Re-Resinated Wood Strand Panels: Enhancing Performance Through Waste Recycling

Abstract

1. Introduction

- Assess the recycling effects of re-resinated strands on panel performance, including bond performance among the strands and mechanical properties.

- Understand the influence of recycling on the dimensional stability of the panels.

- Compare the fire performance of the panels made from control and re-resinated strands.

2. Materials and Methods

2.1. Materials

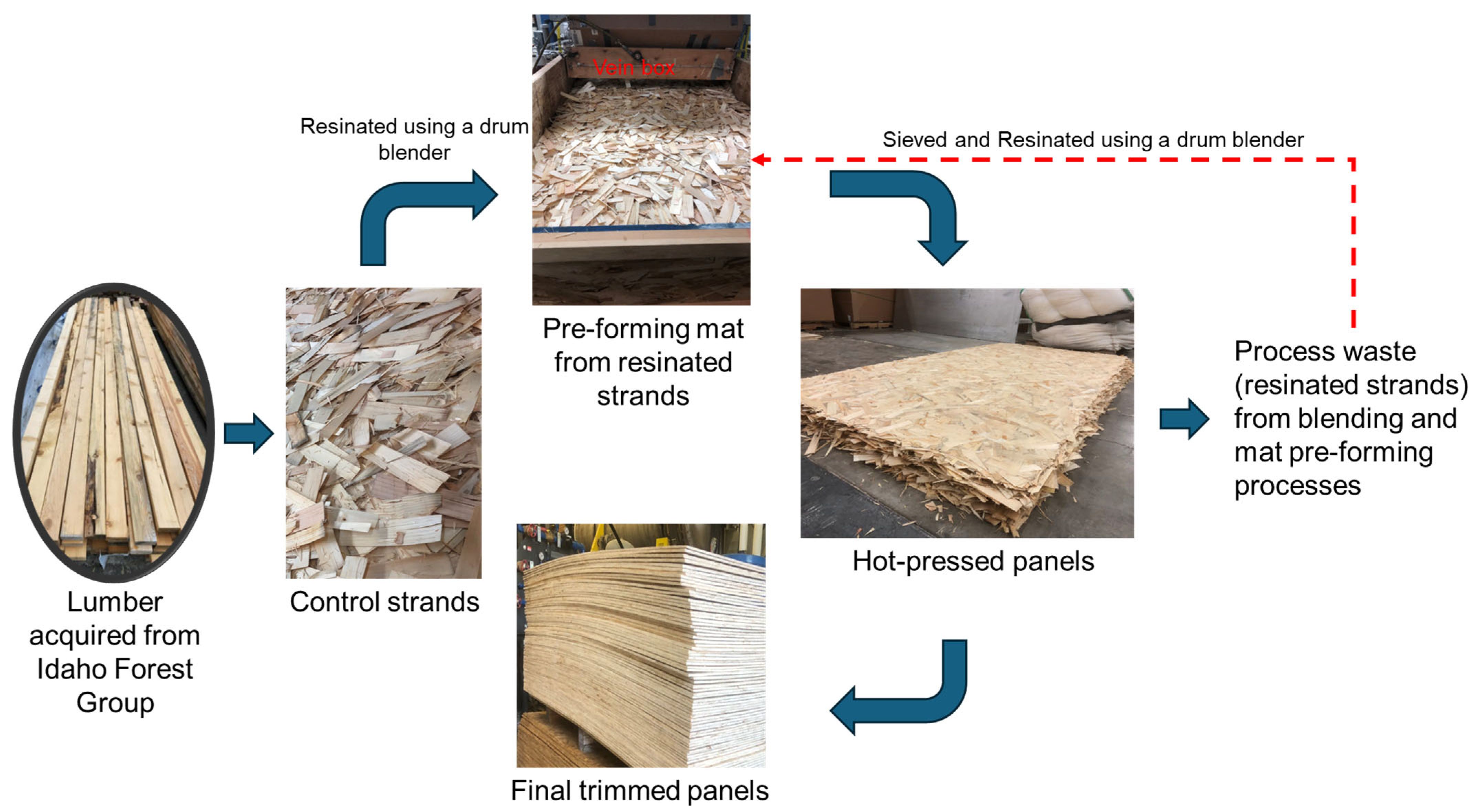

2.2. Fabrication Process

2.3. Experimental Methods

