Sustainable Lifespan Re-Extension Management of Energy Facilities: Economic Assessment and Decision-Making Model for Phased Decommissioning

Abstract

1. Introduction

2. Analysis of Approaches to Justification of NPP Lifetime Extension

3. Methods and Materials

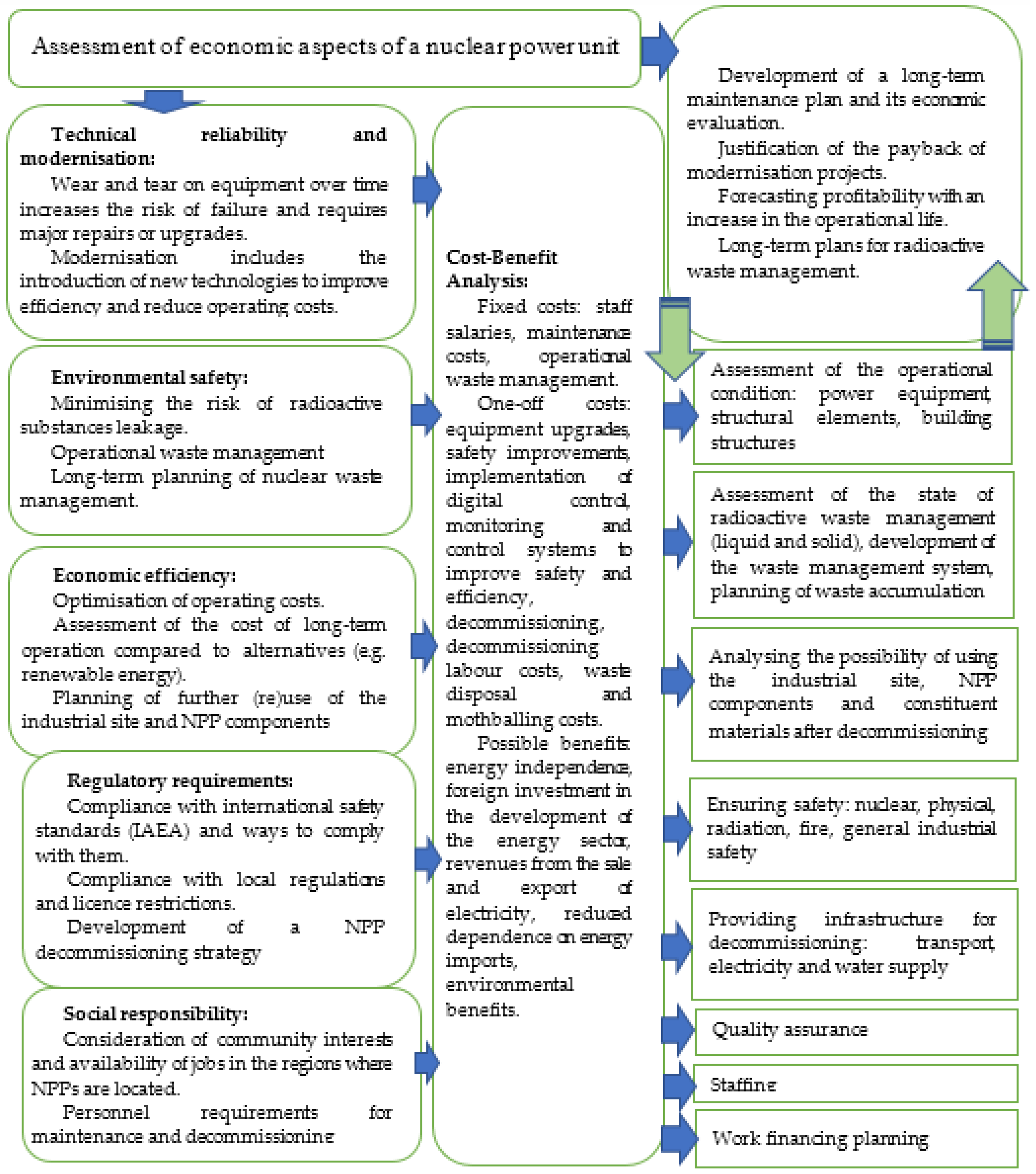

3.1. Development of the Concept of Economic Justification for the Sustainable Operation of NPPs

- Safety priority: strict adherence to all safety standards and regulations, as well as minimising negative impacts on personnel, the population, and the environment from nuclear installations and radioactive waste management facilities during the final stage of their life cycle, along with the waste generated at this stage;

- Priority of justification of capital investments: ensuring efficient use of existing facilities and existing infrastructure at the industrial site to solve the tasks of decommissioning or prolongation of the operation period;

- Priority of stability in the future: ensuring the possibility of operating the existing facilities and creating new facilities at the NPP site to replace the decommissioned facilities;

- Priority of protection of future generations: minimisation of negative economic, social, environmental, and other consequences beyond the planned period from decisions made and decommissioning activities implemented at the NPP site during the planned period.

3.2. Predictive Assessment of Activity of Main Equipment and Structural Elements of Power Units by the Time of Their Final Shutdown

- Assessment of contamination of systems and elements resulting from their direct activation during reactor plant operation;

- Assessment of contamination of systems and elements not related to their direct activation;

- Assessment of dose fields.

