1. Introduction

Global supply chains now operate under two main forces, which include the pressing need to reach sustainable development goals (SDGs) and fast-moving technological changes [

1]. Businesses now need sustainability transformation as an essential strategy since they experience increasing pressure from governments, consumers, investors, and international organizations. Supply chains must shift their focus from cost-driven models toward sustainability-based operations across environmental, social, and economic sectors because environmental damage, resource shortages, and social and economic inequality require this transformation [

2].

Major supply chain operations now transform through the introduction of Industry 4.0 technologies, including the Internet of Things (IoT), cyber–physical systems, and cloud computing [

3]. The implementation of digital technologies enables businesses to monitor their operations better while maintaining operational flexibility toward sustainable performance during worldwide crises. AI, along with advanced analytics, creates predictive insights through real-time optimization along with smarter resource allocation. Multiple technologies operating together make it possible to reshape supply chains as flexible, information-based, and environmentally friendly systems [

4].

Organizations normally find it challenging to develop structured evaluation methods to select important digital technologies alongside sustainability elements for their strategic planning processes [

5]. Virtual transformation initiatives have become common among firms, but their sustainability outcomes tend to remain undefined or show varying results. The complex nature of sustainable supply chain performance makes it difficult to evaluate because different criteria, such as environmental sustainability and economic and technological factors, must be balanced [

6]. Strategic decision-making relies on a methodical approach that allows decision-makers to evaluate and rank environmental, economic, and technological supply chain factors. The existing literature demonstrates expanding scholarship about Industry 4.0 together with AI applications in supply chains along with different conceptual models of sustainable supply chain management. Research has identified an essential shortcoming in using the Best–Worst Method (BWM) from multi-criteria decision-making (MCDM) approaches to establish sustainability-related driver priorities during digital transformation programs. The implementation of MCDM approaches for supply chain risk evaluation and performance assessment and technology selection exists in the research literature, but few studies evaluate how digital enablers boost sustainability in worldwide supply networks [

7].

The current methods fail to connect technological progress with sustainability while treating these fields as separate entities. Few research frameworks exist to establish systematic relationships between particular technologies like predictive AI or blockchain traceability, which support sustainability achievements. Poor coordination of investments and inconsistent sustainability results appear throughout the global supply chain network because of fragmented understanding of available insights [

8]. The objective of this paper focuses on connecting methodological shortcomings with knowledge gaps.

A Best–Worst Method-based (BWM) decision framework development and application system will be established in this research to determine and assess the critical sustainability-related elements of global supply chains that benefit from Industry 4.0 and AI applications [

9]. BWM provides an ideal solution for this situation because it offers optimized expert input management and decreased inconsistency alongside effective weight assessment with a minimal number of comparisons compared to traditional AHP procedures. The main objective behind this study analyzes the essential sustainability-related elements that appear in global supply chains after the implementation of Industry 4.0 and AI technological integration.

The following central research question guides this study: Which sustainability-related indicators, influenced by Industry 4.0 and AI technologies, should be prioritized in global supply chain performance?

This research makes several important contributions to the literature. The first contribution is to provide a novel integration of BWM with a sustainability–digital transformation framework in global supply chain contexts. Second, the evidence and methodology are offered to decision makers to help rank and prioritize the digital sustainability factors. Third, it helps to understand the relative magnitude of the enablers of supply chain performance that are enabled by AI and that are enabled by Industry 4.0.

From a practical perspective, the framework developed here can serve as a decision support tool to managers and policymakers when making data-supported, informed decisions of the type of technology to invest in and how to maintain product or service development in an eco-friendly manner [

10]. Second, it can also help steer the future of digital transformation roadmaps by multinational enterprises to promote sustainability performance metrics and strategic priorities [

11]. Firms can unlock greater value creation by aligning investment decisions with high-impact sustainability criteria and, hence, take care of long-term environmental and social responsibilities.

Overall, the ability to strategically prioritize sustainability related factors is needed as global supply chains experience unparalleled challenges and opportunities through digitalization. However, relatively little has been written about how the combination of Industry 4.0 and AI can affect a firm’s sustainable supply chain performance, and thus, this study aims to fill this gap via an application of the Best–Worst Method (BWM). The rest of the sections will provide a detailed review of the literature, methodological design, empirical findings, and the implications for academic inquiry as well as for managerial actions.