2.3.1. Dimensional Stability and Moisture Interaction

2.3.2. Mechanical Performance

2.3.3. Fire Performance

3. Results and Discussions

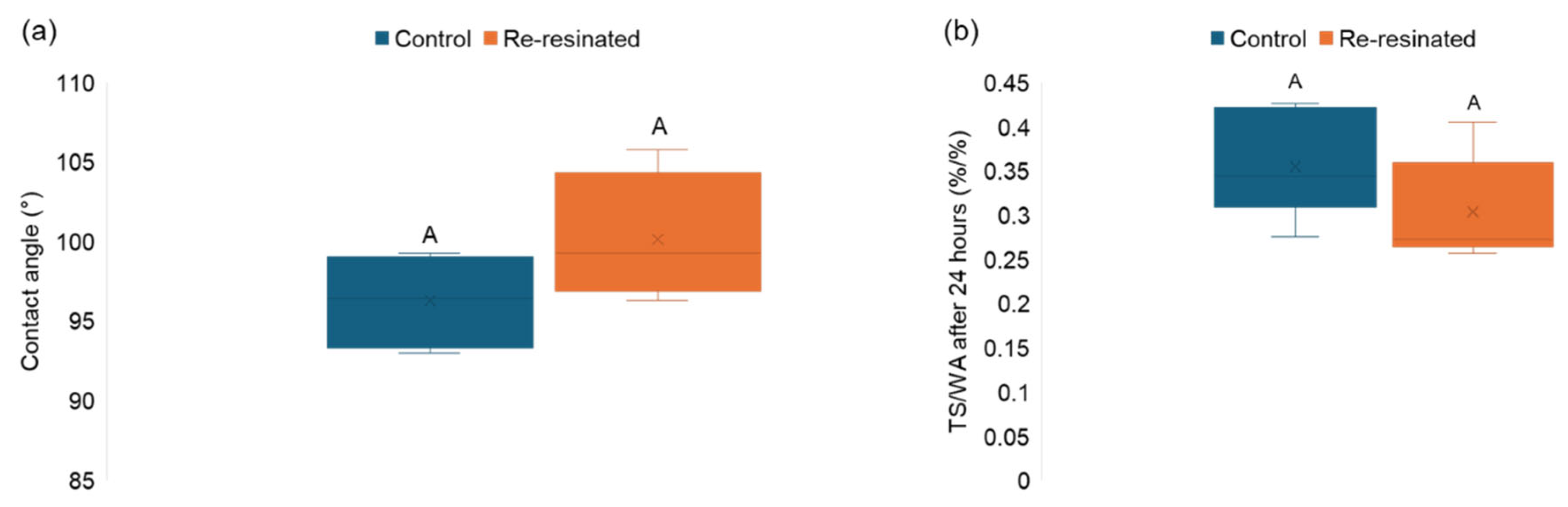

3.1. Dimensional Stability

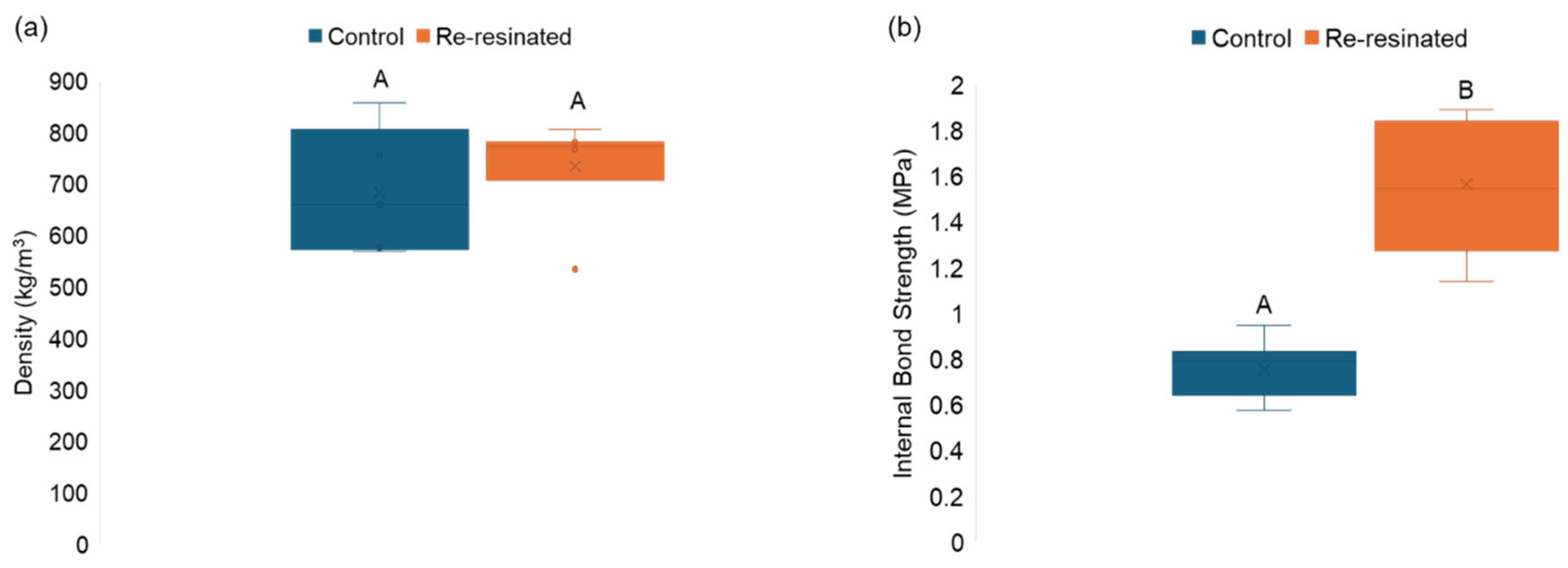

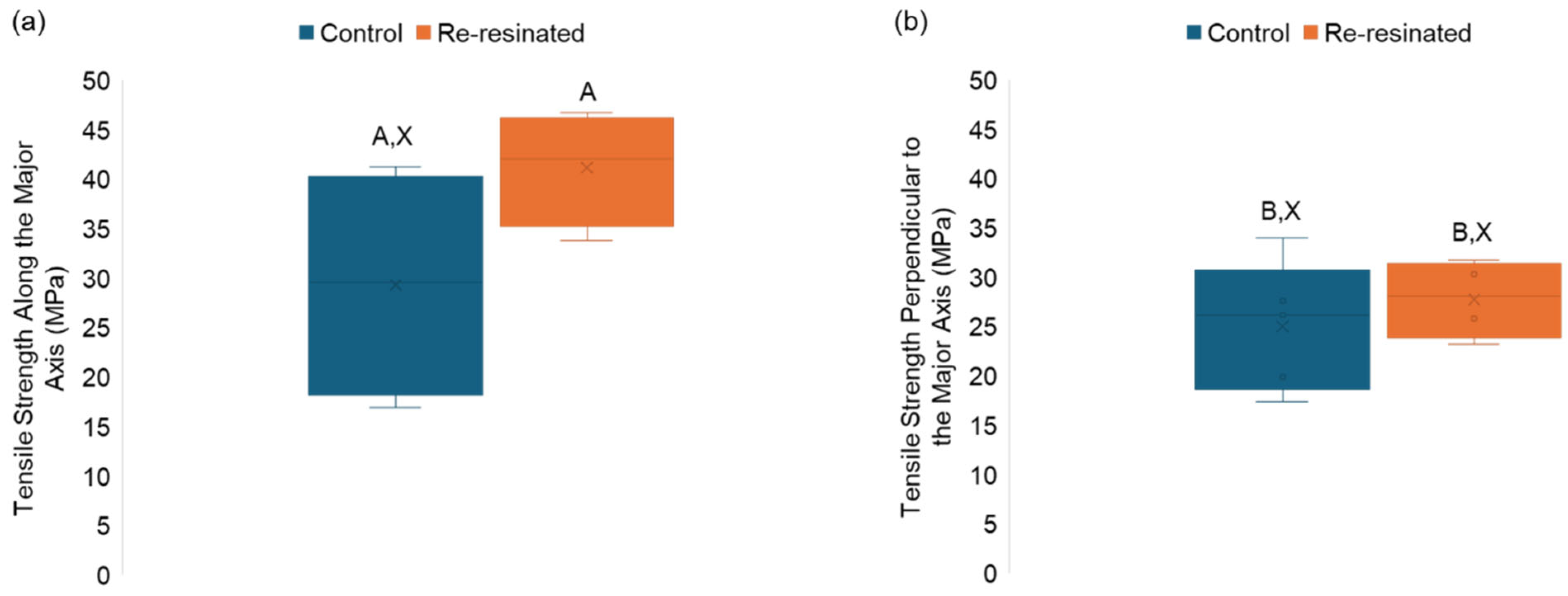

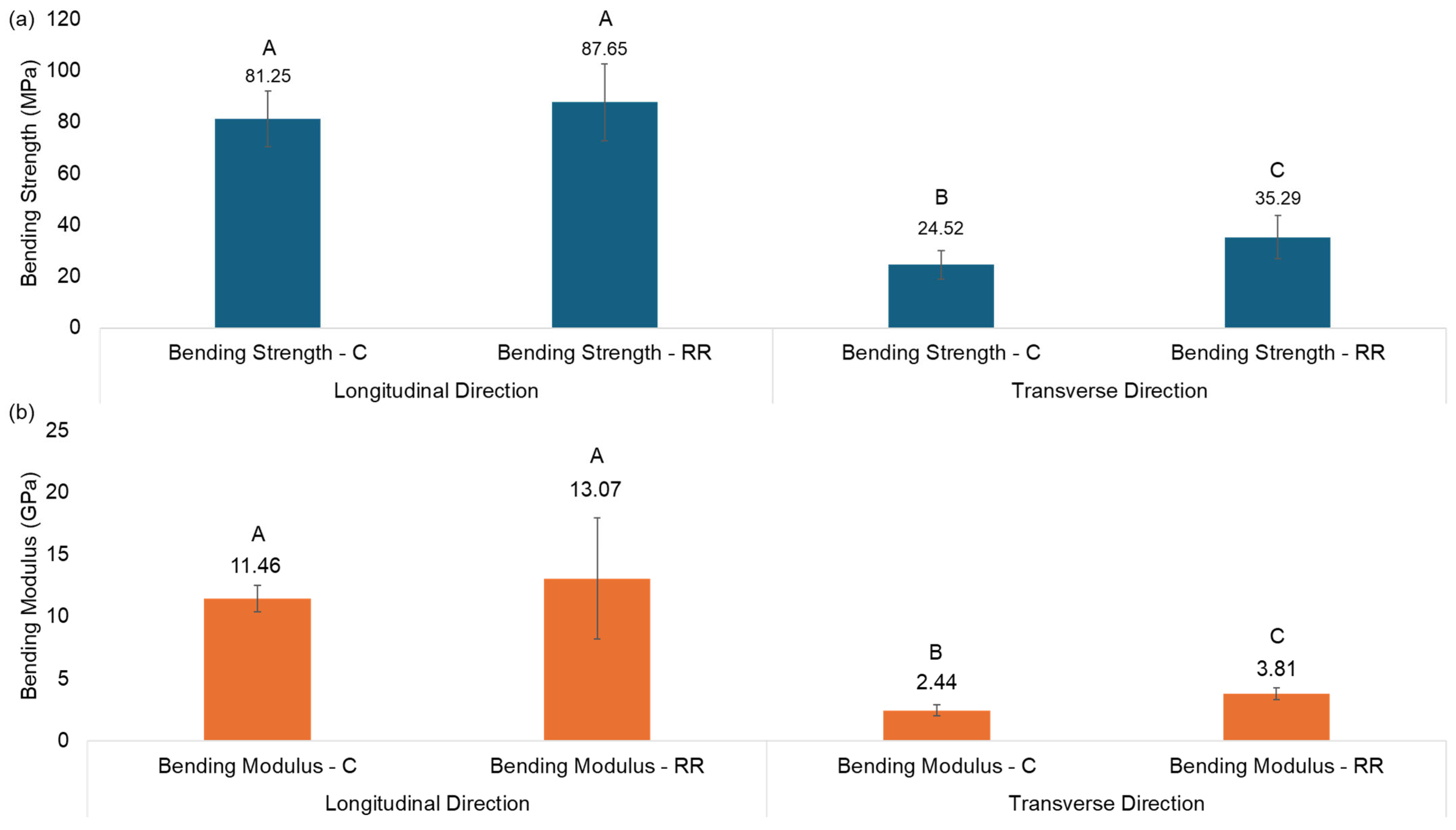

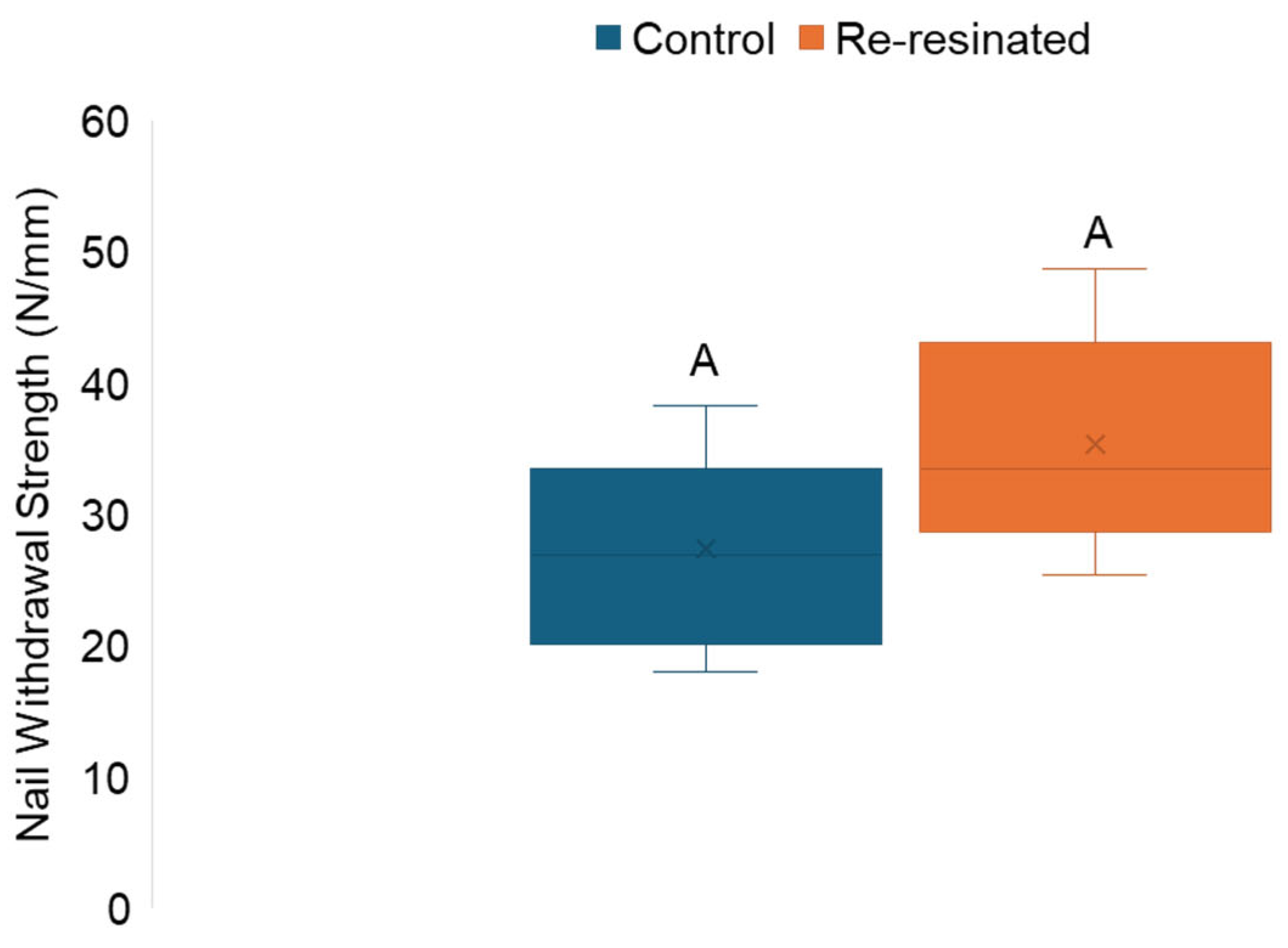

3.2. Mechanical Properties

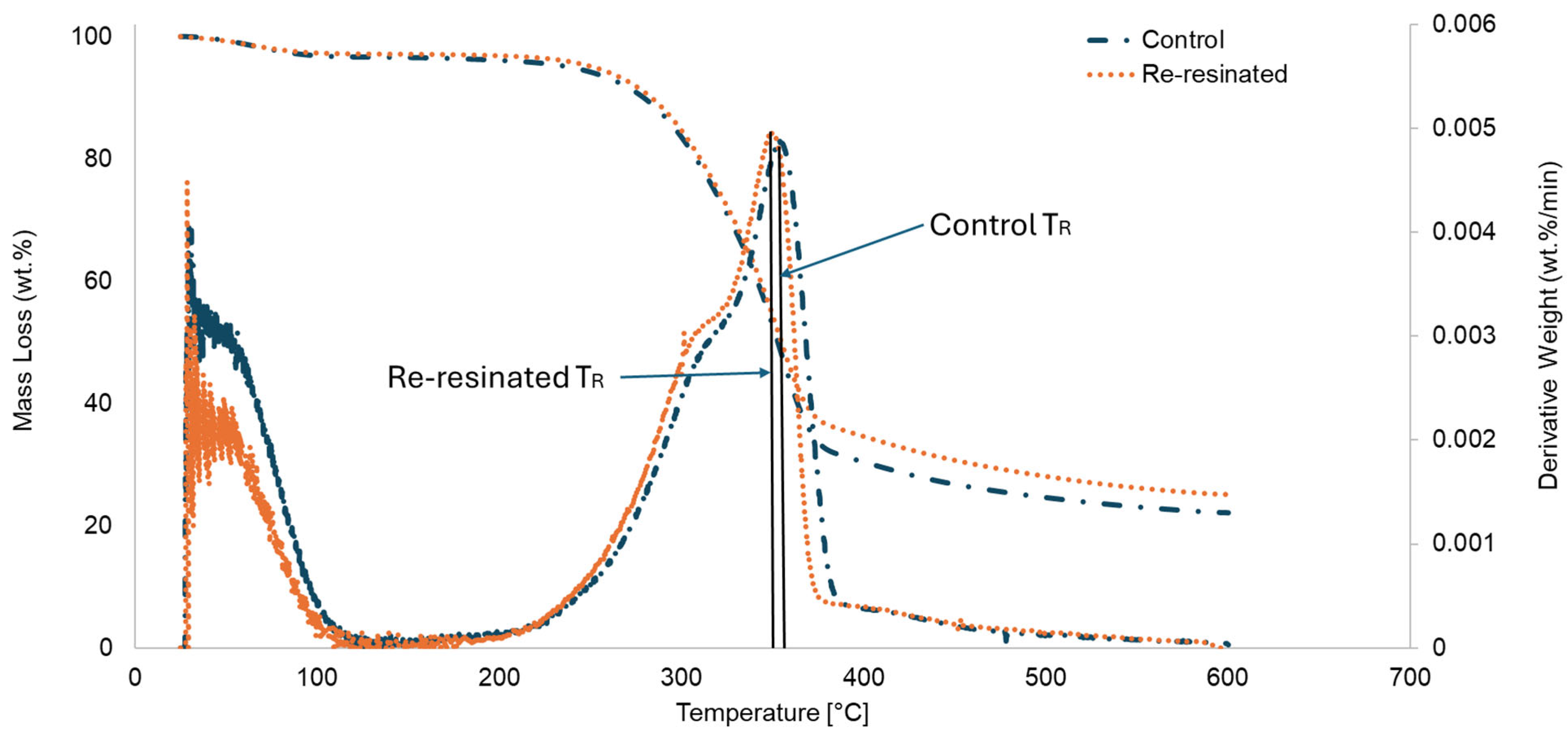

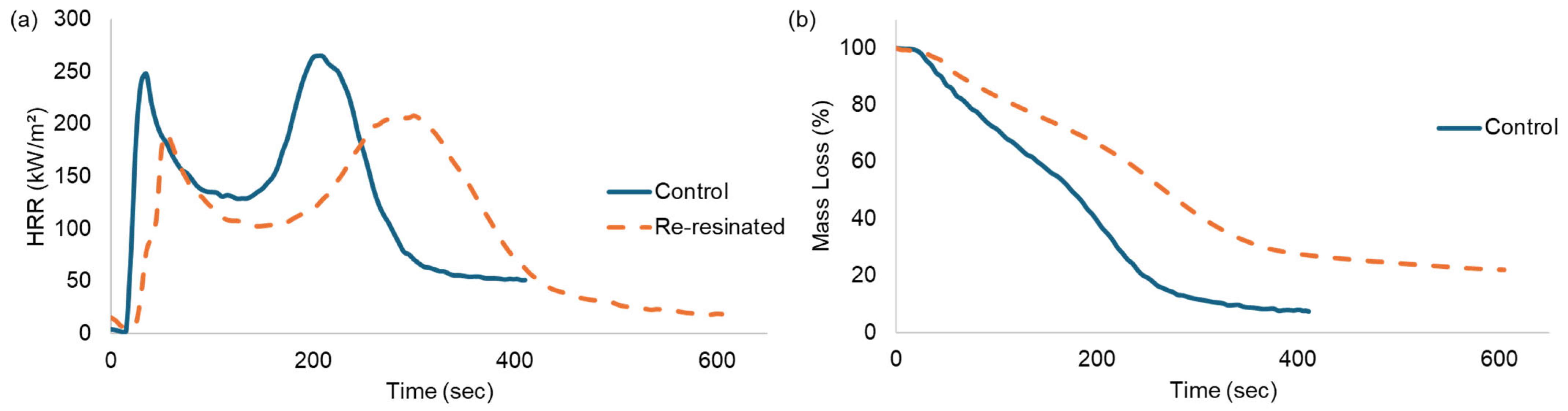

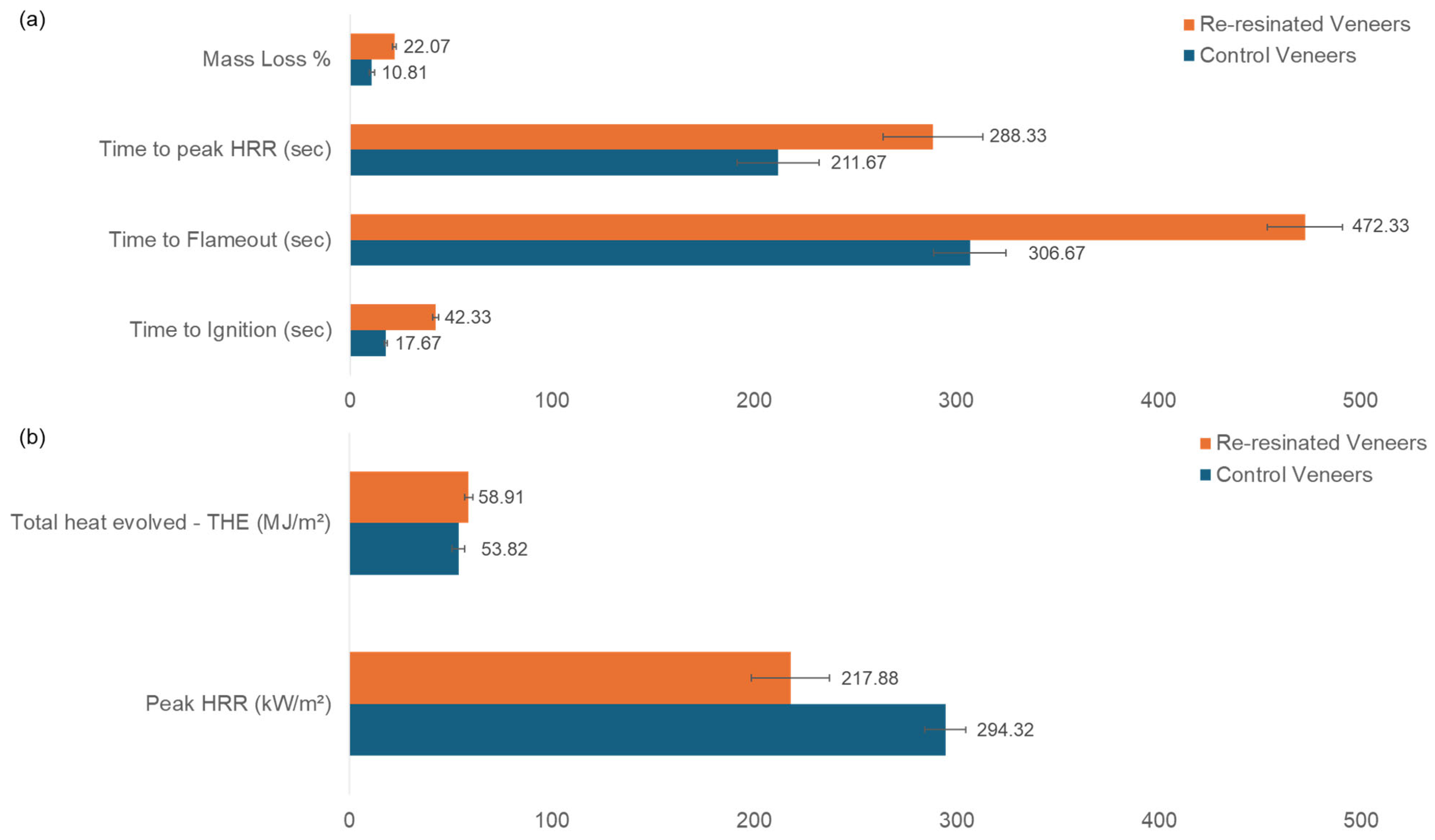

3.3. Fire Reaction Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CO2 | Carbon Dioxide |