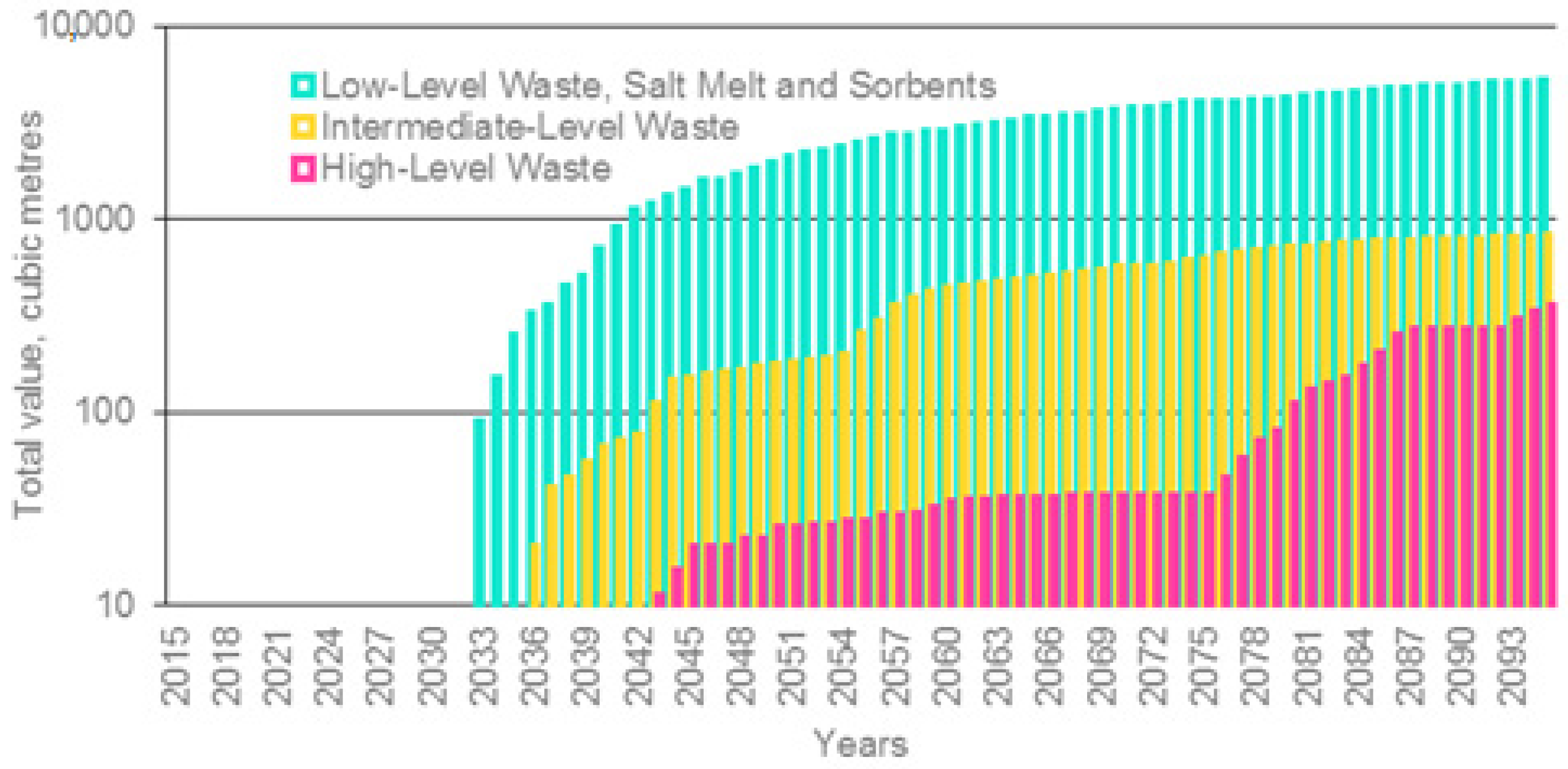

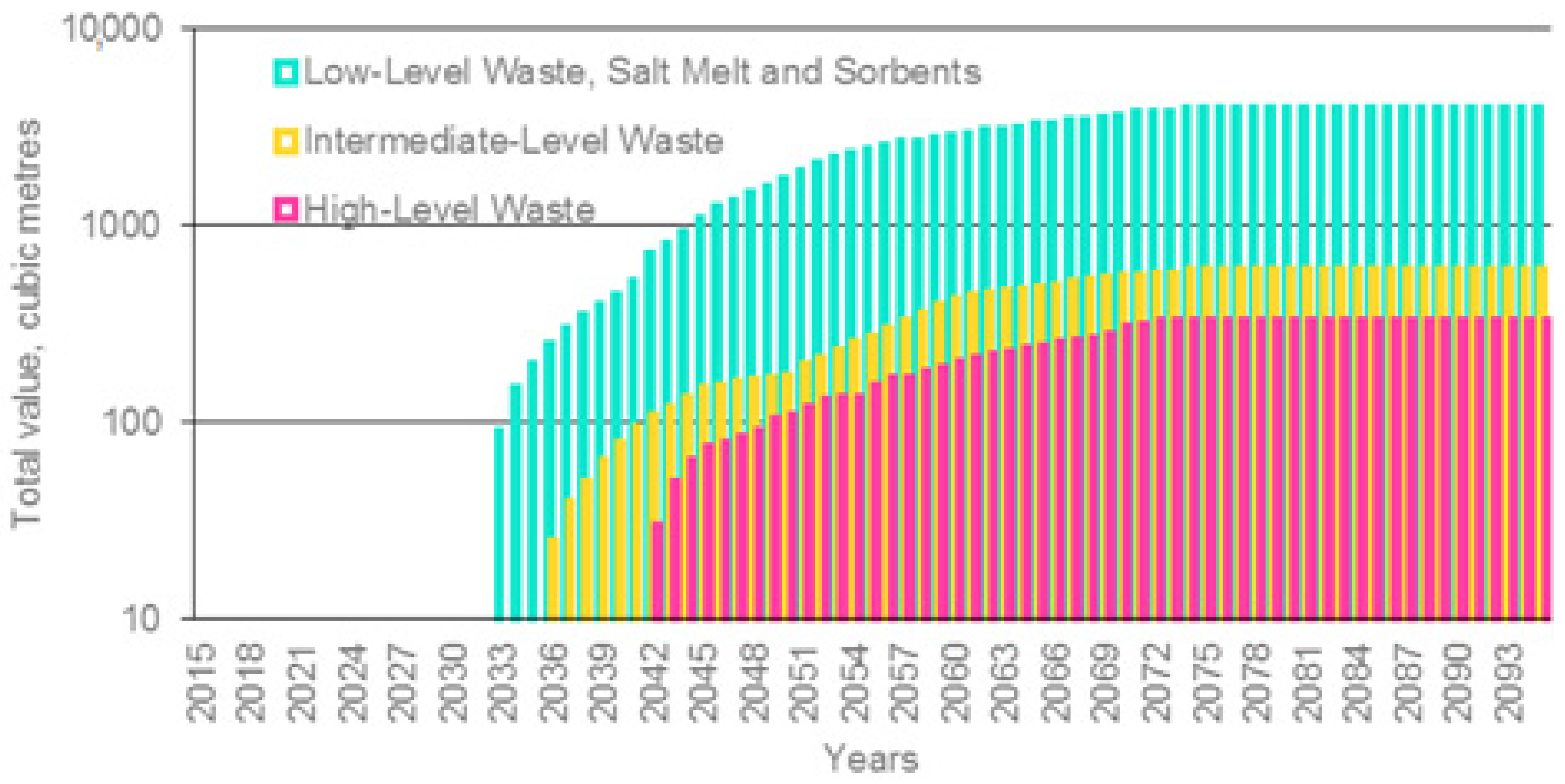

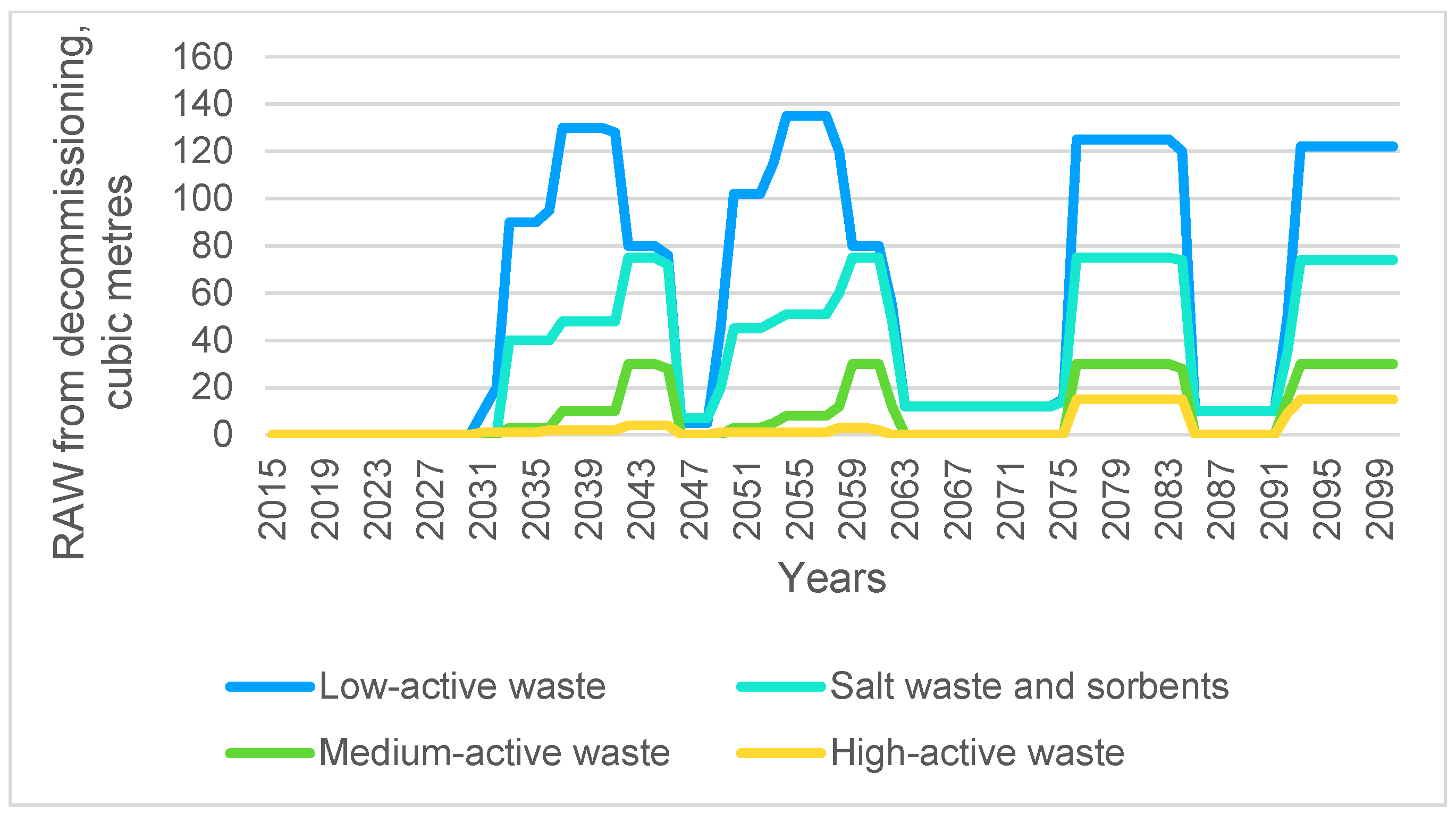

3.3. Methodology for Estimating the Amount of Radioactive Waste Generated During Decommissioning

- Annual volumes of radioactive waste generated during decommissioning at the stages of final closure, mothballing and dismantling are predicted to be equal to the annual volumes of operational waste for a power unit of this type;

- Annual volumes of radioactive waste generated during decommissioning at the stage of ageing are an order of magnitude less than annual volumes of operational radioactive waste for the power unit of this type;

- The volume of high-level solid radioactive waste generated during the dismantling phase is determined by the reactor, including all internal and external components, as well as the internal biological shielding layer;

- The volume of intermediate-level solid radioactive waste generated during the dismantling phase is equal to the volume of high-level solid radioactive waste produced at the same stage;

- The volume of high-level radioactive solid waste generated during the final closure and mothballing phases is significantly lower than the volume produced during the dismantling phase;

- The volume of low-level radioactive solid waste generated during the dismantling phase is much greater than the volume of intermediate-level radioactive solid waste produced at the same stage;

- No medium- or high-level radioactive solid waste is generated during the holding phase;

- During the final closure phase, the volume of low-level radioactive solid waste is equal to the volume generated during the dismantling phase;

- In the preservation phase, the volume of low-level radioactive solid waste is significantly smaller than that produced during the dismantling phase;

- In the ageing phase, the volume of low-level radioactive solid waste is two orders of magnitude smaller than that produced during the dismantling phase;

- The volume of intermediate-level solid radioactive waste generated during the final closure and mothballing phases is the same as the volume generated during the dismantling phase;

- In the case of the immediate dismantling option, where there is no mothballing phase, the corresponding volumes of all types of solid radioactive waste are generated additionally during the dismantling phase.

