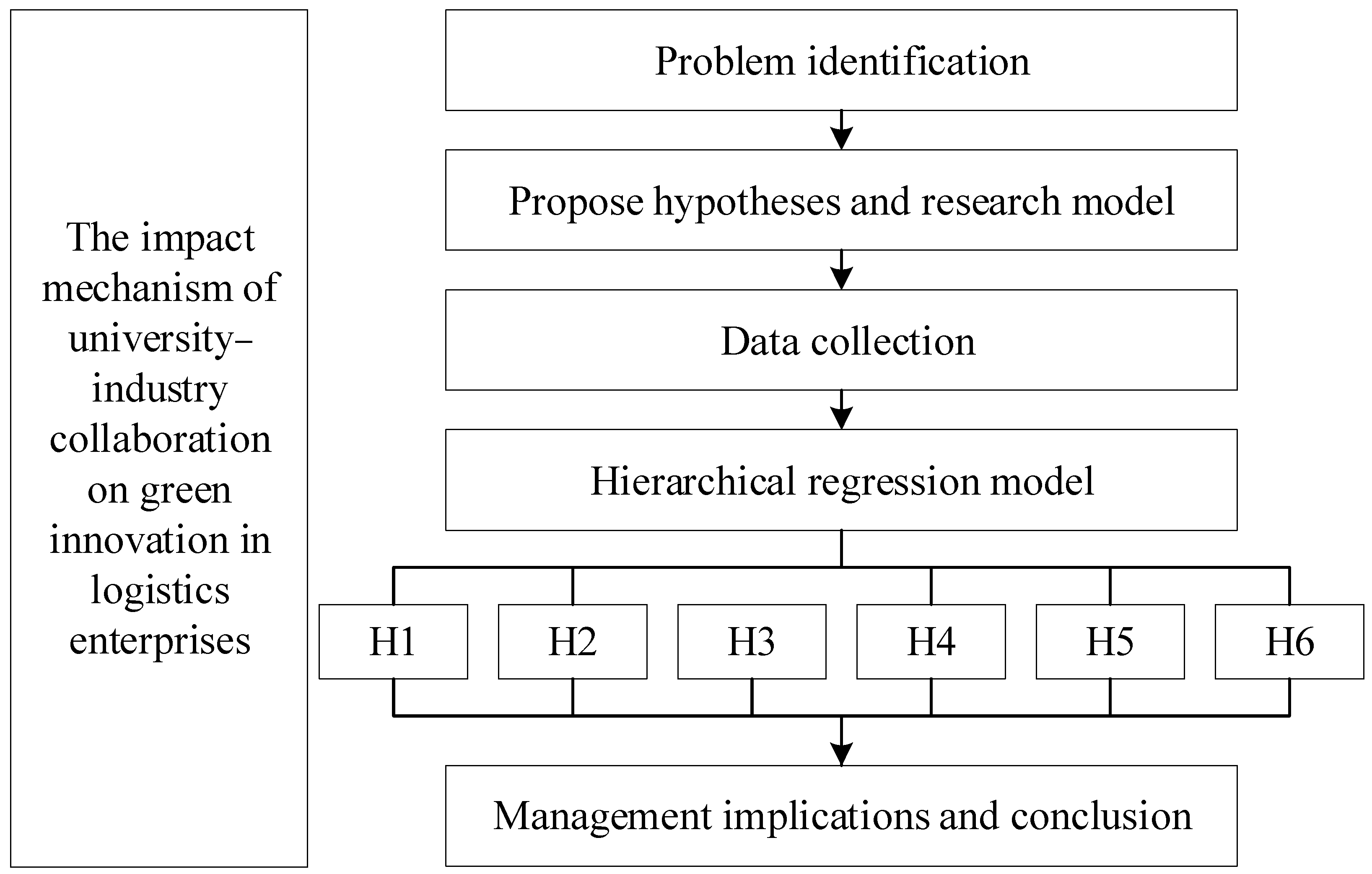

Research on the Impact of University–Industry Collaboration on Green Innovation of Logistics Enterprises in China

