From General to Company-Specific Ecodesign Strategies: Developing Guidelines for Eco-Efficient Product Design Across the Entire Product Portfolio of an Appliance Company

Abstract

1. Introduction

2. Ecodesign for Life Cycle Environmental Impact Reduction

3. Guidelines for Designing a Range of Low-Environmental-Impact Domestic Appliances (SDA)

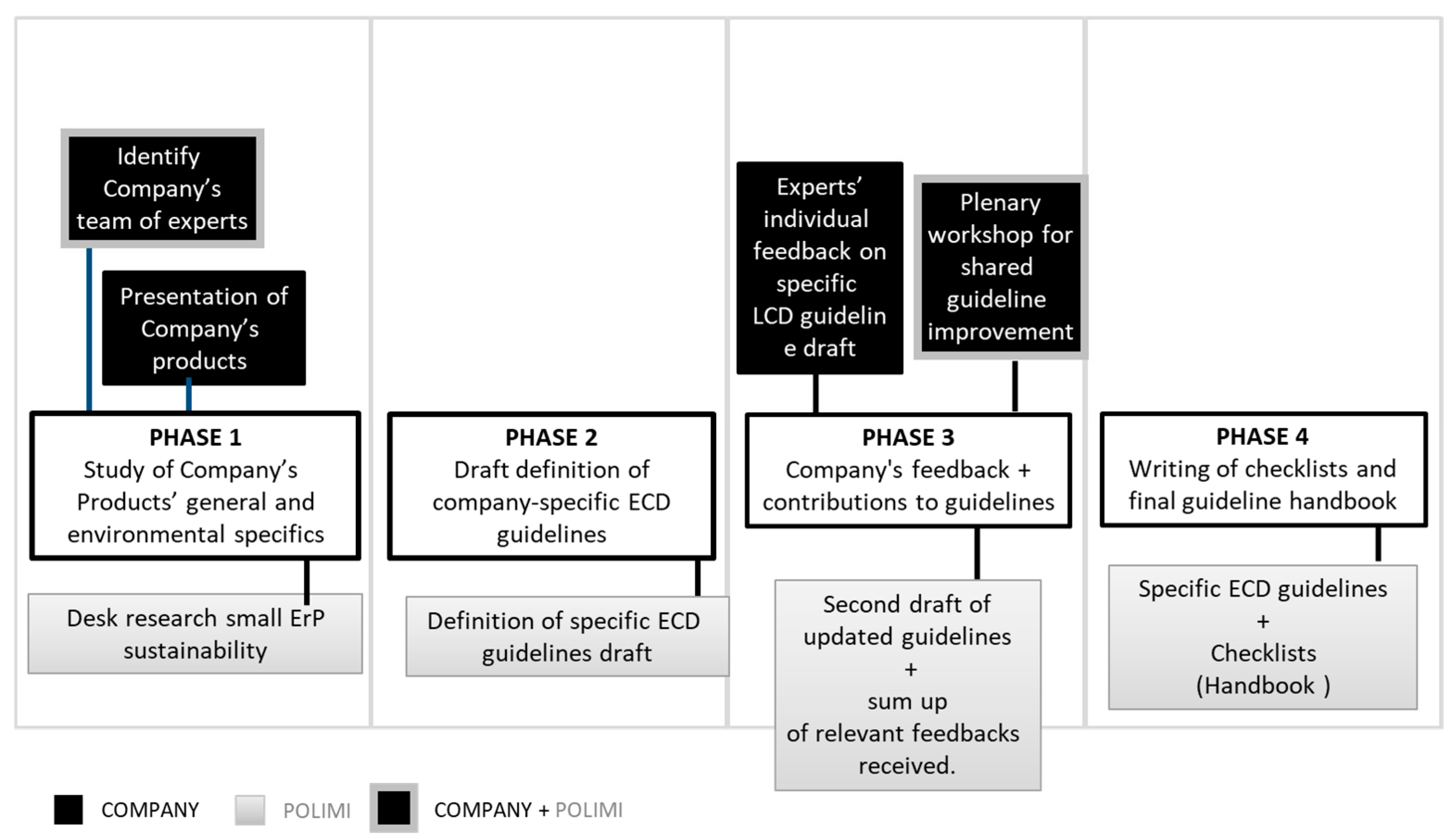

4. Method for the Development of Company-Specific Ecodesign Guidelines

- (1)

- Minimise material consumption;

- (2)

- Minimise energy consumption;

- (3)

- Minimise material toxicity and harmfulness;

- (4)

- Optimise material conservation/renewability;

- (5)

- Optimise product lifespan (lifespan extension, use intensification, reliability);

- (6)

- Extend material life (Facilitate material recycling, composting, and energy recovery);

- (7)

- Facilitate disassembly.

