A Sustainable Multi-Criteria Optimization Approach for the Energy Retrofit of Collective Housing in Algeria Using the ELECTRE III Tool

Abstract

1. Introduction

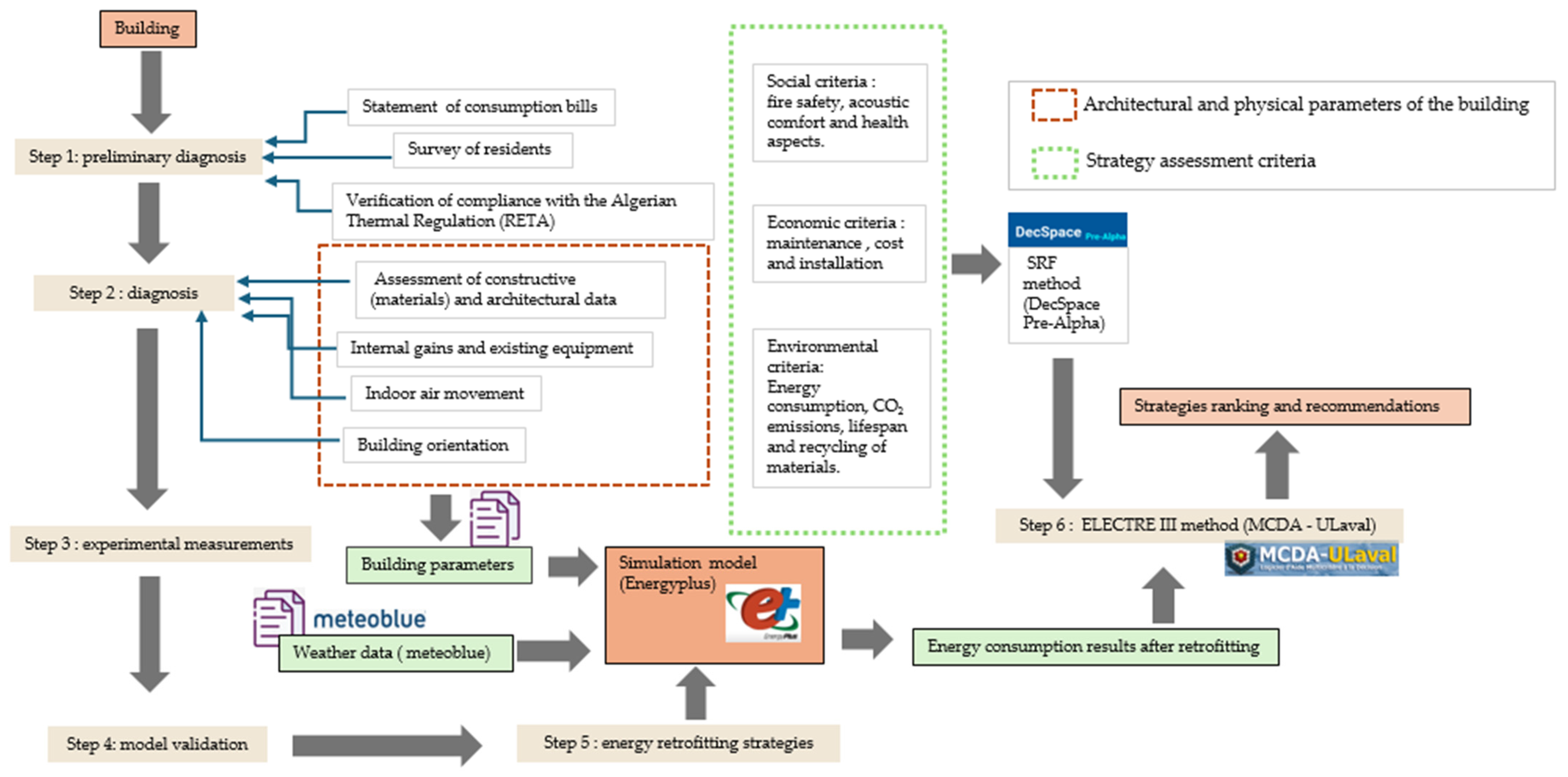

2. Methodology and Tools

2.1. The Methodological Approach

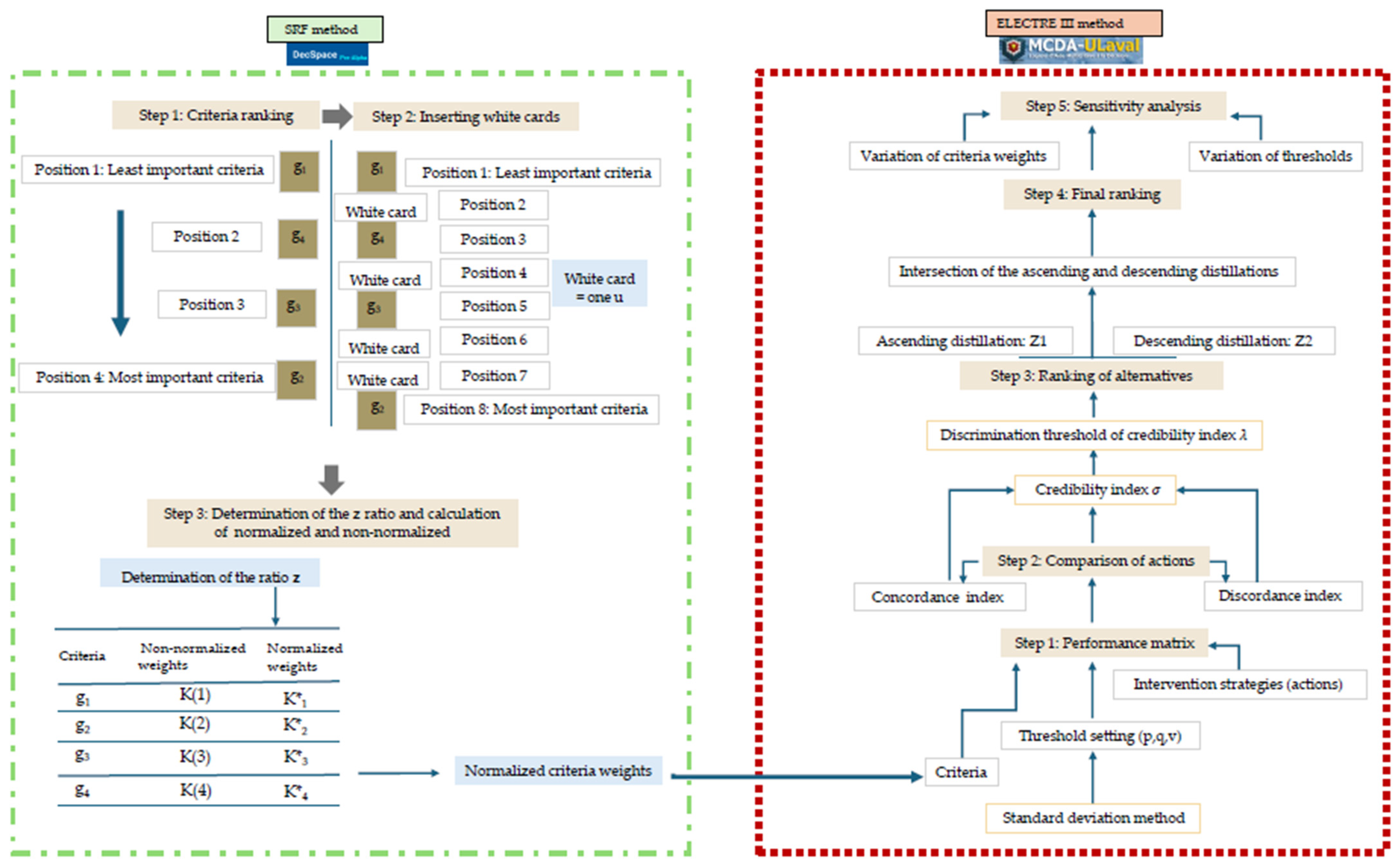

2.2. Decision-Support Method: ELECTRE III

Conceptual Framework of the ELECTRE III Method

- (1)

- Performance Matrix Construction:

- (2)

- Weighting the Criteria:

- If the cost difference is below q (e.g., 50 DZD), the two strategies are considered indifferent.

- If the cost difference falls between q and p (e.g., 70 DZD), a weak preference is expressed.

- If the difference exceeds p (e.g., 120 DZD), a strong preference is established.

- If the difference exceeds the veto threshold (e.g., 350 DZD), the alternative is considered unacceptable, and the outranking is blocked.

- (3)

- Concordance and Discordance Indices:

- (4)

- Credibility Index and Final Ranking:

- (5)

- Sensitivity Analysis:

