Abstract

This paper presents an algorithm for evaluating the environmental impact of clothing swaps, promoting extended use and responsible consumption. Implemented in an online swapping platform, the algorithm quantifies reductions in environmental impact due to extended clothing lifespan and avoided purchase of new garments, promoting swapping activities. Developed through scientific literature analysis, life cycle assessment (LCA), and swapping practice studies, the algorithm uses the following key environmental indicators: carbon footprint, water use, energy consumption, and land use. It integrates consumer behavior insights and uses both default and user-entered clothing data to calculate environmental savings. Results show that clothing impact varies by fabric. Viscose and polyester clothing have the lowest environmental impact, while swapping cotton and wool items yields the highest savings, as these materials are more resource intensive. The platform-integrated algorithm recorded 251 swaps over two months, preventing 4203 kg CO2 emissions, 6813 m3 of water use, 3118 m2a crop eq of land use, and 88.79 GJ of energy consumption. These findings highlight the significant environmental benefits of prolonging clothing use through swapping.

1. Introduction

The textile industry is a significant contributor to environmental pollution, with each stage of a piece of clothing’s life cycle producing different types of pollutants. This impact stems from the high consumption of natural resources and energy, extensive use of chemicals, water pollution, greenhouse gas emissions, and waste generation [1,2,3]. The supply chain of textiles is extensive and complex, with substantial environmental impacts that differ according to fabric type, covering raw fiber, yarn, and fabric production, clothing manufacturing, use, and end-of-life (EoL) stages. Fiber production alone can account for up to 60% of a clothing’s total environmental footprint, while the use phase—particularly laundering—can contribute 20–30% of energy and water consumption over a piece of clothing’s life cycle. Fast fashion accelerates these impacts, with over 92 million tons of textile waste generated annually and significant emissions tied to rapid production and disposal cycles. Additionally, synthetic textiles contribute to microplastic pollution during use and at EoL [4,5,6,7].

In more detail, raw cotton fiber production involves cotton cultivation and the use of agrochemicals, which contribute to water consumption, land use, and terrestrial ecotoxicity [8,9]. Polyester yarn and fabric production, on the other hand, significantly contributes to global warming potential and fossil resource scarcity because the spinning and weaving stages are energy-intensive [8,10]. Dyeing and finishing processes of all kinds of fabrics may be particularly harmful, releasing persistent coloring pollutants, heavy metals, and other toxic chemicals into water bodies, leading to high chemical oxygen demand and biochemical oxygen demand—in wastewater [11]. The textile industry is a major source of microfiber pollution, which occurs during synthetic yarn and fabric production, use, and disposal, posing a growing environmental risk [12,13]. The use phase of textile products also contributes significantly to environmental impacts, particularly through water use, energy and chemicals consumption, and CO2 emissions, which are influenced by consumer behavior such as washing and drying practices [14,15,16]. The EoL stage further adds to the environmental burden, especially if textile waste ends up in landfills [4]. Reuse and recycling are proposed as the best options for EOL while reuse has significant environmental savings compared to recycling [4,17].

The rise of fast fashion has not only increased consumption rates but also altered perceptions around clothing longevity and value, leading to a culture of disposability that exacerbates waste generation and resource depletion [18].

The linear model of production and consumption affects negatively the environment [19] and efforts to mitigate it include the development of sustainable practices such as eco-labeling, which encourages the production and consumption of eco-friendly textiles [3]. Innovative recycling and circular economy models are being explored to reduce resource use and waste, however, challenges remain in achieving their widespread adoption [20,21].

According to [4,22], life cycle assessment (LCA) is crucial for understanding and reducing the environmental impacts of clothing, guiding towards more sustainable practices. Also, LCA is a critical method providing a holistic view from raw materials to EOL stages [23,24]. LCA’s ability to provide detailed insights into each stage of the textile production process, such as fiber production, yarn manufacturing, and fabric dyeing, makes it invaluable for identifying environmental hotspots and potential areas for improvement [8,25]. Moreover, LCA supports the transition towards circular economy practices by evaluating the benefits of recycling and reuse, which are essential for reducing the environmental footprint of textiles [24].

The European Commission has adopted the EU Strategy for Sustainable and Circular Textiles to extend clothing life-cycle loops via reuse and repair activities [26,27]. For instance, business models that focus on selling secondhand clothes or renting clothing can effectively displace the need for new clothing, thus decreasing the environmental burden of production processes [28].

According to [29,30], the transition to a circular economy in the textile industry that involves recycling and reusing materials can mitigate environmental impacts by reducing water stress, the need for virgin resources, fossil fuel consumption, and pollution through greenhouse gas emissions and waste. Increasing the lifespan of clothing can dramatically reduce these impacts [5,31] because extending textile use requires less frequent replacement and, thus, lower overall impacts [32]. Thus, reuse models are crucial to mitigate environmental impacts and promote sustainability within the textile industry.

The reuse practices of selling, renting, repairing, and swapping used clothes each offer distinct approaches to extending the lifespan of clothing and reducing environmental impacts, yet they differ significantly in their implementation and consumer engagement [33]. Used clothes reselling involves selling pre-owned clothing through physical or online stores including monetary transactions [34]. Renting practice allows consumers to temporarily use clothing items for a fee. It appeals to those interested in clothing variety without the commitment of ownership [34,35]. Repairing clothes encourages consumers to maintain and care for their clothing, though it requires a shift in consumer behavior towards valuing longevity over newness [36]. Swapping involves exchanging clothing items with others for free, often facilitated by events or online platforms without purchasing new items, often informally. It is driven by social interaction but can be limited by unfamiliarity and materialism [37,38].

One way to encourage consumers to adopt one or another reuse option is to demonstrate the environmental benefits of doing so. This requires having targeted calculation tools and presenting them in a way that is acceptable to consumers.

The examples of existing calculators are the RREUSE tool, the Consumer Donations Calculator, and the Textile Eco Calculator, which are integrated into the websites of organizations engaged in reuse: social enterprise network RREUSE [39], charitable organization Charitable Reuse Australia [40], and textile waste management company group TexCycle [41], respectively. These websites perform educational work, providing consumers with opportunities to check the possible reduction in environmental impact when choosing used clothing over new. Another example is the used clothing resale platform ThreadUp [42], where the environmental impact is measured on the scale of an entire personal wardrobe using the Fashion Footprint Calculator. Here reuse is just one of the aspects evaluated, and the result is not presented separately. The impact of a wardrobe is similarly assessed using the Personal Fashion GHG Footprint Calculator on the website of consulting company GreenStitch‘s [43], where, for educational purposes, clients can learn about the environmental (greenhouse gases emissions/carbon footprint) impact of their existing clothing.

One more example is Selflessclothes platform [44], selling new clothes and encouraging consumers to choose those that are sustainable. They provide the calculation of the reduction in environmental impact that comes from using sustainable clothing vs. those manufactured traditionally. Such an approach of comparing two items can serve as an idea for calculating environmental benefits of clothing swapping, just in the latter case a comparison should be made between new and swapped clothing.

The review of existing calculators shows that some platforms dealing with the resale of used clothes assess the environmental impact of clothing, including the aspect of reuse. In case of other reuse models (rental, repair, swapping), a practice of assessing environmental impact was not identified. Selling unnecessary clothes, renting, or repairing them creates a clear monetary value—the clothing or the related service is priced and sold to an interested consumer, thus generating a financial reward for the reused item. In the swapping model, monetary value disappears. Thus, our study explores what other value, potentially important to users, is created through clothing swapping platforms and in this case, the following environmental value was chosen: the reduction of environmental impact.

The research question of this study is the following: how can environmental benefits of clothing swapping be calculated? The study was conducted in cooperation with an online swapping platform [45]. This allowed us to combine theoretical research with practical insights into the behavior of users of clothing offered for swapping, and to have the real-world implementation and testing of environmental impact calculations. As a result, an algorithm to calculate the environmental impact reduction through swapping was developed, and the calculation results are presented to customers in order to promote swapping practices instead of throwing clothes away or buying new clothes.

2. Materials and Methods

The method for the development of an algorithm to calculate the environmental impact of clothing swaps represents an approach to understanding and quantifying the environmental consequences of this practice. This integrates insights from the scientific literature, swapping practice analysis, and LCA using SimaPro 9.1 software to assess fabric impacts, creating a database with constant (default) and variable data to calculate and display changes in environmental impact for individual clothing, user wardrobes (group of clothing provided for swaps), and platform-wide activity. The algorithm subtracts the impact of swapped items from the impact of new ones, refining the process via continuous input analysis and improvements.