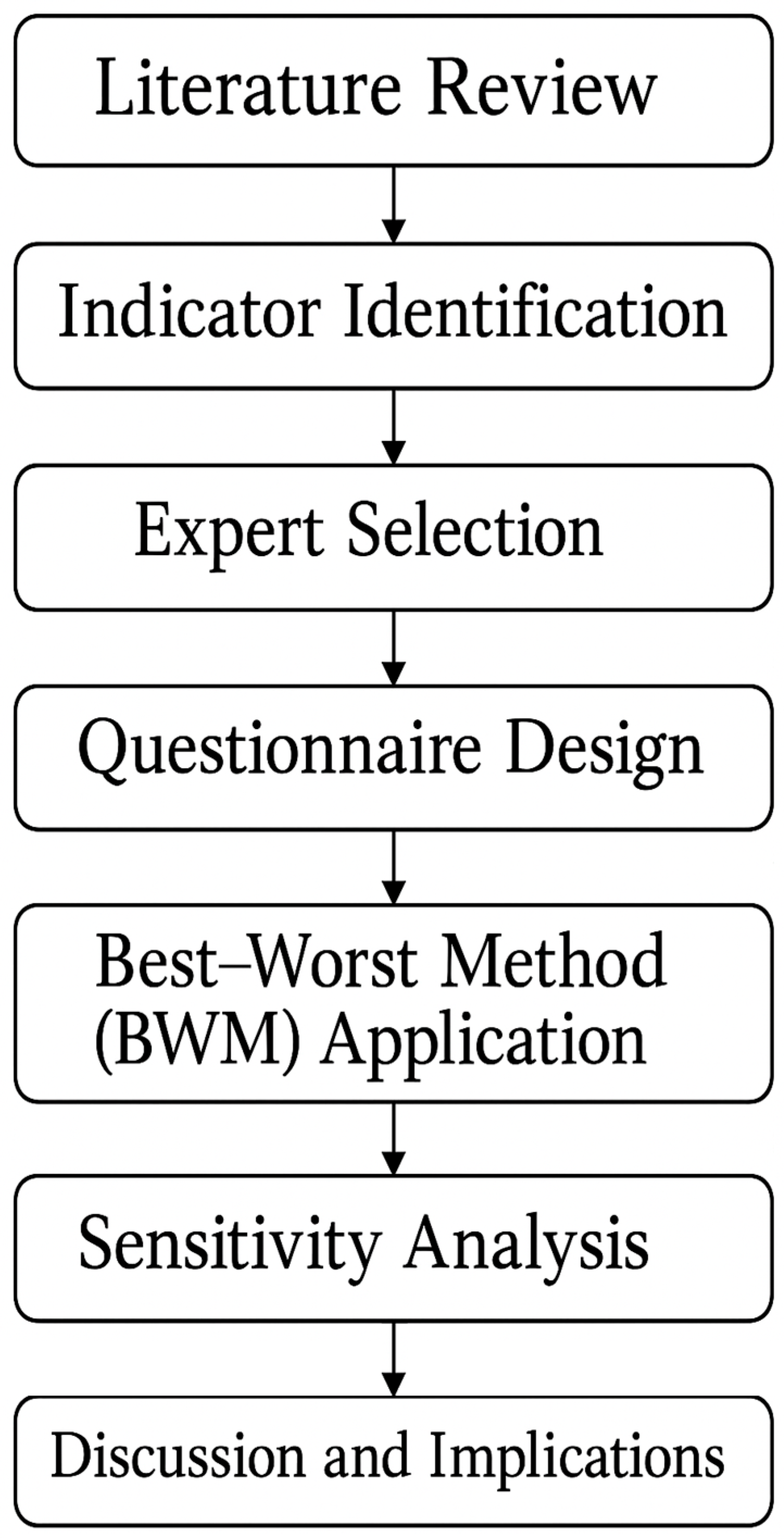

The remainder of this paper is structured as follows:

Section 2 provides a comprehensive literature review on the role of Industry 4.0 and AI in sustainable supply chain management and identifies key sustainability indicators.

Section 3 outlines the research methodology, including the application of the Best–Worst Method (BWM).

Section 4 presents the empirical results based on expert evaluations.

Section 5 conducts a sensitivity analysis to assess the robustness of the findings.

Section 6 offers a detailed discussion of the implications and contributions of this study. Finally,

Section 7 concludes this paper, outlines limitations, and provides directions for future research.

2. Background and Literature Review

In the past two decades, globalization, technological advancement, and heightened stakeholder expectations for transparency and sustainability dictate that global supply chains have gone into a new groove [

12]. Traditional models for supply chains were centered much on cost efficiency and lean operations and today they are not sufficient enough to cover up the multi-dimensional challenges of business ecosystems. In reaction, the concept of sustainable supply chain management (SSCM) has come to be held for the integration of environmental stewardship, economic performance, and social responsibility from the supply chain lifecycle [

13].

Within this evolving context, Industry 4.0 technologies have become important enablers to innovation and sustainability in the supply chain. Different from traditional technologies such as the Internet of Things (IoT), cyber–physical systems, additive manufacturing, big data analytics, and cloud computing [

14,

15], these technologies not only improve the visibility and responsiveness in supply chain operations but also enable cost reduction and improved efficiency. Furthermore, Artificial Intelligence (AI) brings advanced analytical capability, including predictive modeling, autonomous decision-making, and dynamic optimization to resource allocation, logistics, and inventory management [

16]. These technological capabilities come with the aim of achieving not only operational gains but also great environmental and social performance improvements for supply chains [

17].

