1. Introduction

Food packaging performs essential functions such as holding, protecting, facilitating handling, and conveying information [

1]. The protection function encompasses characteristics to reduce food losses and waste, such as mechanical protection, barriers against external agents, and thermal and sealing properties [

2]. However, packaging can suffer damage, compromising its protective function, which is to preserve the product against adverse weather conditions, crushing, and other undesirable situations. In addition, packaging design and product appearance are important factors to avoid the negative impact damages have on purchasing decisions [

3].

Traditionally, research in this field has explored sustainability by focusing on specific aspects such as material reduction or improved recyclability. For example, ref. [

4] proposed an environmental scoring tool for food packaging based on three pillars of sustainability: Materials, Functionality, and Post-Usage Fate. This tool was developed through a participatory process involving experts and end users, translating criteria into a scoring system ranging from 0 (worst) to 1 (best) for each pillar. Applied to three case studies—milk, sugar, and strawberries—the methodology highlighted the critical yet often overlooked role of packaging functionality in food preservation and waste reduction. The developed tool demonstrated accessibility for non-experts, such as food manufacturers and policymakers, offering practical indicators for selecting sustainable packaging options. Such approaches underscore the importance of integrating multiple dimensions of sustainability into packaging design, a perspective that remains underrepresented in contemporary research.

Similarly, ref. [

5] developed and validated a packaging innovation scorecard to assess the effectiveness of packaging innovation processes within a retail context, linking these processes to both cost and climate performance. Using a case study methodology with a major retail company, data collection involved semi-structured interviews, workshops, and observations. The results revealed the scorecard’s effectiveness in measuring the complexity of packaging innovation processes, identifying areas for improvement, and benchmarking company performance against best practices. While the scorecard showed promising usability and functionality, the study also emphasized the need for further validation of its long-term impact on action plan formulation and performance outcomes.

Food losses and waste are widely recognized as a significant threat to food security, economic stability, and environmental preservation [

6]. It is noteworthy that approximately one-third of all production intended for human consumption, equivalent to 1.3 billion tons of edible food, is wasted along the supply chain every year, which is enough to meet the food needs of approximately one-eighth of the world’s population suffering from malnutrition [

7]. Moreover, it represents a significant challenge for the global food demand, which is foreseen to increase to around 150 to 170% of the current need by 2050 [

8]. Addressing food waste is a critical component of the United Nations’ Sustainable Development Goal (SDG) 12, particularly target 12.3 [

9], which aims to halve per capita food waste by 2030 and minimize losses along the production and supply chain, reinforcing the need for sustainable actions globally.

Searching for progress in the food-loss-and-waste area, a preliminary study conducted on food waste in the European Union found that the largest proportion of food waste originates in households (42%), followed by the distribution sector (39%), food services (14%), and retail and wholesale sales (5%) [

10]. In Brazil, this waste revolves around 41,000 tons of food per day, triggered from production to final consumption, with 20% happening in planting and harvesting, 8% in transportation and storage, 15% in industrial processing, 1% in retail, and 17% in final consumption, amounting to nearly 30% of the food produced per year, i.e., 46 million tons [

11]. Ref. [

12] analyzed the problem of losses and waste of fruit, vegetables, and greens (FV) in Brazil, highlighting that these foods represent a significant part of the total annual waste. Quantitative data estimate that, specifically in this segment, up to 45% of FV production is lost along the supply chain, from harvest to final consumption, with not only economic losses but also environmental and social impacts, considering the volume of natural resources, such as water and land, used to produce these foods. In addition, the qualitative data highlight the importance of policies and practices aimed at valuing and consuming these foods, promoting awareness of the importance of healthy and sustainable eating.

