Research on New Energy Vehicle Battery (NEV) Recycling Model Considering Carbon Emission

Abstract

1. Introduction

2. Literature Background and Theoretical Analysis

2.1. EPR

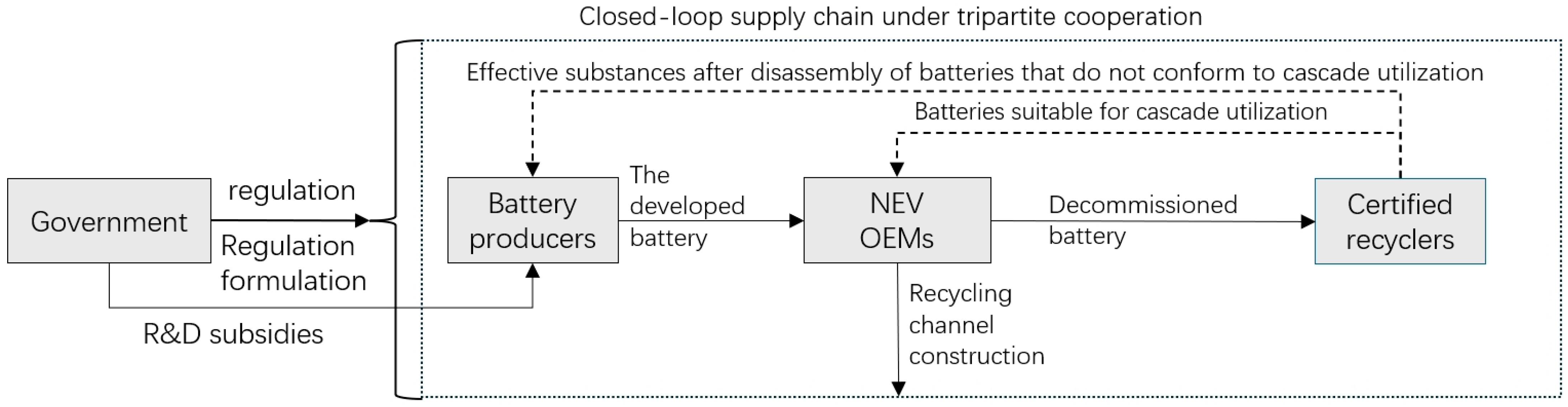

2.2. Supply Chain

2.3. Carbon Emission

2.4. Capacity Requirements and Processes for NEV Battery Recycling

2.5. Applications of Evolutionary Game Theory

2.6. Innovativeness

3. Basic Assumptions and Model Building

3.1. Game Sides

3.2. Game Strategy

3.3. Basic Assumption

4. Modeling and Analysis of a Three-Way Evolutionary Game Considering Carbon Emissions

4.1. Model Construction

4.2. Stability Analysis of Subjective Evolutionary Games

4.2.1. Stability Analysis of Evolutionary Equilibrium Strategies of Power Battery Producers

- (1)

- , , , Regardless of the value , power cell producers are always stabilized.

- (2)

- , , , , at this point is the equilibrium point; , G(y) < 0, , at this point is the equilibrium point.