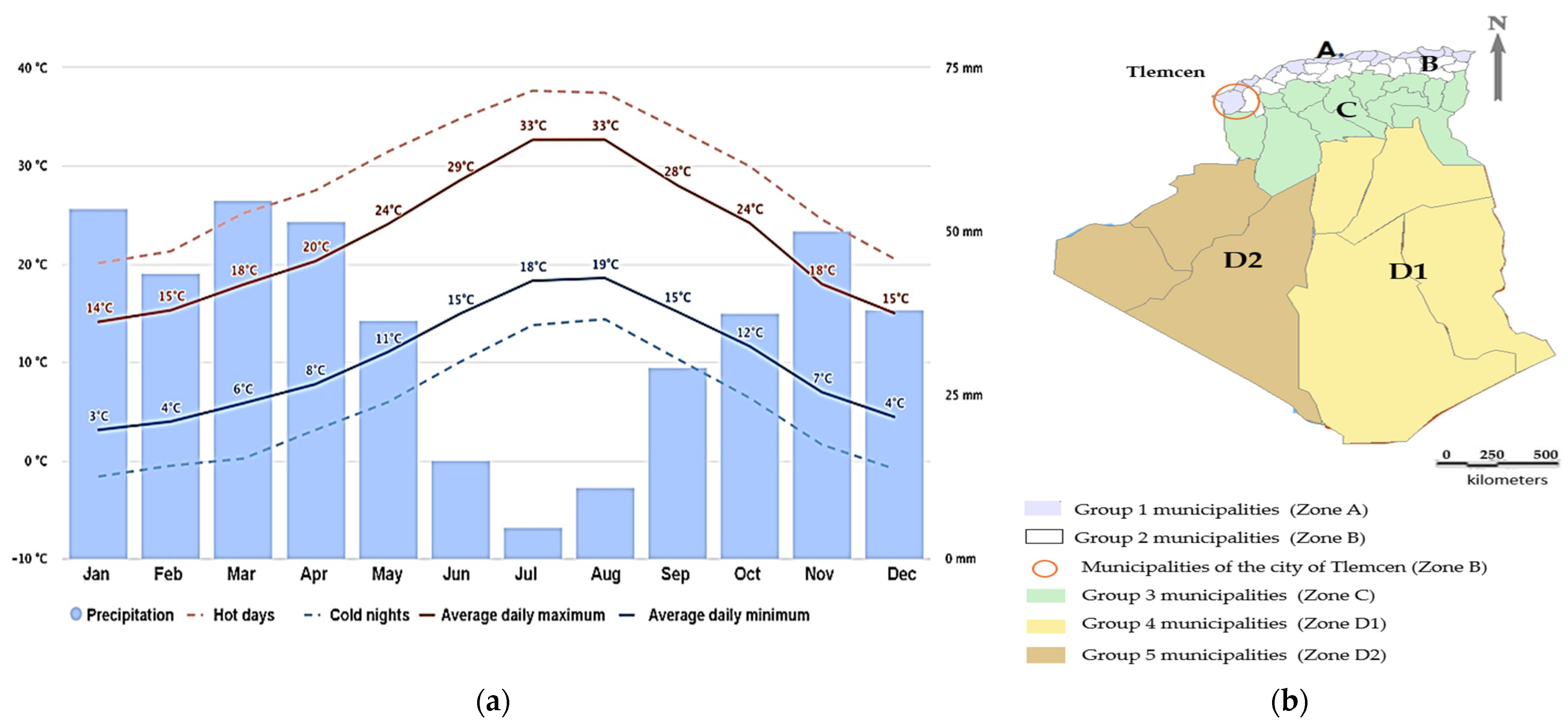

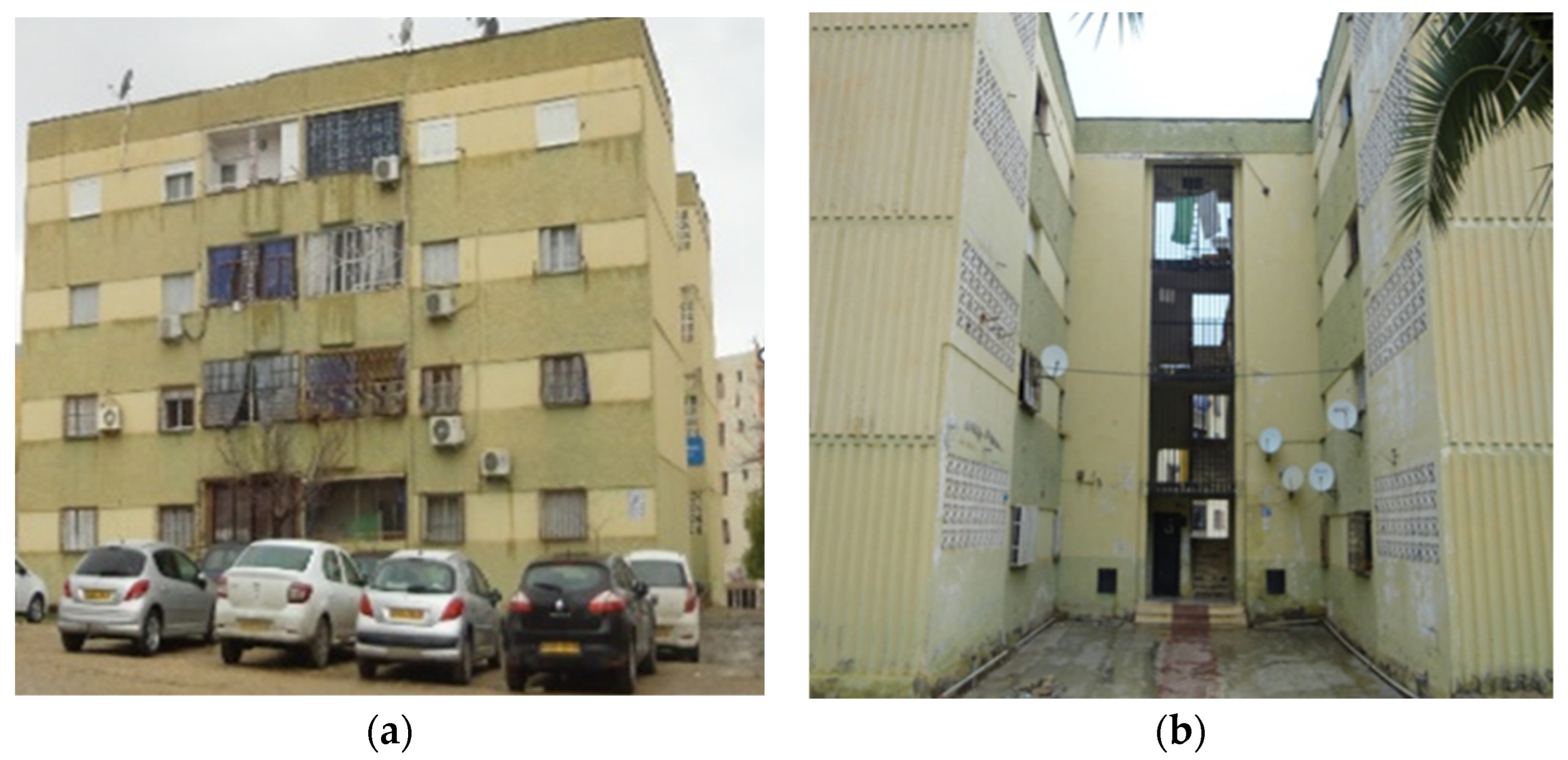

3. Case Study

3.1. Energy Balance

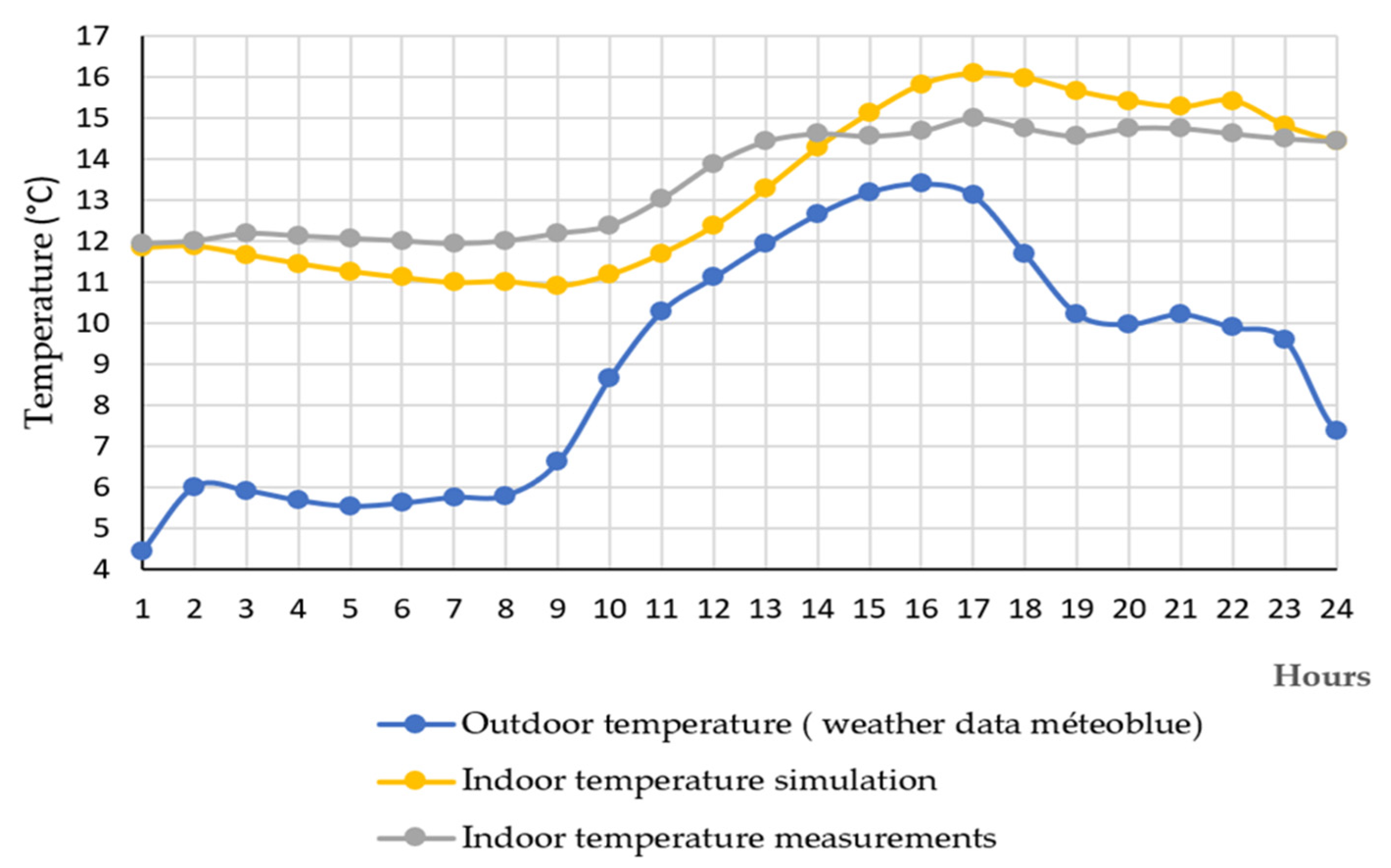

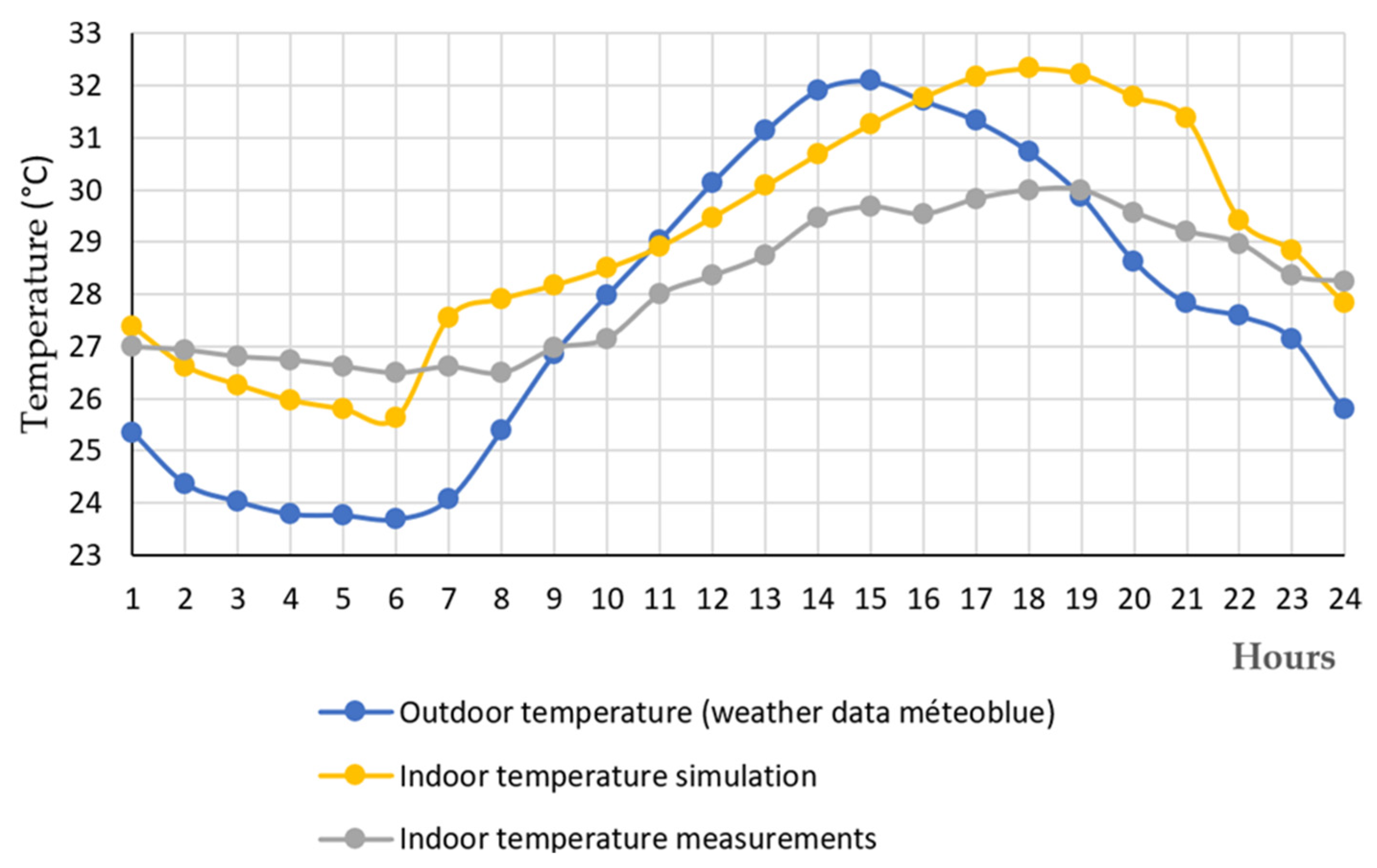

3.2. Validation of the Simulation Model

4. Results and Discussion

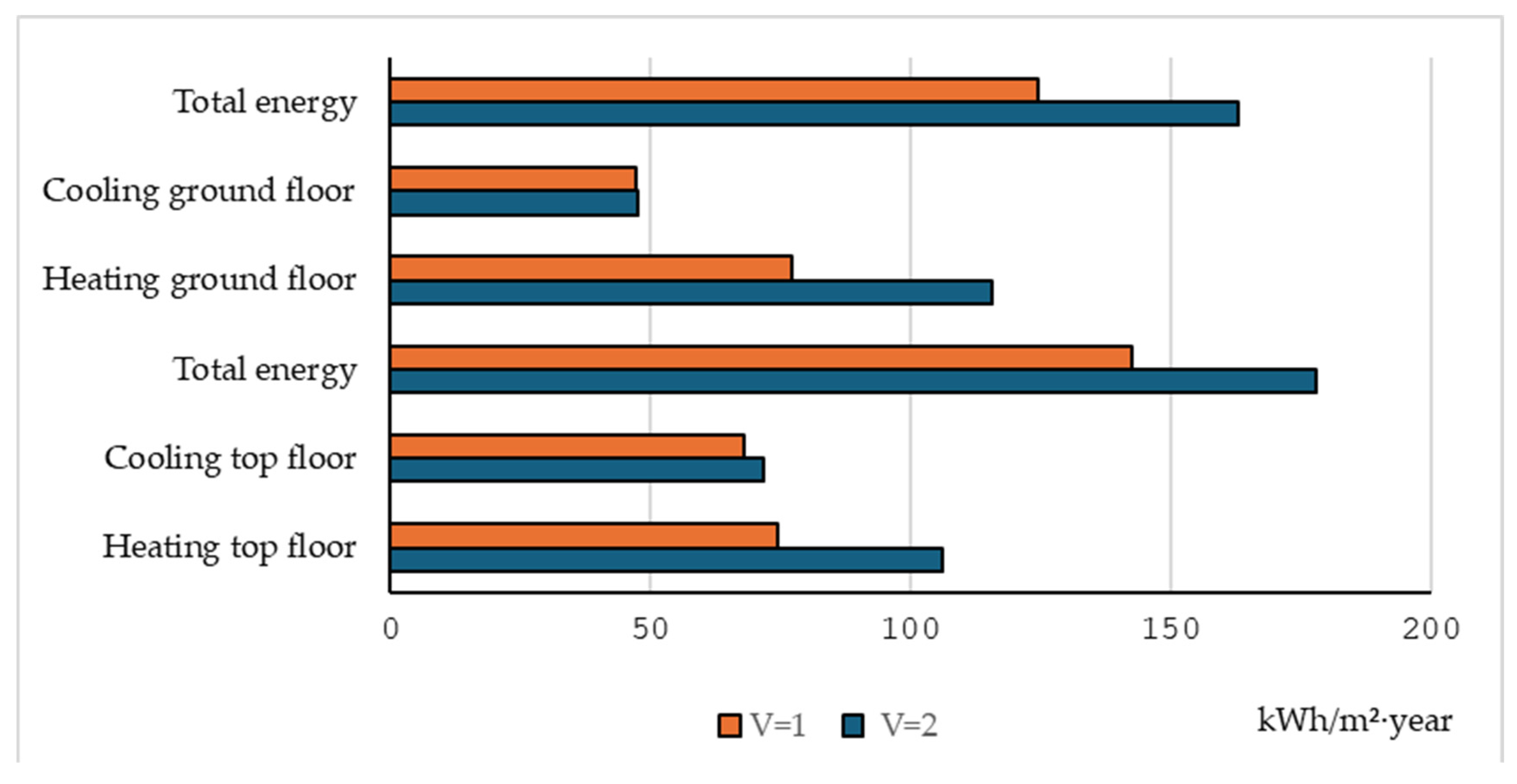