4. Results and Discussion

Selection of the Optimal Option for Decommissioning of NPP Power Units

- Financial and economic indicators;

- Organisational and technical indicators;

- Indicators of negative impact on personnel, population, and the environment;

- Socio-psychological indicators, excluding those from the first three groups.

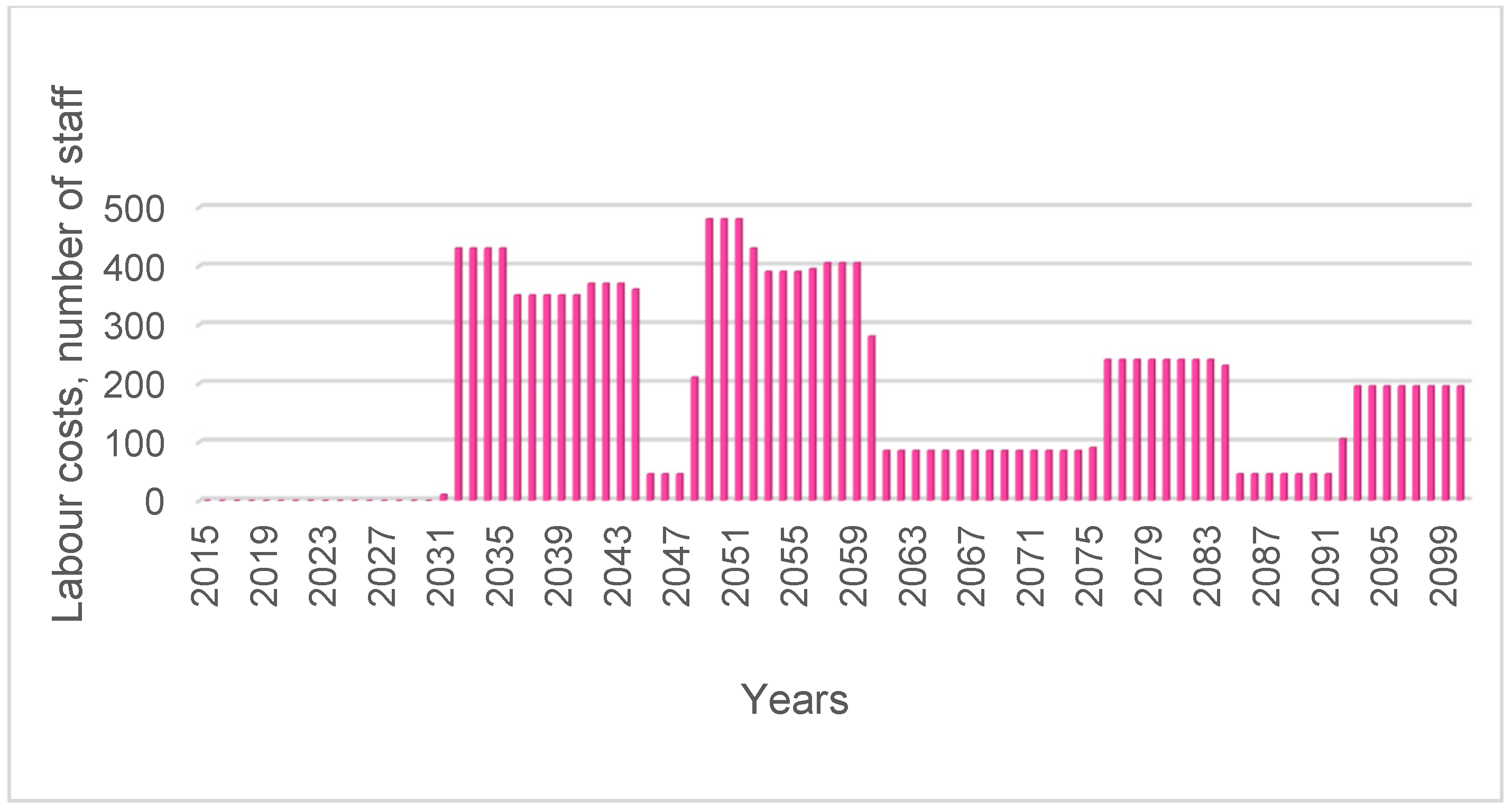

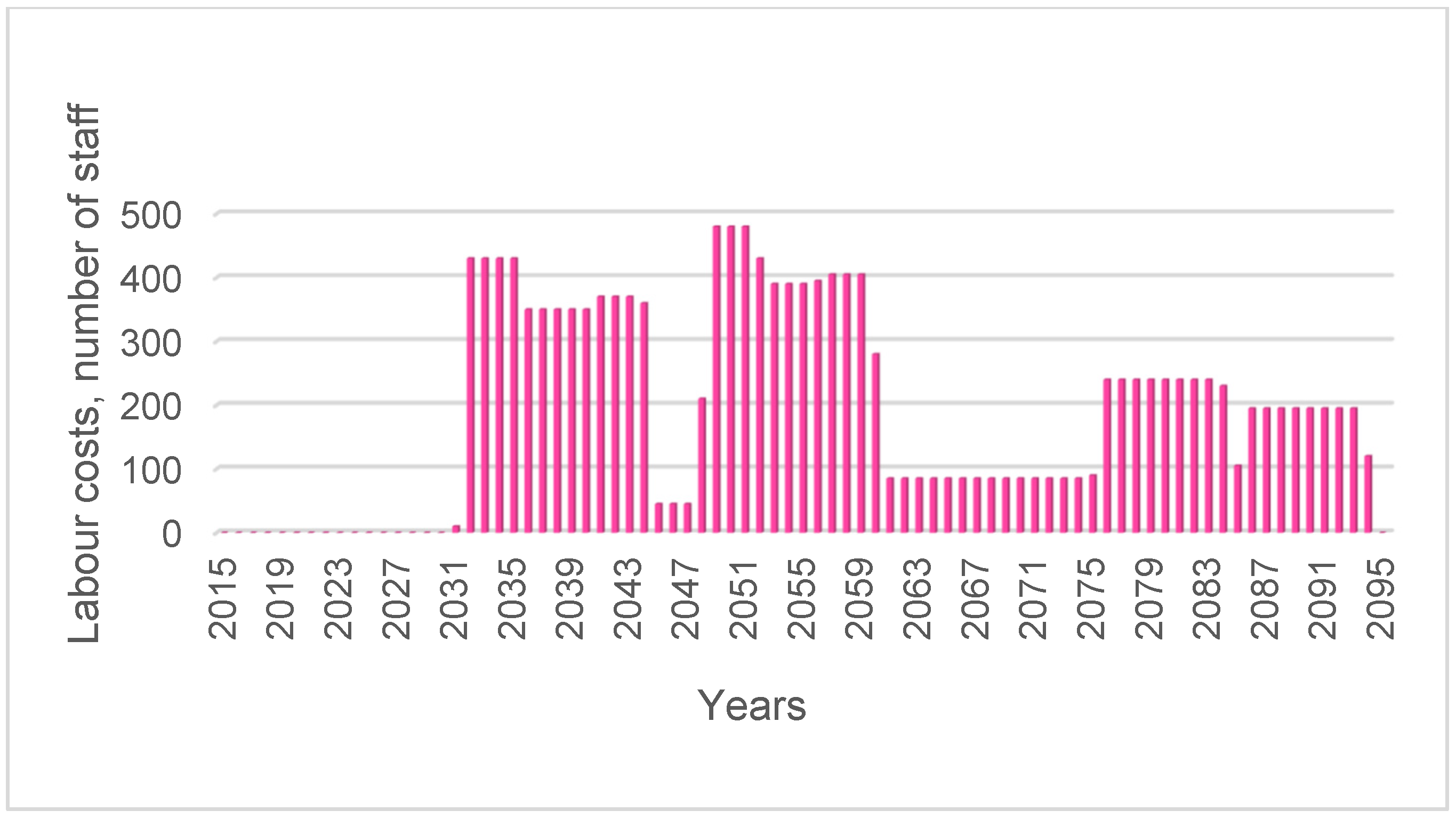

- Minimisation of gaps in the schedule of implementation of each of the ‘active’ stages of decommissioning (decommissioning, final closure, conservation, and dismantling stages) consolidated for all units;

- Achievement of maximum uniformity across all blocks of the schedule of labour costs for decommissioning;

- Achievement of maximum uniformity of the aggregate schedule of RAW generation and processing from decommissioning across all units at the above mentioned ‘active’ stages.