There have been many studies of individual digital enablers that provide support for sustainability objectives [

5,

18]. For instance, IoT-based real-time monitoring and control systems have enabled the companies to reduce the raw material consumption and also result in the elimination of production inefficiencies [

19]. Intelligent automation and smart manufacturing systems monitor and adjust energy use to increase energy efficiency. It also supports circular economy integration through reuse, recycling, and remanufacturing of materials in a supply network [

20,

21]. Innovations other than these environmentally oriented ones include sustainable product design and emissions monitoring (also via data-driven platforms together with AI-enhanced analytics).

To contextualize these developments,

Table 1 summarizes key sustainability-related indicators influenced by Industry 4.0 and AI, categorized into environmental, operational, strategic, and social dimensions. These indicators are derived from the latest scholarly literature and reflect the multidimensional impact of digital transformation on supply chain sustainability.

Operationally, predictive maintenance, smart inventory management, and demand forecasting technologies all help minimize downtime, optimize the stock levels, and synchronize the supply with the demand, reducing operational waste [

17]. AI and geospatial data bring about logistics optimization that assists in more fuel-efficient routing and reduced emissions. In the meantime, product lifecycle management maintains product status from cradle (birth) to grave (death) so that companies can make decisions based on the entire value equation of the product, leading to better sustainability [

61]. Real-time product origins, certifications, and environmental impact are further boosts to the ethical and environmental compliance of the supply chain, and traceability further keeps the supply chain fully compliant [

62].

Technological developments such as those under Industry 4.0 also afford supply chain resilience at the strategic level, particularly in uncertain environments, which make supply disruptions quickly apparent and mitigated [

63]. AI allows organizations to make real-time decisions and manage risks to adapt in adequate time to changes in demand, supplier reliability, or regulatory constraints. Moreover, supplier collaboration and regulatory compliance platforms create a strategic alignment to sustainability goals by creating transparency, coordination, and legal compliance across geographies [

64].

Digital transformation also affects the social dimension of sustainability. Ideal workplace ergonomics, reducing injuries, and maintaining productivity are possible through human–robot collaboration [

65]. AI analytics facilitates sustainable consumption and promotes personalized and eco-friendly product recommendations to customers. It also helps companies become more ethical through technological support of ethical sourcing in its supply chains, which ensures that responsible labor practices and environmental compliance are provided. With the inclusion of these social and ethical considerations, the region of digital transformation continues to broaden the scope of the overall goals of comprehensive sustainability [

66].

These contributions have been well documented in respective areas but dispersed. While most studies examine one or two sustainability indicators in isolation, there are few that study together digital technology’s effects on them as a whole [

67]. Additionally, most of the studies that address multiple indicators do not rank them or evaluate the importance of each in terms of overall supply chain sustainability performance. Decision makers need a structured and equivalent evaluation framework to evaluate which digital investment would be most effective in helping to reach sustainability aims [

68].

Unlike previous studies that have often focused on isolated indicators or conceptual models, this study introduces a comprehensive and structured prioritization of twenty sustainability-related indicators influenced by Industry 4.0 and AI. These indicators are categorized into four key dimensions: environmental, operational, strategic, and social, providing a holistic and replicable framework for sustainability assessment in digitally transforming global supply chains. This multidimensional integration distinguishes the current investigation from earlier works and adds significant value to the literature.

To deal with such complexity, researchers have been resorting more and more to multi-criteria decision-making (MCDM) methods such as AHP, TOPSIS, and DEMATEL in order to make trade-offs and rank alternatives [

69,

70]. Nevertheless, these methods can be tedious, involve a large number of pairwise comparisons, and fail under consistency criteria in the expert setting. An alternative that is very promising and has a very low cognitive burden and full consistency in expert judgments is the Best–Worst Method (BWM) developed by Rezaei (2015) [

71]. The prioritization of digital technology-driven enablers for sustainability through BWM has not been applied in other supply chain contexts other than green supplier selection (Ghamari et al., 2022) and sustainability indicator assessment [

72].

There has been recent literature to assess the sustainability readiness and digital barriers in BWMs, e.g., Sohail and Gupta et al. (2024) and Haji Abadi and Darestani (2023), but most of the work has hence been on internal operations rather than a holistic take on how Industry 4.0 and AI will enable sustainability across a number of performance dimensions [

73,

74]. Furthermore, there is little exploration of how expert judgement can be systematically harnessed to guide the selection of such factors as priorities in the bounds of international, digitally transforming supply networks. It is also pronounced in view of the growing complexity of the global digital transformation and the immense importance of driving these efforts to be in line with sustainability strategies.