| NFC | Natural Fiber Composites |

| OSB | Oriented Strand Board |

| CLT | Cross Laminated Timber |

| OSL | Oriented Strand Lumber |

| ESLP | Englemann Spruce and Lodgepole Pine |

| WSU | Washington State University |

| CMEC | Composite Materials and Engineering Center |

| pMDI | Polymeric Methyl Diphenyl Diisocyanate |

| WA | Water Absorption |

| TS | Thickness Swell |

| VDP | Vertical Density Profile |

| IB | Internal Bond |

| UTM | Universal Testing Machine |

| MOE | Modulus of Elasticity |

| MOR | Modulus of Rapture |

| ESG | Equivalent Specific Gravity |

| TGA | Thermogravimetric Analysis |

| DTGA | Derivative Thermogravimetric Analysis |

| HRR | Heat Release Rate |

| α | Significance level |

| MPa | Mega Pascal |

| GPa | Giga Pascal |

| ANOVA | Analysis of Variance |

| TR | Reference Temperature |

| PHRR | Peak Heat Release Rate |

| THE | Total Heat Evolved |

| N | Newton |

| mm | Millimeters |

| MPa | Mega Pascal |

| GPa | Giga Pascal |

| g | Gram |

| kg | Kilograms |

| wt.% | Weight Percentage |

| kW | Kilo Watt |

| m | Meter |

| min | Minute |

| sec | Second |

| C | Celsius |

| MJ | Mega Joule |