- Optimising the organisational structure by clearly defining the functions of existing NPP departments based on their functional purpose and assigning responsibilities among involved third-party organisations;

- Establishing necessary (including temporary) organisational structures to effectively carry out the tasks at hand;

- Implementing flexible planning of activities, including resource allocation, based on regulatory requirements, necessity, and priority of specific tasks;

- Defining requirements for the content and procedures of task execution;

- Preparation, approval, and implementation of necessary documents;

- Training, retraining, and certification of necessary personnel, as well as maintaining their qualifications;

- Control over the execution of works;

- Obtaining permits (licences) to carry out activities in accordance with the legislation;

- Provision of resources of the required quality, at the required time, and in the required quantities.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Commission Delegated Regulation (EU) 2021/2139 of 4 June 2021 Supplementing Regulation (EU) 2020/852 of the European Parliament and of the Council by Establishing the Technical Screening Criteria for Determining the Conditions Under Which an Economic Activity Qualifies as Contributing Substantially to Climate Change Mitigation or Climate Change Adaptation and for Determining Whether That Economic Activity Causes No Significant Harm to Any of the Other Environmental Objectives (Text with EEA Relevance). Available online: http://data.europa.eu/eli/reg_del/2021/2139/oj (accessed on 19 February 2025).

- WENRA. Safety Reference Levels for Existing Reactors 2020, Western European Nuclear Regulators’ Association (WENRA). Available online: https://www.wenra.eu/rhwg (accessed on 30 April 2024).

- Kurbatova, T.; Sidortsov, R. Trash to Hryvnias: The economics of electricity generation from landfill gas in Ukraine. Int. J. Sustain. Energy Plan. Manag. 2022, 33, 53–64. [Google Scholar] [CrossRef]

- Kurbatova, T.; Sotnyk, I.; Kubatko, O.; Gorbachova, L.; Khrystiuk, B. Small hydropower development in Ukraine under global climate change patterns: Is state economic support sufficient? Int. J. Environ. Sustain. Dev. 2022, 21, 465–473. [Google Scholar] [CrossRef]

- Kurbatova, T.; Hyrchenko, Y. Energy co-ops as a driver for bio-energy sector growth in Ukraine. In Proceedings of the IEEE 3rd International Conference on Intelligent Energy and Power Systems (IEPS), Kremenchuk, Ukraine, 10–14 September 2018; pp. 210–213. [Google Scholar] [CrossRef]

- Kurbatova, T.; Skibina, T. Renewable energy policy in Ukraine’s household sector: Measures, outcomes, and challenges. In Proceedings of the IEEE International Conference on Modern Electrical and Energy Systems, Kremenchuk, Ukraine, 23–25 September 2019; pp. 234–237. [Google Scholar] [CrossRef]

- Sotnyk, I.; Sasse, J.-P.; Trutnevyte, E. Decarbonizing Ukraine’s electricity sector in 2035: Scenario analysis. Energy Clim. Chang. 2025, 6, 100170. [Google Scholar] [CrossRef]

- Kurbatova, T.; Sotnyk, I.; Prokopenko, O.; Sidortsov, R.; Tu, Y.-X. Balancing Ukraine’s energy system: Challenges under high renewable energy penetration and the COVID-19 pandemic. E3S Web Conf. 2021, 280, 05007. [Google Scholar] [CrossRef]

- Regulation (EU) 2020/852 of the European Parliament and of the Council of 18 June 2020 on the Establishment of a Framework to Facilitate Sustainable Investment, and Amending Regulation (EU) 2019/2088. Available online: http://data.europa.eu/eli/reg/2020/852/oj (accessed on 19 February 2025).

- Hinca, R.; Slugen, V.; Stribrnsky, B. Seismic safety issue for operation and lifetime extension of nuclear facilities in Slovakia. AIP Conf. Proc. 2024, 3251, 080003. [Google Scholar] [CrossRef]

- Kiegiel, K.; Chmielewska-Śmietanko, D.; Herdzik-Koniecko, I.; Miśkiewicz, A.; Smoliński, T.; Rogowski, M.; Ntang, A.; Rotich, N.K.; Madaj, K.; Chmielewski, A.G. The Future of Nuclear Energy: Key Chemical Aspects of Systems for Developing Generation III+, Generation IV, and Small Modular Reactors. Energies 2025, 18, 622. [Google Scholar] [CrossRef]

- Kawasaki, K. Fukushima twelve years after the nuclear accident. Disaster Prev. Manag. 2024, 33, 598–607. [Google Scholar] [CrossRef]

- Kato, T.; Hayashi, M.; Hongyo, T. Comment on Sokawa, Y. Radiation-Induced Childhood Thyroid Cancer after the Fukushima Daiichi Nuclear Power Plant Accident. Int. J. Environ. Res. Public Health 2024, 21, 1162. Int. J. Environ. Res. Public Health 2025, 22, 674. [Google Scholar] [CrossRef]

- Farmer, M.T.; Corradini, M.; Rempe, J.; Reister, R.; Peko, D. United States Department of Energy Severe Accident Research Following the Fukushima Daiichi Accidents. Nucl. Technol. 2016, 196, 141–148. [Google Scholar] [CrossRef]

- Schneider, M.; Froggatt, A.; Hazemann, J.; von Hirschhausen, C.; Ramana, M.V.; Wimmers, A.J.; Sailer, M.; Schneider, N.; Suzuki, T.; Stienne, A.; et al. World Nuclear Industry Status Report 2022; Mycle Schneider Consulting: Paris, France, 2022; Available online: https://www.worldnuclearreport.org/IMG/pdf/wnisr2022-hr.pdf (accessed on 6 October 2022).

- Wimmers, A.; Bärenbold, R.; Bah, M.M.; Lordan-Perret, R.; Steigerwald, B.; von Hirschhausen, C.; Weigt, H.; Wealer, B. Decommissioning of Nuclear Power Plants: Regulation, Financing, and Production, DIW Data Documentation 104; DIW Berlin, German Institute for Economic Research: Berlin, Germany, 2023; Available online: https://www.diw.de/documents/publikationen/73/diw_01.c.864222.de/diw_datadoc_2023-104.pdf (accessed on 17 March 2023).

- Bärenbold, R.; Bah, M.M.; Lordan-Perret, R.; Steigerwald, B.; von Hirschhausen, C.; Wealer, B.; Weigt, H.; Wimmers, A. Cross-country survey on the decommissioning of commercial nuclear reactors: Status, insights, and knowledge gaps. Saf. Nucl. Waste Dispos. 2023, 2, 3–4. [Google Scholar] [CrossRef]

- Barenbold, R.; Bah, M.M.; Lordan-Perret, R.; Steigerwald, B.; Hirschhausen, C.V.; Wealer, B.; Weigt, H.; Wimmers, A. Decommissioning of commercial nuclear power plants: Insights from a multiple-case study. Renew. Sustain. Energy Rev. 2024, 201, 114621. [Google Scholar] [CrossRef]

- Hrinchenko, H.; Trisch, R.; Burdeina, V.; Chelysheva, S. Algorithm of technical diagnostics of the complicated damage to the continued resource of the circulation pipeline of the nuclear power plant. Probl. At. Sci. Technol. 2019, 120, 104–110. [Google Scholar] [CrossRef]

- Koval, V.; Hrinchenko, H.; Fomenko, A.; Didenko, N.; Medvedovska, Y. Compliance Management Implementation in Energy Sector Enterprises of the National Economy. In Renewables in the Circular Economy and Business; Koval, V., Ed.; SpringerBriefs in Applied Sciences and Technology; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Sotnyk, I.; Kurbatova, T.; Kubatko, O.; Prokopenko, O.; Prause, G.; Kovalenko, Y.; Trypolska, G.; Pysmenna, U. Energy Security Assessment of Emerging Economies under Global and Local Challenges. Energies 2021, 14, 5860. [Google Scholar] [CrossRef]

- Hrinchenko, H.; Prokopenko, O.; Shmygol, N.; Koval, V.; Filipishyna, L.; Palii, S.; Cioca, L.-I. Sustainable Energy Safety Management Utilizing an Industry-Relative Assessment of Enterprise Equipment Technical Condition. Sustainability 2024, 16, 771. [Google Scholar] [CrossRef]

- Skibina, T.; Kurbatova, T.; Sotnyk, I.; Telizhenko, O.; Sotnyk, M.; Hyrchenko, Y. Estimation of management effectiveness of electricity supply enterprises in emerging economies. TEM J. 2021, 10, 238–248. [Google Scholar] [CrossRef]

- Bashynska, I.; Niekrasova, L.; Malynovska, Y. Bayesian Network as a Decision Support System in the Company’s Risk Management System of Emergency Situations. In Proceedings of the 2023 IEEE 4th KhPI Week on Advanced Technology (KhPIWeek), Kharkiv, Ukraine, 2–6 October 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Kuzmynchuk, N.; Kutsenko, T.; Aloshyn, S.; Terovanesova, O. Energy Marketing and Fiscal Regulation of a Competitive Energy Efficiency System. Econ. Ecol. Socium 2024, 8, 112–121. [Google Scholar] [CrossRef]