While prior studies have applied MCDM methods, including AHP, TOPSIS, and DEMATEL, to rank sustainability drivers in specific sectors or isolated dimensions, they often lack a cross-dimensional, holistic integration of environmental, operational, strategic, and social indicators. Furthermore, most existing studies do not prioritize indicators within the context of AI and Industry 4.0 jointly using BWM. For example, Ghamari et al. (2022) apply BWM to green supplier selection, but not across multiple sustainability dimensions [

72]. Similarly, Sohail and Gupta (2024) explore BWM in internal operations but without linking to broader supply chain transformations. This study fills that gap by developing a comprehensive, expert-validated BWM framework that simultaneously integrates four key sustainability dimensions influenced by digital technologies in global supply chains [

73].

Hence, the purpose is to enable the gap by developing a BWM-based framework to articulate and rank sustainability-related factors affected by Industry 4.0 and AI in global supply chains. This study provides a robust, evidence-based tool for strategic decision-making by synthesizing the most frequently cited indicators in the recent literature and soliciting the views of the expert stakeholders through structured comparison. It facilitates directing companies’ digital transformation activities to the maximum enablers of sustainable supply chain performance.

This research makes a theoretical contribution by extending the methodological application of BWM to a new domain and a practical contribution by offering actionable insights for policymakers, industry leaders, and supply chain strategists in the wake of digital innovation and sustainability. Finally, this work contributes to the global agenda to move toward resilient, transparent, and sustainable global supply chains.

3. Methodology

This study uses a mixed-methods research design, which consists of a qualitative expert elicitation alongside quantitative analysis utilizing the Best–Worst Method (BWM). Sustainability-related decision-making in the context of digital transformation, with its complexity and multidimensionality, lends itself to the use of the mixed-method approach. Both the qualitative component as well as the quantitative component facilitate expert-based identification and refinement of critical sustainability indicators from known data and, respectively, facilitate structured prioritization through BWM. The use of BWM is based on methodological strengths of BWM, such as lessening the number of pairwise comparisons involved in any other classical MCDM method, such as AHP, reducing inconsistency, and yielding more reliable weight measurements [

71].

A literature review was conducted on sustainability-related criteria and was refined by expert consultation to set options for the criteria. The first 20 sustainability indicators that are associated with Industry 4.0 and AI were initially collected from the literature of peer-reviewed articles, industry reports, and recent empirical studies, which are summarized in

Table 1. The indicators span across 4 thematic dimensions: environmental, operational, strategic, and social. Three domain experts reviewed the preliminary list to confirm contextual relevance, remove redundancy, and ensure clarity. Twenty main criteria related to the most important digital enablers of sustainable supply chain performance were listed as the final list.

For example, the BWM was applied with a purposive sampling to choose qualified experts who have significant knowledge on the areas of supply chain management, sustainability, and digital technologies. Some 37 experts of various academic research, industry practitioners, as well as consultants participated in this study. By ensuring diversity in professional backgrounds in terms of professors and their diversity of perspective (theoretical and practical), these participants were selected. This included sustainable supply chain design, digital transformation implementation, and supporting manufacturing, logistics, and agribusiness sectors.

Although the expert panel consisted of 37 individuals, this size is consistent with the existing MCDM literature, particularly in studies applying the Best–Worst Method (BWM). Similar expert-based studies in transport, logistics, and sustainability often employ sample sizes ranging from 15 to 40. For instance, Govindan et al. (2024) used 34 experts in a BWM-based evaluation of sustainable transport networks [

75], while Reefke and Sundaram (2017) demonstrated methodological robustness in BWM with similar sample sizes [

76]. These studies affirm the adequacy of our panel size for generating consistent, reliable prioritizations in expert-driven decision-making contexts.

The sample of 37 experts was selected using purposive sampling, targeting individuals with demonstrable experience in supply chain management, sustainability, and digital transformation. Participants included academics, consultants, and practitioners from multiple sectors such as manufacturing, logistics, and digital technology. This diversity ensured that the panel reflected a broad and balanced range of theoretical, practical, and industry-specific perspectives. The representativeness of the sample is therefore based on domain expertise, sectoral diversity, and relevance to this study’s thematic scope rather than statistical generalizability, which aligns with established norms in expert-based MCDM research.

The expert panel consisted of 37 participants with substantial experience in the fields of supply chain management, digital transformation, and sustainability. On average, the participants had 12.4 years of professional experience, with roles ranging from senior academics and researchers to supply chain consultants, operations managers, and digital transformation specialists. Experts were drawn from both academic institutions and private-sector firms across Europe, the Middle East, and Asia, ensuring a balanced perspective that integrates theoretical rigor with practical insights. This diversity was critical in achieving reliable, context-aware judgments for indicator prioritization.

Best–Worst Method

A decision-making process known as the “Best–Worst” Method typically involves evaluating the value or worth of various options in order to select the most advantageous one. To make an informed choice, it entails a thorough assessment of numerous variables, including cost, benefits, risks, and long-term effects. The “Best–Worst” Method seeks to balance a variety of conflicting priorities and goals, ultimately choosing the course of action that provides the highest overall value or return on investment. This technique is frequently used to make sure that decisions are in line with organizational objectives and provide the greatest benefit in complex decision-making situations, such as project selection, procurement, or resource allocation [

71]. The steps of the original BWM can be briefly described as follows:

Step 1: Establish a set of decision-making criteria (the decision maker does this): (c1, c2, …, cn).