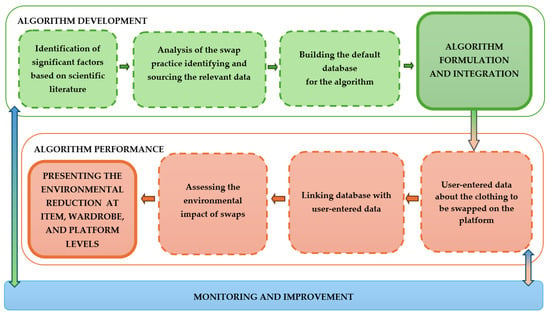

The methodology for the development and implementation of an algorithm is presented in Figure 1, which explains the steps of development (green fields) and the logic of algorithm performance (red fields). An explicit description of algorithm development steps is presented further.

Figure 1.

The methodology for developing and implementing the algorithm for assessing the change in environmental impact through clothing swaps.

2.1. Algorithm Development

At this stage, the algorithm logic and formula were established, the necessary data and their sources were identified, a database of default data used in calculations was created, and interaction between default and user-entered data was found.

2.1.1. Identification of Significant Factors Based on the Scientific Literature

A identification of significant factors based on the scientific literature served to identify factors that influence the environmental aspects of clothing, and relevant environmental impact categories that further provided the basis for the logic of the algorithm and the development of the database.

The search strategy for the literature review involved the use of online databases such as Scopus, ScienceDirect Journals, and Springer LINK Journals. The literature from 2014 to 2024 was reviewed to capture the most current studies related to the environmental impact of clothing reuse. The review was structured around a specific set of keywords grouped into three categories: environmental impact assessment, clothing, and reuse. Key search terms included “life cycle assessment”, “environmental impact categories”, “clothing”, “garment”, “apparel”, “textile”, “consumption”, “reuse”, “extended lifespan”, and “swapping”.

Articles were first filtered to include only research articles (243 articles) containing data, methods, and results relevant to the categorized keywords. A second screening (88 articles) focused on the relevance of the papers, particularly those related to life cycle assessment, environmental impact, and reuse practices, with unrelated articles being eliminated. The final selection involved a thorough review of the full papers (21 articles), with eliminations based on the lack of life cycle inventory data, the lack of impact assessment in every life cycle stage, and no key environmental categories, life cycle stage, and clarity of data, such as the clarity of data sources, and data collection methods. Analysis of the literature review is summarized in Section 3.1.1, highlighting the most significant impact categories and the reasons behind these impacts, as well as documenting reuse and swapping practices.

2.1.2. Analysis of the Swapping Practice

The analysis of the clothing swap online platform was conducted in the online swapping platform GiverTag [45], which was established in July 2022, focusing on free clothing swaps among registered users. The users upload photos of their unwanted wardrobe contents (clothes, shoes, small leather goods, accessories) to the platform, providing requested information (brief description, category, condition, size, brand, location), thus creating their virtual closets to swap clothes among each other. During the study period (August 2023 to June 2024), the platform was in the testing stage, with several dozen members registering and forming their wardrobes. There were initial trial swaps of approximately 900 clothes, and user feedback was provided to GiverTag creators.

Given the iterative approach of the study, at first, the surveyed platform users helped to clarify which fabrics dominate and, therefore, are relevant to be included in the algorithm. The platform was later supplemented with questions that allow for the collection of all other information necessary for calculations, the need for which was identified during the literature analysis and formula development.

The summarized results of the analysis of swapping practices—the dominant composition of clothing by fabric and other data required by the algorithm—are presented in Section 3.1.2.

2.1.3. Development of Algorithm Database with Default Data

Developing the formula and analyzing the swapping practice, it became evident which data should be set as defaults in the algorithm database and how these defaults correlate with the information provided by users.

To support the calculations, a database containing default data was created following these steps:

- Default data was collected based on the scientific literature.

- LCA [46] data for 11 different fabrics was compiled using 1 kg of fabric as the functional unit. The analysis was conducted using the LCA software SimaPro [47], utilizing inventory data from the Ecoinvent v3.8 database [48] and relevant scientific sources to calculate:

- The environmental impact of 1 kg of new fabrics, with system boundaries set from cradle to grave (including raw material extraction, production, distribution and retail, first use, and end-of-life (EoL) stages);

- The impact of 1 kg of swapped fabrics during their use phase (washing, drying, and ironing). In this scenario, each time the clothing changes ownership, its wear time decreases by 30%, reducing the number of wash cycles [49].

The LCA took the following assumptions into account:

- The use phase includes transportation, as well as washing, drying, and ironing.

- Transportation in the use phase accounts for travel to and from the store or swap location for both new and swapped clothing.

- The distribution and retail phase includes transportation to the retail store.

- As information on the country of origin was not collected when assessing the environmental impact of clothing swaps, average data from the Ecoinvent database—including global or rest-of-the-world datasets—were used to evaluate the impact of raw material extraction, production, distribution, and retail stages. For other life cycle stages—use (including energy consumption for travel, washing, drying, and ironing) and EoL (such as the proportion of clothing separated for reuse, incineration, or disposal)—data from Lithuania or rest-of-Europe datasets were applied.

- Additionally, since each clothing category differs in weight and fabric composition, 1 kg of a specific fabric was selected as the functional unit. This allows the algorithm, using user-provided data, to calculate the environmental impact of each swapped clothing item based on the proportions of different fabrics it contains.

An important decision in conducting an LCA is how to allocate the environmental burden of multifunctional processes among their various outputs. In this study, several processes were identified as multifunctional. For instance, cotton cultivation produces both seeds and fiber; viscose production generates fiber and several by-products; waste incineration results in both heat and electricity, which offsets energy use; and washing machines clean multiple clothing items simultaneously.

Accordingly, the environmental burdens of production, transportation, and washing processes were allocated based on mass, under the assumption that their impacts are mass dependent.

In the Ecoinvent database, which accounts for reuse at the EoL stage, the environmental burden of primary material production is assigned to the original (first) user of the material. No environmental credit is given for providing reused material to subsequent users. As a result, the secondary user assumes the burden of reuse (in this study, the burden of swapping), but not the impacts related to the production of primary materials or other life cycle stages.

2.1.4. Algorithm Formulation

The algorithm formula was developed in parallel with the other steps of this stage, adding or excluding relevant data. During this stage, the algorithm logic (Figure 2) was refined, and an algorithm formula was created based on it. Default parameters from database and varying data entered by users are required for calculations (Section 3.1.4).

Figure 2.

The logic of the algorithm for calculating environmental impact reduction through clothing swaps.

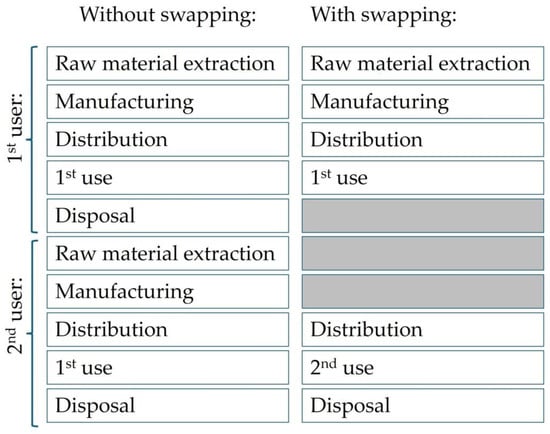

The algorithm’s logic is based on the product displacement principle that a swapped clothing eliminates a need for a new clothing. In the traditional case, the first user would simply throw away the purchased clothing when he/she no longer wanted it, even though it was still suitable for wearing. The second user would buy a new clothing item when he/she needed it. Thus, we would have a case where two new clothing are purchased, both of which go through a full lifecycle (extraction of raw materials, production, distribution, use, disposal). In the case of swapping, instead of throwing away the clothing, the first user submits it to a swap: this avoids the disposal stage. The second user takes over this clothing: this extends the use stage, at the same time avoiding the extraction of raw materials and the production stage; the disposal stage is postponed to a later time.

These considerations result in the following calculations:

2.2. Algorithm Performance

At this stage, the algorithm was integrated into the swapping platform. It was implemented and tested as a key component of the IT solution. The environmental reductions were subsequently evaluated to ensure accuracy and functionality.