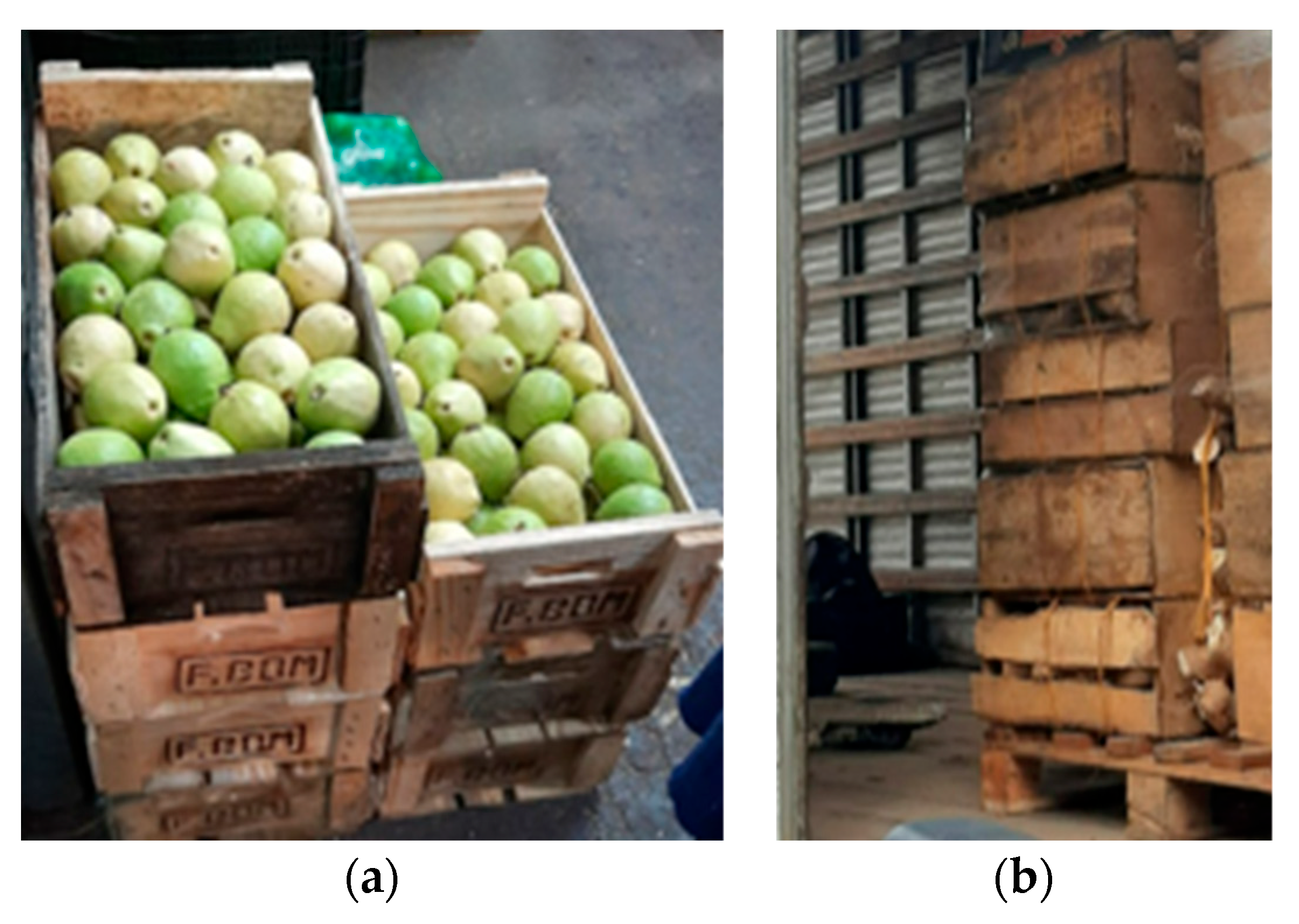

Although Brazil is one of the world’s largest producers of FV, the lack of comprehensive data on losses and waste hinders the formulation of effective strategies to mitigate their social, economic, and environmental impacts. Recent research has identified critical points in the supply chain, contributing to specific solutions. A study conducted by [

13] estimated that, over a decade, Brazil lost approximately 143.9 million tons of fruits. The research analyzed the stages of production, transportation, and commercialization, revealing that these losses are associated with factors such as inadequate packaging, inefficient handling, and precarious transportation. This significant volume of losses reflects not only economic waste but also negative impacts on the environment and food security. The authors emphasized the need for public policies aimed at implementing better logistical practices and developing technologies to reduce waste along the production chain.