Abstract

1. Introduction

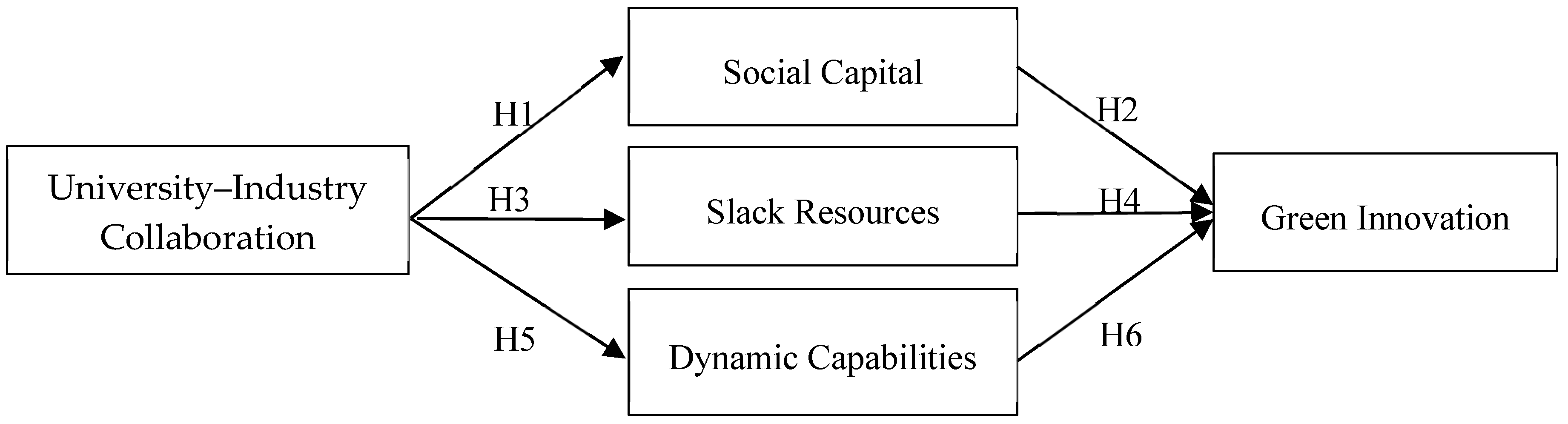

2. Theoretical Basis and Hypothesis Development

2.1. Theoretical Basis

2.1.1. Green Innovation

2.1.2. University–Industry Collaboration

2.1.3. Social Capital Theory

2.1.4. Dynamic Capability

2.2. Hypothesis Development

2.2.1. University–Industry Collaboration and Social Capital

2.2.2. Social Capital and Green Innovation in Logistics Enterprises

2.2.3. University–Industry Collaboration and Slack Resources

2.2.4. Slack Resources and Green Innovation in Logistics Enterprises

2.2.5. University–Industry Collaboration and Dynamic Capability

2.2.6. Dynamic Capabilities and Green Innovation in Logistics Enterprises

3. Data and Methods

3.1. Preliminary Test

3.2. Data Collection

3.3. Descriptive Statistics

3.4. Variable Measurement

4. Empirical Results

4.1. Reliability and Validity Analysis

4.2. Correlation Analysis

4.3. Common Method Bias Analysis

4.4. Regression Results Analysis

4.5. Robustness Test

5. Discussion and Conclusions

5.1. Discussion

5.2. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lian, L.G.; Xu, A.; Zhu, Y. Substantive Green Innovation or Symbolic Green Innovation? The Impact of ER on Enterprise Green Innovation Based on the Dual Moderating Effects. J. Innov. Knowl. 2022, 7, 100203. [Google Scholar] [CrossRef]

- Ouni, M.; Ben Abdallah, K. Environmental Sustainability and Green Logistics: Evidence from BRICS and Gulf Countries by Cross-Sectionally Augmented Autoregressive Distributed Lag (CS-ARDL) Approach. Sustain. Dev. 2024, 32, 3753–3770. [Google Scholar] [CrossRef]

- Giannetti, B.F.; Agostinho, F.; Eras, J.J.C.; Yang, Z.; Almeida, C.M.V.B. Cleaner Production for Achieving the Sustainable Development Goals. J. Clean. Prod. 2020, 271, 122127. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, W. State Ownership and Green Innovation in China: The Contingent Roles of Environmental and Organizational Factors. J. Clean. Prod. 2021, 314, 128029. [Google Scholar] [CrossRef]

- Guyader, H.; Ottosson, M.; Frankelius, P.; Witell, L. Identifying the Resource Integration Processes of Green Service. J. Serv. Manag. 2019, 31, 839–859. [Google Scholar] [CrossRef]

- Orji, I.J.; Kusi-Sarpong, S.; Gupta, H.; Okwu, M. Evaluating Challenges to Implementing Eco-Innovation for Freight Logistics Sustainability in Nigeria. Transp. Res. Part A Policy Pract. 2019, 129, 288–305. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, X.; Huang, X.; Cao, W. Research on Logistics Service Supply Chain Coordination in the Context of Green Innovation. Sustainability 2025, 17, 646. [Google Scholar] [CrossRef]

- Wan, B.; Wan, W.; Hanif, N.; Ahmed, Z. Logistics Performance and Environmental Sustainability: Do Green Innovation, Renewable Energy, and Economic Globalization Matter? Front. Environ. Sci. 2022, 10, 996341. [Google Scholar] [CrossRef]

- Takalo, S.K.; Tooranloo, H.S.; Parizi, Z.S. Green Innovation: A Systematic Literature Review. J. Clean. Prod. 2021, 279, 122474. [Google Scholar] [CrossRef]

- Nan, Y.A.; Tian, Y.; Xu, M.Q.; Wu, Y.P. Evaluation of Green Innovation Capability and Influencing Factors in the Logistics Industry. Environ. Dev. Sustain. 2024. [Google Scholar] [CrossRef]

- Chu, Z.; Wang, L.; Lai, F. Customer Pressure and Green Innovations at Third Party Logistics Providers in China: The Moderation Effect of Organizational Culture. Int. J. Logistics Manag. 2019, 30, 57–75. [Google Scholar] [CrossRef]

- Morash, E.A.; Droge, C.L.M.; Vickery, S.K. Strategic Logistics Capabilities for Competitive Advantage and Firm Success. J. Bus. Logist. 1996, 17, 1–22. [Google Scholar]

- Grawe, S.J.; Autry, C.W.; Daugherty, P.J. Organizational Implants and Logistics Service Innovation: A Relational Social Capital Perspective. Transp. J. 2014, 53, 180–210. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, X.; Dong, K.L.; Sui, L.H.; Wang, M.; Hong, Q. Green Innovation in Regional Logistics: Level Evaluation and Spatial Analysis. Int. J. Environ. Res. Public Health 2023, 20, 735. [Google Scholar] [CrossRef]

- Evangelista, P. Environmental Sustainability Practices in the Transport and Logistics Service Industry: An Exploratory Case Study Investigation. Res. Transp. Bus. Manag. 2014, 12, 63–72. [Google Scholar] [CrossRef]

- Buysse, K.; Verbeke, A. Proactive Environmental Strategies: A Stakeholder Management Perspective. Strategic Manag. J. 2003, 24, 453–470. [Google Scholar] [CrossRef]

- Albort-Morant, G.; Leal-Millán, A.; Cepeda-Carrión, G. The Antecedents of Green Innovation Performance: A Model of Learning and Capabilities. J. Bus. Res. 2016, 69, 4912–4917. [Google Scholar] [CrossRef]

- Huang, J.W.; Li, Y.H. Green Innovation and Performance: The View of Organizational Capability and Social Reciprocity. J. Bus. Ethics 2017, 145, 309–324. [Google Scholar] [CrossRef]

- Schmitz, E.A.; Baum, M.; Huett, P.; Kabst, R. The Contextual Role of Regulatory Stakeholder Pressure in Proactive Environmental Strategies: An Empirical Test of Competing Theoretical Perspectives. Organ. Environ. 2019, 32, 281–308. [Google Scholar] [CrossRef]

- Hao, Y.; Fan, C.; Long, Y.; Pan, J. The Role of Returnee Executives in Improving Green Innovation Performance of Chinese Manufacturing Enterprises: Implications for Sustainable Development Strategy. Bus. Strat. Environ. 2019, 28, 804–818. [Google Scholar] [CrossRef]

- Rossoni, A.L.; de Vasconcellos, E.P.G.; de Castilho Rossoni, R.L. Barriers and Facilitators of university-industry collaboration for Research, Development and Innovation: A Systematic Review. Manag. Rev. Q. 2024, 74, 1841–1877. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, H.; Du, L.; Lin, C.; Lu, W. How Does Alliance-Based Government-University-Industry Foster Cleantech Innovation in a Green Innovation Ecosystem? J. Clean. Prod. 2021, 283, 124559. [Google Scholar]

- Gámez-Pérez, K.M.; Sarmiento, A.M.; Garcia-Reyes, H.; Velázquez-Martínez, J.C. An international university-industry collaboration Model to Develop Supply Chain Competences. Supply Chain Manag. Int. J. 2020, 25, 475–487. [Google Scholar] [CrossRef]