- Pavlin, G.; Emil, K.; Petya, P. Reassessment of the Importance of the Passive Equipment Availability in the NPP Accident Progression. In Proceedings of the 6th International Symposium on Environment-Friendly Energies and Applications (EFEA), Sofia, Bulgaria, 24–26 March 2021; pp. 1–8. [Google Scholar] [CrossRef]

- D’Onorio, M.; Giannetti, F.; Caruso, G.; Porfiri, M.T. In-box LOCA accident analysis for the European DEMO water-cooled reactor. Fusion Eng. Des. 2019, 146, 732–735. [Google Scholar] [CrossRef]

- Groudev, P.; Petrova, P.; Kichev, E.; Mancheva, K. Use of level 2 PSA to support NPP operators training on severe accident. In Proceedings of the Risk, Reliability and Safety: Innovating Theory and Practice—Proceedings of the 26th European Safety and Reliability Conference, ESREL, Glasgow, Scotland, UK, 25–29 September 2016; p. 24. [Google Scholar]

- Zhang, M.; Xu, Z.; Zhang, G.; Wang, B.; Zhang, B.; Liu, Y. Review on the Application of Living PSA in Nuclear Power. Energies 2024, 17, 5578. [Google Scholar] [CrossRef]

- Wang, F.; Wang, J.; Wang, J.; Li, Y.; Hu, L.; Wu, Y. Risk monitor riskangel for risk-informed applications in nuclear power plants. Ann. Nucl. Energy 2016, 91, 142–147. [Google Scholar] [CrossRef]

- Mori, K.; Muta, H.; Ohtori, Y. Development of interaction model on the risk assessment method for nuclear facilities using a system model with a multi-layer structure. J. Nucl. Sci. Technol. 2020, 58, 542–566. [Google Scholar] [CrossRef]

- Kumar, A.; Shukla, V.; Kumar, N.; Hari, V.; Kansal, M.; Hajela, S. Estimation of Source Term and Large Early Release Frequency for Level-2 PSA of 700 MWe Indian PHWR. In Advances in Risk and Reliability Modelling and Assessment; Varde, P.V., Vinod, G., Joshi, N.S., Eds.; ICRESH 2024. Lecture Notes in Mechanical Engineering; Springer: Singapore, 2024. [Google Scholar] [CrossRef]

- Peng, H.; Wang, Y.; Zhang, X.; Hu, Q.; Xu, B. Optimization of preventive maintenance of nuclear safety-class DCS based on reliability modeling. Nucl. Eng. Technol. 2022, 54, 3595–3603. [Google Scholar] [CrossRef]

- Vijayan, P.K.; Kamble, M.T.; Nayak, A.K.; Vaze, K.K.; Sinha, R.K. Safety features in nuclear power plants to eliminate the need of emergency planning in public domain. Sadhana 2013, 38, 925–943. [Google Scholar] [CrossRef]

- Zhang, D.; Zhou, T.; Liu, Z.; Yang, H.; Bie, R.; Zhang, M. Matching Analysis of Technical Parameters and Safety Standards for Nuclear Replacement of Coal-Fired Units. Energies 2024, 17, 5583. [Google Scholar] [CrossRef]

- Ahad, J.; Farooq, A.; Ahmad, M.; Irfan, N.; Waheed, K. Review of Filtered Containment Venting System (FCVS) Eleven Years After Fukushima Accident. Nucl. Technol. 2024, 210, 1767–1823. [Google Scholar] [CrossRef]

- Veneau, T.; Cabane, F.; Barbaud, J. Improvements on French nuclear power plants following Fukushima accidents and consistency with new WENRA safety reference levels. Int. Congr. Adv. Nucl. Power Plants ICAPP 2016, 1, 23–31. [Google Scholar]

- Barbaud, J.; Roux, J.-P. Improvements on French nuclear power plants taking into account the Fukushima accidents. In Proceedings of the 2013 International Congress on Advances in Nuclear Power Plants, ICAPP, Jeju Island, Republic of Korea, 14–18 April 2013; pp. 993–1001. [Google Scholar]

- Horinouchi, R.; Yamamoto, Y.; Kasahara, N. Fundamental Study on Passive Safety Characteristics of Piping System Against Excessive Earthquake. In Proceedings of the ASME 2024 Pressure Vessels & Piping Conference, Bellevue, WA, USA, 28 July–2 August 2024; p. V005T08A016. [Google Scholar] [CrossRef]

- Rakyta, M.; Bubenik, P.; Binasova, V.; Gabajova, G.; Staffenova, K. The Change in Maintenance Strategy on the Efficiency and Quality of the Production System. Electronics 2024, 13, 3449. [Google Scholar] [CrossRef]

- Chai, G.; Yang, Z.; Xiao, J.; Wang, Y.; Ding, C.; Chong, Y. Nuclear Safety Improvement Actions and Safety Requirements in Post-Fukushima Era. At. Energy Sci. Technol. 2022, 56, 399–409. [Google Scholar] [CrossRef]

- Skeen, D.L.; Brown, D.D. United States Nuclear Regulatory Commission actions as a result of the Fukushima Dai-ichi accident. In Proceedings of the International Meeting on Severe Accident Assessment and Management 2012: Lessons Learned from Fukushima Dai-ichi, San Diego, CA, USA, 11–15 November 2012; pp. 404–409. Available online: https://www.nrc.gov/docs/ML1220/ML12202A024.pdf (accessed on 17 March 2023).

- Dudek, M.; Bashynska, I.; Filyppova, S.; Yermak, S.; Cichoń, D. Methodology for assessment of inclusive social responsibility of the energy industry enterprises. J. Clean. Prod. 2023, 394, 136317. [Google Scholar] [CrossRef]

- Sala, D.; Pavlov, K.; Bashynska, I.; Pavlova, O.; Tymchyshak, A.; Slobodian, S. Analyzing regulatory impacts on household natural gas consumption: The case of the western region of Ukraine. Appl. Sci. 2024, 14, 6728. [Google Scholar] [CrossRef]

- Jiang, P. Discuss on Severe Accident Management Guidelines for an Advanced NPP. In Proceedings of the 23rd Pacific Basin Nuclear Conference, Volume 2, Beijing & Chengdu, China, 1–4 November 2022; Liu, C., Ed.; Springer Proceedings in Physics. Springer: Singapore, 2023; Volume 284. [Google Scholar] [CrossRef]

- Beini, X.; Wang, J.; Wu, Y.; Fang, J. System theory safety analysis of network malfunction in nuclear power plant distributed control systems. Kerntechnik 2024, 89, 458–471. [Google Scholar] [CrossRef]

- D’Onorio, M.; Glingler, T.; Porfiri, M.T.; Dongiovanni, D.N.; Ciattaglia, S.; Gliss, C.; Elbez-Uzan, J.; Cortes, P.; Caruso, G. Development of a Thermal-Hydraulic Model for the EU-DEMO Tokamak Building and LOCA Simulation. Energies 2023, 16, 1149. [Google Scholar] [CrossRef]

- Pinna, T.; Carloni, D.; Carpignano, A.; Ciattaglia, S.; Johnston, J.; Porfiri, M.; Savoldi, L.; Taylor, N.; Sobrero, G.; Uggenti, A.; et al. Identification of accident sequences for the DEMO plant. Fusion Eng. Des. 2017, 124, 1277–1280. [Google Scholar] [CrossRef]

- Benabid, R.; Henneaux, P.; Labeau, P.E. Probabilistic assessment of switchyard-centered LOOP event frequency and duration in an NPP. Int. J. Syst. Assur. Eng. Manag. 2024, 15, 4105–4123. [Google Scholar] [CrossRef]

- Agwa, A.M.; Hassan, H.M. Onsite power system risk assessment for nuclear power plants considering components ageing. Prog. Nucl. Energy 2019, 110, 384–392. [Google Scholar] [CrossRef]

- Benabid, R. Ageing Impact on Reliability and Components Importance of an NPP’s Emergency Power Supply Model. In Proceedings of the 5th International Conference on Electrical Engineering and Control Applications—Volume 2, Khenchela, Algeria, 15–17 November 2022; Ziani, S., Chadli, M., Bououden, S., Zelinka, I., Eds.; ICEECA 2022. Lecture Notes in Electrical Engineering. Springer: Singapore, 2024; Volume 1224. [Google Scholar] [CrossRef]

- Hrinchenko, H.; Udovychenko, V.; Generalov, O.; Parfentieva, O.; Neskhodovskyi, I.; Kopacz, M. Sustainability assurance optimization-based approach to energy infrastructure diagnostics in energy systems management. Polityka Energetyczna—Energy Policy J. 2024, 27, 109–132. [Google Scholar] [CrossRef]

