Abstract

With the increasing global emphasis on renewable energy, the generation of biomass fly ash is anticipated to rise substantially in the coming years. This trend highlights the urgent need for effective strategies to manage and utilize this byproduct sustainably. This study reviews and classifies selected types of biomass ashes, treating them as representative examples that illustrate the wide variability in chemical compositions and physical properties across different biomass sources. These include ashes derived from woody biomass, agricultural residues, animal-origin biomass, and sewage sludge. Biomass ashes exhibit significant heterogeneity compared to coal ashes, which makes understanding their chemical composition—particularly the major components such as calcium (Ca), silicon (Si), and phosphorus (P)—critical for identifying suitable industrial applications. Special categories of ashes with elevated heavy metals and chlorine (Cl) levels are also identified and discussed. This approach enables the identification of sustainable utilization pathways, ranging from traditional uses, such as agricultural fertilizers and construction materials, to emerging applications in advanced engineering materials. Additionally, this paper addresses the assessment and mitigation of potential risks related to hazardous metals in biomass ashes.

1. Introduction

Biomass combustion plays a crucial role in the global energy sector, offering a sustainable and renewable alternative to fossil fuels [1]. As the world faces the growing challenges of climate change, energy security, and the need for sustainable development, biomass emerges as a key player in transitioning to cleaner energy sources. Derived from organic materials, such as wood, agricultural residues, and animal waste, biomass is an abundant resource that can be utilized to produce heat, electricity, and biofuels [2,3].

One of the primary benefits of biomass combustion is its potential to reduce greenhouse gas emissions. By replacing coal, oil, and natural gas with biomass, countries can visibly decrease their carbon footprints and contribute to global efforts to mitigate climate change [4]. Another significant advantage of biomass combustion is its contribution to energy security. Many countries, such as Poland, rely heavily on imported fossil fuels, which makes them vulnerable to geopolitical tensions and price fluctuations. Meanwhile, biomass can be sourced locally, reducing dependence on foreign energy supplies and stimulating local economies [5]. Rural areas, in particular, benefit from biomass energy projects, as they create jobs in farming, harvesting, processing, and energy production, fostering economic development in regions that might otherwise struggle [6]. Thermal conversion also helps in waste management by utilizing agricultural residues, forestry byproducts, and organic waste that would otherwise contribute to environmental pollution. By converting this waste into energy, biomass combustion not only provides a renewable energy source but also addresses issues related to waste disposal and landfill use [7].

Biomass, sewage sludge, and refuse-derived fuel (RDF) differ from solid fossil fuels such as coal or lignite in terms of ash and moisture contents, elemental composition, and heating value, as shown in Table 1. Woody biomass typically contains less ash, which translates into fewer solid residues that need to be managed after energy generation. Biomass, on the other hand, contains higher levels of moisture, particularly when freshly harvested. In terms of elemental composition, biomass generally has a higher oxygen content and lower carbon content compared to coal and contains less sulfur than fossil fuels, which is beneficial due to lower emissions of sulfur oxides [8]. The heating value of biomass is typically lower than that of solid fossil fuels. While high-grade coal can have a calorific value of over 30 MJ/kg, biomass usually ranges between 14 to 20 MJ/kg. These parameters affect the storage, transportation, and handling logistics of biomass fuels. Despite this, the renewable nature and lower environmental impact of biomass make it an attractive alternative, especially when sustainability and carbon neutrality are considered.

Table 1.

Basic parameters of various solid fuels (d.b.—dry basis; a.r.—as received) [9,10,11,12,13].

Scientific Originality and Methodology of Review

Such a wide variety of biomass characteristics results in ashes with very different chemical compositions and physical properties [14]. Understanding the chemical composition of biomass ashes, particularly the forms in which key elements such as calcium, phosphorus, and silicon occur, including their associated mineral phases and reactive components, provides a foundation for identifying sustainable utilization pathways. Established applications include phosphorus-rich ashes used in agriculture and calcium-rich ashes employed in construction materials, while emerging opportunities involve advanced engineering materials.

Numerous review papers focusing on biomass ash can be found in the literature. Some of them primarily address problems resulting from the presence of alkali metals in ash and the associated risks, such as high-temperature corrosion, agglomeration, and sintering [15,16]. For example, Nunes et al. [16] provided a detailed characterization of biomass ash, with particular attention to chemical transformations occurring at high temperatures. Other review articles concentrate on ash recycling and utilization methods [17,18,19]. Tan et al. [18] discussed the recovery of phosphorus from biomass ash. Munawer et al. [19] reviewed possible applications of biomass ash in agriculture, construction, and the cement industry. Their paper also explored more advanced uses, such as nanotechnology, industrial catalysis, and environmental technologies. A comprehensive analysis of the chemical composition of various types of biomass (86 cases) was presented by Vassilev et al. [20], who emphasized the significant variability in biomass ash composition, largely influenced by factors such as the moisture content.

In contrast to the above studies, this review does not focus solely on the chemical composition of ash, its corrosion-related properties, or utilization technologies. Instead, this work aims to classify a wide range of biomass ashes according to the content of selected key elements, such as silicon (Si), phosphorus (P), calcium (Ca), chlorine (Cl), and heavy metals. Particular attention is paid to identifying biomass types that are rich in these elements and to discussing the related opportunities and challenges of their management. This review also outlines the potential benefits and limitations associated with their further use. This publication provides a practical complement to the existing literature by enabling a quick assessment of biomass ashes in terms of critical elemental composition. As a result, this paper can serve as a tool for the rapid identification of biomass types based on ash content and for determining potential application sectors and environmental risks.

This review was conducted based on the available peer-reviewed scientific literature. The authors analyzed selected types of biomass, treating them as representative examples that illustrated the diversity of ash properties from various biomass types, such as woody biomass, agricultural residues, animal-origin biomass, and sewage sludge. This selection aims to highlight the main trends and challenges related to ash management, but it does not cover the entire spectrum of possible feedstocks. The review largely reflects current research interests, with particular emphasis on animal-derived biomass and sewage sludge. The analyzed publications cover the last 20 years, with a predominance of studies from the last decade due to the limited availability of more recent research on some traditional biomass types. Regarding ash utilization methods, this review incorporates the most recent studies available, providing an up-to-date overview of existing solutions.

The proposed ash classification system has practical soundness and can be used to:

- Identify suitable utilization routes (e.g., soil amendment, construction materials, or advanced materials);

- Predict behavior (e.g., high-temperature corrosion tendency);

- Flag environmental risks (e.g., high heavy metal content).

Such a system can serve as a guide for ash producers, energy companies, public administration bodies, and all entities who are willing to manage the ash in line with the circular economy idea.

2. The Quantity of Biomass Ashes

Research from 2021 [21] estimates that a total of ~170 Mt/yr of ash is currently produced globally. This amount is a result of biomass combustion to produce energy, and in the future, it is estimated to rise to a maximum of ~1000 Mt/yr.

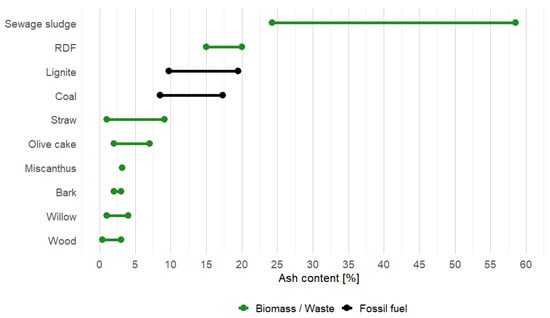

As indicated in Table 1, biomass is a diverse category of organic materials used for energy production, and one of the key factors that differentiates various types of biomass is their ash content. Different types of biomass exhibit wide variations in ash content due to their species or origin, as presented in Figure 1.

Figure 1.

Ash contents in selected fuel types [9,10,11,12,13].

Wood biomass generally has a low ash content compared to other biomass types. The ash content of clean, untreated wood may be less than 1% [14]. However, the ash content can increase if the wood includes bark or is contaminated with dirt or if it comes from certain species with higher mineral content [22,23]. Agricultural residues like straw, husks, and corn stover tend to have a slightly higher ash content. For example, wheat straw can contain 4% to 8% ash, while rice husks may have an ash content as high as 10% to 20% [24,25,26,27,28,29]. The high ash levels in agricultural residues are due to the presence of minerals absorbed from the soil, such as silica, potassium, and calcium [30,31]. Another group of biomass includes energy crops, such as switchgrass and miscanthus, that are specifically grown for energy purposes. They typically have an ash content in the range of 2% to 5% [32,33,34,35,36,37].

Animal waste, sewage sludge, and organic municipal waste represent a category of biomass with the highest ash content. For example, dried animal litter can have an ash content ranging up to 60%, depending on the type of animal, breeding conditions, bedding, and feed [38,39]. Similarly, municipal solid waste and sewage sludge can have a highly variable ash content due to the mix of organic and inorganic materials [40,41,42]. The high ash levels in these biomass types present challenges for combustion but also offer opportunities for nutrient recovery in the form of fertilizers.

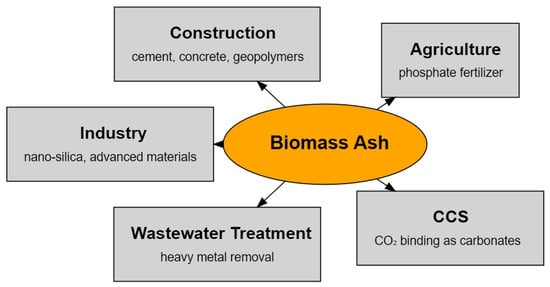

Depending on its mineral phase, reactive components, and predominant elements like silicon, calcium, potassium, and phosphorus, biomass ash can be utilized in various sectors, contributing to sustainable practices and resource efficiency, as presented in Figure 2. While some methods are already commercially applied, ongoing research is exploring innovative uses to further expand their potential.

Figure 2.

Paths of biomass ash utilization.