- Perkmann, M.; Tartari, V.; McKelvey, M.; Autio, E.; Broström, A.; D’Este, P.; Fini, R.; Geuna, A.; Grimaldi, R.; Hughes, A.; et al. Academic Engagement and Commercialization: A Review of the Literature on University–Industry Relations. Res. Policy 2013, 42, 423–442. [Google Scholar] [CrossRef]

- Yuan, B.; Cao, X. Do Corporate Social Responsibility Practices Contribute to Green Innovation? The Mediating Role of Green Dynamic Capability. Technol. Soc. 2022, 68, 101868. [Google Scholar] [CrossRef]

- Wang, C.; Qureshi, I.; Guo, F.; Zhang, Q. Corporate Social Responsibility and Disruptive Innovation: The Moderating Effects of Environmental Turbulence. J. Bus. Res. 2021, 139, 1435–1450. [Google Scholar] [CrossRef]

- Chen, Z.; Liang, M. How Do External and Internal Factors Drive Green Innovation Practices Under the Influence of Big Data Analytics Capability: Evidence from China. J. Clean. Prod. 2023, 404, 136862. [Google Scholar] [CrossRef]

- Roh, T.; Lee, K.; Yang, J.Y. How Do Intellectual Property Rights and Government Support Drive a Firm’s Green Innovation? The Mediating Role of Open Innovation. J. Clean. Prod. 2021, 317, 128422. [Google Scholar] [CrossRef]

- Kraus, S.; Rehman, S.U.; García, F.J.S. Corporate Social Responsibility and Environmental Performance: The Mediating Role of Environmental Strategy and Green Innovation. Technol. Forecast. Soc. Chang. 2020, 160, 120262. [Google Scholar] [CrossRef]

- Delgado-Ceballos, J.; Aragón-Correa, J.A.; Mandojana, N. The Effect of Internal Barriers on the Connection Between Stakeholder Integration and Proactive Environmental Strategies. J. Bus. Ethics 2012, 107, 281–293. [Google Scholar] [CrossRef]

- Lin, H.; Zeng, S.X.; Ma, H.Y.; Qi, G.Y.; Tam, V.W. Can Political Capital Drive Corporate Green Innovation? Lessons from China. J. Clean. Prod. 2014, 64, 63–72. [Google Scholar]

- Chen, X.; Yi, N.; Zhang, L.; Li, D. Does Institutional Pressure Foster Corporate Green Innovation? Evidence from China’s Top 100 Companies. J. Clean. Prod. 2018, 188, 304–311. [Google Scholar] [CrossRef]

- Carfora, A.; Scandurra, G.; Thomas, A. Determinants of Environmental Innovations Supporting Small- and Medium-Sized Enterprises Sustainable Development. Bus. Strat. Environ. 2021, 30, 2621–2636. [Google Scholar] [CrossRef]

- Ketata, I.; Sofka, W.; Grimpe, C. The Role of Internal Capabilities and Firms’ Environment for Sustainable Innovation: Evidence for Germany. R&D Manag. 2015, 45, 60–75. [Google Scholar]

- Lin, Y.H.; Chen, Y.S. Determinants of Green Competitive Advantage: The Roles of Green Knowledge Sharing, Green Dynamic Capabilities, and Green Service Innovation. Qual. Quant. 2017, 51, 1663–1685. [Google Scholar] [CrossRef]

- Chen, Y.S.; Chang, C.H.; Wu, F.S. Origins of Green Innovations: The Differences Between Proactive and Reactive Green Innovations. Manag. Decis. 2012, 50, 368–398. [Google Scholar] [CrossRef]

- Sharma, S. Managerial Interpretations and Organizational Context as Predictors of Corporate Choice of Environmental Strategy. Acad. Manag. J. 2000, 43, 681–716. [Google Scholar] [CrossRef]

- Chu, Z.; Xu, J.; Lai, F.; Collins, B.J. Institutional Theory and Environmental Pressures: The Moderating Effect of Market Uncertainty on Innovation and Firm Performance. IEEE Trans. Eng. Manag. 2018, 65, 392–403. [Google Scholar] [CrossRef]

- Jazairy, A.; Haartman, R. von. Analyzing the Institutional Pressures on Shippers and Logistics Service Providers to Implement Green Supply Chain Management Practices. Int. J. Logist. Res. Appl. 2020, 23, 44–84. [Google Scholar] [CrossRef]

- Lieb, K.J.; Lieb, R.C. Environmental Sustainability in the Third-Party Logistics (3PL) Industry. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 524–533. [Google Scholar] [CrossRef]

- Rossi, S.; Colicchia, C.; Cozzolino, A.; Christopher, M. The logistics service providers in eco-efficiency innovation: An empirical study. Supply Chain. Manag. Int. J. 2013, 18, 583–603. [Google Scholar] [CrossRef]

- El-Ferik, S.; Al-Naser, M. University Industry Collaboration: A Promising Trilateral Co-Innovation Approach. IEEE Access 2021, 9, 112761–112769. [Google Scholar] [CrossRef]

- Bogers, M.; Chesbrough, H.; Moedas, C. Open Innovation: Research, Practices, and Policies. Calif. Manag. Rev. 2018, 60, 5–16. [Google Scholar] [CrossRef]

- Audretsch, B.D.; Belitski, M. The Limits to Open Innovation and Its Impact on Innovation Performance. Technovation 2023, 119, 102519. [Google Scholar] [CrossRef]

- Duque-Grisales, E.; Aguilera-Caracuel, J.; Guerrero-Villegas, J.; García-Sánchez, E. Does Green Innovation Affect the Financial Performance of Multilatinas? The Moderating Role of ISO 14001 and R&D Investment. Bus. Strat. Environ. 2020, 29, 3286–3302. [Google Scholar]

- Chesbrough, H.; Euchner, J. The Evolution of Open Innovation: An Interview with Henry Chesbrough. Res. Technol. Manag. 2011, 54, 13–18. [Google Scholar] [CrossRef]

- Rybnicek, R.; Königsgruber, R. What Makes Industry–University Collaboration Succeed? A Systematic Review of the Literature. J. Bus. Econ. 2019, 89, 221–250. [Google Scholar] [CrossRef]

- Skute, I.; Zalewska-Kurek, K.; Hatak, I.; de Weerd-Nederhof, P. Mapping the Field: A Bibliometric Analysis of the Literature on University–Industry Collaborations. J. Technol. Transf. 2019, 44, 916–947. [Google Scholar] [CrossRef]