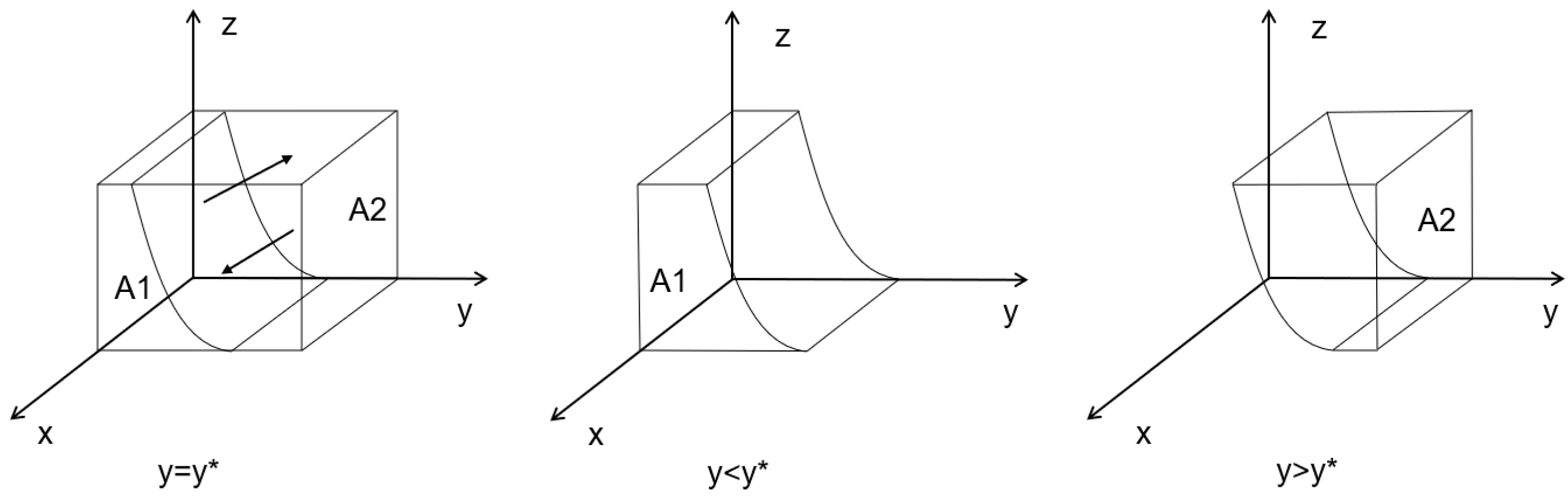

4.2.2. Stability Analysis of Evolutionary Equilibrium Strategies of NEV OEMs

- (1)

- , , , Regardless of the value of , the power cell producer is in a steady state.

- (2)

- , , so the point is the equilibrium point., , so the point is the equilibrium point.

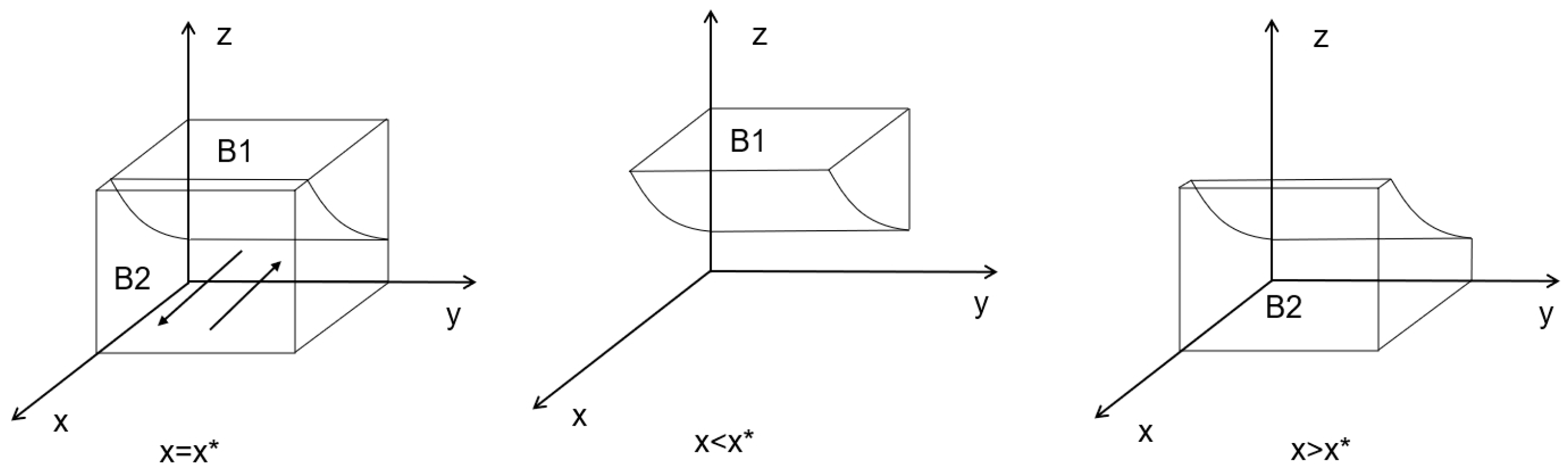

4.2.3. Stability Analysis of Evolutionary Equilibrium Strategies of Certified Recyclers

- (1)

- , , , no matter what the value of x is certified recyclers are all in an evolutionary steady state.

- (2)

- : , , , at this point, is the equilibrium point; , , , so at this point, is the equilibrium point.