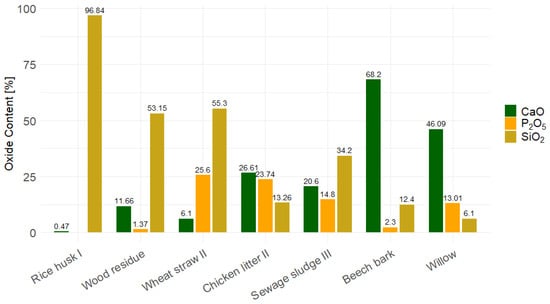

The utilization path is strictly dependent on the chemical composition of the ash, which includes the following main elements, usually expressed in oxide forms, including sulfur as SO3, potassium as K2O, silicon as SiO2, iron as Fe2O3, aluminum as Al2O3, manganese as Mn3O4, titanium as TiO2, calcium as CaO, magnesium as MgO, phosphorus as P2O5, sodium as Na2O, barium as BaO, and strontium as SrO, with the usual predominant contents of SiO2, CaO, and P2O5, as presented in Figure 3. The so-called “ash oxide analysis” is the most popular form of presenting ash compositions. This method, however, assumes that the elements have been completely oxidized during combustion. Such an assumption may not reflect reality because, for example, alkali metals may also occur in ash in the form of chlorides, sulfates, and carbonates. Nevertheless, it is widely used in most research and practical analyses, and it was also used in this paper. The characteristics of ash are also dependent on combustion conditions, such as temperature and furnace type [43], which is another complex research problem.

Figure 3.

Examples of the main components of biomass ashes [38,44,45,46].

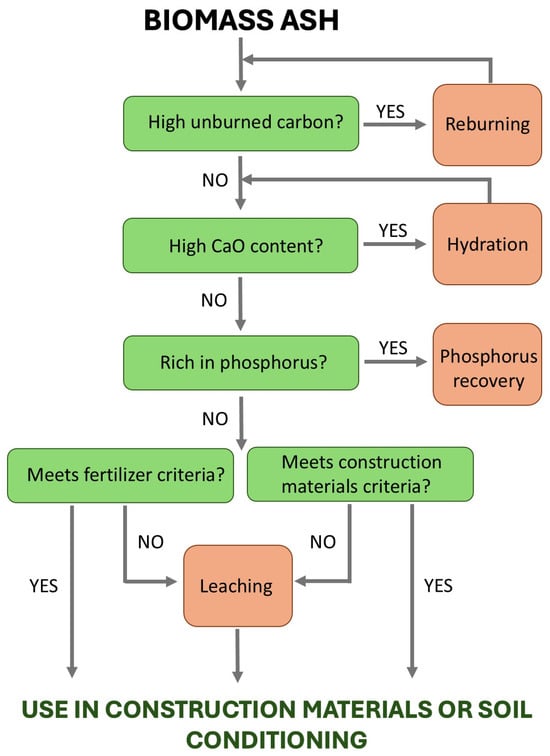

The common management process for biomass ash involves a systematic evaluation to determine its most suitable application or necessary treatment. According to Figure 4, the process includes assessing whether the ash contains an elevated level of unburned carbon. If it does, the ash requires a reburning process to reduce the carbon content. The next step is to check whether the ash has a high calcium oxide (CaO) content. In cases where CaO is abundant, hydration is advised, a process that can stabilize the material or enhance its properties for further use. When the ash is rich in phosphorus, it is processed for phosphorus recovery, which is valuable for producing fertilizers. The ash is evaluated based on whether it meets the criteria for use as a fertilizer. If it does, it can be used directly in soil conditioning. Another option is the use of construction materials. If the ash fails both the fertilizer and construction criteria, it may undergo a leaching process to remove undesired substances. Therefore, the ash is reused either in construction materials or for soil conditioning, ensuring environmentally responsible and resource-efficient utilization.

Figure 4.

Decision flowchart on ash utilization paths based on [47].

Conclusions

The chemical composition of biomass ash, influenced by the type of biomass and combustion conditions, is crucial for determining its potential uses across various industries. Although the commonly used oxide analysis assumes a complete oxidation of elements and may not fully reflect reality, it remains an effective tool for characterizing ash properties and identifying possible applications, as well as the environmental risks associated with its utilization.

3. Ashes Rich in Silicon (Si)

3.1. Sources of Silicon-Rich Ashes

In the case of plant-derived biomass, the silica content can vary significantly and depends not only on the species but also on the growing conditions and the age of the plant. Silicon accumulates in the plant as it ages because it is bound in the form of silicic acid, which ensures the appropriate stiffness and durability of the stem [48].

The highest silica content in biomass ash is attributed to rice husk (RH). The ash content of RH ranges from 10 to 20% and is relatively high compared to other biomass fuels [24,25,26]. The ash consists of up to 97% silica, is highly porous, lightweight, and has a large external surface area, making it valuable for industrial applications [49]. The content of other elements is minor, with a slight presence of potassium, sodium, and calcium.

Rice straw, similar to RH, is characterized by a predominant content of silica; however, the typical levels are lower, usually up to 80%. In the case of rice straw, the presence of other elements, such as potassium, can be more pronounced.

Wood ash is usually characterized by a significant content of calcium; however, in the case of wood residue or contaminated/demolished wood, the main component in the ash can be SiO2. According to the literature data, silica can also be expected in pine chip ash [20].

When it comes to agricultural residues and energy crops, miscanthus and wheat straw are highly heterogeneous fuels, with a SiO2 content ranging from 40% to 60% [50,51] for miscanthus and 30% to 70% for wheat straw [52,53,54,55,56]. In the case of miscanthus, the harvest time can significantly impact the elemental composition of the ash. Alkali metals and chlorine play a key role in the photosynthesis process during the summer [51] and are mostly leached out in the late autumn and winter as the plant ages. As a result, miscanthus harvested at the end of the summer season may exhibit a SiO2 content below 40% [51]. A selection of biomass ashes with high silica content is presented in Table 2.

Table 2.

Ashes with high contents of silica (n.d.—no data available).

3.2. Utilization Paths of Silicon-Rich Ashes

One of the most commonly investigated applications of biomass ash, especially ash from wood and agricultural residues, is in the production of cement and concrete. Biomass ash, rich in silica and alumina, can act as a pozzolanic material, improving the strength and durability of concrete [61]. It is often used to partially replace Portland cement, reducing CO2 emissions associated with cement production [62]. For example, rice husk ash, with its high silica content, is used as a supplementary cementitious material in countries like India and Brazil [63].

Silica can be extracted from the ash. The extraction involves eliminating impurities or unwanted substances from the raw ash, which can be achieved through various methods, including physical (thermal), chemical, and microbial processing [64]. Silica derived from rice husks is a valuable, natural, and renewable resource with diverse industrial applications, particularly in the ceramic and glass industries [65,66,67,68,69]. In the last years, it gained significant attention as an additive in the plastic and rubber industries [70,71,72,73].

In recent years, research has focused on employing biomass ash in nanomaterials for use in electronics, catalysis, and biomedical applications. Nano-silica extracted from rice husk ash is being studied for its potential to produce high-performance materials with applications ranging from drug delivery systems to solar cells [74,75]. In the work by Bianchini et al. [76], rice husk ash was applied as a starting material to obtain silica-supported carbon nanomaterials, which were tested for their affinity towards steroid hormones. Silica from rice husk ash can also be used as a catalytic material in various processes, including esterification and biodiesel production [49]. This is due to its highly porous structure and large specific surface area, which generally enhances mass transport and increases reaction rates [77].

Components of biomass ashes display catalytic performance. The results published in [78] suggested that bagasse ash-derived catalysts had better performance than commercial SiO2-derived catalysts during hydrogen production via dry reforming of methane.

Research is ongoing into using biomass ash in geopolymers, a type of environmentally friendly binder that could replace traditional cement [79]. Geopolymers are synthesized from materials rich in aluminosilicates, and biomass ash offers a renewable, low-carbon feedstock. Studies suggest that geopolymers made with rice husk ash or wood ash exhibit excellent mechanical properties and chemical resistance [80]. Jittin et al. [81] highlight in their work that sugarcane bagasse ash exhibits similar properties to rice husk ash, and as a result, it also shows high potential for geopolymer production.

Biomass ash with a high silica content is also being investigated for its application in carbon dioxide capture processes [82,83]. For example, Xu et al. [82], in their work, demonstrated that mesoporous silica derived from biomass ash, including a mixture of wheat straw, corn straw, and forest waste (5:2:3), can serve as a substrate material for creating solid adsorbents from amine materials, thereby enhancing their CO2 adsorption efficiency.

3.3. Conclusions

Due to the wide range of applications for silica and the ongoing development of extraction technologies, silica-rich ashes are considered particularly valuable. Future research should focus not only on improving the recovery methods for amorphous silica but also on assessing how its quality and structure affect its use in engineering materials.

4. Ashes Rich in Phosphorous (P)

4.1. Sources of Phosphorous-Rich Ashes

The most phosphorus-rich ashes originate from animal-derived materials, such as pig manure and chicken litter, which contain significant amounts of phosphorus (see Table 3). Notably, bone meal stands out, with a P2O5 content of approximately 40% [84,85,86]. Blue-green algae ashes are also rich in phosphorus, with levels comparable to or even exceeding those found in bone meal. Additionally, agricultural residues and energy crops, such as Jatropha seed cake, willow, and corn stalks, produce phosphorus-rich ash. Moreover, ash derived from sewage sludge can contain over 15% P2O5, making it also an attractive source of phosphorus.

Table 3.

Ashes with high contents of phosphorous (n.d.—no data available).

4.2. Utilization Paths of Phosphorous-Rich Ashes

Biomass ashes rich in phosphorus can serve as sustainable alternatives to conventional fertilizers. The application of biomass ash in agriculture helps reduce the reliance on synthetic phosphate fertilizers, which are becoming increasingly scarce due to the depletion of global phosphate rock reserves [93,94]. Biomass ash can also be rich in other nutrients like potassium and calcium, and therefore, can help neutralize acidic soils, improve the soil structure, and supply essential minerals for crop growth [94,95]. Especially, poultry litter ash is widely recognized for its high phosphorus content and may be used as a fertilizer to support plant growth [96,97]. Phosphorus-rich biomass ash offers an environmentally friendly solution for enhancing soil fertility while reducing waste and promoting resource efficiency in agricultural systems. However, careful management is required to ensure that heavy metal concentrations in biomass ashes remain within safe limits for agricultural use.