- Li, Y.; Zhen Hong, X.; Fu, Z.; Wu, Y.; Wang, Y. Green Technology Innovation Models, Environmental Regulation, and the Willingness of Government-University-Industry to Collaborate on Green Innovation. J. Energy Rep. 2024, 12, 2901–2912. [Google Scholar]

- Yi, H.; Zhang, Q. Knowledge-Sharing Strategies of University-Industry Alliances Promoting Green Technology Innovation in Ecosystems: Based on the Utility of Multichannel Funding. J. IEEE Access 2022, 10, 65728–65743. [Google Scholar] [CrossRef]

- Nahapiet, J.; Ghoshal, S. Social Capital, Intellectual Capital, and the Organizational Advantage. Acad. Manag. Rev. 1998, 23, 242–266. [Google Scholar] [CrossRef]

- Putnam, R.D. The Prosperous Community: Social Capital and Public Life. Am. Prospect. 1993, 13, 35–42. [Google Scholar]

- Meltzer, D.; Chung, J.; Khalili, P.; Marlow, E.; Arora, V.; Schumock, G.; Burt, R. Exploring the Use of Social Network Methods in Designing Healthcare Quality Improvement Teams. Soc. Sci. Med. 2010, 71, 1119–1130. [Google Scholar] [CrossRef]

- Ozgun, A.H.; Tarim, M.; Delen, D.; Zaim, S. Social Capital and Organizational Performance: The Mediating Role of Innovation Activities and Intellectual Capital. Healthc. Anal. 2022, 2, 100046. [Google Scholar] [CrossRef]

- Hasan, I.; Hoi, C.K.S.; Wu, Q.; Zhang, H. Is Social Capital Associated with Corporate Innovation? Evidence from Publicly Listed Firms in the US. J. Corp. Financ. 2020, 62, 16–23. [Google Scholar] [CrossRef]

- Zheng, W. A Social Capital Perspective from Individuals to Nations: Where Is Empirical Literature Directing Us? Int. J. Manag. Rev. 2010, 12, 151–183. [Google Scholar] [CrossRef]

- Lyu, C.; Peng, C.; Yang, H.; Li, H.; Gu, X. Social Capital and Innovation Performance of Digital Firms: Serial Mediation Effect of Cross-Border Knowledge Search and Absorptive Capacity. J. Innov. Knowl. 2022, 7, 100187. [Google Scholar]

- Li, Q.; Maqsood, U.S.; Zahid, R.M.A.; Anwar, W. Regulating CEO Pay and Green Innovation: Moderating Role of Social Capital and Government Subsidy. Environ. Sci. Pollut. Res. 2024, 31, 46163–46177. [Google Scholar] [CrossRef]

- Xie, X.; Hoang, T.T.; Zhu, Q. Green Process Innovation and Financial Performance: The Role of Green Social Capital and Customers’ Tacit Green Needs. J. Innov. Knowl. 2022, 7, 100165. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strat. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Jiang, W.; Mavondo, F.; Zhao, W. The Impact of Business Networks on Dynamic Capabilities and Product Innovation: The Moderating Role of Strategic Orientation. Asia Pac. J. Manag. 2020, 37, 1239–1266. [Google Scholar] [CrossRef]

- Wu, K.; Liao, C.; Chen, C.; Lin, Y.; Tsai, C.F. Exploring Eco-Innovation in Dynamic Organizational Capability Under Incomplete Information in the Taiwanese Lighting Industry. Int. J. Prod. Econ. 2016, 181, 419–440. [Google Scholar]

- Qiu, L.; Jie, X.; Wang, Y.; Zhao, M. Green Product Innovation, Green Dynamic Capability, and Competitive Advantage: Evidence from Chinese Manufacturing Enterprises. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 146–165. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, G.H. The Influence of Green Technology Cognition in Adoption Behavior: On the Consideration of Green Innovation Policy Perception’s Moderating Effect. J. Discret. Math. Sci. Cryptogr. 2017, 20, 1551–1559. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Ali, S.Y.; Kusi-Sarpong, S.; Shaikh, M.A.A. Assessing Challenges for Implementing Industry 4.0: Implications for Process Safety and Environmental Protection. Process Saf. Environ. Prot. 2018, 117, 730–741. [Google Scholar] [CrossRef]

- De Marchi, V.; Grandinetti, R. Knowledge strategies for environmental innovations: The case of Italian manufacturing firms. J. Knowl. Manag. 2013, 17, 569–582. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and micro foundations of (sustainable) enterprise performance. Strategic Manag. J. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Yang, Z.; Jiang, Y.; Xie, E. Buyer-supplier relational strength and buying firm’s marketing capability: An outside-in perspective. Ind. Mark. Manag. 2019, 82, 27–37. [Google Scholar] [CrossRef]

- Acharya, C.; Ojha, D.; Gokhale, R.; Patel, P.C. Managing information for innovation using knowledge integration capability: The role of boundary spanning objects. Int. J. Inf. Manag. 2022, 62, 102438. [Google Scholar] [CrossRef]

- Liang, H.; Hussain, M.; Iqbal, A. The Dynamic Role of Green Innovation Adoption and Green Technology Adoption in the Digital Economy: The Mediating and Moderating Effects of Creative Enterprise and Financial Capability. Sustainability 2025, 17, 3176. [Google Scholar] [CrossRef]

- Hoenig, D.; Henkel, J. Quality signals? The role of patents, alliances, and team experience in venture capital financing. Res. Policy 2015, 44, 1049–1064. [Google Scholar] [CrossRef]

- Bruton, G.D.; Chahine, S.; Filatotchev, I. Founders, private equity investors, and underpricing in entrepreneurial IPOs. Entrep. Theory Pract. 2009, 33, 909–928. [Google Scholar] [CrossRef]

- Czarnitzki, D.; Hottenrott, H. Inter-organizational collaboration and financing constraints for R&D. Econ. Lett. 2017, 161, 15–18. [Google Scholar]

- Tsai, W.; Ghoshal, S. Social capital and value creation: The role of intrafirm networks. Acad. Manag. J. 1998, 41, 464–476. [Google Scholar] [CrossRef]

- Adler, P.S.; Kwon, S.W. Social capital: Prospects for a new concept. Acad. Manag. Rev. 2002, 27, 17–40. [Google Scholar] [CrossRef]

- Manafe, M.W.N.; Rizani, A.; Purnawati, E. Analysis of the influence of technical expertise, market orientation, social capital, and innovation on the performance of micro and small businesses in the technology sector. Int. J. Bus. Law Educ. 2024, 5, 983–995. [Google Scholar] [CrossRef]