5. Results

6. Discussion

7. Conclusions

- Generalised scope: The guidelines developed are intentionally broad, to address a wide range of products, which limits their specificity and depth compared to one single product-specific Ecodesign approach.

- Lack of product-level detail: Unlike previous projects, which used the detailed disassembly and LCA of individual products, this approach does not offer tailored recommendations for each product type.

- Context-specific scope: As this study was developed within a single home appliance company, a broader application across other industries is needed to evaluate the framework’s generalisability.

- Lack of longitudinal impact assessment: This study does not include empirical data measuring the environmental or organisational impacts of the implemented handbook over time. Without longitudinal evaluation, the level of effectiveness of the tool in achieving sustained Ecodesign performance improvements remains to be assessed.

- Limited exploration of behavioural and organisational change factors: While the framework was implemented with executive support, this study does not systematically explore the behavioural, managerial, or cultural variables that mediate the successful adoption of Ecodesign tools within design teams.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Directive—2009/125—EN—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/dir/2009/125/oj/eng (accessed on 14 March 2025).

- ISO 14006:2020; Environmental Management Systems—Guidelines for Incorporating Ecodesign. ISO: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/72644.html (accessed on 16 February 2025).

- EU Commission. A New Circular Economy Action Plan. 2020. Available online: https://www.un.org/sustainabledevelopment/sustainable-consumption-production/ (accessed on 27 April 2025).

- EU Commission. Regulation (EU) 2024/1781 of the European Parliament and of the Council of 13 June 2024 Establishing a Framework for the Setting of Ecodesign Requirements for Sustainable Products, Amending Directive (EU) 2020/1828 and Regulation (EU) 2023/1542 and Repealing Directive 2009/125/EC (Text with EEA Relevance). 2024. Available online: http://data.europa.eu/eli/reg/2024/1781/oj (accessed on 9 May 2025).

- Ceschin, F.; Gaziulusoy, I. Design for Sustainability: An Evolutionary Review. In Future Focused Thinking, Proceedings of the DRS International Conference, Brighton, UK, 27–30 June 2016; Design Research Society: London, UK, 2016; Available online: https://dl.designresearchsociety.org/drs-conference-papers/drs2016/researchpapers/14/ (accessed on 14 March 2025).

- Brezet, J.; van Hemel, C.G. Ecodesign a Promising Approach to Sustainable Production and Consumption; UNEP: Paris, France, 1997. [Google Scholar]

- Tischner, U.; Ceschin, F.; Vezzoli, C.; Zhang, J. Design for Sustainability: Where are we and where do we need to go? In Sustainability in Design: Now; Greenleaf Publishing: Sheffield, UK, 2010. [Google Scholar]

- Manzini, E.; Vezzoli, C. Lo Sviluppo di Prodotti Sostenibili. I Requisiti Industriali dei Prodotti Industriali; Maggioli Editore: Rimini, Italy, 1998. [Google Scholar]

- ISO 14050:2020; Environmental Management—Vocabulary. ISO: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/75300.html (accessed on 2 April 2025).

- Tischner, U.; Schmincke, E.; Rubik, F.; Prösler, M. How to do EcoDesign?: A Guide for Environmentally and Economically Sound Design; Verlag Form: Frankfurt am Main, Germany, 2000. [Google Scholar]

- Vezzoli, C.; Manzini, E. Design for Environmental Sustainability; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Fiksel, J. Design for Environment: A Guide to Sustainable Product Development; McGraw-Hill Education: New York, NY, USA, 2009. [Google Scholar]

- Niemann, J.; Tichkiewitch, S.; Westkämper, E. Design of Sustainable Product Life Cycles; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Rossi, M.; Cappelletti, F.; Germani, M. Design for environmental sustainability: Collect and use company information to design green products. Procedia CIRP 2022, 105, 823–828. [Google Scholar] [CrossRef]

- Suppipat, S.; Hu, A.H. Achieving sustainable industrial ecosystems by design: A study of the ICT and electronics industry in Taiwan. J. Clean. Prod. 2022, 369, 133393. [Google Scholar] [CrossRef]

- Singh, P.K.; Sarkar, P. An Approach for Identifying and Customizing the Effective Ecodesign Tools for Environmentally Sustainable Product Development. In Proceedings of the ASME Design Engineering Technical Conference, Virtual, 17–19 August 2021; Volume 5. [Google Scholar] [CrossRef]