- Murtza Qamar, H.G.; Guo, X.; Seif Ghith, E.; Tlija, M.; Siddique, A. Author Correction: Assessment of energy management and power quality improvement of hydrogen based microgrid system through novel PSO-MWWO technique. Sci. Rep. 2025, 15, 863. [Google Scholar] [CrossRef]

- Tainter, J.A.; Taylor, T.G. Complexity, problem-solving, sustainability and resilience. Build. Res. Inf. 2013, 42, 168–181. [Google Scholar] [CrossRef]

- Pollitt, M.G. Energy Markets Under Stress: Some Reflections on Lessons From the 2021–2023 Energy Price Crisis in Europe. Econ. Energy Environ. Policy 2024, 13, 83–102. [Google Scholar] [CrossRef]

- Park, K.; Son, S.; Oh, J.; Kim, S. Sustainable Decommissioning Strategies for Nuclear Power Plants: A Systematic Literature Review. Sustainability 2022, 14, 5947. [Google Scholar] [CrossRef]

- Monteiro, D.B.; Moreira, J.M.L.; Maiorino, J.R. A Method for Decommissioning Strategy Proposal and a Cost Estimation Considering a Multiple Reactor Site with Interdependent Plants. Prog. Nucl. Energy 2020, 127, 103440. [Google Scholar] [CrossRef]

- Volk, R.; Hübner, F.; Hünlich, T.; Schultmann, F. The Future of Nuclear Decommissioning—A Worldwide Market Potential Study. Energy Policy 2019, 124, 226–261. [Google Scholar] [CrossRef]

- OECD Nuclear Energy Agency. Costs of Decommissioning Nuclear Power Plants; Nuclear Development, OECD Publishing: Paris, France, 2016. [Google Scholar] [CrossRef]

- Lough, W.T.; White, K.P., Jr. A Critical Review of Nuclear Power Plant Decommissioning Planning Studies. Energy Policy 1990, 18, 471–479. [Google Scholar] [CrossRef]

- Chatzimouratidis, A.I.; Pilavachi, P.A. Pilavachi, Technological, economic and sustainability evaluation of power plants using the Analytic Hierarchy Process. Energy Policy 2009, 37, 778–787. [Google Scholar] [CrossRef]

- Bhola, P.; Chronis, A.-G.; Kotsampopoulos, P.; Hatziargyriou, N. Business Model Selection for Community Energy Storage: A Multi Criteria Decision Making Approach. Energies 2023, 16, 6753. [Google Scholar] [CrossRef]

- Hrinchenko, H.; Trishch, R.; Mykolaiko, V.; Kovtun, O. Qualimetric approaches to assessing sustainable development indicators. E3S Web Conf. 2023, 408, 01013. [Google Scholar] [CrossRef]

- Ngulimi, M.F.; Kim, S.; Asghar, K.; Seo, B.K.; Roh, C. Nuclear Decommissioning and Sustainable Environment: Insights on Decontamination Processes. Adv. Energy Sustain. Res. 2025, 6, 2400243. [Google Scholar] [CrossRef]

- On Approval of the Energy Strategy of Ukraine Until 2050. Order of the Cabinet of Ministers of Ukraine of 21 April 2023 No. 373-p. Available online: https://zakon.rada.gov.ua/laws/show/373-2023-%D1%80#n6 (accessed on 19 February 2025).

- Pavlenko, I.; Ciszak, O.; Kondus, V.; Ratushnyi, O.; Ivchenko, O.; Kolisnichenko, E.; Kulikov, O.; Ivanov, V. An Increase in the Energy Efficiency of a New Design of Pumps for Nuclear Power Plants. Energies 2023, 16, 2929. [Google Scholar] [CrossRef]

- Cano-Megias, P.; Hidalgo-Salaverri, J.; Chacartegui, R.; Ayllon-Guerola, J.; Becerra-Villanueva, J.A.; Viezzer, E. Boosting the Efficiency of Future Fusion Power Plants Combining Energy and Heat Production. IEEE Trans. Plasma Sci. 2022, 50, 4430–4439. [Google Scholar] [CrossRef]

- Danish, M.S.S.; Pinter, G. Environmental and Economic Efficiency of Nuclear Projects. In Clean Energy Investments for Zero Emission Projects; Dinçer, H., Yüksel, S., Eds.; Contributions to Management Science; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Saylan, E.; Aygün, C. Thermoeconomic analysis and environmental impact assessment of the Akkuyu nuclear power plant. J. Therm. Anal. Calorim. 2024, 149, 6531–6550. [Google Scholar] [CrossRef]

- El-Emam, R.S.; Ozcan, H.; Dincer, I. Comparative cost evaluation of nuclear hydrogen production methods with the Hydrogen Economy Evaluation Program (HEEP). Int. J. Hydrogen Energy 2015, 40, 11168–11177. [Google Scholar] [CrossRef]

- Jasiūnas, J.; Lund, P.D.; Mikkola, J. Energy System Resilience—A Review. Renew. Sustain. Energy Rev. 2021, 150, 111476. [Google Scholar] [CrossRef]

- Koivunen, T.; Syri, S. Analysis of Severe Scarcity Situations in Finland’s Low Carbon Electricity System Until 2030. Energies 2024, 17, 5928. [Google Scholar] [CrossRef]

- Bompard, E.; Carpaneto, E.; Huang, T.; Pi, R.J.; Fulli, G.; Purvins, A.; Mutule, A. Electricity Independence of the Baltic States: Present and Future Perspectives. Sustain. Energy Grids Netw. 2017, 10, 55–64. [Google Scholar] [CrossRef]

- Wankouo Ngouleu, C.A.; Koholé, Y.W.; Fohagui, F.C.V.; Tchuen, G. Optimum design and scheduling strategy of an off-grid hybrid photovoltaic-wind-diesel system with an electrochemical, mechanical, chemical, and thermal energy storage systems: A comparative scrutiny. Appl. Energy 2025, 377, 124646. [Google Scholar] [CrossRef]

- Kuznietsov, P.; Biedunkova, O. Application of methods for the chemical and radiometric monitoring of liquid radioactive waste processing. J. Nucl. Sci. Technol. 2024, 62, 98–110. [Google Scholar] [CrossRef]

- Jääskeläinen, J.; Lager, J.; Syri, S. Development of Energy Security in Finland and in the Baltic States since 1991. In Proceedings of the 16th International Conference on the European Energy Market (EEM), Ljubljana, Slovenia, 18–20 September 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Atstaja, D.; Cudecka-Purina, N.; Koval, V.; Kuzmina, J.; Butkevics, J.; Hrinchenko, H. Waste-to-Energy in the Circular Economy Transition and Development of Resource-Efficient Business Models. Energies 2024, 17, 4188. [Google Scholar] [CrossRef]

- Sribna, Y.; Skakovska, S.; Paniuk, T.; Hrytsiuk, I. The Economics of Technology Transfer in The Environmental Safety of Enterprises for the Energy Transition. Econ. Ecol. Socium 2023, 7, 74–81. [Google Scholar] [CrossRef]

- Poenitz, E.; Roode-Gutzmer, Q.I.; Barkleit, A.; Konheiser, J. Activity measurements and calculations for gamma-emitting radionuclides in concrete drill cores of unit 2 of the Greifswald NPP. EPJ Web Conf. 2024, 308, 03005. [Google Scholar] [CrossRef]

- Rindelhardt, U.; Viehrig, H.; Konheiser, J.; Schuhknecht, J. Weld Material Investigations of a WWER-440 Reactor Pressure Vessel: Results From the First Trepan Taken From the Former Greifswald NPP. J. Eng. Gas Turbines Power 2009, 131, 022904. [Google Scholar] [CrossRef]

- Weil, L. Clearance Levels in Germany and Their Application in D&D Projects. In Proceedings of the ASME 2003 9th International Conference on Radioactive Waste Management and Environmental Remediation, Oxford, UK, 21–25 September 2003; pp. 1095–1099. [Google Scholar] [CrossRef]

- Thierfeldt, S. The role of clearance in Germany—Release of materials, buildings and sites. Kerntechnik 2005, 70, 47–52. [Google Scholar] [CrossRef]

- Halimi, A.; Shirvan, K. Scale effects on core design, fuel costs, and spent fuel volume of pressurized water reactors. Ann. Nucl. Energy 2024, 209, 110847. [Google Scholar] [CrossRef]

- Kaplan, D.I.; Almond, P.M. Radionuclide Solid:liquid partitioning in an aged, reducing-grout wasteform recovered from a disposal facility. J. Environ. Radioact. 2024, 279, 107514. [Google Scholar] [CrossRef] [PubMed]

- Pysmennyy, Y.; Filatov, V.; Boyko, N. Analysis of Regulatory Support Issues for Preparation for NPP Decommissioning. Nucl. Radiat. Saf. 2022, 1, 40–45. [Google Scholar] [CrossRef] [PubMed]

- Boyko, N.; Kondratyuk, V.; Filatov, V.; Pysmennyy, Y.; Bibik, T. Risk Assessment in Determination and Justification of NPP Unit Decommissioning Option Using Multifactor Analysis Methodology. Nucl. Radiat. Saf. 2024, 2, 58–66. [Google Scholar] [CrossRef]