The extraction of phosphorus from biomass ash enables the recovery of this essential nutrient for agricultural or industrial applications. Since phosphorus in biomass ash is primarily present in inorganic forms, it can be solubilized and recovered using various chemical and physical methods [18]. A common approach is acid leaching, where acids such as sulfuric or hydrochloric acid are used to dissolve phosphorus compounds, making them available for further processing and purification [98]. Alkaline treatments using sodium hydroxide or ammonium-based solutions can also be employed to extract phosphorus while minimizing the dissolution of heavy metals [99]. In the case of meat and bone meal ash, phosphorous is predominantly present as hydroxyapatite (Ca5(PO4)3OH), a highly stable and crystalline mineral with low solubility. This limits its direct extractability and makes phosphorous recovery more challenging compared to sewage sludge ash, where phosphorous often exists in more amorphous or loosely bound forms, such as iron or aluminum phosphates, which are more readily solubilized.

In recent years, innovative technologies like supercritical hydrothermal treatment and electrodialysis have been explored for more efficient phosphorus recovery with reduced environmental impact [100,101,102]. After extraction, the recovered phosphorus can be precipitated as struvite (magnesium ammonium phosphate) or other phosphate salts, which can be directly used as fertilizers [102,103]. This process reduces dependency on finite phosphate rock reserves. However, challenges such as optimizing extraction efficiency, reducing energy consumption, and minimizing contaminants must be addressed to make phosphorus recovery from biomass ash a widely adopted and economically viable solution.

4.3. Conclusions

Although phosphorus recovered from biomass ashes is a valuable resource for agriculture and industry, its highest concentrations are mainly found in ashes from animal-origin biomass, which still has a marginal energy significance. Effective phosphorus recovery requires leaching processes or advanced technologies (e.g., hydrothermal treatment, electrodialysis), which still need to be optimized in terms of efficiency, energy consumption, and contaminant control. Therefore, future research should focus on developing energy-efficient, selective phosphorus extraction methods and on increasing the energy potential of biomass rich in this element.

5. Ashes Rich in Calcium (Ca)

5.1. Sources of Calcium-Rich Ashes

Calcium is the main mineral present in woody biomass. It serves as a crucial structural component of cell walls and membranes, contributing to cell formation and maintaining physical barriers against pathogens. Additionally, it acts as a secondary messenger in intracellular signaling, regulating various physiological processes [104]. As a result, woody biomass and its residues, such as bark, wood chips, and sawdust, are characterized by a high CaO content in their ash. In addition to woody biomass, bone meal and poultry litter ashes can also contain substantial amounts of CaO. However, in the case of poultry litter, the calcium content in the ash is highly dependent on the type of feed used and the poultry farming practices. Table 4 presents a summary of biomass ashes with a high calcium content.

Table 4.

Ashes with high contents of calcium (n.d.—no data available).

5.2. Utilization Path of Calcium-Rich Ashes

Calcium-rich wood biomass ash was investigated as a mineral filler in a hot mix asphalt by Moura et al. [110], and improved the stability by up to 27% as well as increased the fatigue response by approximately three times, with no harmful effects on the other evaluated properties. However, the use of calcium-rich ash is not always desired in the construction industry and geopolymers production [111]. Therefore, different disposal ways are under consideration and research.

Ashes rich in calcium oxide can be used in wastewater treatment for neutralizing acidic effluents or removing heavy metals and phosphates from industrial wastewater [112]. The adsorption properties make the ash an economical alternative to traditional chemical treatments.

Experimental methods explore the potential of biomass ash in carbon capture and utilization (CCU) technologies. The alkaline components in ash, such as calcium oxide, can react with carbon dioxide to form stable carbonates, offering a way to sequester CO2 from industrial emissions [113,114]. Wood ash carbonation could be used as a low-cost CO2 sequestration technology, as presented in the research by Koch et al. [115]. It is beneficial compared to the existing carbon capture and storage (CCS) technologies, which are energy-consuming and cost-intensive. The minerals responsible for the CCS performance of biomass ash are Ca, K, K-Ca, and Ca-Mg carbonates and bicarbonates [116]. According to the research by Vassilev and Vassileva [117], there is an intensive formation of new carbonates as a result of solid–gas reactions between alkaline-earth and alkaline oxyhydroxides in biomass ash and volatile CO2 from combustion. This method is still in the research phase but holds promise for reducing greenhouse gas emissions.

Biomass ash is being explored as a catalyst or catalyst support in thermochemical processes, such as pyrolysis [118,119]. Biomass ash contains naturally occurring, catalytically active minerals, such as alkali and alkaline-earth metals (Ca, K, Mg, and Na), which play a crucial role in facilitating cracking and various thermolysis reactions in the vapor phase. These minerals influence the chemical composition of the resulting pyrolysis liquid and alter the distribution of pyrolysis products [120]. The presence of calcium and potassium compounds can enhance reaction rates, making biofuel production more efficient [121]. Ashes rich in calcium show promising potential as catalysts for biodiesel synthesis [122,123]. Compared to conventional homogeneous catalysts, Ca-rich ash-based catalysts offer advantages of low cost, reusability, and simplified separation from the reaction mixture [124]. However, pre-treatment, such as calcination, may be required to enhance catalytic activity and remove impurities that could hinder performance.

Firewood ash with 23.8% calcium was tested as a calcium source in the initial diet of broiler chickens by Saccomani et al. [125]. The ash can be used as a substitute for limestone in the diet of broiler chickens without a change in performance and bone development.

5.3. Conclusions

Calcium-rich ashes can find application in new areas of ash management. Due to their high catalytic and adsorption capacities, they can be used in biofuel synthesis, as well as in CCU processes. There is also the advantage that a high calcium content is mainly characterized by the ashes of woody biomass, which is widely used energetically, ensuring their widespread availability.

6. Ashes with High Chlorine (Cl) Content

6.1. Ashes Rich in Chlorine

Some types of biomass ash display a high content of chlorides. This is particularly the case with straw, animal waste such as poultry litter, municipal waste, and RDF. As presented in Table 5, chlorides may be especially present in large amounts in straw ash, making even over 21% of its total weight. Animal-derived waste also exhibits notable concentrations of chlorides, exceeding 7%. Certain types of wood, especially from salt-affected areas or driftwood, can contain higher chlorine concentrations due to environmental exposure. Additionally, ashes from municipal solid waste (MSW) and RDF often have high chlorine levels, as chlorine in RDF comes from both organic and inorganic sources. Organic sources mainly include materials such as polyvinyl chloride (PVC), artificial leather, synthetic rubber, and polystyrene foam, and inorganic sources stem from kitchen waste containing inorganic chlorides like NaCl, KCl, and MgCl2 [126,127].

Table 5.

Examples of ashes with high levels of Cl.

6.2. Dangers and Risks

Heated surfaces of power boilers covered with high-chlorine ashes are prone to high-temperature corrosion. This process is associated with the presence of potassium and sodium in biomass, leading to the formation of alkali metal chlorides such as KCl and NaCl [134,135]. These compounds can form low-melting eutectics, accelerating material degradation. Their presence not only increases the oxidation rate but also causes the loss of the protective oxide layer, the formation of corrosion pits, and the initiation of subsurface corrosion mechanisms [136]. Additionally, chlorine released in flue gases in the form of HCl and Cl2 can further intensify high-temperature corrosion [137,138].

6.3. Remedies

The Cl in biomass is mostly in the form of KCl, as observed through XRD analysis by Lima et al. [139]. Similarly, Hansen et al. [129] found high levels of both K and Cl in straw ash, which also confirms the presence of KCl. Due to its high solubility, KCl can be easily removed by water leaching or leaching coupled with other methods, such as electrodialytic extraction. According to [128], during water pre-treatment, an average of 75% of the chloride content was removed from straw ash. In total, over 90% of the Cl in ash was dissolved after pre-treatment and electrodialytic extraction. Specifically, in experiments lasting two weeks and four weeks, 92.5% and 94.3% of the ash dissolved, respectively. The findings suggest that most of the dissolution happens during pre-washing and the initial phase of electrodialytic extraction.

Water washing is highlighted for its high Cl removal efficiency and low cost, but with the disadvantage of generating wastewater that requires treatment [140]. Moreover, water leaching can only remove water-soluble chloride salts, such as CaCl2, NaCl, KCl, and Ca(OH)Cl, while water-insoluble chloride salts are difficult to remove. Therefore, acid solutions can be used, whose costs are, however, higher than water [141]. Chemical treatments offer high selectivity but are limited by reagent costs and environmental considerations. Thermal treatment, such as low-temperature volatilization, is effective for the decomposition of insoluble chlorides but is energy-intensive and may cause a loss of volatile nutrients [142].

The high content of chlorine in biomass may also be managed during the combustion process. To avoid chlorine-induced corrosion, fuel additives can be used. In biomass-fired boilers, to facilitate the sulfation of KCl, granulated or liquid sulfur and its compounds, primarily in the form of solid or aqueous ammonium sulfate, are used. When subjected to thermal decomposition in the furnace, these substances generate SO3, which reacts with alkali chlorides to form sulfates. The resulting potassium sulfate (K2SO4) has a much higher melting point (1074 °C) compared to KCl (774 °C) [143].

Aluminosilicate mineral additives such as kaolin or halloysite can also be used during combustion. They influence ash properties by binding potassium and sodium into high-melting-point compounds while releasing chlorine as hydrogen chloride (HCl) [144]. As described in detail in previous work by the authors [130,145], they react with potassium chloride (KCl), which has a melting point of 770 °C, to form kalsilite (KAlSiO4) and leucite (KAlSi2O6), which have significantly higher melting points of over 1600 °C and 1500 °C, respectively. Aluminosilicates also interact with other potassium compounds, including potassium sulfate (K2SO4) and potassium carbonate (K2CO3).

6.4. Conclusions

A high chlorine content may limit the energy utilization potential of alternative biomass sources, such as animal-origin biomass and RDF fuels. Additionally, these fuels are characterized by their heterogeneous composition, resulting from material diversity and feedstock variability, which further complicates combustion process stability and increases the risk of corrosion.