Step 2: Rank the criteria by importance, choose the best (B) and the worst (W).

Step 3: Use a number between 1 and 9 to indicate how much the best criterion is preferred to the other criteria. The best-to-others (BO) vector is then shown as AB = (aB1, aB2, aB3, …, aBn), where aBn represents the preference of criterion CB over criterion Cn.

Step 4: Using a number between 1 and 9, calculate each criterion’s preference to the worst criterion. The others-to-worst (OW) vector is then shown as AW = (a1W, a2W, a3W, …, anW)T, where ajW denotes criterion cj’s preference over criterion cW.

Step 5: The objective of this step is to determine the weights of the criteria by minimizing the maximum absolute differences and for all j. To solve this problem, a min–max model, Model (1), is formed:

s.t.

Model (1) is equivalent to Model (2) by using ξ to denote the maximal deviation.

s.t.

The value of the ideal weight is discovered by solving Model (2) for each criterion. The criteria would be prioritized based on the weights that were obtained. Priority would be given to the criterion with the highest weight. The consistency ratio in this method ranges from 0 to 1, as determined by Equation (2). Higher consistency is indicated by a value nearer to 0.

Table 2 is used to calculate the consistency index in relation to the number of criteria. Given the benefits, the BWM has received more and more attention in recent years.

The aggregated results from all expert responses were used to derive global weights for the 20 criteria, which reflect their relative importance in enhancing sustainable global supply chain performance through Industry 4.0 and AI.

Structured online questionnaires developed specifically for BWM applications were carried out to collect the data. Templates for pairwise comparisons were provided along with instructions and definitions of each criterion for each questionnaire, and each questionnaire included instructions on the BWM procedure. The survey was conducted over four weeks, and follow-up clarification interviews were carried out when necessary to check the accuracy and consistency of expert judgments.

The Best–Worst Method (BWM) was individually applied to each expert’s responses, resulting in a unique set of local weights for each participant. To derive a single global weight for each indicator, we aggregated the individual weights using the arithmetic mean across all experts, which is a commonly accepted practice in MCDM studies. This approach ensures that all expert perspectives are equally represented in the final prioritization. Alternative aggregation techniques, such as geometric mean or consensus modeling, may be considered in future research to explore their influence on outcome stability.

Figure 1 presents the methodological framework of this study, outlining the sequential steps followed for the identification and prioritization of sustainability indicators using the Best–Worst Method (BWM).

4. Results

4.1. Environmental Group Indicator

The first type of indicators is environmental indicators. In this group there are six indicators.

Table 3 presents the results of the Best–Worst Method (BWM) analysis of the environmental sustainability indicators based on the average judgment of 37 experts. Among the six criteria of the environmental indicators, Emissions Monitoring and Reduction was the most crucial factor with the highest weight (0.286). This is reflective of an increased emphasis on regulatory compliance and the necessity for suppliers to keep a finger on the pulse of greenhouse gas emissions within the global supply chain. Also, Energy Efficiency (0.276) and Sustainable Product Design (0.276) were highly prioritized, which implies the need to incorporate digital tools during the product development phase to achieve energy optimization as well as eco-friendly innovation. However, Waste-to-Energy Initiatives (0.055) and Resource Efficiency and Waste Minimization (0.054) were endowed with lower degrees of weight, possibly because they are of higher implementation complexity or best short-term impact. The results yielded a computed consistency ratio of 0.0, which implies very reliable and consistent evaluations through the expert group. Translating findings into these structured environmental indicators adds priority to emissions and energy management in sustainable supply chain strategies under Industry 4.0 and AI integration.

4.2. Operational Group Results

The operational sustainability indicators results presented in

Table 4 indicate the aggregated evaluation from 37 expert participants using the Best–Worst Method (BWM) analysis. Supply Chain Traceability is the highest weighted among the six operational criteria assessed (weight of 0.288), signifying the growing need for visibility on accountability and real-time views of data across the supply networks. The second most influential factor was Smart Inventory Management (0.282), which underpins the significance of digital systems and AI in lean operation and minimizing resource waste. The second valued technique was Predictive Maintenance (0.259) to reduce downtime of the equipment and increase the operational efficiency through investigating proactive equipment monitoring. On the contrary, Logistics Optimization (0.058) and Product Lifecycle Management (0.057) were given lower weights, which might be justified by their longer implementation horizon as well as the involvement of external actors. The consistency ratio for this group was 0.0, indicating a high degree of coherence amongst the expert judgments. Operational sustainability in the digital age is therefore found to be highly dependent on visibility, data integration, and intelligent stock management systems.