References

- Zhang, M.; Wong, E.-D.; Kawai, S.; Kwon, J.-H. Manufacture and properties of high-performance oriented strand board composite using thin strands. J. Wood Sci. 1998, 44, 191–197. [Google Scholar] [CrossRef]

- Prion, H.G.L.; Li, H.; Boehner, W.; Moses, D.M. Composite behavior of laminated strand lumber. Wood Sci. Technol. 2003, 37, 59–77. [Google Scholar] [CrossRef]

- Zhang, M. <Preliminary> Production and Properties of Composite Fiberboard. Wood Res. Bull. Wood Res. Inst. Kyoto Univ. 1994, 81, 31–33. [Google Scholar]

- Mohammadabadi, M.; Miller, J.; Street, J.; Kim, Y.; Ragon, K. Wood-based corrugated core sandwich panels manufactured using a wooden mold. BioResources 2023, 18, 3033–3043. [Google Scholar] [CrossRef]

- Chanda, A.; Bhattacharyya, D. Formability of wood veneers: A parametric approach for understanding some manufacturing issues. Holzforschung 2018, 72, 881–887. [Google Scholar] [CrossRef]

- Chanda, A. Formability and Flammability of Thin Walled Veneer Structures. Ph.D. Dissertation, University of Auckland, Auckland, New Zealand, 2021. Available online: https://hdl.handle.net/2292/56945 (accessed on 21 April 2023).

