Interruption Risk Propagation and Resilience Evaluation of Supply Chain of Emergency Medical Supplies Under Information Sharing Mechanism

Abstract

1. Introduction

2. Literature Review

2.1. Emergency Supply Chain

2.2. The Risk of Supply Chain Interruption and Its Propagation Mechanism

2.3. Supply Chain Resilience and Its Evaluation Methods

2.4. Information Sharing in the Supply Chain

- (1)

- An information sharing mechanism for a supply chain of emergency medical supplies is constructed. After considering the information transfer relationship of each node in the supply chain of emergency medical supplies, this paper constructs an information sharing mechanism for the supply chain of emergency medical supplies.

- (2)

- A Bayesian risk propagation model for an emergency supply chain under information sharing mechanism is proposed. In this paper, a risk propagation model for an interruption in the supply chain of emergency medical supplies based on a Bayesian network is constructed, the propagation process of the risk in the supply chain network and its impact on the overall sustainability are studied, and the do-calculus technique is introduced to transform the intervention effect of information sharing into the quantification of supply chain risk probability, which enriches the theoretical framework of emergency supply chain risk propagation under the new situation and provides theoretical support for supply chain resilience optimization under the perspective of information empowerment.

- (3)

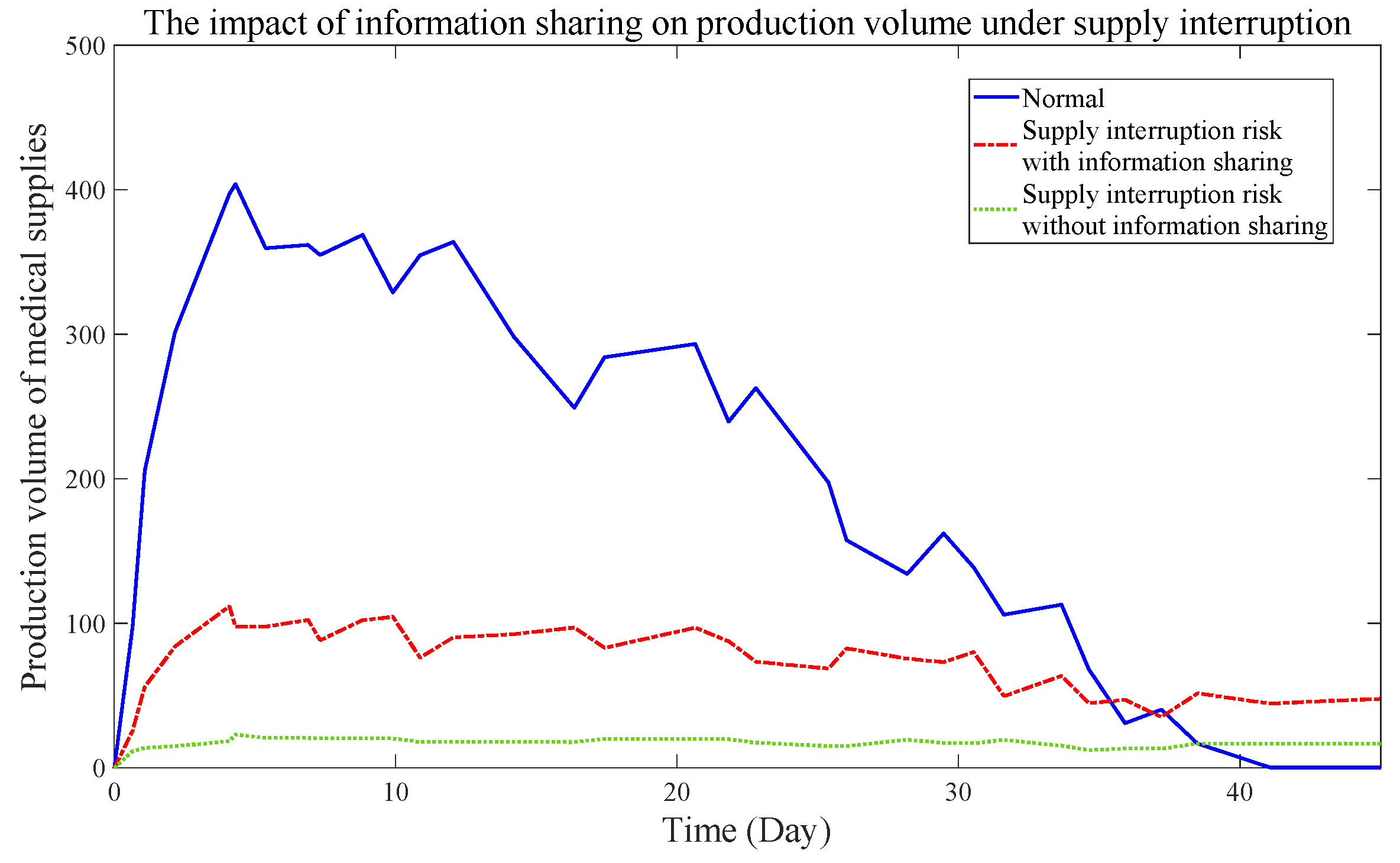

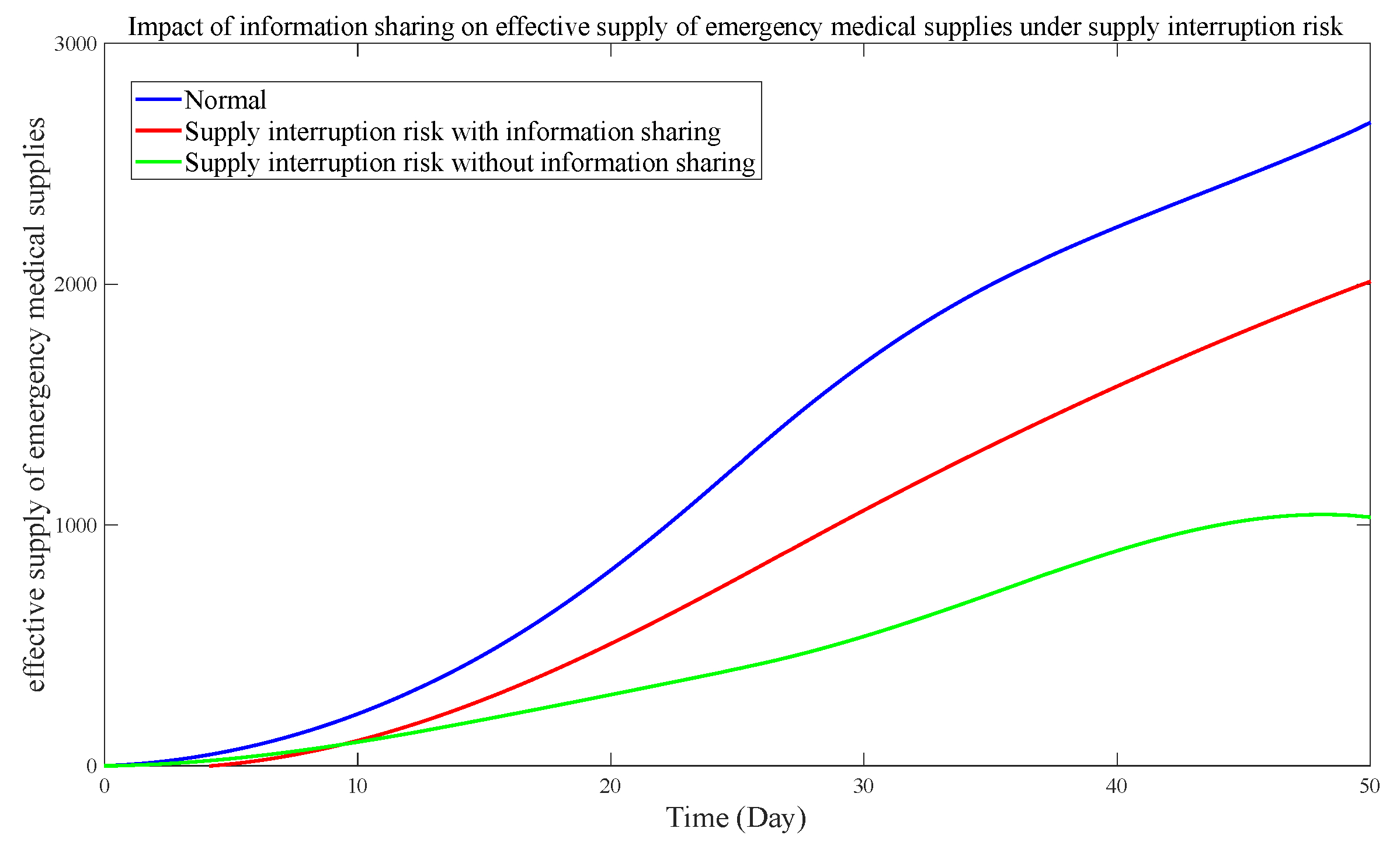

- From a dynamic perspective, a dynamic model of the supply chain system of emergency medical supplies is constructed, and its resilience is evaluated through the variable of “demand fulfillment rate” in the model. The impact of different interruption scenarios and the presence or absence of information sharing on the resilience of the supply chain is analyzed. This model can reflect the changing trends of material production and effective supply in the face of emergencies in the supply chain, thus comprehensively evaluating the resilience level of the supply chain and providing a new perspective and method for in-depth research on sustainable supply chain management.

3. Risk Scenario Analysis of Interruption in Supply Chain of Emergency Medical Supplies Under Sudden Public Health Emergencies

