

Time distribution of engine load and speed in CH operations.

Although we can see that a significant part of the 1800–1900 min−1 range was not at the optimum >80% engine load, we cannot say that all this work was harvesting, as some of this time could have been for transport. A more detailed analysis of this issue would be needed in the future.

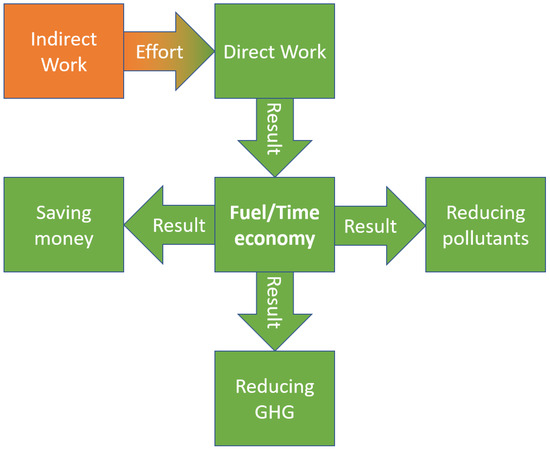

The approach presented in Figure 5 defines a simplified method for improving the performance of CH, specifically targeting the environmental impact during indirect operating states. The approach can be summarized as follows:

Figure 5.

Indirect and direct work contribution to efficiency and sustainability.

- (I)

- Indirect operation and direct operation. Indirect work refers to activities that do not directly contribute to the main function of the CH, such as idling, non-harvesting movements, or maintenance-related operations. Direct labor includes the harvesting process itself, as well as the unloading of the grain during threshing and the headland turns.

- (II)

- Efforts leading to fuel/time savings. Focusing on reducing indirect labor time provides a clear path to more efficient use of resources—fuel and time. This is categorized as “Effort”, indicating the need for targeted strategies and action planning to reduce the use of less productive work stages.

- (III)

- The results are savings in money, air pollution, and GHG reductions. Reduced fuel consumption is directly linked to lower operating costs. Spending less time on fuel-intensive indirect operations reduces emissions of pollutants and GHG.

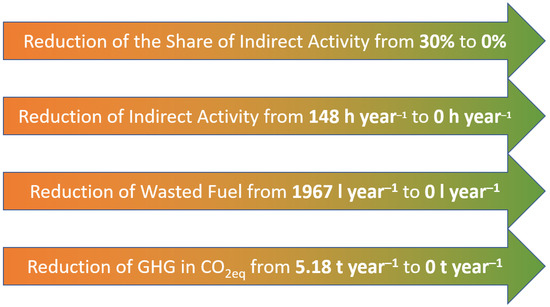

Scientists have found that telematics systems can optimize drivers’ driving habits, which reduces fuel consumption, vehicle wear and tear, and maintenance costs. Specific savings have been calculated, averaging 3964.30 Eur for every 100,000 km driven [61]. To further highlight the benefits of such a shift, we have quantified the potential for reducing indirect activity in Figure 6. The clear presentation of figures can in principle change farmers’ attitudes and other stakeholders towards the relevant issue of increasing agricultural productivity without harming the environment around us.

Figure 6.

Elimination of indirect activity: potential maximum effect and environmental benefits.

This study brings a number of innovative insights into the sustainable use of agricultural machinery. Firstly, it is based on a real-life case of a CH operating intensively throughout the season on an area of almost 900 ha, a scale and diversity of activity rarely reflected in published studies. Secondly, the telemetry data was analyzed in detail, breaking down fuel consumption and machine operating time into specific categories of activity (harvesting, idling, transport, unloading) and linking them to environmental pollution. In addition, this study quantifies the environmental cost of indirect activity, showing not only how much time and fuel is wasted, but also how much CO2eq is emitted in unproductive states. This allows more targeted, data-driven GHG reduction strategies to be developed. Another new aspect is the comparison of specific crops, which reveals significant differences in CH efficiency between different types of cereals—an aspect often overlooked in similar studies. Finally, the proposed conceptual model (Figure 5 and Figure 6) simplifies the relationship between machine utilization, operational efficiency, and environmental impact. The maximum reduction target should be the figures in Figure 6. Real life will probably not allow us to achieve them, but if we can see concrete targets, we can work towards them.