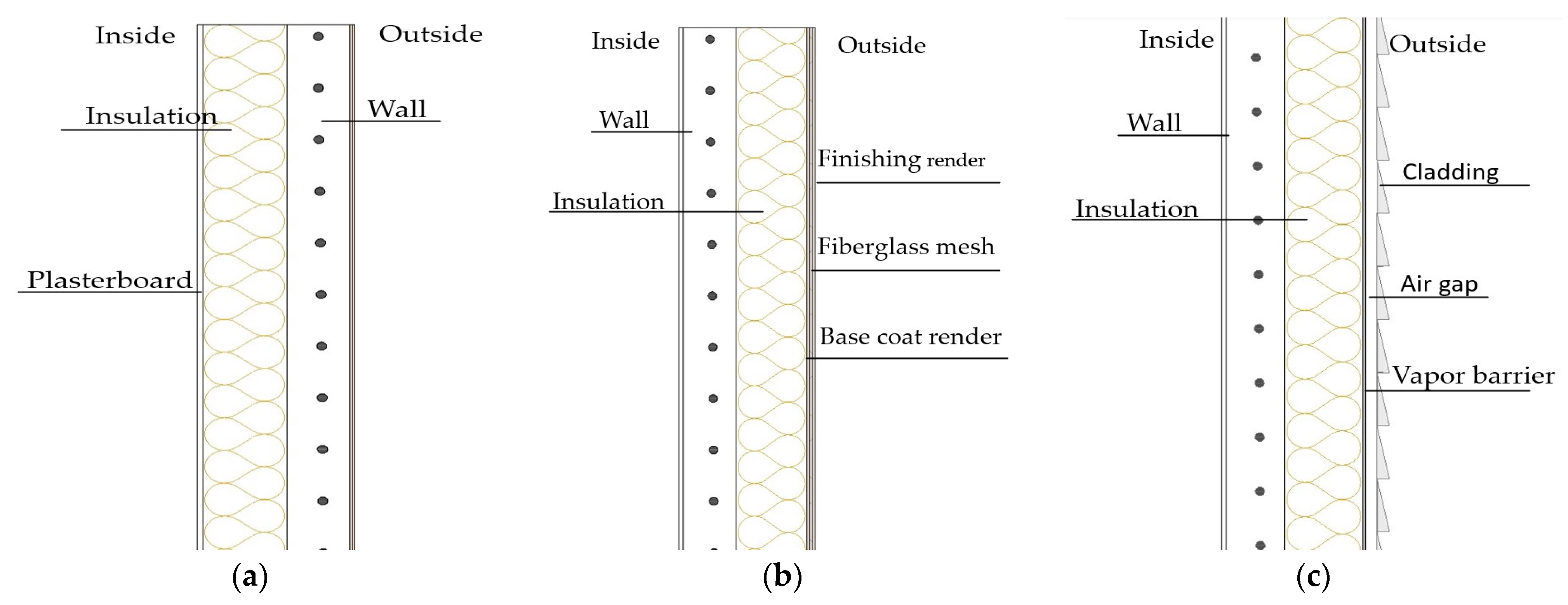

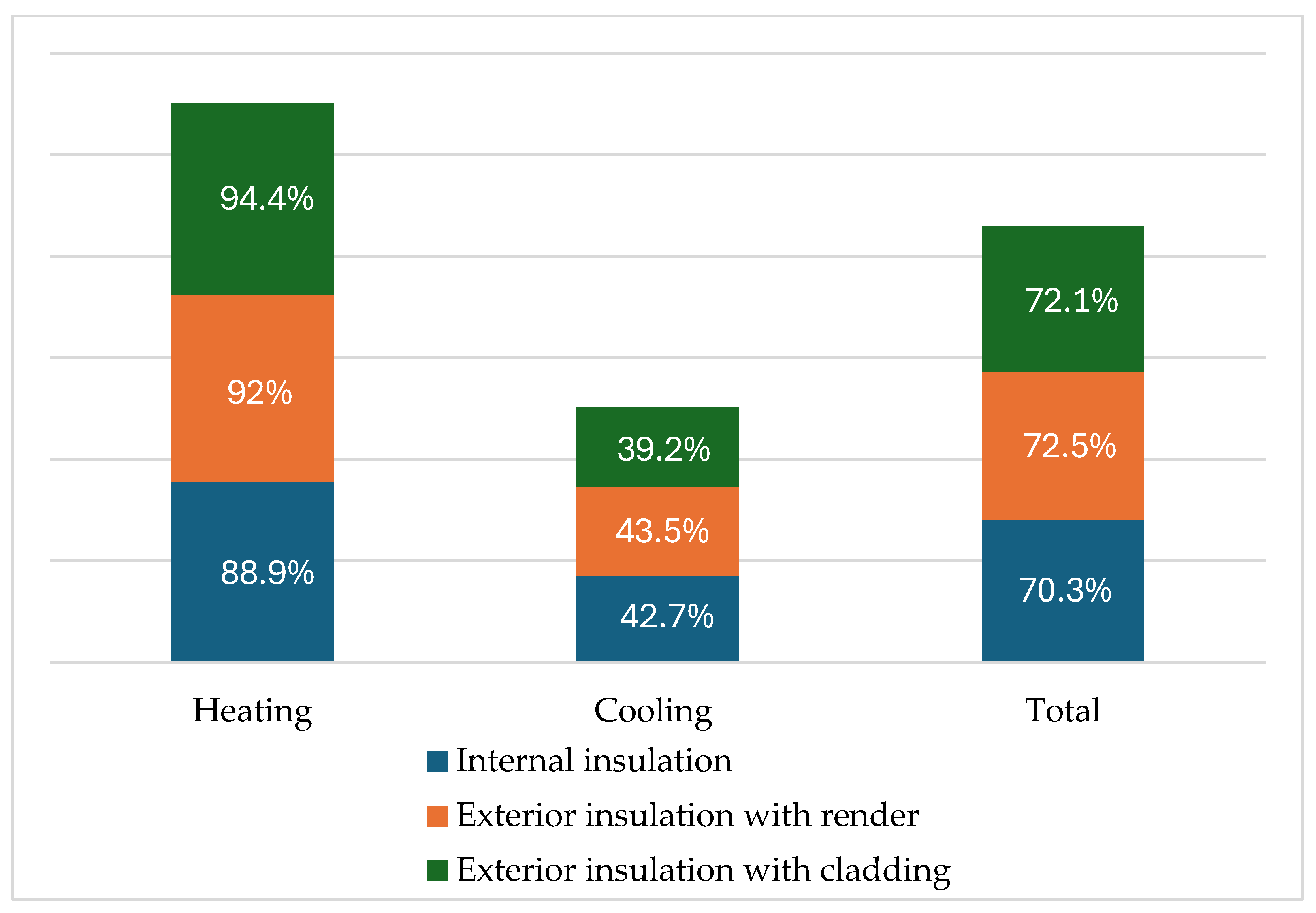

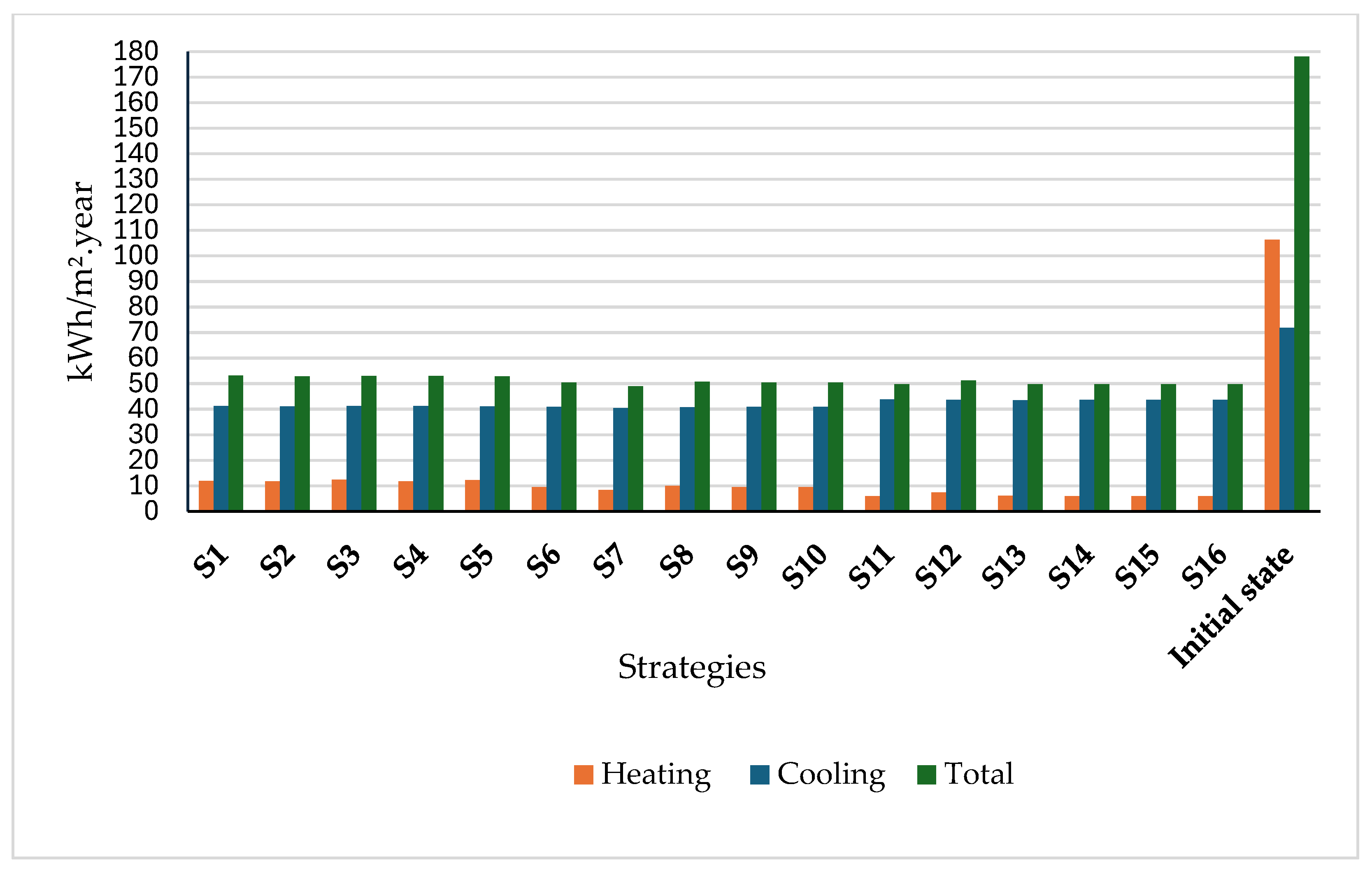

4.1. Energy Consumption After Retrofit

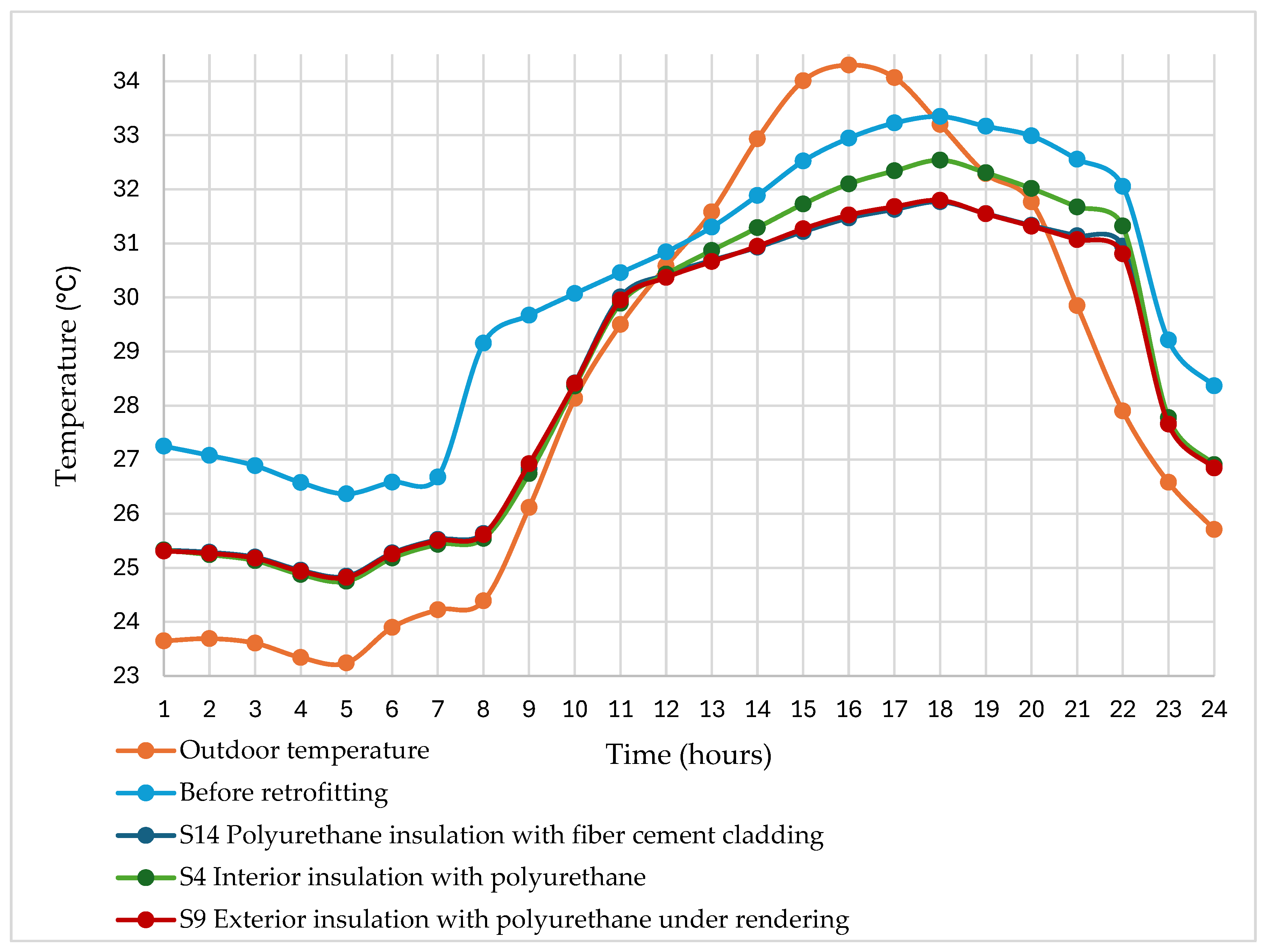

4.2. Variation in Indoor Temperature After Retrofit

4.3. Applying the ELECTRE III Method

- C1—CO2 emissions (Kg CO2/m2);

- C2—Sustainability and recycling potential;

- C3—Energy consumption (Wh/year);

- C3′—Maintenance;

- C4—Economic cost (DZD);

- C5—Fire resistance scoring;

- C6—Acoustic comfort scoring;

- C7—Health hazard scoring;

- C8—Installation convenience scoring.