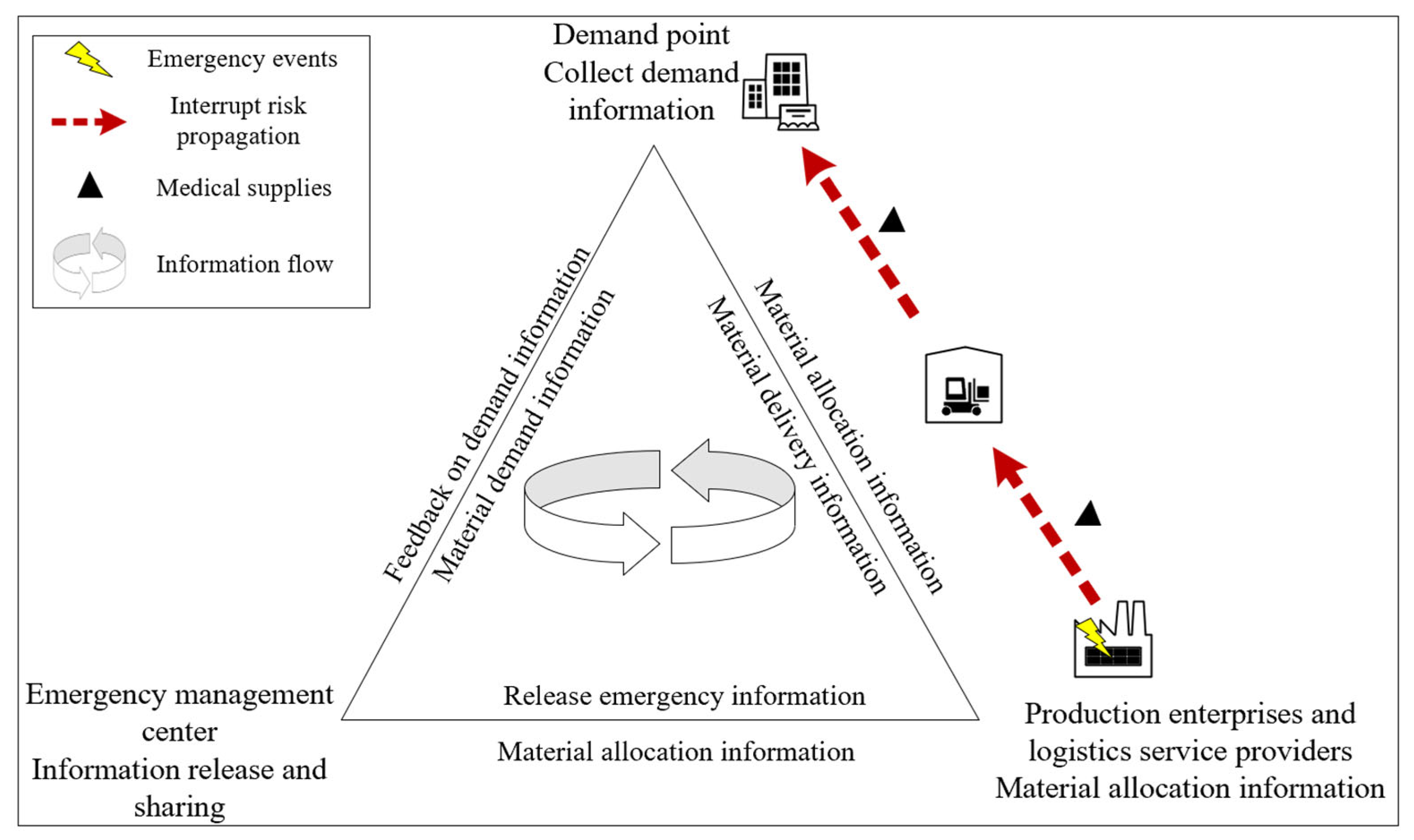

3.1. Operation Process of Supply Chain of Emergency Medical Supplies

3.2. Risk Propagation of Supply Chain Interruption Under Information Sharing Mechanism

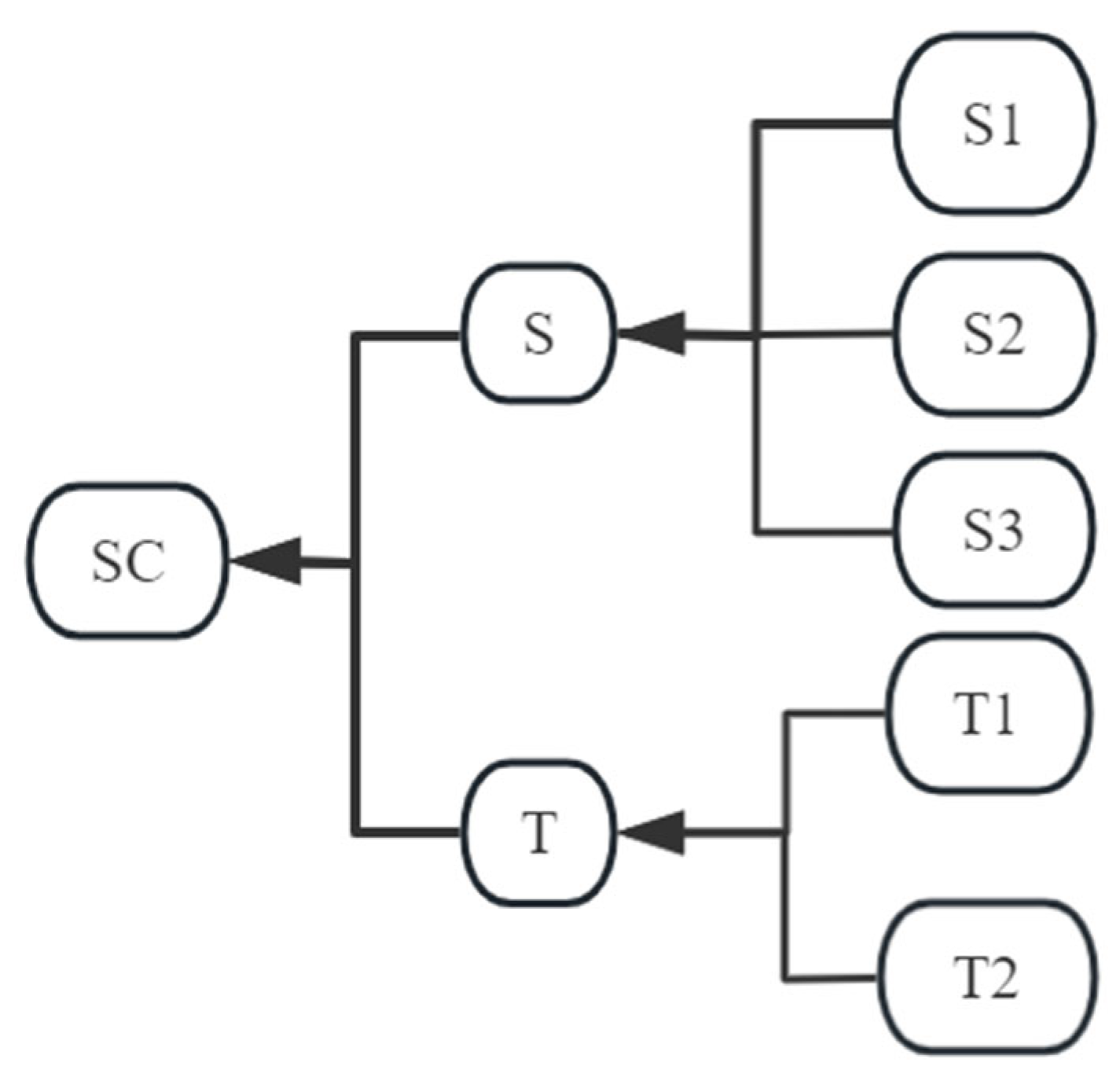

4. Risk Propagation Model of Interruption in Supply Chain of Emergency Medical Supplies Based on Bayesian Network

4.1. Identification of Factors Influencing the Risk of Interruption in the Supply Chain of Emergency Medical Supplies

4.2. Bayesian Network Construction of Interruption Risk in Supply Chain of Emergency Medical Supplies

- (1)

- The risk factors of each root node (such as insufficient supply of raw materials, traffic interruption, etc.) are independent of each other, and there is no direct causal relationship or coupling effect [80].

- (2)

- Risk propagation is unidirectional, only transmitted from higher-level nodes to lower-level nodes (such as insufficient supply of raw materials → supply interruption nodes), without considering the situation of risk transmission from same-level nodes and lower-level nodes to higher-level nodes [81].

- (3)

- There is no circular loop in the risk propagation path of the supply chain, that is, the risk will not form a closed-loop propagation through multiple nodes (such as supply interruption → transportation interruption → supply interruption) [80].

- (4)

- If at least one type of interruption occurs in supply or transportation, it will lead to the supply chain interruption.

4.2.1. Probability Calculation of Supply Chain Interruption Risk Based on Bayesian Network

4.2.2. Probability Calculation of Supply Chain Interruption Risk Under Information Sharing Mechanism

5. Resilience Evaluation of Supply Chain of Emergency Medical Supplies Based on System Dynamics

5.1. Model Assumptions

- (1)

- The stronger the resilience of the supply chain, the higher the supply ratio. Therefore, the total demand fulfillment rate of emergency medical supplies was selected to indirectly measure the resilience of the supply chain. The total demand fulfillment rate is represented by the ratio of the total amount of emergency supplies obtained by all demand areas in all scenarios to the total demand of all demand areas [82].

- (2)

- After a sudden public health emergency occurs, the charity organization that receives donated materials is located in the vicinity of the disaster area, and its transportation delay is mainly reflected in the donation transportation process [82].

- (3)

- Considering the disaster situation, the disaster area has a basic demand for medical supplies, and unexpected events can cause demand fluctuations. Therefore, a combination of basic demand and random numbers was used to represent it.

- (4)

- To simulate the impact of information sharing on various variables in the supply chain, the information disturbance was introduced to represent incomplete information transmission.