3. Results

3.1. The Development and Implementation of Algorithm

3.1.1. The Significant Factors for Environmental Impact Assessment

The literature review outlined the direction in which the algorithm should be developed, i.e., what aspects should be included in the calculation of the environmental impact of clothing.

The environmental impact of clothing is influenced by various factors throughout its lifecycle, from raw material extraction, manufacturing, retail and distribution, and use to EoL disposal. For example, 80% of the total climate impact of Swedish clothing consumption is linked to its production mostly provided by fossil fuels and water scarcity, and 14% is linked to the usage stage including transport back and forth from the store and laundering due to energy use [50]. Clothing manufacturing processes, including spinning, weaving, dyeing, and finishing, release harmful chemicals and wastewater, with approximately 2000 chemicals involved, particularly in wet processing [4].

The environmental impact category that is most affected depends on the fabric produced. [51]. Cotton production, unlike other fabrics, demands substantial water, pesticides, and fertilizers, leading to water scarcity, soil degradation [4,52], energy demand, and land occupation [53]. Wool production, particularly in the farming stage, contributes heavily to greenhouse gas emissions, while water stress and energy demand impacts are distributed across fiber production and fabric processing [5]. Viscose, a man-made cellulose fiber, is evaluated for its primary energy demand, water use, and land use, with variations in impact depending on the production region, as seen in comparisons between viscose produced in Asia and Austria [5,54].

Polyester, a synthetic fiber derived from fossil fuels, has a notable impact on terrestrial ecotoxicity, fossil resource scarcity, and greenhouse gas emissions, with minor effects on stratospheric ozone depletion [8,55,56]. In 2018, global textile fiber production exceeded 107 million tons, with synthetic fibers comprising nearly two-thirds and expected to rise further [57], together with the environmental impact attributable to synthetic fibers.

Another significant lifecycle stage—use—involves washing, drying, and ironing, which consumes water, energy, and detergents, releases microplastic emissions when laundering polyester clothes, and significantly contributes to environmental impacts [52,58]. Frequent washing, especially with inefficient machines, and extensive use of dryers increase energy and water consumption, highlighting the potential for environmental improvement through reduced laundering frequency and more efficient care practices [59,60]. In the jeans LCA case [4], the use stage accounted for around 58% of overall energy use while fabric production and cutting/sewing consumed 21% and 10% of total energy, respectively.

One of the most preferable ways to significantly reduce the environmental impact of textiles is to extend their lifetime, for which the design of the textile and practices of domestic use are of great importance. More durable textiles are worn for longer and encourage the increased development of circular textile business models, such as reuse, rent and repair, end-of-life collection services, and second-hand clothing retailing, which at the same time provide consumers with opportunities for savings [26,50]. Prolonging the wearing time can dramatically reduce the overall environmental impact, as demonstrated in studies on wool sweaters where increased clothing use led to a substantial decrease in impacts [31]. Also, the choice of fiber affects the clothing’s durability while durable fibers that support longer clothing lifespans can reduce the need for frequent replacements, thereby lowering overall environmental impacts [61]. According to WRAP research [62], extending the lifespan of clothing by an additional nine months can lead to a reduction in carbon, water, and waste footprints by 20 to 30%; if clothing were worn twice as often, greenhouse gas emissions would drop by about four times.

To summarize, the results of the analysis indicate that it is advisable to develop a clothing swapping algorithm by calculating environmental reduction based on the type of clothing fabric. Fabric selection is crucial in determining the environmental impact of clothing and varies significantly with the type of fiber used, influencing resource use, emissions, and waste throughout their lifecycle.

The review of the literature highlights four key environmental impact categories especially in clothing production and use: global warming, driven by fossil fuel-based processes and high carbon outputs from materials like polyester and cotton; water consumption, particularly high in cotton farming, fabric processing, and home washing; energy consumption, which is substantial across manufacturing and laundering, especially for synthetic fibers; and land use, which is significant in the cultivation of natural fibers such as cotton and viscose, due to the need for land and agricultural inputs [1,51].

3.1.2. Analysis of the Swapping Practice

A situation analysis of the clothing swap online platform identified the data that must be collected to build a dataset to calculate environmental impact reduction.

Since the literature analysis found that clothing fabric is important in assessing environmental impact, platform users were instructed to provide an information on the fabric composition of the clothing being swapped. A total of 68 out of 532 swapped clothes did not have a label, making it impossible to identify the type of fabrics accurately. In this case, it was decided to develop the algorithm in such a way that the average composition of all blended-fiber fabric clothing included in the algorithm development practice was used.

In addition to the provided information on fabric composition, users also provided information about clothing categories.

Table 1 shows the flow of the swapped units of clothing and composition of fabrics.

Table 1.

Data on clothing swapping flows and fiber composition (based on data submitted to the platform during its testing phase).

The other relevant data include:

- The clothing category and weight—the weight depends on the category, and the amount of fabric in the clothing depends on the weight;

- The number of wear cycles for both new and used clothing—this affects the number of washes, ironing, and drying cycles, which, in turn, impacts the environmental effect during the use phase of the life cycle;

- The condition of the cloth being swapped—both unused and used clothes could be swapped;

- How the swapped clothing was acquired—whether it was purchased new or used. If purchased new, after the swap, it is passed to the second owner; if purchased second-hand, it is passed to at least the third owner;

- The environmental impact assessment results of the fabrics to evaluate the environmental savings in both new and used clothing contexts.

The identification of significant factors and the swap platform analysis resulted in a list of data that must be considered when calculating how much the environmental impact is reduced due to clothing being swapped instead of the first user throwing away the garment and the second user buying a new one (Table 2).

Table 2.

Data relevant to algorithm development in the online platform case.

3.1.3. The Developed Algorithm Database

Based on data relevant to the development of the algorithm (Table 2), at this stage, using SimaPro software, a life cycle assessment was performed for eleven fabrics (cotton, polyester, viscose, wool, acrylic, linen, silk, leather, elastane, polyamide, and rubber for shoe soles) taking 1 kg of fabric as a functional unit. Ecoinvent v.3.6 database along with research from the literature (polyester [52], cotton [52], viscose [52], leather [63], wool [64], acrylic [64], elastane [52], polyamide [52], rubber [65], linen [66], silk [67]) were also used.

Frequency of wear, laundering practices, and the average weight of clothing in every clothing category were taken from the literature [49,52,68,69,70] and entered into the algorithm database as default values.

According to LCA calculations, among the most commonly used fabrics, viscose and polyester have the lowest environmental impact of all the assessed fabrics, while cotton, wool, and leather have the highest impact on the environment. Thus, when swapping, the best results, i.e., the biggest impact reductions, are achieved for clothes made of the latter fabrics (Table 3).

Table 3.

LCA results of new and swapped fabrics and environmental impact reduction due to swapping, per 1 kg of fabric.

The following methods were used in the LCA for the selected environmental impact categories: ReCiPe 2016 [71]—water consumption and land use, cumulative energy demand (CED) [72]—energy demand, and IPPC 2013/GWP100a (global warming potential) [72]—global warming.

LCA results for all fabrics, when considering an average number of launderings from all clothing categories, are shown in Appendix A, Table A1.

3.1.4. The Formulated Algorithm

Formula (1) was designed to calculate environmental impact reductions (ER) in each environmental impact category, achieved by swapping clothes and prolonging their lifespan instead of purchasing new ones, according to the logic presented in Section 2.1.4.

where

ER = (2 × (IRawMat + IManuf + IDistr + INewUse + IEOL)) − (IRawMat + IManuf + IDistr + INewUse1 + ISwappedDistr + ISwappedUse + IEOL) =

(IRawMat + IManuf + IDistr + INewUse + IEOL) − (ISwappedDistr + ISwappedUse) = INW − ISW

(IRawMat + IManuf + IDistr + INewUse + IEOL) − (ISwappedDistr + ISwappedUse) = INW − ISW

ER—environmental impact reduction;

IRawMat, IManuf, IDistr, INewUse, IDisp—impact of raw materials extraction, manufacturing, retail/distribution, use of new clothing, and disposal stages, respectively;

IEOL—impact of disposal stage (does not differ for new and swapped clothing);

ISwappedDistr and ISwappedUse—environmental impact of distribution (transportation) and use of swapped clothing;

INW—impact of the new clothing;

ISW—impact of swapped clothing.

Thus, the net environmental reduction (ER) is calculated by subtracting the environmental impact of the swapped clothing from the impact of the new clothing. The result, ER, indicates how much environmental impact is reduced due to clothing being swapped instead of the first user throwing away the clothing and the second user buying a new one.

