Technical Insights into Crude Palm Oil (CPO) Production Through Water–Energy–Product (WEP) Analysis

Abstract

1. Introduction

2. Materials and Methods

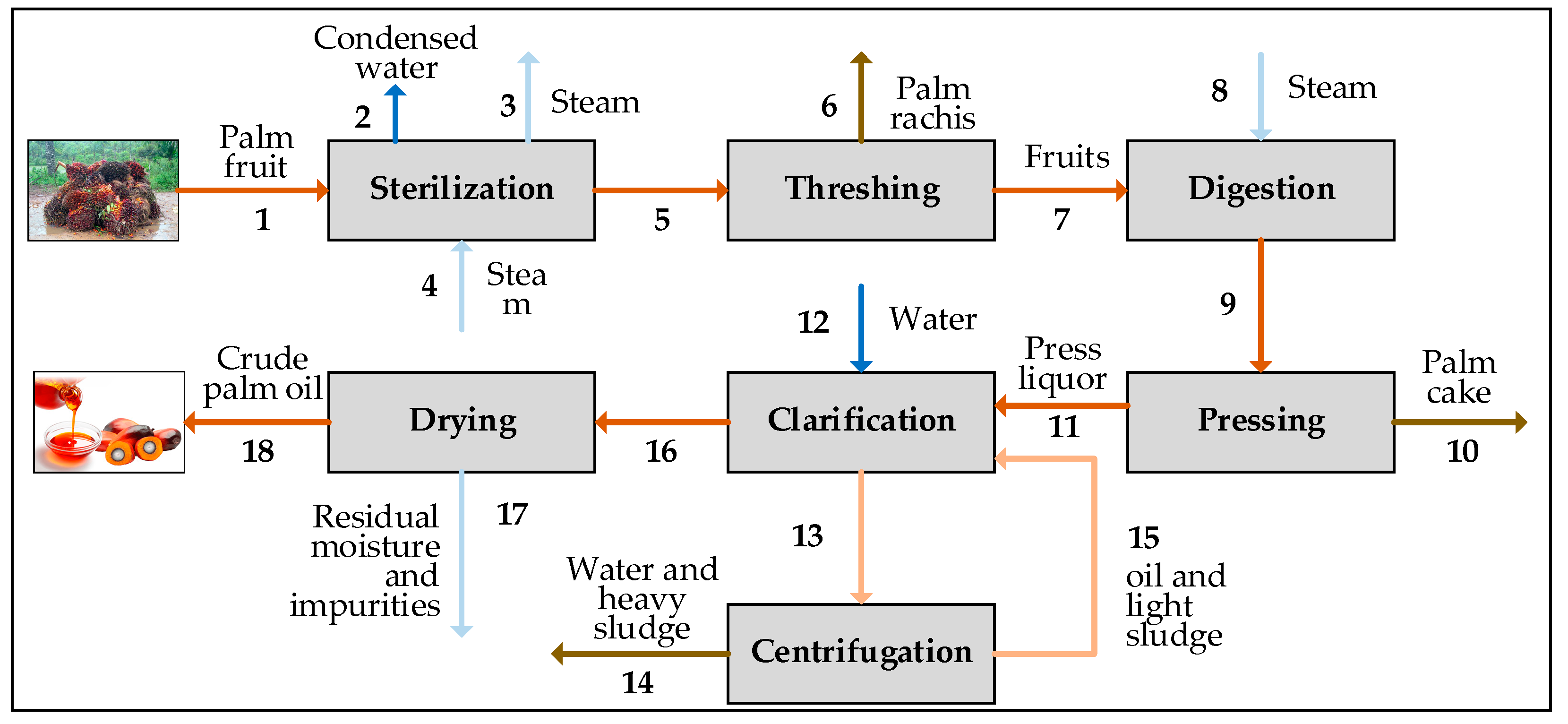

2.1. Process Description

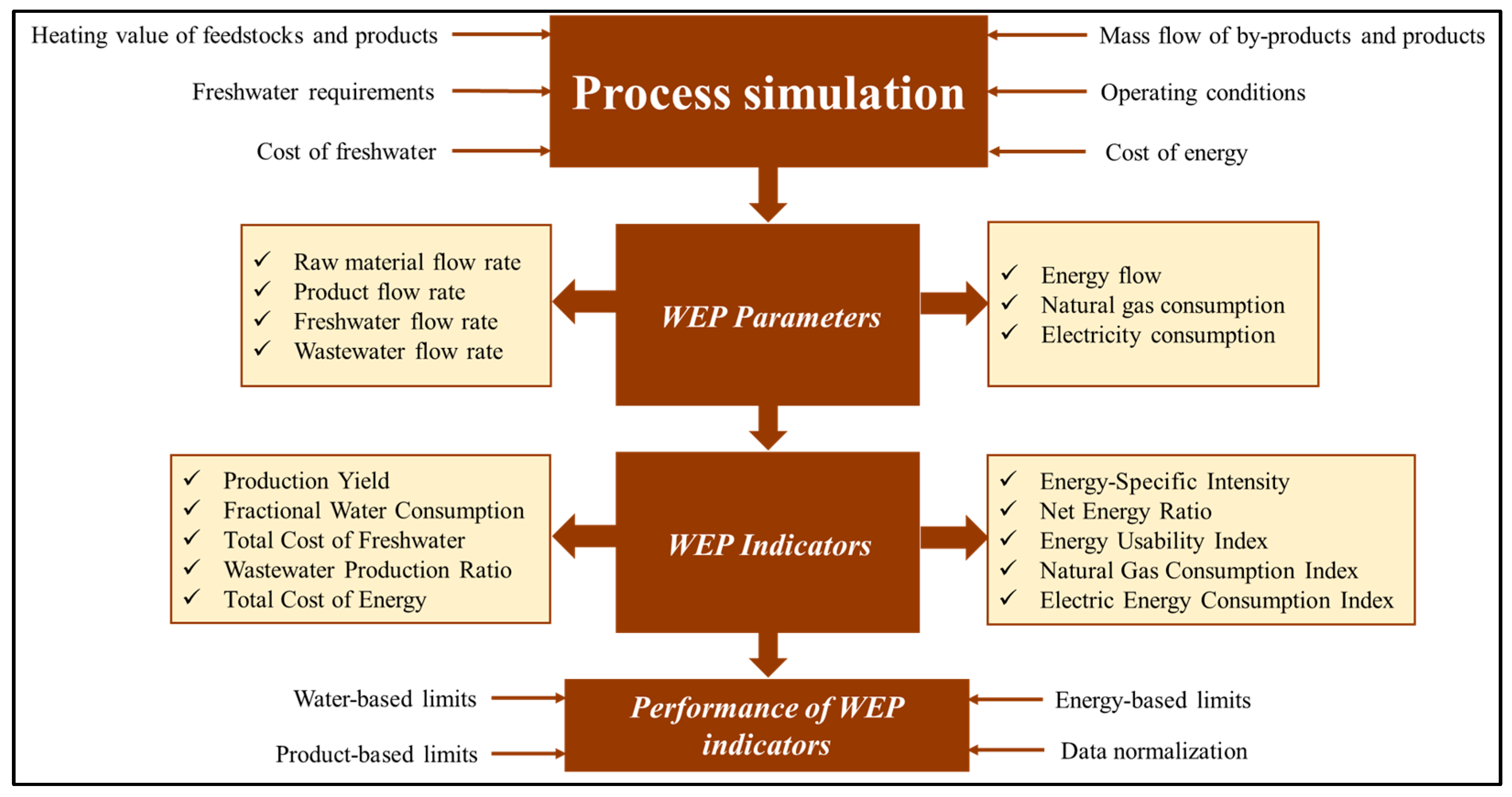

2.2. Technical Evaluation of the Crude Palm Oil Production via Water–Energy–Product (WEP)

3. Results and Discussion

3.1. WEP Technical Parameters and Indicators of the Crude Palm Oil Production

3.2. Performance of the WEP Technical Indicators of the Crude Palm Oil Production

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barriuso, B.; Astiasarán, I.; Ansorena, D. A review of analytical methods measuring lipid oxidation status in foods: A challenging task. Eur. Food Res. Technol. 2013, 236, 1–15. [Google Scholar] [CrossRef]