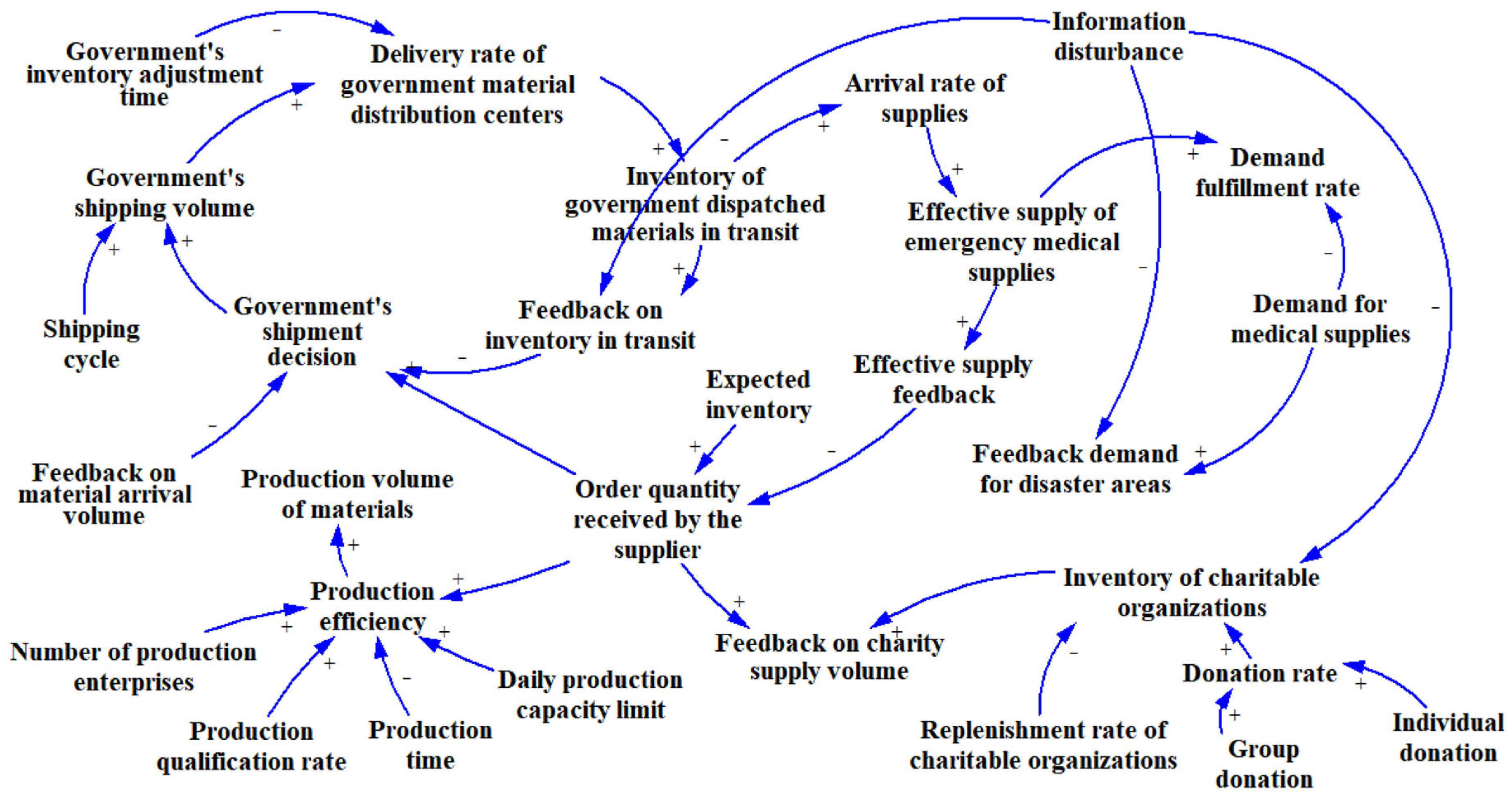

5.2. Causal Relationship Construction

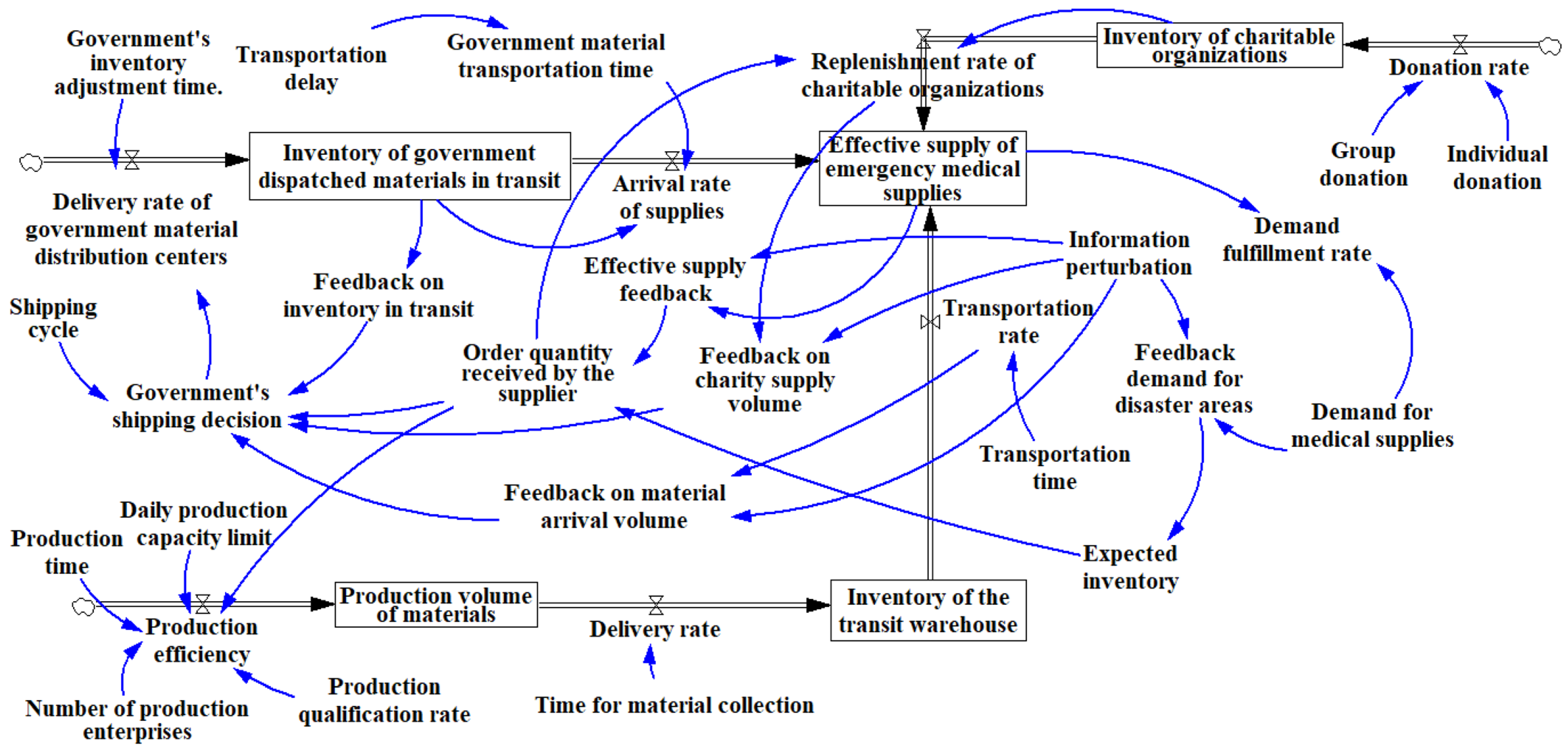

5.3. Construction of Stock Flow Diagram

- (1)