INW is calculated by multiplying the proportion of different fabrics () in the clothing by mass in kg (PFCm) with the environmental impact of the life cycle stages (production, retail/distribution, use, EoL) of the new garment (LCA1) for 1 kg of relevant fabric:

INW = (PFCm1 × LCA1) + (PFCm2 × LCA1) + …

LCA1 is the sum of the impact of the new clothing use stage from driving/return from the shop (USE1), and the impact of use stage from washing, drying, and ironing (USE2) multiplied by the number of these cycles for new clothing (WSH1), and the sum of impacts from production (P), retail/distribution (R), and EoL (W):

LCA1 = USE1 + (USE2 × WSH1) + P + R + W

ISW is calculated by multiplying the proportion of different fabrics () in the clothing by mass in kg (PFCm) with the environmental impact of the life cycle stages (second use) of the swapped clothing (LCA2) for 1 kg of relevant fabric:

ISW = (PFCm1 × LCA2) + (PFCm2 × LCA2) + …

LCA2 is determined by adding the impact of clothing use phases related to washing, drying, and ironing (USE2) multiplied by the number of these cycles for swapped clothing (WSH2) to the impact of the clothing use phase from driving/return from the shop (USE1):

LCA2 = (USE × WSH2) + USE1

PFCm1 and PFCm1 calculates the proportion of fabrics in clothing by mass (kg) using the average clothing category weight (CWm) and the proportion of fabrics in the cloth (%).

PFCm1 = (CWm × PFC%)/100

The algorithm along with the created database of default data was integrated into an online platform to assess the environmental impact reductions at the clothing, virtual wardrobe, and platform levels. The operation of the algorithm and the results obtained are described in the following section.

3.2. Algorithm Performance to Calculate Environmental Impact Using the Developed Algorithm Implemented on an Online Clothing Swapping Platform

The default datasets have been integrated into the platform’s database. This integration forms the foundation for a real-time feedback algorithm that links user inputs with environmental impact data. This algorithm enables users to visualize the environmental impact reductions associated with the clothing they swap on the platform. Using an LCA approach, the platform provides item-specific impact reductions based on clothing category, fabric type, and user behavior, thereby enhancing the precision of environmental impact assessments. Unlike tools such as RREUSE, ThreadUp, or GreenStitch that focus on generalized assessments, it quantifies impact at the individual clothing level, providing real-time feedback and addressing a gap in reuse platforms: the lack of clear, personalized data that makes environmental benefits tangible for users.

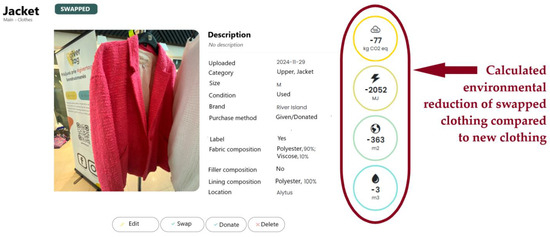

Moreover, the platform’s summary of its overall contribution to environmental impact reduction allows for trend monitoring and further motivates users to enhance their sustainable behaviors. By making environmental savings visible and personalized (Figure 3), the platform promotes deeper user engagement, motivation, and accountability—key aspects missing from conventional environmental calculators.

Figure 3.

Representation of the calculated environmental impact reduction of a sample swapped clothing in the online platform (carbon footprint—kg CO2 eq, water consumption—m3, energy consumption—MJ, and land use—m2a crop eq).

After the integration of the algorithm into the platform, it was calculated that 251 clothing items were swapped over two months (December 2024 to January 2025). These swaps avoided emissions of 4137 kg CO2 eq and consumption of 6809 m3 of water, 3080 m2a crop eq of land, and 87.23 GJ of energy.

Following the implementation of the algorithm on the platform, 20 new users joined, and 251 clothing were swapped. The most swapped items were dresses (25%), blouses (18%), trousers (9%), skirts and sweaters (each 7%), jackets, t-shirts, and jeans (each 5%), and footwear (3%). The least swapped items included outerwear, vests, swimsuits, and various accessories.

Clothing made from single-fiber fabrics dominated, accounting for about 70% of all swapped items, with the remainder (30%) being blended-fiber fabric clothing. Among single-fabric clothing, polyester (40%), cotton (30%), viscose/natural leather (7% each), and wool/linen (4% each) were predominant.

The results were also influenced by the weight of the clothing and the number of washes for both new and swapped items, which depend on the clothing category. For example, a dress weighs an average of 478 g, is washed approximately 46 times before being swapped when new, and 22.5 times after being swapped. As a blouse weighs an average of 163 g, is washed about 28.5 times when new, and 14 times after being swapped [49,52,68,69].

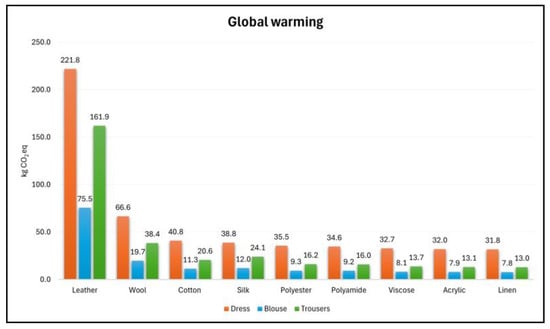

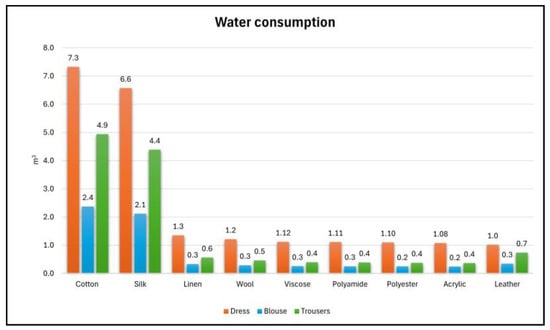

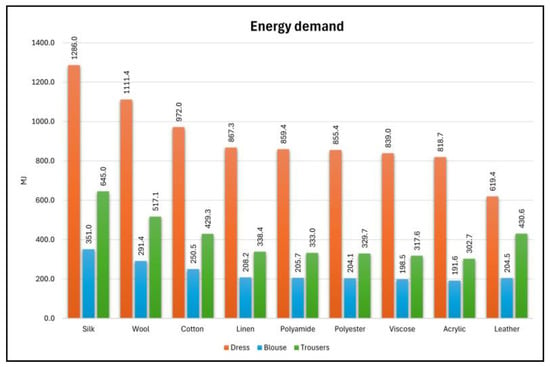

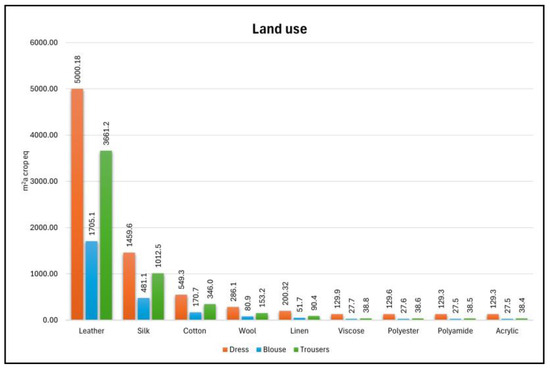

Comparing the environmental impact reductions of the most popular swapped clothing category (dress, blouse, trousers) depending on the fabric, the results varied by environmental impact category (Figure 4, Figure 5, Figure 6 and Figure 7).

Figure 4.

Environmental reduction in global warming from swapping dress, blouse, and trousers according to fabric type.

Figure 5.

Environmental reduction in water consumption from swapping dress, blouse, and trousers according to fabric type.

Figure 6.

Environmental reduction in energy demand from swapping dress, blouse, and trousers according to fabric type.

Figure 7.

Environmental reduction in land use from swapping dress, blouse, and trousers according to fabric type.