Although a detailed study of the performance of a single machine has been carried out, there are limitations. In order to refine the results, it would be necessary to include a wider range of CH manufacturers and different engine powers. It would also be helpful to collect data over several seasons in order to obtain statistically reliable data, as well as a comprehensive range of different fields, crops, and drivers. All of this would be of undoubted benefit, but at the same time, it is difficult to achieve in practice due to the high cost of technology, data protection restrictions, commercial secrets, etc. The authors of another study recommend that future studies provide demographic information on their sample so that the impact of telematics installed in vehicles on the driving behavior of different groups can be understood. It is also recommended that future studies use multi-level models to consider the hierarchical structure of telematics data. This hierarchical structure means the individual working conditions of each driver, considering both the driver and the working environment (e.g., machines, fields being worked, weather conditions, etc.) [62].

4. Conclusions

The study showed that the CH spent a significant 30% of the time during the season in idle and transport modes. Although the overall environmental impact of the machine was significant and amounted to >46 t of GHG in CO2eq, >10% of the fuel and GHG were generated by the indirect activities of the CH. This indirect work must approach zero. The results show that most of the time fuel consumption was at 1800–1900 min−1 engine speed and 40–100% at engine load. It was found that CH indirect work and fuel consumption per hectare also varied between cereal crops, ranging from 22 to 44% and 10.71 to 19.67 L ha−1, respectively. There are some explanations for this variation, but further research would be needed to fully understand the reasons.

There is no doubt that greater use and analysis of telematics data can contribute to more sustainable agricultural development. The interests of the stakeholders are aligned—in many cases, the farmer is interested in the financial benefits, which can be achieved through fuel and time savings. Reducing fuel and time costs automatically leads to lower pollution and GHG emissions. And this is generally in line with the principles of sustainable development and sustainability. In the future, there is a need for more research into the use of telematics data, with a particular focus on the use of new information technology tools, including artificial intelligence.

In addition, recommendations can be made to stakeholders: Farmers and Agricultural Operators. (I) Minimize indirect activities (idling, transport) by optimizing logistics and reducing downtime. (II) Monitor and analyze telematics data regularly to identify inefficiencies. (III) Coordinate grain unloading operations to avoid idling with a full tank. For Machinery Manufacturers and Technology Providers. (I) Enhance automation for optimal engine speed and load control during various work modes. (II) Improve telematics data accessibility and user-friendly analytics platforms. For Researchers and Developers. (I) Develop AI-based decision support tools to interpret machine data and recommend improvements. (II) Conduct broader regional and seasonal studies to validate the findings.

Author Contributions

Conceptualization A.J., E.J., A.G. and D.S.; methodology A.J., E.J., A.G. and D.S.; software A.G. and D.S.; validation A.J. and E.J.; formal analysis A.J. and E.J.; investigation A.J., D.S. and E.J.; resources A.J. and E.J.; data curation A.J. and E.J.; writing—original draft preparation A.J., E.J., A.G. and D.S.; writing—review and editing A.J., E.J., A.G. and D.S.; visualization A.J., E.J. and D.S.; supervision A.J. and E.J.; project administration E.J. and A.J.; funding acquisition D.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Xue, J.F.; Pu, C.; Liu, S.L.; Zhao, X.; Zhang, R.; Chen, F.; Xiao, X.P.; Zhang, H.L. Carbon and Nitrogen Footprint of Double Rice Production in Southern China. Ecol. Indic. 2016, 64, 249–257. [Google Scholar] [CrossRef]

- Johnsson, F.; Kjärstad, J.; Rootzén, J. The Threat to Climate Change Mitigation Posed by the Abundance of Fossil Fuels. Clim. Policy 2019, 19, 258–274. [Google Scholar] [CrossRef]

- Londoño-Pulgarin, D.; Cardona-Montoya, G.; Restrepo, J.C.; Muñoz-Leiva, F. Fossil or Bioenergy? Global Fuel Market Trends. Renew. Sustain. Energy Rev. 2021, 143, 110905. [Google Scholar] [CrossRef]