Future research should continue efforts to mitigate the negative effects of chlorine presence through pre-treatment methods (e.g., leaching), optimization of fuel additives, and the development of advanced combustion strategies aimed at minimizing corrosion and improving the efficiency and durability of biomass energy conversion processes.

7. Ashes with High Contents of Metals

7.1. Sources of Metals in Ashes

The metal and metalloid contents in biomass ashes are shown in Table 6. The presence of heavy metals represents one of the greatest environmental challenges associated with the management of ash from biomass combustion. One of the most contaminated groups is considered to be wood biomass. Some tree species have a high capacity for accumulating metals from the soil, groundwater, and atmospheric air [146,147]. This is particularly significant in the case of long-lived plants such as poplar, spruce, and birch, which have well-developed root systems that enable them to accumulate metals over a long life cycle.

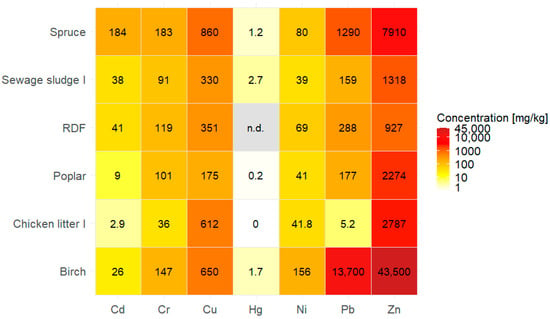

Table 6.

Metal and metalloid contents in biomass ashes, mg/kg (n.d.—no data available).

Not only does wood biomass contain metals, but they are also present throughout the entire food chain. Heavy metals are found in agricultural soils, contaminating animal feed, which, in turn, contributes to their presence in the biomass of animal origins [153]. Refuse-derived fuel and sewage sludge, due to their anthropogenic origin, are also considered fuels with a high content of heavy metals, primarily from industrial processes.

Figure 5 illustrates the variability in heavy metal content depending on the biomass type and origin. Wood-based ashes (birch and spruce) tend to have higher concentrations of Zn and Pb, which may reflect environmental contamination or intrinsic uptake by the tree species. The exceptionally high Zn in birch ash (43,500 mg/kg) raises concerns about its potential toxicity and necessitates careful management if the ash is to be reused, for example, in soil amendment or construction materials.

Figure 5.

The concentration of metals in selected biomass ashes (n.d.—no data available) [38,106].

Sewage sludge and RDF are known to contain variable and often elevated levels of heavy metals due to their origin from mixed waste streams. The relatively high Hg concentration in sewage sludge (2.7 mg/kg) is particularly concerning, as mercury poses serious environmental and health risks, even at low concentrations.

Chicken litter, while being a promising fertilizer due to its nutrient content, also requires monitoring because of its elevated Cu and Zn, which may originate from animal feed additives. Long-term application could lead to soil accumulation and toxicity to plants or microorganisms.

Further speciation studies are recommended to assess the bioavailability and environmental mobility of these metals, particularly in high-concentration samples like birch and chicken litter ash. Pre-treatment or purification technologies may be required for ashes with high heavy metal contents before reuse.

7.2. Dangers and Risks

The presence of heavy metals in biomass ash poses a serious environmental and health risk. These metals can be secondary leached into soil or groundwater and released into the atmosphere, contaminating the environment and posing a risk to ecosystems and human health. Their leachability into the soil can lead to the reaccumulation of these elements in crops, which presents a threat to food quality and the health of livestock [154]. Although biomass ash is rich in various mineral compounds, such as phosphorous and potassium, which makes it a desired fertilizer for plant growth, the presence of heavy metals constitutes a significant barrier. However, studies indicate that, based on accepted environmental standards, most ashes can be safely disposed of, with the primary issue being a high variability in heavy metal contents [155,156]. Pei et al. studied fly ash samples from woody biomass collected from 60 different biomass energy generation plants in Japan. The results showed that 80% of the ashes could be used as fertilizer without exceeding national standards. In terms of ash disposal, the leachability tests indicated that 95% of the ashes could be safely landfilled [155]. For this reason, it is proposed that the monitoring of heavy metal contents in biomass ash is conducted to ensure that its use does not pose a threat to the environment [156].

For ashes with elevated levels of metals, it is essential to stabilize them before utilization or disposal in landfills. Suitable treatment methods include leaching or extraction, thermal processes, and solidification or chemical stabilization [157]. In the extraction process, unwanted elements can be removed using electrodialysis or a leaching solution, typically water or acid. Water washing is the most straightforward separation technique, primarily removing soluble salts. Acid washing is effective for extracting heavy metals, but it significantly alters the pH and physical properties of the material. Despite its effectiveness, this method generates wastewater and is not cost-effective [158,159].

Among the available options, solidification/stabilization is the most widely used method for neutralizing fly ash. The release of heavy metals can be effectively managed by incorporating cement or polymer binders. This technique limits the emission of harmful metals through physical and chemical processes that encapsulate, immobilize, or adsorb contaminants [146]. Thermal treatments—such as vitrification, melting/fusion, and sintering—offer more effective stabilization compared to other methods [160]. However, they come with major disadvantages, including the potential emission of volatile heavy metals, high energy demands, and significant operational and capital costs [161].

As presented in this section, biomass ash often contains a complex mixture of heavy metals, such as Cd, Pb, Zn, Cu, and Cr, which may interact during treatment processes. These interactions can influence both the chemical behavior and mobility of individual metals, which are also connected to Cl volatilization [162]. Synergistic effects may also arise, such as the enhanced leaching of certain metals under altered pH conditions caused by other components in the ash [163]. To prevent the formation of secondary pollutants or more mobile metal complexes, a synergistic treatment approach is often beneficial. These include methods such as sequential extraction and multi-step washing, which target specific metal groups, stabilization using polymers, and composite binders [164] that can immobilize multiple metals simultaneously, as well as mixed methods [165]. Controlled thermal treatment, which minimizes the volatilization of toxic metals while facilitating stable mineral phase formation, can also be applied during the conversion of biomass [166].

7.3. Conclusions

The presence of heavy metals is one of the major limitations related to the utilization of biomass ash. High concentrations of heavy metals can be found in both plant-based biomass and its alternative forms. Therefore, systematic monitoring of heavy metal contents in biomass ashes is necessary to ensure their safe use and to minimize environmental and health risks. Future research should pay particular attention to issues related to metal leachability and possibilities for its reduction, for example, through the use of fuel additives.

8. Conclusions and Future Directions

The utilization of biomass ash is gaining increasing attention in the context of renewable energy deployment, resource recovery, and sustainable development. As biomass becomes a more widely adopted low-carbon energy source, the generation of biomass ash is expected to rise significantly. These ashes often contain valuable elements such as silica, phosphorus, potassium, and calcium, making them attractive for various applications. In particular, they hold promise as soil amendments or fertilizers in agriculture and as supplementary cementitious materials in the construction industry, while the latest utilization paths are high-performance composite materials. Among the new pathways for biomass ash utilization, its catalytic properties stand out, which can be applied, for example, in the synthesis of biofuels such as biodiesel. The beneficial use of ash not only supports waste valorization and circular economy strategies but also contributes to lowering the greenhouse gas emissions associated with conventional fertilizer and cement production.

However, the heterogeneity of biomass ashes poses a key challenge. Ash composition is strongly influenced by the type of biomass (e.g., wood, agricultural residues, or animal waste), combustion conditions, and the specific technology used. This variability complicates the development of standardized utilization pathways. Moreover, certain ashes may contain elevated levels of potentially toxic elements such as cadmium, lead, chromium, or zinc, which raise environmental and health concerns if not properly managed. High concentrations of alkali metals and chlorine can also cause technical issues, including slagging, fouling, and increased leaching risks when applied to soils.

Importantly, the elemental composition varies not only by biomass type but also due to environmental and agricultural factors. In plant-based biomass, element accumulation is closely linked to air and soil pollution and the mineral content of the growing medium. Plant age also significantly affects elemental concentrations. For animal-derived biomass, the composition is shaped by breeding methods (e.g., cage vs. free-range), feed type, and seasonal dietary changes. Similarly, sewage sludge exhibits substantial elemental heterogeneity, stemming from variations in treatment technologies and the proportion of industrial versus municipal wastewater. These factors underscore the need for comprehensive ash characterization and context-specific risk assessment protocols to ensure safe and effective utilization.

Future research should focus on developing robust classification frameworks that account for the chemical, physical, and thermal properties of different types of biomass ash. Analytical techniques, such as X-ray fluorescence (XRF), sequential extraction, and thermogravimetric analysis (TGA), can be instrumental in evaluating ash behavior under various environmental and processing conditions. Pre-treatment methods, including acid leaching, thermal processing, or blending with inert materials, should be further optimized to reduce the mobility of contaminants and enhance nutrient availability.

In agriculture, long-term field studies are needed to assess the impacts of repeated ash application on soil health, plant uptake, and microbial dynamics. In the construction sector, further work is required to understand how biomass ash affects mechanical performance, durability, and compliance with technical standards when used as a cement substitute or concrete additive. In the case of catalysis in biofuel synthesis, further research is needed on the possibility of extracting desired elements as well as on the activity of biomass ash as a catalyst, including its stability and the impact of contaminants.

Policy frameworks must also evolve to facilitate the safe and efficient use of biomass ashes. Current regulatory uncertainties often hinder the market deployment of ash-based products. Establishing harmonized guidelines, supported by life cycle assessment (LCA) and techno-economic analysis, will be essential for broader adoption. Cross-disciplinary collaboration among environmental scientists, agronomists, material engineers, and policymakers will be critical to overcoming existing barriers and unlocking the full potential of biomass ash utilization.