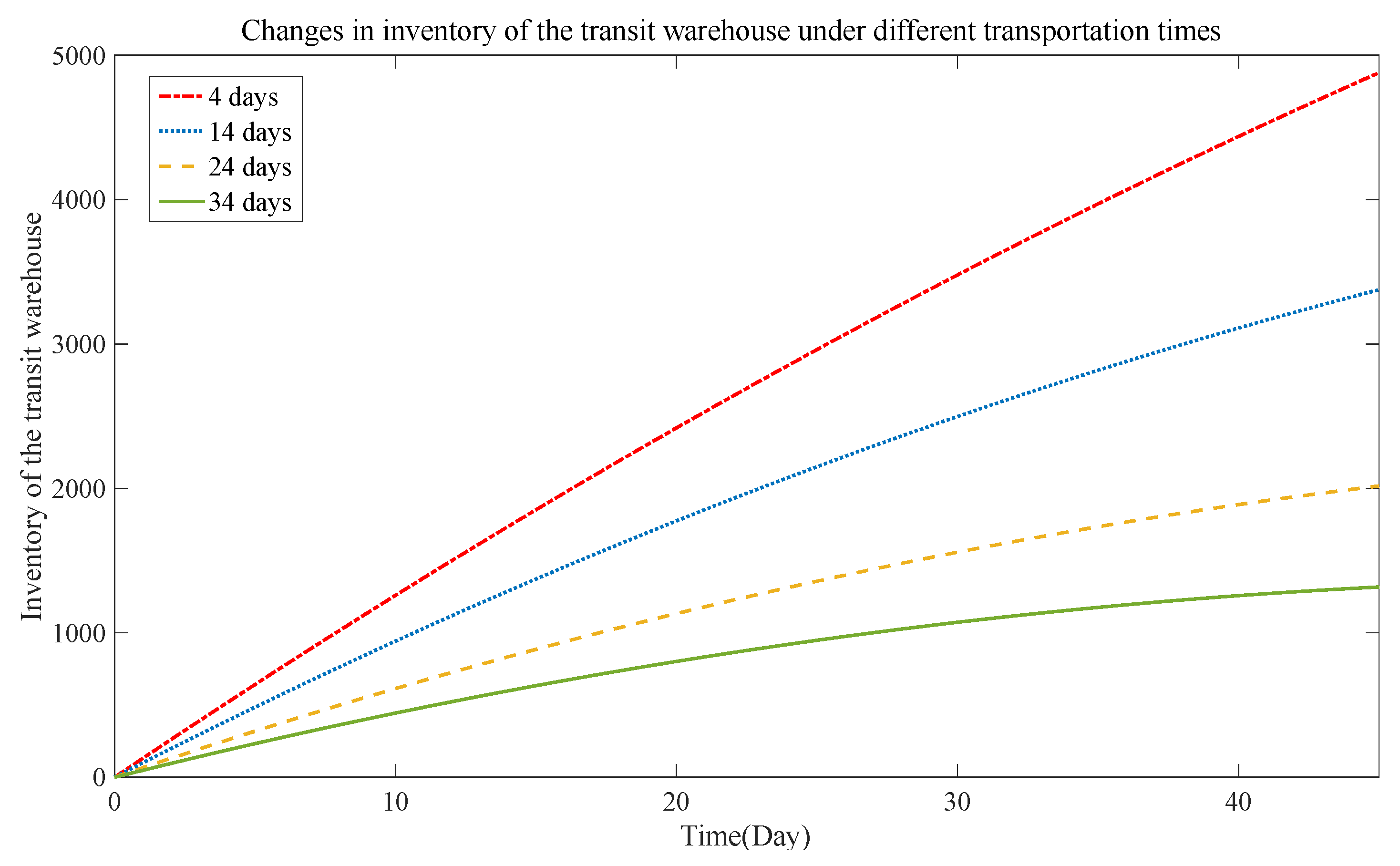

- Stock: the government dispatches inventory of materials in transit, material production volume, transit warehouse inventory, and charitable organization inventory.

- (2)

- Flow: delivery rate of government material distribution center, material arrival rate, charity organization supply rate, donation rate, productivity, delivery rate, transportation rate.

- (3)

- Constant: government inventory adjustment time, delivery cycle, inventory adjustment time for charitable organizations, productive time, number of production enterprises, production qualification rate, transportation delay, information disturbance, infrastructure construction.

- (4)

- Auxiliary: government shipment volume, government shipping decision, feedback on inventory in transit, the quantity of orders received by the supplier, the supply of feedback, feedback on the arrival quantity of materials, feedback on the supply of charitable organizations, required fulfillment rate, feedback on the demand for disaster areas, expected inventory.

5.4. Establishment of Model Equations

6. Model Simulation and Decision Analysis

6.1. Simulation Background and Parameter Settings

6.2. Model Simulation Analysis

6.2.1. Model Verification

6.2.2. Simulation Results and Analysis of Different Interruption Risks

6.2.3. Model Simulation and Analysis Considering Information Sharing Mechanism

7. Conclusions, Implications and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Anbo, W.; Yue, S.; Huiling, Z.; Sun, L.; Wang, X.; Li, B. Research on Resilience Evaluation of Coal Industrial Chain and Supply Chain Based on Interval Type-2F-PT-TOPSIS. Processes 2023, 11, 566. [Google Scholar]

- Zeng, Z.; Xi, L.; Liu, X. Influencing Factors and Evaluation of Medical Supplies Supply Chain Resilience under the COVID-19 Epidemic. Soc. Secur. Adm. Manag. 2023, 4, 19–31. [Google Scholar] [CrossRef]

- Hu, Z.; Tian, J.; Feng, G. A relief supplies purchasing model based on a put option contract. Comput. Ind. Eng. 2018, 127, 253–262. [Google Scholar] [CrossRef]

- Wang, S.L.; Sun, B.Q. Model of multi-period emergency material allocation for large-scale sudden natural disasters in humanitarian logistics: Efficiency, effectiveness and equity. Int. J. Disaster Risk Reduct. 2023, 85, 103530. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, R.; Panchal, R.; Tiwari, M.K. Impact of COVID-19 on logistics systems and disruptions in food supply chain. Int. J. Prod. Res. 2021, 59, 1993–2008. [Google Scholar] [CrossRef]

- Haishi, L.; Yuxuan, S.; Nan, P.; Yi, L.; Yuqiang, A.; Dilin, P. Study on the optimization of urban emergency supplies distribution paths for epidemic outbreaks. Comput. Oper. Res. 2022, 146, 105912. [Google Scholar]

- Yuqing, P.; Cheng, T.C.E.; Yuxuan, H.; To, N.C.; Sethi Suresh, P. Foresighted medical resources allocation during an epidemic outbreak. Transp. Res. Part E 2022, 164, 102762. [Google Scholar]

- Chen, Y.; Zheng, W.; Li, W.; Huang, Y. The Robustness and Sustainability of Port Logistics Systems for Emergency Supplies from Overseas. J. Adv. Transp. 2020, 2020, 8868533. [Google Scholar] [CrossRef]

- Vipul, J.; Sameer, K.; Umang, S.; Chandra, C. Supply chain resilience: Model development and empirical analysis. Int. J. Prod. Res. 2017, 55, 6779–6800. [Google Scholar]

- Luo, L.; Li, X.; Zhao, Y. A two-stage stochastic-robust model for supply chain network design problem under disruptions and endogenous demand uncertainty. Transp. Res. Part E 2025, 196, 104013. [Google Scholar] [CrossRef]

- Tao, Y.; Lai, X.; Zhou, S. Information sharing in a transparent supply chain with transportation disruptions and supplier competition. Ann. Oper. Res. 2020, 329, 307–329. [Google Scholar] [CrossRef]

- Alexandre, D.; Dmitry, I.; Maxim, R. Does the ripple effect influence the bullwhip effect? An integrated analysis of structural and operational dynamics in the supply chain. Int. J. Prod. Res. 2020, 58, 1285–1301. [Google Scholar]

- Farradia, Y. Toward Firm Sustainability Through Green Supply Chain Management and Green Marketing in the New Norm. In Proceedings of the 1st International Conference on Sustainable Management and Innovation, Bogor, Indonesia, 14–16 September 2020. [Google Scholar]

- Ding, J.F.; Weng, J.H.; Chou, C.C. Assessment of key risk factors in the cold chain logistics operations of container carriers using best worst method. Int. J. Refrig. 2023, 153, 116–126. [Google Scholar] [CrossRef]

- Lihua, C.; Lu, W.; Huaqing, H. Thoughts on the Construction of Public Service System for Emergency Supply Chain of Major Epidemic Relief Materials. Logist. Technol. 2020, 39, 1–6. (In Chinese) [Google Scholar]

- Teng, Y.; Zhou, L.G.; Chen, J.L. The Research on Supply Chain Portfolio Default Risk of Financial Enterprises Based on Architectonic No. 12 Copula. In Proceedings of the 2015 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 6–9 December 2015; IEEE: Piscataway, NJ, USA, 2016; pp. 99–104. [Google Scholar]