- Filipovic, D.; Kosutic, S.; Gospodaric, Z.; Zimmer, R.; Banaj, D. The Possibilities of Fuel Savings and the Reduction of CO2 Emissions in the Soil Tillage in Croatia. Agric. Ecosyst. Environ. 2006, 115, 290–294. [Google Scholar] [CrossRef]

- Yamaka, W.; Phadkantha, R.; Rakpho, P. Economic and Energy Impacts on Greenhouse Gas Emissions: A Case Study of China and the USA. Energy Rep. 2021, 7, 240–247. [Google Scholar] [CrossRef]

- Waheed, R.; Chang, D.; Sarwar, S.; Chen, W. Forest, Agriculture, Renewable Energy, and CO2 Emission. J. Clean. Prod. 2018, 172, 4231–4238. [Google Scholar] [CrossRef]

- Li, K.; Xiong, P.; Wu, Y.; Dong, Y. Forecasting Greenhouse Gas Emissions with the New Information Priority Generalized Accumulative Grey Model. Sci. Total Environ. 2022, 807, 150859. [Google Scholar] [CrossRef]

- Friedlingstein, P.; O’Sullivan, M.; Jones, M.W.; Andrew, R.M.; Hauck, J.; Olsen, A.; Peters, G.P.; Peters, W.; Pongratz, J.; Sitch, S.; et al. Global Carbon Budget 2020. Earth Syst. Sci. Data 2020, 12, 3269–3340. [Google Scholar] [CrossRef]

- Jackson, R.B.; Saunois, M.; Bousquet, P.; Canadell, J.G.; Poulter, B.; Stavert, A.R.; Bergamaschi, P.; Niwa, Y.; Segers, A.; Tsuruta, A. Increasing Anthropogenic Methane Emissions Arise Equally from Agricultural and Fossil Fuel Sources. Environ. Res. Lett. 2020, 15, 071002. [Google Scholar] [CrossRef]

- Lamb, W.F.; Wiedmann, T.; Pongratz, J.; Andrew, R.; Crippa, M.; Olivier, J.G.J.; Wiedenhofer, D.; Mattioli, G.; Al Khourdajie, A.; House, J.; et al. A Review of Trends and Drivers of Greenhouse Gas Emissions by Sector from 1990 to 2018. Environ. Res. Lett. 2021, 16, 73005. [Google Scholar] [CrossRef]

- Hoffman, E.; Cavigelli, M.A.; Camargo, G.; Ryan, M.; Ackroyd, V.J.; Richard, T.L.; Mirsky, S. Energy Use and Greenhouse Gas Emissions in Organic and Conventional Grain Crop Production: Accounting for Nutrient Inflows. Agric. Syst. 2018, 162, 89–96. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, B.; Ambus, P.; Zhang, Y.; Hansen, V.; Lin, Z.; Shen, D.; Liu, G.; Bei, Q.; Zhu, J.; et al. Carbon Footprint of Rice Production under Biochar Amendment—A Case Study in a Chinese Rice Cropping System. GCB Bioenergy 2016, 8, 148–159. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon Footprint and Cumulative Energy Demand of Greenhouse and Open-Field Tomato Cultivation Systems under Southern and Central European Climatic Conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Garnett, T. Where Are the Best Opportunities for Reducing Greenhouse Gas Emissions in the Food System (Including the Food Chain)? Food Policy 2011, 36, S23–S32. [Google Scholar] [CrossRef]

- Plath, E.; Rischen, T.; Mohr, T.; Fischer, K. Agriculture, Ecosystems and Environment Biodiversity in Agricultural Landscapes: Grassy Field Margins and Semi-Natural Fragments Both Foster Spider Diversity and Body Size. Agric. Ecosyst. Environ. 2021, 316, 107457. [Google Scholar] [CrossRef]

- Tubiello, F.N.; Salvatore, M.; Rossi, S.; Ferrara, A.; Fitton, N.; Smith, P. The FAOSTAT Database of Greenhouse Gas Emissions from Agriculture. Environ. Res. Lett. 2013, 8, 015009. [Google Scholar] [CrossRef]