In conclusion, the utilization of biomass ash in industry offers a sustainable solution to managing the byproducts of biomass combustion. Established methods, such as its use in cement production, fertilizers, and construction materials, demonstrate its versatility and environmental benefits. Meanwhile, innovative applications—ranging from geopolymer production to nanomaterials, catalysis, and energy storage—are under active investigation, promising to further expand the role of biomass ash in the circular economy. As research progresses, these emerging technologies could unlock new value chains, making biomass energy systems even more sustainable and economically viable. While biomass ashes represent a valuable secondary resource, their sustainable use requires coordinated scientific, technological, and regulatory efforts. With continued research and policy support, biomass ash utilization can play a significant role in advancing environmental sustainability and supporting the transition to a more circular and resource-efficient economy.

Funding

This research was supported by the National Science Centre, Poland, grant number 2021/43/D/ST8/02609, “The influence of aluminosilicate additives on high-temperature corrosion and ash properties of animal-origin biomass”. For the purpose of Open Access, the author has applied a CC-BY public copyright license to any Author Accepted Manuscript (AAM) version arising from this submission.

Data Availability Statement

All data are published in the paper.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| A | Ash content in fuel |

| a.r. | As received |

| CCS | Carbon capture and storage |

| CCU | Carbon capture and utilization |

| d.b. | Dry basis |

| RH | Rice husk |

| LCA | Life cycle assessment |

| LHV | Lower heating value of fuel |

| M | Moisture content in fuel |

| MSW | Municipal solid waste |

| RDF | Refuse-derived fuel |

References

- Mignogna, D.; Szabó, M.; Ceci, P.; Avino, P. Biomass Energy and Biofuels: Perspective, Potentials, and Challenges in the Energy Transition. Sustainability 2024, 16, 7036. [Google Scholar] [CrossRef]

- Zhu, J.; Guo, Y.; Chen, N.; Chen, B. A Review of the Efficient and Thermal Utilization of Biomass Waste. Sustainability 2024, 16, 9506. [Google Scholar] [CrossRef]

- Ufitikirezi, J.d.D.M.; Filip, M.; Ghorbani, M.; Zoubek, T.; Olšan, P.; Bumbálek, R.; Strob, M.; Bartoš, P.; Umurungi, S.N.; Murindangabo, Y.T.; et al. Agricultural Waste Valorization: Exploring Environmentally Friendly Approaches to Bioenergy Conversion. Sustainability 2024, 16, 3617. [Google Scholar] [CrossRef]

- Gładysz, P.; Strojny, M.; Bartela, Ł.; Hacaga, M.; Froehlich, T. Merging Climate Action with Energy Security through CCS—A Multi-Disciplinary Framework for Assessment. Energies 2022, 16, 35. [Google Scholar] [CrossRef]

- Banaś, J.; Utnik-Banaś, K.; Zięba, S. Optimizing Biomass Supply Chains to Power Plants under Ecological and Social Restrictions: Case Study from Poland. Energies 2024, 17, 3136. [Google Scholar] [CrossRef]

- Okunevičiūtė Neverauskienė, L.; Dirma, V.; Tvaronavičienė, M.; Danilevičienė, I. Assessing the Role of Renewable Energy in the Sustainable Economic Growth of the European Union. Energies 2025, 18, 760. [Google Scholar] [CrossRef]

- Xu, Q.; Zhang, T.; Niu, Y.; Mukherjee, S.; Abou-Elwafa, S.F.; Nguyen, N.S.H.; Al Aboud, N.M.; Wang, Y.; Pu, M.; Zhang, Y.; et al. A Comprehensive Review on Agricultural Waste Utilization through Sustainable Conversion Techniques, with a Focus on the Additives Effect on the Fate of Phosphorus and Toxic Elements during Composting Process. Sci. Total Environ. 2024, 942, 173567. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Mahamood, R.M.; Jen, T.-C.; Loha, C.; Akinlabi, E.T. An Overview of Biomass Solid Fuels: Biomass Sources, Processing Methods, and Morphological and Microstructural Properties. J. Bioresour. Bioprod. 2023, 8, 333–360. [Google Scholar] [CrossRef]

- Rybak, W.; Moroń, W.; Ferens, W. Dust Ignition Characteristics of Different Coal Ranks, Biomass and Solid Waste. Fuel 2019, 237, 606–618. [Google Scholar] [CrossRef]

- Qu, Z.; Fatehi, H.; Schmidt, F.M. Potassium Release from Biomass Particles during Combustion—Real-Time In Situ TDLAS Detection and Numerical Simulation. Appl. Sci. 2021, 11, 8887. [Google Scholar] [CrossRef]

- Xue, X.; Chen, D.; Song, X.; Dai, X. Hydrothermal and Pyrolysis Treatment for Sewage Sludge: Choice from Product and from Energy Benefit 1. Energy Procedia 2015, 66, 301–304. [Google Scholar] [CrossRef]

- Maj, I.; Kalisz, S.; Wejkowski, R.; Pronobis, M.; Gołombek, K. High-Temperature Corrosion in a Multifuel Circulating Fluidized Bed (CFB) Boiler Co-Firing Refuse Derived Fuel (RDF) and Hard Coal. Fuel 2022, 324, 124749. [Google Scholar] [CrossRef]

- Chomiak, L. Variation of Lignite Ash in Vertical and Horizontal Sections of Mining Wallsin the Konin Lignite Mine, Central Poland. Geol. Geophys. Environ. 2020, 46, 17. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef]

- Abioye, K.J.; Harun, N.Y.; Sufian, S.; Yusuf, M.; Jagaba, A.H.; Ekeoma, B.C.; Kamyab, H.; Sikiru, S.; Waqas, S.; Ibrahim, H. A Review of Biomass Ash Related Problems: Mechanism, Solution, and Outlook. J. Energy Inst. 2024, 112, 101490. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Biomass Combustion Systems: A Review on the Physical and Chemical Properties of the Ashes. Renew. Sustain. Energy Rev. 2016, 53, 235–242. [Google Scholar] [CrossRef]

- Voshell, S.; Mäkelä, M.; Dahl, O. A Review of Biomass Ash Properties towards Treatment and Recycling. Renew. Sustain. Energy Rev. 2018, 96, 479–486. [Google Scholar] [CrossRef]

- Tan, Z.; Lagerkvist, A. Phosphorus Recovery from the Biomass Ash: A Review. Renew. Sustain. Energy Rev. 2011, 15, 3588–3602. [Google Scholar] [CrossRef]

- Munawar, M.A.; Khoja, A.H.; Naqvi, S.R.; Mehran, M.T.; Hassan, M.; Liaquat, R.; Dawood, U.F. Challenges and Opportunities in Biomass Ash Management and Its Utilization in Novel Applications. Renew. Sustain. Energy Rev. 2021, 150, 111451. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Zhai, J.; Burke, I.T.; Stewart, D.I. Beneficial Management of Biomass Combustion Ashes. Renew. Sustain. Energy Rev. 2021, 151, 111555. [Google Scholar] [CrossRef]

- Chowdhury, S.; Mishra, M.; Suganya, O. The Incorporation of Wood Waste Ash as a Partial Cement Replacement Material for Making Structural Grade Concrete: An Overview. Ain Shams Eng. J. 2015, 6, 429–437. [Google Scholar] [CrossRef]

- Adhikari, S.; Nam, H.; Chakraborty, J.P. Conversion of Solid Wastes to Fuels and Chemicals Through Pyrolysis. In Waste Biorefinery: Potential and Perspectives; Elsevier: Amsterdam, The Netherlands, 2018; pp. 239–263. [Google Scholar] [CrossRef]

- Kuprianov, V.I.; Kaewklum, R.; Sirisomboon, K.; Arromdee, P.; Chakritthakul, S. Combustion and Emission Characteristics of a Swirling Fluidized-Bed Combustor Burning Moisturized Rice Husk. Appl. Energy 2010, 87, 2899–2906. [Google Scholar] [CrossRef]

- Armesto, L.; Bahillo, A.; Veijonen, K.; Cabanillas, A.; Otero, J. Combustion Behaviour of Rice Husk in a Bubbling Fluidised Bed. Biomass Bioenergy 2002, 23, 171–179. [Google Scholar] [CrossRef]

- Fang, M.; Yang, L.; Chen, G.; Shi, Z.; Luo, Z.; Cen, K. Experimental Study on Rice Husk Combustion in a Circulating Fluidized Bed. Fuel Process. Technol. 2004, 85, 1273–1282. [Google Scholar] [CrossRef]

- Yang, Q.; Wang, T.; Wang, J.; Sui, Z.; Wang, L.; Zhang, Y.; Pan, W.-P. Combustion, Emission and Slagging Characteristics for Typical Agricultural Crop Straw Usage in Heating Plants. Thermochim Acta 2021, 702, 178979. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar Nandi, B. Combustion Characteristics of High Ash Indian Coal, Wheat Straw, Wheat Husk and Their Blends. Mater. Sci. Energy Technol. 2021, 4, 274–281. [Google Scholar] [CrossRef]

- Bradna, J.; Malaťák, J.; Hájek, D. The Properties of Wheat Straw Combustion and Use of Fly Ash as a Soil Amendment. Agron. Res. 2016, 14, 1257–1265. [Google Scholar]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical Properties of Solid Biofuels—Significance and Impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Praspaliauskas, M.; Pedišius, N.; Čepauskienė, D.; Valantinavičius, M. Study of Chemical Composition of Agricultural Residues from Various Agro-Mass Types. Biomass Convers. Biorefin. 2020, 10, 937–948. [Google Scholar] [CrossRef]

- Kowalczyk-juśko, A.; Mazur, A.; Pochwatka, P.; Janczak, D.; Dach, J. Evaluation of the Effects of Using the Giant Miscanthus (Miscanthus × Giganteus) Biomass in Various Energy Conversion Processes. Energies 2022, 15, 3486. [Google Scholar] [CrossRef]

- Lanzerstorfer, C. Combustion of Miscanthus: Composition of the Ash by Particle Size. Energies 2019, 12, 178. [Google Scholar] [CrossRef]

- Baxter, X.C.; Darvell, L.I.; Jones, J.M.; Barraclough, T.; Yates, N.E.; Shield, I. Study of Miscanthus × Giganteus Ash Composition–Variation with Agronomy and Assessment Method. Fuel 2012, 95, 50–62. [Google Scholar] [CrossRef]