Ref. [

14] presented alarming data on food waste in Brazil, estimating that approximately 27 million tons of food are lost annually. Of this total, 80% of losses occur during handling, transportation, and at supply centers. The study highlighted that inadequate infrastructure, such as insufficient refrigerated transportation and storage facilities, is one of the main factors contributing to these losses. Furthermore, the packaging often fails to provide the necessary protection to preserve FV quality, particularly during long-distance transportation. The author suggests that investments in infrastructure and the use of advanced packaging technologies could significantly reduce waste.

Ref. [

15] characterized logistical practices in the distribution of FV at the Campinas Supply Center (Ceasa) in São Paulo. The authors observed that the use of non-refrigerated transportation and inadequate packaging is directly associated with the loss of fresh products. The study also found that many foods are discarded due to physical damage or deterioration, exacerbated by inadequate storage and transportation conditions. The research reinforces the importance of interventions that promote the use of more durable and appropriate packaging, as well as improvements in logistical processes. Such actions could minimize losses along the supply chain while contributing to the sustainability of the food system.

Regarding the context of mitigating food waste by optimizing food packaging, ref. [

16] examined the issue of peanut shell disposal in Brazil, where this agro-industrial byproduct was often regarded as a low-value waste, leading to improper disposal and contributing to environmental pollution. The research proposed an innovative solution by transforming peanut shells, which constituted a significant portion of peanut production, into raw material for particleboard manufacturing. This approach not only mitigated disposal-related challenges but also enhanced the value of a material that would otherwise have been incinerated or discarded in landfills. By incorporating peanut shells into production processes, the study contributed to waste reduction and the promotion of sustainable practices in the region, fostering a circular economy that converted waste into valuable resources.

Ref. [

17] highlighted the importance of rationally designing packaging for food products to reduce the environmental impact of single-use plastics, especially in beverage packaging. The researchers explored reducing the use of plastics or the lifespan of products simultaneously, keeping open the possibilities of introducing innovative designs to the market and providing consumers with positive experiences. The study results demonstrated the effectiveness of the proposed computational framework for optimizing packaging design. It contributed to more sustainable development in the food industry and facilitated the simulation of coupled mass transfer. This process refers to the simultaneous modeling and analysis of mass transfer in packaging, considering how the interaction between various substances, such as through mass loss (e.g., evaporation of water or migration of compounds), affects the quality and shelf life of packaged food products.