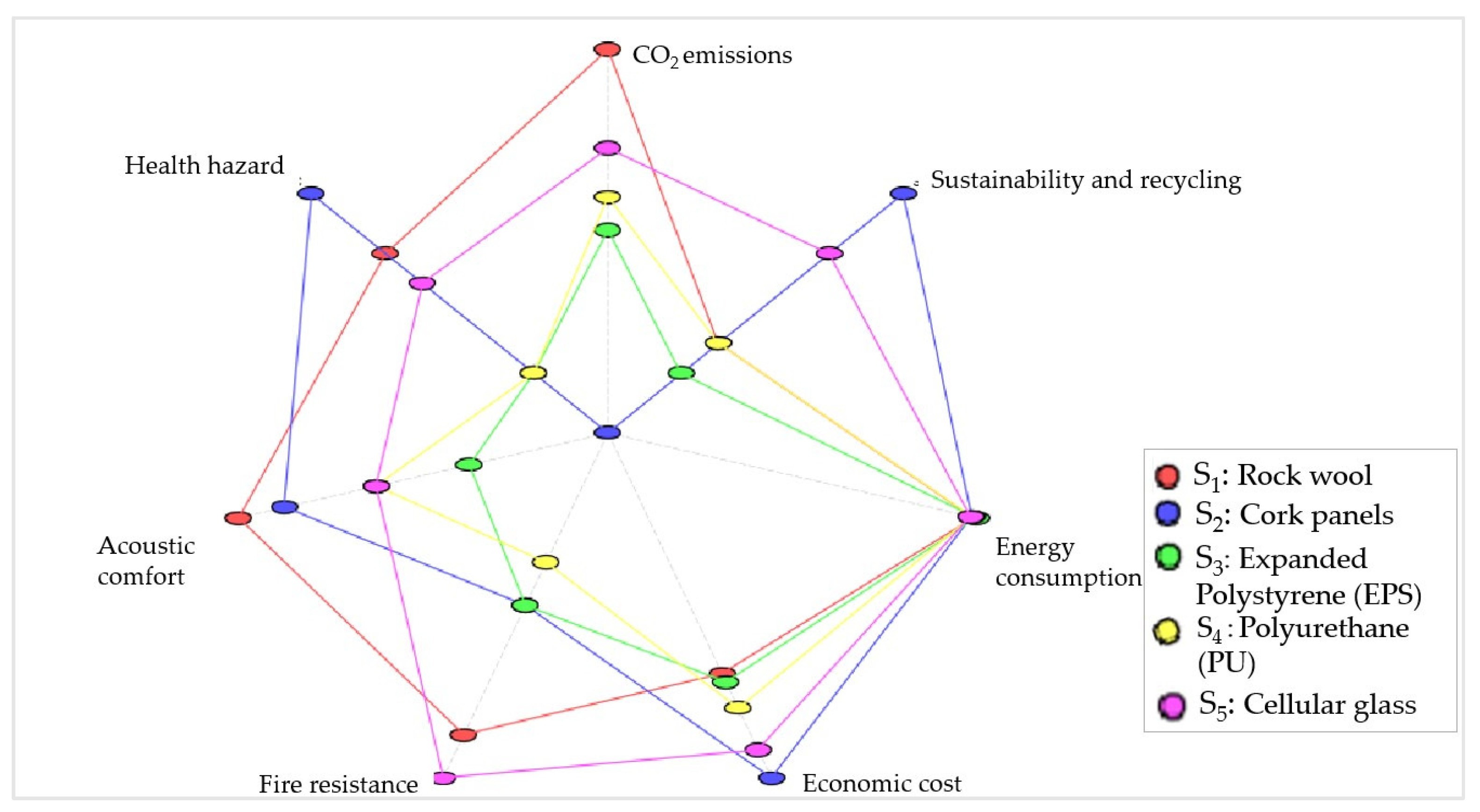

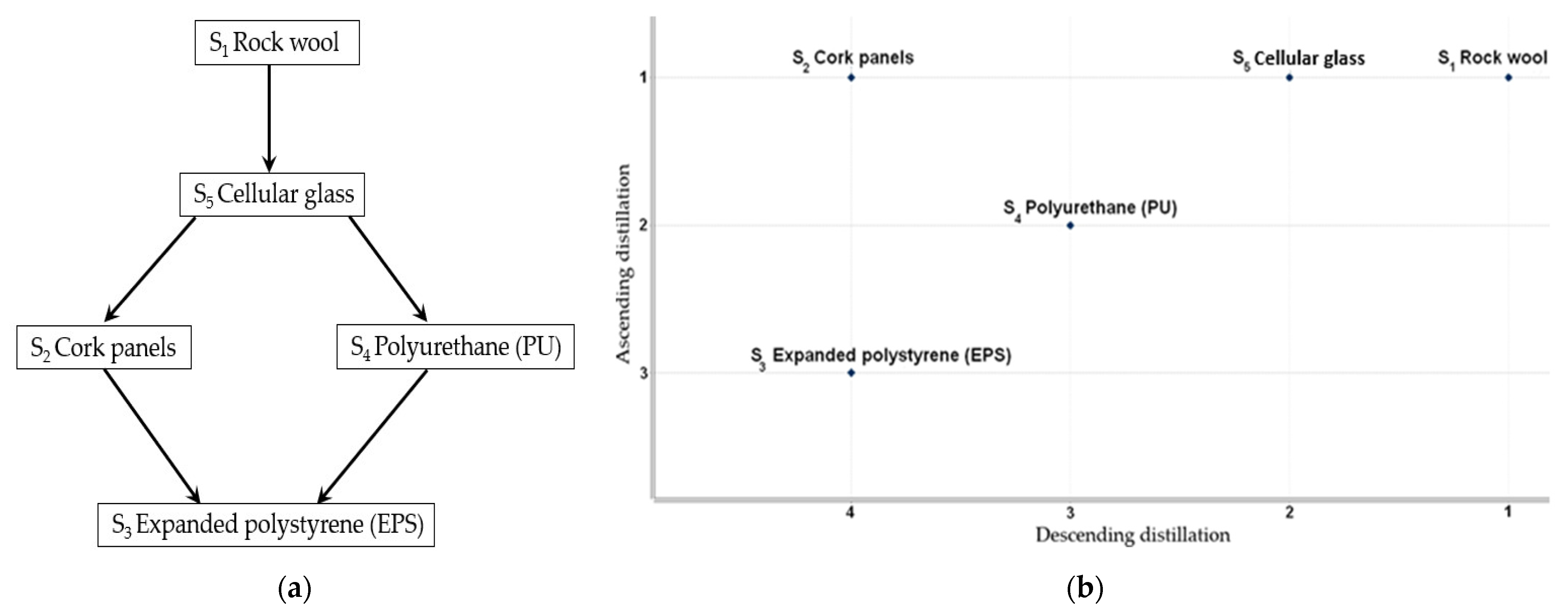

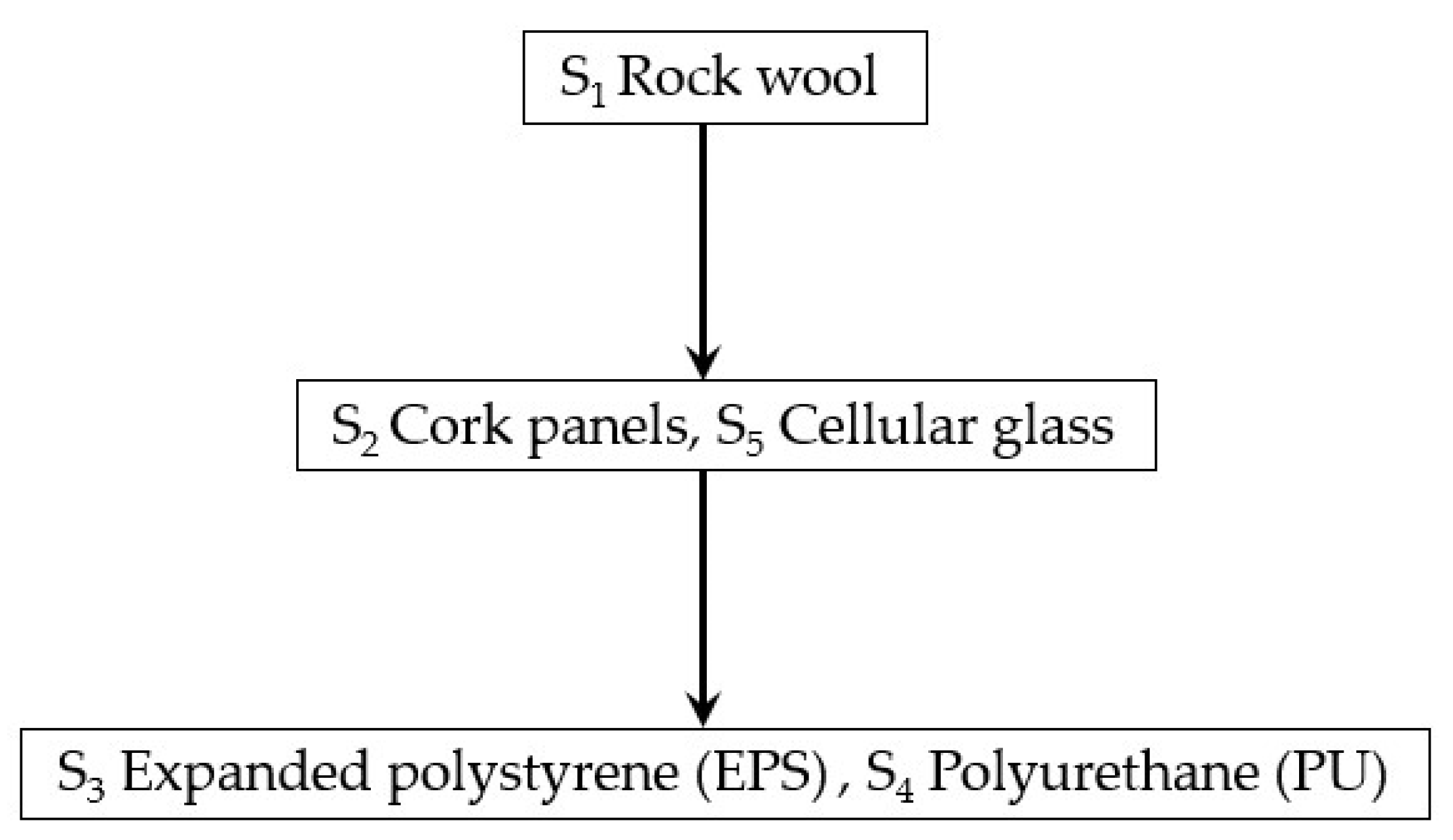

4.3.1. Interior Insulation

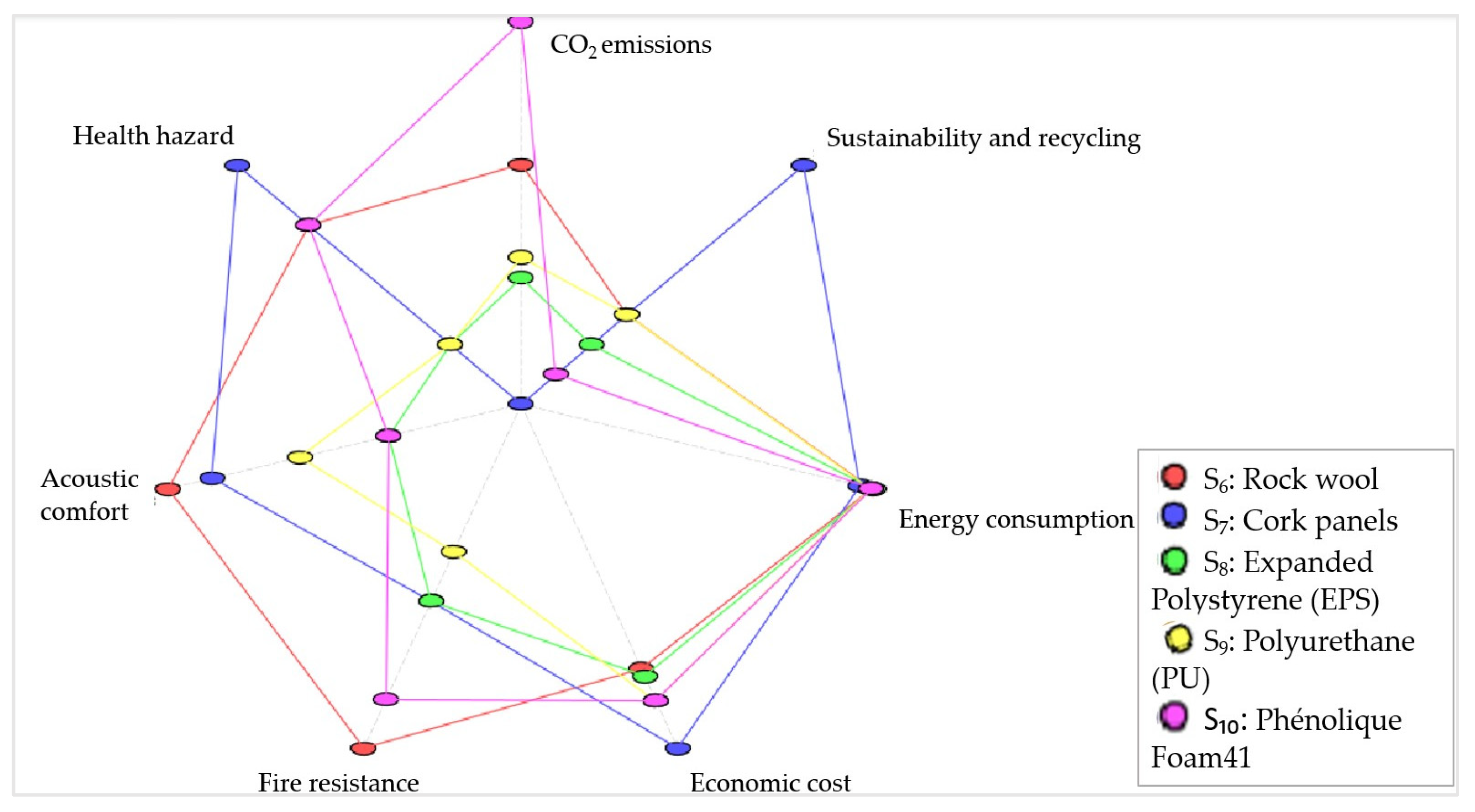

4.3.2. Exterior Insulation with Rendering

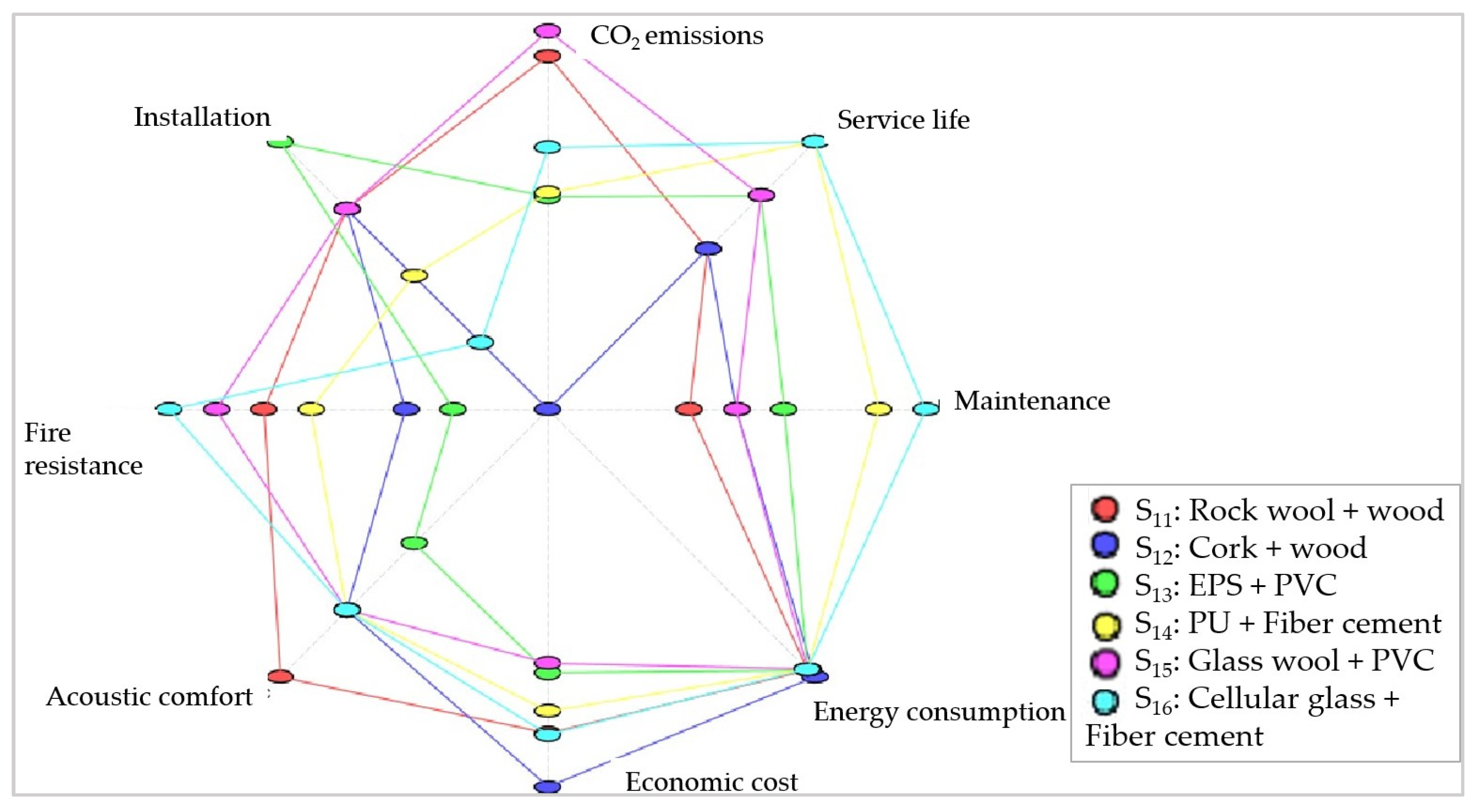

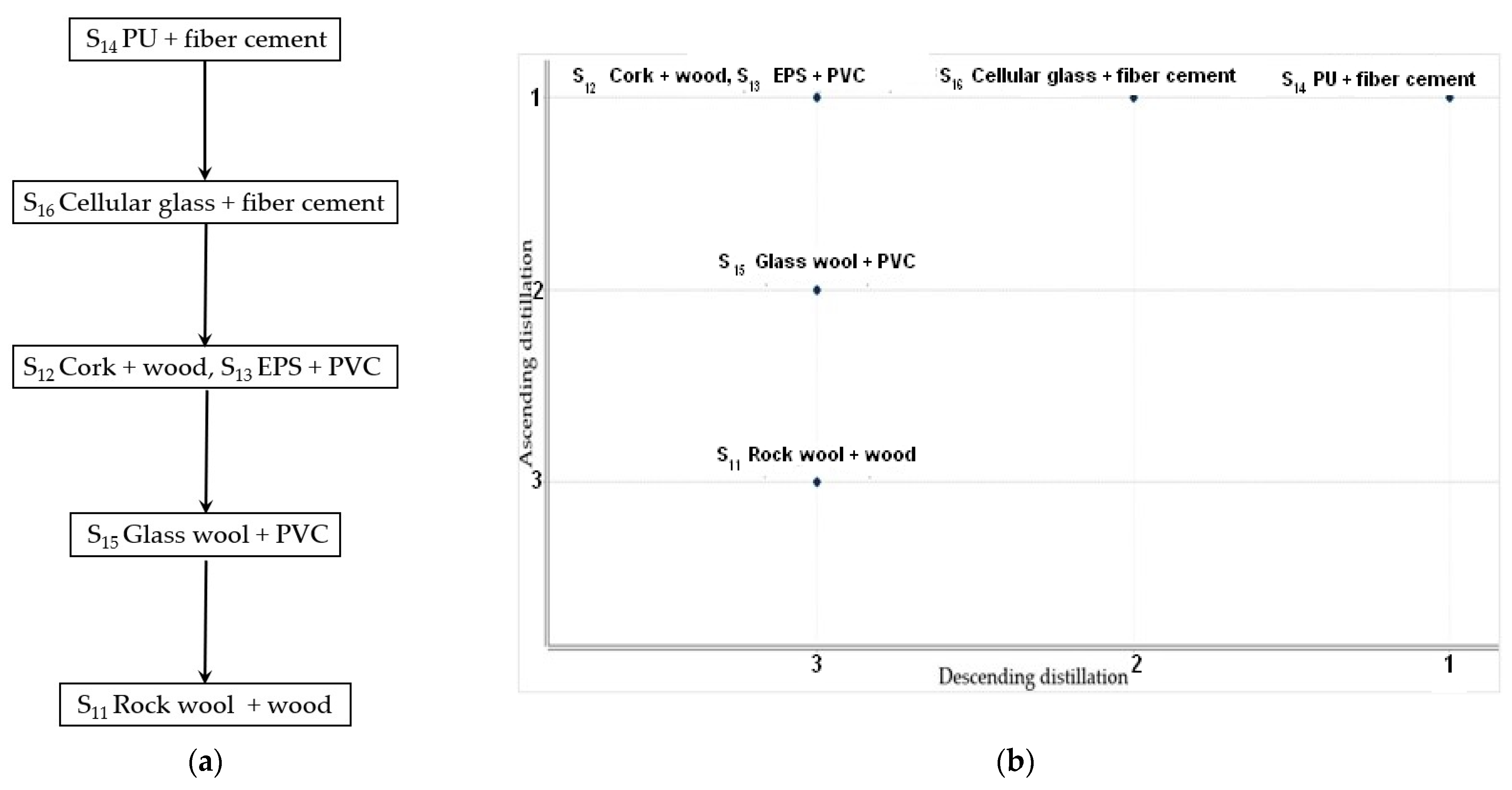

4.3.3. Exterior Insulation with Cladding

4.4. Results and Sensitivity Study of the ELECTRE III Method

4.5. Broader Implications for Retrofit Decision Making and Sustainability

5. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Set of alternatives to choose from |

| F | Family of criteria that evaluate each of A’s alternatives |

| according to criterion j | |

| The weight associated with criterion j, expressing its relative importance in the set F | |

| z | Coefficient for normalizing criterion weights |

| Low preference threshold for criterion j | |

| Veto threshold for criterion j | |

| on all criteria | |

| Dc | Set of j such that its partial discordance is greater than the global concordance |

| action pair comparison | |

| s(λ) | Credibility index discrimination threshold |

| Z1 | Partial pre-order obtained by downward breakdown |

| Z2 | Partial pre-order obtained by upward breakdown |

| Z | The intersection of Z1 and Z2 to obtain the final ranking |

| λ | Thermal conductivity, W·m−1·K−1 |

| Cp | Specific heat, J·kg−1·K−1 |

| Material density, Kg/m3 | |

| kWhpe | Kilowatt-hour Primary Energy |

| DZD | Algerian Dinar |

Appendix A

| Position | Criteria | Non-Normalized Weights | Normalized Weights |

|---|---|---|---|

| 1 | CO2 | 1 | 4.82 |

| 1 | Sustainability | 1 | 4.82 |

| 1 | Health hazard | 1 | 4.82 |

| (2) * | / | / | / |

| 3 | Acoustic comfort | 2.10 | 10.12 |

| (4), (4) | / | / | / |

| 5 | Fire resistance | 3.75 | 18.07 |

| (6), (6) | / | / | / |

| 7 | Economic cost | 5.40 | 26.02 |

| (8) | / | / | / |

| 9 | Energy consumption | 6.50 | 31.33 |

| Position | Criteria | Non-Normalized Weights | Normalized Weights |

|---|---|---|---|

| 1 | CO2 | 1 | 3 |

| 1 | Installation | 1 | 3 |

| (2) * | / | / | / |

| 3 | Acoustic comfort | 2.53 | 7.59 |

| (4) | / | / | / |

| 5 | Maintenance | 4.07 | 12.21 |

| 5 | Service life | 4.07 | 12.21 |

| 6 | Fire resistance | 4.84 | 14.53 |

| (7) | (7) | / | / |

| (8) | (8) | / | / |

| 9 | Economic cost | 7.14 | 21.43 |

| (10) | (10) | / | / |

| 11 | Energy consumption | 8.67 | 26.03 |

References

- Cantin, R.; Mourtada, A.; Guarracino, G.; Adra, N.; Nasser, M.; Maamari, F. Scenarios of application of energy certification procedure for residential buildings in Lebanon. Energy Policy 2007, 35, 3167–3178. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A Review on Buildings Energy Consumption Information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- République Algérienne Démocratique et Populaire. Ministère de L’énergie et des Mines, T. Bilan Energétique National 2022. Available online: https://www.energy.gov.dz/?article=bilan-energetique-national-du-secteur (accessed on 29 January 2025).

- Ouahab, A. Les Gisements d’économie d’énergie et Des Émissions de CO2 à l’horizon 2050 Dans Le Secteur Résidentiel Algérien. J. Renew. Energ. 2015, 18, 667–682. [Google Scholar] [CrossRef]

- Seddiki, M.; Anouche, K.; Bennadji, A.; Boateng, P. A Multi-Criteria Group Decision-Making Method for the Thermal Renovation of Masonry Buildings: The Case of Algeria. Energy Build. 2016, 129, 471–483. [Google Scholar] [CrossRef]

- Ding, Z.; Li, J.; Wang, Z.; Xiong, Z. Multi-Objective Optimization of Building Envelope Retrofits Considering Future Climate Scenarios: An Integrated Approach Using Machine Learning and Climate Models. Sustainability 2024, 16, 8217. [Google Scholar] [CrossRef]

- Biega, K.; Krarti, M. Evaluation of Exterior Insulated Panels for Residential Deep Energy Retrofits. Energies 2024, 17, 3988. [Google Scholar] [CrossRef]

- Fezzioui, N.; Belkacem, D.; Mebirika, B.; Larbi, S. Influence of Dynamic Characteristics of the Building Envelope on Thermal Comfort in Southern Algeria (in French). Rev. Energ. Renouvelables 2008, 11, 25–34. [Google Scholar]

- Bentoumi, L.; Bouacida, T.; Bessaïh, R.; Bouttout, A. Impact of Thermal Insulation on Energy Consumption in Buildings. J. Therm. Eng. 2024, 10, 924–935. [Google Scholar] [CrossRef]