- Mba, O.I.; Dumont, M.J.; Ngadi, M. Palm oil: Processing, characterization and utilization in the food industry—A review. Food Biosci. 2015, 10, 26–41. [Google Scholar] [CrossRef]

- Berger, K.G. Palm oil. In Encyclopedia of Food Sciences and Nutrition; Elsevier: Amsterdam, The Netherlands, 2003; pp. 4325–4331. [Google Scholar]

- Sitepu, M.H.; Matondang, A.R.; Sembiring, M.T. Sustainability assessment in crude palm oil production: A review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 725, 012074. [Google Scholar] [CrossRef]

- Gourichon, H. Analysis of incentives and disincentives for palm oil in Nigeria. Gates Open Res. 2019, 3, 580. [Google Scholar]

- Inyang, J.; Andrew-Munot, M.; Tarmizi, S.; Shazali, S.; Tanjong, S.J. A model to manage crude palm oil production system. MATEC Web Conf. 2019, 255, 02001. [Google Scholar]

- Mohamad, F.; Mat Tahar, R. Measuring Palm Oil Mill Capacity Using Modelling and Simulation; UMPSA Institutional Repository: Pekan Pahang, Malaysia, 2010; Volume 1. [Google Scholar]

- Chin, C.M.; Ho, C.C. Surface active properties of palm oil with respect to the processing of palm oil. J. Oil Palm Res. 2000, 12, 107–116. [Google Scholar]

- Kabutey, A.; Herak, D.; Mizera, C.; Hrabe, P. Compressive loading experiment of non-roasted bulk oil palm kernels at varying pressing factors. Int. Agrophysics. 2018, 32, 357–363. [Google Scholar] [CrossRef]

- Nadzim, U.K.H.M.; Yunus, R.; Omar, R.; Lim, B.Y. Factors contributing to oil losses in crude palm oil production process in Malaysia: A review. Int. J. Biomass Renew. 2020, 9, 10–24. [Google Scholar] [CrossRef]

- Zulkefli, F.; Othman, N.; Syahlan, S.; Zaini, M.R.; Bakar, M.A. Fresh fruit bunch quality and oil losses in milling processes as factors that affect the extraction rate of palm oil. Int. J. Agric. For. Plant. 2017, 5, 99–103. [Google Scholar]

- Aguilar-Vásquez, E.; Ramos-Olmos, M.; González-Delgado, Á.D. A Joint Computer-Aided Simulation and Water-Energy-Product (WEP) Approach for Technical Evaluation of PVC Production. Sustainability. 2023, 15, 8096. [Google Scholar] [CrossRef]

- García-Maza, S.; Herrera-Rodríguez, T.C.; González-Delgado, Á.D. Process Simulation and Technical Evaluation Using Water-Energy-Product (WEP) Analysis of an Extractive-Based Biorefinery of Creole-Antillean Avocado Produced in the Montes De María. Sustainability. 2024, 16, 9575. [Google Scholar] [CrossRef]

- El-Halwagi, M.M. Sustainable Design Through Process Integration: Fundamentals and Applications to Industrial Pollution Prevention, Resource Conservation, and Profitability Enhancement; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Yusoff, S.; Hansen, S.B. Feasibility study of performing an life cycle assessment on crude palm oil production in Malaysia. Int. J. Life Cycle Assess. 2007, 12, 50–58. [Google Scholar]

- Subramaniam, V.; May, C.Y.; Muhammad, H.; Hashim, Z.; Tan, Y.A.; Wei, P.C. Life cycle assessment of the production of crude palm oil (part 3). J. Oil Palm Res. 2010, 22, 895–903. [Google Scholar]