4.2.4. Stability Analysis of Three-Party Evolutionary Games

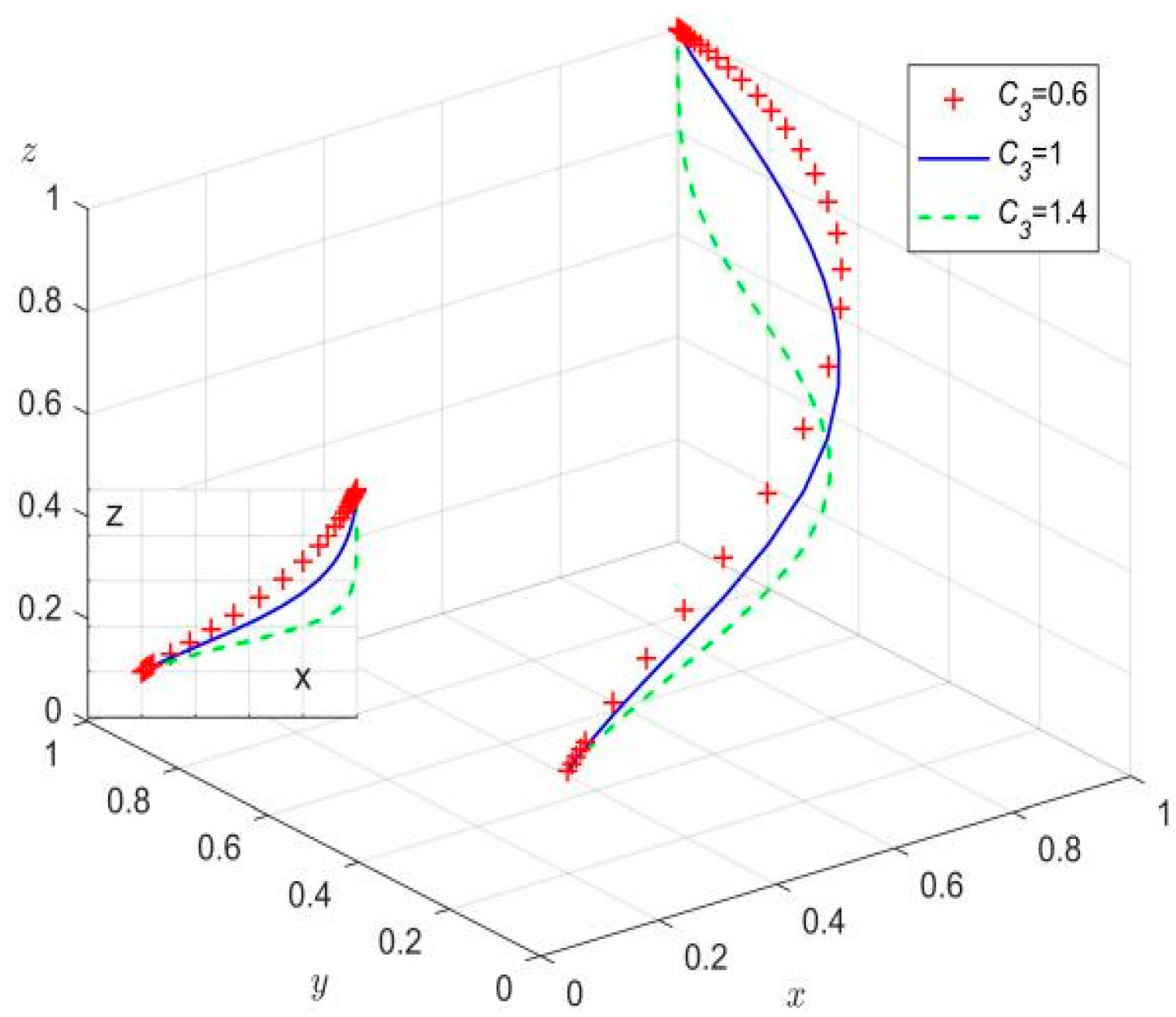

5. Simulation and Analysis

5.1. Impact of Battery Breakdown Costs

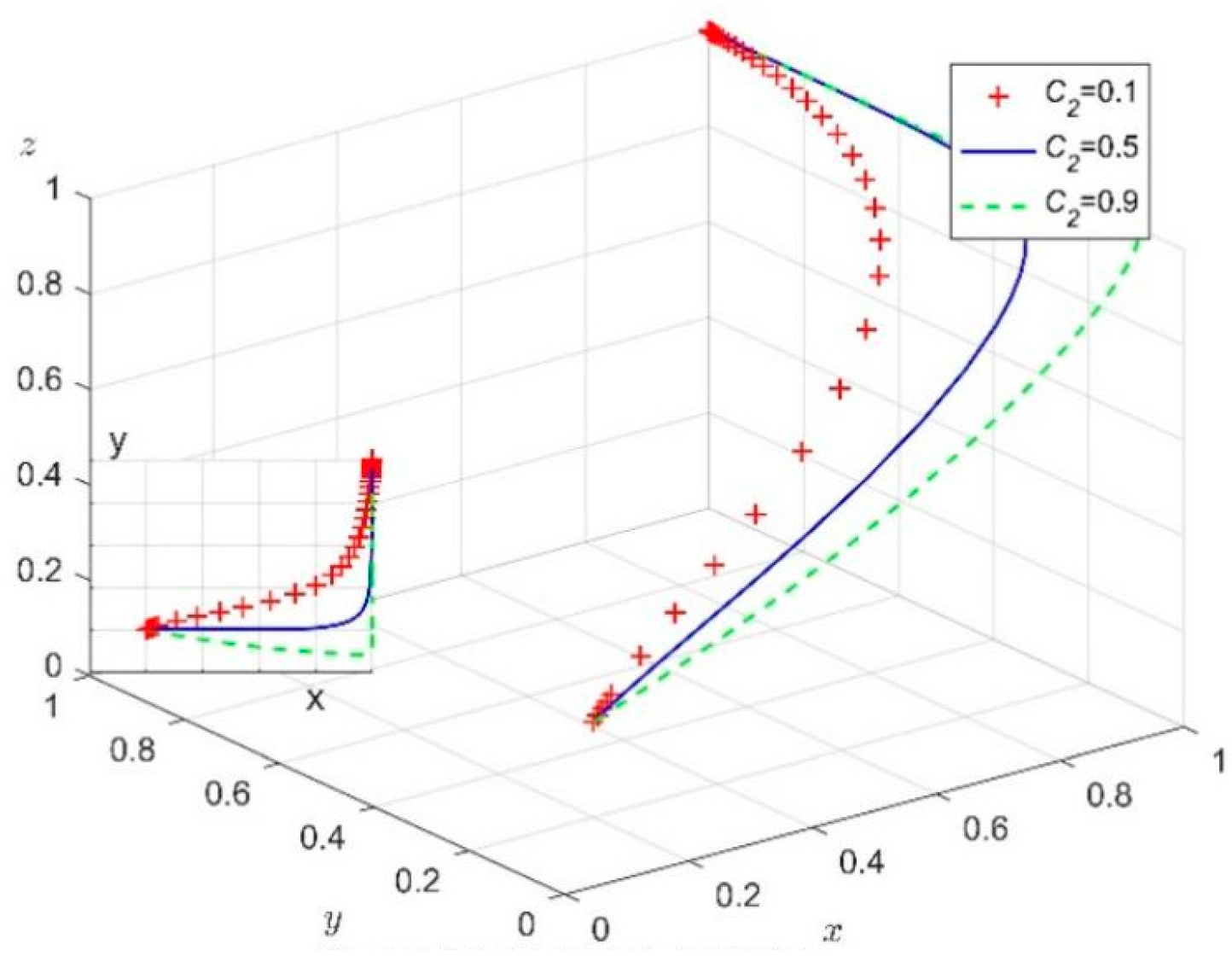

5.2. Impact of Recycling Channel Construction Costs

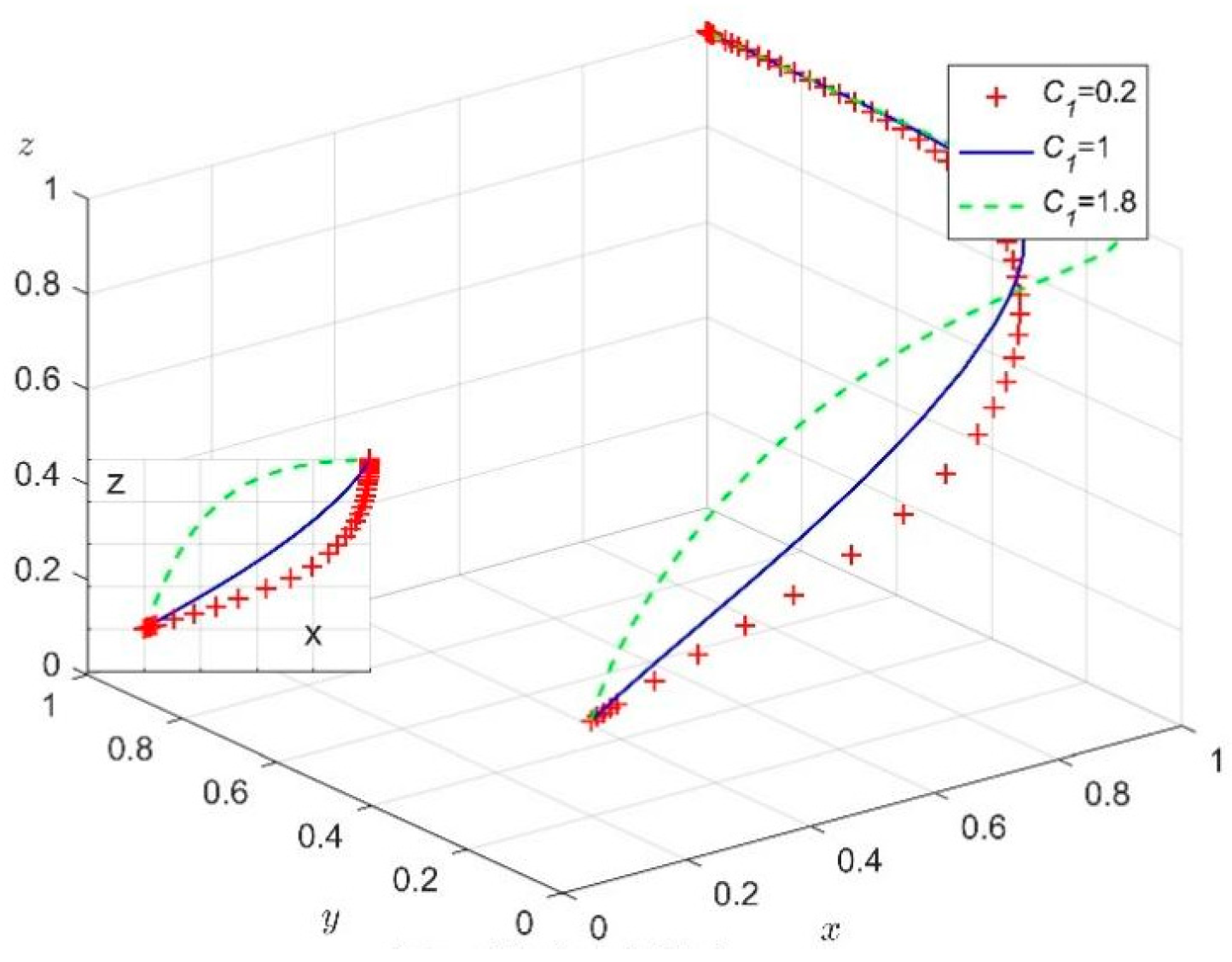

5.3. The Impact of Low Carbon Power Battery R&D Costs

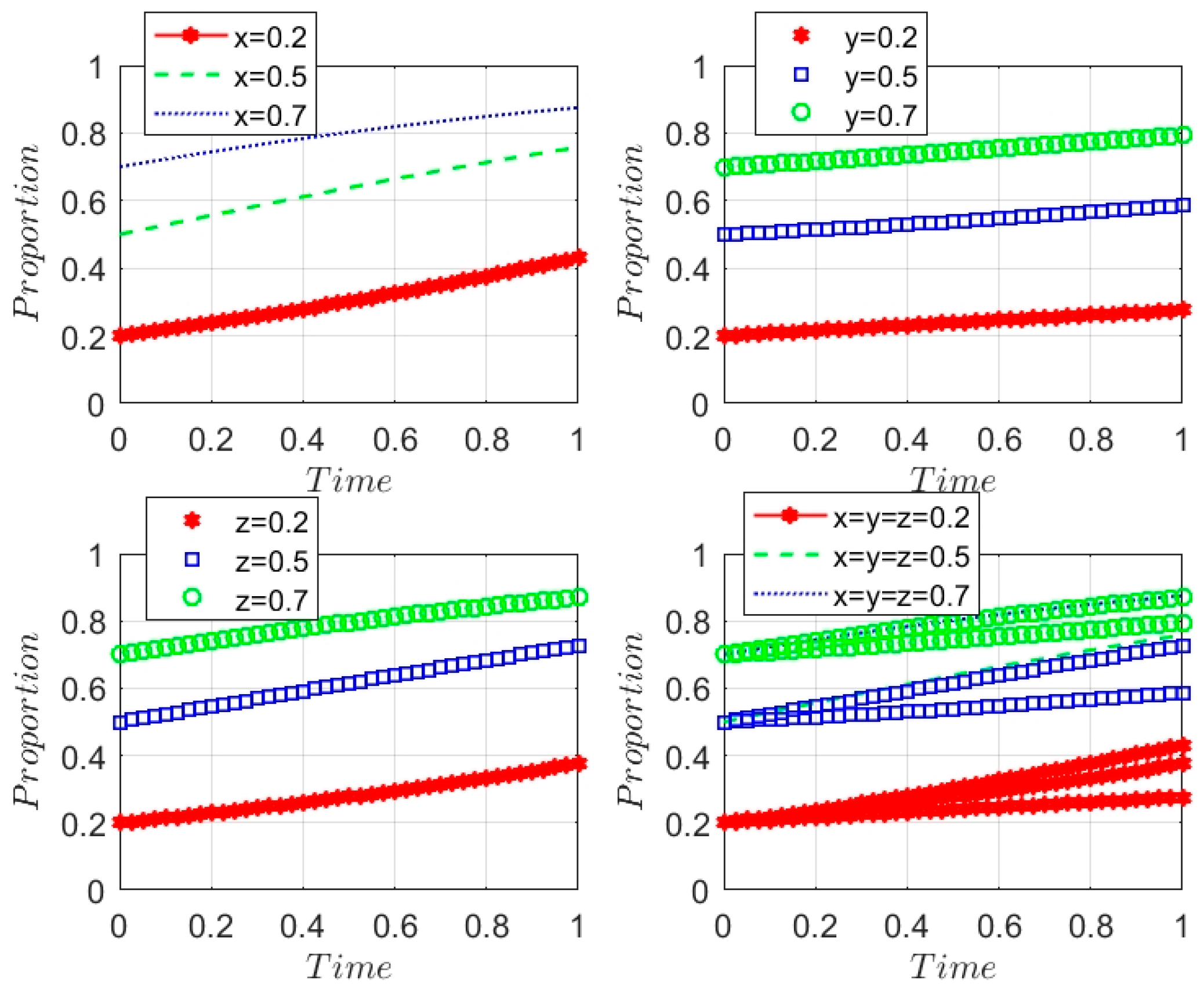

5.4. Interaction Between the Three Parties

5.5. Discussion on NEV Battery Recycling Model

6. Conclusions

7. Shortcomings and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Organisation Internationale des Constructeurs d’Automobiles. Passenger Car Production by Region 2018–2023. OICA Statistical Portal. 2023. Available online: https://www.oica.net/statistics (accessed on 20 August 2024).

- Fortune. The Fortune 500. 2024. Available online: https://fortune.com/fortune500 (accessed on 13 April 2025).