- Ahn, B.-L.; Kim, J.-H.; Jang, C.-Y.; Leigh, S.-B.; Jeong, H. Window Retrofit Strategy for Energy Saving in Existing Residences with Different Thermal Characteristics and Window Sizes. Build. Serv. Eng. Res. Technol. 2015, 37, 18–32. [Google Scholar] [CrossRef]

- Shu, L.; Mo, Y.; Zhao, D. Energy retrofits for smart and connected communities: Scopes and technologies. Renew. Sustain. Energy Rev. 2024, 199, 114510. [Google Scholar] [CrossRef]

- Desvallées, L. Low-carbon retrofits in social housing: Energy efficiency, multidimensional energy poverty, and domestic comfort strategies in southern Europe. Energy Res. Soc. Sci. 2022, 85, 102413. [Google Scholar] [CrossRef]

- Djafri, R.; Osman, M.M.; Rabe, N.S.; Shuid, S. Algerian Housing Policies. Asian J. Environ. Behav. Stud. 2019, 4, 1–14. [Google Scholar] [CrossRef]

- Benmicia, N. The Energy Efficiency Diagnosis of Residential Buildings in Algeria. E3S Web Conf. 2023, 436, 01009. [Google Scholar] [CrossRef]

- Taylor, N.W.; Searcy, J.K.; Jones, P.H. Multifamily Energy-Efficiency Retrofit Programs: A Florida Case Study. Energy Effic. 2016, 9, 385–400. [Google Scholar] [CrossRef]

- Hens, H. Energy Efficient Retrofit of an End of the Row House: Confronting Predictions with Long-Term Measurements. Energy Build. 2010, 42, 1939–1947. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Hou, C.; Hou, J.; Wei, D.; Hou, Y. Optimization Analysis of Thermal Insulation Layer Attributes of Building Envelope Exterior Wall Based on DeST and Life Cycle Economic Evaluation. Case Stud. Therm. Eng. 2019, 14, 100410. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Jin, L.W.; Wang, Z.N.; Zhang, J.Y.; Liu, X.; Zhang, L.H. Effects of Wall Configuration on Building Energy Performance Subject to Different Climatic Zones of China. Appl. Energy 2017, 185, 1565–1573. [Google Scholar] [CrossRef]

- Ozel, M. Effect of Insulation Location on Dynamic Heat-Transfer Characteristics of Building External Walls and Optimization of Insulation Thickness. Energy Build. 2014, 72, 288–295. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M.F. Effect of Insulation Location on Initial Transient Thermal Response of Building Walls. J. Therm. Envel. Build. Sci. 2001, 24, 275–300. [Google Scholar] [CrossRef]

- Ali, A.; Issa, A.; Elshaer, A. A Comprehensive Review and Recent Trends in Thermal Insulation Materials for Energy Conservation in Buildings. Sustainability 2024, 16, 8782. [Google Scholar] [CrossRef]

- Napoli, G.; Bottero, M.; Ciulla, G.; Dell’Anna, F.; Figueira, J.R.; Greco, S. Supporting Public Decision Process in Buildings Energy Retrofitting Operations: The Application of a Multiple Criteria Decision Aiding Model to a Case Study in Southern Italy. Sustain. Cities Soc. 2020, 60, 102214. [Google Scholar] [CrossRef]

- Wątróbski, J.; Jankowski, J.; Ziemba, P.; Karczmarczyk, A.; Zioło, M. Generalised Framework for Multi-Criteria Method Selection. Omega 2019, 86, 107–124. [Google Scholar] [CrossRef]

- Dell’Anna, F.; Bottero, M.; Becchio, C.; Corgnati, S.P.; Mondini, G. Designing a Decision Support System to Evaluate the Environmental and Extra-Economic Performances of a Nearly Zero-Energy Building. Smart Sustain. Built Environ. 2020, 9, 413–442. [Google Scholar] [CrossRef]

- Daniel, S.; Ghiaus, C. Multi-Criteria Decision Analysis for Energy Retrofit of Residential Buildings: Methodology and Feedback from Real Application. Energies 2023, 16, 902. [Google Scholar] [CrossRef]

- Taherdoost, H.; Madanchian, M. A Comprehensive Overview of the ELECTRE Method in Multi-Criteria Decision-Making. J. Manag. Sci. Eng. Res. 2023, 6, 5–16. [Google Scholar] [CrossRef]

- Salminen, P.; Hokkanen, J.; Lahdelma, R. Comparing Multicriteria Methods in the Context of Environmental Problems. Eur. J. Oper. Res. 1998, 104, 485–496. [Google Scholar] [CrossRef]

- Kokaraki, N.; Hopfe, C.J.; Robinson, E.; Nikolaidou, E. Testing the Reliability of Deterministic Multi-Criteria Decision-Making Methods Using Building Performance Simulation. Renew. Sustain. Energy Rev. 2019, 112, 991–1007. [Google Scholar] [CrossRef]

- Caillet, R. Analyse Multicritère: Étude de Comparaison Des Méthodes Existantes En Vue d’une Application En Analyse de Cycle de Vie. 1 August 2003. Available online: https://cirano.qc.ca/files/publications/2003s-53.pdf (accessed on 10 January 2025).