4.3. Strategic Group Results

The results of the Best–Worst Method (BWM) analysis of strategic sustainability indicators as based on input from 37 experts are presented in

Table 5. In this, Supply Chain Resilience was clearly identified as the most influential factor and had a significant weight of 0.440. As more and more global uncertainties arise, including supply disruptions, geopolitical instabilities, and environmental risks, this accurately portrays it as playing a key role in preserving the continuity, agility, and steadiness of businesses in these inherently tumultuous conditions. With a weight of 0.314, Risk Management proved to be supportive in terms of proactively identifying and mitigating threats across the supply network. Next was Supplier Collaboration (0.110), reflecting the importance of partnership and cooperative making of decisions in creating resilient, sustainable operations. On the opposite side of the scale, Regulatory Compliance (0.073) and Real-Time Decision-Making (0.063) received lower weights, echoing that while important, they are not seen as the driving forces of strategic activity but as a way to better enable operations. With a consistency ratio of 0.0, we see that responses to this group are also high in consensus among the experts. Lastly, these results highlight the fact that strengthening resilience and managing risks remain top strategic priorities of sustainable supply chain transformation in a digital and AI era.

4.4. Social Group Results

Table 6 illustrates the analysis of social sustainability indicators via the Best–Worst Method (BWM) derived through the input of an expert. Overall, experts preferred Ethical Sourcing, with it obtaining the heaviest weight of 0.706. This illustrates the key role responsible and transparent procurement practices of a supply chain can play in developing a socially sustainable supply chain at a time when regulatory scrutiny and consumer calls for ethical accountability are on the rise. Human–Robot Collaboration carried a moderate weight of 0.176, as its increasing importance in worker safety and productivity in digital work environments is becoming more relevant. While customer-driven sustainability strategies remain important, they are considered to be downstream results of more general organizational ethics and labor standards; Customer Engagement (0.118) was ranked lowest. With a consistency ratio of 0.0, it showed highly reliable judgments by experts for this group. The results provide further support of ethical sourcing as an important foundational element in driving social sustainability in global supply chains.

Using the Best–Worst Method (BWM) across the four dimensions of sustainability (environmental, operational, strategic, and social) allowed for the application of a structured input of the importance of key indicators as determined by the experts. From an environmental perspective, Emissions Monitoring and Reduction and Energy Efficiency have become central elements of sustainability, while companies are relying on real-time data and intelligent systems to monitor and reduce the environmental footprint. The dominant factors observed in the operational group were Supply Chain Traceability and Smart Inventory Management, evidencing the importance of visibility and lean practices possible via Industry 4.0 technologies. In the strategy of capabilities, Supply Chain Resilience was by far the most critical capability, as disruptions were globally recognized as a concern and highlighted the need for a resilient and agile supply network. Finally, in the social dimension, Ethical Sourcing showed a clearly higher weight among competitor indicators, confirming the key place of this indicator in maintaining labor standards, assuring transparency, and follower trust.

Consistency ratios were zero across groups, which indicated high agreement amongst the expert participants, and they showed that the results were reliable. By differentiating the representation of indicators, this delivers a clearer understanding of the relations that Industry 4.0 and AI have to supply chain sustainable performance and hence actionable insights about how decision makers can promote digital transformation aligned with targeted sustainable results. These results underline the need for a well-thought-out, balanced but concentrated strategy at a global scale where emission, traceability, resilience, and ethics take center stage within sustainable global supply chain management.

5. Sensitivity Analysis

Sensitivity analysis is instrumental in validating the robustness of a multidimensional criteria decision-making (MCDM) model through assessment of how those input variations influence the output rankings. In order to assess the sensitivity of the Best–Worst Method (BWM) results to small changes in the responses of experts, the prioritization of sustainability indicators based on the four dimensions that include environmental, strategic, operational, and social dimensions was carried out with sensitivity analysis.

To conduct the sensitivity analysis, we selected one representative criterion from the environmental group Sustainable Product Design and systematically perturbed its input values by ±1 in both the Best-to-Others and Others-to-Worst vectors. All other criteria were held constant during each scenario. The BWM optimization model was then recalculated for each perturbation to assess the effect on the final weights.

The calculations are presented in

Table 7 below:

The results show, aside from slightly changing weights of some mid-ranked indicators, stable weights of the top-ranked indicators, including Energy Efficiency and Emissions Monitoring and Reduction. For instance, if we decreased the input by one unit for Sustainable Product Design, the indicator became totally unimportant; however, the ranking of the dominant indicators was not changed. Similarly, the top-ranking outcome did not change in an appreciable manner as the input value increased. The results imply that the changes in marginals on input to the BWM are not too sensitive to the prioritizations derived by the BWM.

In general, the sensitivity analysis validates the results of the prioritization and reinforces the validity of recommendations given to stakeholders. This additional step guarantees that the decision frame will be resistant to very slight uncertainties of the expert input and still provide consistent guidance for sustainable supply chain management in the process of Industry 4.0 and AI integration.