- Chapman, R.L.; Soosay, C.; Kandampully, J. Innovation in logistic services and the new business model: A conceptual framework. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 630–650. [Google Scholar] [CrossRef]

- Zhang, Q.; Pan, J.; Jiang, Y.; Feng, T. The impact of green supplier integration on firm performance: The mediating role of social capital accumulation. J. Purch. Supply Manag. 2020, 26, 100579. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, T.; Shi, H. External involvement and green product innovation: The moderating role of environmental uncertainty. Bus. Strateg. Environ. 2018, 27, 1167–1180. [Google Scholar] [CrossRef]

- Cheng, W.; Wu, Q.; Li, Q.; Ye, F.; Tan, L. Dynamic incentive mechanisms for collaborative innovation of green supply chain considering digital capability and consumer green preference. J. Theor. Appl. Electron. Commer. Res. 2024, 19, 1267–1302. [Google Scholar]

- Baz, J.E.; Laguir, I. Third-party logistics providers (TPLs) and environmental sustainability practices in developing countries: The case of Morocco. Int. J. Oper. Prod. Manag. 2017, 37, 1451–1474. [Google Scholar] [CrossRef]

- Liu, X.; Ding, W.; Zhao, X. Firm’s strength of ties within innovation network, absorptive capacity and innovation performance in the Chinese manufacturing industries. Nankai Bus. Rev. 2016, 19, 30–42. [Google Scholar]

- Wang, B.; Kang, Y.; Childerhouse, P.; Huo, B. Service supply chain integration: The role of interpersonal relationships. Ind. Manag. Data Syst. 2018, 118, 828–849. [Google Scholar] [CrossRef]

- Al-Tabbaa, O.; Ankrah, S. Social capital to facilitate ‘engineered’ university–industry collaboration for technology transfer: A dynamic perspective. Technol. Forecast. Soc. Change 2016, 104, 1–15. [Google Scholar] [CrossRef]

- Hernandez-Vivanco, A.; Bernardo, M. Are certified firms more prone to eco-product innovation? The moderating role of slack resources. J. Clean. Prod. 2022, 377, 134364. [Google Scholar] [CrossRef]

- Álvarez-Gil, M.J.; Berrone, P.; Husillos, F.J.; Lado, N. Reverse logistics, stakeholders’ influence, organizational slack, and managers’ posture. J. Bus. Res. 2007, 60, 463–473. [Google Scholar] [CrossRef]

- Rennings, K. Redefining innovation—Eco-innovation research and the contribution from ecological economics. Ecol. Econ. 2000, 32, 319–332. [Google Scholar] [CrossRef]

- Kuo, Y.; Chen, M. Impact of eco-innovation on environment performance and competitive advantage: Moderating effect of green reputation. Int. J. Manag. Appl. Sci. 2016, 2, 69–77. [Google Scholar]

- Abdullah, M.; Zailani, S.; Iranmanesh, M.; Jayaraman, K. Barriers to green innovation initiatives among manufacturers: The Malaysian case. Rev. Manag. Sci. 2016, 10, 683–709. [Google Scholar] [CrossRef]

- Gong, R.; Wu, Y.Q.; Chen, F.W.; Yan, T.H. Labor costs, market environment and green technological innovation: Evidence from high-pollution firms. Int. J. Environ. Res. Public Health 2020, 17, 522. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. A Framework to Overcome Barriers to Green Innovation in SMEs Using BWM and Fuzzy TOPSIS. Sci. Total Environ. 2018, 633, 122–139. [Google Scholar] [CrossRef]

- Leyva-de la Hiz, D.I.; Ferron-Vilchez, V.; Aragon-Correa, J.A. Do Firms’ Slack Resources Influence the Relationship between Focused Environmental Innovations and Financial Performance? More Is Not Always Better. J. Bus. Ethics 2019, 159, 1215–1227. [Google Scholar] [CrossRef]

- Nohria, N.; Gulati, R. Is Slack Good or Bad for Innovation? Acad. Manag. J. 1996, 39, 1245–1264. [Google Scholar] [CrossRef]

- Conz, E.; Magnani, G.; Zucchella, A.; De Massis, A. Responding to Unexpected Crises: The Roles of Slack Resources and Entrepreneurial Attitude to Build Resilience. Small Bus. Econ. 2023, 61, 957–981. [Google Scholar] [CrossRef] [PubMed]

- Sheppard, M. The Relationship between Discretionary Slack and Growth in Small Firms. Int. Entrep. Manag. J. 2020, 16, 195–219. [Google Scholar] [CrossRef]

- Troilo, G.; De Luca, L.M.; Atuahene-Gima, K. More Innovation with Less? A Strategic Contingency View of Slack Resources, Information Search, and Radical Innovation. J. Prod. Innov. Manag. 2014, 31, 259–277. [Google Scholar] [CrossRef]

- Chen, C.J.; Huang, Y.F. Creative Workforce Density, Organizational Slack, and Innovation Performance. J. Bus. Res. 2010, 63, 411–417. [Google Scholar] [CrossRef]

- Bao, G.; Zhang, W.; Xiao, Z.; Hine, D. Slack Resources and Growth Performance: The Mediating Roles of Product and Process Innovation Capabilities. Asian J. Technol. Innov. 2020, 28, 60–76. [Google Scholar] [CrossRef]

- Ghosh, S.; Hughes, M.; Hodgkinson, I.; Hughes, P. Digital Transformation of Industrial Businesses: A Dynamic Capability Approach. Technovation 2022, 113, 101920. [Google Scholar] [CrossRef]

- Figueiredo, N.L.; Ferreira, J.J.M. More Than Meets the Partner: A Systematic Review and Agenda for University–Industry Cooperation. Manag. Rev. Q. 2022, 72, 231–273. [Google Scholar] [CrossRef]

- Hu, S.; Wang, X.; Zhang, B. Are All Innovation Modes Beneficial to Firms’ Innovation Performance? New Findings from an Emerging Market. China Manag. Stud. 2020, 14, 1015–1034. [Google Scholar] [CrossRef]

- Mao, H.; Liu, S.; Zhang, J.; Deng, Z. Information Technology Resource, Knowledge Management Capability, and Competitive Advantage: The Moderating Role of Resource Commitment. Int. J. Inf. Manag. 2016, 36, 1062–1074. [Google Scholar] [CrossRef]

- Inkpen, A.C.; Tsang, E.W. Reflections on the 2015 Decade Award—Social Capital, Networks, and Knowledge Transfer: An Emergent Stream of Research. Acad. Manag. Rev. 2016, 41, 573–588. [Google Scholar] [CrossRef]