- Jakes, J.E. Recent Advances in Forest Products Research and Development. JOM 2016, 68, 2381–2382. [Google Scholar] [CrossRef]

- Jakes, J.E.; Arzola, X.; Bergman, R.; Ciesielski, P.; Hunt, C.G.; Rahbar, N.; Tshabalala, M.; Wiedenhoeft, A.C.; Zelinka, S.L. Not Just Lumber—Using Wood in the Sustainable Future of Materials, Chemicals, and Fuels. JOM 2016, 68, 2395–2404. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 1–15. [Google Scholar] [CrossRef]

- Arockiam, N.J.; Jawaid, M.; Saba, N. Sustainable bio composites for aircraft components. Sustain. Compos. Aerosp. Appl. 2018, 2018, 109–123. [Google Scholar] [CrossRef]

- Gunathilake, T.M.S.U.; Ching, Y.C.; Ching, K.Y.; Chuah, C.H.; Abdullah, L.C. Biomedical and Microbiological Applications of Bio-Based Porous Materials: A Review. Polymers 2017, 9, 160. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Aider, M. Chitosan application for active bio-based films production and potential in the food industry: Review. LWT Food Sci. Technol. 2010, 43, 837–842. [Google Scholar] [CrossRef]

- Zhan, M.; Wool, R.P. Design and evaluation of bio-based composites for printed circuit board application. Compos. Part A Appl. Sci. Manuf. 2013, 47, 22–30. [Google Scholar] [CrossRef]

- Singh, B.; Gupta, M.; Tarannum, H.; Randhawa, A. Natural Fiber-Based Composite Building Materials. In Cellulose Fibers: Bio- and Nano-Polymer Composites; Kalia, S., Kaith, B.S., Kaur, I., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 701–720. [Google Scholar] [CrossRef]

- Ahmed, S.; Arocho, I. Mass timber building material in the U.S. construction industry: Determining the existing awareness level, construction-related challenges, and recommendations to increase its current acceptance level. Clean. Eng. Technol. 2020, 1, 100007. [Google Scholar] [CrossRef]

- Mohammadabadi, M.; Yadama, V.; Dolan, J.D. Evaluation of wood composite sandwich panels as a promising renewable building material. Materials 2021, 14, 2083. [Google Scholar] [CrossRef]

- Voth, C.; White, N.; Yadama, V.; Cofer, W. Design and evaluation of thin-walled hollow-core wood-strand sandwich panels. J. Renew. Mater. 2015, 3, 234–243. [Google Scholar] [CrossRef]

- Puettmann, M.; Oneil, E.; Kline, E.; Johnson, L. Cradle to Gate Life Cycle Assessment of Oriented Strandboard Production from the Southeast; CORRIM: Oshkosh, WI, USA, 2013; Available online: https://corrim.org/SE-OSB-LCA-May-2013-final.pdf (accessed on 15 February 2025).

- Gumisiriza, R.; Hawumba, J.F.; Okure, M.; Hensel, O. Biomass waste-to-energy valorisation technologies: A review case for banana processing in Uganda. Biotechnol. Biofuels 2017, 10, 11. [Google Scholar] [CrossRef] [PubMed]

- Mohammadabadi, M. Design, Fabrication, Evaluation, and Testing of Multilayered Wood-Based Composite Sandwich Panels. Ph.D. Dissertation, Washington State University, Pullman, WA, USA, 2020. Available online: https://www.proquest.com/dissertations-theses/design-fabrication-evaluation-testing/docview/2454093316/se-2 (accessed on 12 May 2025).

- ASTM D933-16; Guide for Moisture Conditioning of Wood and Wood-Based Materials. D07 Committee; ASTM: West Conshohocken, PA, USA, 2021. [CrossRef]

- Pouzet, M.; Gautier, D.; Charlet, K.; Dubois, M.; Béakou, A. How to decrease the hydrophilicity of wood flour to process efficient composite materials. Appl. Surf. Sci. 2015, 353, 1234–1241. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Dukarska, D.; Barczewski, M.; Dziurka, D.; Mirski, R. Optimization of Isocyanate Content in PF/pMDI Adhesive for the Production of High-Performing Particleboards. Polymers 2023, 15, 4645. [Google Scholar] [CrossRef]

- ASTM D7490-13; Test Method for Measurement of the Surface Tension of Solid Coatings, Substrates and Pigments using Contact Angle Measurements. D01 Committee; ASTM: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM D1037-13; Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle. ASTM: West Conshohocken, PA, USA, 2013.

- ASTM D4442-20; Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials. D07 Committee; ASTM: West Conshohocken, PA, USA, 2020. [CrossRef]

- U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. Wood Handbook: Wood as an Engineering Material; General Technical Report FPL-GTR-190; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010. [CrossRef]

- American Wood Council. 2024 National Design Specification (NDS), 8 December 2021. Available online: https://awc.org/publications/2024-nds/ (accessed on 7 February 2025).

- ASTM E1131-20; Test Method for Compositional Analysis by Thermogravimetry. E37 Committee; ASTM: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM E2102-17; Test Method for Measurement of Mass Loss and Ignitability for Screening Purposes Using a Conical Radiant Heater. E05 Committee; ASTM: West Conshohocken, PA, USA, 2024. [CrossRef]

- ISO 17554:2014; Reaction to Fire Tests—Mass Loss Measurement. ISO/TC 92/SC 1 Committee, International Standard Confirmed; International Organization for Standardization: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/55678.html (accessed on 12 May 2025).