- Flessa, H.; Ruser, R.; Dörsch, P.; Kamp, T.; Jimenez, M.A.; Munch, J.C.; Beese, F. Integrated Evaluation of Greenhouse Gas Emissions (CO2, CH4, N2O) from Two Farming Systems in Southern Germany. Agric. Ecosyst. Environ. 2002, 91, 175–189. [Google Scholar] [CrossRef]

- Babatunde, D.E.; Anozie, A.N.; Omoleye, J.A.; Oyebode, O.; Babatunde, O.M.; Agboola, O. Prediction of Global Warming Potential and Carbon Tax of a Natural Gas-Fired Plant. Energy Rep. 2020, 6, 1061–1070. [Google Scholar] [CrossRef]

- Understanding Global Warming Potentials | US EPA. Available online: https://www.epa.gov/ghgemissions/understanding-global-warming-potentials (accessed on 23 November 2022).

- Hou, X.; Tian, J.; Song, C.; Wang, J.; Zhao, J.; Zhang, X. Emission Inventory Research of Typical Agricultural Machinery in Beijing, China. Atmos. Environ. 2019, 216, 116903. [Google Scholar] [CrossRef]

- Lovarelli, D.; Bacenetti, J. Exhaust Gases Emissions from Agricultural Tractors: State of the Art and Future Perspectives for Machinery Operators. Biosyst. Eng. 2019, 186, 204–213. [Google Scholar] [CrossRef]

- Miu, P. The Potential of Controlled Traffic Farming to Mitigate Greenhouse Gas Emissions and Enhance Carbon Sequestration in Arable Land: A Critical Review; Transactions of the ASABE: St. Joseph, MI, USA, 2015; Volume 58. [Google Scholar]

- Mehlig, D.; Woodward, H.; Oxley, T.; Holland, M. Electrification of Road Transport and the Impacts on Air Quality and Health in the UK. Atmosphere 2021, 12, 1491. [Google Scholar] [CrossRef]

- Gualtieri, G.; Crisci, A.; Tartaglia, M.; Toscano, P.; Gioli, B. A Statistical Model to Assess Air Quality Levels at Urban Sites. Water Air Soil. Pollut. 2015, 226, 394. [Google Scholar] [CrossRef]

- He, P.; Li, J.; Fang, E.; DeVoil, P.; Cao, G. Reducing Agricultural Fuel Consumption by Minimizing Inefficiencies. J. Clean. Prod. 2019, 236, 117619. [Google Scholar] [CrossRef]

- Van Linden, V.; Herman, L. A Fuel Consumption Model for Off-Road Use of Mobile Machinery in Agriculture. Energy 2014, 77, 880–889. [Google Scholar] [CrossRef]

- Fontaras, G.; Zacharof, N.G.; Ciuffo, B. Fuel Consumption and CO2 Emissions from Passenger Cars in Europe—Laboratory versus Real-World Emissions. Prog. Energy Combust. Sci. 2017, 60, 97–131. [Google Scholar] [CrossRef]

- Helmers, E.; Leitão, J.; Tietge, U.; Butler, T. CO2-Equivalent Emissions from European Passenger Vehicles in the Years 1995–2015 Based on Real-World Use: Assessing the Climate Benefit of the European “Diesel Boom”. Atmos. Environ. 2019, 198, 122–132. [Google Scholar] [CrossRef]

- Lal, R. Carbon Emission from Farm Operations. Environ. Int. 2004, 30, 981–990. [Google Scholar] [CrossRef]

- Mokhtor, S.A.; el Pebrian, D.; Johari, N.A.A. Actual Field Speed of Rice Combine Harvester and Its Influence on Grain Loss in Malaysian Paddy Field. J. Saudi Soc. Agric. Sci. 2020, 19, 422–425. [Google Scholar] [CrossRef]

- Yamasaki, H.; Horio, M.; Fujita, K. Research on Fuel Consumption in Harvesting Paddy Rice Plant with Head-Feeding Combine Harvesters. Biosyst. Eng. 2021, 202, 96–105. [Google Scholar] [CrossRef]

- Shojaei, K. Intelligent Coordinated Control of an Autonomous Tractor-Trailer and a Combine Harvester. Eur. J. Control 2021, 59, 82–98. [Google Scholar] [CrossRef]