- Gao, X. Does Structural Social Capital Lead to Proactive Green Innovation? A Three-Part Serial Mediation Model. PLoS ONE 2024, 19, e0301286. [Google Scholar] [CrossRef]

- Lin, C.Y.; Ho, Y.H. Determinants of Green Practice Adoption for Logistics Companies in China. J. Bus. Ethics 2011, 98, 67–83. [Google Scholar] [CrossRef]

- Aliasghar, A.O.; Rose, E.L.; Asakawa, K. Sources of Knowledge and Process Innovation: The Moderating Role of Perceived Competitive Intensity. Int. Bus. Rev. 2022, 31, 101920. [Google Scholar] [CrossRef]

- Hu, Y.; Duan, Y.R.; Qu, S.N.; Huo, J.Z. Logistics Service Openness Strategy of Online Platforms with Vertical Differentiation and Endogenous Service Level. Asia-Pac. J. Oper. Res. 2024, 41, 101656. [Google Scholar] [CrossRef]

- Gauthier, C.; Genet, C. Nanotechnologies and Green Knowledge Creation: Paradox or Enhancer of Sustainable Solutions? J. Bus. Ethics 2014, 124, 571–583. [Google Scholar] [CrossRef]

- Xiao, J.; Zeng, P.; Ren, G.; Zhang, L. How to Drive Strategic Green Innovation Behavior? A Qualitative Comparative Analysis (QCA) Based on Chinese Manufacturing Enterprises. Environ. Sci. Pollut. Res. 2023, 30, 77784–77797. [Google Scholar] [CrossRef]

- de Winter, J.C.F.; Dodou, D.; Wieringa, P.A. Exploratory Factor Analysis with Small Sample Sizes. J. Multiv. Behav. Res. 2009, 44, 147–181. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Podsakoff, N.P. Sources of Method Bias in Social Science Research and Recommendations on How to Control It. Annu. Rev. Psychol. 2012, 63, 539–569. [Google Scholar] [CrossRef]

- Du, L.; Zhang, Z.; Feng, T. Linking Green Customer and Supplier Integration with Green Innovation Performance: The Role of Internal Integration. Bus. Strategy Environ. 2018, 27, 1583–1595. [Google Scholar] [CrossRef]

- Liao, Z. Institutional Pressure, Knowledge Acquisition, and a Firm’s Environmental Innovation. Bus. Strategy Environ. 2018, 27, 849–857. [Google Scholar] [CrossRef]

- Chang, C.H. How to Enhance Green Service and Green Product Innovation Performance? The Roles of Inward and Outward Capabilities. Corp. Soc. Responsib. Environ. Manag. 2018, 25, 411–425. [Google Scholar] [CrossRef]

- Mora-Valentin, E.M.; Montoro-Sanchez, A.; Guerras-Martin, L.A. Determining Factors in the Success of R&D Cooperative Agreements between Firms and Research Organizations. Res. Policy 2004, 33, 17–40. [Google Scholar]

- Sherwood, A.L.; Covin, J.G. Knowledge Acquisition in University-Industry Alliances: An Empirical Investigation from a Learning Theory Perspective. J. Prod. Innov. Manag. 2010, 25, 162–179. [Google Scholar] [CrossRef]

- Yli-Renko, H.; Autio, E.; Sapienza, H.J. Social Capital, Knowledge Acquisition, and Knowledge Exploitation in Young Technology-Based Firms. Strateg. Manag. J. 2001, 22, 1163–1180. [Google Scholar] [CrossRef]

- Tan, J.; Peng, M.W. Organizational Slack and Firm Performance During Economic Transitions: Two Studies from an Emerging Economy. Strateg. Manag. J. 2003, 24, 1249–1263. [Google Scholar] [CrossRef]

- Kline, R.; Kline, R.B.; Kline, R. Principles and Practice of Structural Equation Modelling. J. Am. Stat. Assoc. 2011, 101, 12. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis: A Global Perspective; Pearson: London, UK, 2010. [Google Scholar]

- Podsakoff, P.M.; Mackenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Baron, R.M.; Kenny, D.A. The Moderator–Mediator Variable Distinction in Social Psychological Research: Conceptual, Strategic, and Statistical Considerations. J. Pers. Soc. Psychol. 1986, 51, 1173–1182. [Google Scholar] [CrossRef] [PubMed]

- Aiken, L.S.; West, S.G.; Reno, R.R. Multiple Regression: Testing and Interpreting Interactions; Sage: Thousand Oaks, CA, USA, 1991. [Google Scholar]

- Xi, Q.; Li, Z.; Zhao, J.; Ding, J. How Can Technology Orientation Promote Green Process Innovation? The Mediating Effect of Digital Capability and the Moderating Role of Innovation-Oriented Leadership. Sustainability 2025, 17, 4071. [Google Scholar] [CrossRef]

- Asbeetah, Z.; Alzubi, A.; Khadem, A.; Iyiola, K. Harnessing Digital Transformation for Sustainable Performance: Exploring the Mediating Roles of Green Knowledge Acquisition and Innovation Performance Under Digital Transformational Leadership. Sustainability 2025, 17, 2285. [Google Scholar] [CrossRef]

| Variable | Item Coding | Cronbach’s α | KMO |

|---|---|---|---|

| University–industry collaboration | UIC1 | 0.820 | 0.859 |

| UIC2 | |||

| UIC3 | |||

| UIC4 | |||

| UIC5 | |||

| UIC6 | |||

| Social capital | SC1 | 0.779 | 0.787 |

| SC2 | |||

| SC3 | |||

| SC4 | |||

| Slack resources | SR1 | 0.709 | 0.792 |

| SR2 | |||

| SR3 | |||

| SR4 | |||

| Dynamic capabilities | DC1 | 0.740 | 0.718 |

| DC2 | |||

| DC3 | |||

| DC4 | |||

| Logistics enterprises green innovation | LEGI1 | 0.779 | 0.743 |

| LEGI2 | |||

| LEGI3 | |||

| LEGI4 |

| Variables | Options | Percentage |

|---|---|---|

| Gender | Men | 73.6 |

| Female | 26.4 | |

| Age | 18–30 | 19.6 |

| 30–40 | 68.9 | |

| 40–50 | 8.6 | |

| 50–69 | 2.9 | |

| Education | High school | 2.9 |

| Junior college | 8.2 | |

| Undergraduate | 77.1 | |

| Master’s degree or above | 11.8 | |

| Position | Senior managers | 5.7 |

| Middle managers | 27.9 | |

| Grassroots managers | 65.0 | |

| Grassroots personnel | 1.4 | |

| Enterprise age | Less than 5 years | 8.2 |

| 5–10 years | 20.4 | |

| 10–15 years | 28.2 | |

| 15–20 years | 20.0 | |

| More than 20 | 23.2 | |

| Enterprise scale | Less than 20 people | 6.8 |

| 20–100 persons | 20.0 | |

| 100–500 persons | 30.7 | |

| 500–1000 people | 12.1 | |

| More than 1000 | 30.4 | |

| Enterprise nature | State-owned | 11.4 |

| Privately owned | 85.7 | |

| Foreign investment | 2.1 | |

| Sino-foreign joint venture | 0.7 |

| Variables | Code | Item | Source |

|---|---|---|---|

| Logistics enterprises green innovation | LEGI | LEGI1. Our enterprise creates and builds new services based on our focus on the environment. | [114] |