- Fahmi, R.; Bridgwater, A.V.; Darvell, L.I.; Jones, J.M.; Yates, N.; Thain, S.; Donnison, I.S. The Effect of Alkali Metals on Combustion and Pyrolysis of Lolium and Festuca Grasses, Switchgrass and Willow. Fuel 2007, 86, 1560–1569. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, Y.; Darko Matovic, M.; Whalen, J.K. Exploring Switchgrass and Hardwood Combustion on Excess Air and Ash Fouling/Slagging Potential: Laboratory Combustion Test and Thermogravimetric Kinetic Analysis. Energy Convers. Manag. 2015, 97, 409–419. [Google Scholar] [CrossRef]

- Bakker, R.R.; Elbersen, H.W. Managing Ash Content and Quality in Herbaceous Biomass: An Analysis from Plant to Product. In Proceedings of the 14th European Biomass Conference and Exhibition, Paris, France, 17–21 October 2005. [Google Scholar]

- Maj, I.; Kalisz, S.; Ciukaj, S. Properties of Animal-Origin Ash—A Valuable Material for Circular Economy. Energies 2022, 15, 1274. [Google Scholar] [CrossRef]

- Maj, I. Significance and Challenges of Poultry Litter and Cattle Manure as Sustainable Fuels: A Review. Energies 2022, 15, 8981. [Google Scholar] [CrossRef]

- Chen, Y.-C. Effects of Urbanization on Municipal Solid Waste Composition. Waste Manag. 2018, 79, 828–836. [Google Scholar] [CrossRef]

- Shi, T.; Zhou, J.; Ren, J.; Ayub, Y.; Yu, H.; Shen, W.; Li, Q.; Yang, A. Co-Valorisation of Sewage Sludge and Poultry Litter Waste for Hydrogen Production: Gasification Process Design, Sustainability-Oriented Optimization, and Systematic Assessment. Energy 2023, 272, 127131. [Google Scholar] [CrossRef]

- Sakiewicz, P.; Piotrowski, K.; Rajca, M.; Maj, I.; Kalisz, S.; Ober, J.; Karwot, J.; Pagilla, K. Innovative Technological Approach for the Cyclic Nutrients Adsorption by Post-Digestion Sewage Sludge-Based Ash Co-Formed with Some Nanostructural Additives under a Circular Economy Framework. Int. J. Environ. Res. Public Health 2022, 19, 11119. [Google Scholar] [CrossRef]

- Fuller, A.; Carbo, M.; Savat, P.; Kalivodova, J.; Maier, J.; Scheffknecht, G. Results of Fly Ash Quality for Disposal Options from High Thermal Shares up to Pure Biomass Combustion in a Pilot-Scale and Large Scale Pulverized Fuel Power Plants. Renew. Energy 2015, 75, 899–910. [Google Scholar] [CrossRef]

- Sanou, I.; Sawadogo, M.; Seynou, M.; Zerbo, L.; Ouedraogo, R. Study of the Mechanical Behaviour of Mortars Modified with Rice Husk Ash. J. Miner. Mater. Charact. Eng. 2019, 7, 373–384. [Google Scholar] [CrossRef]

- Kang, Q.; Appels, L.; Tan, T.; Dewil, R. Bioethanol from Lignocellulosic Biomass: Current Findings Determine Research Priorities. Sci. World J. 2014, 2014, 298153. [Google Scholar] [CrossRef]

- Coutand, M.; Cyr, M.; Clastres, P. Use of Sewage Sludge Ash as Mineral Admixture in Mortars. Proc. Inst. Civ. Eng. Constr. Mater. 2006, 159, 153–162. [Google Scholar] [CrossRef]

- van Dijen, F.; Pels, J. Classification of Ashes and Identification of Possible Future Utilisations; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Ma, J.F.; Yamaji, N. Silicon Uptake and Accumulation in Higher Plants. Trends Plant Sci 2006, 11, 392–397. [Google Scholar] [CrossRef] [PubMed]

- Nzereogu, P.U.; Omah, A.D.; Ezema, F.I.; Iwuoha, E.I.; Nwanya, A.C. Silica Extraction from Rice Husk: Comprehensive Review and Applications. Hybrid Adv. 2023, 4, 100111. [Google Scholar] [CrossRef]

- Lv, Y.; Ye, G.; De Schutter, G. Utilization of Miscanthus Combustion Ash as Internal Curing Agent in Cement-Based Materials: Effect on Autogenous Shrinkage. Constr. Build. Mater. 2019, 207, 585–591. [Google Scholar] [CrossRef]

- Kaknics, J.; Michel, R.; Poirier, J. Miscanthus Ash Transformation and Interaction with Bed Materials at High Temperature. Fuel Process. Technol. 2016, 141, 178–184. [Google Scholar] [CrossRef]

- Memon, S.A.; Wahid, I.; Khan, M.K.; Tanoli, M.A.; Bimaganbetova, M. Environmentally Friendly Utilization of Wheat Straw Ash in Cement-Based Composites. Sustainability 2018, 10, 1322. [Google Scholar] [CrossRef]

- Schmitt, V.E.M.; Kaltschmitt, M. Effect of Straw Proportion and Ca- and Al-Containing Additives on Ash Composition and Sintering of Wood–Straw Pellets. Fuel 2013, 109, 551–558. [Google Scholar] [CrossRef]

- Li, F.; Zhao, C.; Li, J.; Li, Y.; Zhao, H.; Fan, H.; Xu, M.; Wang, Z.; Huang, J.; Fang, Y. Investigation on Ash Fusion Behavior Modification of Wheat Straw by Sludge Addition. J. Energy Inst. 2021, 98, 1–10. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, Y.; Huang, S.; Wei, X.; Li, X.; Wu, S. Comparative Study on the Effects of Wood Dust and Rice Husk on Wheat Straw Gasification Process: Ash Fusion Characteristics and Gasification Reactivity. Fuel 2022, 326, 124942. [Google Scholar] [CrossRef]

- Tsvetkov, M.V.; Podlesnyi, D.N.; Zaichenko, A.Y.; Salganskaya, M.V.; Tsvetkova, Y.Y.; Freiman, V.M.; Salganskii, E.A. Fusibility of Agricultural Plant Waste Ash under the Conditions of High-Temperature Processing. Russ. J. Appl. Chem. 2021, 94, 354–361. [Google Scholar] [CrossRef]

- Buyondo, K.A.; Olupot, P.W.; Kirabira, J.B.; Yusuf, A.A. Optimization of Production Parameters for Rice Husk Ash-Based Geopolymer Cement Using Response Surface Methodology. Case Stud. Constr. Mater. 2020, 13, e00461. [Google Scholar] [CrossRef]

- Singh, N.S.; Thokchom, S.; Debbarma, R. Correlation Study on Microstructure and Mechanical Properties of Rice Husk Ash-Sodium Aluminate Geopolymer Pastes. Adv. Concr. Constr. 2021, 11, 73–80. [Google Scholar]

- Pandey, A.; Kumar, B. Effects of Rice Straw Ash and Micro Silica on Mechanical Properties of Pavement Quality Concrete. J. Build. Eng. 2019, 26, 100889. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R.; Miles, T.R. Combustion Properties of Biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Olatoyan, O.J.; Kareem, M.A.; Adebanjo, A.U.; Olawale, S.O.A.; Alao, K.T. Potential Use of Biomass Ash as a Sustainable Alternative for Fly Ash in Concrete Production: A Review. Hybrid Adv. 2023, 4, 100076. [Google Scholar] [CrossRef]

- Kaminskas, R.; Eisinas, A.; Barauskas, I.; Gaivenis, M. Hydrothermally Treated Biomass Fly Ash as an Additive for Portland Cement. Sustainability 2024, 16, 2754. [Google Scholar] [CrossRef]

- Gomes, C.M.; de Paulo Peruzzi, A. Effective Contribution of Brazilian Rice Husk Silica (RHS) as Eco-Friendly Silica in Concrete Plants. J. Civ. Eng. Archit. 2022, 16, 531–540. [Google Scholar] [CrossRef]

- Malpani, S.K.; Goyal, D. Synthesis, Analysis, and Multi-Faceted Applications of Solid Wastes-Derived Silica Nanoparticles: A Comprehensive Review (2010–2022). Environ. Sci. Pollut. Res. 2022, 30, 28321–28343. [Google Scholar] [CrossRef] [PubMed]

- Andreola, F.; Martín, M.I.; Ferrari, A.M.; Lancellotti, I.; Bondioli, F.; Rincón, J.M.; Romero, M.; Barbieri, L. Technological Properties of Glass-Ceramic Tiles Obtained Using Rice Husk Ash as Silica Precursor. Ceram. Int. 2013, 39, 5427–5435. [Google Scholar] [CrossRef]

- Lee, T.; Othman, R.; Yeoh, F.Y. Development of Photoluminescent Glass Derived from Rice Husk. Biomass Bioenergy 2013, 59, 380–392. [Google Scholar] [CrossRef]

- Lee, C.S.; Matori, K.A.; Ab Aziz, S.H.; Kamari, H.M.; Ismail, I.; Zaid, M.H.M. Fabrication and Characterization of Glass and Glass-Ceramic from Rice Husk Ash as a Potent Material for Opto-Electronic Applications. J. Mater. Sci. Mater. Electron. 2017, 28, 17611–17621. [Google Scholar] [CrossRef]

- Siqueira, E.J.; Yoshida, I.V.P.; Pardini, L.C.; Schiavon, M.A. Preparation and Characterization of Ceramic Composites Derived from Rice Husk Ash and Polysiloxane. Ceram. Int. 2009, 35, 213–220. [Google Scholar] [CrossRef]

- Hossain, S.K.S.; Mathur, L.; Roy, P.K. Rice Husk/Rice Husk Ash as an Alternative Source of Silica in Ceramics: A Review. J. Asian Ceram. Soc. 2018, 6, 299–313. [Google Scholar] [CrossRef]

- Choi, N.W.; Mori, I.; Ohama, Y. Development of Rice Husks–Plastics Composites for Building Materials. Waste Manag. 2006, 26, 189–194. [Google Scholar] [CrossRef]