- Li, X.H. The development status and future trends of NEVs in China. People’s Trib. 2024, 9, 76–79. [Google Scholar]

- Chen, Y.Q.; Cha, W.K.; Zhang, X.; Usaporn, S. Status quo and suggestions on the recycling of NEV power batteries. Battery 2024, 54, 94–97. [Google Scholar] [CrossRef]

- Wang, J.; Huang, X.R. Hazards and recycling of waste power batteries. Ecol. Econ. 2021, 37, 5–8. [Google Scholar]

- Ministry of Industry and Information Technology of the People’s Republic of China. Measures for the Comprehensive Utilization Management of NEV Power Batteries; Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2023. Available online: https://www.miit.gov.cn/ (accessed on 13 April 2025).

- Feng, R.; Hua, Z.; Yu, J.; Zhao, Z.; Dan, Y.; Zhai, H.; Shu, X. A comparative investigation on the energy flow of pure battery electric vehicle under different driving conditions. Appl. Therm. Eng. 2025, 269, 126035. [Google Scholar] [CrossRef]

- Ministry of Industry and Information Technology of the People’s Republic of China. 2025 Recycling Action Plan. 2024. Available online: https://www.miit.gov.cn/ (accessed on 31 December 2024).

- CRU International. Global Battery Recycling Market Analysis 2023. 2023. Available online: http://www.crugroup.com (accessed on 13 April 2025).

- Xie, J.Y.; Le, W.; Guo, B.H. Pareto equilibrium in power battery recycling for NEVs based on extended producer responsibility. Chin. J. Manag. Sci. 2022, 30, 309–320. [Google Scholar] [CrossRef]

- Shen, Y.; Song, Z.Z.; Gao, T.; Ma, J. Research on closed-loop supply chain decision making of power battery considering subsidy transfer under EPR system. Sustainability 2022, 14, 12488. [Google Scholar] [CrossRef]

- Ding, J.F.; Pu, X.J.; Cao, Y.X.; Li, J. Research on the recycling cost-sharing mechanism of the closed-loop supply chain for NEVs under the EPR system. Chin. J. Manag. Sci. 2024, 32, 257–268. [Google Scholar] [CrossRef]

- Wei, L.; Wang, C.X.; Li, Y.Q. Simulation research on the impact effects of policies for recycling NEV power batteries. J. Saf. Environ. 2024, 24, 2837–2848. [Google Scholar] [CrossRef]

- Liu, B.P.; Liu, L.L.; Yuan, W.Z.; Wan, Z.R. Decision-making and coordination of closed-loop supply chains for automotive power battery remanufacturing under dual policies. Logist. Technol. 2023, 42, 135–144. [Google Scholar]

- Wu, W.Q.; Zhang, M. Decision analysis of closed-loop supply chain for power batteries under carbon cap-and-trade and subsidy policies. Chin. J. Manag. Sci. 2024, 32, 1–19. [Google Scholar] [CrossRef]