Ref. [

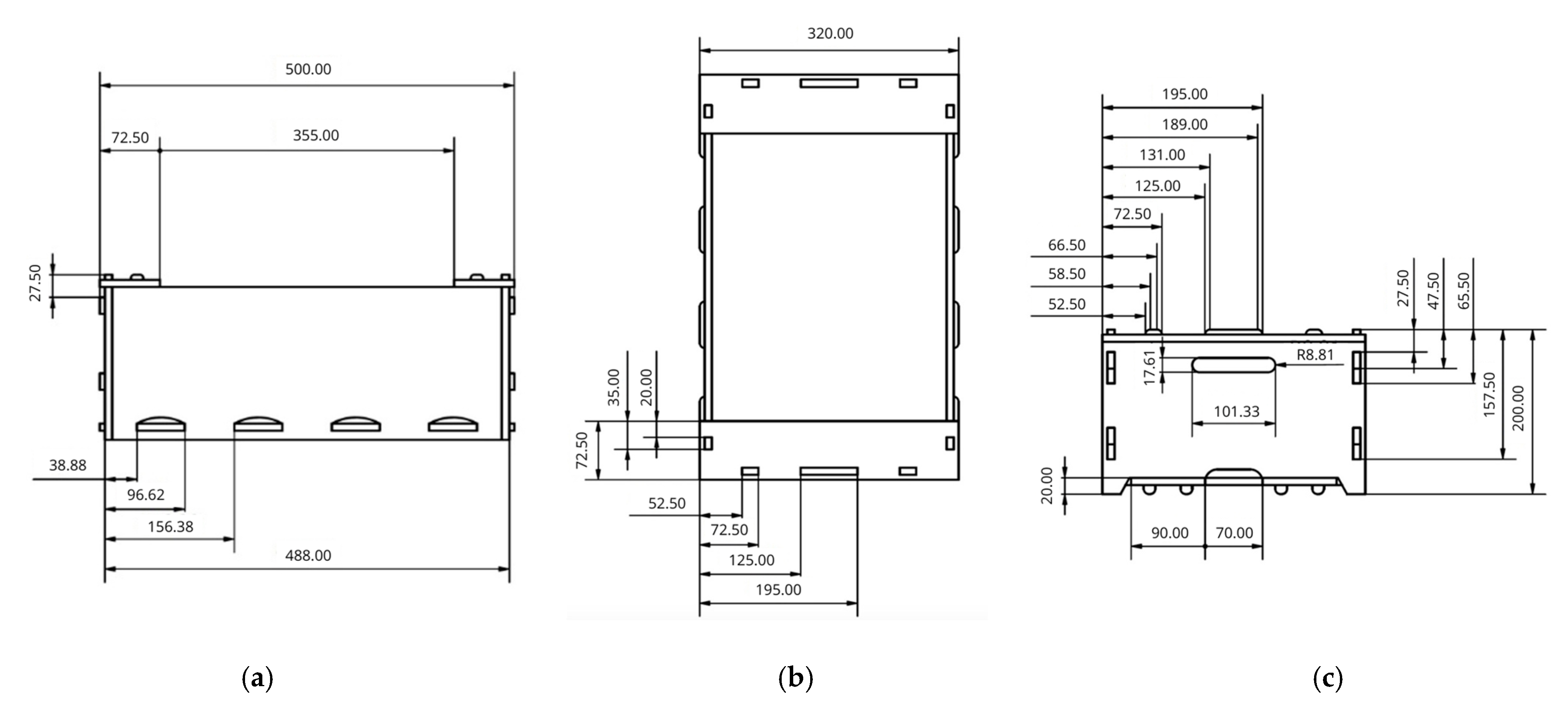

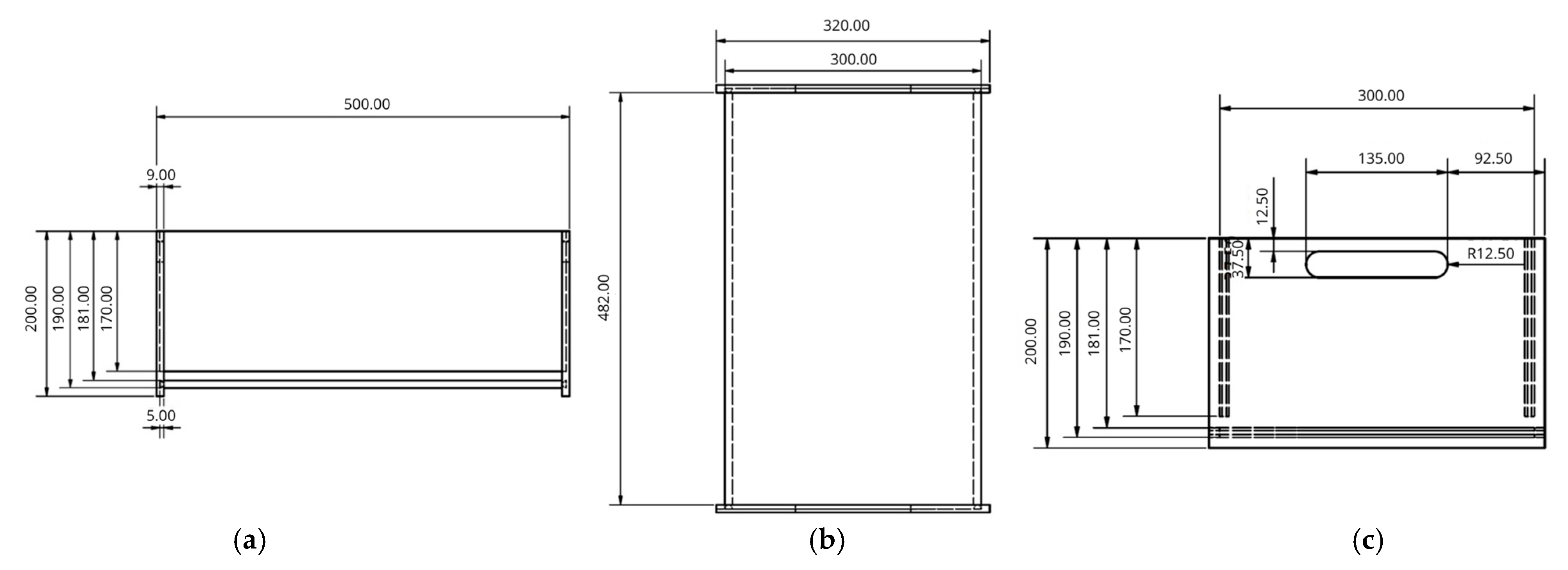

18] underscored the importance of developing packaging with effective ventilation to preserve the quality of fresh produce during transportation and storage. Using life cycle analysis, numerical modeling, and multi-scale approaches, the researchers emphasized the need to consider factors such as ventilation, temperature, humidity distribution, and the packaging’s mechanical strength. The authors’ results indicated that the numerical models and multi-scale approaches were essential for evaluating packaging performance, highlighting the logistical aspects, and manufacturing costs, such as the cooling efficiency, to develop quality ventilated packaging in the cold chain.

Ref. [

19] studied the need to improve the conservation of perishable products, such as fruit, during storage and transportation. The research focused on the influence of the design of ventilation holes in packaging boxes on their thermal performance. Using Computational Fluid Dynamics (CFD) modeling, different packing box configurations were evaluated experimentally and numerically. The ventilation holes in the packaging box configuration with the best thermal performance were strategically located, with specific dimensions and positions, and the packaging that showed the best results was the one whose fruit reached temperatures 1.5 °C to 5 °C lower than the other configurations after 8 h of cooling.

Ref. [

20], focusing on the adoption of sustainable packaging materials, carried out a case study that addressed the complexity of the current scenario in the food packaging industry, highlighting the importance of the packaging designs regarding the aspects of circular economy and sustainability. The authors reported a research gap on the subject and applied the Quality Function Deployment (QFD) method, a methodology that integrates consumer expectations and technical requirements through semi-structured interviews, allowing for the prioritization of customer needs, and the correlation between these needs and product characteristics. The results highlighted the importance of aspects such as “product identification”, “type of food product to be packaged”, and “robustness” for consumer expectations. The analysis revealed that by considering the different needs of users and food products, technical characteristics can be integrated efficiently, prioritizing product safety and considering its conformation in the packaging.

Aiming to identify and analyze the challenges of food packaging in the context of the circular economy, ref. [

21] conducted a systematic literature review highlighting the specific challenges that FV packaging presents, such as the need for compostable materials, which turn into humus and do not leave toxic residues when decomposed, becoming a more sustainable option. One given material example was wood, which is used to make cellulose packaging, presenting a more sustainable alternative to plastic, and promoting waste reduction and resource conservation in the food supply chain.