- Kenechi, N.-O.; Linus, C.; Kayode, A. Utilization of Rice Husk as Reinforcement in Plastic Composites Fabrication-A Review. Am. J. Mater. Synth. Process. 2016, 1, 32–36. [Google Scholar]

- Sae-Oui, P.; Rakdee, C.; Thanmathorn, P. Use of Rice Husk Ash as Filler in Natural Rubber Vulcanizates: In Comparison with Other Commercial Fillers. J. Appl. Polym. Sci. 2002, 83, 2485–2493. [Google Scholar] [CrossRef]

- Arayapranee, W.; Naranong, N.; Rempel, G.L. Application of Rice Husk Ash as Fillers in the Natural Rubber Industry. J. Appl. Polym. Sci. 2005, 98, 34–41. [Google Scholar] [CrossRef]

- Wang, Z.; Smith, A.T.; Wang, W.; Sun, L. Versatile Nanostructures from Rice Husk Biomass for Energy Applications. Angew. Chem. Int. Ed. 2018, 57, 13722–13734. [Google Scholar] [CrossRef] [PubMed]

- Venkateswaran, S.; Yuvakkumar, R.; Rajendran, V. Nano Silicon from Nano Silica Using Natural Resource (Rha) for Solar Cell Fabrication. Phosphorus Sulfur. Silicon. Relat. Elem. 2013, 188, 1178–1193. [Google Scholar] [CrossRef]

- Bianchini, P.; Merlo, F.; Maraschi, F.; Brescia, R.; Prato, M.; Profumo, A.; Speltini, A. From Rice Husk Ash to Silica-Supported Carbon Nanomaterials: Characterization and Analytical Application for Pre-Concentration of Steroid Hormones from Environmental Waters. Molecules 2023, 28, 745. [Google Scholar] [CrossRef]

- Gariya, D.; Bhamidimarri, R.B.; Satyavathi, B. Functionalized Rice Husk Ash as a Potential Catalytic Monolith: Preparation, Optimization and Application. Biomass. Convers. Biorefin. 2023, 13, 5107–5123. [Google Scholar] [CrossRef]

- Kanchanakul, I.; Srinophakun, T.R.; Kuboon, S.; Kaneko, H.; Kraithong, W.; Miyauchi, M.; Yamaguchi, A. Development of Photothermal Catalyst from Biomass Ash (Bagasse) for Hydrogen Production via Dry Reforming of Methane (DRM): An Experimental Study. Molecules 2023, 28, 4578. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Deng, P.; Zhang, Z. Application of Silica-Rich Biomass Ash Solid Waste in Geopolymer Preparation: A Review. Constr. Build. Mater. 2022, 356, 129142. [Google Scholar] [CrossRef]

- Kang, S.H.; Hong, S.G.; Moon, J. The Use of Rice Husk Ash as Reactive Filler in Ultra-High Performance Concrete. Cem. Concr. Res. 2019, 115, 389–400. [Google Scholar] [CrossRef]

- Jittin, V.; Minnu, S.N.; Bahurudeen, A. Potential of Sugarcane Bagasse Ash as Supplementary Cementitious Material and Comparison with Currently Used Rice Husk Ash. Constr. Build. Mater. 2021, 273, 121679. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, C.; Fang, H.; Zhu, W.; Shi, J.; Liu, G. Synthesis of Ordered Mesoporous Silica from Biomass Ash and Its Application in CO2 Adsorption. Environ. Res. 2023, 231, 116070. [Google Scholar] [CrossRef]

- Usas, S.A.; Ricardez-Sandoval, L. Biomass Fly-Ash Derived Li4SiO4 Solid for Pilot-Scale CO2 Capture, Part II: Waste Management and Utilization. Chem. Eng. Res. Des. 2025, 216, 73–89. [Google Scholar] [CrossRef]

- Beck, J.; Brandenstein, J.; Unterberger, S.; Hein, K.R.G. Effects of Sewage Sludge and Meat and Bone Meal Co-Combustion on SCR Catalysts. Appl. Catal. B 2004, 49, 15–25. [Google Scholar] [CrossRef]

- Kowalski, Z.; Makara, A. Sustainable Systems for the Production of District Heating Using Meat-Bone Meal as Biofuel: A Polish Case Study. Energies 2022, 15, 3615. [Google Scholar] [CrossRef]

- Kowalski, Z.; Banach, M.; Makara, A. Optimisation of the Co-Combustion of Meat–Bone Meal and Sewage Sludge in Terms of the Quality Produced Ashes Used as Substitute of Phosphorites. Environ. Sci. Pollut. Res. 2021, 28, 8205–8214. [Google Scholar] [CrossRef] [PubMed]

- Park, M.-H.; Kumar, S.; Ra, C. Solid Waste from Swine Wastewater as a Fuel Source for Heat Production. Asian-Australas. J. Anim. Sci. 2012, 25, 1627–1633. [Google Scholar] [CrossRef]

- Shen, X.; Huang, G.; Yang, Z.; Han, L. Compositional Characteristics and Energy Potential of Chinese Animal Manure by Type and as a Whole. Appl. Energy 2015, 160, 108–119. [Google Scholar] [CrossRef]

- Kasina, M.; Jarosz, K.; Stolarczyk, M.; Göttlicher, J.; Steininger, R.; Michalik, M. Characteristic of Phosphorus Rich Compounds in the Incinerated Sewage Sludge Ashes: A Case for Sustainable Waste Management. Sci. Rep. 2023, 13, 9137. [Google Scholar] [CrossRef]

- Kai, X.; Zhang, Y.; Yang, T.; Wang, J.; Sun, Y.; Zhu, Y. Study on the Effect of Oil Shale Ash on Potassium Retention Characteristics during Pyrolysis of Corn Stalk. J. Anal. Appl. Pyrolysis 2024, 180, 106552. [Google Scholar] [CrossRef]

- Zhao, C.; Bai, Y.; Zhao, W.; Li, Y.; Song, X.; Wang, J.; Su, W.; Lv, P.; Yu, G.; Yao, M. Interaction between Phosphorus and Alkali/Alkaline Earth Metals and Their Effect on Ash Transformation Thermal Kinetics during Phosphorus-Rich Biomass and Coal Co-Gasification. Fuel 2025, 394, 135088. [Google Scholar] [CrossRef]

- He, C.; Du, Y.; Cai, X.; Wang, J.; Qin, Y.; Zhao, Z.; Li, H.; Vassilev, S.V.; Vassileva, C.G. In-Situ Analysis of the Sintering Behavior of Coal Ash and a Phosphorus-Rich Biomass Ash under Gasification Condition. Biomass Bioenergy 2023, 168, 106671. [Google Scholar] [CrossRef]

- Cooper, J.; Lombardi, R.; Boardman, D.; Carliell-Marquet, C. The Future Distribution and Production of Global Phosphate Rock Reserves. Resour. Conserv. Recycl. 2011, 57, 78–86. [Google Scholar] [CrossRef]

- Schiemenz, K.; Eichler-Löbermann, B. Biomass Ashes and Their Phosphorus Fertilizing Effect on Different Crops. Nutr. Cycl. Agroecosyst. 2010, 87, 471–482. [Google Scholar] [CrossRef]

- Mozaffari, M.; Russelle, M.P.; Rosen, C.J.; Nater, E.A. Nutrient Supply and Neutralizing Value of Alfalfa Stem Gasification Ash. Soil Sci. Soc. Am. J. 2002, 66, 171–178. [Google Scholar] [CrossRef]

- Faridullah; Irshad, M.; Eneji, A.E.; Mahmood, Q. Plant Nutrient Release from Poultry Litter and Poultry Litter Ash Amended Soils by Various Extraction Methods. J. Plant. Nutr. 2013, 36, 357–371. [Google Scholar] [CrossRef]

- Kan, S.; Yilmaz, F.G.; Yagcioglu, K.D.; Kadioglu, Y.K.; Gezgin, S.; Gunes, A.; Taskin, M.B. Valorization of Poultry Litter Incineration Ash as a Sustainable and Balanced Fertilizer Source. J. Soil Sci. Plant Nutr. 2024, 24, 7570–7580. [Google Scholar] [CrossRef]

- Tominc, S.; Ducman, V.; Wisniewski, W.; Luukkonen, T.; Kirkelund, G.M.; Ottosen, L.M. Recovery of Phosphorus and Metals from the Ash of Sewage Sludge, Municipal Solid Waste, or Wood Biomass: A Review and Proposals for Further Use. Materials 2023, 16, 6948. [Google Scholar] [CrossRef]

- Semerci, N.; Ahadi, S.; Coşgun, S. Comparison of Dried Sludge and Sludge Ash for Phosphorus Recovery with Acidic and Alkaline Leaching. Water Environ. J. 2021, 35, 359–370. [Google Scholar] [CrossRef]

- Guedes, P.; Couto, N.; Ottosen, L.M.; Ribeiro, A.B. Phosphorus Recovery from Sewage Sludge Ash through an Electrodialytic Process. Waste Manag. 2014, 34, 886–892. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Kirkelund, G.M.; Jensen, P.E.; Pedersen, K.B. Extraction of Phosphorus from Sewage Sludge Ash—Influence of Process Variables on the Electrodialytic Process. Sustainability 2023, 15, 13953. [Google Scholar] [CrossRef]

- Zhang, J.; Li, H.; Zhang, Z.Z.; Chen, T.; Tu, S.; Chen, C.; Xu, P.; Hao, T.; Zhou, J.; Yan, B. Improvement of Wet-Chemical Phosphorus Extraction Efficiency in Incinerated Sewage Sludge Ash (ISSA) by Supercritical Hydrothermal Mineral Phase Transformation of ISSA. Sep. Purif. Technol. 2025, 364, 132489. [Google Scholar] [CrossRef]

- Pérez-Piqueres, A.; Ribó, M.; Rodríguez-Carretero, I.; Quiñones, A.; Canet, R. Struvite as a Sustainable Fertilizer in Mediterranean Soils. Agronomy 2023, 13, 1391. [Google Scholar] [CrossRef]