- Li, X.; Du, J.; Liu, P.; Wang, C.; Hu, X.; Ghadimi, P. Optimal choice of power battery joint recycling strategy for electric vehicle manufacturers under a deposit-refund system. Int. J. Prod. Res. 2023, 61, 7281–7301. [Google Scholar] [CrossRef]

- Noudeng, V.; Quan, N.V.; Xuan, T.D. A future perspective on waste management of lithium-ion batteries for electric vehicles in Lao PDR: Current status and challenges. Int. J. Environ. Res. Public Health 2022, 19, 16169. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.; Rhee, S.W. Current status and perspectives on recycling of end-of-life battery of electric vehicle in Korea (Republic of). Waste Manag. 2020, 106, 261–270. [Google Scholar] [CrossRef]

- Giosuè, C.; Marchese, D.; Cavalletti, M.; Isidori, R.; Conti, M.; Orcioni, S.; Ruello, M.L.; Stipa, P. An exploratory study of the policies and legislative perspectives on the end-of-life of lithium-ion batteries from the perspective of producer obligation. Sustainability 2021, 13, 11154. [Google Scholar] [CrossRef]

- Asokan, V.A.; Teah, H.Y.; Kawazu, E.; Hotta, Y. Ambitious EV policy expedites the e-waste and socio-environmental impacts in India. Resour. Conserv. Recycl. 2023, 190, 106829. [Google Scholar] [CrossRef]

- Tasaki, T.; Tojo, N.; Lindehewrst, T. Stakeholders’ differing views on extended producer responsibility and product management: An international questionnaire survey and statistical analysis. J. Ind. Ecol. 2019, 23, 438–451. [Google Scholar] [CrossRef]

- Pazuki, M.; Zakur, G. Dynamic strategic interaction between municipal authorities and companies under the existence of extended producer responsibility legislation. J. Clean. Prod. 2021, 292, 125966. [Google Scholar] [CrossRef]

- Winternitz, K.; Hegge, M.; Bield, J. EU extended producer responsibility for waste tyres: Lessons learned from three case studies—Belgium, Italy, and the Netherlands. Waste Manag. 2019, 89, 386–396. [Google Scholar] [CrossRef]

- Zeng, F.; Lu, Z.; Lu, C. Power Battery Recycling Model of Closed-Loop Supply Chains Considering Different Power Structures Under Government Subsidies. Sustainability 2024, 16, 9589. [Google Scholar] [CrossRef]

- Wang, E.; Nie, J.; Wang, Y. Government Subsidy Strategies for the NEV Power Battery Recycling Industry. Sustainability 2023, 15, 2090. [Google Scholar] [CrossRef]

- Hu, W.J.; Zhou, J.; Ma, C.L.; Zhao, H.; Dong, T. Mode selection for closed-loop supply chains of retired power batteries with dual channels. Syst. Eng.—Theory Pract. 2024, 44, 2572–2595. [Google Scholar]

- Lou, G.X.; Lei, P.; Ma, H.C.; Wan, N. Research on operational decisions of closed-loop supply chains for NEV power batteries under different recycling subsidy policies. Chin. J. Manag. 2023, 20, 267–277. [Google Scholar]

- Fan, J.; Teng, H.; Wang, Y.B. Research on the recycling strategy of NEV waste power battery based on consumer responsibility awareness. Sustainability 2022, 14, 10016. [Google Scholar] [CrossRef]

- Cao, X.G.; Cao, B.W.; Wen, H. Research on closed-loop supply chain decision-making considering fairness concerns in mixed recycling channels. Chin. J. Manag. Sci. 2024, 32, 1–21. [Google Scholar] [CrossRef]

- Wang, Y.B.; Dong, B.Q.; Ge, J.P. How can the recycling of power batteries for EVs be promoted in China? A multiparty cooperative game analysis. Waste Manag. 2024, 186, 64–76. [Google Scholar] [CrossRef]

- Jiao, J.; Pan, Z.; Li, J. Selection of Power Battery Recycling Modes Considering Economic Benefits and Emission Efficiency. Chin. J. Manag. Sci. 2024, 32, 1–16. [Google Scholar] [CrossRef]

- Wang, Z.P.; Zhan, W.P.; Sun, F.C.; Deng, J.J.; Cui, D.S.; Li, X.H. Analysis of carbon emission reduction potential of NEVs. Trans. Beijing Inst. Technol. 2024, 44, 111–122. [Google Scholar] [CrossRef]

- Lai, Z.Y.; Lai, W.B.; Lin, C.Y.; He, L.J.; Lin, H.; Xiao, F.Y.; Qian, Q.R.; Zhang, J.X.; Chen, Q.H.; Zeng, L.X. Research progress on the recycling and carbon accounting of retired power batteries. Chin. J. Process Eng. 2024, 24, 139–150. [Google Scholar]