- Chen, H.; Wen, J. Financing Model Analysis and Risk Management of Supply Chain Finance Based on Gray Evaluation. Res. Gate 2017, 19, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Feng, Z.; Zhang, S. Managing supply chain resilience in the era of VUCA. Front. Eng. Manag. 2021, 8, 465. [Google Scholar] [CrossRef]

- Dai, T.; Bai, G.; Anderson, G.F. PPE Supply Chain Needs Data Transparency and Stress Testing. J. Gen. Intern. Med. 2020, 35, 2748–2749. [Google Scholar] [CrossRef]

- Ganesh, D.A.; Kalpana, P. Factors influencing proactiveness in supply chain risk identification: A fuzzy-set qualitative comparative analysis. Int. J. Disaster Risk Reduct. 2023, 88, 103614. [Google Scholar]

- Sun, W.; Liao, W. Risk propagation in emergency supply chain during public health events—From a reliability perspective. Heliyon 2025, 11, e41423. [Google Scholar] [CrossRef]

- Liang, W.; Yiming, C.; Yuanxin, Z. Exploring the risk propagation mechanisms of supply chain for prefabricated building projects. J. Build. Eng. 2023, 74, 106771. [Google Scholar]

- Yao, Q.; Fan, R.; Chen, R.; Qian, R. A model of the enterprise supply chain risk propagation based on partially mapping two-layer complex networks. Phys. A Stat. Mech. Its Appl. 2023, 613, 128506. [Google Scholar] [CrossRef]

- Jianjun, Z.; Yamin, C.; Yuhuai, Z. Risk Propagation Mechanism Research Based on SITR Model of Complex Supply Networks. Int. J. Inf. Syst. Supply Chain Manag. 2021, 14, 18–38. [Google Scholar]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Ripple effect modelling of supplier disruption: Integrated Markov chain and dynamic Bayesian network approach. Int. J. Prod. Res. 2020, 58, 3284–3303. [Google Scholar] [CrossRef]

- Dmitry, I. Correction to: Viable supply chain model: Integrating agility, resilience and sustainability perspectives-lessons from and thinking beyond the COVID-19 pandemic. Ann. Oper. Res. 2022, 319, 1411–1431. [Google Scholar]

- Yi, L.; Rui, Z.; Ju’e, G. Managing disruption risk in competing multitier supply chains. Int. Trans. Oper. Res. 2022, 29, 3622–3656. [Google Scholar]

- Kamalahmadi, M.; Parast, M.M. An assessment of supply chain disruption mitigation strategies. Int. J. Priduction Econ. 2017, 184, 210–230. [Google Scholar] [CrossRef]

- Li, Y.; Chen, K.; Collignon, S.; Ivanov, D. Ripple Effect in the Supply Chain Network: Forward and Backward Disruption Propagation, Network Health and Firm Vulnerability. Eur. J. Oper. Res. 2021, 291, 1117–1131. [Google Scholar] [CrossRef]

- Ojha, R.; Ghadge, A.; Tiwari, K.M.; Bititci, U.S. Bayesian network modelling for supply chain risk propagation. Int. J. Prod. Res. 2018, 56, 5795–5819. [Google Scholar] [CrossRef]

- Pavlov, A.; Ivanov, D.; Werner, F.; Dolgui, A.; Sokolov, B. Integrated detection of disruption scenarios, the ripple effect dispersal and recovery paths in supply chains. Ann. Oper. Res. 2019, 319, 609–631. [Google Scholar] [CrossRef]

- Hao, H.; Xing, W.; Wang, A.; Song, H.; Han, Y.; Zhao, P.; Xie, Z.; Chen, X. Multi-layer networks research on analyzing supply risk transmission of lithium industry chain. Resour. Policy 2022, 79, 102933. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, H.; Jin, X. Risk transmission in complex supply chain network with multi-drivers. Chaos Solitons Fractals 2021, 143, 110259. [Google Scholar] [CrossRef]

- Guo, H.; Cheng, Y.; Xie, X. A new model for supply chain risk propagation considering herd mentality and risk preference under warning information on multiplex networks. Phys. A Stat. Mech. Its Appl. 2020, 545, 123506. [Google Scholar]

- Hongchun, W.; Xinyan, Z. Research on Supply Chain Risk Transmission Mechanism Based on Improved SIRS Model. Math. Probl. Eng. 2022, 2022, 9502793. [Google Scholar]

- Jianhua, C.; Ting, Y. Transmission Mechanism of Post-COVID-19 Emergency Supply Chain Based on Complex Network: An Improved SIR Model. Sustainability 2023, 15, 3059. [Google Scholar] [CrossRef]

- Brasil, L.A.C.; Faria, D.P.L.B.; Costa, D.A.M.L.; de Farias, M.M.; Carvalho, H.S. Modelling the spread of COVID-19 in the capital of Brazil using numerical solution and cellular automata. Comput. Biol. Chem. 2021, 94, 107554. [Google Scholar]

- Wang, Y.; Sun, R.; Ren, L.; Geng, X.; Wang, X.; Lv, L. Risk Propagation Model and Simulation of an Assembled Building Supply Chain Network. Buildings 2023, 13, 981. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the resilient supply chain. Int. J. Logist. Manag. 2004, 15, 1–14. [Google Scholar] [CrossRef]

- Zhao, S.; You, F. Resilient supply chain design and operations with decision-dependent uncertainty using a data-driven robust optimization approach. AIChE J. 2019, 65, 1006–1021. [Google Scholar] [CrossRef]

- Ponomarov, Y.S.; Holcomb, C.M. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Torabi, S.; Baghersad, M.; Mansouri, S. Resilient supplier selection and order allocation under operational and disruption risks. Transp. Res. Part E 2015, 79, 22–48. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M. Supply chain readiness, response and recovery for resilience. Supply Chain Manag. Int. J. 2016, 21, 709–731. [Google Scholar] [CrossRef]

- Scholten, K.; Sharkey, S.P.; Fynes, B. Building routines for non-routine events: Supply chain resilience learning mechanisms and their antecedents. Supply Chain Manag. Int. J. 2019, 24, 430–442. [Google Scholar] [CrossRef]

- Darouich, C.; Dhiba, Y. Supply chain resilience strategies: The case of pharmaceutical firms in Morocco. Int. J. Account. Financ. Audit. Manag. Econ. 2020, 1, 136–165. [Google Scholar]

- Melnyk, S.A.; Closs, D.J.; Griffis, S.E.; Zobel, C. Understanding supply chain resilience. Supply Chain. Manag. Rev. 2014, 18, 34–41. [Google Scholar]

- Shekarian, M.; Parast, M.M. An Integrative approach to supply chain disruption risk and resilience management: A literature review. Int. J. Logist. Res. Appl. 2020, 24, 427–455. [Google Scholar] [CrossRef]

- Durach, F.C.; Kembro, H.J.; Wieland, A. How to advance theory through literature reviews in logistics and supply chain management. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 1090–1107. [Google Scholar] [CrossRef]

- Gopalakrishnan, N.; Guilherme, T. Impact of COVID-19 outbreak on employee performance—Moderating role of industry 4.0 base technologies. Int. J. Prod. Econ. 2021, 234, 108075. [Google Scholar]

- Leung, T. Key Advantages of Sustainable Manufacturing. 2020. Available online: https://www.winman.com/blog/key-advantages-of-sustainable-manufacturing (accessed on 23 October 2020).