The highest environmental reductions in global warming were observed by swapping leather and wool clothing. Leather has the highest global warming impact among common fabrics due to its production process. Raising livestock, especially cattle, generates significant methane emissions—a potent greenhouse gas. Additionally, deforestation for grazing land increases carbon emissions by reducing CO2 absorption. The tanning process also consumes large amounts of energy and uses chemicals, further increasing the carbon footprint [63]. Polyester, acrylic, viscose, and linen generally have lower carbon footprints during production, with synthetic fibers requiring less land and natural inputs, and plant-based fibers like viscose and linen having more efficient, lower-emission farming methods [22,52,64,66,73]. In the clothing care phase, all fabric types create a similar environmental impact because the study applies standardized assumptions (except for leather) for washing, ironing, and drying. Therefore, the greater the impact during the production phase, the higher the environmental savings achieved by swapping it and this tendency is seen in all environmental impact categories.

Silk has the highest environmental impact in energy demand due to its labor-intensive and time-consuming production process. Raising silkworms, maintaining precise climate conditions, and harvesting cocoons require significant energy. Additionally, degumming and dyeing processes are energy-intensive, contributing to silk’s exceptionally high overall energy consumption per kilogram of fabric produced [67].

The highest environmental reduction in water consumption was observed when swapping cotton and silk clothes. Cotton and silk have the highest water impact because cotton requires heavy irrigation for growth, and silk production demands water-intensive mulberry cultivation to feed silkworms throughout their lifecycle [55,67]. Clothes made from other fabrics demonstrate alike reduction levels, being five to seven times lower than those of cotton and silk. Swapping leather clothing had the highest level of environmental impact reduction in the global warming category but resulted in the lowest reduction in the water consumption category. This is because leather clothing requires the least amount of water among all studied fabrics, both during production and use, as it is typically not washed but rather cleaned with minimal effort.

Leather and silk have the highest land-use impact because they come from livestock, which require large areas for grazing and feed production. Raising animals also involves maintaining pastures and often leads to deforestation or land degradation. Compared to plant-based or synthetic fibers, animal-based textiles demand significantly more land throughout their production, contributing to higher overall environmental impact [5,63,74].

According to the results, silk and leather clothing are the most beneficial to swap, i.e., to extend their lifespan. However, only 1.6% of silk and 7% of leather clothing are swapped on the platform. Among the most popular fabrics—polyester and cotton—cotton clothing is the most beneficial to swap, as it leads to the largest reduction in environmental impact reduction for water consumption and ranks in the top three for other categories (global warming, energy demand, and land use).

4. Discussion

This study supports the European Commission’s vision for circular textile systems by introducing a scientifically grounded algorithm to quantify the environmental impacts of clothing swaps.

The developed clothing research platform offers a clear and user-friendly tool that quantifies and visualizes the environmental impact reduction from swapping clothing. Unlike existing calculators focused on resale or generalized assessments, this algorithm provides real-time, clothing-specific evaluations based on user inputs and life cycle assessment (LCA) data. By displaying comprehensive environmental savings instantly for each swapped item, the platform promotes user awareness and encourages the preference for reuse over purchasing new. Additionally, the algorithm highlights the added environmental value of swapping, positioning it as a sustainable alternative to traditional resale models centered on monetary exchange. Swapping can be viewed as a collaborative consumption pattern. Formal swapping, like in the research platform, is organized and structured through events, apps, and online platforms, whereas informal swapping is more casual and spontaneous and occurs in community settings, highlighting social interaction and personal networks [37,75,76].

The algorithm operates within a consumer-to-business-to-consumer (C2B2C) business model and offers a universal structure that can be adapted to various geographic locations and other reuse platforms such as rental services or resale channels. Its core methodology—grounded in fabric-specific LCA data—enables transferability while remaining sensitive to regional contexts. For example, it accounts for different electricity generation profiles and transportation practices, offering a reliable mechanism for global adaptation. Additionally, the algorithm’s structure allows the user to include more environmental impact categories, such as hazardous chemical use or microplastic pollution, depending on regional or sectoral priorities needing more complete assessments.

From a systems perspective, the research reveals how consumer-level tools like this algorithm can indirectly influence business-to-business (B2B) practices. Although not the central focus of the study, the implications for shifts in design, production, and circular economy models are evident. For instance, enhanced clarity regarding fabric types and extended clothing lifespans—possibly supported by innovations like Digital Product Passports—can feed back into production-side decisions and support circular design principles. These links between individual choices and systemic change require deeper exploration in future research by tracking fabric origin, care, and swap history.

Although the algorithm has shown its value in evaluating the environmental benefits of clothing swaps, this study concentrates on the tool’s development and technical implementation, suggesting that future investigations should examine its impact on behavioral outcomes. However, user reactions to the presented data and potential changes in clothing consumption habits due to greater environmental awareness represent critical areas for future research. Understanding how users respond to quantified environmental benefits could provide information on efficient methodologies for advancing sustainable practices at scale.

The results also reveal that certain fabrics such as leather, silk, and cotton yield the highest environmental savings when swapped. These insights can inform stakeholders—including designers, retailers, and policymakers—about the priority materials and categories to target in sustainable fashion strategies.

5. Limitations and Future Research

Several limitations emerged throughout the development and testing of the algorithm, which offer directions for future research. First, the assumption that each clothing swap prevents the purchase of new clothing in a 1:1 ratio is primarily intended to encourage users to swap instead of buying new items. While this simplification serves well for communication and comparison purposes, it fails to accurately reflect the actual rate of clothing reuse.

In the European context, the rate of clothing reuse substitution typically ranges from 0.3 to 0.6, while in African or Asian countries, it is around 0.8 [17]. This suggests that the current algorithm model may overestimate the environmental savings achieved through swapping. A high substitution rate indicates that consumers purchase used clothing primarily due to socioeconomic factors or environmental awareness. On the contrary, a low substitution rate suggests that reuse is considered a secondary option to buying new clothes, and, therefore, the environmental impact of reuse may be lower than expected [77].

Integrating realistic substitution rates into the algorithm could enhance accuracy, though it may reduce user motivation by presenting more modest benefits. This trade-off between motivational effectiveness and empirical accuracy is an important area for further refinement.

Incorporating realistic substitution rates into the algorithm could enhance accuracy, although it may reduce user motivation by presenting more modest benefits. This trade-off between motivational effectiveness and empirical accuracy is an important area for further refinement.

Another limitation lies in the standardized assumptions applied to clothing maintenance and special care such as dry cleaning or hand washing. The current model uses average Lithuanian energy mix for washing, ironing, and drying, and transportation to and from swapping spots. Also clothing of different fabric types—such as silk versus polyester—requires vastly different care. These variations in maintenance not only affect wear frequency but also contribute differently to environmental impacts. Future improvements to the algorithm should allow for more detailed information on garment care, not just by fabric but also by clothing category, or provide pre-defined regions and fabrics to more accurately reduce environmental impact.

However, the platform allows users to indicate whether the item being swapped was originally purchased as new or used. Based on this information, the algorithm can determine whether the current swap involves the clothing’s second or third owner. While this feature provides insight into the lifecycle, it does not capture clothing usage beyond the third owner. This constraint could be addressed by integrating Digital Product Passports to enhance traceability and allow for more comprehensive lifecycle assessments. Such innovation could also support a better understanding of material aging, degradation, and repair cycles, further deepening the algorithm’s relevance in circular economy contexts.

In addition to algorithmic improvements, future research should consider expanding the platform’s database to include a wider range of textile types, particularly as recycled and organic fabrics become more prevalent, to ensure that the tool remains relevant and accurate in assessing environmental impacts. This update would align the tool with the evolving textile market and promote low-impact consumption choices. Similarly, including culturally specific or regionally common clothing in the platform would improve impact evaluations and ensure relevance across diverse user populations.

Although the tool currently focuses on clothing, its logic is universal and could be extended to other reuse-orientated platforms such as tool rental, furniture swapping, swapping events, or electronic device reuse. This cross-sector adaptability opens the possibilities for comparative studies on reductions in environmental impact across different product categories and user habits.

The study did not examine the direct behavioral effects of displaying a reduction in environmental impact on users. Although it is assumed that transparency fosters responsible consumption, empirical evidence is needed to validate this assumption. Future research should explore whether providing personalized environmental savings data influences users’ long-term choices about clothing acquisition, reuse, and disposal. Insights from such investigations could inform further platform development, enhance user engagement strategies, and contribute to the broader discourse on reuse models.

6. Conclusions

While clothing resale is well established due to its financial value, clothing swapping remains underutilized, despite its significant environmental benefits. The developed algorithm, which allows users to calculate the environmental impact avoided when a garment is not purchased new, but is acquired through swapping, thus extending the life of the old garment and avoiding the production of a new garment, can make clothing swapping as attractive as resale by enhancing its appeal. Both methods extend the clothing life cycle, but promoting swapping could yield additional sustainability benefits. By compensating for the lack of monetary value with environmental benefits and fostering environmental consciousness, swapping can be elevated from a niche practice to a mainstream alternative. This would complement resale in the overall reuse volumes.