- Savickas, D.; Steponavičius, D.; Kemzūraitė, A. A Novel Approach for Analysing Environmental Sustainability Aspects of Combine Harvesters through Telematics Data. Part II: An IT Tool for Comparative Analysis. Precis. Agric. 2024, 25, 221–234. [Google Scholar] [CrossRef]

- Gundoshmian, T.M.; Ghassemzadeh, H.R.; Abdollahpour, S.; Navid, H. Application of Artificial Neural Network in Prediction of the Combine Harvester Performance. J. Food Agric. Environ. 2010, 8, 721–724. [Google Scholar]

- Christie, N.; O’Toole, S.; Holcombe, A.; Bull, N.; Helman, S. Managing the Road Safety Risks of Last Mile Deliveries: Do Telematics Have a Role to Play? Traffic Inj. Prev. 2024, 26, 300–306. [Google Scholar] [CrossRef]

- Lunner-Kolstrup, C.; Hörndahl, T.; Karttunen, J.P. Farm Operators’ Experiences of Advanced Technology and Automation in Swedish Agriculture: A Pilot Study. J. Agromed. 2018, 23, 215–226. [Google Scholar] [CrossRef]

- Oksanen, T.; Linkolehto, R.; Seilonen, I. Adapting an Industrial Automation Protocol to Remote Monitoring of Mobile Agricultural Machinery: A Combine Harvester with IoT. IFAC-Pap. 2016, 49, 127–131. [Google Scholar] [CrossRef]

- Olt, J.; Ilves, R.; Kuut, A. Overview of Developments of Cereal Harvester Fleet in Estonia. Eng. Rural. Dev. 2019, 18, 179–184. [Google Scholar] [CrossRef]

- Savickas, D.; Steponavičius, D.; Kemzūraitė, A. A Novel Approach for Analysing Environmental Sustainability Aspects of Combine Harvester through Telematics Data. Part I: Evaluation and Analysis of Field Tests. Precis. Agric. 2024, 25, 100–118. [Google Scholar] [CrossRef]

- Bernhardt, H.; Mederle, M.; Treiber, M.; Woerz, S. Aspects of Digitization in Agricultural Logistics in Germany. Actual. Tasks Agric. Eng. 2018, 46, 245–251. [Google Scholar]

- Bernhardt, H.; Bozkurt, M.; Brunsch, R.; Colangelo, E.; Herrmann, A.; Horstmann, J.; Kraft, M.; Marquering, J.; Steckel, T.; Tapken, H.; et al. Challenges for Agriculture through Industry 4.0. Agronomy 2021, 11, 1935. [Google Scholar] [CrossRef]

- Goltyapin, V.; Golubev, I. Global Trends in the Development of Monitoring Systems for Mobile Agricultural Equipment. E3S Web Conf. 2020, 157, 1013. [Google Scholar] [CrossRef]

- Chinnasamy, C.; Tamilselvam, P.; Ranjith, R. Influence of Aluminum Oxide Nanoparticle with Different Particle Sizes on the Working Attributes of Diesel Engine Fueled with Blends of Diesel and Waste Plastic Oil. Environ. Sci. Pollut. Res. 2019, 26, 29962–29977. [Google Scholar] [CrossRef]

- Savickas, D.; Steponavičius, D.; Špokas, L.; Saldukaitė, L.; Semenišin, M. Impact of Combine Harvester Technological Operations on Global Warming Potential. Appl. Sci. 2021, 11, 8662. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Prashumn, C.K. Di-Ethyl Ether-Diesel Blends Fuelled off-Road Tractor Engine: Part-I: Technical Feasibility. Fuel 2021, 308, 121972. [Google Scholar] [CrossRef]

- Venkatesan, V.; Nallusamy, N.; Nagapandiselvi, P. Performance and Emission Analysis on the Effect of Exhaust Gas Recirculation in a Tractor Diesel Engine Using Pine Oil and Soapnut Oil Methyl Ester. Fuel 2021, 290, 120077. [Google Scholar] [CrossRef]

- European Environmrnt Agency. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2023; European Environment Agency: Copenhagen, Denmark, 2023. [Google Scholar] [CrossRef]