- Adhikari, R. Cross-Laminated Strand-Veneer Composite Mass Timber Panels for Building Construction. Ph.D. Dissertation, Washington State University, Pullman, WA, USA, 2024. [Google Scholar] [CrossRef]

- Jerves, R.; Yadama, V.; Aro, M.; Pelaez-Samaniego, M.R. Cross-laminated strand veneer lumber mass timber panels from thermally modified strands. Constr. Build. Mater. 2023, 368, 130370. [Google Scholar] [CrossRef]

- Barnes, D. A Model of the Effect of Strand Length and Strand Thickness on the Strength Properties of Oriented Wood Composites. For. Prod. J. 2001, 51, 36. [Google Scholar]

- Herzog, B.; Yeh, B. Nail withdrawal and pull-through strength of structural-use panels. In Proceedings of the 9th World Conference on Timber Engineering, Portland, OR, USA, 6–10 August 2006; APA Wood: Tacoma, DC, USA, 2006. Available online: www.apawood.org/Data/Sites/1/documents/technicalresearch/paper-2006-wcte-nail-withdrawal-and-pull-through.pdf (accessed on 10 March 2025).

- International Code Council Evaluation Service (ICC-ES). Structural Composite Lumber: 1.7E, 1.55E, 1.35E Durastrand Laminated Strand Lumber (LSL) and 1.5E, 1.3E, 0.8E Durastrand Oriented Strand Lumber (OSL); Evaluation Service Report 1053; International Code Council: Washington, DC, USA, 2024. [Google Scholar]

- Rao, R.R.; Mondy, L.A.; Long, K.N.; Celina, M.C.; Wyatt, N.; Roberts, C.C.; Soehnel, M.M.; Brunini, V.E. The kinetics of polyurethane structural foam formation: Foaming and polymerization. AIChE J. 2017, 63, 2945–2957. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Park, B.-D.; Lee, S.-M. Modification of urea-formaldehyde resin adhesives with blocked isocyanates using sodium bisulfite. Int. J. Adhes. Adhes. 2017, 73, 118–124. [Google Scholar] [CrossRef]

- Sałasińska, K.; Leszczyńska, M.; Celiński, M.; Kozikowski, P.; Kowiorski, K.; Lipińska, L. Burning Behaviour of Rigid Polyurethane Foams with Histidine and Modified Graphene Oxide. Materials 2021, 14, 1184. [Google Scholar] [CrossRef] [PubMed]

- Camino, G.; Costa, L.; Trossarelli, L. Study of the mechanism of intumescence in fire retardant polymers: Part III—Effect of urea on the ammonium polyphosphate-pentaerythritol system. Polym. Degrad. Stab. 1984, 7, 221–229. [Google Scholar] [CrossRef]

- Chanda, A.; Kim, N.K.; Wijaya, W.; Bhattacharyya, D. Fire reaction of sandwich panels with corrugated and honeycomb cores made from natural materials. J. Sandw. Struct. Mater. 2021, 23, 4196–4217. [Google Scholar] [CrossRef]

| Panel Type | Water Absorption at 24 h | Thickness Swell at 24 h | ||||

|---|---|---|---|---|---|---|

| Mean (%) | Standard Deviation (%) | Coefficient of Variation (%) | Mean (%) | Standard Deviation (%) | Coefficient of Variation (%) | |

| Control Panel | 44.38 | 6.4 | 14.4 | 15.54 | 1.96 | 12.6 |

| Re-Resinated Panel | 21.65 | 4.5 | 20.6 | 6.46 | 1.03 | 16.02 |

| Panel Type | Through Thickness Density | Internal Bond Strength | ||||

|---|---|---|---|---|---|---|

| Mean (kg/m3) | Standard Deviation (kg/m3) | Coefficient of Variation (%) | Mean (MPa) | Standard Deviation (MPa) | Coefficient of Variation (%) | |

| Control Panel | 683.6 | 123.1 | 18.01 | 0.76 | 0.15 | 19.4 |

| Re-Resinated Panel | 735 | 93.2 | 12.68 | 1.57 | 0.28 | 18.2 |

| Panel Type | Nail Withdrawal Strength | ||

|---|---|---|---|

| Mean (N/mm) | Coefficient of Variation (%) | Equivalent Specific Gravity | |

| Control Panel | 27.4 ± 6.4 | 23.27 | 0.43 ± 0.04 |

| Re-Resinated Panel | 35.4 ± 8.6 | 24.37 | 0.48 ± 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chanda, A.; Bakri, M.K.B.; Adhikari, R.; Yadama, V. Re-Resinated Wood Strand Panels: Enhancing Performance Through Waste Recycling. Sustainability 2025, 17, 4596. https://doi.org/10.3390/su17104596

Chanda A, Bakri MKB, Adhikari R, Yadama V. Re-Resinated Wood Strand Panels: Enhancing Performance Through Waste Recycling. Sustainability. 2025; 17(10):4596. https://doi.org/10.3390/su17104596

Chicago/Turabian StyleChanda, Avishek, Muhammad Khusairy Bin Bakri, Rajan Adhikari, and Vikram Yadama. 2025. "Re-Resinated Wood Strand Panels: Enhancing Performance Through Waste Recycling" Sustainability 17, no. 10: 4596. https://doi.org/10.3390/su17104596

APA StyleChanda, A., Bakri, M. K. B., Adhikari, R., & Yadama, V. (2025). Re-Resinated Wood Strand Panels: Enhancing Performance Through Waste Recycling. Sustainability, 17(10), 4596. https://doi.org/10.3390/su17104596