Calculations according to the developed algorithm take into account the clothing category and fabric from which the clothing is made, clothing wearing, and care practices. These practices are taken as default data, derived from the literature analysis. LCA of 11 fabrics was conducted during the algorithm implementation process, allowing for individual and comparative evaluation of each fabric’s environmental impact and contributing to informed purchasing and swapping decisions. It turns out that cotton and polyester, the commonly used fabrics, have a lower potential for environmental impact reduction. Less frequently used fabrics, leather and silk, have a higher potential for impact reduction, due to these fabrics’ intensive resource demands. Although silk and leather clothes offer the greatest environmental impact reductions, their share among swapped items remained low.

The algorithm developed in this study not only enables an individualized assessment of the environmental impact of clothing swapping but also has the potential to be applied to other forms of reuse and product groups. This solution develops digital tools to encourage environmentally responsible consumption and is useful for consumers and businesses integrating circular economy principles.

The success of swapping platform will depend on changes in consumer behavior and their motivation to assess and lessen their environmental impact consuming clothing. Further investigation is necessary to understand how the algorithm influences users’ decisions and under which conditions digital engagement translates into sustainable consumption actions. Integrating additional variables like case-specific maintenance, time of wearing clothing, or specifics of regional energy use could enable the tool to provide even more accurate and personalized results adaptable to different consumption circumstances.

Author Contributions

Conceptualization, A.J. and I.G.; methodology, A.J.; software, A.J.; validation A.J., I.G. and J.K.; formal analysis, A.J.; investigation, A.J.; resources, I.G. and A.J.; data curation, A.J.; writing—original draft preparation, A.J.; writing—review and editing, I.G. and J.K.; visualization, A.J. and I.G.; supervision, J.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the Ministry of Economy and Innovation of the Republic of Lithuania under the measure “Development of new R&D products” under the Economic Transformation and Competitiveness Development Program for the period 2020–2030, which invests in new R&D product development activities and enables researchers to participate in R&D activities of companies, promotes intellectual property, early pilot production of new products and market readiness of the developed new products, project grant number 02-006-K-0136.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article and Appendix A; further inquiries can be directed to the corresponding author/s.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the study’s design; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Appendix A

Table A1.

LCA results of and new and swapped 11 fabrics and swapping environmental reduction per 1 kg of fabric.

Table A1.

LCA results of and new and swapped 11 fabrics and swapping environmental reduction per 1 kg of fabric.

| Average Environmental Impact of NEW Fabrics, 1 kg (Raw Material Extraction, Production, Retail and Distribution, First Use *, EoL) | |||||||||||

| Impact | Acrylic | Cotton | Leather | Linen | Polyamide | Polyester | Rubber | Silk | Spandex | Viscose | Wool |

| Global warming, kg CO2 eq | 64.0 | 85.2 | 469.4 | 63.6 | 72.1 | 73.2 | 17.4 | 83.2 | 73.1 | 65.5 | 136.3 |

| Water consumption, m3 | 1.9 | 15 | 2.1 | 2.5 | 2 | 1.9 | 0.2 | 13.4 | 2 | 2 | 2.2 |

| Energy demand, MJ | 1549.4 | 1911 | 1358.4 | 1651.2 | 1635.9 | 1626.4 | 335.5 | 2527.2 | 1646.4 | 1592 | 2161.9 |

| Land use, m2a crop eq | 224.1 | 1102.9 | 10,460.6 | 372.7 | 224.2 | 224.7 | 5.1 | 3007.1 | 224.5 | 225.3 | 552.1 |

| * Average laundering (washing, drying, ironing) time per second user 19.4 times. Leather use includes just cleaning with appropriate cleaners. First use also includes transportation to and from the swap. | |||||||||||

| Average environmental impact of SWAPPED fabrics, 1 kg (second use *) | |||||||||||

| Impact | Acrylic | Cotton | Leather | Linen | Polyamide | Polyester | Rubber | Silk | Spandex | Viscose | Wool |

| Global warming, kg CO2 eq | 22.8 | 22.8 | 4 | 22.8 | 22.8 | 22.8 | 6.8 | 22.8 | 22.8 | 22.8 | 22.8 |

| Water consumption, m3 | 0.8 | 0.8 | 0.01 | 0.8 | 0.8 | 0.8 | 0.01 | 0.8 | 0.8 | 0.8 | 0.8 |

| Energy demand, MJ | 608 | 608 | 84.76 | 608 | 608 | 608 | 125.5 | 608 | 608 | 608 | 608 |

| Land use, m2a crop eq | 107.5 | 107.5 | 0.08 | 107.5 | 107.5 | 107.5 | 0.1 | 107.5 | 107.5 | 107.5 | 107.5 |

| * Average laundering (washing, drying, ironing) time per first user 9.5 times. Leather use includes just cleaning it with appropriate cleaners. Second use also includes transportation to and from the swap. | |||||||||||

| Average environmental impact reduction due to clothing swapping, by fabric type, for 1 kg | |||||||||||

| Impact | Acrylic | Cotton | Leather | Linen | Polyamide | Polyester | Rubber | Silk | Spandex | Viscose | Wool |

| Global warming, kg CO2 eq | 41.2 | 62.4 | 465.4 | 40.8 | 49.3 | 50.4 | 10.6 | 60.4 | 50.3 | 42.7 | 113.5 |

| Water consumption, m3 | 1.1 | 14.2 | 2.1 | 1.7 | 1.2 | 1.1 | 0.2 | 12.6 | 1.2 | 1.2 | 1.4 |

| Energy demand, MJ | 941.4 | 1303.0 | 1273.6 | 1043.2 | 1027.9 | 1018.4 | 210.0 | 1919.2 | 1038.4 | 984.0 | 1553.9 |

| Land use, m2a crop eq | 116.6 | 995.4 | 10,460.5 | 265.2 | 116.7 | 117.2 | 5.0 | 2899.6 | 117.0 | 117.8 | 444.6 |

References

- ETC/CE Textiles and the Environment—The Role of Design in Europe’s Circular Economy. Available online: https://www.eionet.europa.eu/etcs/etc-ce/products/etc-ce-products/etc-ce-report-2-2022-textiles-and-the-environment-the-role-of-design-in-europes-circular-economy (accessed on 10 March 2024).

- Yılmaz, K.; Aksu, I.O.; Göçken, M.; Demirdelen, T. Sustainable Textile Manufacturing with Revolutionizing Textile Dyeing: Deep Learning-Based, for Energy Efficiency and Environmental-Impact Reduction, Pioneering Green Practices for a Sustainable Future. Sustainability 2024, 16, 8152. [Google Scholar] [CrossRef]

- Plakantonaki, S.; Kiskira, K.; Zacharopoulos, N.; Chronis, I.; Coelho, F.; Togiani, A.; Kalkanis, K.; Priniotakis, G. A Review of Sustainability Standards and Ecolabeling in the Textile Industry. Sustainability 2023, 15, 11589. [Google Scholar] [CrossRef]

- Moazzem, S.; Crossin, E.; Daver, F.; Wang, L. Environmental Impact of Apparel Supply Chain and Textile Products. Environ. Dev. Sustain. 2022, 24, 9757–9775. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Biggs, L.; Nebel, B.; Bauch, K.; Laitala, K.; Klepp, I.G.; Swan, P.G.; Watson, K. Environmental Impacts Associated with the Production, Use, and End-of-Life of a Woollen Garment. Int. J. Life Cycle Assess. 2020, 25, 1486–1499. [Google Scholar] [CrossRef]

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The Environmental Price of Fast Fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Sofeast Lifecycle Impact on the Environment of Textiles and Garments [Analysis]. Available online: https://www.sofeast.com/resources/green-manufacturing/lifecycle-impact-on-environment-of-textiles-garments/ (accessed on 9 December 2024).