- Eltantawy, R. Towards sustainable supply management: Requisite governance and resilience capabilities. J. Strateg. Mark. 2016, 24, 118–130. [Google Scholar] [CrossRef]

- Shin, N.; Park, S. Evidence-based resilience management for supply chain sustainability: An interpretive structural modelling approach. Sustainability 2019, 11, 484. [Google Scholar] [CrossRef]

- Akbari-Kasgari, M.; Khademi-Zare, H.; Fakhrzad, M.B.; Hajiaghaei-Keshteli, M.; Honarvar, M. Designing a resilient and sustainable closed-loop supply chain network in copper industry. Clean Technol. Environ. Policy 2022, 24, 1553–1580. [Google Scholar] [CrossRef]

- Cheraghalipour, A.; Farsad, S. A bi-objective sustainable supplier selection and order allocation considering quantity discounts under disruption risks: A case study in plastic industry. Comput. Ind. Eng. 2018, 118, 237–250. [Google Scholar] [CrossRef]

- Gholami-Zanjani, S.M.; Jabalameli, M.S.; Pishvaee, M.S. A resilient-green model for multi-echelon meat supply chain planning. Comput. Ind. Eng. 2021, 152, 107018. [Google Scholar] [CrossRef]

- Hasani, A.; Mokhtari, H.; Fattahi, M. A multi-objective optimization approach for green and resilient supply chain network design: A real-life case study. J. Clean. Prod. 2021, 278, 123199. [Google Scholar] [CrossRef]

- Khezeli, M.; Najafi, E.; Molana, M.H.; Seidi, M. A sustainable and resilient supply chain (RS-SCM) by using synchronisation and load-sharing approach: Application in the oil and gas refinery. Int. J. Syst. Sci. Oper. Logist. 2023, 10, 2198055. [Google Scholar] [CrossRef]

- Sabouhi, F.; Jabalameli, M.S.; Jabbarzadeh, A. An optimization approach for sustainable and resilient supply chain design with regional considerations. Comput. Ind. Eng. 2021, 159, 107510. [Google Scholar] [CrossRef]

- Olfati, M.; Paydar, M.M. Towards a responsive-sustainable-resilient tea supply chain network design under uncertainty using big data. Socio-Econ. Plan. Sci. 2023, 88, 101646. [Google Scholar] [CrossRef]

- Gebhardt, M.; Spieske, A.; Kopyto, M.; Birkel, H. Increasing global supply chains’ resilience after the COVID-19 pandemic: Empirical results from a Delphi study. J. Bus. Res. 2022, 150, 59–72. [Google Scholar] [CrossRef]

- Wenyu, D. Research on Supply Chain Resilience of Agricultural Products Based on AHP-FCE Model. Learn. Educ. 2020, 25, 325–334. [Google Scholar]

- Feng, J.; Yuan, B.; Li, X.; Tian, D.; Mu, W. Evaluation on risks of sustainable supply chain based on optimized BP neural networks in fresh grape industry. Comput. Electron. Agric. 2021, 183, 105988. [Google Scholar]

- Moosavi, J.; Hosseini, S. Simulation-based assessment of supply chain resilience with consideration of recovery strategies in the COVID-19 pandemic context. Comput. Ind. Eng. 2021, 160, 107593. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D. A new resilience measure for supply networks with the ripple effect considerations: A Bayesian network approach. Ann. Oper. Res. 2019, 319, 581–607. [Google Scholar] [CrossRef]

- Shao, L.; Jin, S. Resilience assessment of the lithium supply chain in China under impact of new energy vehicles and supply interruption. J. Clean. Prod. 2020, 252, 119624. [Google Scholar] [CrossRef]

- Rajesh, R. A novel advanced grey incidence analysis for investigating the level of resilience in supply chains. Ann. Oper. Res. 2020, 308, 441–490. [Google Scholar] [CrossRef]

- Ayyildiz, E. Interval valued intuitionistic fuzzy analytic hierarchy process-based green supply chain resilience evaluation methodology in post COVID-19 era. Environ. Sci. Pollut. Res. 2021, 30, 42476–42494. [Google Scholar] [CrossRef]

- Ramezankhani, M.; Torabi, A.S.; Vahidi, F. Supply Chain Performance Measurement and Evaluation: A Mixed Sustainability and Resilience Approach. Comput. Ind. Eng. 2018, 126, 531–548. [Google Scholar] [CrossRef]

- Weilong, N.; Yongtu, L.; Zhengbing, L.; Liao, Q.; Cai, S.; Wang, B.; Zhang, H.; Wang, Y. Resilience assessment of the downstream oil supply chain considering the inventory strategy in extreme weather events. Comput. Chem. Eng. 2022, 163, 107831. [Google Scholar]

- Titah, R.; Shuraida, S.; Rekik, Y. Integration breach: Investigating the effect of internal and external information sharing and coordination on firm profit. Int. J. Prod. Econ. 2016, 181, 34–47. [Google Scholar] [CrossRef]

- Ha, A.Y.; Huajiang, L.; Weixin, S. Supplier encroachment, information sharing, and channel structure in online retail platforms. Prod. Oper. Manag. 2022, 31, 1235–1251. [Google Scholar] [CrossRef]

- Zhou, R.; Liao, Y.; Shen, W.; Yang, S. Channel selection and fulfillment service contracts in the presence of asymmetric service information. Int. J. Prod. Econ. 2020, 222, 107504. [Google Scholar] [CrossRef]

- Khan, M.; Hussain, M.; Saber, M.H. Information sharing in a sustainable supply chain. Int. J. Prod. Econ. 2016, 181, 208–214. [Google Scholar] [CrossRef]

- Dubey, R.; Altay, N.; Gunasekaran, A.; Blome, C.; Papadopoulos, T.; Childe, S.J. Supply chain agility, adaptability and alignment Empirical evidence from the Indian auto components industry. Int. J. Oper. Prod. Manag. 2018, 38, 129–148. [Google Scholar] [CrossRef]

- Lixin, W.; Xiaolong, J.; Qian, H. Modeling the Incentive Mechanism of Information Sharing in a Dual-Channel Supply Chain. Discret. Dyn. Nat. Soc. 2021, 2021, 2769353. [Google Scholar]

- Richa, N.; Arunava, M.; Mowmita, M. A multi-retailer sustainable supply chain model with information sharing and quality deterioration. RAIRO Oper. Res. 2021, 55, S2773–S2794. [Google Scholar]

- Fu, L.; Yang, Q.; Liu, X.; He, L. Risk assessment of infectious disease epidemic based on fuzzy Bayesian network. Risk Anal. Off. Publ. Soc. Risk Anal. 2023, 44, 40–53. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Zhang, Z.; Huang, Y.; Dai, L.; Hu, H. Risk assessment of marine accidents with Fuzzy Bayesian Networks and causal analysis. Ocean. Coast. Manag. 2022, 228, 106323. [Google Scholar] [CrossRef]

- Yazdi, M.; Mohammadpour, J.; Li, H.; Huang, H.Z.; Zarei, E.; Pirbalouti, R.G.; Adumene, S. Fault tree analysis improvements: A bibliometric analysis and literature review. Qual. Reliab. Eng. Int. 2023, 39, 1639–1659. [Google Scholar] [CrossRef]