- Calixto, W.P.; Araújo, W.R.H.; Morais, L.D.S.; Reis, M.R.C. Parametric Regression and Sensitivity Analysis. In Control and Tracking Techniques for Switched Reluctance Machines; Power Systems; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

| No Powerunit | Deferred Dismantling * | Immediate Dismantling | ||||||

|---|---|---|---|---|---|---|---|---|

| Solt Melt and Sorbents | Low-Level Waste | Intermediate-Level Waste | High-Level Waste | Solt Melt and Sorbents | Low-Level Waste | Intermediate-Level Waste | High-Level Waste | |

| 1 | 967 | 1130 | 312 | 167 | 851 | 1126 | 312 | 167 |

| 2 | 967 | 1130 | 312 | 167 | 851 | 1126 | 312 | 167 |

| No. | Criterion Name | Related Factors | Commentary | Weight Factor |

|---|---|---|---|---|

| Financial and economic indicators | 3.00 | |||

| 1 | Total costs of decommissioning activities | A, B, C, D, E, F, G, H, I, K, L, M | 0.75 | |

| 2 | Costs of implementation of individual stages of decommissioning | A, B, C, D, E, F, G, H, I, K, L, M | Excluded as highly correlated with criterion 1 | 0 |

| 3 | Total RAW disposal costs from decommissioning | A, B, C, E, F, G, I, K, L, M | 0.75 | |

| 4 | Possibility to optimise the decommissioning cost schedule | D, E, F, I, K, M | 0.75 | |

| 5 | Time to peak decommissioning costs | C, D, E, I, K, M | Excluded as highly correlated with criteria 4 and 15 | 0 |

| 6 | Recyclability of elements and materials | B, C, D, E, F, G, H, L | 0.75 | |

| Organisational and technical indicators | 3.00 | |||

| 7 | Ensuring compliance with safety requirements | A, B, C, D, E, F, G, H, I, J, K, L, M | Excluded as a prerequisite for any scenario | 0 |

| 8 | Labour costs for decommissioning and individual stages of decommissioning | C, D, E, F, G, H, I, J, L | Excluded as highly correlated with criterion 1 | 0 |

| 9 | Possibility to optimise the schedule of labour costs for decommissioning | B, C, D, E, H, I, J, K, L | 0.60 | |

| 10 | Timeline for achieving the ultimate goal of decommissioning | A, B, C, D, E, G, H, I, L | 0.60 | |

| 11 | Duration of the individual phases of decommissioning | C, D, E, G, H, I, L | Excluded as highly correlated with the previous criterion | 0 |

| 12 | Staffing of the works | A, E, H, J, M | Excluded as a prerequisite for any scenario | 0 |

| 13 | Information support of works | A, C, D, E, I, J, L, M | 0.60 | |

| 14 | Perspective on the application of improved technologies | A, C, D, E, F, G, I, K, L, M | 0.60 | |

| 15 | Time margin until peak receipts of radioactive waste from decommissioning for disposal | A, E, I, K, M | 0.60 | |

| Indicators of negative impact on personnel, population, and the environment | 3.00 | |||

| 16 | Relative magnitude of the collective dose to personnel during decommissioning | A, B, C, E, I, L, M | 1.50 | |

| 17 | Absolute value of the collective dose to personnel during decommissioning | A, B, C, E, I, L, M | Excluded as highly correlated with the previous criterion | 0 |

| 18 | Relative and absolute values of individual and collective doses to the population during withdrawal from operation | A, B, C, E, I, L, M | Excluded as negligible under conditions of further NPP operation | 0 |

| 19 | Relative and absolute values of emissions and discharges into the environment from the decommissioning of operations | A, B, C, D, E, I, L, M | Excluded as negligible under conditions of further NPP operation | 0 |

| 20 | Total volume of recycled RAW from decommissioning of operation | A, B, C, D, E, F, G, H, I, L, M | 1.50 | |

| 21 | Volumes of RAW generated at individual stages of decommissioning | A, B, C, D, E, F, G, H, I, L, M | Excluded as highly correlated with the previous criterion | 0 |

| Socio-psychological indicators | 1.00 | |||

| 22 | Public opinion preferences | A, E, H, J, K, L, M | 0.50 | |

| 23 | Burden on subsequent generations | A, B, C, D, E, G, K, L, M | 0.50 | |

| No. | Criterion Name | (Option 1) Immediate Dismantling | (Option 2) Delayed Dismantling |

|---|---|---|---|

| Financial and economic indicators | 4.51 | 4.51 | |

| 1 | Total costs of decommissioning activities | 1.50 | 0.75 |

| 2 | Total RAW disposal costs from decommissioning | 1.13 | 1.13 |

| 3 | Possibility to optimise the decommissioning cost schedule | 0.75 | 1.50 |

| 4 | Recyclability of elements and materials | 1.13 | 1.13 |

| Organisational and technical indicators | 3.90 | 5.10 | |

| 5 | Possibility to optimise the schedule of labour costs for decommissioning | 0.60 | 1.20 |

| 6 | Timeline for achieving the ultimate goal of decommissioning | 1.20 | 0.60 |

| 7 | Information support of works | 0.90 | 0.90 |

| 8 | Perspective on the application of improved technologies | 0.60 | 1.20 |

| 9 | Time margin until peak receipts of radioactive waste from decommissioning for disposal | 0.60 | 1.20 |

| Indicators of negative impact on personnel, population, and the environment | 3.75 | 5.25 | |

| 10 | Relative magnitude of the collective dose to personnel during decommissioning | 1.50 | 3.00 |

| 11 | Total volume of recycled RAW from decommissioning of operation | 2.25 | 2.25 |

| Socio-psychological indicators | 2.00 | 1.00 | |

| 12 | Public opinion preferences | 1.00 | 0.50 |

| 13 | Burden on subsequent generations | 1.00 | 0.50 |

| Total scores | 14.16 | 15.86 | |

| No. | Criterion Name | Delayed Dismantling | ||

|---|---|---|---|---|

| (Option 2.1) 20 Years | (Option 2.2) 30 Years | (Option 2.3) 40 Years | ||

| Financial and economic indicators | 4.89 | 4.52 | 4.14 | |

| 1 | Total costs of decommissioning activities | 1.50 | 1.13 | 0.75 |

| 2 | Total RAW disposal costs from decommissioning | 1.13 | 1.13 | 1.13 |

| 3 | Possibility to optimise the decommissioning cost schedule | 1.13 | 1.13 | 1.13 |

| 4 | Recyclability of elements and materials | 1.13 | 1.13 | 1.13 |

| Organisational and technical indicators | 4.20 | 4.50 | 5.10 | |

| 5 | Possibility to optimise the schedule of labour costs for decommissioning | 0.90 | 0.90 | 0.90 |

| 6 | Timeline for achieving the ultimate goal of decommissioning | 1.20 | 0.90 | 0.60 |

| 7 | Information support of works | 0.90 | 0.90 | 0.90 |

| 8 | Perspective on the application of improved technologies | 0.60 | 0.90 | 1.20 |

| 9 | Time margin until peak receipts of radioactive waste from decommissioning for disposal | 0.60 | 0.90 | 1.20 |

| Indicators of negative impact on personnel, population, and the environment | 3.75 | 4.50 | 4.50 | |

| 10 | Relative magnitude of the collective dose to personnel during decommissioning | 1.50 | 2.25 | 2.25 |

| 11 | Total volume of recycled RAW from decommissioning of operation | 2.25 | 2.25 | 2.25 |