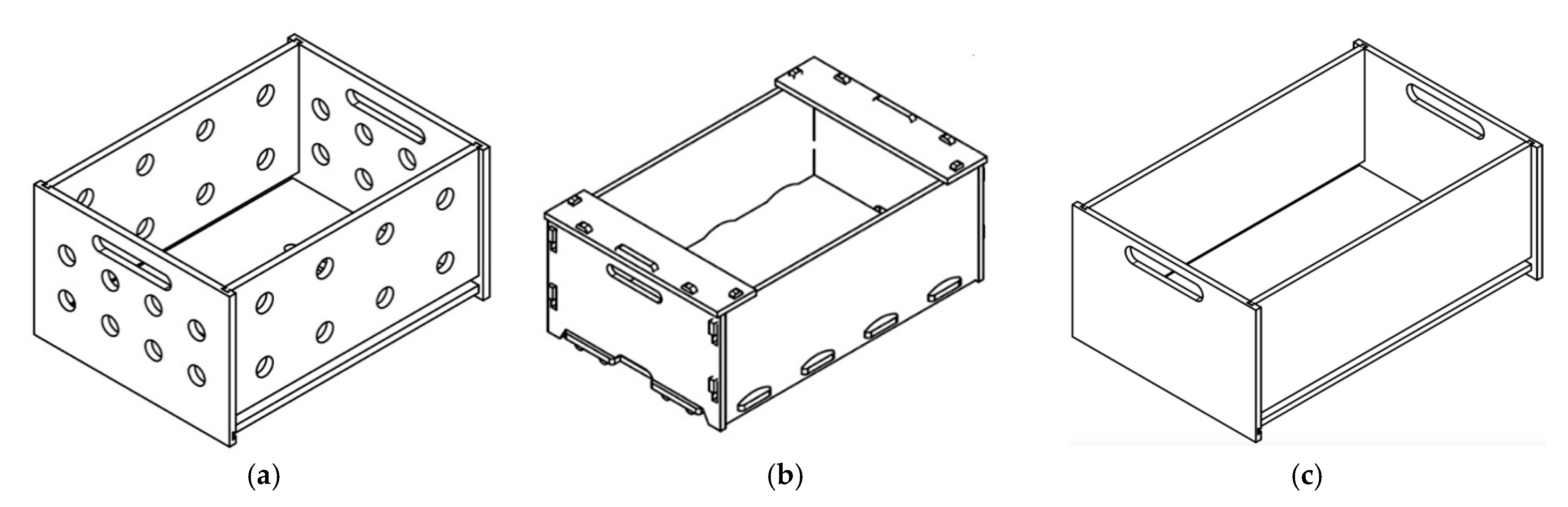

Despite the growing awareness of reducing losses and waste, there is still a lack of research focused in Brazil on food packaging innovation as a strategic solution within the food supply chain. Therefore, this study aimed to develop innovative designs for FV packaging to reduce losses and waste in the food transportation chain. The aim is to provide relevant knowledge that contributes to logistical efficiency, sustainability, and economy in the Brazilian food industry, offering a solid basis for future research and improved practices in the sector.

4. Conclusions

This study underscores the persistent challenges in the food supply chain arising from inadequate packaging design, as highlighted in the literature over the past decade. Key problems include the fragility of materials, lack of standardization, and limited consideration of ventilation and stacking stability, which collectively contribute to significant food losses. In response, this study developed five innovative packaging prototypes designed to mitigate the identified shortcomings. The designs incorporate standardized dimensions, enhanced structural integrity, and optimized ventilation, addressing both the functional and sustainability requirements of modern supply chains. The findings not only provide a viable solution to reduce food losses and waste but also contribute to advancing knowledge in the domain by bridging the gap between theoretical research and practical application.

Beyond packaging innovations, this research emphasizes the importance of training handlers and workers who interact with tertiary packaging. Proper techniques, understanding packaging limitations, and adherence to hygiene protocols are crucial to ensure these innovations achieve their intended impact. Training programs on the correct use, maintenance, and disposal of packaging can reduce damage, improve hygiene compliance, and enhance supply chain efficiency. Promoting a culture of responsibility and sustainability among handlers further contributes to minimizing food losses and waste.

Future research should explore the scalability and long-term impact of these prototypes, including their adaptability to various food types and their alignment with global sustainability goals. The methodologies and designs presented here lay a solid foundation for further innovations in food packaging, fostering a more resilient and efficient supply chain.