- Behzadian, M.; Kazemzadeh, R.B.; Albadvi, A.; Aghdasi, M. PROMETHEE: A Comprehensive Literature Review on Methodologies and Applications. Eur. J. Oper. Res. 2010, 200, 198–215. [Google Scholar] [CrossRef]

- Rey, E. Office Building Retrofitting Strategies: Multicriteria Approach of an Architectural and Technical Issue. Energy Build. 2004, 36, 367–372. [Google Scholar] [CrossRef]

- Roulet, C.-A.; Flourentzou, F.; Labben, H.H.; Santamouris, M.; Koronaki, I.; Dascalaki, E.; Richalet, V. ORME: A Multicriteria Rating Methodology for Buildings. Build. Environ. 2002, 37, 579–586. [Google Scholar] [CrossRef]

- Catalina, T.; Virgone, J.; Blanco, E. Multi-Source Energy Systems Analysis Using a Multi-Criteria Decision Aid Methodology. Renew. Energy 2011, 36, 2245–2252. [Google Scholar] [CrossRef]

- Almeida, M.; Bragança, L.; Silva, P.; Silva, S.; Mateus, R.; Barbosa, J.; Araújo, C. Selection of Rehabilitation Construction Solutions Using ELECTRE III Method. In Proceedings of the Reabilitação Energética de Edifícios, Guimaraes, Portugal, 28 September 2012. [Google Scholar]

- Centre de Developpement des Energies Renouvelables Réglementation Thermique Algérienne RETA. Available online: https://reta.cder.dz/ (accessed on 22 December 2024).

- Ministere de L’habitat Document Technique Réglementaire (DTR C3-2). Réglmentation Thermique Des Batiments D’habitation. Règles de Calcul Des Déperditions Calorifiques; Centre National d’Etudes et de Recherches Intégrées du Bâtiment: Souidania, Algeria, 1998.

- Ministere de L’habitat Document Technique Réglementaire (DTR C3-4). Climatisation. Règles de Calcul Des Apports Calorifiques Des Batiments; Centre National d’Etudes et de Recherches Intégrées du Bâtiment: Souidania, Algeria, 1998.

- Meteoblue. Available online: https://www.meteoblue.com/fr/meteo/aujourd%27hui/suisse_suisse_2658434 (accessed on 20 December 2024).

- EnergyPlus. Available online: https://energyplus.net/ (accessed on 29 January 2025).

- Université Laval, C. Logiciel d’aide Multicritère à la Décision MCDA-ULaval|Université Laval. Available online: https://mcda.fsa.ulaval.ca/fr/ (accessed on 29 January 2025).

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative Analysis of Building Insulation Material Properties and Performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Rathan, N.S.; Raut, A.; Rahul, B.G. Comparative Analysis of Various Insulation Materials for Building Envelope Components. IOP Conf. Ser. Earth Environ. Sci. 2021, 822, 012014. [Google Scholar] [CrossRef]

- Iqbal, A.; Mubin, S.; Gavrishyk, E.; Masood, R.; Roy, K.; Moradibistouni, M. A Comparative Performance Analysis of Different Insulation Materials Installed in a Residential Building of a Cold Region in Pakistan. J. Compos. Sci. 2022, 6, 165. [Google Scholar] [CrossRef]

- Lu, X.; Memari, A. Comparative Analysis of Energy Performance for Residential Wall Systems with Conventional and Innovative Insulation Materials: A Case Study. Open J. Civ. Eng. 2019, 9, 240–254. [Google Scholar] [CrossRef][Green Version]

- ASTM C1639-19; Standard Specification for Fabrication of Cellular Glass Pipe and Tubing Insulation. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C1696-20; Standard Guide for Industrial Thermal Insulation Systems. ASTM International: West Conshohocken, PA, USA, 2020.

- Rockwool. Product Application Guide; ROCKWOOL Limited: Mumbai, India. Available online: https://www.rockwool.com/group/products-and-applications/ (accessed on 5 February 2025).

- Figueira, J.R.; Greco, S.; Roy, B.; Słowiński, R. An Overview of ELECTRE Methods and Their Recent Extensions. J. Multi-Criteria Decis. Anal. 2013, 20, 61–85. [Google Scholar] [CrossRef]

- Figueira, J.; Roy, B. Determining the Weights of Criteria in the ELECTRE Type Methods with a Revised Simos’ Procedure. Eur. J. Oper. Res. 2002, 139, 317–326. [Google Scholar] [CrossRef]

- Roy, B.; Bouyssou, D. Aide Multicritère à La Décision: Méthodes et Cas; Economica: Paris, France, 1993. [Google Scholar]

- Stephan, E. Méthode d’aide à La Décision Multicritère Des Stratégies de Réhabilitation Des Bâtiments Anciens En Pierre Calcaire: Application Au Patrimoine En Tuffeau. Ph.D. Thesis, Université de Lyon, Lyon, France, 17 December 2014. [Google Scholar]

- Ouahab, A. Modélisation Des Consommations d’énergie et Des Émissions de CO2 à Long Terme Appliquée Au Secteur Résidentiel Algérien. Doctoral Theses, École Doctorale Sciences de L’homme et de la Société, Tours, France, 2015. [Google Scholar]

- Pompeo, C.; Gueret, C. Conductivité Thermique Des Matériaux-Fascicule 2/5; Centre Scientifique et Technique du Batiment CSTB: Paris, France, 2000. [Google Scholar]

- Imessad, K.; Kharchi, R.; Bouchaib, S.; Chenak, A.; Hakem, S.; Hamidat, A.; Larbi-youcef, S.; Sami, S.; Sahnoune, F. Mise En Application de La Nouvelle Réglementation Thermique Algérienne Du Bâtiment. J. Renew. Energ. 2017, 20, 591–597. [Google Scholar] [CrossRef]

- Belgherras, S.; Bekkouche, S.M.A.; Benouaz, T.; Benamrane, N. Prospective Analysis of the Energy Efficiency in a Farm Studio under Saharan Weather Conditions. Energy Build. 2017, 145, 342–353. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, Y.; Li, J.; Fan, Q. Experimental Study on Seismic Performance of L-shaped Partly Precast Reinforced Concrete Shear Wall with Cast-in-situ Boundary Elements. Struct. Des. Tall Spec. Build. 2019, 28, e1602. [Google Scholar] [CrossRef]

- Vitorino, H.; Batalha, N.; Sousa, R.; Fernandes, P.; Varum, H.; Rodrigues, H. Assessment of Seismic Behavior of an RC Precast Building. In Proceedings of the International Conference on Automation Innovation in Construction (CIAC-2019), Leiria, Portugal, 7–8 November 2019. [Google Scholar] [CrossRef]

- Hallik, J.; Kalamees, T.; Pikas, E. (PDF) Airtightness of Estonian Dwellings—Median and Base-Values for Heat Loss Estimation. In Proceedings of the 13th Nordic Symposium on Building Physics, Aalborg, Denmark, 12 June 2023. [Google Scholar] [CrossRef]

- Understanding the Energy Label. Available online: https://energy-efficient-products.ec.europa.eu/ecodesign-and-energy-label/understanding-energy-label_en (accessed on 22 March 2025).

- Rehman, H.U. Experimental Performance Evaluation of Solid Concrete and Dry Insulation Materials for Passive Buildings in Hot and Humid Climatic Conditions. Appl. Energy 2017, 185 Pt 2, 1585–1594. [Google Scholar] [CrossRef]

- Bendouma, M. Systèmes D’isolation Thermique Par L’extérieur: Études Expérimentales et Numériques des Transferts de Chaleur et D’humidité. Ph.D. Thesis, Université de Bretagne Sud, Lorient, France, 2018. [Google Scholar]

- Wu, S.; Zhou, P.; Xiong, Y.; Ma, C.; Wu, D.; Lu, W. Strategies for Driving the Future of Educational Building Design in Terms of Indoor Thermal Environments: A Comprehensive Review of Methods and Optimization. Buildings 2025, 15, 816. [Google Scholar] [CrossRef]

| Elements | Outside to Inside Layers | Composition | Thickness (m) | Thermal Conductivity λ (W·m−1·K−1) | (Kg/m3) | Specific Heat Capacity Cp (J·Kg−1·K−1) |

|---|---|---|---|---|---|---|

| North exterior wall (load-bearing) | 1 | Cement mortar | 0.02 | 1.15 | 1800 | 1080 |

| 2 | Concrete | 0.15 | 2.5 | 2500 | 1000 | |

| 3 | Plaster | 0.02 | 0.57 | 1300 | 1000 | |

| Exterior wall (East/West) | 1 | Cement mortar | 0.02 | 1.15 | 1800 | 1080 |

| 2 | Hollow brick | 0.1 | 0.48 | 900 | 936 | |

| 3 | Air gap | 0.05 | 0.025 | 1.23 | 1008 | |

| 4 | Hollow brick | 0.05 | 0.48 | 900 | 936 | |

| 5 | Plaster | 0.02 | 0.57 | 1300 | 1000 | |

| Interior wall (load-bearing) | 1 | Plaster | 0.02 | 0.57 | 1300 | 1000 |

| 2 | Concrete | 0.15 | 2.5 | 2500 | 1000 | |

| 3 | Plaster | 0.02 | 0.57 | 1300 | 1000 | |

| Interior wall | 1 | Cement mortar | 0.02 | 1.15 | 1800 | 1080 |

| 2 | Hollow brick | 0.10 | 0.48 | 900 | 936 | |

| 3 | Cement mortar | 0.02 | 1.15 | 1800 | 1080 | |

| Ground and upper floors | 1 | Concrete | 0.10 | 2.5 | 2500 | 1000 |

| 2 | Concrete screed | 0.05 | 1.15 | 1800 | 1080 | |

| 3 | Tiles | 0.03 | 2.1 | 2200 | 336 | |

| Roof | 1 | Water-tightness | 0.02 | 0.04 | 670 | 200 |

| 2 | Concrete screed | 0.07 | 1.15 | 1800 | 1080 | |

| 3 | Concrete | 0.1 | 2.5 | 2500 | 1000 | |

| 4 | Cement mortar | 0.02 | 1.15 | 1800 | 1080 |

| Spaces | Equipment | Design Level (W) | Lighting Level (W) |

|---|---|---|---|

| Living room | Television | 140 | 40 |

| Iron | 925 | ||

| Vacuum cleaner | 720 | ||

| Laptop | 60 | ||

| Bedrooms | Hairdryer | 450 | 30 |

| Laptops | 60 | ||

| Kitchen | Refrigerator | 175 | 20 |

| Stove with oven | 1500 | ||

| Robots | 150 | ||

| Bathroom | Washing machine | 500 | 20 |

| Hours | Day of 13 January | Day of 23 July | ||||

|---|---|---|---|---|---|---|

| Measures (°C) | Simulation (°C) | Relative Deviation | Measures (°C) | Simulation (°C) | Relative Deviation | |