| Socio-psychological indicators | 1.75 | 1.50 | 1.25 | |

| 12 | Public opinion preferences | 0.75 | 0.75 | 0.75 |

| 13 | Burden on subsequent generations | 1.00 | 0.75 | 0.50 |

| Total scores | 14.59 | 15.02 | 14.99 | |

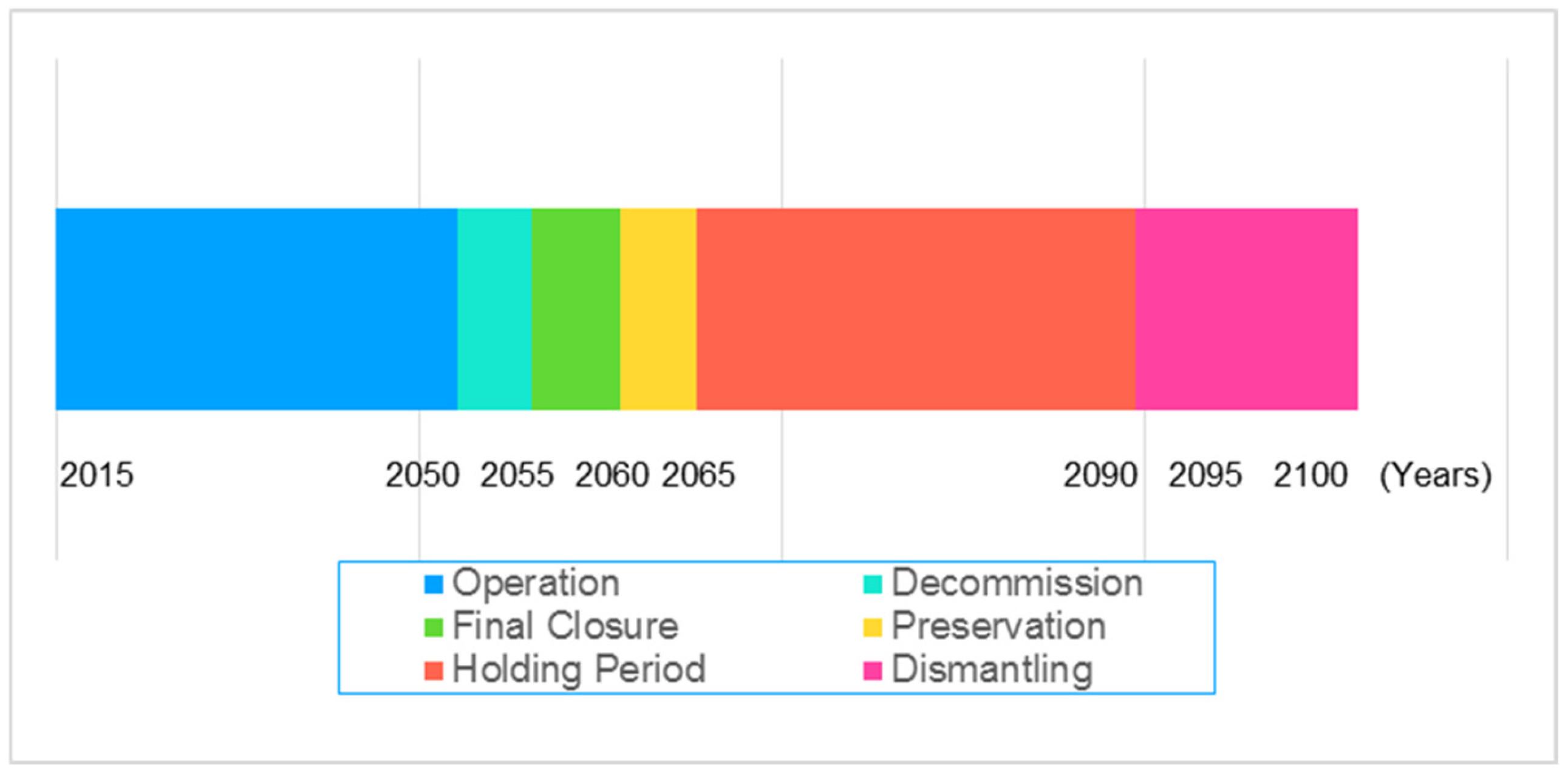

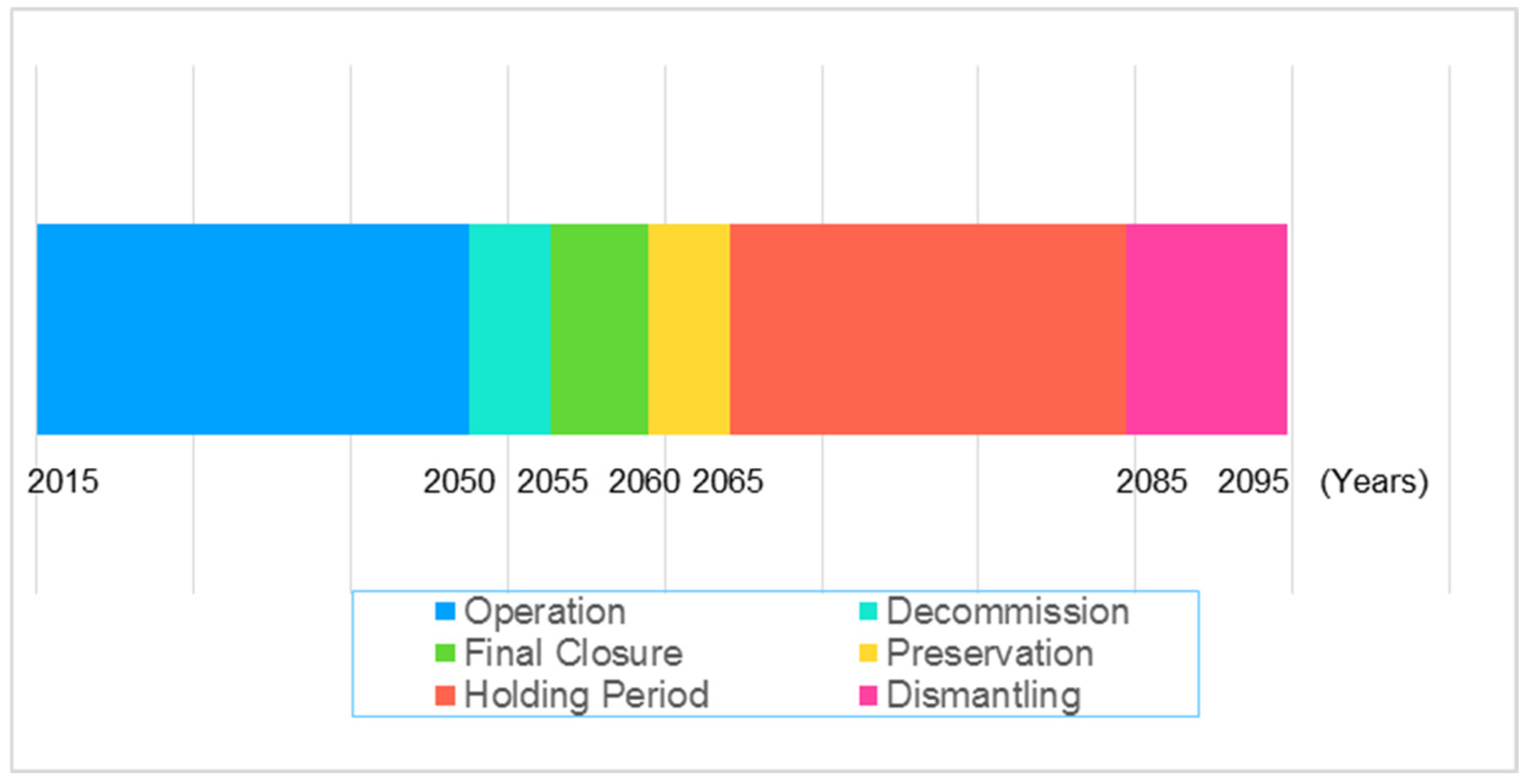

| Stage Name | Start Date | Duration, Years | Labour Costs, Person–Years |

|---|---|---|---|

| Termination of operation | 2032 | 4 | 1745.5 |

| Final closure | 2036 | 5 | 1714 |

| Preservation | 2041 | 4 | 1441 |

| Maturation | 2045 | 30 | 1279 |

| Dismantling | 2075 | 9 | 1753.5 |

| Total | 52 | 7933 | |

| Unit No. | Salt Fusion and Sorbents | Low-Active Solid Radioactive Waste | Medium-Active Solid Radioactive Waste | Highly Active Solid Radioactive Waste |

|---|---|---|---|---|

| 1 | 967.3 | 1130.3 | 312.6 | 167.4 |

| 2 | 940.2 | 1130.3 | 312.6 | 167.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hrinchenko, H.; Prokopenko, O.; Karbekova, A.; Antonenko, N.; Kovshun, N.; Kubakh, T.; Poliushkin, S. Sustainable Lifespan Re-Extension Management of Energy Facilities: Economic Assessment and Decision-Making Model for Phased Decommissioning. Sustainability 2025, 17, 4610. https://doi.org/10.3390/su17104610

Hrinchenko H, Prokopenko O, Karbekova A, Antonenko N, Kovshun N, Kubakh T, Poliushkin S. Sustainable Lifespan Re-Extension Management of Energy Facilities: Economic Assessment and Decision-Making Model for Phased Decommissioning. Sustainability. 2025; 17(10):4610. https://doi.org/10.3390/su17104610

Chicago/Turabian StyleHrinchenko, Hanna, Olha Prokopenko, Aziza Karbekova, Nataliia Antonenko, Nataliia Kovshun, Tetiana Kubakh, and Serhii Poliushkin. 2025. "Sustainable Lifespan Re-Extension Management of Energy Facilities: Economic Assessment and Decision-Making Model for Phased Decommissioning" Sustainability 17, no. 10: 4610. https://doi.org/10.3390/su17104610

APA StyleHrinchenko, H., Prokopenko, O., Karbekova, A., Antonenko, N., Kovshun, N., Kubakh, T., & Poliushkin, S. (2025). Sustainable Lifespan Re-Extension Management of Energy Facilities: Economic Assessment and Decision-Making Model for Phased Decommissioning. Sustainability, 17(10), 4610. https://doi.org/10.3390/su17104610