- Niels, B.; Rainer, L. Analyzing upstream and downstream risk propagation in supply networks by combining Agent-based Modeling and Bayesian networks. J. Bus. Econ. 2023, 93, 859–889. [Google Scholar]

- Nicknezhad, J.; Zegordi, H.S. Petroleum supply chain dynamic risk assessment using Bayesian network. Comput. Chem. Eng. 2024, 189, 108771. [Google Scholar] [CrossRef]

- Shi, W.; He, J.; Wang, M. System dynamics model of emergency medical materials supply chain considering decision maker’s confidence bias. J. Saf. Environ. 2023, 23, 1545–1555. (In Chinese) [Google Scholar]

- Liu, M.; Ding, Y.; Chu, F.; Dolgui, A.; Zheng, F. Robust actions for improving supply chain resilience and viability. Omega 2023, 123, 102972. [Google Scholar] [CrossRef]

- Forrester, J.W. Industrial dynamics. J. Oper. Res. Soc. 1997, 48, 1037–1041. [Google Scholar] [CrossRef]

| Reference | Methodology | Method Description | Characteristics |

|---|---|---|---|

| Maximilian et al. [60] | Delphi method | The Delphi method is essentially a feedback anonymous inquiry method. Its general process is to obtain the opinions of experts on the problems to be predicted, organize, summarize, and statistically analyze them, then anonymously provide feedback to each expert, solicit opinions again, summarize them, and provide feedback again until a consensus is reached. | Anonymity, statistical, multiple rounds of feedback. |

| Dong [61] | AHP-FCE method | The Analytic Hierarchy Process (AHP) is combined with Fuzzy Comprehensive Evaluation (FCE). The former is used to determine the weight of each evaluation indicator, while the latter is used to comprehensively evaluate each indicator and obtain the final evaluation result. | Systematic analysis, flexible and practical, widely applicable, capable of handling ambiguity issues. |

| Feng et al. [62] | BP neural network | A multi-layer feed-forward neural network trained using error back-propagation algorithm. | A flexible network structure with strong model generalization ability and non-linear mapping ability. |

| Moosavi et al. [63] | Discrete-event simulation model | Discrete-event simulation model is a modeling method that studies the dynamic behavior and performance of a system by simulating the sequence and interaction of discrete events in the system. | Event-centered dynamic modeling capabilities and quantitative analysis of stochasticity in complex systems. |

| Hosseini S et al. [64] | Bayesian network | Bayesian network is a machine learning tool based on a probabilistic graphical model, used to represent probability dependencies and uncertainty inference between variables. | Probabilistic inference, independence hypothesis, capable of handling uncertainty. |

| Wu Anbo [1] | Interval Type-2F-PT-TOPSIS | The Interval Type-2 Fuzzy Prospect Theory is combined with Technique for Order Preference by Similarity to an Ideal Solution (Interval Type-2F-PT-TOPSIS). | Ability to deal with the complexity, ambiguity, and uncertainty of decision-making problems, as well as the different individual capabilities and behavioral preferences of decision makers. |

| Zhiwen Zeng [2] | Entropy weight method combined with the approximate ideal solution sorting technology | Entropy weighting is used for objective weighting, which determines indicator weights by the degree of dispersion of the data; TOPSIS is used for program ranking, which compares the advantages and disadvantages of each program by calculating its distance from the “ideal solution” and the “negative ideal solution”. | Strong objectivity, high flexibility, visualization of the decision-making process. |

| Liuguo Shao et al. [65] | System dynamics | System dynamics is an interdisciplinary methodology based on feedback theory and systems thinking, used to analyze the behavioral patterns, causal relationships, and long-term evolutionary trends of complex dynamic systems. | Systematic and dynamic. |

| Rajesh [66] | Grey system | The core idea of grey system is to study systems with incomplete or uncertain information, and to reveal the inherent laws of the system by processing some known information. | Low data requirements, simple calculation, and wide applicability. |

| Ayyildiz [67] | Intuitive fuzzy evaluation method | The intuitive fuzzy evaluation method is a comprehensive evaluation method based on fuzzy mathematics, which transforms qualitative evaluation into quantitative evaluation. By comprehensively evaluating multiple factors, it achieves a comprehensive, objective, and accurate evaluation of things. | Ability to deal with ambiguity and difficult-to-quantify issues, with clear and systematic results. |

| Ramezankhani et al. [68] | Data envelopment analysis | Data Envelopment Analysis (DEA) is a nonparametric efficiency analysis method based on linear programming that measures the relative efficiency of decision-making units by evaluating their input and output data. | No need to artificially set the weights of indicators, strong objectivity, can handle multiple input indicators and multiple output indicators at the same time, and has a wide range of applications. |

| Ni et al. [69] | Monte Carlo simulation | Monte Carlo simulation is a numerical method for approximating the solution of complex problems by generating large numbers of random numbers and statistical sampling. | Ability to deal with uncertainty, flexibility, and wide applicability. |

| Interrupt Type | Interfering Factor |

|---|---|

| Supply interruption | Insufficient supply of raw materials |

| Insufficient production capacity of manufacturing enterprises | |

| Supply chain too centralized | |

| Low production qualification rate | |

| Transportation interruption | Traffic interruption |

| Insufficient transportation capacity |

| Node | S | T | SC |

|---|---|---|---|

| Interruption probability | 0.4299 | 0.3775 | 0.4176 |

| Node | S | T | SC |

|---|---|---|---|

| Interruption risk probability | 0.3175 | 0.1729 | 0.2337 |

| Variable | Numerical Value |

|---|---|

| Collection time for medical supplies/d | 2 |

| Transportation time/d | 1 |

| Productive time/d | 2 |

| Maximum daily production capacity/ten thousand pieces | 2000 |

| Raw material stocking time/d | 5 |

| Mean demand/piece | 6,920,000 |

| Demand variance/piece | 276,520,620,527 |

| Demand point inventory adjustment time/d | 1.5 |

| Basic demand quantity/ten thousand pieces | 2500 |

| Production qualification rate | 98% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, J.; Wang, J.; Li, X. Interruption Risk Propagation and Resilience Evaluation of Supply Chain of Emergency Medical Supplies Under Information Sharing Mechanism. Sustainability 2025, 17, 5303. https://doi.org/10.3390/su17125303

Bai J, Wang J, Li X. Interruption Risk Propagation and Resilience Evaluation of Supply Chain of Emergency Medical Supplies Under Information Sharing Mechanism. Sustainability. 2025; 17(12):5303. https://doi.org/10.3390/su17125303

Chicago/Turabian StyleBai, Jing, Jiahui Wang, and Xingyuan Li. 2025. "Interruption Risk Propagation and Resilience Evaluation of Supply Chain of Emergency Medical Supplies Under Information Sharing Mechanism" Sustainability 17, no. 12: 5303. https://doi.org/10.3390/su17125303

APA StyleBai, J., Wang, J., & Li, X. (2025). Interruption Risk Propagation and Resilience Evaluation of Supply Chain of Emergency Medical Supplies Under Information Sharing Mechanism. Sustainability, 17(12), 5303. https://doi.org/10.3390/su17125303