While this study adopted an equal-weight aggregation of expert responses for the Best–Worst Method (BWM), future studies could explore the impact of alternative weighting schemes on the prioritization outcomes. These include experience-based weighting, where more experienced experts receive greater influence; familiarity-based weighting, where self-rated knowledge is considered; and strict equal weighting for all participants. Such sensitivity analysis can be performed using weighted BWM aggregation frameworks as proposed by Rezaei (2015) and expanded by Haji Abadi and Darestani (2021) [

71,

74]. Incorporating respondent-weight variability may help uncover robustness in ranking outcomes under different cognitive or experiential perspectives and is recommended for future validation studies.

6. Discussion

A huge gap in the literature exists for the lack of a structured prioritization of factors related to sustainability due to the impacts of Industry 4.0 and Artificial Intelligence (AI) on global supply chain management, which is addressed by this study. While the enablers of virtual technologies have so far been identified as the means to transform environmental, operational, strategic, and social performance, very few such studies have operationalized their comparisons in a unified decision-making framework. Additionally, these dimensions are still dealt with in isolation in many previous works, and such an integrated approach is currently not available, which explicitly considers the interdependencies between these dimensions and their contextual relevance within supply networks.

The purpose of this study was to determine the main indicators that influence sustainability and to prioritize them through a structured multi-criteria evaluation process. A comprehensive literature review (CLL) and inputs from 37 domain experts resulted in the identification of 20 key indicators falling into four dimensions of sustainability, namely environmental, operational, strategic, and social. Each dimension of sustainability was separately evaluated and prioritized for each group, and a nuanced understanding of which factors are most important within each dimension could be achieved.

What the findings revealed was a clear disparity in prioritization. In the environmental dimension, Emissions Monitoring and Reduction and Energy Efficiency are high priorities, and hence, real-time tracking systems and intelligent energy management are sought. These results corroborate the studies of Hernández et al. (2024) and Fakhabi et al. (2024) in highlighting emissions control and optimal resource use as key digital sustainability outcomes [

77,

78]. Supply Chain Traceability and Smart Inventory Management in the operational dimension were the points of interest, further enriching previously published works by Liu et al. (2023) and Zhou et al. (2022) about the significance of transparency and inventory agility in decreasing waste and inefficiencies [

15,

79].

Based on that result, Supply Chain Resilience had the highest weight assigned to it, indicating that it would serve as an anchor of a digital sustainability plan, particularly considering the ground of recent disruptions to the world: the COVID-19 pandemic and geopolitical turbulence. This is in agreement with Das et al. (2022), propounding resilience as a future-ready supply chain capability [

80]. In this social dimension, Ethical Sourcing was extremely important, reflecting the continuing pressure on companies to fulfill human rights and environmental accountability in procurement practices, echoing the worries of Tandon et al. (2025) [

81].

This study makes several theoretical contributions to the literature on sustainable supply chain management and decision-making under digital transformation. First, it extends the application of the Best–Worst Method (BWM) to a multidimensional sustainability context influenced by Industry 4.0 and AI, where previous studies typically focused on narrower scopes such as green supplier selection. Second, it proposes an integrated framework that positions sustainability indicators not as isolated dimensions but as components within a digitally enabled, systemic transformation process. Third, it contributes to the theory of digital sustainability by empirically identifying and ranking enablers across environmental, operational, strategic, and social categories—offering a theoretical lens for prioritization. Finally, this study addresses a methodological gap in linking expert-based prioritization with structured, replicable decision-making under technological uncertainty. These contributions lay the groundwork for developing dynamic, sector-specific sustainability theories in global supply chain contexts.

Although the current research employed structured expert surveys to derive quantitative prioritizations using BWM, future studies could enhance the methodological richness by incorporating qualitative validation approaches. These may include in-depth expert interviews or case vignettes that provide contextual insight into how and why specific sustainability indicators are prioritized within different organizational or industry settings. This form of triangulation would not only deepen the interpretation of results but also enhance their practical relevance for specific supply chain contexts. Such mixed-method designs are increasingly recommended in MCDM research to bridge empirical generalization with contextual specificity [

82].

Overall, this research offers an integrative framework to address the key research questions: What factors about sustainability enhancements can be caused by Industry 4.0 and AI, and based on these, what factors can be prioritized in strategic decisions? Results reveal that all indicators have relevance; however, decision-making places the greatest value on emissions control, traceability, resilience, and ethics in digitization in relation to sustainability objectives. First, this research adds to the academic literature and provides a roadmap for locating digital enablers that support sustainable performance in global supply chains, and second, there are important practical lessons in this research as it reveals the dynamics between higher-order impacts and feedback processes among the integrated elements of international supply chains.