- Martínez, D.; Puerta, A.; Mestre, R.; Peralta-Ruiz, Y.; Gonzalez-Delgado, A.D. Exergy-based evaluation of crude palm oil production in North-Colombia. Aust. J. Basic Appl. Sci. 2016, 10, 1–8. [Google Scholar]

- Arteaga-Díaz, S.; González-Díaz, J.; Pájaro-Morales, M.; Ojeda-Delgado, K.; Gonzalez-Delgado, A. Computer-Aided Exergy Analysis of a Palm Based-Biorefinery for Producing Palm Oil, Kernel Oil, and Hydrogen. Contemp. Eng. Sci. 2018, 11, 537–545. [Google Scholar] [CrossRef]

- Romero-Perez, J.C.; Vergara-Echeverry, L.A.; Peralta-Ruiz, Y.Y.; Gonzalez-Delgado, A.D. A techno-economic sensitivity approach for development of a palm-based biorefineries in Colombia. Chem. Eng. Trans. 2017, 57, 13–18. [Google Scholar]

- González-Delgado, A.D.; Peralta-Ruíz, Y.Y. Environmental assessment of a crude palm oil production process under North-Colombian conditions using WAR algorithm. Int. J. ChemTech Res. 2016, 9, 833–843. [Google Scholar]

- Herrera-Aristizábal, R.; Salgado-Dueñas, J.S.; Peralta-Ruiz, Y.Y.; González-Delgado, Á.D. Environmental evaluation of a palm-based biorefinery under North-Colombian conditions. Chem. Eng. Trans. 2017, 57, 193–198. [Google Scholar]

- Paul, O.U.; John, I.H.; Ndubuisi, I.; Peter, A.; Godspower, O. Calorific value of palm oil residues for energy utilisation. Int. J. Eng. Res. Innov. 2015, 4, 664–667. [Google Scholar]

- Patthanaissaranukool, W.; Polprasert, C.; Englande, A.J. Potential reduction of carbon emissions from Crude Palm Oil production based on energy and carbon balances. Appl. Energy. 2013, 102, 710–717. [Google Scholar] [CrossRef]

- Muhamad, H.; Subramaniam, V.; Hashim, Z.; Khairuddin, N.S.K.; May, C.Y. Water footprint: Part 1-production of oil palm seedlings in Peninsular Malaysia. J. Oil Palm Res. 2014, 26, 273–281. [Google Scholar]

- Hashim, Z.; Muhamad, H.; Chan, K.W.; Choo, Y.M.; Mohd Basri, W. Life Cycle Assessment for oil palm fresh fruit bunch production from continued land use for oil palm planted on mineral soil (Part 2). J. Oil Palm Res. 2010, 22, 887–894. [Google Scholar]

- Schwerter, C.; Yarur Sairafi, I. Water Resilience for Santiago de Chile. Managing Water for Economic Resilience: De-risking Is Not Enough; Alliance for Global Water Adaptation (AGWA): Corvallis, OR, USA, 2023. [Google Scholar]

- Saldarriaga, C.A.; Hincapié, R.A.; Salazar, H. A holistic approach for planning natural gas and electricity distribution networks. IEEE Trans. Power Syst. 2013, 28, 4052–4063. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Furnaces and Boilers. Energy.gov. 2025. Available online: https://www.energy.gov/energysaver/furnaces-and-boilers (accessed on 19 February 2025).

- Okafor, B.E. Development of Palm Oil Extraction System. Int. J. Eng. Technol. 2015, 5, 68–75. [Google Scholar]

- Corley, R.H.V.; Tinker, P.B. The Oil Palm; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Chungsiriporn, J.; Prasertsan, S.; Bunyakan, C. Minimization of water consumption and process optimization of palm oil mills. Clean Technol. Environ. Policy. 2006, 8, 151–158. [Google Scholar] [CrossRef]

- Subramaniam, V.; Hashim, Z. Charting the water footprint for Malaysian crude palm oil. J. Clean. Prod. 2018, 178, 675–687. [Google Scholar] [CrossRef]