- Thor, K. Calcium—Nutrient and Messenger. Front. Plant Sci. 2019, 10, 449564. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, H.; Wang, X.; Du, W.; Mikulčić, H.; Duić, N. Study on Extracting Available Salt from Straw/Woody Biomass Ashes and Predicting Its Slagging/Fouling Tendency. J. Clean. Prod. 2017, 155, 164–171. [Google Scholar] [CrossRef]

- Odzijewicz, J.I.; Wołejko, E.; Wydro, U.; Wasil, M.; Jabłońska-Trypuć, A. Utilization of Ashes from Biomass Combustion. Energies 2022, 15, 9653. [Google Scholar] [CrossRef]

- Link, S.; Yrjas, P.; Lindberg, D.; Trikkel, A.; Mikli, V. Ash Melting Behaviour of Reed and Woody Fuels Blends. Fuel 2022, 314, 123051. [Google Scholar] [CrossRef]

- Nik Norizam, N.N.A.; Yang, X.; Ingham, D.; Szuhánszki, J.; Yang, W.; Rezende, J.; Ma, L.; Pourkashanian, M. An Improved Index to Predict the Slagging Propensity of Woody Biomass on High-Temperature Regions in Utility Boilers. J. Energy Inst. 2023, 109, 101272. [Google Scholar] [CrossRef]

- Acharya, B.; Dutta, A.; Mahmud, S.; Tushar, M.; Leon, M. Ash Analysis of Poultry Litter, Willow and Oats for Combustion in Boilers. J. Biomass Biofuel 2014, 1, 16–26. [Google Scholar] [CrossRef]

- Moura, L.S.d.; Silva, C.C.V.P.d.; Oliveira, S.M.d.; Carneiro, A.M.P.; Lucena, L.C.d.F.L.; Nóbrega, A.C.V.d. Use of Calcium-Rich Wood Biomass Combustion Ashes as Filler in Hot Mix Asphalt. Road Mater. Pavement Des. 2022, 23, 2375–2393. [Google Scholar] [CrossRef]

- Sharko, A.; Louda, P.; Nguyen, V.V.; Buczkowska, K.E.; Stepanchikov, D.; Ercoli, R.; Kascak, P.; Le, V.S. Multicriteria Assessment for Calculating the Optimal Content of Calcium-Rich Fly Ash in Metakaolin-Based Geopolymers. Ceramics 2023, 6, 525–537. [Google Scholar] [CrossRef]

- Cui, J.; Li, J.; Cui, J.; Wang, W.; Wu, Y.; Xu, B.; Chang, Y.; Liu, X.; Li, H.; Yao, D. Removal Effects of a Biomass Bottom Ash Composite on Tailwater Phosphate and Its Application in a Rural Sewage Treatment Plant. Sci. Total Environ. 2022, 812, 152549. [Google Scholar] [CrossRef]

- Uliasz-Bocheńczyk, A. A Comprehensive Review of CO2 Mineral Sequestration Methods Using Coal Fly Ash for Carbon Capture, Utilisation, and Storage (CCUS) Technology. Energies 2024, 17, 5605. [Google Scholar] [CrossRef]

- Tripathi, N.; Hills, C.D.; Singh, R.S.; Atkinson, C.J. Biomass Waste Utilisation in Low-Carbon Products: Harnessing a Major Potential Resource. Npj Clim. Atmos. Sci. 2019, 2, 35. [Google Scholar] [CrossRef]

- Koch, R.; Sailer, G.; Paczkowski, S.; Pelz, S.; Poetsch, J.; Müller, J. Lab-Scale Carbonation of Wood Ash for CO2-Sequestration. Energies 2021, 14, 7371. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Petrova, N.L. Mineral Carbonation of Thermally Treated and Weathered Biomass Ashes with Respect to Their CO2 Capture and Storage. Fuel 2022, 321, 124010. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. Extra CO2 Capture and Storage by Carbonation of Biomass Ashes. Energy Convers. Manag. 2020, 204, 112331. [Google Scholar] [CrossRef]

- Wang, S. Application of Solid Ash Based Catalysts in Heterogeneous Catalysis. Environ. Sci. Technol. 2008, 42, 7055–7063. [Google Scholar] [CrossRef]

- Yildiz, G.; Ronsse, F.; Venderbosch, R.; van Duren, R.; Kersten, S.R.A.; Prins, W. Effect of Biomass Ash in Catalytic Fast Pyrolysis of Pine Wood. Appl. Catal. B 2015, 168–169, 203–211. [Google Scholar] [CrossRef]

- Wang, W.; Lemaire, R.; Bensakhria, A.; Luart, D. Review on the Catalytic Effects of Alkali and Alkaline Earth Metals (AAEMs) Including Sodium, Potassium, Calcium and Magnesium on the Pyrolysis of Lignocellulosic Biomass and on the Co-Pyrolysis of Coal with Biomass. J. Anal. Appl. Pyrolysis 2022, 163, 105479. [Google Scholar] [CrossRef]

- Tian, X.; Wang, Y.; Zeng, Z.; Dai, L.; Peng, Y.; Jiang, L.; Yang, X.; Yue, L.; Liu, Y.; Ruan, R. Study on the Mechanism of Co-Catalyzed Pyrolysis of Biomass by Potassium and Calcium. Bioresour. Technol. 2021, 320, 124415. [Google Scholar] [CrossRef]

- Sun, H.; Sun, K.; Wang, F.; Liu, Y.; Ding, L.; Xu, W.; Sun, Y.; Jiang, J. Catalytic Self-Activation of Ca-Doped Coconut Shell for in-Situ Synthesis of Hierarchical Porous Carbon Supported CaO Transesterification Catalyst. Fuel 2021, 285, 119192. [Google Scholar] [CrossRef]

- Sun, H.; Ma, M.; Fan, M.; Sun, K.; Xu, W.; Wang, K.; Li, B.; Jiang, J. Controllable Preparation of Biomass Derived Mesoporous Activated Carbon Supported Nano-CaO Catalysts for Biodiesel Production. Energy 2022, 261, 125369. [Google Scholar] [CrossRef]

- Nahuelcura, B.; González, M.E.; Gutierrez, N.; Ñanculeo, J.; Romero-García, J.M. Biodiesel Production from Waste Frying Oil (WFO) Using a Biomass Ash-Based Catalyst. Catalysts 2024, 14, 553. [Google Scholar] [CrossRef]

- Saccomani, A.; DE, F.F.; França, X.; Dias, A.; Matos Júnior, J.; Faria, D. Firewood Ash as Calcium Source in the Initial Diet of Broiler Chickens. Rev. Bras. Cienc. Avic. 2016, 18, 645–648. [Google Scholar] [CrossRef]

- Ma, W.; Hoffmann, G.; Schirmer, M.; Chen, G.; Rotter, V.S. Chlorine Characterization and Thermal Behavior in MSW and RDF. J. Hazard. Mater. 2010, 178, 489–498. [Google Scholar] [CrossRef]

- Becidan, M.; Sørum, L.; Frandsen, F.; Pedersen, A.J. Corrosion in Waste-Fired Boilers: A Thermodynamic Study. Fuel 2009, 88, 595–604. [Google Scholar] [CrossRef]

- Lima, A.T.; Ottosen, L.M.; Ribeiro, A.B.; Hansen, H.K. Electrodialytic Removal of Cd from Straw Ash in a Pilot Plant. J. Environ. Sci. Health Part A 2008, 43, 844–851. [Google Scholar] [CrossRef] [PubMed]

- Hansen, H.K.; Pedersen, A.J.; Ottosen, L.M.; Villumsen, A. Speciation and Mobility of Cadmium in Straw and Wood Combustion Fly Ash. Chemosphere 2001, 45, 123–128. [Google Scholar] [CrossRef]

- Maj, I.; Niesporek, K.; Matus, K.; Miccio, F.; Mazzocchi, M.; Łój, P. The Impact of Aluminosilicate Additives upon the Chlorine Distribution and Melting Behavior of Poultry Litter Ash. Energies 2024, 17, 1854. [Google Scholar] [CrossRef]

- Zhovmir, M.M.; Moško, J.; Farták, J.; Jiříček, I.; Pohořelý, M. Complex Study of Straw Suitability for the Production of Nonindustrial Straw Pellets. ACS Omega 2023, 8, 47100–47112. [Google Scholar] [CrossRef]

- Kaniowski, W.; Taler, J.; Wang, X.; Kalemba-Rec, I.; Gajek, M.; Mlonka-Mędrala, A.; Nowak-Woźny, D.; Magdziarz, A. Investigation of Biomass, RDF and Coal Ash-Related Problems: Impact on Metallic Heat Exchanger Surfaces of Boilers. Fuel 2022, 326, 125122. [Google Scholar] [CrossRef]

- Wang, Q.; Han, K.; Wang, P.; Li, S.; Zhang, M. Influence of Additive on Ash and Combustion Characteristics during Biomass Combustion under O2/CO2 Atmosphere. Energy 2020, 195, 116987. [Google Scholar] [CrossRef]

- Maj, I.; Kalisz, S.; Szymajda, A.; Łaska, G.; Gołombek, K. The Influence of Cow Dung and Mixed Straw Ashes on Steel Corrosion. Renew. Energy 2021, 177, 1198–1211. [Google Scholar] [CrossRef]

- Mlonka-Mędrala, A.; Gołombek, K.; Buk, P.; Cieślik, E.; Nowak, W. The Influence of KCl on Biomass Ash Melting Behaviour and High-Temperature Corrosion of Low-Alloy Steel. Energy 2019, 188, 116062. [Google Scholar] [CrossRef]

- Nielsen, H.P.; Frandsen, F.J.; Dam-Johansen, K.; Baxter, L.L. The Implications of Chlorine-Associated Corrosion on the Operation of Biomass-Fired Boilers. Prog. Energy Combust. Sci. 2000, 26, 283–298. [Google Scholar] [CrossRef]

- Karuana, F.; Prismantoko, A.; Suhendra, N.; Darmawan, A.; Hariana, H.; Darmadi, D.B.; Akhsin Muflikhun, M. Investigation of Austenitic Stainless Steel Corrosion Resistance against Ash Deposits from Co-Combustion Coal and Biomass Waste. Eng. Fail. Anal. 2023, 150, 107368. [Google Scholar] [CrossRef]