| 1 | 11.92 | 11.83 | 0.007 | 26.99 | 27.38 | 0.014 |

| 2 | 11.99 | 11.87 | 0.009 | 26.92 | 26.62 | 0.011 |

| 3 | 12.17 | 11.66 | 0.041 | 26.80 | 26.26 | 0.020 |

| 4 | 12.11 | 11.44 | 0.054 | 26.74 | 25.96 | 0.028 |

| 5 | 12.05 | 11.25 | 0.065 | 26.61 | 25.79 | 0.030 |

| 6 | 11.99 | 11.10 | 0.073 | 26.49 | 25.62 | 0.032 |

| 7 | 11.92 | 10.98 | 0.078 | 26.61 | 27.55 | 0.035 |

| 8 | 11.99 | 11.00 | 0.081 | 26.49 | 27.90 | 0.053 |

| 9 | 12.17 | 10.89 | 0.104 | 26.96 | 28.17 | 0.044 |

| 10 | 12.36 | 11.17 | 0.096 | 27.15 | 28.49 | 0.049 |

| 11 | 13.01 | 11.68 | 0.101 | 27.99 | 28.90 | 0.032 |

| 12 | 13.86 | 12.35 | 0.108 | 28.35 | 29.47 | 0.039 |

| 13 | 14.42 | 13.26 | 0.080 | 28.75 | 30.07 | 0.045 |

| 14 | 14.61 | 14.26 | 0.023 | 29.45 | 30.68 | 0.041 |

| 15 | 14.55 | 15.10 | 0.038 | 29.67 | 31.26 | 0.053 |

| 16 | 14.67 | 15.80 | 0.077 | 29.53 | 31.77 | 0.075 |

| 17 | 14.99 | 16.08 | 0.075 | 29.82 | 32.17 | 0.078 |

| 18 | 14.74 | 15.97 | 0.083 | 29.99 | 32.32 | 0.077 |

| 19 | 14.55 | 15.64 | 0.075 | 29.99 | 32.21 | 0.074 |

| 20 | 14.74 | 15.40 | 0.045 | 29.56 | 31.78 | 0.075 |

| 21 | 14.74 | 15.25 | 0.035 | 29.20 | 31.36 | 0.073 |

| 22 | 14.61 | 15.41 | 0.054 | 28.97 | 29.42 | 0.015 |

| 23 | 14.49 | 14.80 | 0.021 | 28.35 | 28.83 | 0.016 |

| 24 | 14.42 | 14.42 | 0.000 | 28.25 | 27.83 | 0.014 |

| 1 | 14.36 | 14.16 | 0.013 | 28.15 | 27.33 | 0.028 |

| Type of Insulation | Strategy | Composition | Thickness (m) | Thermal Conductivity λ (W·m−1·K−1) | Density (Kg/m3) | Specific Heat Capacity Cp (J·Kg−1·K−1) |

|---|---|---|---|---|---|---|

| Internal insulation | S1 | Rock wool | 0.2 | 0.041 | 26 | 612 |

| S2 | Cork panels | 0.2 | 0.040 | 120 | 1670 | |

| S3 | Expanded polystyrene (EPS) | 0.15 | 0.038 | 30 | 1404 | |

| S4 | Polyurethane (PU) | 0.15 | 0.029 | 25 | 1300 | |

| S5 | Cellular glass | 0.23 | 0.045 | 120 | 1100 | |

| S1, S2, S3, S4, S5 | Plasterboard | 0.013 | 0.35 | 900 | 1460 |

| Type of Insulation | Strategy | Composition | Thickness (m) | Thermal Conductivity λ (W·m−1·K−1) | Density (Kg/m3) | Specific Heat Capacity Cp (J·Kg−1·K−1) |

|---|---|---|---|---|---|---|

| External wall insulation with render | S6 | Rock wool | 0.2 | 0.041 | 26 | 612 |

| S7 | Cork panels | 0.2 | 0.040 | 120 | 1670 | |

| S8 | Expanded polystyrene (EPS) | 0.15 | 0.038 | 30 | 1404 | |

| S9 | Polyurethane (PU) | 0.15 | 0.029 | 25 | 1300 | |

| S10 | Phenolic foam | 0.11 | 0.022 | 30 | 1300 | |

| Render | S7 | Organic base coat | 0.007 | 0.87 | 1800 | 1080 |

| Organic finishing render | 0.006 | 0.87 | 1800 | 1080 | ||

| S6, S8, S9, S10 | Mineral base coat | 0.007 | 0.57 | 1400 | 1080 | |

| Mineral finishing render | 0.006 | 0.76 | 1700 | 1080 |

| Type of Insulation | Strategy | Composition | Thickness (m) | Thermal Conductivity λ (W·m−1·K−1) | Density (Kg/m3) | Specific Heat Capacity Cp (J·Kg−1·K−1) |

|---|---|---|---|---|---|---|

| External wall insulation with cladding | S11 | Rock wool | 0.2 | 0.041 | 26 | 612 |

| S12 | Cork panels | 0.2 | 0.040 | 120 | 1670 | |

| S13 | Expanded polystyrene (EPS) | 0.15 | 0.038 | 30 | 1404 | |

| S14 | Polyurethane (PU) | 0.15 | 0.029 | 25 | 1300 | |

| S15 | Glass wool | 0.15 | 0.04 | 40 | 800 | |

| S16 | Cellular glass | 0.23 | 0.045 | 120 | 1100 | |

| Cladding | S11, S12 | Scots pine wood | 0.022 | 0.15 | 450 | 2160 |

| S13, S15 | Polyvinyl chloride | 0.015 | 0.17 | 1380 | 1046 | |

| S14, S16 | Fiber cement | 0.012 | 0.58 | 1800 | 1500 |

| Type of Insulation | Strategy | Composition | Thickness (m) | Thermal Conductivity λ (W·m−1·K−1) | Density (Kg/m3) | Specific Heat Capacity Cp (J·Kg−1·K−1) |

|---|---|---|---|---|---|---|

| Ground floor and upper floor | Polystyrene (EPS) | 0.15 | 0.038 | 30 | 1404 | |

| For all | Concrete | 0.10 | 2.5 | 2500 | 1000 | |

| strategies | Concrete screed | 0.05 | 1.15 | 1800 | 1080 | |

| Tiles | 0.03 | 2.1 | 2200 | 336 | ||

| Roof | Water-tightness | 0.02 | 0.04 | 670 | 200 | |

| Airium® | 0.1 | 0.05 | 180 | 1001 | ||

| For all | Concrete | 0.1 | 2.5 | 2500 | 1000 | |

| strategies | Rock wool | 0.2 | 0.041 | 26 | 612 | |

| Plasterboard | 0.013 | 0.35 | 900 | 1460 |

| Strategies | Criteria | ||||||

|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | |

| Rock wool (S1) | 43 | 3 | 2,526,154.00 | 617,134.00 | 7 | 8 | 6 |

| Cork panels (S2) | −27 | 8 | 2,512,601.00 | 883,748.00 | 4 | 7 | 8 |

| Expanded polystyrene (EPS) (S3) | 10 | 2 | 2,548,504.00 | 638,794.00 | 4 | 3 | 2 |

| Polyurethane (PU) (S4) | 16 | 3 | 2,519,706.00 | 703,781.00 | 3 | 5 | 2 |

| Cellular glass (S5) | 25 | 6 | 2,511,489.00 | 812,089.00 | 8 | 5 | 5 |

| Normalized weight z = 6.5 | 4.82 | 4.82 | 31.33 | 26.020 | 18.07 | 10.12 | 4.82 |

| Indifference threshold | 6.92 | 0.67 | 4046.12 | 30,628.10 | 0.58 | 0.52 | 0.7 |

| Preference threshold | 18.45 | 1.79 | 10,789.67 | 81,674.94 | 1.55 | 1.39 | 1.87 |

| Veto threshold | 34.6 | 3.36 | 20,230.64 | 153,140.53 | 2.9 | 2.62 | 3.5 |

| Objective | MIN | MAX | MIN | MIN | MAX | MAX | MAX |

| Strategies | Criteria | ||||||

|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | |

| Rock wool (S6) | 43 | 3 | 2,397,499.00 | 717,736.00 | 7 | 8 | 6 |

| Cork panels (S7) | −27 | 8 | 2,323,415.00 | 934,377.00 | 4 | 7 | 8 |

| Expanded polystyrene (EPS) (S8) | 10 | 2 | 2,412,908.00 | 739,423.00 | 4 | 3 | 2 |

| Polyurethane (PU) (S9) | 16 | 3 | 2,395,679.00 | 804,410.00 | 3 | 5 | 2 |

| Phenolic foam (S10) | 85 | 1 | 2,397,955.00 | 804,277.00 | 6 | 3 | 6 |

| Normalized weight z = 6.5 | 4.82 | 4.82 | 31.33 | 26.02 | 18.07 | 10.12 | 4.82 |

| Indifference threshold | 3.72 | 0.24 | 3164.95 | 7553.40 | 0.14 | 0.20 | 0.24 |

| Preference threshold | 11.17 | 0.72 | 9494.85 | 22,660.22 | 0.44 | 0.61 | 0.72 |

| Veto threshold | 33. 51 | 2.17 | 28,484.56 | 67,980.66 | 1.32 | 1.83 | 2.16 |

| Objective | MIN | MAX | MIN | MIN | MAX | MAX | MAX |

| Strategies | Criteria | |||||||

|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C3′ | C4 | C5 | C6 | C8 | |

| Rock wool + wood (S11) | 63 | 30 | 2,364,784.00 | 3 | 1,452,781.00 | 6 | 8 | 6 |

| Cork panels + wood (S12) | −7 | 30 | 2,429,512.00 | 4 | 1,698,986.00 | 3 | 6 | 6 |

| Expanded polystyrene (EPS) + PVC (S13) | 35 | 40 | 2,365,168.00 | 5 | 1,184,716.00 | 2 | 4 | 8 |

| Polyurethane (PU) + fiber cement (S14) | 36 | 50 | 2,361,545.00 | 7 | 1,356,139.00 | 5 | 6 | 4 |

| Glass wool + PVC (S15) | 68 | 40 | 2,360,687.00 | 4 | 1,139,540.00 | 7 | 6 | 6 |

| Cellular glass + fiber cement (S16) | 45 | 50 | 2,361,207.00 | 8 | 1,464,424.00 | 8 | 6 | 2 |

| Normalized weight z = 8.67 | 3 | 12.21 | 26.03 | 12.21 | 21.43 | 14.53 | 7.59 | 3 |

| Indifference threshold | 3.25 | 2.64 | 9173.75 | 0.65 | 68,846.06 | 0.78 | 0.42 | 0.69 |

| Preference threshold | 10.85 | 8.80 | 30,579.17 | 2.16 | 229,486.88 | 2.59 | 1.41 | 2.30 |

| Veto threshold | 27.71 | 17.61 | 61,158.35 | 4.33 | 458,973.75 | 5.18 | 2.83 | 4.62 |

| Objective | MIN | MAX | MIN | MAX | MIN | MAX | MAX | MAX |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chabane, N.; Mokhtari, A.M.; Kacemi, M.; Harrat, Z.R.; Hilal, N.; Ademović, N.; Hadzima-Nyarko, M. A Sustainable Multi-Criteria Optimization Approach for the Energy Retrofit of Collective Housing in Algeria Using the ELECTRE III Tool. Sustainability 2025, 17, 4273. https://doi.org/10.3390/su17104273

Chabane N, Mokhtari AM, Kacemi M, Harrat ZR, Hilal N, Ademović N, Hadzima-Nyarko M. A Sustainable Multi-Criteria Optimization Approach for the Energy Retrofit of Collective Housing in Algeria Using the ELECTRE III Tool. Sustainability. 2025; 17(10):4273. https://doi.org/10.3390/su17104273

Chicago/Turabian StyleChabane, Nesrine, Abderahemane Mejedoub Mokhtari, Malika Kacemi, Zouaoui R. Harrat, Nahla Hilal, Naida Ademović, and Marijana Hadzima-Nyarko. 2025. "A Sustainable Multi-Criteria Optimization Approach for the Energy Retrofit of Collective Housing in Algeria Using the ELECTRE III Tool" Sustainability 17, no. 10: 4273. https://doi.org/10.3390/su17104273

APA StyleChabane, N., Mokhtari, A. M., Kacemi, M., Harrat, Z. R., Hilal, N., Ademović, N., & Hadzima-Nyarko, M. (2025). A Sustainable Multi-Criteria Optimization Approach for the Energy Retrofit of Collective Housing in Algeria Using the ELECTRE III Tool. Sustainability, 17(10), 4273. https://doi.org/10.3390/su17104273