This study provides several actionable insights for managers and policymakers in global supply chains undergoing digital transformation. First, the prioritized indicators offer a practical roadmap for aligning digital investment with sustainability objectives—focusing on high-impact areas such as emissions monitoring, energy efficiency, supply chain resilience, and ethical sourcing. Second, the results help managers assess trade-offs and identify digital enablers that deliver both operational and environmental value. For instance, technologies that enhance supply chain traceability or enable predictive maintenance can also drive sustainability outcomes. Third, the indicator rankings can inform strategic planning and ESG reporting by helping organizations benchmark progress across key sustainability dimensions. Lastly, the BWM-based framework itself can serve as a decision-support tool, allowing firms to customize indicator weightings based on industry context or strategic focus. These findings support informed, data-driven decision-making for building resilient, future-ready, and sustainable global supply chains.

7. Conclusions

The aim of this study was to bridge a wide gap in the literature by structuring the prioritization of sustainability-related indicators pertaining to Industry 4.0 and Artificial Intelligence (AI) in the global supply chain network. While the relevance of digital technologies to sustainable development has been widely recognized, there are very few systematic empirical comparisons of these enablers using robust decision-making techniques. To tackle this, this study used the Best–Worst Method (BWM) to obtain responses from 37 experts that stored the evaluation and order of 20 key sustainability indicators in four dimensions: environmental, operational, strategic, and social.

There was a clear emphasis in each ranking. Emissions Monitoring and Reduction and Energy Efficiency were considered the most important environmentally, indicating the necessity of decarbonization and sustainable energy practices. In operation, Supply Chain Traceability and Smart Inventory Management turned out to be critical to making visibility and waste elimination possible. Supply Chain Resilience emerged as the most strategic enabler, highlighting its leading role in enabling uncertainty and continuing to operate on the global scale. Ethical Sourcing received overwhelming social approval, so there was a clear demand for responsible and transparent procurement.

These findings offer valuable guidance for policymakers, industry leaders, and sustainability officers. Governments aiming to foster green and digital transitions should prioritize investments and regulations that promote emissions-monitoring technologies, resilient infrastructure, and ethical supply chain practices. For private-sector stakeholders, the results provide a decision-support tool to align digital transformation initiatives with targeted sustainability outcomes. Firms can use the ranked indicators to prioritize technology adoption, supplier engagement, and resource allocation in ways that generate both environmental and economic value.

Although this study adopts a generalizable, cross-sectoral framework for prioritizing sustainability indicators, future research could contextualize the findings by applying the methodology to specific industries such as healthcare, retail, or aviation. Such sectoral studies would validate the robustness of the framework and offer additional managerial insights tailored to distinct operational environments.

Despite its contributions, this study has several limitations. First, the prioritization of sustainability indicators is based on aggregated expert judgments, which, although consistent and well-informed, may reflect contextual biases linked to specific sectors or regions. Second, the analysis focused on twenty key indicators derived from the literature and expert validation; expanding this scope to include sub-criteria or emerging indicators could provide further insights. Third, the BWM methodology assumes independence among indicators. However, in practice, many indicators, such as energy efficiency and emissions reduction, are interdependent or exhibit trade-offs. Future research could apply hybrid MCDM approaches, such as BWM-DEMATEL or BWM-ANP, to capture these interrelationships and model systemic dynamics. Finally, longitudinal studies may help uncover how indicator priorities evolve over time in response to technological innovation and regulatory change.

Another promising avenue for future research involves adopting a longitudinal perspective. As sustainability priorities are shaped by evolving technological capabilities and regulatory developments, such as the EU Artificial Intelligence Act or emerging digital product regulations, the relative importance of indicators may shift over time. Longitudinal expert tracking, wherein expert judgments are reassessed periodically, could help capture these dynamics. Alternatively, dynamic extensions of the Best–Worst Method (e.g., time-series BWM or adaptive weighting schemes) may enable more responsive decision frameworks. Such methods would enhance the real-world applicability of sustainability indicator prioritization in rapidly transforming supply chain environments.

This study opens several promising avenues for future research. First, longitudinal studies could examine how indicator priorities evolve over time due to changes in technology, policy, or organizational learning. Second, the BWM framework can be expanded through hybrid models such as BWM-ANP or BWM-DEMATEL to incorporate interdependencies among indicators. Third, sector-specific applications (e.g., healthcare, retail, or logistics) can help contextualize the findings and validate the framework across industry settings. Fourth, the use of dynamic MCDM techniques or fuzzy logic could enhance the model’s adaptability to uncertain or imprecise expert input. Lastly, future work could explore cross-country comparisons to account for regional policy differences and institutional pressures in shaping sustainability priorities. Together, these directions will support a more nuanced, scalable, and context-sensitive understanding of sustainable digital supply chains.

In conclusion, this research offers a replicable and robust framework for identifying the most impactful sustainability enablers in the digital supply chain era. By quantifying expert consensus through BWM, it advances both the academic understanding and practical application of sustainability performance measurement in digitally transforming supply chains. Future research and policy development should continue to integrate digital, environmental, and social innovations to support resilient, responsible, and future-ready global value networks.