- Pirjola, L.; Rönkkö, T.; Saukko, E.; Parviainen, H.; Malinen, A.; Alanen, J.; Saveljeff, H. Exhaust Emissions of Non-Road Mobile Machine: Real-World and Laboratory Studies with Diesel and HVO Fuels. Fuel 2017, 202, 154–164. [Google Scholar] [CrossRef]

- Savickas, D.; Steponavičius, D.; Kliopova, I.; Saldukaitė, L. Combine Harvester Fuel Consumption and Air Pollution Reduction. Water Air Soil. Pollut. 2020, 231, 95. [Google Scholar] [CrossRef]

- Huang, R.; Liu, J.; He, X.; Xie, D.; Ni, J.; Xu, C.; Zhang, Y.; Ci, E.; Wang, Z.; Gao, M. Reduced Mineral Fertilization Coupled with Straw Return in Field Mesocosm Vegetable Cultivation Helps to Coordinate Greenhouse Gas Emissions and Vegetable Production. J. Soils Sediments 2020, 20, 1834–1845. [Google Scholar] [CrossRef]

- Kaur-Sidhu, M.; Ravindra, K.; Mor, S.; John, S. Emission Factors and Global Warming Potential of Various Solid Biomass Fuel-Cook Stove Combinations. Atmos. Pollut. Res. 2020, 11, 252–260. [Google Scholar] [CrossRef]

- Jia, Q.; Zhang, H.; Wang, J.; Xiao, X.; Chang, S.; Zhang, C.; Liu, Y.; Hou, F. Planting Practices and Mulching Materials Improve Maize Net Ecosystem C Budget, Global Warming Potential and Production in Semi-Arid Regions. Soil. Tillage Res. 2021, 207, 104850. [Google Scholar] [CrossRef]

- Liao, P.; Sun, Y.; Zhu, X.; Wang, H.; Wang, Y.; Chen, J.; Zhang, J.; Zeng, Y.; Zeng, Y.; Huang, S. Identifying Agronomic Practices with Higher Yield and Lower Global Warming Potential in Rice Paddies: A Global Meta-Analysis. Agric. Ecosyst. Environ. 2021, 322, 107663. [Google Scholar] [CrossRef]

- Molari, G.; Mattetti, M.; Lenzini, N.; Fiorati, S. An Updated Methodology to Analyse the Idling of Agricultural Tractors. Biosyst. Eng. 2019, 187, 160–170. [Google Scholar] [CrossRef]

- Wargula, L.; Kukla, M.; Krawiec, P.; Wieczorek, B. Impact of Number of Operators and Distance to Branch Piles on Woodchipper Operation. Forests 2020, 11, 598. [Google Scholar] [CrossRef]

- Perozzi, D.; Mattetti, M.; Molari, G.; Sereni, E. Methodology to Analyse Farm Tractor Idling Time. Biosyst. Eng. 2016, 148, 81–89. [Google Scholar] [CrossRef]

- Rodias, E.; Berruto, R.; Busato, P.; Bochtis, D.; Sørensen, C.G.; Zhou, K. Energy Savings from Optimised In-Field Route Planning for Agricultural Machinery. Sustainability 2017, 9, 1956. [Google Scholar] [CrossRef]

- Kaiser, N.; Barstow, C.K. Rural Transportation Infrastructure in Low-and Middle-Income Countries: A Review of Impacts, Implications, and Interventions. Sustainability 2022, 14, 2149. [Google Scholar] [CrossRef]

- Janulevičius, A.; Juostas, A.; Pupinis, G. Engine Performance during Tractor Operational Period. Energy Convers. Manag. 2013, 68, 11–19. [Google Scholar] [CrossRef]

- Janulevičius, A.; Juostas, A.; Pupinis, G. Tractor Engine Load and Fuel Consumption in Road Construction Works. Transport 2010, 25, 403–410. [Google Scholar] [CrossRef][Green Version]

- Ujlacká, K.; Konečný, V. Streamlining the Operational Costs of Transport Companies through the Implementation of Telematics Systems. Transp. Res. Procedia 2025, 87, 248–259. [Google Scholar] [CrossRef]

- Boylan, J.; Meyer, D.; Chen, W.S. A Systematic Review of the Use of In-Vehicle Telematics in Monitoring Driving Behaviours. Accid. Anal. Prev. 2024, 199, 107519. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).