- Marconi, M.; Favi, C. Eco-design teaching initiative within a manufacturing company based on LCA analysis of company product portfolio. J. Clean. Prod. 2020, 242, 118424. [Google Scholar] [CrossRef]

- Rossi, M.; Papetti, A.; Marconi, M.; Germani, M. A multi-criteria index to support ecodesign implementation in manufacturing products: Benefits and limits in real case studies. Int. J. Sustain. Eng. 2019, 12, 376–389. [Google Scholar] [CrossRef]

- Rossi, M.; Germani, M.; Zamagni, A. Review of ecodesign methods and tools. Barriers and strategies for an effective implementation in industrial companies. J. Clean. Prod. 2016, 129, 361–373. [Google Scholar] [CrossRef]

- Vezzoli, C.; Sciama, D. Life Cycle Design: From general methods to product type specific guidelines and checklists: A method adopted to develop a set of guidelines/checklist handbook for the eco-efficient design of NECTA vending machines. J. Clean. Prod. 2006, 14, 1319–1325. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; Rozenfeld, H. Ecodesign Maturity Model: The ecodesign practices. In Design for Innovative Value Towards a Sustainable Society: Proceedings of EcoDesign 2011: 7th International Symposium on Environmentally Conscious Design and Inverse Manufacturing; Springer: Berlin/Heidelberg, Germany, 2012; pp. 424–429. [Google Scholar] [CrossRef]

- Luttropp, C.; Lagerstedt, J. EcoDesign and The Ten Golden Rules: Generic advice for merging environmental aspects into product development. J. Clean. Prod. 2006, 14, 1396–1408. [Google Scholar] [CrossRef]

- Knight, P.; Jenkins, J.O. Adopting and applying eco-design techniques: A practitioners perspective. J. Clean. Prod. 2009, 17, 549–558. [Google Scholar] [CrossRef]

- Domingo, L.; Buckingham, M.; Dekoninck, E.; Cornwell, H. The importance of understanding the business context when planning eco-design activities. J. Ind. Prod. Eng. 2015, 32, 3–11. [Google Scholar] [CrossRef]

- O’Hare, J.; Dekoninck, E.; McMahon, C.; Turnbull, A. Adapting innovation tools to the eco-innovation requirements of industry: Case study results. Int. J. Des. Eng. 2010, 3, 172. [Google Scholar] [CrossRef]

- Johansson, G. Incorporating environmental concern in product development: A study of project characteristics. Manag. Environ. Qual. Int. J. 2006, 17, 421–436. [Google Scholar] [CrossRef]

- Bey, N.; Hauschild, M.Z.; McAloone, T.C. Drivers and barriers for implementation of environmental strategies in manufacturing companies. CIRP Ann. 2013, 62, 43–46. [Google Scholar] [CrossRef]

- Dekoninck, E.A.; Domingo, L.; O’Hare, J.A.; Pigosso, D.C.A.; Reyes, T.; Troussier, N. Defining the challenges for ecodesign implementation in companies: Development and consolidation of a framework. J. Clean. Prod. 2016, 135, 410–425. [Google Scholar] [CrossRef]

- Waste from Electrical and Electronic Equipment (WEEE)—European Commission. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/waste-electrical-and-electronic-equipment-weee_en (accessed on 7 May 2025).

- Blessing, L.T.M.; Chakrabarti, A. DRM, a Design Research Methodology; Springer: London, UK, 2009. [Google Scholar] [CrossRef]

- Cramer, J.; Stevels, A. The unpredictable process of implementing eco-efficiency strategies. In Sustainable Solutions: Developing Products and Services for the Future; Routledge: Oxfordshire, UK, 2017; pp. 326–339. [Google Scholar] [CrossRef]

- Luttropp, C. Strategies and material flow in EcoDesign. In Innovation in Life Cycle Engineering and Sustainable Development; Springer: Dordrecht, The Netherlands, 2006; pp. 271–280. [Google Scholar] [CrossRef]

- Schiavone, F.; Pierini, M.; Eckert, V. Strategy-based approach to eco-design: An innovative methodology for systematic integration of ecologic/economic considerations into product development process. Int. J. Sustain. Des. 2008, 1, 29. [Google Scholar] [CrossRef]

- Köhler, J.; Geels, F.W.; Kern, F.; Markard, J.; Onsongo, E.; Wieczorek, A.; Alkemade, F.; Avelino, F.; Bergek, A.; Boons, F.; et al. An agenda for sustainability transitions research: State of the art and future directions. Environ. Innov. Soc. Transit. 2019, 31, 1–32. [Google Scholar] [CrossRef]