- Zhang, C.; Chen, Y.X.; Tian, Y.X. Collection and recycling decisions for electric vehicle end-of-life power batteries in the context of carbon emissions reduction. Comput. Ind. Eng. 2023, 175, 108869. [Google Scholar] [CrossRef]

- Zhang, C.; Tian, Y.X.; Cui, M.Y. Recycling mode selection and carbon emission reduction decisions for a multi-channel closed-loop supply chain of electric vehicle power batteries. Chin. J. Manag. Sci. 2024, 32, 184–195. [Google Scholar] [CrossRef]

- Qi, Y.; Yao, W.; Zhu, J. Study on the Selection of Recycling Strategies for the Echelon Utilization of Electric Vehicle Batteries under the Carbon Trading Policy. Sustainability 2024, 16, 7737. [Google Scholar] [CrossRef]

- Xu, X.; Liu, Z.; Liu, W.; Pei, C.; Nie, Z.; Wu, X. A sustainable development benchmarking framework for energy companies based on topic mining and knowledge graph: The case of oil and gas industry. Renew. Sustain. Energy Rev. 2024, 196, 114350. [Google Scholar] [CrossRef]

- Xu, A.; Wang, W.; Zhu, Y. Does smart city pilot policy reduce CO2 emissions from industrial firms? Insights from China. J. Innov. Knowl. 2023, 8, 100367. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, X. Determinants of carbon emissions from road transportation in China: An extended input-output framework with production-theoretical approach. Energy 2025, 316, 134493. [Google Scholar] [CrossRef]

- Friedman, D. Evolutionary Game in Economics. Econ. Erica 1991, 59, 637–666. [Google Scholar] [CrossRef]

- Zhu, L.; Rong, J.; Zhang, S. Tripartite Evolutionary Game and Simulation Analysis of Drug Safety Quality Supervision under Government Reward-Penalty Mechanism. Chin. J. Manag. Sci. 2021, 29, 55–67. [Google Scholar]

- Wu, R.; Zhang, Y.; Jiao, L. Tripartite Evolutionary Game and Simulation Analysis of Research Team Collaboration Behavior Based on Academic Social Networks. China Soft Sci. 2024, 9, 174–184. [Google Scholar]

- Zhou, D.; Cheng, X.; Wang, Q.; Yu, X. Analysis of the Impact Effects of Heterogeneous Policy Combinations on the Development of the NEV Industry. Chin. J. Manag. Sci. 2024, 1–14. [Google Scholar] [CrossRef]

- Lyu, X.; Xu, Y.; Sun, D. An Evolutionary Game Research on Cooperation Mode of the NEV Power Battery Recycling and Gradient Utilization Alliance in the Context of China’s NEV Power Battery Retired Tide. Sustainability 2021, 13, 4165. [Google Scholar] [CrossRef]

| Relevant Parameter Settings | Definition |

|---|---|

| Battery Manufacturers | |

| Active R&D | |

| Passive R&D | |

| R&D cost | |

| Carbon emission subsidies | |

| Carbon emission cost | |

| Additional cooperation benefit | |

| Cost for construction of network | |

| Disassembly costs | |

| NEV OEMs | |

| Active cooperation | |

| Non-cooperation | |

| Purchase cost | |

| Cost for construction of network | |

| Additional revenue | |

| Certified Recyclers | |

| Full service | |

| Partial service | |

| Carbon emission cost | |

| Additional cooperation benefit | |

| Cost for construction of network | |

| Disassembly costs |

| Strategy | BP R | OEM R | T-PR R |

|---|---|---|---|

| 0 | |||

| 0 | |||

| Local Equilibrium Point | Eigenvalue 1 | Eigenvalue 2 | Eigenvalue 3 |

|---|---|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Liu, Y. Research on New Energy Vehicle Battery (NEV) Recycling Model Considering Carbon Emission. Sustainability 2025, 17, 4356. https://doi.org/10.3390/su17104356

Li F, Liu Y. Research on New Energy Vehicle Battery (NEV) Recycling Model Considering Carbon Emission. Sustainability. 2025; 17(10):4356. https://doi.org/10.3390/su17104356

Chicago/Turabian StyleLi, Feng, and Yuan Liu. 2025. "Research on New Energy Vehicle Battery (NEV) Recycling Model Considering Carbon Emission" Sustainability 17, no. 10: 4356. https://doi.org/10.3390/su17104356

APA StyleLi, F., & Liu, Y. (2025). Research on New Energy Vehicle Battery (NEV) Recycling Model Considering Carbon Emission. Sustainability, 17(10), 4356. https://doi.org/10.3390/su17104356