- Niño-Villalobos, A.; Puello-Yarce, J.; González-Delgado, Á.D.; Ojeda, K.A.; Sánchez-Tuirán, E. Biodiesel and hydrogen production in a combined palm and jatropha biomass biorefinery: Simulation, techno-economic, and environmental evaluation. ACS Omega. 2020, 5, 7074–7084. [Google Scholar] [CrossRef]

- Khalid, A.; Suardi, M.; Chin, R.Y.S.; Amirnordin, S.H. Effect of Biodiesel-water-air Derived from Biodiesel Crude Palm Oil Using Premix Injector and Mixture Formation in Burner Combustion. Energy Procedia. 2017, 111, 877–884. [Google Scholar] [CrossRef]

- Tan, Y.D.; Lim, J.S.; Alwi, S.R.W. Optimal design of integrated palm oil complex with palm oil mill effluent elimination strategy. Chem. Eng. Trans. 2020, 78, 1–6. [Google Scholar] [CrossRef]

- Aziz, M.; Oda, T.; Kashiwagi, T. Design and analysis of energy-efficient integrated crude palm oil and palm kernel oil processes. J. Jpn. Inst. Energy. 2015, 94, 143–150. [Google Scholar] [CrossRef]

| Variable | Worst-Case Scenario | Best-Case Scenario |

|---|---|---|

| Yield | 0.00% | 100.00% |

| FWC | 17.80 m3/t | 1.20 m3/t |

| TCF | 2815.80 USD/day | 14.60 USD/day |

| WPR | 100.00% | 0.00% |

| TCE | 67,985.68 USD/day | 10,626.95 USD/day |

| ESI | 5514.38 MJ/t | 4735.25 MJ/t |

| NGCI | 0.00% | 92.03% |

| EECI | 100.00% | 7.97% |

| Parameter | Value |

|---|---|

| Raw material mass flow (kg/h) | 30,000.00 |

| Product mass flow (kg/h) | 5070.23 |

| Total freshwater volumetric flow (m3/h) | 12.06 |

| Total wastewater volumetric flow (m3/h) | 7.07 |

| Total electricity consumed (MJ/h) | 3024.00 |

| Total natural gas consumed (MJ/h) | 21,848.81 |

| Total energy consumed (MJ/h) | 24,872.81 |

| Indicator | Value |

|---|---|

| Yield (%) | 69.63 |

| WPR (%) | 58.64 |

| FWC (m3/t) | 2.38 |

| TCF (USD/day) | 347.33 |

| TCE (USD/day) | 13,235.95 |

| ESI (MJ/t) | 4905.66 |

| NGCI (m3/t) | 103,421.65 |

| EECI (kWh/t) | 165.67 |

| NER (Dimensionless) | 1.15 |

| EUI (Dimensionless) | 7.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Maza, S.; Rojas-Flores, S.; González-Delgado, Á.D. Technical Insights into Crude Palm Oil (CPO) Production Through Water–Energy–Product (WEP) Analysis. Sustainability 2025, 17, 4485. https://doi.org/10.3390/su17104485

García-Maza S, Rojas-Flores S, González-Delgado ÁD. Technical Insights into Crude Palm Oil (CPO) Production Through Water–Energy–Product (WEP) Analysis. Sustainability. 2025; 17(10):4485. https://doi.org/10.3390/su17104485

Chicago/Turabian StyleGarcía-Maza, Sofía, Segundo Rojas-Flores, and Ángel Darío González-Delgado. 2025. "Technical Insights into Crude Palm Oil (CPO) Production Through Water–Energy–Product (WEP) Analysis" Sustainability 17, no. 10: 4485. https://doi.org/10.3390/su17104485

APA StyleGarcía-Maza, S., Rojas-Flores, S., & González-Delgado, Á. D. (2025). Technical Insights into Crude Palm Oil (CPO) Production Through Water–Energy–Product (WEP) Analysis. Sustainability, 17(10), 4485. https://doi.org/10.3390/su17104485