- Gonzalez, V.; Lou, X.; Chi, T. Evaluating Environmental Impact of Natural and Synthetic Fibers: A Life Cycle Assessment Approach. Sustainability 2023, 15, 7670. [Google Scholar] [CrossRef]

- Baydar, G.; Ciliz, N.; Mammadov, A. Life Cycle Assessment of Cotton Textile Products in Turkey. Resour. Conserv. Recycl. 2015, 104, 213–223. [Google Scholar] [CrossRef]

- Zhang, Y.; Kang, H.; Hou, H.; Shao, S.; Sun, X.; Qin, C.; Zhang, S. Improved Design for Textile Production Process Based on Life Cycle Assessment. Clean. Technol. Environ. Policy 2018, 20, 1355–1365. [Google Scholar] [CrossRef]

- Kishor, R.; Purchase, D.; Saratale, G.D.; Saratale, R.G.; Ferreira, L.F.R.; Bilal, M.; Chandra, R.; Bharagava, R.N. Ecotoxicological and Health Concerns of Persistent Coloring Pollutants of Textile Industry Wastewater and Treatment Approaches for Environmental Safety. J. Environ. Chem. Eng. 2021, 9, 105012. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Q.; An, L.; Wang, M.; Yang, Q.; Zhu, B.; Ding, J.; Ye, C.; Xu, Y. Microfiber Pollution in the Earth System. Rev. Environ. Contam. Toxicol. 2022, 260, 13. [Google Scholar] [CrossRef]

- Ramasamy, R.; Subramanian, R.B. Synthetic Textile and Microfiber Pollution: A Review on Mitigation Strategies. Environ. Sci. Pollut. Res. 2021, 28, 41596–41611. [Google Scholar] [CrossRef] [PubMed]

- Steinberger, J.K.; Friot, D.; Jolliet, O.; Erkman, S. A Spatially Explicit Life Cycle Inventory of the Global Textile Chain. Int. J. Life Cycle Assess 2009, 14, 443–455. [Google Scholar] [CrossRef]

- Muthu, S.S. Environmental Impacts of the Use Phase of the Clothing Life Cycle. In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Woodhead Publishing: Sawston, UK, 2015; pp. 93–102. ISBN 9780081001875. [Google Scholar]

- Luo, Y.; Wu, X.; Ding, X. Environmental Impacts of Textiles in the Use Stage: A Systematic Review. Sustain. Prod. Consum. 2023, 36, 233–245. [Google Scholar] [CrossRef]

- Koligkioni, A.; Parajuly, K.; Sørensen, B.L.; Cimpan, C. Environmental Assessment of End-of-Life Textiles in Denmark. Procedia CIRP 2018, 69, 962–967. [Google Scholar] [CrossRef]

- Singh, A.; Goel, A. Design of the Supply Chain Network for the Management of Textile Waste Using a Reverse Logistics Model under Inflation. Energy 2024, 292, 130615. [Google Scholar] [CrossRef]

- Stefan, D.S.; Bosomoiu, M.; Stefan, M. Methods for Natural and Synthetic Polymers Recovery from Textile Waste. Polymers 2022, 14, 3939. [Google Scholar] [CrossRef]

- Rubik, F.; Nebel, K.; Klusch, C.; Karg, H.; Hecht, K.; Gerbig, M.; Gärtner, S.; Boldrini, B. Textiles on the Path to Sustainability and Circularity—Results of Application Tests in the Business-to-Business Sector. Sustainability 2024, 16, 5954. [Google Scholar] [CrossRef]

- Tummino, M.L.; Varesano, A.; Copani, G.; Vineis, C. A Glance at Novel Materials, from the Textile World to Environmental Remediation. J. Polym. Environ. 2023, 31, 2826–2854. [Google Scholar] [CrossRef]

- Li, C.; Zhang, T.; Zhou, X.; Cheng, Z.; Xu, T.; Li, Z.; Hong, J. Carbon–Water–Energy Footprint Impacts of Dyed Cotton Fabric Production in China. J. Clean. Prod. 2024, 467, 142898. [Google Scholar] [CrossRef]

- Fonseca, A.; Ramalho, E.; Gouveia, A.; Henriques, R.; Figueiredo, F.; Nunes, J. Systematic Insights into a Textile Industry: Reviewing Life Cycle Assessment and Eco-Design. Sustainability 2023, 15, 15267. [Google Scholar] [CrossRef]

- Abagnato, S.; Rigamonti, L.; Grosso, M. Life Cycle Assessment Applications to Reuse, Recycling and Circular Practices for Textiles: A Review. Waste Manag. 2024, 182, 74–90. [Google Scholar] [CrossRef] [PubMed]

- Islam, S.; Hasan, A.K.M.M.; Bhuiyan, M.A.R.; Bhat, G. Evaluation of Environmental Impacts of Cotton Polo Shirt Production in Bangladesh Using Life Cycle Assessment. Sci. Total Environ. 2024, 926, 172097. [Google Scholar] [CrossRef] [PubMed]

- COM(2022) 141 Final EU Strategy for Sustainable and Circular Textiles. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52022DC0141 (accessed on 26 May 2022).

- COM/2020/98 Final COMMUNICATION FROM THE COMMISSION TO THE EUROPEAN PARLIAMENT, THE COUNCIL, THE EUROPEAN ECONOMIC AND SOCIAL COMMITTEE AND THE COMMITTEE OF THE REGIONS A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 29 April 2022).

- Gray, S.; Druckman, A.; Sadhukhan, J.; James, K. Reducing the Environmental Impact of Clothing: An Exploration of the Potential of Alternative Business Models. Sustainability 2022, 14, 6292. [Google Scholar] [CrossRef]

- Furferi, R.; Volpe, Y.; Mantellassi, F. Circular Economy Guidelines for the Textile Industry. Sustainability 2022, 14, 1111. [Google Scholar] [CrossRef]

- Harmsen, P.; Scheffer, M.; Bos, H. Textiles for Circular Fashion: The Logic behind Recycling Options. Sustainability 2021, 13, 9714. [Google Scholar] [CrossRef]

- Wiedemann, S.; Biggs, L.; Van Nguyen, Q.; Clarke, S.J.; Laitala, K.; Klepp, I.G. Reducing Environmental Impacts from Garments through Best Practice Garment Use and Care, Using the Example of a Merino Wool Sweater. Int. J. Life Cycle Assess. 2021, 26, 1188–1197. [Google Scholar] [CrossRef]

- Laitala, K.; Klepp, I.G.; Henry, B. Does Use Matter? Comparison of Environmental Impacts of Clothing Based on Fiber Type. Sustainability 2018, 10, 2524. [Google Scholar] [CrossRef]

- Gwozdz, W.; Steensen Nielsen, K.; Müller, T. An Environmental Perspective on Clothing Consumption: Consumer Segments and Their Behavioral Patterns. Sustainability 2017, 9, 762. [Google Scholar] [CrossRef]

- Brand, S.; Jacobs, B.; Taljaard-Swart, H. I Rent, Swap or Buy Second-Hand—Comparing Antecedents for Online Collaborative Clothing Consumption Models. Int. J. Fash. Des. Technol. Educ. 2023, 16, 275–287. [Google Scholar] [CrossRef]

- Armstrong, C.M.; Niinimäki, K.; Lang, C.; Kujala, S. A Use-Oriented Clothing Economy? Preliminary Affirmation for Sustainable Clothing Consumption Alternatives. Sustain. Dev. 2016, 24, 18–31. [Google Scholar] [CrossRef]

- Maguire, H.; Fahy, F. Unlocking Insights in the Everyday: Exploring Practices to Foster Sustainable Maximum Use of Clothing. Clean. Responsible Consum. 2023, 8, 100095. [Google Scholar] [CrossRef]

- Laitala, K.; Klepp, I. Clothing Reuse: The Potential in Informal Exchange. Cloth. Cult. 2017, 4, 61–77. [Google Scholar] [CrossRef]

- Weber, S.; Lynes, J.; Young, S.B. Fashion Interest as a Driver for Consumer Textile Waste Management: Reuse, Recycle or Disposal. Int. J. Consum. Stud. 2017, 41, 207–215. [Google Scholar] [CrossRef]

- RREUSE CO2 Emissions Calculator. Available online: https://rreuse.org/ (accessed on 9 November 2024).

- Charitable Reuse Australia Consumer Donations Calculator. Available online: https://www.charitablereuse.org.au/reusecalculator/ (accessed on 9 December 2024).

- TEXCYCLE Textile Eco Calculator. Available online: https://texcycle.bg/en/eco-calculator/ (accessed on 9 December 2024).

- ThreadUP Fashionfootprint. Available online: https://www.thredup.com/fashionfootprint/ (accessed on 9 December 2024).

- GreenStitch Personal Fashion GHG Footprint Calculator. Available online: https://greenstitch.io/personal-footprint-calculator (accessed on 12 March 2025).