| LEGI2. Our enterprise reduces resource and energy consumption in the service process. | |||

| LEGI3. We minimize the release of harmful substances during the service process of our enterprises. | |||

| LEGI4. We use clean technology to treat and recycle waste. | |||

| University–industry collaboration | UIC | UIC1. There are many transfers of scientific and technological achievements between our enterprises and universities. | [115,116] |

| UIC2. There is a large flow of talents between our enterprises and universities. | |||

| UIC3. The forms of collaboration between our enterprises and universities are diversified. | |||

| UIC4. Our enterprise cooperates closely with a university (research institute, research institute) to carry out R&D activities of a project. | |||

| UIC5. Our enterprises and universities build a joint laboratory and school-enterprise communication platform. | |||

| UIC6. Our enterprise invites university professionals to guide the problems encountered in the work of employees, or to hire technical consultants for the enterprise. | |||

| Social capital | SC | SC1. The relationship between our enterprise and the enterprise that establishes the connection is trustworthy. | [74,117] |

| SC2. Enterprises that establish contact with our enterprise are willing to support the work of our enterprise. | |||

| SC3. Our enterprise is the same or similar in the rules of conduct with the enterprise that has established contact with our enterprise. | |||

| SC4. Enterprises that establish contact with our enterprise can communicate sincerely and effectively with our enterprise. | |||

| Slack resources | SR | SR1. We have enough financial resources within the enterprise that can be used for free control. | [118] |

| SR2. Our enterprise ‘s retained earnings (such as undistributed profits) are sufficient to support market expansion. | |||

| SR3. Our enterprise has more potential relationship resources to use. | |||

| SR4. We enterprises can obtain bank loans or other financial institutions’ funding when needed. | |||

| Dynamic capabilities | DC | DC1. Our enterprise can understand government policy in many ways. | [60] |

| DC2. Our enterprise has more advantages in obtaining government policies than other enterprises in the industry. | |||

| DC3. Our enterprise can transfer external knowledge to internal applications. | |||

| DC4. Our enterprise often communicates with stakeholders (such as distributors and retailers). |

| Variable | Item Coding | Mean | Skewness | Kurtosis |

|---|---|---|---|---|

| University–industry collaboration | UIC1 | 4.95 | −0.464 | 0.009 |

| UIC2 | 5.21 | −0.847 | 0.36 | |

| UIC3 | 4.98 | −0.643 | −0.114 | |

| UIC4 | 5.29 | −0.965 | 1.192 | |

| UIC5 | 5.36 | −1.107 | 1.078 | |

| UIC6 | 4.86 | −0.652 | −0.152 | |

| Social capital | SC1 | 5.62 | −1.25 | 2.559 |

| SC2 | 5.35 | −1.109 | 1.94 | |

| SC3 | 5.31 | −1.034 | 1.338 | |

| SC4 | 5.51 | −1.13 | 2.098 | |

| Slack resources | SR1 | 5.45 | −0.926 | 1.446 |

| SR2 | 5.18 | −0.902 | 0.964 | |

| SR3 | 5.39 | −1.238 | 2.864 | |

| SR4 | 5.21 | −0.906 | 1.171 | |

| Dynamic capabilities | DC1 | 5.65 | −0.994 | 1.631 |

| DC2 | 5.50 | −1.211 | 2.118 | |

| DC3 | 5.52 | −1.172 | 2.106 | |

| DC4 | 5.61 | −0.91 | 1.171 | |

| Logistics enterprises green innovation | LEGI1 | 5.44 | −1.048 | 1.759 |

| LEGI2 | 5.55 | −1.091 | 1.684 | |

| LEGI3 | 5.66 | −1.107 | 1.724 | |

| LEGI4 | 5.52 | −1.236 | 2.318 |

| Variable | Item Coding | Cronbach’s α | CR |

|---|---|---|---|

| University–industry collaboration | UIC1 | 0.820 | 0.797 |

| UIC2 | |||

| UIC3 | |||

| UIC4 | |||

| UIC5 | |||

| UIC6 | |||

| Social capital | SC1 | 0.779 | 0.742 |

| SC2 | |||

| SC3 | |||

| SC4 | |||

| Slack resources | SR1 | 0.709 | 0.643 |

| SR2 | |||

| SR3 | |||

| SR4 | |||

| Dynamic capabilities | DC1 | 0.740 | 0.738 |

| DC2 | |||

| DC3 | |||

| DC4 | |||

| Logistics enterprises green innovation | LEGI1 | 0.779 | 0.780 |

| LEGI2 | |||

| LEGI3 | |||

| LEGI4 |

| Variables | Number of Items | KMO | Bartlett Test of Sphericity | ||

|---|---|---|---|---|---|

| Approximate Chi-Square | DF | Sig. | |||

| Logistics enterprises green innovation | 4 | 0.735 | 303.818 | 6 | 0.000 |

| University–industry collaboration | 6 | 0.865 | 496.655 | 15 | 0.000 |

| Social capital | 4 | 0.770 | 295.836 | 6 | 0.000 |

| Slack resources | 4 | 0.739 | 192.683 | 6 | 0.000 |

| Dynamic capabilities | 4 | 0.734 | 234.941 | 6 | 0.000 |

| Measure Item | LEGI | UIC | SC | SR | DC |

|---|---|---|---|---|---|

| LEGI1 | 0.749 | ||||

| LEGI2 | 0.743 | ||||

| LEGI3 | 0.627 | ||||

| LEGI4 | 0.620 | ||||

| UIC1 | 0.731 | ||||

| UIC2 | 0.420 | ||||

| UIC3 | 0.655 | ||||

| UIC4 | 0.789 | ||||

| UIC5 | 0.693 | ||||

| UIC6 | 0.450 | ||||

| SC1 | 0.594 | ||||

| SC2 | 0.751 | ||||

| SC3 | 0.621 | ||||

| SC4 | 0.619 | ||||

| SR1 | 0.737 | ||||

| SR2 | 0.480 | ||||

| SR3 | 0.406 | ||||

| SR4 | 0.591 | ||||

| DC1 | 0.611 | ||||

| DC2 | 0.698 | ||||

| DC3 | 0.693 | ||||

| DC4 | 0.567 |

| Variable | Mean | Standard Deviation | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|---|---|