- Vezzoli, C.A. Design for Environmental Sustainability: Life Cycle Design of Products; Springer: London, UK, 2018. [Google Scholar]

- Yang, D.; Vezzoli, C. Designing Environmentally Sustainable Furniture Products: Furniture-Specific Life Cycle Design Guidelines and a Toolkit to Promote Environmental Performance. Sustainability 2024, 16, 2628. [Google Scholar] [CrossRef]

- Shove, E.; Walker, G. Governing transitions in the sustainability of everyday life. Res. Policy 2010, 39, 471–476. [Google Scholar] [CrossRef]

- Rotmans, J.; Loorbach, D. Transition management: Reflexive governance of societal complexity through searching, learning and experimenting. In Managing the Transition to Renewable Energy; Edward Elgar Publishing: Cheltenham, UK, 2008. [Google Scholar]

- Yström, A.; Agogué, M.; Rampa, R. Preparing an Organization for Sustainability Transitions—The Making of Boundary Spanners through Design Training. Sustainability 2021, 13, 8073. [Google Scholar] [CrossRef]

- Italia, M. Design-Led Sustainable Transition in Organization: A framework to guide and evaluate employee change. In Proceedings of the IASDR 2023: Life-Changing Design, Milan, Italy, 9–13 October 2023; pp. 1–19. [Google Scholar] [CrossRef]

- Bögel, P.; Pereverza, K.; Upham, P.; Kordas, O. Linking socio-technical transition studies and organisational change management: Steps towards an integrative, multi-scale heuristic. J. Clean. Prod. 2019, 232, 359–368. [Google Scholar] [CrossRef]

- Gaziulusoy, A.I. A critical review of approaches available for design and innovation teams through the perspective of sustainability science and system innovation theories. J. Clean. Prod. 2015, 107, 366–377. [Google Scholar] [CrossRef]

| Literature Reference | Scope and Focus | Methodology | Present Study Novel Contribution |

|---|---|---|---|

| Rossi et al. (2022) [14] | Structured company-specific data to improve Ecodesign practice in SMEs | Assessment framework linking internal product data to design decisions | Create actionable handbook and checklists for diverse products, not just data mapping |

| Suppipat et al. (2022) [15] | Applied Ecodesign to appliances using product-specific rule sets | Focused on energy-related products | Tackle multiple product types and usability across a firm’s product range |

| Singh and Sarkar (2021) [16] | Selected and tailored effective Ecodesign tools for sustainability | Framework identifying relevant Ecodesign tool criteria | Beyond tool selection, real-world implementation with customised hierarchical checklists |

| Marconi and Favi (2020) [17] | Ecodesign teaching initiative in industry: LCA-based educational framework for company-specific Ecodesign | Guidelines generated by Product portfolio LCA | Integrate knowledge generation with design practice tools in product development |

| Rossi et al. (2019) [18] | Structured repository of guidelines, best practices, and training material on Ecodesign | Five-step method to define objectives, assess and acquire knowledge, set strategies, and capitalise learning through designer feedback | Formalisation into a structured handbook ready to be used within development processes |

| Rossi et al. (2016) [19] | Systematic review of Ecodesign tools implementation barriers | Systematic literature review | Bridge theoretical gaps with practical implementation for companies with low-to-medium maturity in product sustainability |

| Vezzoli and Sciama (2006) [20] | Product type-specific guidelines: Life Cycle Design-based toolkits | Single-product type guideline | Extend this study to multi-product portfolios |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monticelli, E.; Vezzoli, C. From General to Company-Specific Ecodesign Strategies: Developing Guidelines for Eco-Efficient Product Design Across the Entire Product Portfolio of an Appliance Company. Sustainability 2025, 17, 4488. https://doi.org/10.3390/su17104488

Monticelli E, Vezzoli C. From General to Company-Specific Ecodesign Strategies: Developing Guidelines for Eco-Efficient Product Design Across the Entire Product Portfolio of an Appliance Company. Sustainability. 2025; 17(10):4488. https://doi.org/10.3390/su17104488

Chicago/Turabian StyleMonticelli, Enrica, and Carlo Vezzoli. 2025. "From General to Company-Specific Ecodesign Strategies: Developing Guidelines for Eco-Efficient Product Design Across the Entire Product Portfolio of an Appliance Company" Sustainability 17, no. 10: 4488. https://doi.org/10.3390/su17104488

APA StyleMonticelli, E., & Vezzoli, C. (2025). From General to Company-Specific Ecodesign Strategies: Developing Guidelines for Eco-Efficient Product Design Across the Entire Product Portfolio of an Appliance Company. Sustainability, 17(10), 4488. https://doi.org/10.3390/su17104488