- Selfless Clothing Sustainability Rank. Available online: https://www.selflessclothes.com/ (accessed on 9 March 2025).

- Givertag Apie Mus. Available online: https://givertag.lt/ (accessed on 9 December 2024).

- ISO Environmental Management—Life Cycle Assessment—Requirements and Guidelines. Available online: https://www.iso.org/standard/38498.html (accessed on 24 January 2025).

- SimaPro About Us. Available online: https://simapro.com/meet-the-developer/ (accessed on 9 December 2024).

- Ecoinvent Ecoinvent Version 3.8. Available online: https://support.ecoinvent.org/ecoinvent-version-3.8 (accessed on 5 May 2024).

- Laitala, K.; Klepp, I. Clothing Longevity: The Relationship Between the Number of Users, How Long and How Many Times Garments Are Used. 26 May 2021. Available online: https://researchrepository.ul.ie/articles/conference_contribution/Clothing_longevity_the_relationship_between_the_number_of_users_how_long_and_how_many_times_garments_are_used/19867156 (accessed on 9 March 2025).

- ECOS Durable, Repairable and Mainstream: How Ecodesign Can Make Our Textiles Circular. Available online: https://ecostandard.org/publications/report-durable-repairable-and-mainstream-how-ecodesign-can-make-our-textiles-circular/ (accessed on 29 May 2024).

- ETC/WMGE Textiles and the Environment in a Circular Economy. Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/textiles-and-the-environment-in-a-circular-economy (accessed on 10 November 2024).

- Sandin, G.; Roos, S.; Spak, B.; Zamani, B.; Peters, G. Environmental Assessment of Swedish Clothing Consumption-Six Garments, Sustainable Futures. Available online: https://research.chalmers.se/en/publication/514322 (accessed on 13 March 2025).

- Van Nguyen, Q.; Wiedemann, S.; Simmons, A.; Clarke, S.J. The Environmental Consequences of a Change in Australian Cotton Lint Production. Int. J. Life Cycle Assess. 2021, 26, 2321–2338. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M.K. Environmental Impact Assessment of Man-Made Cellulose Fibres. Resour. Conserv. Recycl. 2010, 55, 260–274. [Google Scholar] [CrossRef]

- Van Der Velden, N.M.; Patel, M.K.; Vogtländer, J.G. LCA Benchmarking Study on Textiles Made of Cotton, Polyester, Nylon, Acryl, or Elastane. Int. J. Life Cycle Assess. 2014, 19, 331–356. [Google Scholar] [CrossRef]

- Braun, G.; Som, C.; Schmutz, M.; Hischier, R. Environmental Consequences of Closing the Textile Loop—Life Cycle Assessment of a Circular Polyester Jacket. Appl. Sci. 2021, 11, 2964. [Google Scholar] [CrossRef]

- ETC/WMGE Plastic in Textiles: Potentials for Circularity and Reduced Environmental and Climate Impacts. Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/plastic-in-textiles-potentials-for-circularity-and-reduced-environmental-and-climate-impacts (accessed on 12 March 2024).

- Filho, W.L.; Dinis, M.A.P.; Liakh, O.; do Paço, A.; Dennis, K.; Shollo, F.; Sidsaph, H. Reducing the Carbon Footprint of the Textile Sector: An Overview of Impacts and Solutions. Text. Res. J. 2024, 94, 1798–1814. [Google Scholar] [CrossRef]

- Laitala, K.; Klepp, I.G. What Affects Garment Lifespans? International Clothing Practices Based on a Wardrobe Survey in China, Germany, Japan, the UK, and the USA. Sustainability 2020, 12, 9151. [Google Scholar] [CrossRef]

- Laitala, K.; Klepp, I.G.; Kettlewell, R.; Wiedemann, S. Laundry Care Regimes: Do the Practices of Keeping Clothes Clean Have Different Environmental Impacts Based on the Fibre Content? Sustainability 2020, 12, 7537. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Clarke, S.J.; Van Nguyen, Q.; Cheah, Z.X.; Simmons, A. Strategies to Reduce Environmental Impacts from Textiles: Extending Clothing Wear Life Compared to Fibre Displacement Assessed Using Consequential LCA. Resour. Conserv. Recycl. 2023, 198, 107119. [Google Scholar] [CrossRef]

- Cooper, T.; Hill, H.; Kinmouth, J.; Townsend, K.; Hughes, M. Design for Longevity: Guidance on Increasing the Active Life of Clothing. Available online: https://www.researchgate.net/publication/313479112_Design_for_Longevity_Guidance_on_Increasing_the_Active_Life_of_Clothing (accessed on 12 June 2024).

- Bruno, N.; Puig, R.; Raggi, A.; Fullana-i-Palmer, P.; Tassielli, G.; Camillis, C.; Rius, A. Life Cycle Assessment of Italian and Spanish Bovine Leather Production Systems. Available online: https://www.researchgate.net/publication/248707414_Life_Cycle_Assessment_of_Italian_and_Spanish_Bovine_Leather_Production_Systems (accessed on 13 April 2024).

- Torres, C.B. Life Cycle Assessment of Raw White, Dyed and Pigmented Acrylic Fibres and Proposals for the Improvement of Environmental Performance. Available online: http://hdl.handle.net/10362/109862 (accessed on 12 July 2024).

- Gottfridsson, M.; Zhang, Y. Environmental Impacts of Shoe Consumption Combining Product Flow Analysis with an LCA Model for Sweden. Available online: https://hdl.handle.net/20.500.12380/218968 (accessed on 12 June 2024).

- Gomez-Campos, A.; Vialle, C.; Rouilly, A.; Hamelin, L.; Rogeon, A.; Hardy, D.; Sablayrolles, C. Natural Fibre Polymer Composites—A Game Changer for the Aviation Sector? J. Clean. Prod. 2021, 286, 124986. [Google Scholar] [CrossRef]

- Astudillo, M.F.; Thalwitz, G.; Vollrath, F. Life Cycle Assessment of Indian Silk. J. Clean. Prod. 2014, 81, 158–167. [Google Scholar] [CrossRef]

- WRAP How to Use the Clothing Longevity Protocol. Available online: https://www.wrap.ngo/resources/guide/extending-clothing-life-protocol (accessed on 12 March 2024).

- WRAP Citizen Insights—Clothing Longevity and CBM Receptivity in the UK. Available online: https://www.wrap.ngo/resources/report/citizen-insights-clothing-longevity-and-circular-business-models-receptivity-uk (accessed on 12 March 2025).

- Bianco, I.; Picerno, G.; Blengini, G.A. Life Cycle Assessment (LCA) of Worsted and Woollen Processing in Wool Production: ReviWool® Noils and Other Wool Co-Products. J. Clean. Prod. 2023, 415, 137877. [Google Scholar] [CrossRef]

- ReCiPe 2016 LCIA: The ReCiPe Model. Available online: https://www.rivm.nl/en/life-cycle-assessment-lca/recipe (accessed on 1 May 2024).

- SimaPro Database Manual—Methods Library. Available online: https://support.simapro.com/s/article/SimaPro-Methods-manual (accessed on 11 January 2025).

- Smith, G.G.; Barker, R.H. Life Cycle Analysis of a Polyester Garment. Resour. Conserv. Recycl. 1995, 14, 233–249. [Google Scholar] [CrossRef]

- Navarro, D.; Wu, J.; Lin, W.; Fullana-i-Palmer, P.; Puig, R. Life Cycle Assessment and Leather Production. J. Leather Sci. Eng. 2020, 2, 26. [Google Scholar] [CrossRef]

- Armouch, F.; Paulin, M.; Laroche, M. Is It Fashionable to Swap Clothes? The Moderating Role of Culture. J. Consum. Behav. 2024, 23, 2693–2719. [Google Scholar] [CrossRef]

- Cobb, T.S. Share, Don’t Shop: Exploring Value, Sociality and the “alternative” at Clothing Swaps. JOMEC J. 2022, 17, 180–205. [Google Scholar] [CrossRef]

- Andersson, S.; Algurén, P.; Bergman, E.; Blomqvist, E.; Friedl, H.; Hennessy, J.; Johansson, A.; Linder, M.; Mcallister, I. Second-Hand Is [Currently] Bad for Global Sustainability. Available online: https://www.misolutionframework.net/publications/second-hand-is-currently-bad-for-global-sustainability (accessed on 12 December 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).