| Logistics enterprises green innovation | 5.541 | 0.921 | 1 | ||||

| University–industry collaboration | 5.109 | 1.012 | 0.542 *** | 1 | |||

| Social capital | 5.449 | 0.941 | 0.613 *** | 0.615 *** | 1 | ||

| Slack resources | 5.310 | 0.893 | 0.549 *** | 0.656 *** | 0.631 *** | 1 | |

| Dynamic capabilities | 5.572 | 0.881 | 0.526 *** | 0.505 *** | 0.572 *** | 0.622 *** | 1 |

| Component | Unrotated Eigenvalues | ||

|---|---|---|---|

| Total | Variance (%) | Cumulative (%) | |

| 1 | 8.282 | 37.646 | 37.646 |

| 2 | 1.515 | 6.889 | 44.535 |

| 3 | 1.234 | 5.611 | 50.146 |

| 4 | 0.987 | 4.486 | 54.632 |

| 5 | 0.930 | 4.225 | 58.857 |

| Model | Relationship |

|---|---|

| 1 | Control Variable -> Social Capital |

| 2 | University–Industry Collaboration -> Social Capital |

| 3 | Control Variable -> Slack resources |

| 4 | University–Industry Collaboration -> Slack Resources |

| 5 | Control Variable -> Dynamic Capabilities |

| 6 | University–Industry Collaboration -> Dynamic Capabilities |

| 7 | Control Variable -> Green Innovation |

| 8 | University–Industry Collaboration -> Green Innovation |

| 9 | Social Capital -> Green Innovation |

| 10 | Control Variable and Social Capital -> Green Innovation |

| 11 | Slack Resources -> Green Innovation |

| 12 | Control Variable and Slack Resources -> Green Innovation |

| 13 | Dynamic Capabilities -> Green Innovation |

| 14 | Control Variable and Dynamic Capabilities -> Green Innovation |

| Variable | Social Capital | Slack Resources | Dynamic Capabilities | Green Innovation | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | Model 7 | Model 8 | Model 9 | Model 10 | Model 11 | Model 12 | Model 13 | Model 14 | |

| Firm age | 0.085 | 0.000 | 0.141 | 0.043 | 0.139 | 0.078 | 0.068 | −0.003 | 0.018 | 0.004 | −0.010 | −0.023 | −0.011 | −0.033 |

| Firm scale | −0.066 | −0.061 | −0.036 | 0.034 | −0.079 | −0.075 | 0.023 | −0.027 | 0.061 | 0.052 | −0.043 | 0.038 | 0.067 | 0.056 |

| Firm nature | 0.322 | 0.256 | 0.143 | −0.018 | 0.143 | 0.095 | 0.109 | −0.053 | −0.076 | −0.050 | 0.030 | 0.027 | 0.028 | 0.017 |

| University–industry collaboration | 0.609 *** | 0.603 *** | 0.440 *** | 0.509 *** | 0.263** | 0.301 *** | 0.341 *** | |||||||

| Social capital | 0.576 *** | 0.404 *** | ||||||||||||

| Slack resources | 0.554 *** | 0.345 *** | ||||||||||||

| Dynamic capabili | 0.565 *** | 0.383 *** | ||||||||||||

| R2 | 0.029 | 0.414 | 0.036 | 0.439 | 0.036 | 0.263 | 0.018 | 0.359 | 0.425 | 0.480 | 0.369 | 0.438 | 0.363 | 0.480 |

| ΔR2 | 0.029 | 0.385 | 0.036 | 0.403 | 0.036 | 0.227 | 0.018 | 0.341 | 0.407 | 0.121 | 0.351 | 0.079 | 0.351 | 0.121 |

| F | 2.543 | 45.093 | 3.146 | 49.807 | 3.205 | 22.716 | 1.529 | 35.636 | 47.059 | 46.816 | 37.204 | 39.577 | 37.204 | 46.897 |

| ΔF | 2.543 | 167.775 | 3.146 | 183.078 | 3.205 | 78.344 | 1.529 | 135.549 | 180.435 | 59.074 | 141.710 | 35.854 | 141.710 | 59.332 |

| Max VIF | 1.268 | 1.298 | 1.268 | 1.298 | 1.268 | 1.298 | 1.268 | 1.298 | 1.287 | 1.648 | 1.304 | 1.770 | 1.299 | 1.364 |

| Model | Hypotheses | Results |

|---|---|---|

| 1 | H1. University–industry collaboration has a positive impact on social capital. | Supported |

| 2 | H2: Social capital has a positive impact on green innovation in logistics enterprises. | Supported |

| 3 | H3: University–industry collaboration has a positive impact on slack resources. | Supported |

| 4 | H4: Slack resources have a positive impact on green innovation in logistics enterprises. | Supported |

| 5 | H5: University–industry collaboration has a positive impact on dynamic capabilities. | Supported |

| 6 | H6: Dynamic capabilities have a positive impact on green innovation in logistics enterprises. | Supported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bu, F.; Tian, X.; Sun, L.; Zhang, M.; Xu, Y.; Guo, Q. Research on the Impact of University–Industry Collaboration on Green Innovation of Logistics Enterprises in China. Sustainability 2025, 17, 5068. https://doi.org/10.3390/su17115068

Bu F, Tian X, Sun L, Zhang M, Xu Y, Guo Q. Research on the Impact of University–Industry Collaboration on Green Innovation of Logistics Enterprises in China. Sustainability. 2025; 17(11):5068. https://doi.org/10.3390/su17115068

Chicago/Turabian StyleBu, Fei, Xiang Tian, Lulu Sun, Meng Zhang, Yang Xu, and Qinge Guo. 2025. "Research on the Impact of University–Industry Collaboration on Green Innovation of Logistics Enterprises in China" Sustainability 17, no. 11: 5068. https://doi.org/10.3390/su17115068

APA StyleBu, F., Tian, X., Sun, L., Zhang, M., Xu, Y., & Guo, Q. (2025). Research on the Impact of University–Industry Collaboration on Green Innovation of Logistics Enterprises in China. Sustainability, 17(11), 5068. https://doi.org/10.3390/su17115068